SSANGYONG MUSSO 1998 Workshop Repair Manual

Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 331 of 1463

OM600 ENGINE MECHANICAL 1B3-29

1 Threaded Ring........................................130 Nm

2 Prechamber

PRECHAMBER

Preceding Work : Removal of glow plug

Removal of fuel injection nozzle

3 Cylinder Head

Page 332 of 1463

1B3-30 OM600 ENGINE MECHANICAL

Tools Required

2. Install the sliding hammer into the prechamber.

Sliding Hammer 667 589 03 63 00

Removal & Installation Procedure

1. Using the serration wrench (4), remove the threaded ring

(1).

Serration Wrench 603 589 00 09 00

3. Remove the perchamber (2).

Notice

After removing the prechamber, cover over the bores with

clean rag. 603 589 00 09 00 Serration Wrench

667 589 03 63 00 Sliding Hammer

4. Inspect the prechamber.

Notice

If the prechamber seats in the cylinder head are leaking or

if the prechambers are replaced, the sealing surfaces in

the cylinder head must be remachined.

Page 333 of 1463

OM600 ENGINE MECHANICAL 1B3-31

Assembly Procedure

Notice

In case the prechambers are reused, inspect the

prechambers thoroughly, if the ball pin by heat and fire is

broken, it can not be used.

1. Clean the sealing surface of the prechamber.

2. Insert the prechamber into the cylinder head at the same

time aligning the cam on the collar of the prechambers with

the slots in the cylinder head.

Notice

If the spacer rings are fitted to the prechambers, the spacer

rings should be replaced with rings of the same thickness.

Thickness of Spacer Ring 0.3, 0.6, 1.0 mm

3. Coat the threaded ring with oil and assemble the ring by

using the serration wrench.

Tightening Torque 130 Nm

Page 334 of 1463

1B3-32 OM600 ENGINE MECHANICAL

MILLING OF PRECHAMBER SEALING SURFACE

1 Drift

2 Sleeve

3 Milling Cutter4 Counter Sink (Special Tool - 601 589 00 66)

5 Cylinder Head

Tightening Torque 0.3, 0.6, 1.0 mm

Milling of the Prechamber Sealing Surface

Notice

The prechamber sealing surface may only be remachined

once with the cylinder head fitted. It is essential to adhere

to the specified projection ‘C’ of the prechamber of 7.6 -

8.1mm.

This ensures that the required clearance exists between

prechamber and piston crown with the piston in TDC. For

this reason, spacer rings should be inserted on remachined

sealing surfaces.

If a spacer ring is already fitted, or a marking is made on the

cylinder head, the cylinder head must be removed and size

‘C’ measured if further remachining is necessary on a

prechamber sealing surface. Tools Required

601 589 00 66 00 Counter Sink

667 589 00 23 00 Height Gauge

Page 335 of 1463

OM600 ENGINE MECHANICAL 1B3-33

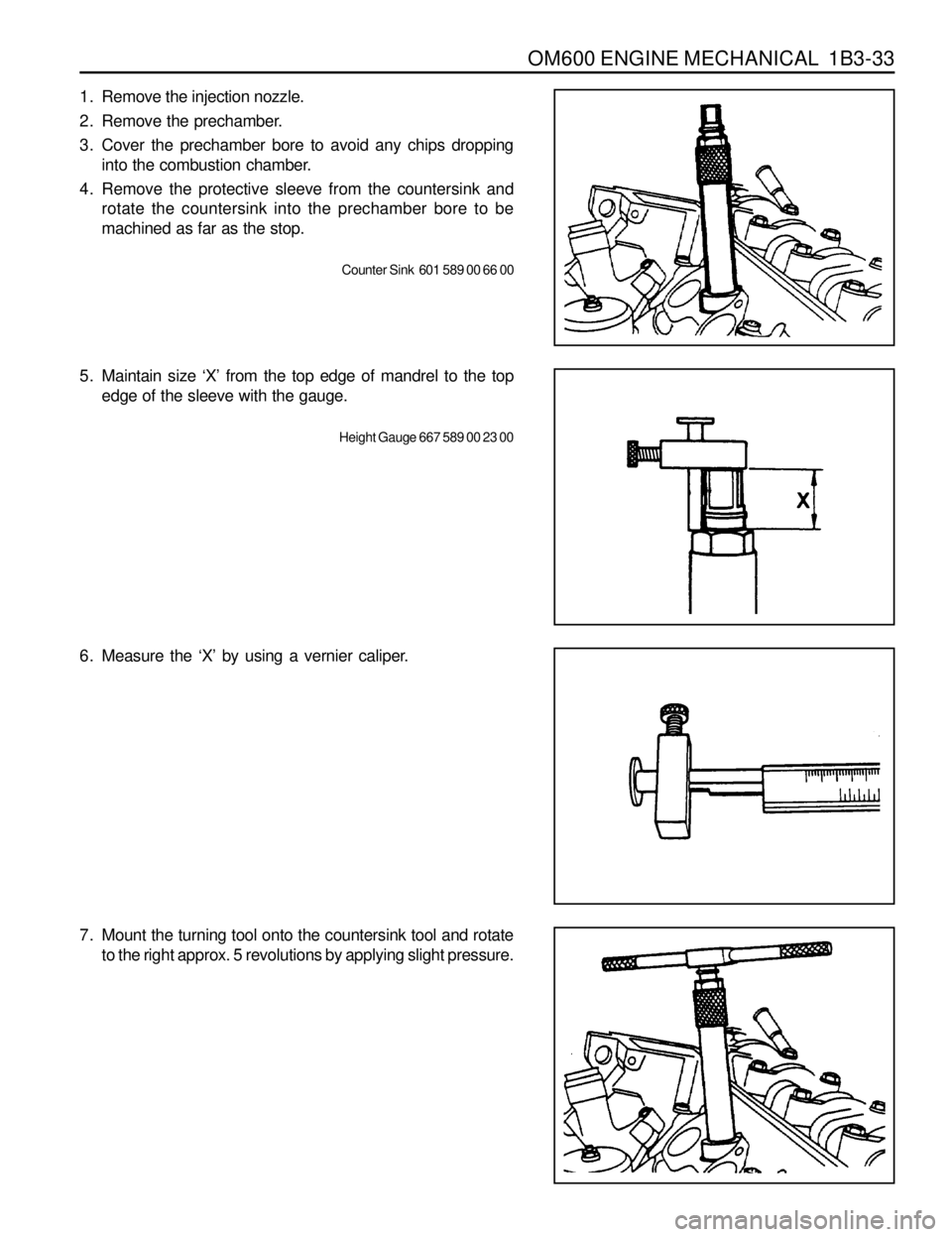

6. Measure the ‘X’ by using a vernier caliper.

7. Mount the turning tool onto the countersink tool and rotate

to the right approx. 5 revolutions by applying slight pressure.

1. Remove the injection nozzle.

2. Remove the prechamber.

3. Cover the prechamber bore to avoid any chips dropping

into the combustion chamber.

4. Remove the protective sleeve from the countersink and

rotate the countersink into the prechamber bore to be

machined as far as the stop.

Counter Sink 601 589 00 66 00

5. Maintain size ‘X’ from the top edge of mandrel to the top

edge of the sleeve with the gauge.

Height Gauge 667 589 00 23 00

Page 336 of 1463

1B3-34 OM600 ENGINE MECHANICAL

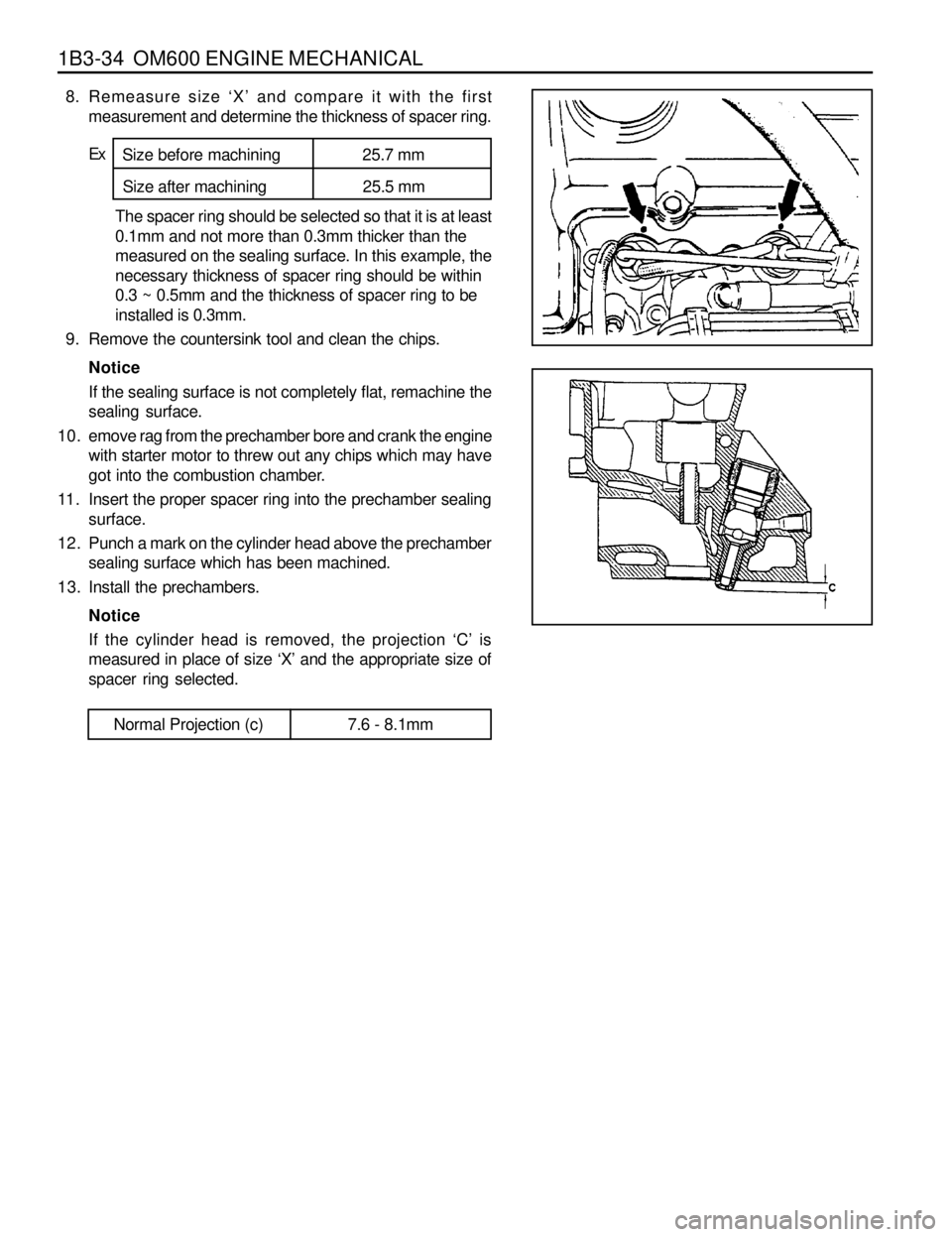

8. Remeasure size ‘X’ and compare it with the first

measurement and determine the thickness of spacer ring.

Size before machining 25.7 mm

Size after machining 25.5 mm Ex

The spacer ring should be selected so that it is at least

0.1mm and not more than 0.3mm thicker than the

measured on the sealing surface. In this example, the

necessary thickness of spacer ring should be within

0.3 ~ 0.5mm and the thickness of spacer ring to be

installed is 0.3mm.

9. Remove the countersink tool and clean the chips.

Notice

If the sealing surface is not completely flat, remachine the

sealing surface.

10. emove rag from the prechamber bore and crank the engine

with starter motor to threw out any chips which may have

got into the combustion chamber.

11. Insert the proper spacer ring into the prechamber sealing

surface.

12. Punch a mark on the cylinder head above the prechamber

sealing surface which has been machined.

13. Install the prechambers.

Notice

If the cylinder head is removed, the projection ‘C’ is

measured in place of size ‘X’ and the appropriate size of

spacer ring selected.

Normal Projection (c) 7.6 - 8.1mm

Page 337 of 1463

OM600 ENGINE MECHANICAL 1B3-35

TDC (TDC SENSOR BRACKET) SETTING

Preceding Work : Removal of No.1 cylinder prechamber

1 Measuring Device

2 Dial Gauge

3 Cylinder Head

4 Piston................................................Set at TDC

Tools Service

001 589 32 21 00 Dial Gauge

601 589 07 21 00 Deqth Gauge

667 589 01 21 00 Fixing Device

Notice

lThe TDC sensor bracket must be adjusted in case of

followings.

lWhen replacing the TDC sensor bracket.

lWhen replacing the crankshaft, the hub or the vibration

damper.

lWhen replacing or installing the timing case cover.

lAfter engine overhauling.

*If the cylinder head is removed, the measuring pin of the

dial gauge can be positioned on the piston crown.

This is done by placing the magnetic dial holder on the

mating surface of the crankcase.

Page 338 of 1463

1B3-36 OM600 ENGINE MECHANICAL

Setting (with cylinder head installed)

1. Remove the prechamber of No. 1 cylinder.

2. Position the piston of No.1 cylinder at BTDC 10.

3. Install the measuring device into the prechamber bore and

position the dial gauge with a preload of 5mm.

Dial Gauge 001 589 53 21 00

Depth Gauge 601 589 07 21 00

4. Slowly rotate the crankshaft in the direction of engine rotation

until the large pointer on the dial gauge stops (TDC position).

Notice

The position of TDC is when the large pointer on the dial

gauge is stopped before moving back.

5. remove the reinstall the measuring device and position the

dial gauge scale at ‘0’.

6. Slowly rotate the crankshaft in the direction of engine rotation

until the dial gauge has moved back (counterclockwise) by

3.65mm.

7. Insert fixing device into the sensor bracket.

Notice

The pin on the vibration damper must engage into the slot

of the fixing device.

Fixing Device 667 589 01 21 00

8. If the pin does not engage, adjust the setting of the sensor

bracket by removing and tightening of the sensor bracket

bolts.

Tightening Torque 10 Nm

Notice

The timing mark on the damper must be positioned at ATDC

20.

Page 339 of 1463

OM600 ENGINE MECHANICAL 1B3-37

CYLINDER HEAD

1 Fuel Injection Pipe.....................................18Nm

2 Cylinder Head

3 Gasket ................................................... Replace

4 Bolt............................................................25Nm

5 Washer

6 Clamp

7 Heater Feed Pipe

8 Bolt

9 Washer

1 0 Bolt

11 Nozzle Washer....................................... Replace

12 Fuel Injection Nozzle............................35-40 Nm

13 Hexagon Socket Bolt................................. 25 Nm

14 Washer

1 5 Bolt........................................................... 25 Nm

16 Cylinder Head Bolt..............................See Table

17 Cylinder Head Cover

1 8 Bolt........................................................... 10 Nm

19 Gasket

2 0 Camshaft21 Camshaft Drive Sprocket....................... Replace

22 Washer

23 Bolt(12-Sided) ..................................25Nm + 90°

24 Sliding Rail

25 Sliding Rail Pin

26 Sliding Rail Pin

27 Chain Tensioner....................................... 80 Nm

28 Gasket ................................................... Replace

29 Cooling Fan.............................................. Check

30 Hexagon Socket Bolt................................. 45 Nm

31 Tensioning Lever

3 2 Bolt........................................................... 25 Nm

3 3 Bolt

34 Nut ............................................................ 23 Nm

35 Fuel Filter

36 Turbo Charger

37 Intake Duct

38 Gasket ................................................... Replace

39 Intake Manifold

Page 340 of 1463

1B3-38 OM600 ENGINE MECHANICAL

000 589 77 03 00 Box Wrench Insert

001 589 65 09 00 Socket Wrench Insert

102 589 03 40 00 Magnetic Bar

116 589 02 34 00 Threaded Pin

116 589 03 07 00 T Type Socket Wrench

116 589 20 33 00 Sliding Hammer

601 589 00 10 00 Cylinder Head Bolt Wrench

602 589 00 40 00 Engine Lock

603 589 00 40 00 Counter Holder

Tools Required

Cylinder Bolts (12-sided socket head)

(Engine cold)

M8 Cylinder Head Bolts

Tightening Torque

stage1

stage2

stage310 Nm

35 Nm

180°

25 Nm

Tightening Sequence for Cylinder Head Bolts

OM 662LA Engine

OM 661LA Engine