lock SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1083 of 1463

5A-106 AUTOMATIC TRANSMISSION

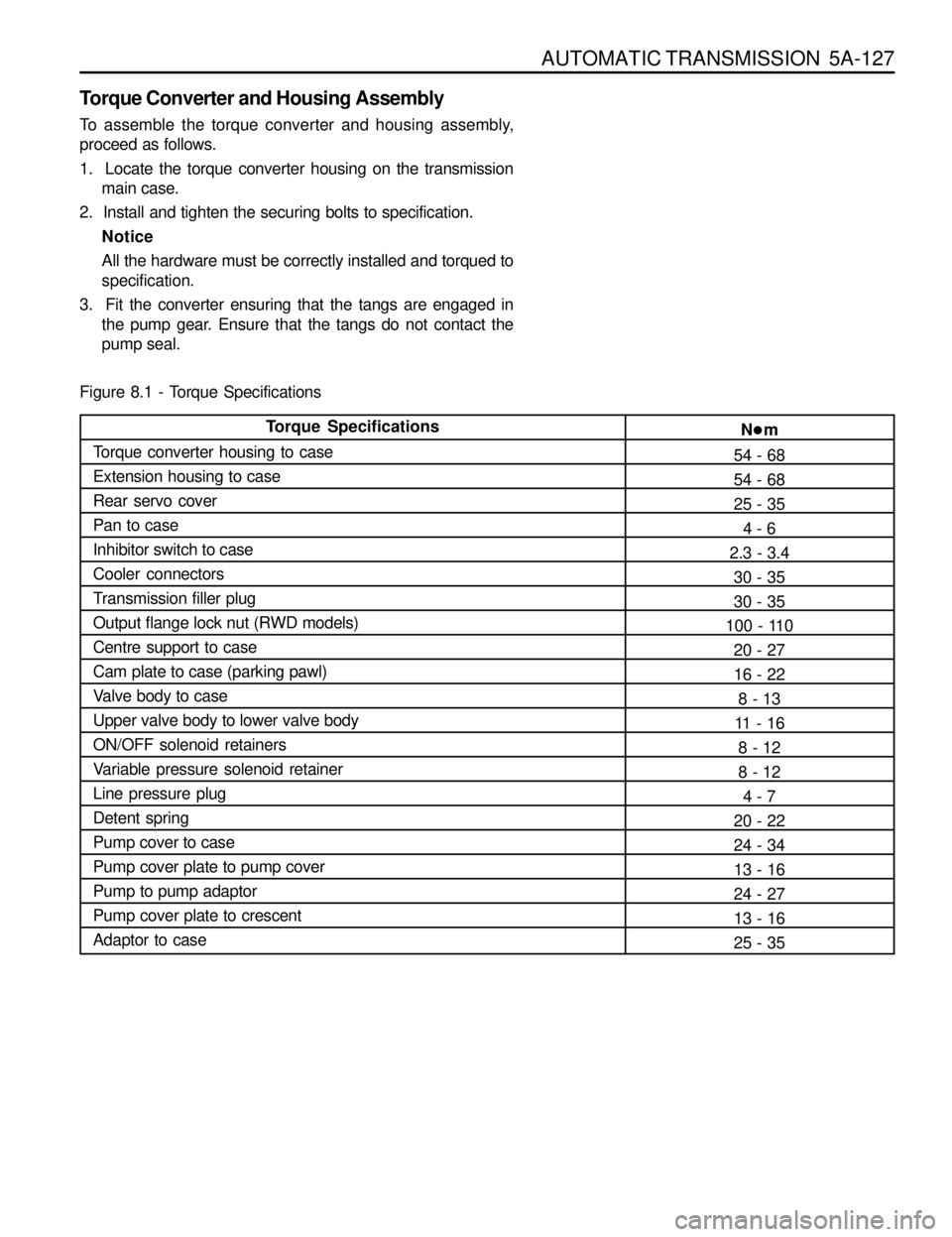

29. Align the tangs and fit the nylon thrust washer onto the

C4 hub. Refer to figure 8.27.

30. Align and fit the C4 hub to the C2 clutch and the OWC

assembly.

31. Check the rotation of the C2 hub. While holding the

C4 hub, the C2 hub should rotate in the clockwise

direction and lockup in the anti-clockwise direction when

viewed from the C2 hub. Refer to figure 8.27.

Figure 8.27 - C2 - Hub Rotation

32. Apply petroleum jelly to the No. 5 thrust bearing and fit

it to the C4 hub. Refer to figure 8.19.

33. Remove the C2 clutch plates from the clutch cylinder.

34. Fit the thrust plate over the cylinder inner hub. Refer

to figures 8.24 and 8.19.

35. Engage the C2/C4 clutch hub assembly in the C4 clutch

plates.

36. Install the C2 clutch plates.

37. Install the C3 hub and secure it with the circlip, ensuring

that the circlip is firmly seated in its groove.

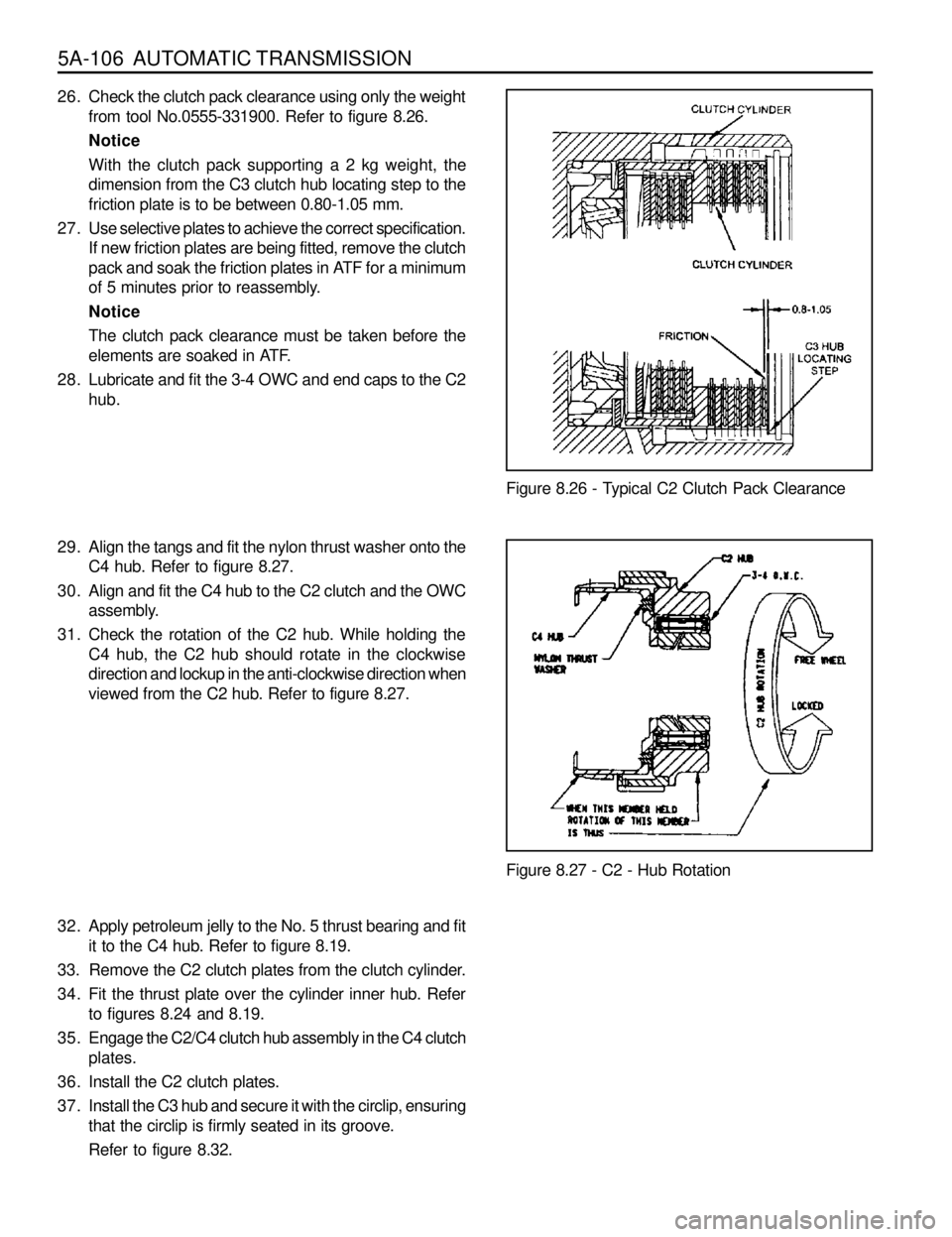

Refer to figure 8.32.Figure 8.26 - Typical C2 Clutch Pack Clearance 26. Check the clutch pack clearance using only the weight

from tool No.0555-331900. Refer to figure 8.26.

Notice

With the clutch pack supporting a 2 kg weight, the

dimension from the C3 clutch hub locating step to the

friction plate is to be between 0.80-1.05 mm.

27. Use selective plates to achieve the correct specification.

If new friction plates are being fitted, remove the clutch

pack and soak the friction plates in ATF for a minimum

of 5 minutes prior to reassembly.

Notice

The clutch pack clearance must be taken before the

elements are soaked in ATF.

28. Lubricate and fit the 3-4 OWC and end caps to the C2

hub.

Page 1099 of 1463

5A-122 AUTOMATIC TRANSMISSION

15. Install solenoid 6 plunger, spring and retaining pin.

16. Position the third feed ball (large nylon) in the valve body

and install the solenoid 5 filter and the solenoid 6 filter.

Refer to figures 8.5 and 8.56.

17. Check the separator plate for burrs and damage. Repair

or replace the separator plate as necessary.

18. Check the upper and lower valve body gaskets for

damage. Replace the gaskets as necessary.

19. Install the lower valve body gasket on the lower valve body.

20. Install the reverse lockout valve, spring, plug and retainer

plate. Ensure that the valve is correctly oriented. Refer to

figure 8.57.

Figure 8.57 - Reverse Lockout Valve

21. Position the five nylon ball checks in the upper valve body.

Refer to figure 8.48.

22. Fit the upper valve body gasket. Install the separator plate

over the upper valve body.

Page 1104 of 1463

AUTOMATIC TRANSMISSION 5A-127

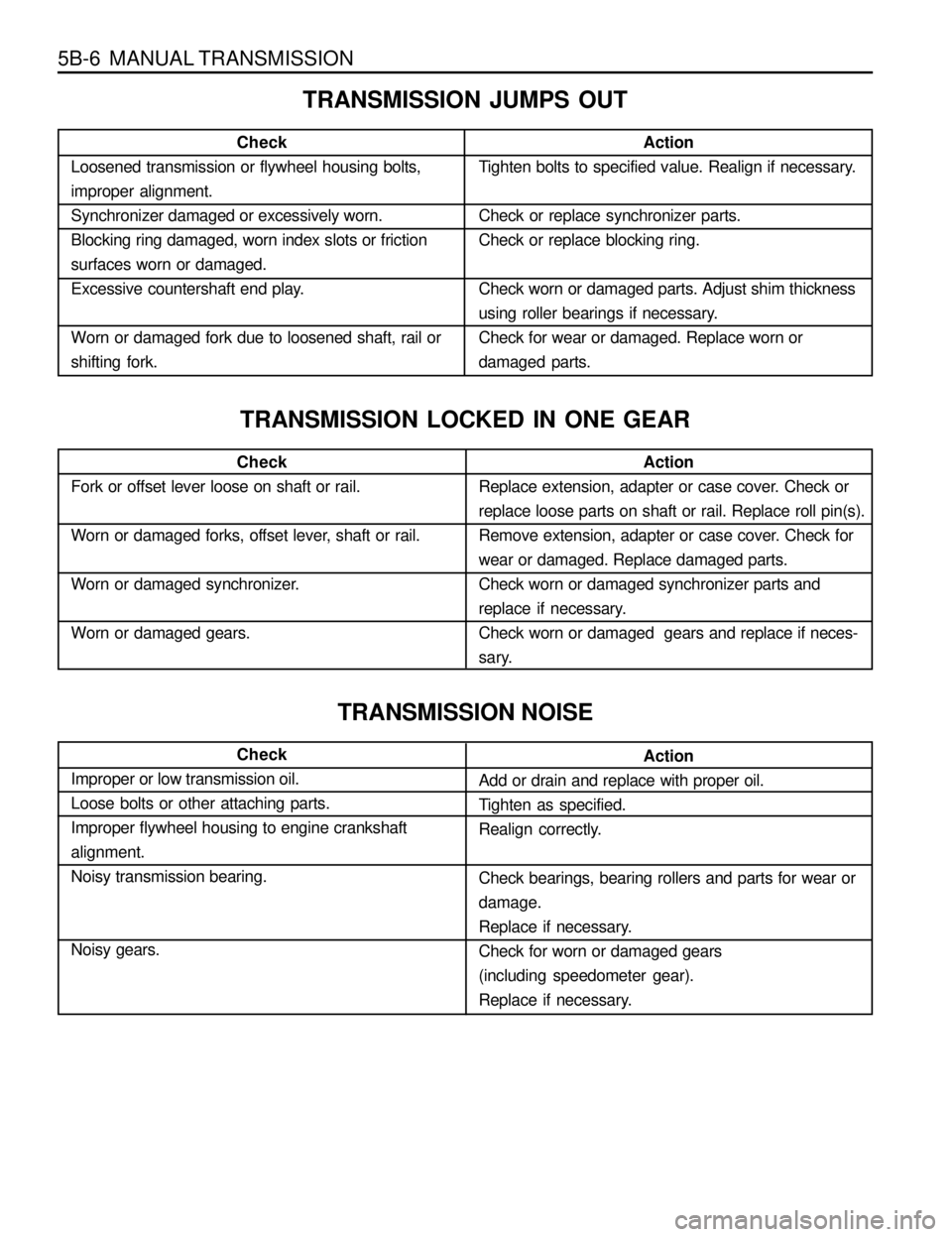

Torque Converter and Housing Assembly

To assemble the torque converter and housing assembly,

proceed as follows.

1. Locate the torque converter housing on the transmission

main case.

2. Install and tighten the securing bolts to specification.

Notice

All the hardware must be correctly installed and torqued to

specification.

3. Fit the converter ensuring that the tangs are engaged in

the pump gear. Ensure that the tangs do not contact the

pump seal.

Figure 8.1 - Torque Specifications

Torque Specifications

Torque converter housing to case

Extension housing to case

Rear servo cover

Pan to case

Inhibitor switch to case

Cooler connectors

Transmission filler plug

Output flange lock nut (RWD models)

Centre support to case

Cam plate to case (parking pawl)

Valve body to case

Upper valve body to lower valve body

ON/OFF solenoid retainers

Variable pressure solenoid retainer

Line pressure plug

Detent spring

Pump cover to case

Pump cover plate to pump cover

Pump to pump adaptor

Pump cover plate to crescent

Adaptor to caseNlm

54 - 68

54 - 68

25 - 35

4 - 6

2.3 - 3.4

30 - 35

30 - 35

100 - 110

20 - 27

16 - 22

8 - 13

11 - 16

8 - 12

8 - 12

4 - 7

20 - 22

24 - 34

13 - 16

24 - 27

13 - 16

25 - 35

Page 1108 of 1463

Model

Type

Gear Ratio

Oil

Weight (Dry)

SECTION 5B

MANUAL TRANSMISSION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 5B-1

General Specifications . . . . . . . . . . . . . . . . . . 5B-1

Fastener Tightening Specifications . . . . . . . . . 5B-2

External View . . . . . . . . . . . . . . . . . . . . . . . . 5B-3

Gear Train . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-3

Power Flow . . . . . . . . . . . . . . . . . . . . . . . . . 5B-4

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-5

Will not Shift (Control Lever Moves) . . . . . . . . 5B-5

Hard Shift or Control Lever Will not Move Into

Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-5

Gears Crash When Shifting . . . . . . . . . . . . . . 5B-5

Transmission Jumps Out . . . . . . . . . . . . . . . . . 5B-6

Transmission Locked in One Gear . . . . . . . . . 5B-6

Transmission Noise . . . . . . . . . . . . . . . . . . . . . 5B-6

Transmission Leakage . . . . . . . . . . . . . . . . . . 5B-7Diagnosis Table . . . . . . . . . . . . . . . . . . . . . . . 5B-8

Component Locator . . . . . . . . . . . . . . . . . . . 5B-9

Maintenance and Repair . . . . . . . . . . . . . . 5B-11

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 5B-11

Shift Control Cable . . . . . . . . . . . . . . . . . . . . 5B-11

Transmission . . . . . . . . . . . . . . . . . . . . . . . . 5B-14

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . 5B-17

Major Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-17

Main Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-27

Input Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-32

Counter Shaft . . . . . . . . . . . . . . . . . . . . . . . . 5B-34

Extension Housing . . . . . . . . . . . . . . . . . . . . 5B-35

Shift Cover . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-36

Inspection of Components . . . . . . . . . . . . . . 5B-40

Pre-Installation Checks . . . . . . . . . . . . . . . . . 5B-45

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Description

T5WC

Floor Change

3.97 : 1

2.34 : 1

1.46 : 1

1.00 : 1

0.85 :1

3.71 : 1

ATF DEXRON II / III

3.4 L

Check : Every 15,000km, Replace : Every 50,000km

33kg 1st

2nd

3rd

4th

5th

Reverse

Specification

Capacity(litre)

Change Interval

Notice

Add LUBRIZOL (280cc) in oil after overhauling.

Page 1113 of 1463

5B-6 MANUAL TRANSMISSION

Check

Loosened transmission or flywheel housing bolts,

improper alignment.

Synchronizer damaged or excessively worn.

Blocking ring damaged, worn index slots or friction

surfaces worn or damaged.

Excessive countershaft end play.

Worn or damaged fork due to loosened shaft, rail or

shifting fork.

TRANSMISSION JUMPS OUT

Action

Tighten bolts to specified value. Realign if necessary.

Check or replace synchronizer parts.

Check or replace blocking ring.

Check worn or damaged parts. Adjust shim thickness

using roller bearings if necessary.

Check for wear or damaged. Replace worn or

damaged parts.

Check

Fork or offset lever loose on shaft or rail.

Worn or damaged forks, offset lever, shaft or rail.

Worn or damaged synchronizer.

Worn or damaged gears.

TRANSMISSION LOCKED IN ONE GEAR

Action

Replace extension, adapter or case cover. Check or

replace loose parts on shaft or rail. Replace roll pin(s).

Remove extension, adapter or case cover. Check for

wear or damaged. Replace damaged parts.

Check worn or damaged synchronizer parts and

replace if necessary.

Check worn or damaged gears and replace if neces-

sary.

Check

Improper or low transmission oil.

Loose bolts or other attaching parts.

Improper flywheel housing to engine crankshaft

alignment.

Noisy transmission bearing.

Noisy gears.

TRANSMISSION NOISE

Action

Add or drain and replace with proper oil.

Tighten as specified.

Realign correctly.

Check bearings, bearing rollers and parts for wear or

damage.

Replace if necessary.

Check for worn or damaged gears

(including speedometer gear).

Replace if necessary.

Page 1115 of 1463

5B-8 MANUAL TRANSMISSION

1 Shift Hop-out

2 Shift Gear Crash

3 Shift Block-out

4 Hard Shift

5 Noise in Reverse Gear

6 Noise in 5th Gear

7 Noise in 4th Gear

8 Noise in 3rd Gear

9 Noise in 2nd Gear

10 Noise in 1st Gear

11 Noise in All Speeds

12 Leak at Transmission Rear Part

13 Leak at Transmission Center Part

14 Leak at Transmission Front

DIAGNOSIS TABLE

Condition

Possible Faulty Part

Transmission Case

Extension Housing

Shift Cover / Shift Shift

Shift Control Lever

Input Bearing Retainer

Input Gear Set

3rd Speed Gear Set

2nd Speed Gear Set

Reverse Speed Gear Set

1st Speed Gear Set

5th Speed Gear Set

Clutch Housing and Release Derive

Crankshaft Pilot Bushing and Release Bearing

Input Bearing

Main Shaft Input Bearing

Main Shaft Thrust Bearing

3rd Speed Gear Bearing

2nd Speed Gear Bearing

1st Speed Gear Bearing

Reverse Idler Gear Bushing

Counter Shaft Front Bearing

Counter Shaft Rear Bearing

Counter Shaft Thrust Bearing

5th Speed Drive Gear Bearing

Slip Yoke Bushing

Slip Yoke Seal

Speedometer Drive / Driven Gears

Speedometer Driven Gear Housing

Input Shaft Seal

1 - 2 Synchronizer Assembly

3 - 4 Synchronizer Assembly

5th Synchronizer Assembly

Ring Oil Seal

T/C Front Facel

l

ll

l

l

l l

l

l

l

l l

l

l

l

l

l

l

l

l

l

ll

l

ll

l

l

ll

l

l

l

ll

l

l

l

ll

l

ll

l

ll

l

ll

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

Page 1117 of 1463

5B-10 MANUAL TRANSMISSION

1 Filler/Drain Plug

2 Shift Mechanism Cover

3 Shift Shaft Lever

4 Outer Select Lever

5 Inner Select Lever

6 Offset Control Lever

7 Bias Spring

8 Bolt

9 Pin

10 Washer

11 Bolt

1 2 Bolt

13 Extension and Plate Assembly

14 O-Ring & Steel Ring

15 Oiling Funnel

1 6 Bolt

17 Alignment Bolt

18 Pin

19 Shift Shaft

20 3/4 Shift Fork

21 1/2 Shift Fork

22 Insert

23 Selector Arm Assembly

24 Interlock Plate Assembly

25 Selector Plate

26 O-ring

2 7 Plug

28 Case Cover

29 Retaining Ring

30 Pivot Pin

31 Back-up Switch

32 5/Reverse Shift Lever

33 Snap Ring

34 5th Synchronizer Retainer

35 5th Synchronizer Assembly

36 Synchronizer Spring

37 Synchronizer Assembly38 Insert

39 Synchronizer Hub

40 Roll Pin

41 5th Shift Fork

42 Insert

43 Shift Rail Assembly

44 Blocking Ring

45 5th Speed Drive Gear

46 Snap Ring

47 Speed Gear

48 Speed Gear Clip

4 9 Bolt

50 Input Bearing Retainer

51 Oil Seal

5 2 Shim

53 Bearing Cup

54 Bearing Cone

55 Input Shaft

56 Roller Bearing

57 Spacer

58 Thrust Bearing

59 Thrust Bearing Race

60 5th Speed Driven Gear

61 Bearing Cup

62 Bearing Cone

63 1st Speed Gear

64 Bearing Sleeve Assembly

65 A. Bearing

65 B. Bearing

65 C. Spacer

66 Sleeve

67 Blocking Ring Assembly

68 3/4 synchronizer Assembly

69 Synchronizer Spring

70 Synchronizer Sleeve

71 Insert

72 Synchronizer Sleeve73 3rd Speed Gear

74 Needle Bearing

75 Spacer

76 Snap Ring

77 Thrust Washer

78 2nd Speed Gear

79 2nd Speed Gear Bearing

80 Spacer

81 Output Shaft Assembly

82 Retaining Ring

83 Thrust Washer

84 Inner Cone

85 Outer Cone Race

86 1/2 Blocking Ring

87 Spring Gear

88 Reverse Sliding Gear

89 Insert Gear

90 Pin

91 Shaft and Hub Assembly

92 Spring

93 Pin Fork and Reverse Roller

Assembly

9 4 Bolt

95 Rear Bearing Retainer

9 6 Shim

97 Roll Pin

98 Reverse Idler Shaft

99 Reverse Idler Gear Assembly

100 O-ring

101 Bearing Cup

102 Bearing Cup Assembly

103 O-ring

104 Bearing Cup

105 Bearing Cone

106 Counter Shaft Gear

107 Transmission Case Assembly

Page 1127 of 1463

5B-20 MANUAL TRANSMISSION

18. Remove the slip yoke snap ring from the main shaft.

19. Remove the 5th speed drive gear snap ring from the main

shaft.

20. Make alignment marks on the case and input bearing

retainer and remove the 4 input shaft bearing retainer bolts,

using a 13 mm wrench.

Notice

Apply sealer on these bolts during assembly.

Remove the input bearing retainer with the bearing outer

race and shim.

21. Remove the input shaft from the case by rotating it until

the flat surface appears.

22. Remove the following parts from the input shaft.

l4th speed gear blocking ring.

lMain shaft thrust race and bearing.

lMain shaft pilot bearing rollers (15 rollers).

Notice

Be careful not to dissipate the pilot bearing rollers.

Page 1128 of 1463

MANUAL TRANSMISSION 5B-21

23. Remove the main shaft in 2 steps.

lTo remove the rear bearing outer race, push the main

shaft rearward.

lTilt and lift the main shaft from the case.

24. Remove the reverse fork and spring from the case.

25. Remove the counter shaft as follows:

lUsing a punch and hammer, pry up the lock tabs.

lUsing a 13 mm wrench or T-40 bit, remove the 4 bolts.

lRemove the retainer and shim from the case.

lPush the counter shaft rearward to remove the rear

bearing outer race.

Page 1131 of 1463

5B-24 MANUAL TRANSMISSION

7. Install the counter shaft rear bearing outer race, shim and

retainer.

Tightening Torque

39 - 52 Nm

lUsing a punch and hammer, bend the lock tabs on the

retainer.

8. Install the following parts :

lInstall the main shaft into case.

lInstall the main shaft rear bearing outer race into the

rear of the case.

lInstall the 4th speed blocking ring onto the front of the

main shaft.

lInstall the input shaft onto the front of the main shaft.

lInstall the input bearing retainer without shim onto the

front of the case.

lUsing a torque wrench, tighten the 4 bolts.

9. Install the 5th speed drive gear and blocking ring on the

counter shaft.

10. Install the 5th synchronizer and rail/fork.

11. Install the 5th synchronizer snap ring and oiling funnel.

12. Align the slots of the lever with the rollers of the reverse

fork and 5th shift rail. Apply sealer on the 5-R lever pivot

bolt and install it into the case.

Tightening Torque 28 Nm

13. Using a needle nose pliers, install the 5-R lever clip.