torque SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1285 of 2053

5A-190 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

15. Install the converter release check ball and spring.

16. Install the gasket on the pump cover.

17. Install the cover plate, solenoid 7 with the retainer

and the solenoid wiring retainer to the pump cover,

ensuring that the periphery of the cover plate is

flush with the periphery of the pump cover.

18. Tighten the screws to specification in the order.

(1-5)

Installation Notice

20. Assemble the pump to the pump cover.

21. Tighten all bolts and the crescent screw finger

tight, ensuring that the pump is flush against the

pump cover. Tighten the bolts and the screw to

specification in the order. (A-F)

Installation Notice 19. Tighten the solenoid 7 screw.

Installation Notice

Check that neither the wiring nor the connector

protrudes excessively, in order that at

assembly neither the wiring and the connector

contacts or rubs on the input shaft or the C1/

C2 clutch cylinder.

22. Install the pump to transmission case gasket onto

the case.

23. Fit the ‘O’ ring to the pump cover outer diameter.

KAA5A1J0

KAA5A1K0

KAA5A1L0

Tightening Torque13 - 16 Nm

(10 - 12 lb-ft)

Tightening Torque13 - 16 Nm

(10 - 12 lb-ft)

Tightening

TorqueBolt (A-E) : 24 - 27 Nm

(18 - 20 lb-ft)

Screw (F) : 13 - 16 Nm

(10 - 12 lb-ft)

Page 1286 of 2053

AUTOMATIC TRANSMISSION 5A-191

SSANGYONG MY2002

24. Install the pump and cover assembly over the

input shaft being careful not to damage the sealing

rings. Apply additional Loctite 202 or equivalent

as required to the pump cover to case bolts.

Install and tighten bolts to specification.

Installation Notice

KAA5A1M0

Tightening Torque24 - 34 Nm

(18 - 25 lb-ft)

25. Check that the transmission end float is 0.50 -

0.65 mm. If the unshimmed end float clearance is

greater than specification, shims are to be placed

between the No. 4 bearing and the input shaft

bearing surface. If the end float clearance is less

than 0.5 mm then the transmission has been

assembled incorrectly or the parts are out of

specification.

26. Perform the following steps to check the end float :

a. Attach a dial indicator to the front of the trans-

mission case with the stylus resting on the end

of the input shaft.

b. Apply a force of approximately 250 N or 25 kg

to the input shaft.

c. Zero the dial indicator.

d. Place a small lever behind the forward clutch

cylinder and lever the cylinder forward.

e. The measurement recorded on the dial indicator

is the transmission end float or clearance be-

tween the No. 4 bearing and the converter sup-

port tube.

27. On completion of this procedure, adjust the front

and rear bands to specifications. Refer to “Front

and Rear Band Adjustment” in this section.

KAA5A1N0

Page 1290 of 2053

AUTOMATIC TRANSMISSION 5A-195

SSANGYONG MY2002

19. Holding the separator plate to the upper valve

body to prevent the check balls from falling out,

install the upper valve body on the lower valve

body. Install all screws finger tight then tighten

the screws to specification in the prescribed

sequence.

Installation Notice

The wiring loom ground wire eyelet terminal is

secured beneath the solenoid 1 retainer. 16. Install the reverse lockout valve, spring, plug and

retaining plate. Ensure that the valve is correctly

oriented.

17. Position the five nylon ball checks in the upper

valve body.

18. Fit the upper valve body gasket. Install the

separator plate over the upper valve body.

KAA5A830 KAA5A840 KAA5A1V0

Tightening Torque11 - 16 Nm

(8 - 12 lb-ft)

20. Install solenoids 1, 2, 3, 4 and 6. Ensure the

solenoid is firmly secured by the retainer and that

the screw is tightened to specification.

Installation Notice

8 - 12 Nm

(71 - 106 lb-in)

Page 1291 of 2053

5A-196 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

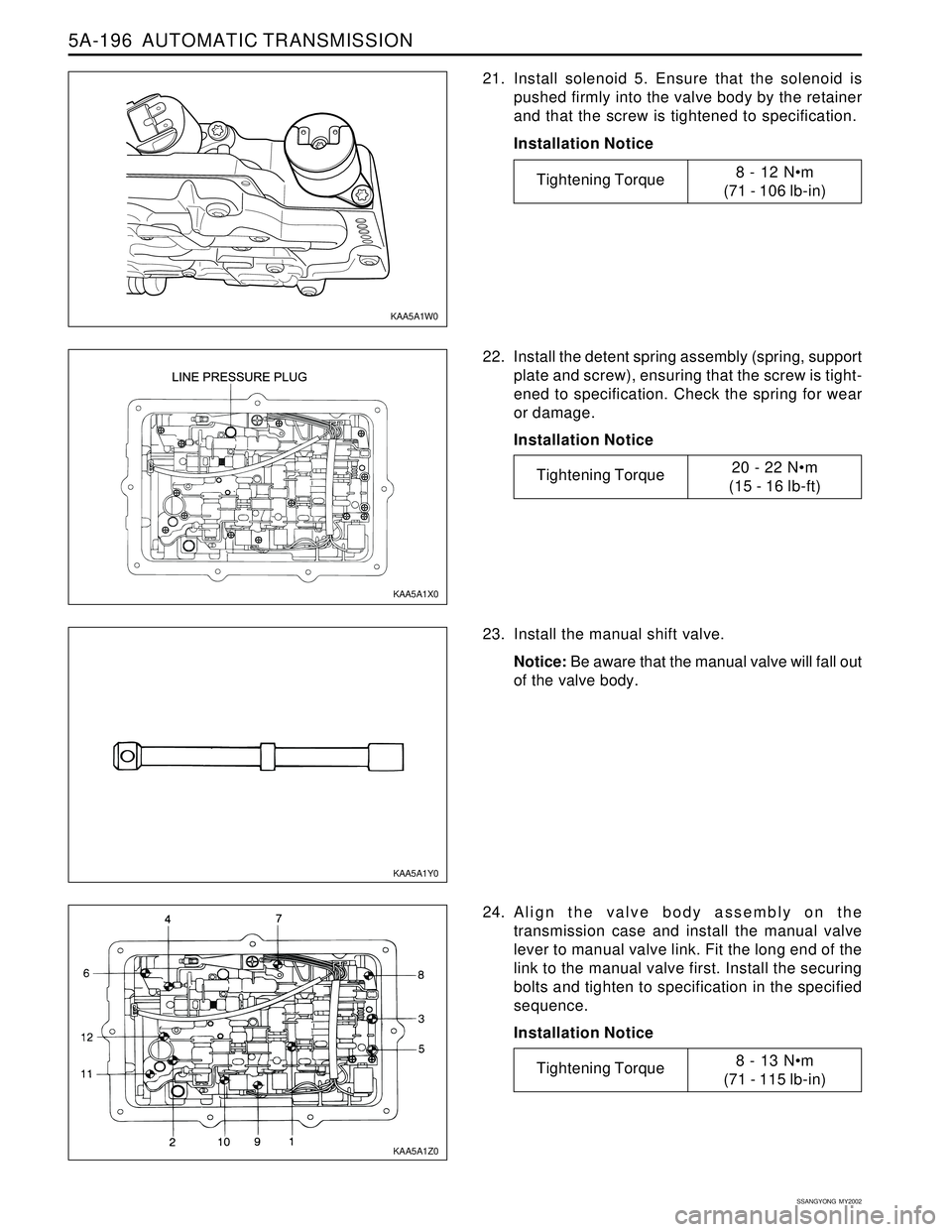

21. Install solenoid 5. Ensure that the solenoid is

pushed firmly into the valve body by the retainer

and that the screw is tightened to specification.

Installation Notice

22. Install the detent spring assembly (spring, support

plate and screw), ensuring that the screw is tight-

ened to specification. Check the spring for wear

or damage.

Installation Notice

23. Install the manual shift valve.

Notice: Be aware that the manual valve will fall out

of the valve body.

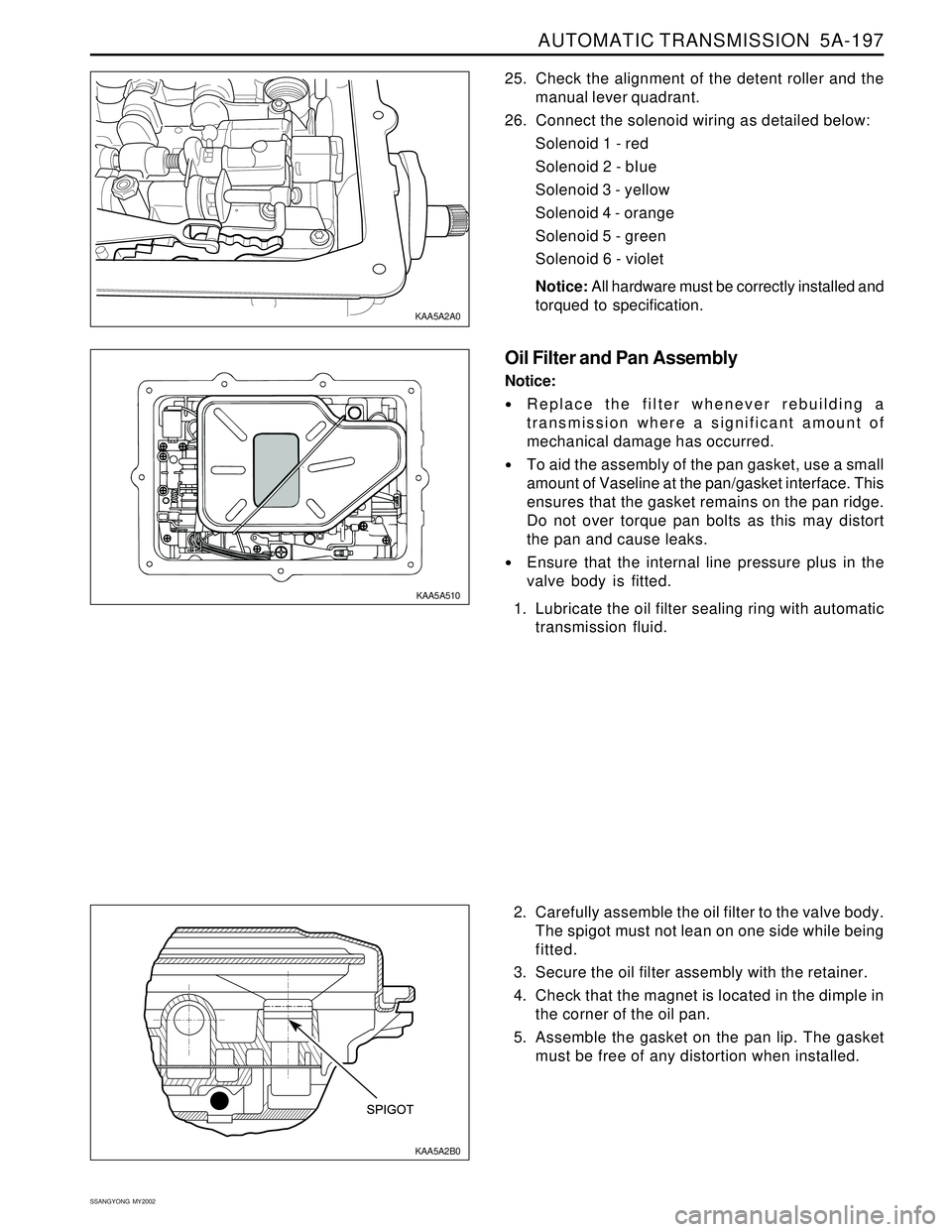

24. Align the valve body assembly on the

transmission case and install the manual valve

lever to manual valve link. Fit the long end of the

link to the manual valve first. Install the securing

bolts and tighten to specification in the specified

sequence.

Installation Notice

KAA5A1Y0 KAA5A1X0

KAA5A1Z0 KAA5A1W0

Tightening Torque8 - 12 Nm

(71 - 106 lb-in)

Tightening Torque20 - 22 Nm

(15 - 16 lb-ft)

Tightening Torque8 - 13 Nm

(71 - 115 lb-in)

Page 1292 of 2053

AUTOMATIC TRANSMISSION 5A-197

SSANGYONG MY2002

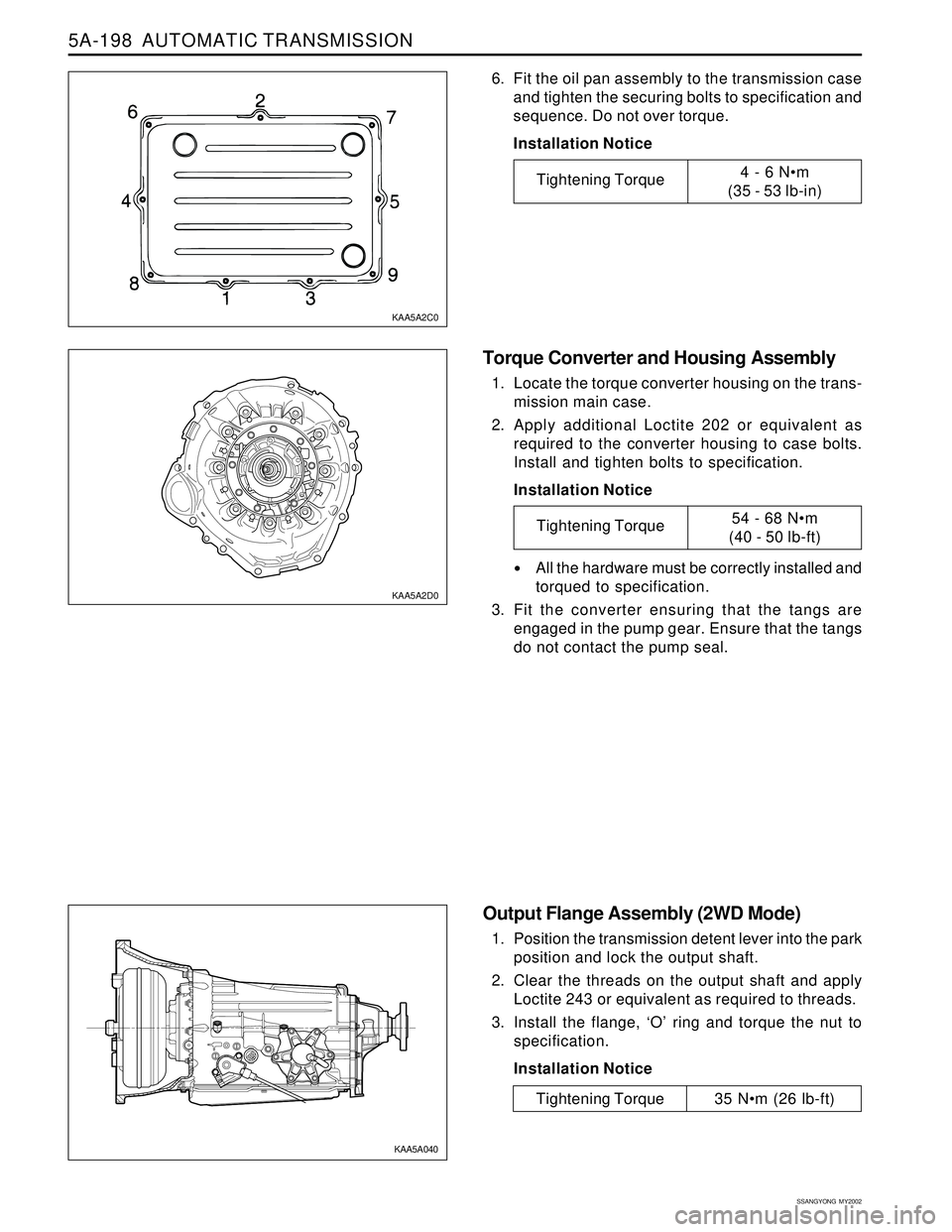

2. Carefully assemble the oil filter to the valve body.

The spigot must not lean on one side while being

fitted.

3. Secure the oil filter assembly with the retainer.

4. Check that the magnet is located in the dimple in

the corner of the oil pan.

5. Assemble the gasket on the pan lip. The gasket

must be free of any distortion when installed. 25. Check the alignment of the detent roller and the

manual lever quadrant.

26. Connect the solenoid wiring as detailed below:

Solenoid 1 - red

Solenoid 2 - bIue

Solenoid 3 - yellow

Solenoid 4 - orange

Solenoid 5 - green

Solenoid 6 - violet

Notice: All hardware must be correctly installed and

torqued to specification.

Oil Filter and Pan Assembly

Notice:

Replace the filter whenever rebuilding a

transmission where a significant amount of

mechanical damage has occurred.

To aid the assembly of the pan gasket, use a small

amount of Vaseline at the pan/gasket interface. This

ensures that the gasket remains on the pan ridge.

Do not over torque pan bolts as this may distort

the pan and cause leaks.

Ensure that the internal line pressure plus in the

valve body is fitted.

1. Lubricate the oil filter sealing ring with automatic

transmission fluid.

KAA5A2B0 KAA5A2A0

KAA5A510

Page 1293 of 2053

5A-198 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Torque Converter and Housing Assembly

1. Locate the torque converter housing on the trans-

mission main case.

2. Apply additional Loctite 202 or equivalent as

required to the converter housing to case bolts.

Install and tighten bolts to specification.

Installation Notice

All the hardware must be correctly installed and

torqued to specification.

3. Fit the converter ensuring that the tangs are

engaged in the pump gear. Ensure that the tangs

do not contact the pump seal.

Output Flange Assembly (2WD Mode)

1. Position the transmission detent lever into the park

position and lock the output shaft.

2. Clear the threads on the output shaft and apply

Loctite 243 or equivalent as required to threads.

3. Install the flange, ‘O’ ring and torque the nut to

specification.

Installation Notice

6. Fit the oil pan assembly to the transmission case

and tighten the securing bolts to specification and

sequence. Do not over torque.

Installation Notice

KAA5A2C0

KAA5A2D0

KAA5A040

Tightening Torque4 - 6 Nm

(35 - 53 lb-in)

Tightening Torque54 - 68 Nm

(40 - 50 lb-ft)

Tightening Torque 35 Nm (26 lb-ft)

Page 1298 of 2053

AUTOMATIC TRANSMISSION 5A-203

SSANGYONG MY2002

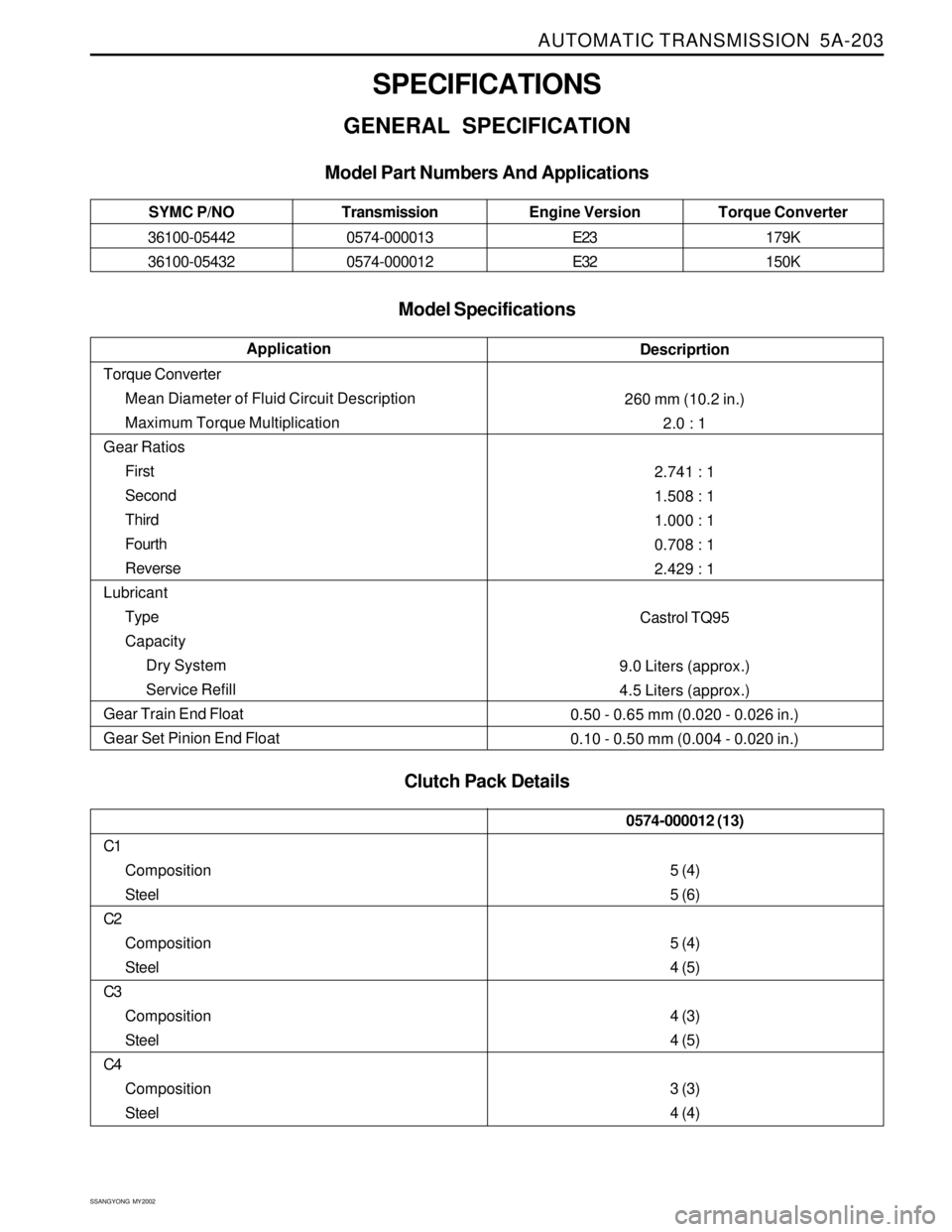

SPECIFICATIONS

GENERAL SPECIFICATION

Model Specifications

Clutch Pack Details Model Part Numbers And Applications

Descriprtion

260 mm (10.2 in.)

2.0 : 1

2.741 : 1

1.508 : 1

1.000 : 1

0.708 : 1

2.429 : 1

Castrol TQ95

9.0 Liters (approx.)

4.5 Liters (approx.)

0.50 - 0.65 mm (0.020 - 0.026 in.)

0.10 - 0.50 mm (0.004 - 0.020 in.)Application

Torque Converter

Mean Diameter of Fluid Circuit Description

Maximum Torque Multiplication

Gear Ratios

First

Second

Third

Fourth

Reverse

Lubricant

Type

Capacity

Dry System

Service Refill

Gear Train End Float

Gear Set Pinion End Float

Transmission

0574-000013

0574-000012Torque Converter

179K

150K Engine Version

E23

E32 SYMC P/NO

36100-05442

36100-05432

C1

Composition

Steel

C2

Composition

Steel

C3

Composition

Steel

C4

Composition

Steel

0574-000012 (13)

5 (4)

5 (6)

5 (4)

4 (5)

4 (3)

4 (5)

3 (3)

4 (4)

Page 1300 of 2053

AUTOMATIC TRANSMISSION 5A-205

SSANGYONG MY2002

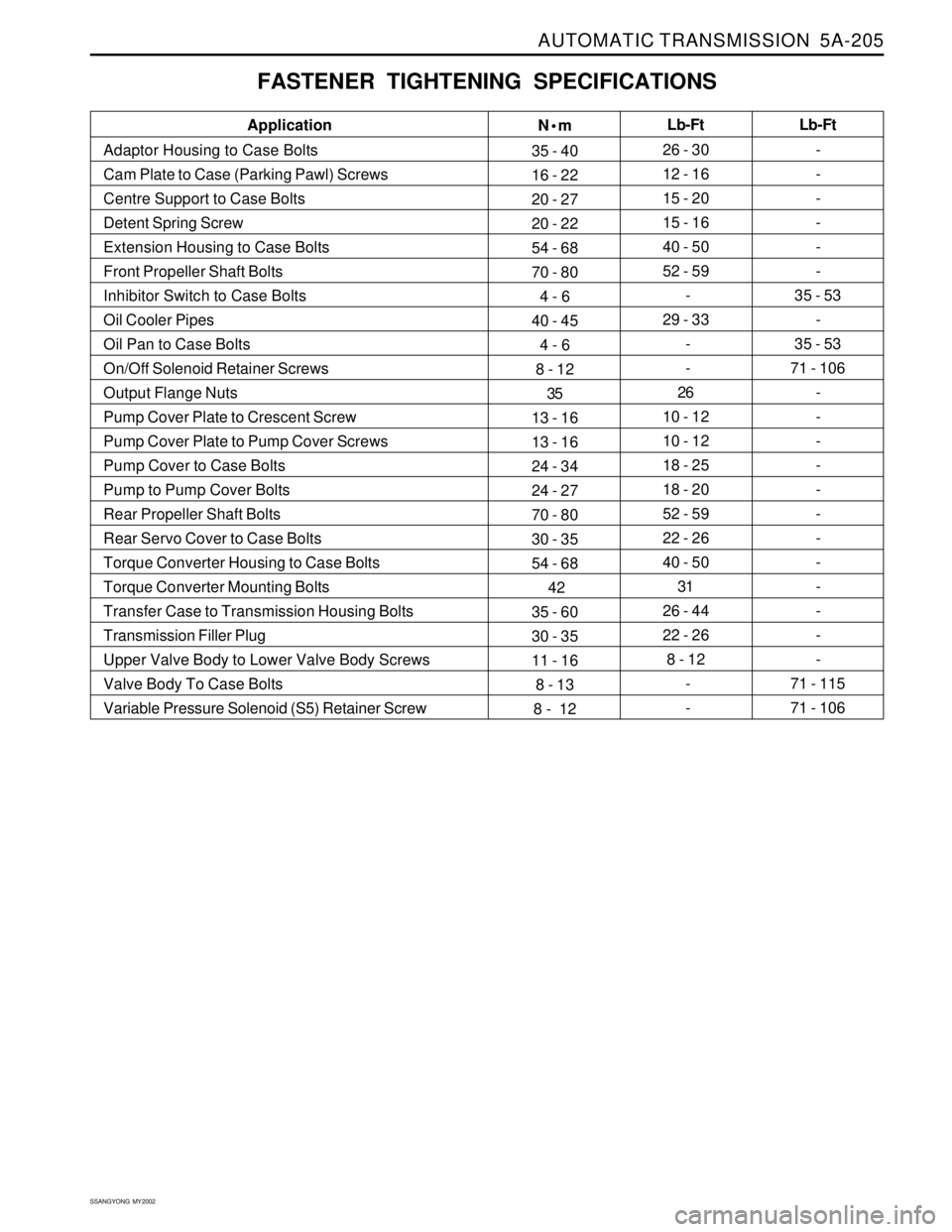

FASTENER TIGHTENING SPECIFICATIONS

N•m

35 - 40

16 - 22

20 - 27

20 - 22

54 - 68

70 - 80

4 - 6

40 - 45

4 - 6

8 - 12

35

13 - 16

13 - 16

24 - 34

24 - 27

70 - 80

30 - 35

54 - 68

42

35 - 60

30 - 35

11 - 16

8 - 13

8 - 12Lb-Ft

26 - 30

12 - 16

15 - 20

15 - 16

40 - 50

52 - 59

-

29 - 33

-

-

26

10 - 12

10 - 12

18 - 25

18 - 20

52 - 59

22 - 26

40 - 50

31

26 - 44

22 - 26

8 - 12

-

- Application

Adaptor Housing to Case Bolts

Cam Plate to Case (Parking Pawl) Screws

Centre Support to Case Bolts

Detent Spring Screw

Extension Housing to Case Bolts

Front Propeller Shaft Bolts

Inhibitor Switch to Case Bolts

Oil Cooler Pipes

Oil Pan to Case Bolts

On/Off Solenoid Retainer Screws

Output Flange Nuts

Pump Cover Plate to Crescent Screw

Pump Cover Plate to Pump Cover Screws

Pump Cover to Case Bolts

Pump to Pump Cover Bolts

Rear Propeller Shaft Bolts

Rear Servo Cover to Case Bolts

Torque Converter Housing to Case Bolts

Torque Converter Mounting Bolts

Transfer Case to Transmission Housing Bolts

Transmission Filler Plug

Upper Valve Body to Lower Valve Body Screws

Valve Body To Case Bolts

Variable Pressure Solenoid (S5) Retainer ScrewLb-Ft

-

-

-

-

-

-

35 - 53

-

35 - 53

71 - 106

-

-

-

-

-

-

-

-

-

-

-

-

71 - 115

71 - 106

Page 1330 of 2053

SSANGYONG MY2002

5B-22 MANUAL TRANSMISSION

62 - 93 Nm

(45 - 69 lb-ft)

21 - 35 Nm

(15 - 26 lb-ft)

Check the housing face alignment.

- Place the dial indicator on the housing face.

- By rotating the crankshaft one revolution,

record the dial indicator reading.

Notice: If the reading is greater than 0.010 inch,

insert the shim between the engine and clutch

housing and adjust the alignment.

5. Check the following parts :

Pressure plate spring assembly

Disc

Flywheel

Input shaft pilot bearing

Notice: Replace the excessively worn parts.

6. Lubricate the clutch release bearing bore, fork

pivot head during assembly.

Installation Procedure

1. Install the transmission to the vehicle. At this time,

seat correctly the input shaft of the transmission

on the pilot bearing of the flywheel.

2. Tighten the transmission mounting bolts as the

specified torque on the vehicle.

Installation Notice

YAD5B390

YAD5B400

YAD5B410

YAD5B420

Tightening Torque77 - 87 Nm

(57 - 64 lb-ft)

3. Install the cross member and tighten as the

specified torque by supporting the suitable jack.

Installation Notice

Tightening

TorqueLeft/Right

Center

Page 1331 of 2053

MANUAL TRANSMISSION 5B-23

SSANGYONG MY2002

4. Install the front and rear propeller shafts to the

transmission.

Installation Notice

5. Connect the cable, the harness and the bleeder.

6. Install the back lamp switch.

7. Install the speedometer cable.

YAD5B430

YAD5B440

YAD5B450

YAD5B310

81 - 89 Nm

(60 - 66 lb-ft)

70 - 90 Nm

(52 - 66 lb-ft)

Tightening

TorqueFront

Rear

8. Charge the approved oil in the transmission

housing and tighten the drain plug and the filler

plug.

Installation Notice

Oil25 Nm (18 lb-ft)

25 Nm (18 lb-ft)

Tightening

TorqueFiller Plug

Drain Plug

Spec.

Capacity

3.4L

2.0L

4WD

2WDATF Dexron II