torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 474 of 2053

1F2 -- 56 M161 ENGINE CONTROLS

D AEW OO M Y_2000

INDUCTION SYSTEM

THROTTLE VALVE ACTUATOR

YAA1F540

The throttle actuator is actuated by the Engine Control Module (ECM) according to the position of the accelerator pedal

position.

It has two potentiometers which signal the position of the throttle valve to the ECM to enable it to recognize the various

engine load states.

Ignition “Off”

In the de-- energized states the throttle valve position is determined to be spring capsule.

Ignition “On”

When the ignition S/W on the servo motor in the throttle actuator is operated by the ECM. The throttle valve adopts a

position in line with the coolant temperature.

Closed position

In the closed throttle position, the servo motor controls engine speed by operating the throttle valve further (greater

mixture) or closing it further (reduced mixture), depending on coolant temperature and engine load. When this is done,

the throttle valve can be closed further by the servo motor overcoming the force of the spring capsule (mechanical end

stop). If the actuator is de-- energized, the throttle valve is resting against the spring capsule.

Consequently, the throttle valve opening is a constant 10-- 12°approximately.

At no load, this produces an engine speed of about 1,800 rpm

Driving

When driving (part/full throttle), the servo motor controls the throttle valve in line with the various load states and ac-

cording to the input signals from the pedal value sensor according to the input signals from the pedal value sensor

according to the position of the accelerator pedal.

The function of the EA (electronic accelerator) in the ECM determines the opening angle of the throttle valve through

the throttle actuator. Further functions are;

DIdle speed control

DCruise control

DReducing engine torque for ASR/ABS operation

DElectronic accelerator emergency running

DStoring faults

DData transfer through CAN

Page 482 of 2053

1F2 -- 64 M161 ENGINE CONTROLS

D AEW OO M Y_2000

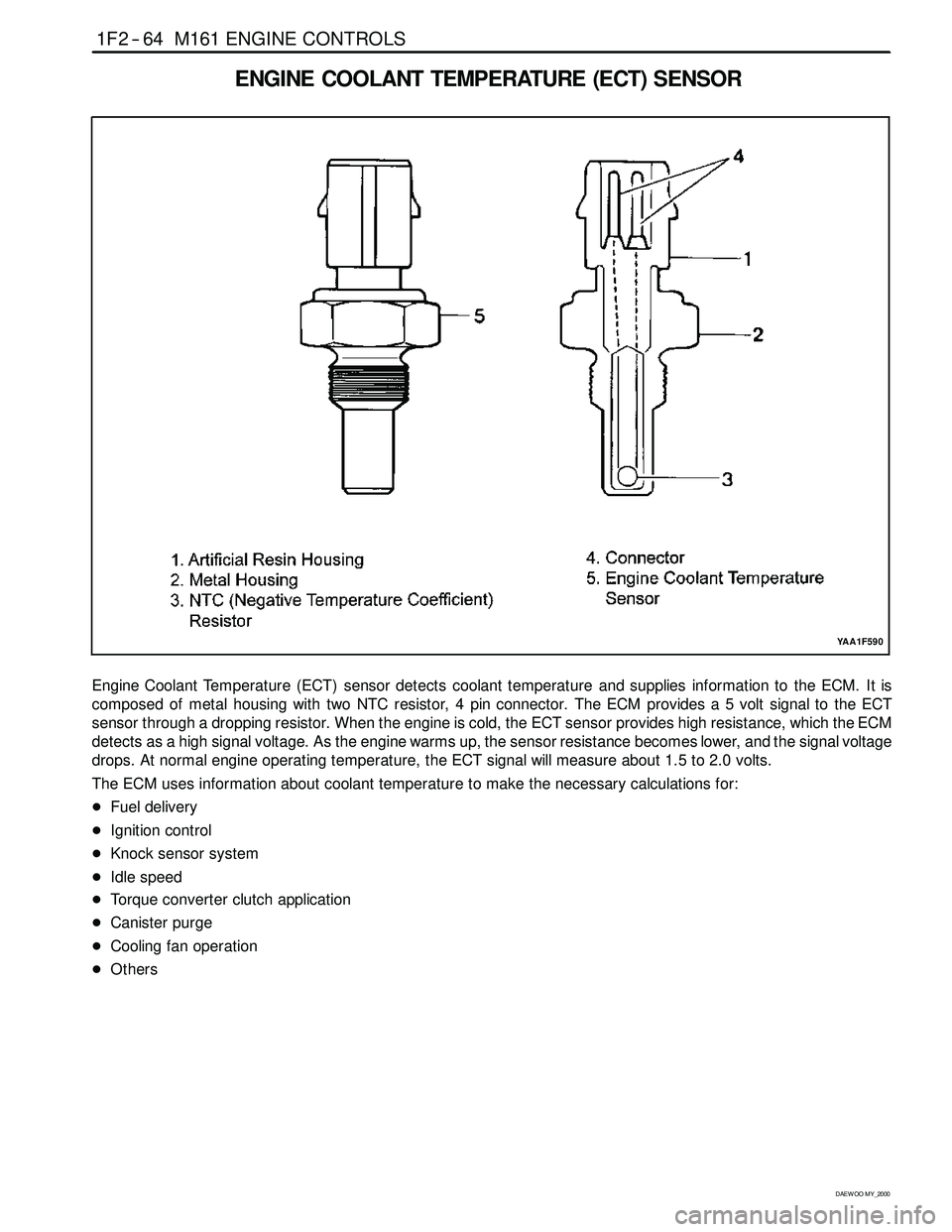

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

YAA1F590

Engine Coolant Temperature (ECT) sensor detects coolant temperature and supplies information to the ECM. It is

composed of metal housing with two NTC resistor, 4 pin connector. The ECM provides a 5 volt signal to the ECT

sensor through a dropping resistor. When the engine is cold, the ECT sensor provides high resistance, which the ECM

detects as a high signal voltage. As the engine warms up, the sensor resistance becomes lower, and the signal voltage

drops. At normal engine operating temperature, the ECT signalwill measure about 1.5 to 2.0 volts.

The ECM uses information about coolant temperature to make the necessary calculations for:

DFuel delivery

DIgnition control

DKnock sensor system

DIdle speed

DTorque converter clutch application

DCanister purge

DCooling fan operation

DOthers

Page 513 of 2053

M161 ENGINE CONTROLS 1F2 -- 95

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

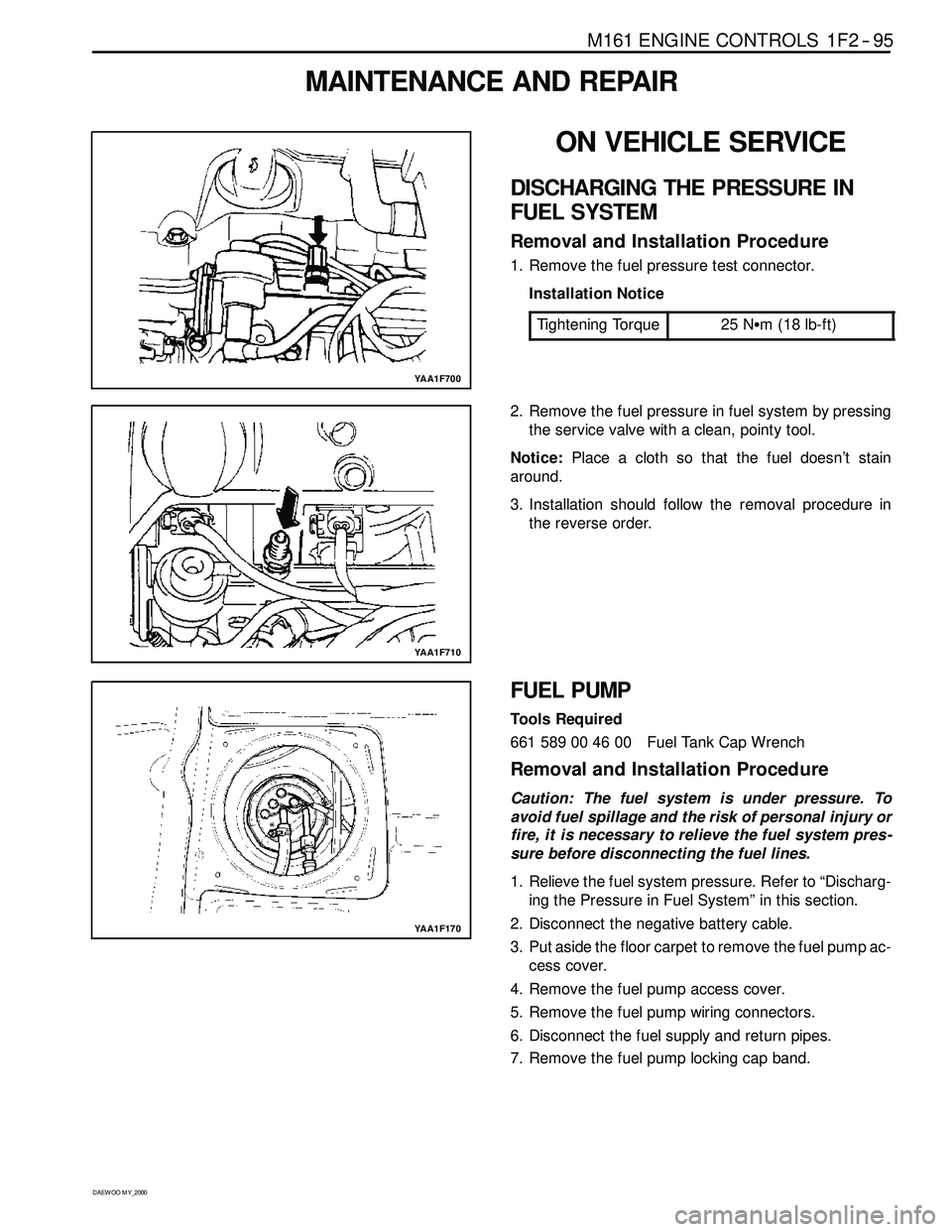

YAA1F700

ON VEHICLE SERVICE

DISCHARGING THE PRESSURE IN

FUEL SYSTEM

Removal and Installation Procedure

1. Remove the fuel pressure test connector.

Installation Notice

Tightening Torque

25 NSm (18 lb-ft)

YAA1F710

2. Remove the fuel pressure in fuel system by pressing

the service valve with a clean, pointy tool.

Notice:Place a cloth so that the fuel doesn’t stain

around.

3. Installation should follow the removal procedure in

the reverse order.

YAA1F170

FUEL PUMP

Tools Required

661 589 00 46 00 Fuel Tank Cap Wrench

Removal and Installation Procedure

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres -

sure before disconnecting the fuel lines.

1. Relieve the fuel system pressure. Refer to “Discharg-

ing the Pressure in Fuel System” in this section.

2. Disconnect the negative battery cable.

3. Put aside the floor carpet to remove the fuel pump ac-

cess cover.

4. Remove the fuel pump access cover.

5. Remove the fuel pump wiring connectors.

6. Disconnect the fuel supply and return pipes.

7. Remove the fuel pump locking cap band.

Page 514 of 2053

1F2 -- 96 M161 ENGINE CONTROLS

D AEW OO M Y_2000

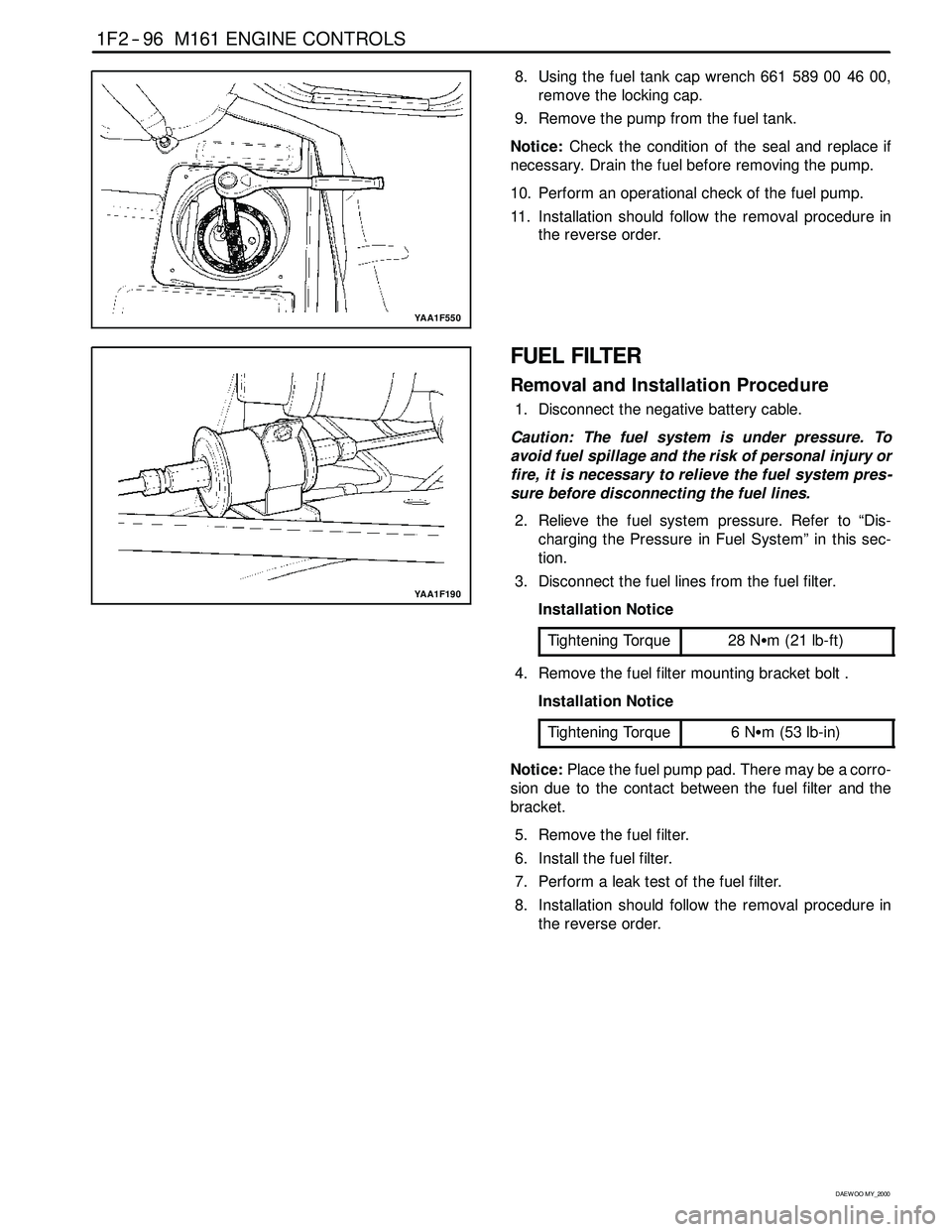

YAA1F550

8. Using the fuel tank cap wrench 661 589 00 46 00,

remove the locking cap.

9. Remove the pump from the fuel tank.

Notice:Check the condition of the seal and replace if

necessary. Drain the fuel before removing the pump.

10. Perform an operational check of the fuel pump.

11. Installation should follow the removal procedure in

the reverse order.

YAA1F190

FUEL FILTER

Removal and Installation Procedure

1. Disconnect the negative battery cable.

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres -

sure before disconnecting the fuel lines.

2. Relieve the fuel system pressure. Refer to “Dis-

charging the Pressure in Fuel System” in this sec-

tion.

3. Disconnect the fuel lines from the fuel filter.

Installation Notice

Tightening Torque

28 NSm (21 lb-ft)

4. Remove the fuel filter mounting bracket bolt .

Installation Notice

Tightening Torque

6NSm (53 lb-in)

Notice:Place the fuel pump pad. There may be a corro-

sion due to the contact between the fuel filter and the

bracket.

5. Remove the fuel filter.

6. Install the fuel filter.

7. Perform a leak test of the fuel filter.

8. Installation should follow the removal procedure in

the reverse order.

Page 515 of 2053

M161 ENGINE CONTROLS 1F2 -- 97

D AEW OO M Y_2000

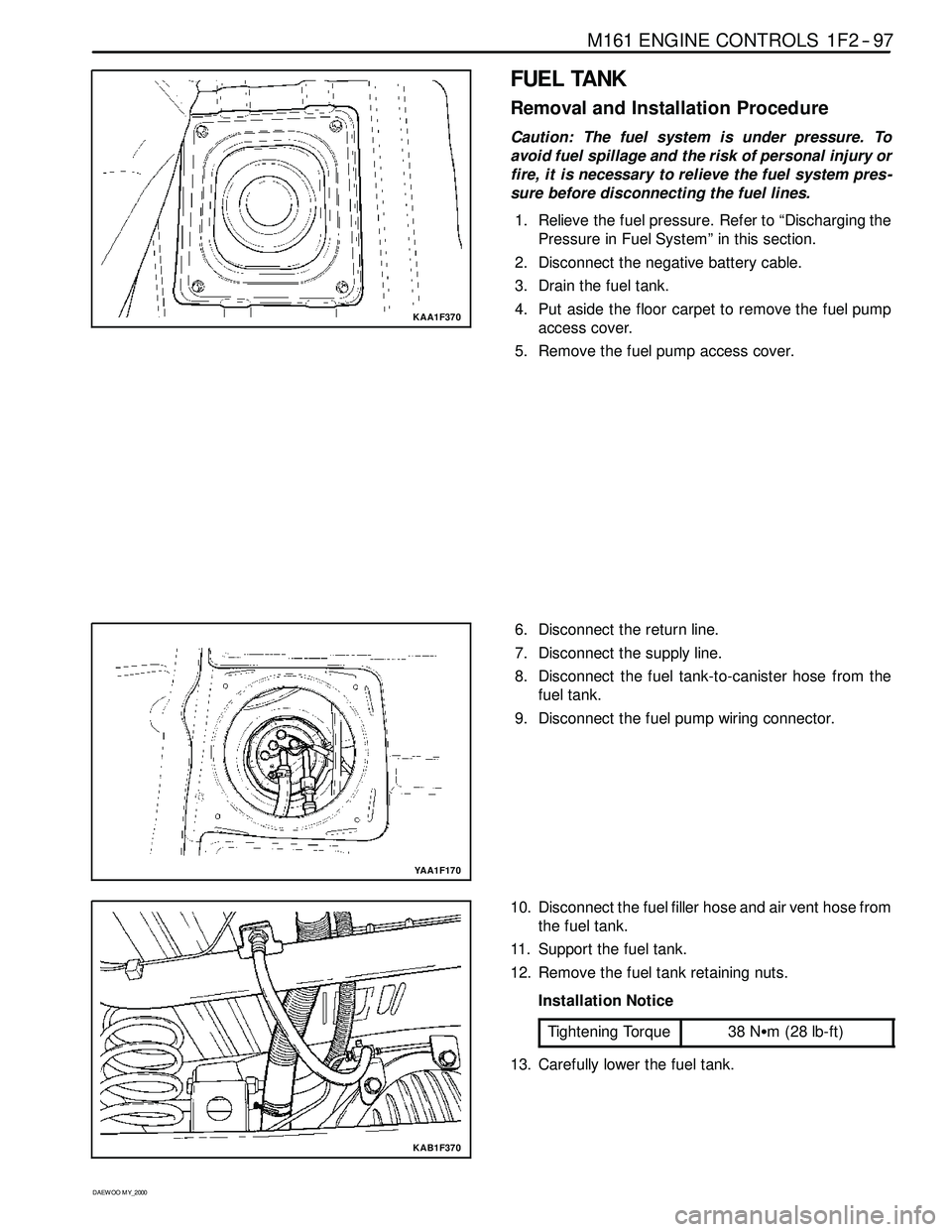

KAA1F370

FUEL TANK

Removal and Installation Procedure

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres -

sure before disconnecting the fuel lines.

1. Relieve the fuel pressure. Refer to “Discharging the

Pressure in Fuel System” in this section.

2. Disconnect the negative battery cable.

3. Drain the fuel tank.

4. Put aside the floor carpet to remove the fuel pump

access cover.

5. Remove the fuel pump access cover.

YAA1F170

6. Disconnect the return line.

7. Disconnect the supply line.

8. Disconnect the fuel tank-to-canister hose from the

fuel tank.

9. Disconnect the fuel pump wiring connector.

KAB1F370

10. Disconnect the fuel filler hose and air vent hose from

the fuel tank.

11. Support the fuel tank.

12. Remove the fuel tank retaining nuts.

Installation Notice

Tightening Torque

38 NSm (28 lb-ft)

13. Carefully lower the fuel tank.

Page 516 of 2053

1F2 -- 98 M161 ENGINE CONTROLS

D AEW OO M Y_2000

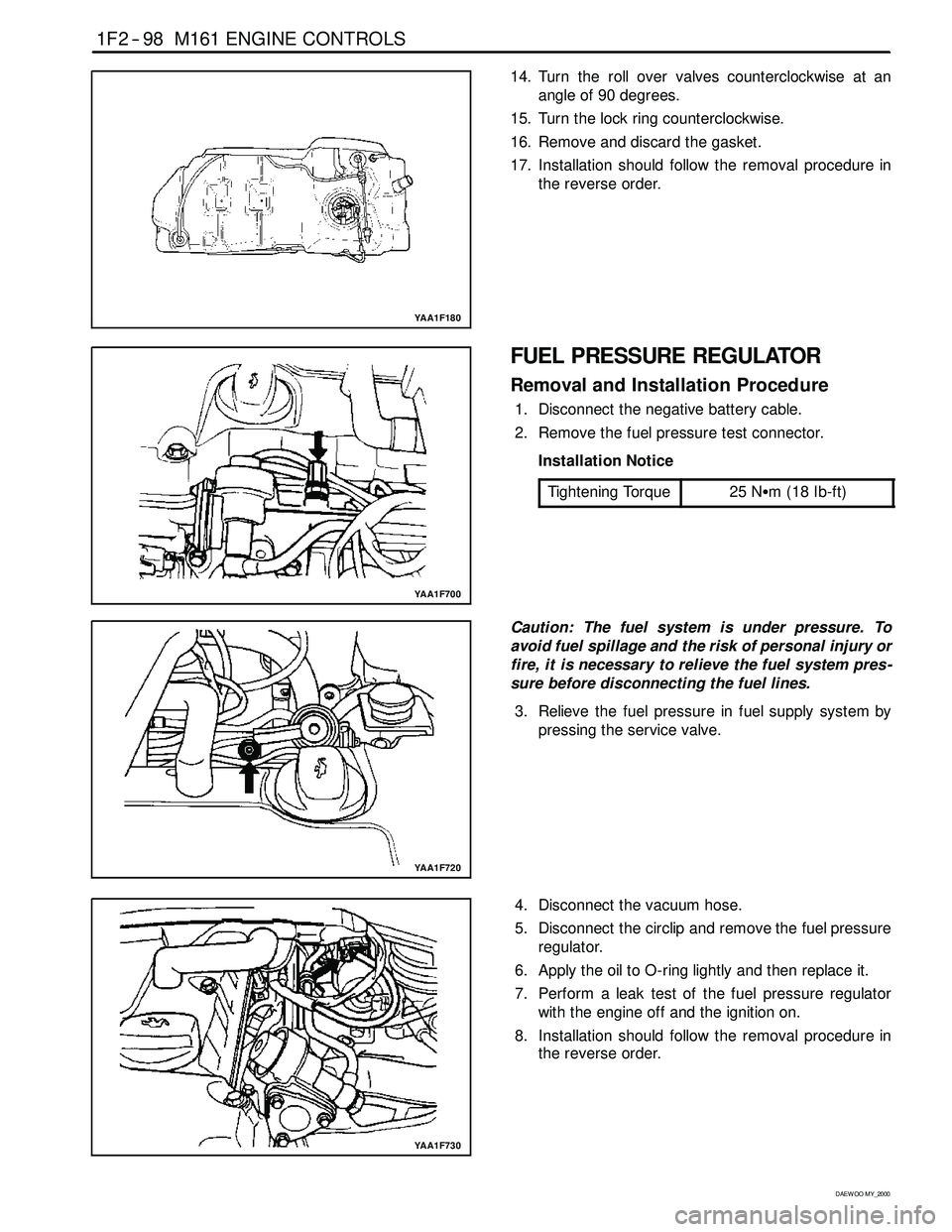

YAA1F180

14. Turn the roll over valves counterclockwise at an

angle of 90 degrees.

15. Turn the lock ring counterclockwise.

16. Remove and discard the gasket.

17. Installation should follow the removal procedure in

the reverse order.

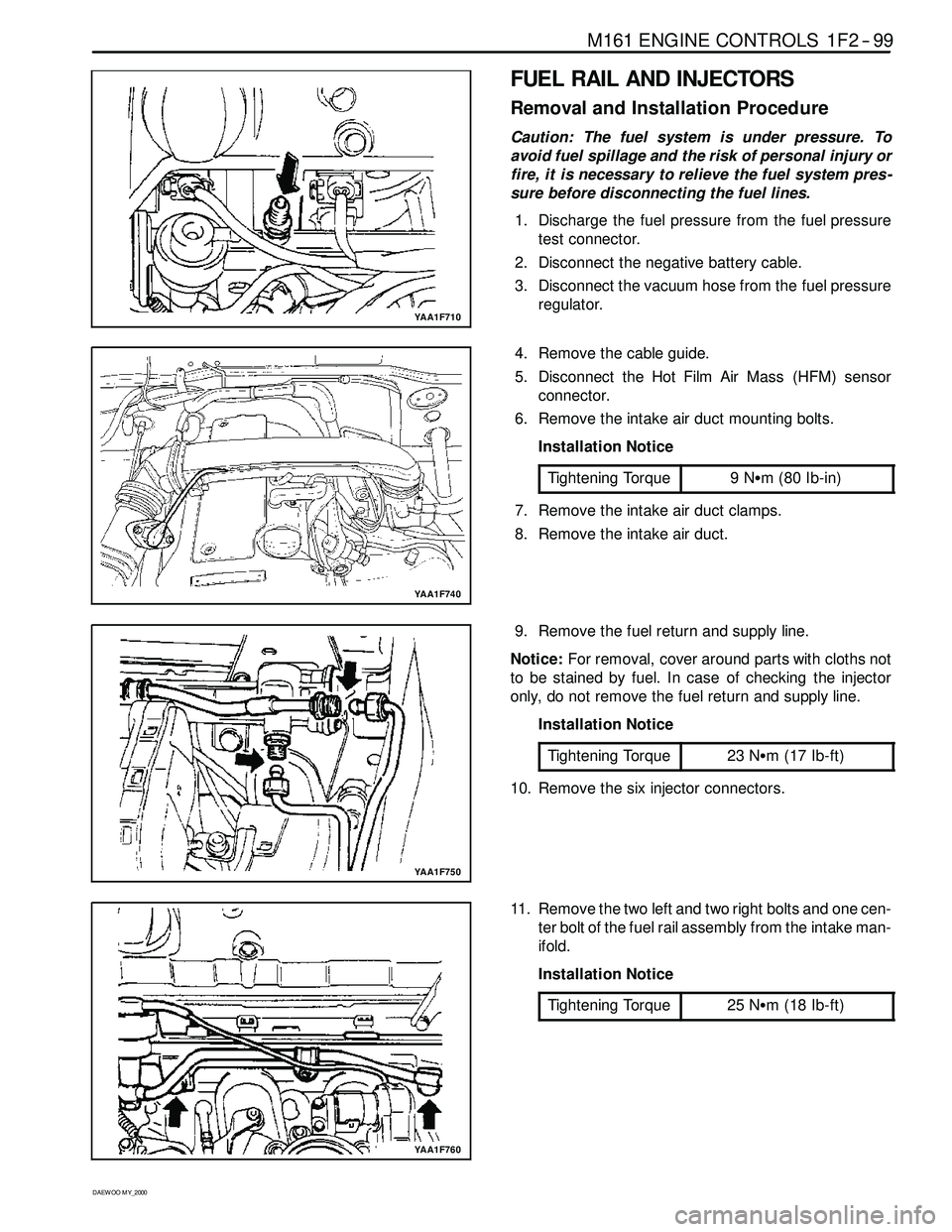

YAA1F700

FUEL PRESSURE REGULATOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the fuel pressure test connector.

Installation Notice

Tightening Torque

25 NSm (18 Ib-ft)

YAA1F720

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres -

sure before disconnecting the fuel lines.

3. Relieve the fuel pressure in fuel supply system by

pressing the service valve.

YAA1F730

4. Disconnect the vacuum hose.

5. Disconnect the circlip and remove the fuel pressure

regulator.

6. Apply the oil to O-ring lightly and then replace it.

7. Perform a leak test of the fuel pressure regulator

with the engine off and the ignition on.

8. Installation should follow the removal procedure in

the reverse order.

Page 517 of 2053

M161 ENGINE CONTROLS 1F2 -- 99

D AEW OO M Y_2000

YAA1F710

FUEL RAIL AND INJECTORS

Removal and Installation Procedure

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres -

sure before disconnecting the fuel lines.

1. Discharge the fuel pressure from the fuel pressure

test connector.

2. Disconnect the negative battery cable.

3. Disconnect the vacuum hose from the fuel pressure

regulator.

YAA1F740

4. Remove the cable guide.

5. Disconnect the Hot Film Air Mass (HFM) sensor

connector.

6. Remove the intake air duct mounting bolts.

Installation Notice

Tightening Torque

9NSm (80 Ib-in)

7. Remove the intake air duct clamps.

8. Remove the intake air duct.

YAA1F750

9. Remove the fuel return and supply line.

Notice:For removal, cover around parts with cloths not

to be stained by fuel. In case of checking the injector

only, do not remove the fuel return and supply line.

Installation Notice

Tightening Torque

23 NSm (17 Ib-ft)

10. Remove the six injector connectors.

YAA1F760

11. Remove the two left and two right bolts and one cen-

ter bolt of the fuel rail assembly from the intake man-

ifold.

Installation Notice

Tightening Torque

25 NSm (18 Ib-ft)

Page 518 of 2053

1F2 -- 100 M161 ENGINE CONTROLS

D AEW OO M Y_2000

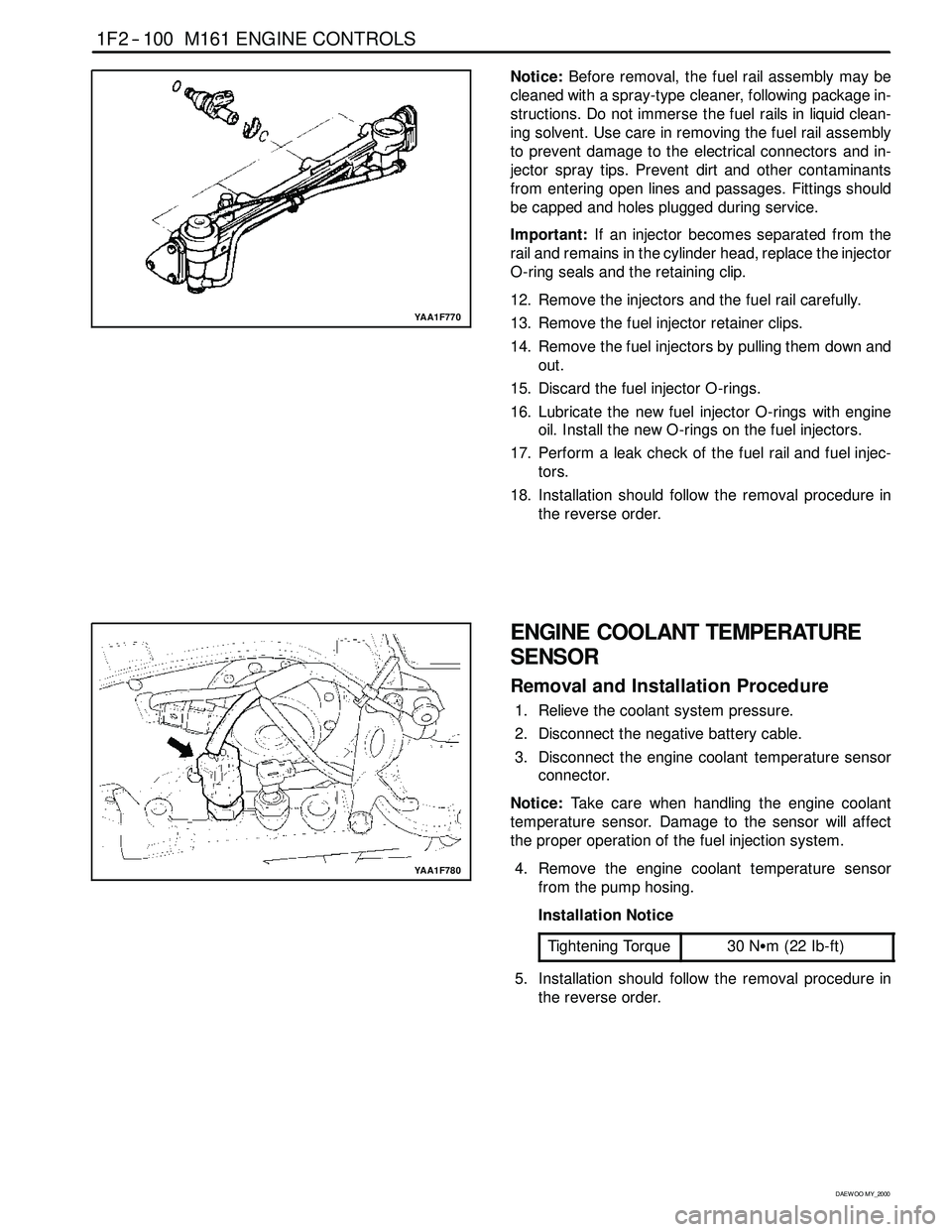

YAA1F770

Notice:Before removal, the fuel rail assembly may be

cleaned with a spray-type cleaner, following package in-

structions. Do not immerse the fuel rails in liquid clean-

ing solvent. Use care in removing the fuel rail assembly

to prevent damage to the electrical connectors and in-

jector spray tips. Prevent dirt and other contaminants

from entering open lines and passages. Fittings should

be capped and holes plugged during service.

Important:If an injector becomes separated from the

rail and remains in the cylinder head, replace the injector

O-ring seals and the retaining clip.

12. Remove the injectors and the fuel rail carefully.

13. Remove the fuel injector retainer clips.

14. Remove the fuel injectors by pulling them down and

out.

15. Discard the fuel injector O-rings.

16. Lubricate the new fuel injector O-rings with engine

oil. Install the new O-rings on the fuel injectors.

17. Perform a leak check of the fuel rail and fuel injec-

tors.

18. Installation should follow the removal procedure in

the reverse order.

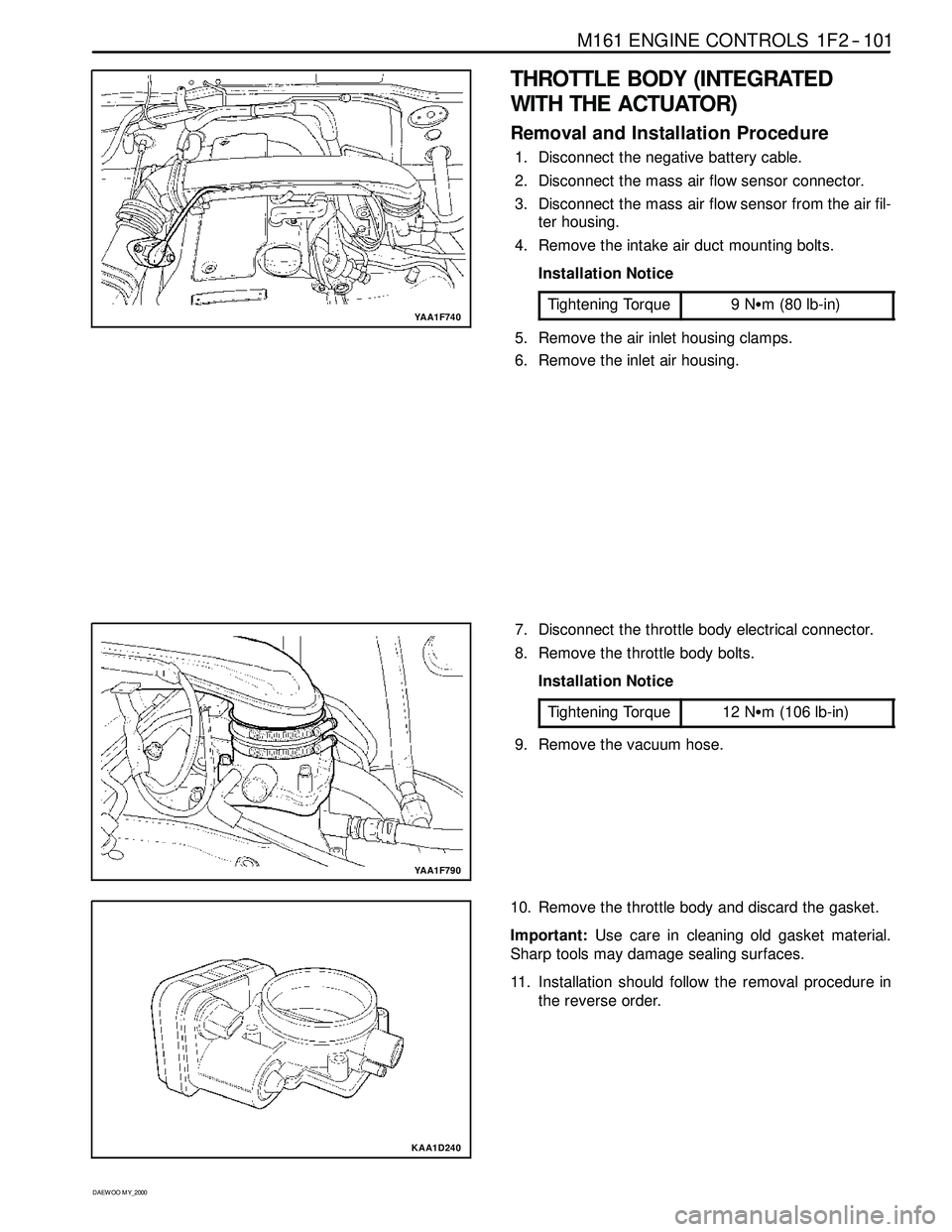

YAA1F780

ENGINE COOLANT TEMPERATURE

SENSOR

Removal and Installation Procedure

1. Relieve the coolant system pressure.

2. Disconnect the negative battery cable.

3. Disconnect the engine coolant temperature sensor

connector.

Notice:Take care when handling the engine coolant

temperature sensor. Damage to the sensor will affect

the proper operation of the fuel injection system.

4. Remove the engine coolant temperature sensor

from the pump hosing.

Installation Notice

Tightening Torque

30 NSm (22 Ib-ft)

5. Installation should follow the removal procedure in

the reverse order.

Page 519 of 2053

M161 ENGINE CONTROLS 1F2 -- 101

D AEW OO M Y_2000

YAA1F740

THROTTLE BODY (INTEGRATED

WITH THE ACTUATOR)

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the mass air flow sensor connector.

3. Disconnect the mass air flow sensor from the air fil-

ter housing.

4. Remove the intake air duct mounting bolts.

Installation Notice

Tightening Torque

9NSm (80 lb-in)

5. Remove the air inlet housing clamps.

6. Remove the inlet air housing.

YAA1F790

7. Disconnect the throttle body electrical connector.

8. Remove the throttle body bolts.

Installation Notice

Tightening Torque

12 NSm (106 lb-in)

9. Remove the vacuum hose.

KAA1D240

10. Remove the throttle body and discard the gasket.

Important:Use care in cleaning old gasket material.

Sharp tools may damage sealing surfaces.

11. Installation should follow the removal procedure in

the reverse order.

Page 520 of 2053

1F2 -- 102 M161 ENGINE CONTROLS

D AEW OO M Y_2000

KAA1F190

HOT FILM AIR MASS (HFM) SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the Hot Film Air Mass (HFM) sensor

electrical connector.

3. Remove the HFM sensor retaining screws.

4. Turn the HFM sensor coupling in the direction

shown in the figure in the left so that it gets sepa-

rated from the contact surface.

Notice:Make sure the HFM sensor coupling connects

completely with the contact surface installation.

5. Remove the HFM sensor.

6. Installation should follow the removal procedure in

the reverse order.

KAA1F180

KNOCK SENSOR

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the knock sensor electrical connector

from the intake manifold bracket.

3. Remove the knock sensor mounting bolt from the

knock sensor installed on the cylinder block.

Installation Notice

Tightening Torque

25 NSm (18 Ib-ft)

4. Remove the knock sensor.

5. Installation should follow the removal procedure in

the reverse order.