SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Trending: wheel torque, air filter, fuel consumption, run flat, brake, alternator belt, length

Page 341 of 1463

OM600 ENGINE MECHANICAL 1B3-39

Length(L) When New

80mm

102mm

115mm Thread Dia.

M10

M10

M10Max. Length(L)

82mm

104mm

117mm

The twelve-sided socket head bolts are tightened with each

stages of torque and torque angle.

It is not necessary to retighten the cylinder head bolts at

the 1000~1500km inspection or after 1000~1500km of

repairs.

Notice

The cylinder head may only be removed when the engine

has cooled down. The cylinder head is removed together

with the exhaust manifold. As the cylinder head bolts

undergo a permanent tightening. They require to be

replaced if they exceed the maximum lengthes indicated

in the table.

Page 342 of 1463

1B3-40 OM600 ENGINE MECHANICAL

Disassembly Procedure

1. Completely drain the coolant from the radiator and cylinder

block.

2. Remove the cooling fan shroud.

3. Hold the fan with counter holder and remove the bolt and

then remove the cooling fan.

Notice

Keep the fan in vertical position.

Counter Holder 603 589 00 40 00

5. Remove the nut.

6. Remove the nut on the tensioning lever and insert the

rod(F12 ´ 180mm). By pushing the rod to the arrow direction,

pull back the bolt.

7. Push the tensioning lever to the opposite direction to release

the spring tension and remove the poly V-belt. 4. Remove the bracket oil dipstick tube.

Page 343 of 1463

OM600 ENGINE MECHANICAL 1B3-41

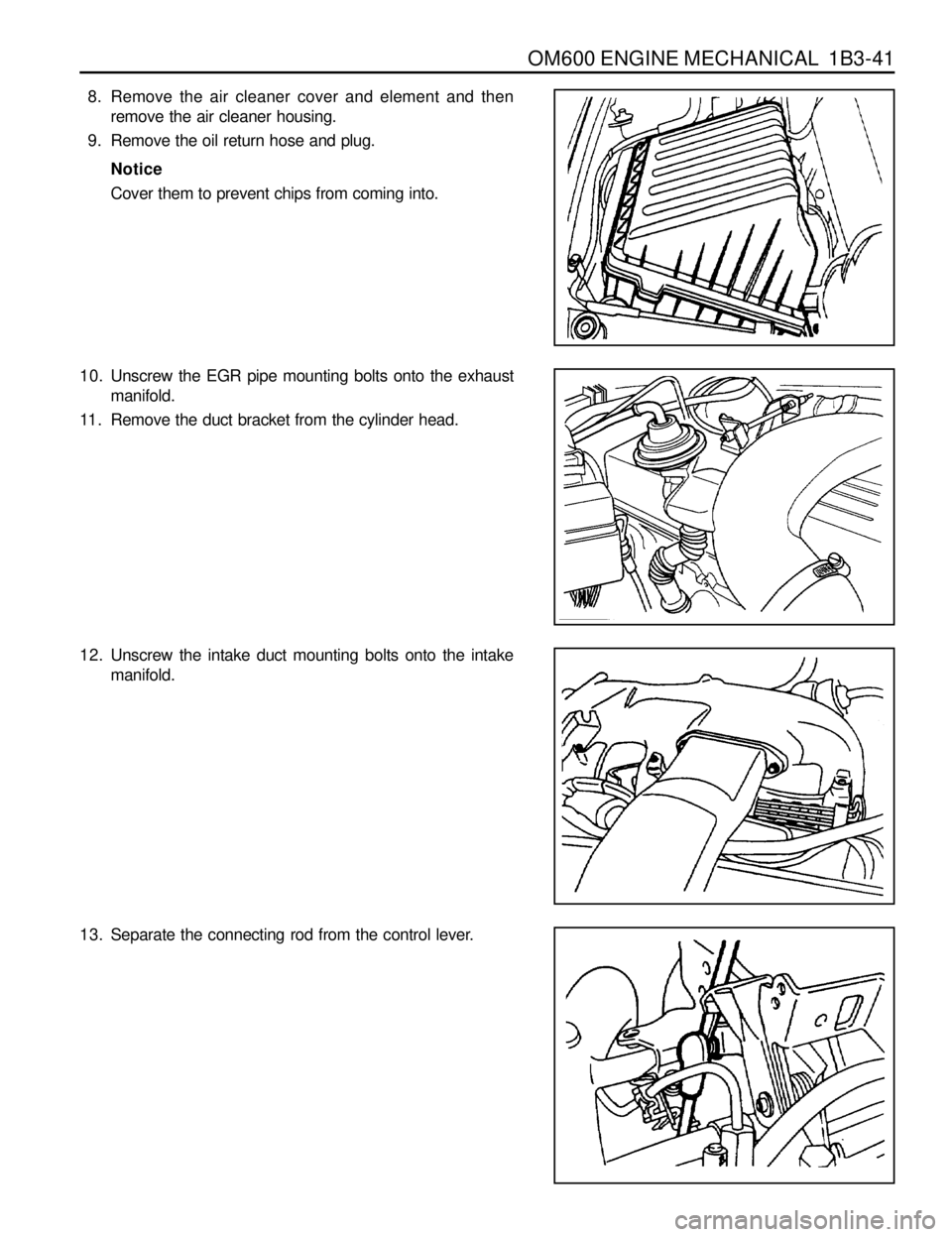

8. Remove the air cleaner cover and element and then

remove the air cleaner housing.

9. Remove the oil return hose and plug.

Notice

Cover them to prevent chips from coming into.

10. Unscrew the EGR pipe mounting bolts onto the exhaust

manifold.

11. Remove the duct bracket from the cylinder head.

12. Unscrew the intake duct mounting bolts onto the intake

manifold.

13. Separate the connecting rod from the control lever.

Page 344 of 1463

1B3-42 OM600 ENGINE MECHANICAL

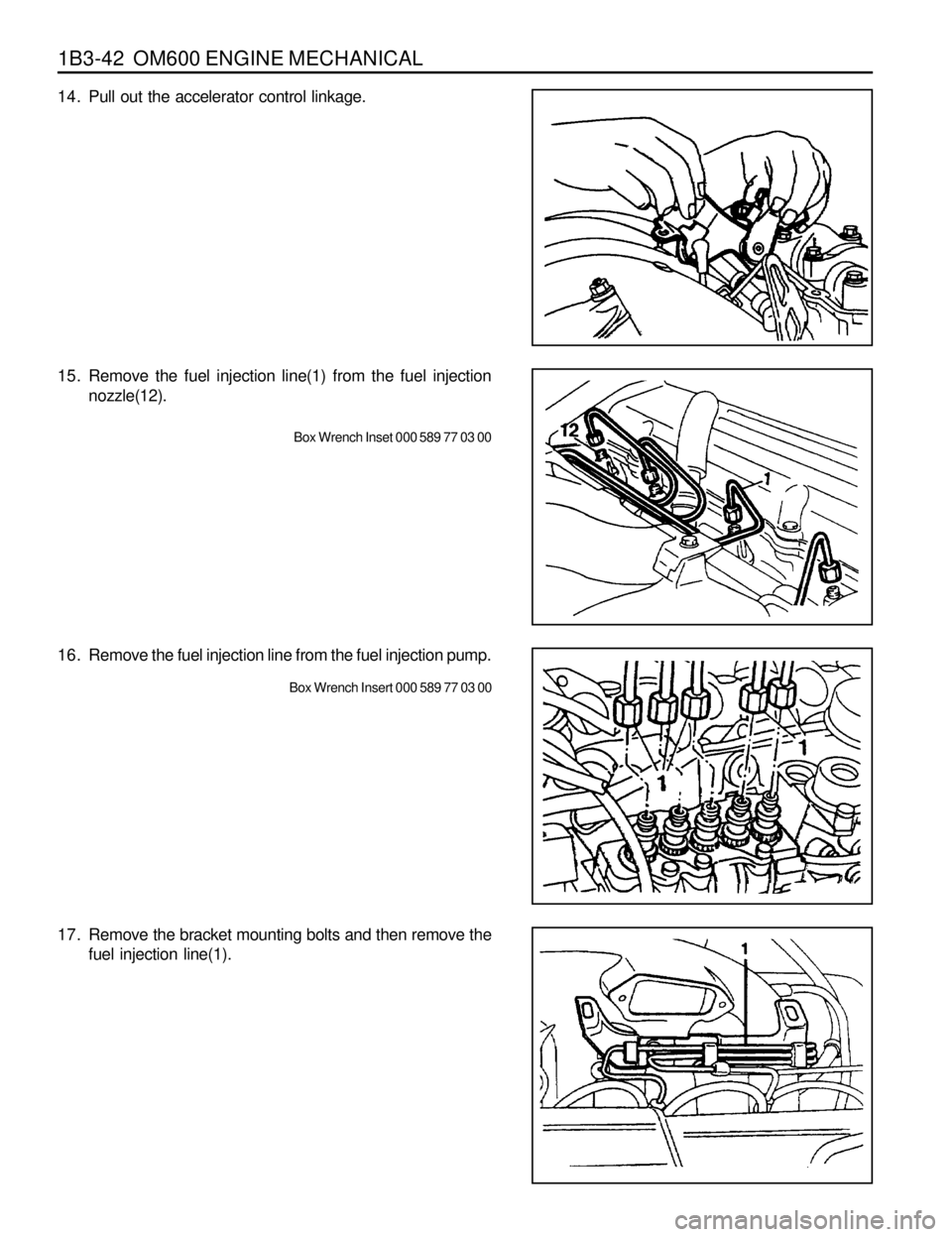

14. Pull out the accelerator control linkage.

15. Remove the fuel injection line(1) from the fuel injection

nozzle(12).

Box Wrench Inset 000 589 77 03 00

16. Remove the fuel injection line from the fuel injection pump.

Box Wrench Insert 000 589 77 03 00

17. Remove the bracket mounting bolts and then remove the

fuel injection line(1).

Page 345 of 1463

OM600 ENGINE MECHANICAL 1B3-43

18. Disconnect the booster hose connected to intake manifold.

19. Remove the intake manifold and gasket.

20. Remove the cylinder head cover and gasket with the blow-

by gas hose.

21. Disconnect the glow plug cables.

Page 346 of 1463

1B3-44 OM600 ENGINE MECHANICAL

22. Remove the cable channel.

23. Disconnect the cables from the glow plug sensor and

coolant temperature sensor.

24. Remove the heater pipe bracket from the oil filter.

25. Pry off the clamp and push the heater feed pipe forward

and then pull out the pipe.

Page 347 of 1463

OM600 ENGINE MECHANICAL 1B3-45

26. Disconnect the fuel lines from the fuel filter.

27. Disconnect the fuel lines from the injection pump.

28. Remove the fuel filter(35).

29. Remove the fuel injection nozzle(12) and nozzle

washer(11).

Socket Wrench Insert 001 589 65 09 00

Page 348 of 1463

1B3-46 OM600 ENGINE MECHANICAL

30. Rotate the crankshaft and set the no.1 cylinder at TDC.

Notice

Do not rotate the crankshaft to the opposite direction of

engine revolution.

31. Place alignment marks on the camshaft gear and timing

chain.

32. Ensure that the camshaft and the bearing cap marking

are aligned.

33. Remove the starter motor and install the engine lock onto

the flywheel ring gear.

Engine Lock 602 589 00 40 00

Page 349 of 1463

OM600 ENGINE MECHANICAL 1B3-47

34. Remove the turbocharger.

35. Remove the exhaust manifold and gasket.

36. Remove the chain tensioner and seal.

37. Remove the bolt and separate the drive sprocket(21).

Notice

During removal, be careful not to drop the sprocket and

chain into the timing case.

Carefully pull off the chain and then pull out the sprocket.

Page 350 of 1463

1B3-48 OM600 ENGINE MECHANICAL

38. Remove the camshaft bearing cap bolts according to the

numerical sequence.

Notice

Remove the No.1 bolts first and then remove the No. 2

bolts. Do not remove the bolts at a time completely but

remove them step by step evenly or camshaft can be

seriously damaged.

OM662LA

39. Remove the bearing caps and then pull out the

camshaft(20) upward.

Notice

Be careful not to miss the locking washer.

40. Remove the locking washer.

Notice

Check the locking washer and replace if necessary.

OM661LA

Trending: oil level, parking sensors, coolant, compression ratio, bonnet, height, hood release