torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 521 of 2053

M161 ENGINE CONTROLS 1F2 -- 103

D AEW OO M Y_2000

KAA1F410

PEDAL POSITION SENSOR

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the pedal position sensor connector.

3. Unscrew the bolts and nut.

Installation Notice

Tightening Torque

6NSm (53 lb-in)

4. Remove the pedal and sensor assembly.

5. Installation should follow the removal procedure in

the reverse order.

YAA1F820

OXYGEN SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

Notice:The oxygen sensor uses a permanently at-

tached pigtail and connector. This pigtail should not be

removed from the oxygen sensor. Damage or removal

of the pigtail or the connector could affect proper opera-

tion of the oxygen sensor. Do not drop the oxygen sen-

sor.

2. Disconnect the electrical connector.

3. Carefully remove the oxygen sensor from the exhaust

pipe.

Installation Notice

Tightening Torque

55 NSm (41 Ib-ft)

Important:A special anti-seize compound is used on

the oxygen sensor threads. This compound consists of

a liquid graphite and glass beads. The graphitewill burn

away, but the glass beadswill remain, making the sen-

sor easier to remove. New or serviced sensors will al-

ready have the compound applied to the threads. If a

sensor is removed from any engine and is to be rein-

stalled, the threads must have an anti-seize compound

applied before reinstallation.

4. Coat the threads of the oxygen sensor with an anti-

seize compound, if needed.

5. Installation should follow the removal procedure in

the reverse order.

Page 522 of 2053

1F2 -- 104 M161 ENGINE CONTROLS

D AEW OO M Y_2000

KAB1F400

PURGE CONTROL VALVE

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the purge control valve connector.

3. Disconnect the throttle body-to-purge control valve

hose from the purge control valve.

4. Disconnect the canister-to-purge control valve hose

from the purge control valve.

5. Remove the purge control valve.

6. Installation should follow the removal provedure in

the reverse order.

KAB1F410

CANISTER

Removal and Installation Procedure

Caution: Canister and vacuum hoses contain fuel

vapors. Do not smoke in the area or permit an open

flame.

1. Disconnect the fuel tank-to-canister hose form the

canister.

2. Disconnect the canister-to-purge control valve hose

form the canister.

KAB1F400

3. Remove the canister mounting bolts.

Installation Notice

Tightening Torque

6NSm (53 lb-in)

4. Remove the canister.

5. Installation should follow the removal procedure in

the reverse order.

YAA1F810

CAMSHAFT POSITION SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector from the cam-

shaft position sensor.

3. Remove the camshaft position sensor retaining bolt.

Installation Notice

Tightening Torque

10 NSm (89 Ib-in)

Page 523 of 2053

M161 ENGINE CONTROLS 1F2 -- 105

D AEW OO M Y_2000

4. Check the O-ring for damage and replace it if neces-

sary.

5. Installation should follow the removal procedure in

the reverse order.

KAA1F160

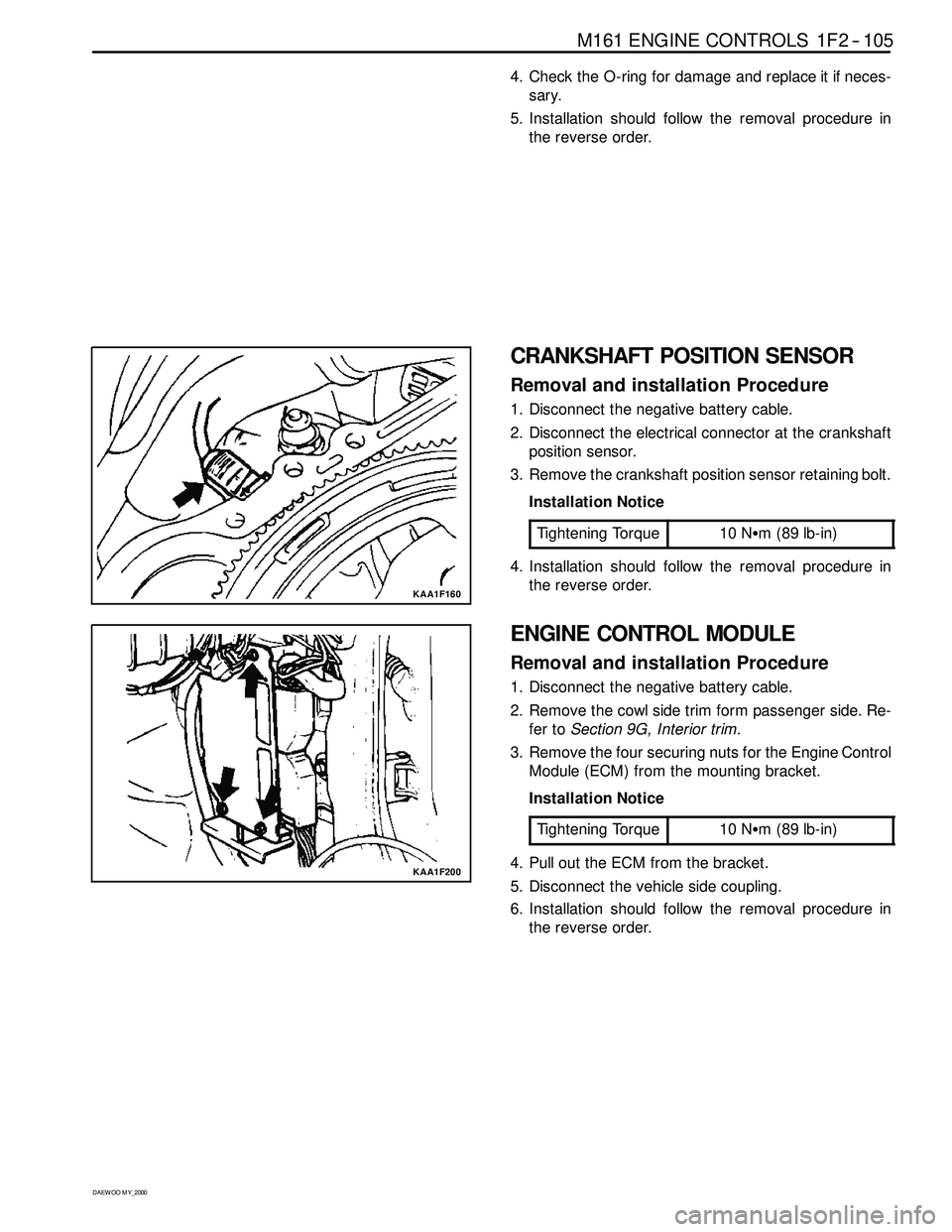

CRANKSHAFT POSITION SENSOR

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector at the crankshaft

position sensor.

3. Remove the crankshaft position sensor retaining bolt.

Installation Notice

Tightening Torque

10 NSm (89 lb-in)

4. Installation should follow the removal procedure in

the reverse order.

KAA1F200

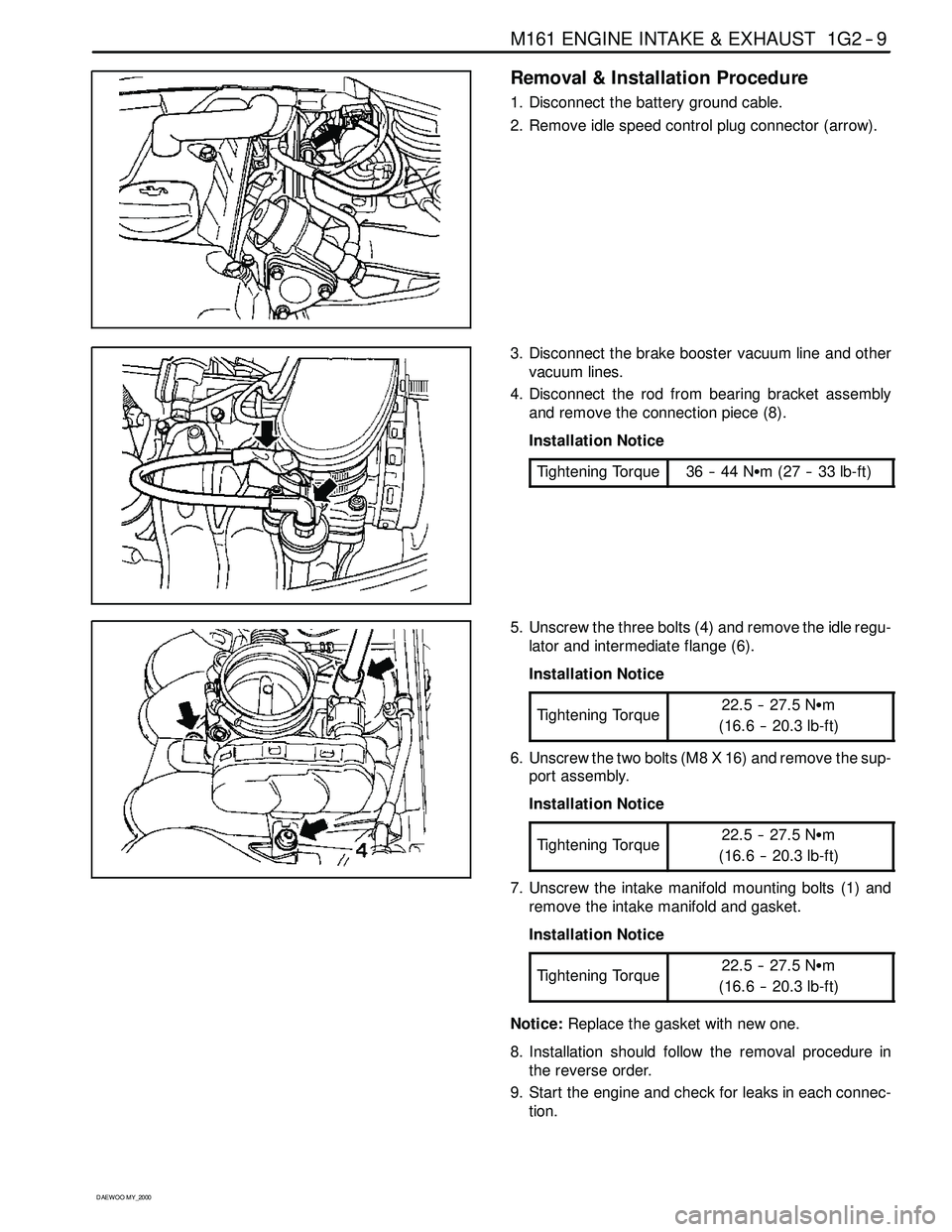

ENGINE CONTROL MODULE

Removal and installation Procedure

1. Disconnect the negative battery cable.

2. Remove the cowl side trim form passenger side. Re-

fer toSection 9G, Interior trim.

3. Remove the four securing nuts for the Engine Control

Module (ECM) from the mounting bracket.

Installation Notice

Tightening Torque

10 NSm (89 lb-in)

4. Pull out the ECM from the bracket.

5. Disconnect the vehicle side coupling.

6. Installation should follow the removal procedure in

the reverse order.

Page 527 of 2053

1G2 -- 4 M161 ENGINE INTAKE & EXHAUST

D AEW OO M Y_2000

Removal and Installation Procedure

1. Disconnect the HFM sensor and the air cleaner by

prying up the clamp.

2. Remove the air cleaner mounting bolt.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

3. Remove air intake shield upper cover, and then re-

move the air cleaner from rubber bearing on bracket.

Notice:For installation, exactly seat the air cleaner into

the rubber bearing.

Page 532 of 2053

M161 ENGINE INTAKE & EXHAUST 1G2 -- 9

D AEW OO M Y_2000

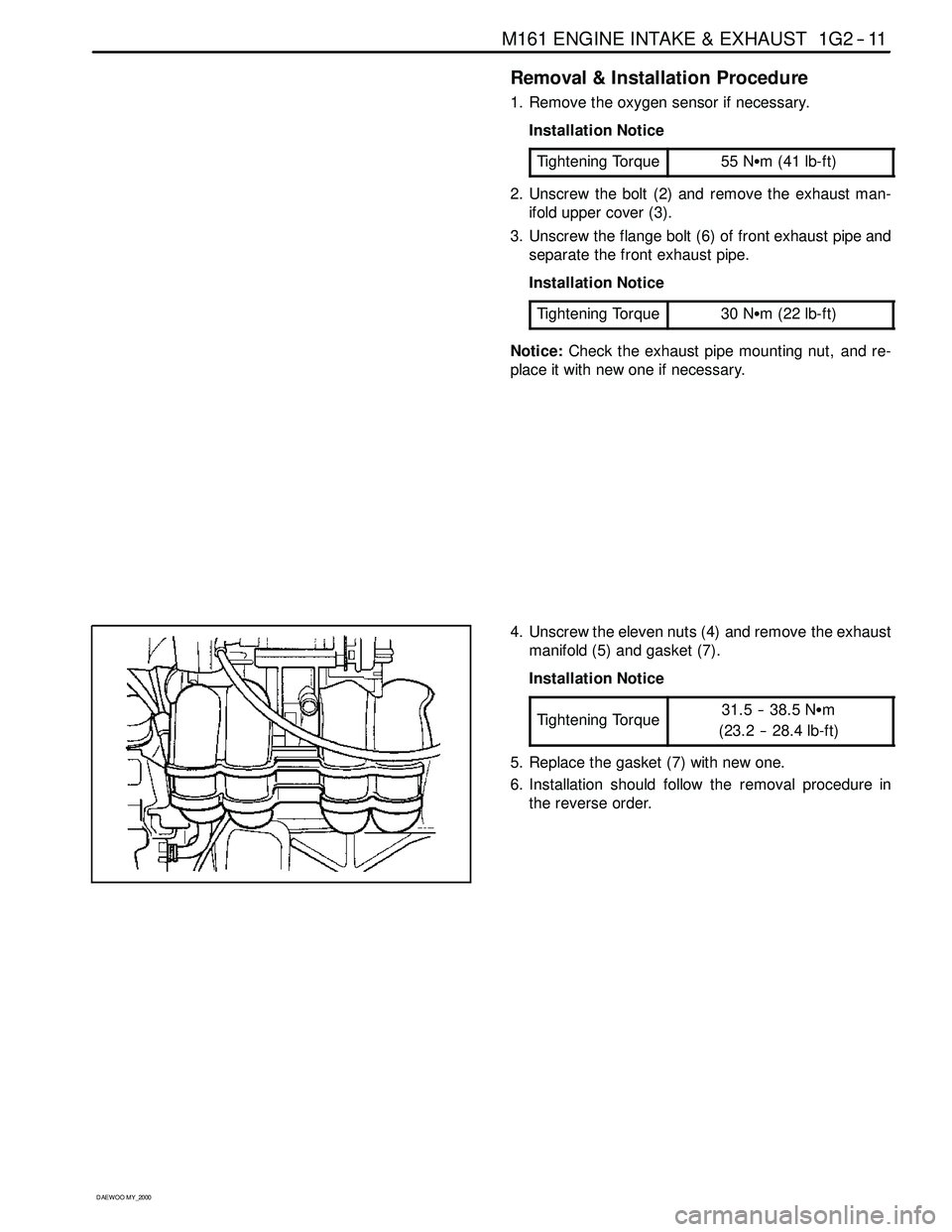

Removal & Installation Procedure

1. Disconnect the battery ground cable.

2. Remove idle speed control plug connector (arrow).

3. Disconnect the brake booster vacuum line and other

vacuum lines.

4. Disconnect the rod from bearing bracket assembly

and remove the connection piece (8).

Installation Notice

Tightening Torque

36 -- 44 NSm (27 -- 33 lb-ft)

5. Unscrew the three bolts (4) and remove the idle regu-

lator and intermediate flange (6).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

6. Unscrew the two bolts (M8 X 16) and remove the sup-

port assembly.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

7. Unscrew the intake manifold mounting bolts (1) and

remove the intake manifold and gasket.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Notice:Replace the gasket with new one.

8. Installation should follow the removal procedure in

the reverse order.

9. Start the engine and check for leaks in each connec-

tion.

Page 534 of 2053

M161 ENGINE INTAKE & EXHAUST 1G2 -- 11

D AEW OO M Y_2000

Removal & Installation Procedure

1. Remove the oxygen sensor if necessary.

Installation Notice

Tightening Torque

55 NSm (41 lb-ft)

2. Unscrew the bolt (2) and remove the exhaust man-

ifold upper cover (3).

3. Unscrew the flange bolt (6) of front exhaust pipe and

separate the front exhaust pipe.

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

Notice:Check the exhaust pipe mounting nut, and re-

place it with new one if necessary.

4. Unscrew the eleven nuts (4) and remove the exhaust

manifold (5) and gasket (7).

Installation Notice

Tightening Torque

31.5 -- 38.5 NSm

(23.2 -- 28.4 lb-ft)

5. Replace the gasket (7) with new one.

6. Installation should follow the removal procedure in

the reverse order.

Page 536 of 2053

D AEW OO M Y_2000

SECTION 1

ENGINE

SECTION 1A3 (OM600 ENGINE)

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Specifications 1A3 -- 1............................

Engine Specifications 1A3-- 1.....................

Sectional View 1A3 -- 3............................

OM662LA Engine 1A3-- 3........................

OM661LA Engine 1A3-- 5........................

Performance Curve 1A3-- 7........................

OM662LA Engine 1A3-- 7........................

OM661LA Engine 1A3-- 8........................

Special Tools 1A3 -- 9.............................Special Tools Table 1A3-- 9.......................

Diagnosis 1A3 -- 10................................

Oil Leak Diagnosis 1A3-- 10.......................

Compression Pressure Test 1A3-- 11..............

Cylinder Pressure Leakage Test 1A3-- 13...........

General Information 1A3 -- 15......................

Cleanliness and Care 1A3 -- 15....................

On-- Engine Service 1A3-- 15......................

SPECIFICATIONS

ENGINE SPECIFICATIONS

ApplicationOM662LAOM661LA

Engine TypeFour -- Stroke DieselFour -- Stroke Diesel

Displacement (CC)28742299

Cylinder (Bore x Stroke)(mm)89 x 92.489 x 92.4

Fuel Injection / Ignition SystemPES 5 M55 C320 RS 168PES 5 M55 C320 RS 167

Compression Ratio22 :122 :1

Number of Cylinders54

Camshaft Valve ArrangementSOHCSOHC

Camshaft Drive TypeChain -- DriveChain-- Drive

Max. Output (ps/rpm)120 / 4000101 / 4000

Max. Torque (kgSm/rpm)25.5 / 400021.5 / 2400

Firing Order1--2--4--5--31--3--4--2

Injection TimingBTDC 18_±10_BTDC 18_±10_

Valve Timing

(t2lift)

IntakeOpen/CloseAT DC 11 . 3 3_/ ABDC 17_AT DC 11 . 3 3_/ ABDC 17_g

(at 2mm lift)ExhaustOpen/CloseBBDC 28_/ BTDC 15.25_BBDC 28_/ BTDC 15.25_

Valve Clearance AdjustmentAutomatic ControlAutomatic Control

Page 544 of 2053

GENERAL ENGINE INFORMATION 1A3 -- 9

D AEW OO M Y_2000

SPECIAL TOOLS

SPECIAL TOOLS TABLE

000 589 10 99 01

Torque Wrench

001 589 76 21 00

Compression Pressure

Tester

601 589 65 09 00

Socket

001 589 73 21 00

Hand Vacuum Pump

Page 562 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 13

D AEW OO M Y_2000

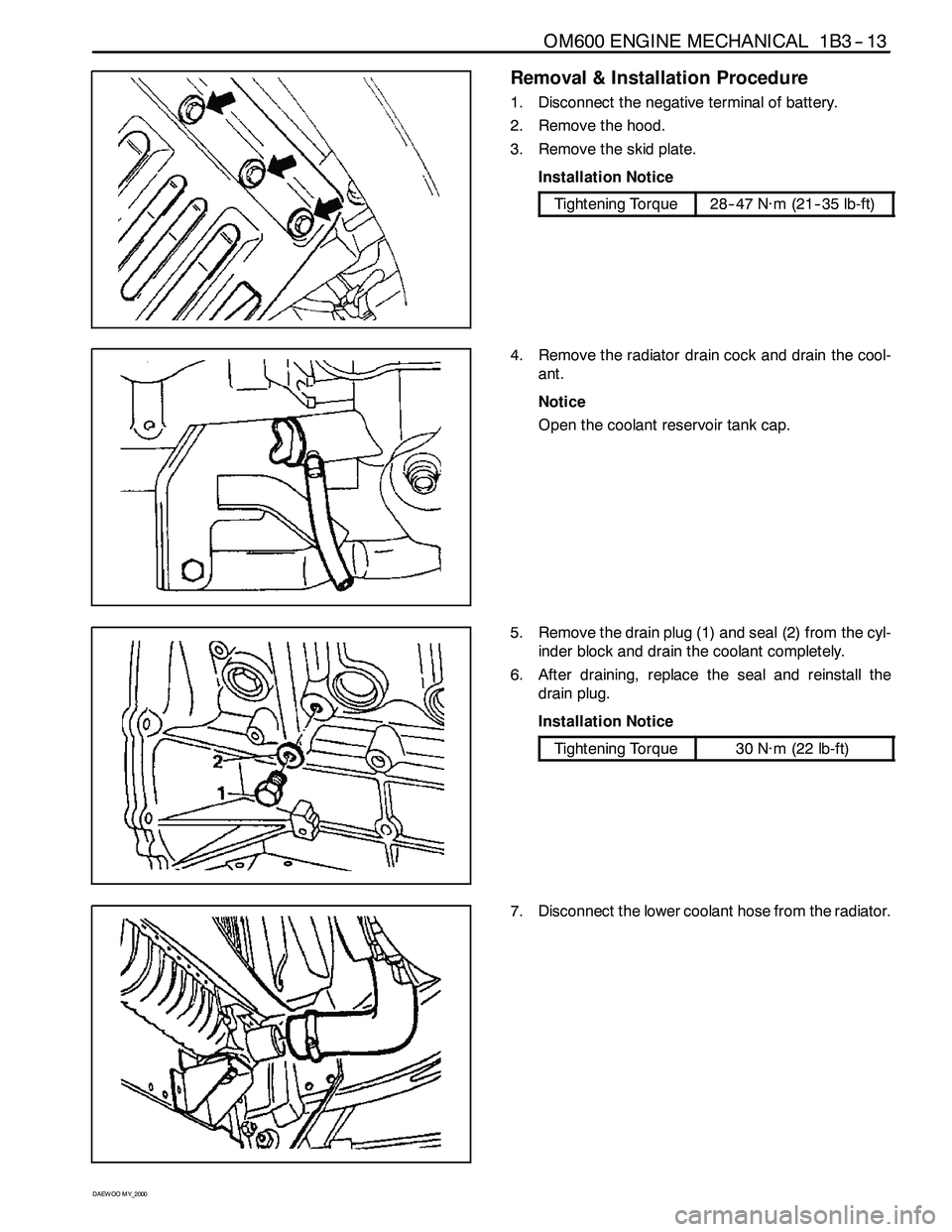

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the skid plate.

Installation Notice

Tightening Torque28-- 47 N∙m (21-- 35 lb-ft)

4. Remove the radiator drain cock and drain the cool-

ant.

Notice

Open the coolant reservoir tank cap.

5. Remove the drain plug (1) and seal (2) from the cyl-

inder block and drain the coolant completely.

6. After draining, replace the seal and reinstall the

drain plug.

Installation Notice

Tightening Torque30 N∙m (22 lb-ft)

7. Disconnect the lower coolant hose from the radiator.

Page 563 of 2053

1B3 -- 14 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

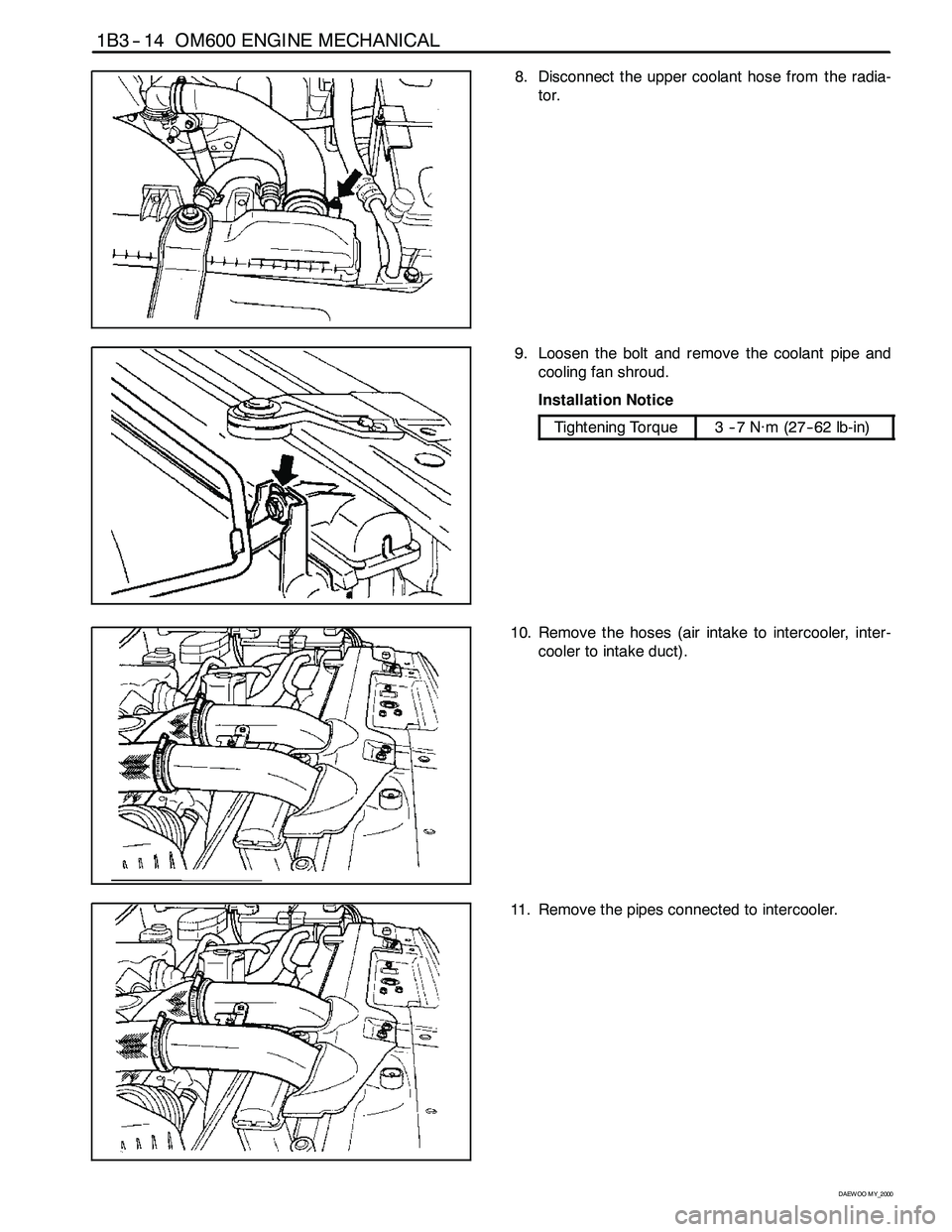

8. Disconnect the upper coolant hose from the radia-

tor.

9. Loosen the bolt and remove the coolant pipe and

cooling fan shroud.

Installation Notice

Tightening Torque3--7N∙m (27-- 62 lb-in)

10. Remove the hoses (air intake to intercooler, inter-

cooler to intake duct).

11. Remove the pipes connected to intercooler.