SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1561 of 2870

ME(H4DOTC)-101

MECHANICAL

Cylinder Block

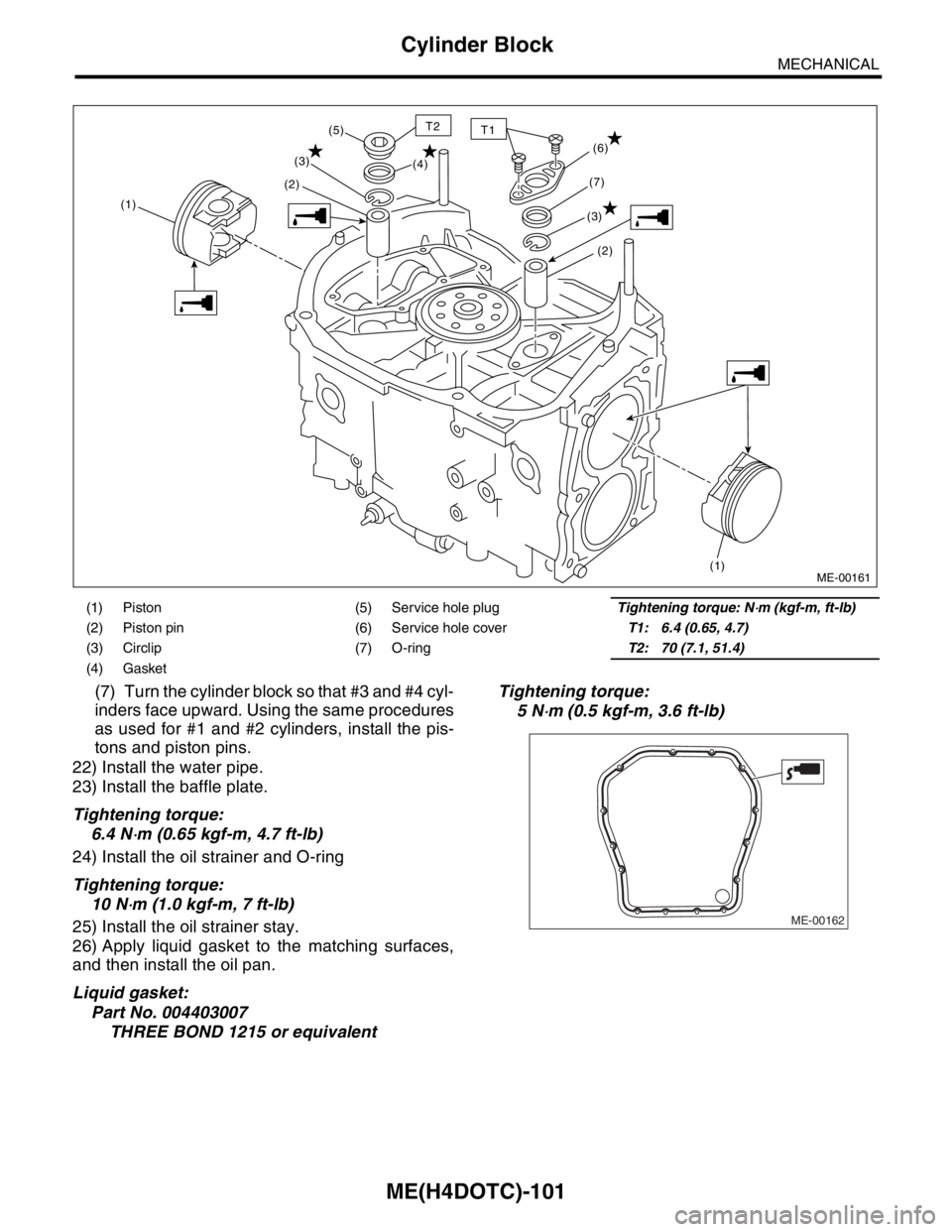

(7) Turn the cylinder block so that #3 and #4 cyl-

inders face upward. Using the same procedures

as used for #1 and #2 cylinders, install the pis-

tons and piston pins.

22) Install the water pipe.

23) Install the baffle plate.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

24) Install the oil strainer and O-ring

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7 ft-lb)

25) Install the oil strainer stay.

26) Apply liquid gasket to the matching surfaces,

and then install the oil pan.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalentTightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

(1) Piston (5) Service hole plugTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (6) Service hole coverT1: 6.4 (0.65, 4.7)

(3) Circlip (7) O-ringT2: 70 (7.1, 51.4)

(4) Gasket

(1)(2)(3)

(1)

(2) (6)

(3)(7) (4) (5)

ME-00161

T2T1

ME-00162

Page 1562 of 2870

ME(H4DOTC)-102

MECHANICAL

Cylinder Block

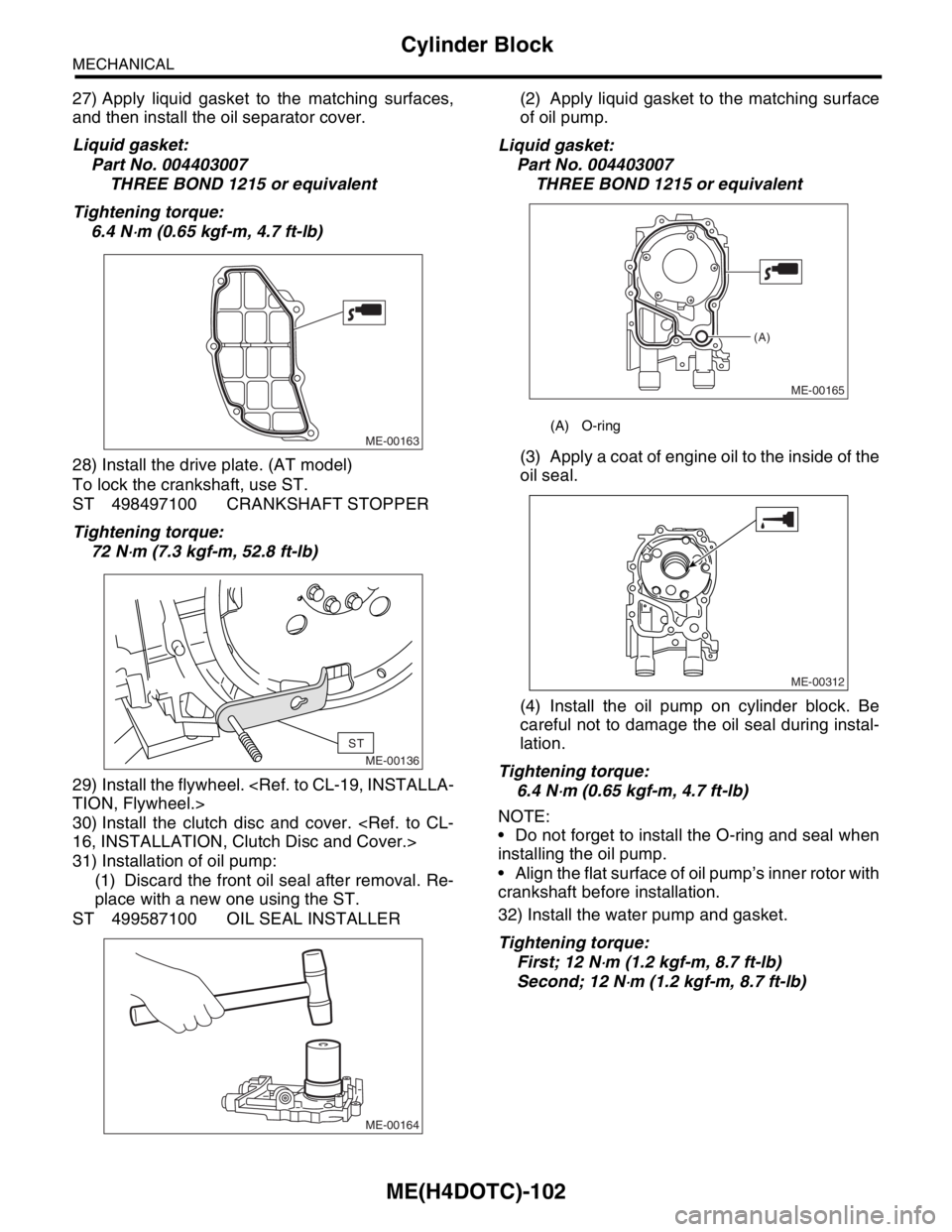

27) Apply liquid gasket to the matching surfaces,

and then install the oil separator cover.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

28) Install the drive plate. (AT model)

To lock the crankshaft, use ST.

ST 498497100 CRANKSHAFT STOPPER

Tightening torque:

72 N

⋅m (7.3 kgf-m, 52.8 ft-lb)

29) Install the flywheel.

30) Install the clutch disc and cover.

31) Installation of oil pump:

(1) Discard the front oil seal after removal. Re-

place with a new one using the ST.

ST 499587100 OIL SEAL INSTALLER(2) Apply liquid gasket to the matching surface

of oil pump.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

(3) Apply a coat of engine oil to the inside of the

oil seal.

(4) Install the oil pump on cylinder block. Be

careful not to damage the oil seal during instal-

lation.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

NOTE:

Do not forget to install the O-ring and seal when

installing the oil pump.

Align the flat surface of oil pump’s inner rotor with

crankshaft before installation.

32) Install the water pump and gasket.

Tightening torque:

First; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Second; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

ME-00163

ME-00136

ST

ME-00164

(A) O-ring

ME-00165

(A)

ME-00312

Page 1563 of 2870

ME(H4DOTC)-103

MECHANICAL

Cylinder Block

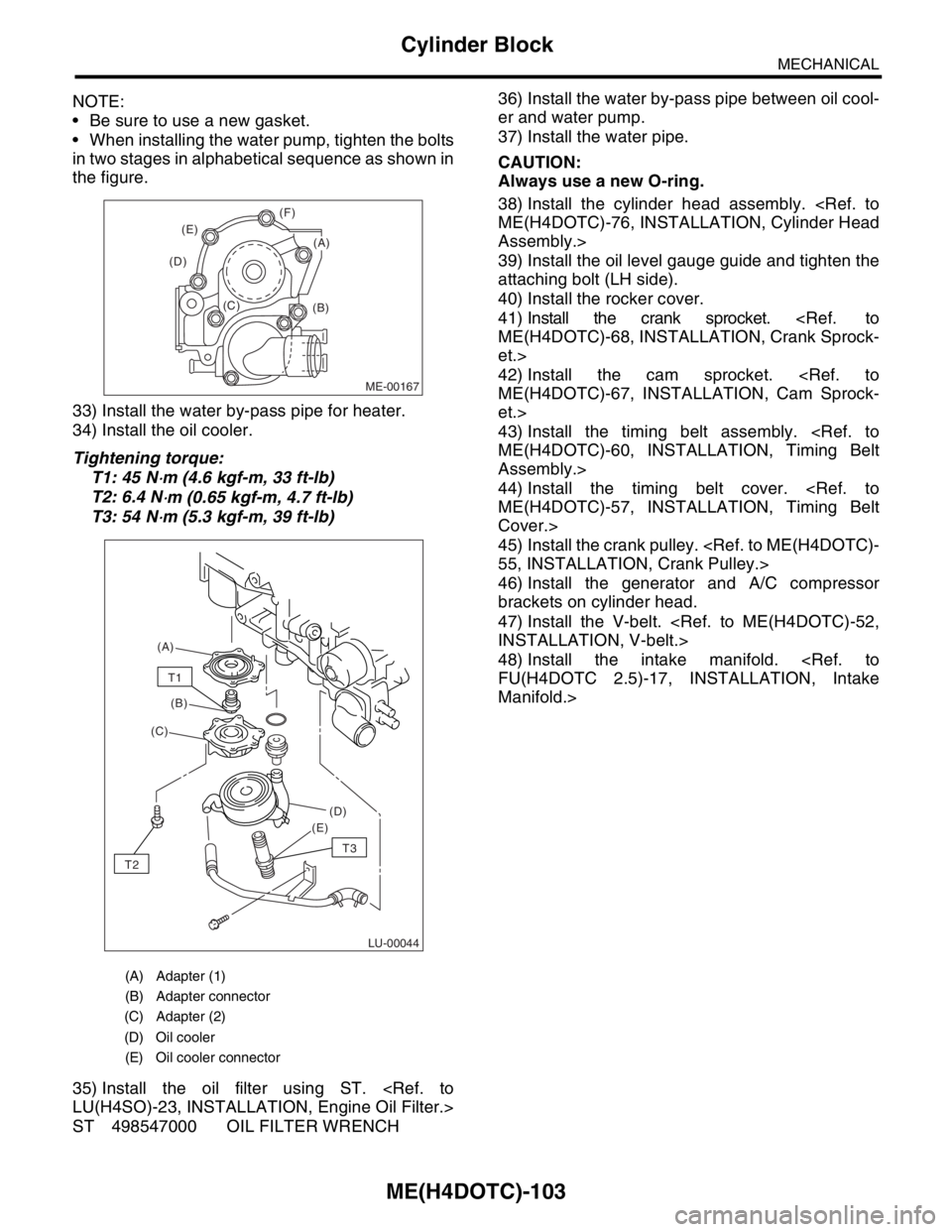

NOTE:

Be sure to use a new gasket.

When installing the water pump, tighten the bolts

in two stages in alphabetical sequence as shown in

the figure.

33) Install the water by-pass pipe for heater.

34) Install the oil cooler.

Tightening torque:

T1: 45 N

⋅m (4.6 kgf-m, 33 ft-lb)

T2: 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

T3: 54 N

⋅m (5.3 kgf-m, 39 ft-lb)

35) Install the oil filter using ST.

ST 498547000 OIL FILTER WRENCH36) Install the water by-pass pipe between oil cool-

er and water pump.

37) Install the water pipe.

CAUTION:

Always use a new O-ring.

38) Install the cylinder head assembly.

Assembly.>

39) Install the oil level gauge guide and tighten the

attaching bolt (LH side).

40) Install the rocker cover.

41) Install the crank sprocket.

et.>

42) Install the cam sprocket.

et.>

43) Install the timing belt assembly.

Assembly.>

44) Install the timing belt cover.

Cover.>

45) Install the crank pulley.

46) Install the generator and A/C compressor

brackets on cylinder head.

47) Install the V-belt.

48) Install the intake manifold.

Manifold.>

(A) Adapter (1)

(B) Adapter connector

(C) Adapter (2)

(D) Oil cooler

(E) Oil cooler connector

ME-00167

(B) (C) (D)(E)(F)

(A)

LU-00044

(A)

(B)

(C)

(D)

(E)

T1

T2

T3

Page 1564 of 2870

ME(H4DOTC)-104

MECHANICAL

Cylinder Block

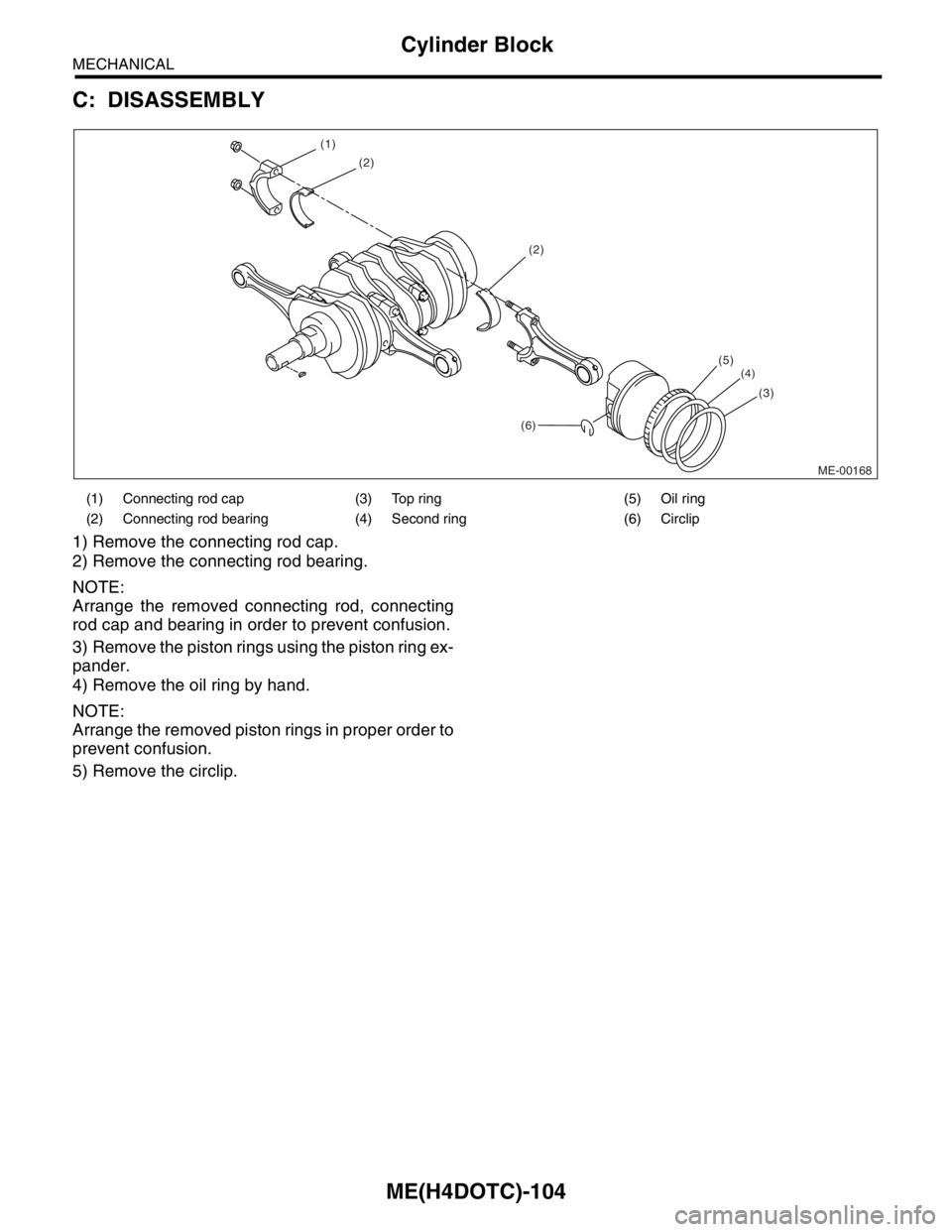

C: DISASSEMBLY

1) Remove the connecting rod cap.

2) Remove the connecting rod bearing.

NOTE:

Arrange the removed connecting rod, connecting

rod cap and bearing in order to prevent confusion.

3) Remove the piston rings using the piston ring ex-

pander.

4) Remove the oil ring by hand.

NOTE:

Arrange the removed piston rings in proper order to

prevent confusion.

5) Remove the circlip.

(1) Connecting rod cap (3) Top ring (5) Oil ring

(2) Connecting rod bearing (4) Second ring (6) Circlip

ME-00168

(2)

(2)

(6)(5)

(4)

(3) (1)

Page 1565 of 2870

ME(H4DOTC)-105

MECHANICAL

Cylinder Block

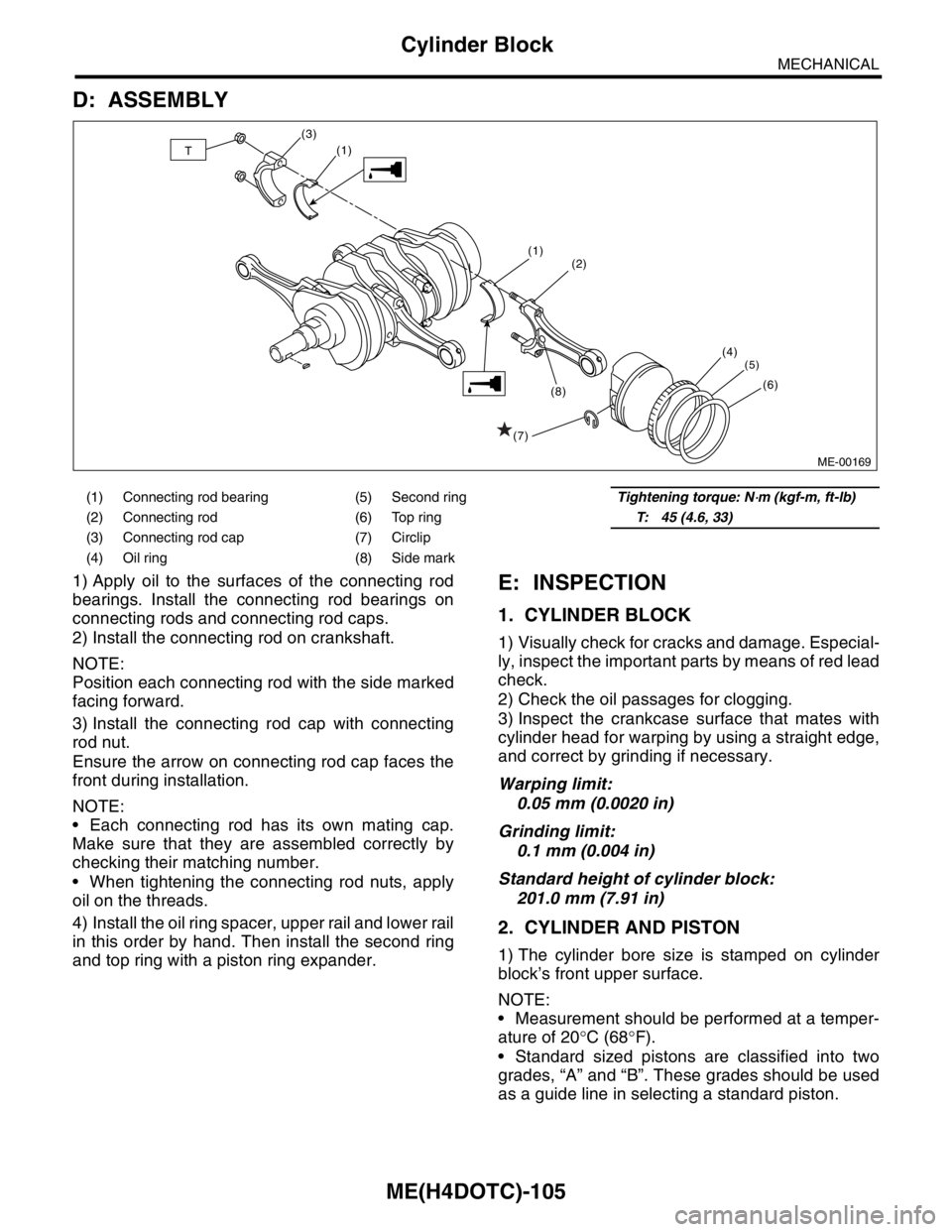

D: ASSEMBLY

1) Apply oil to the surfaces of the connecting rod

bearings. Install the connecting rod bearings on

connecting rods and connecting rod caps.

2) Install the connecting rod on crankshaft.

NOTE:

Position each connecting rod with the side marked

facing forward.

3) Install the connecting rod cap with connecting

rod nut.

Ensure the arrow on connecting rod cap faces the

front during installation.

NOTE:

Each connecting rod has its own mating cap.

Make sure that they are assembled correctly by

checking their matching number.

When tightening the connecting rod nuts, apply

oil on the threads.

4) Install the oil ring spacer, upper rail and lower rail

in this order by hand. Then install the second ring

and top ring with a piston ring expander.E: INSPECTION

1. CYLINDER BLOCK

1) Visually check for cracks and damage. Especial-

ly, inspect the important parts by means of red lead

check.

2) Check the oil passages for clogging.

3) Inspect the crankcase surface that mates with

cylinder head for warping by using a straight edge,

and correct by grinding if necessary.

Warping limit:

0.05 mm (0.0020 in)

Grinding limit:

0.1 mm (0.004 in)

Standard height of cylinder block:

201.0 mm (7.91 in)

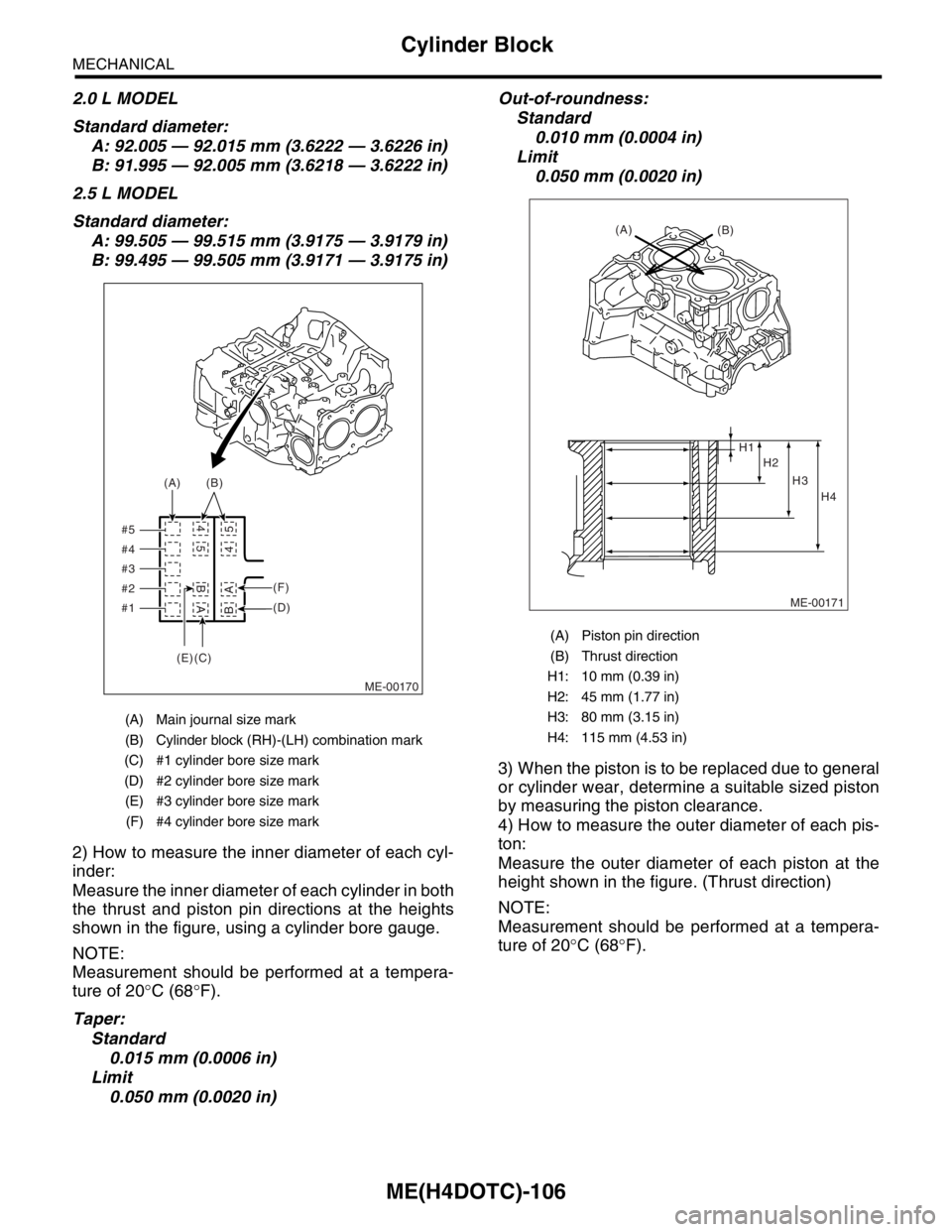

2. CYLINDER AND PISTON

1) The cylinder bore size is stamped on cylinder

block’s front upper surface.

NOTE:

Measurement should be performed at a temper-

ature of 20°C (68°F).

Standard sized pistons are classified into two

grades, “A” and “B”. These grades should be used

as a guide line in selecting a standard piston.

(1) Connecting rod bearing (5) Second ringTightening torque: N⋅m (kgf-m, ft-lb)

(2) Connecting rod (6) Top ringT: 45 (4.6, 33)

(3) Connecting rod cap (7) Circlip

(4) Oil ring (8) Side mark

ME-00169

(2)

(4)

(5)

(6)

(1)

(1)

(7)(8) (3)T

Page 1566 of 2870

ME(H4DOTC)-106

MECHANICAL

Cylinder Block

2.0 L MODEL

Standard diameter:

A: 92.005 — 92.015 mm (3.6222 — 3.6226 in)

B: 91.995 — 92.005 mm (3.6218 — 3.6222 in)

2.5 L MODEL

Standard diameter:

A: 99.505 — 99.515 mm (3.9175 — 3.9179 in)

B: 99.495 — 99.505 mm (3.9171 — 3.9175 in)

2) How to measure the inner diameter of each cyl-

inder:

Measure the inner diameter of each cylinder in both

the thrust and piston pin directions at the heights

shown in the figure, using a cylinder bore gauge.

NOTE:

Measurement should be performed at a tempera-

ture of 20°C (68°F).

Taper:

Standard

0.015 mm (0.0006 in)

Limit

0.050 mm (0.0020 in)Out-of-roundness:

Standard

0.010 mm (0.0004 in)

Limit

0.050 mm (0.0020 in)

3) When the piston is to be replaced due to general

or cylinder wear, determine a suitable sized piston

by measuring the piston clearance.

4) How to measure the outer diameter of each pis-

ton:

Measure the outer diameter of each piston at the

height shown in the figure. (Thrust direction)

NOTE:

Measurement should be performed at a tempera-

ture of 20°C (68°F).

(A) Main journal size mark

(B) Cylinder block (RH)-(LH) combination mark

(C) #1 cylinder bore size mark

(D) #2 cylinder bore size mark

(E) #3 cylinder bore size mark

(F) #4 cylinder bore size mark

ME-00170 #5

#4

#3

#2

#1(A)(B)

(F)

(D)

A BA B

5 45 4

(C) (E)

(A) Piston pin direction

(B) Thrust direction

H1: 10 mm (0.39 in)

H2: 45 mm (1.77 in)

H3: 80 mm (3.15 in)

H4: 115 mm (4.53 in)

ME-00171

(A)

(B)

H2 H1

H3

H4

Page 1567 of 2870

ME(H4DOTC)-107

MECHANICAL

Cylinder Block

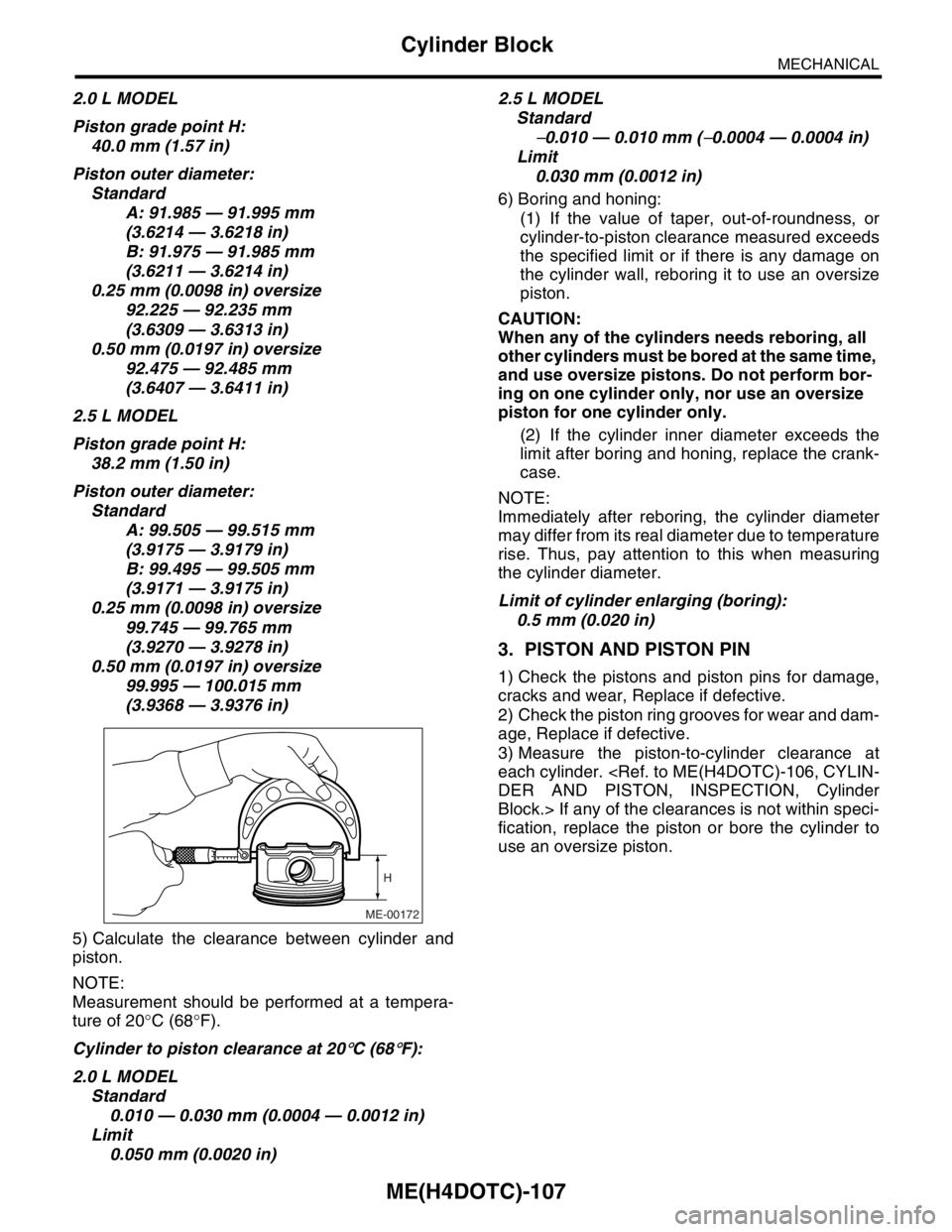

2.0 L MODEL

Piston grade point H:

40.0 mm (1.57 in)

Piston outer diameter:

Standard

A: 91.985 — 91.995 mm

(3.6214 — 3.6218 in)

B: 91.975 — 91.985 mm

(3.6211 — 3.6214 in)

0.25 mm (0.0098 in) oversize

92.225 — 92.235 mm

(3.6309 — 3.6313 in)

0.50 mm (0.0197 in) oversize

92.475 — 92.485 mm

(3.6407 — 3.6411 in)

2.5 L MODEL

Piston grade point H:

38.2 mm (1.50 in)

Piston outer diameter:

Standard

A: 99.505 — 99.515 mm

(3.9175 — 3.9179 in)

B: 99.495 — 99.505 mm

(3.9171 — 3.9175 in)

0.25 mm (0.0098 in) oversize

99.745 — 99.765 mm

(3.9270 — 3.9278 in)

0.50 mm (0.0197 in) oversize

99.995 — 100.015 mm

(3.9368 — 3.9376 in)

5) Calculate the clearance between cylinder and

piston.

NOTE:

Measurement should be performed at a tempera-

ture of 20°C (68°F).

Cylinder to piston clearance at 20

°C (68°F):

2.0 L MODEL

Standard

0.010 — 0.030 mm (0.0004 — 0.0012 in)

Limit

0.050 mm (0.0020 in)2.5 L MODEL

Standard

−0.010 — 0.010 mm (−0.0004 — 0.0004 in)

Limit

0.030 mm (0.0012 in)

6) Boring and honing:

(1) If the value of taper, out-of-roundness, or

cylinder-to-piston clearance measured exceeds

the specified limit or if there is any damage on

the cylinder wall, reboring it to use an oversize

piston.

CAUTION:

When any of the cylinders needs reboring, all

other cylinders must be bored at the same time,

and use oversize pistons. Do not perform bor-

ing on one cylinder only, nor use an oversize

piston for one cylinder only.

(2) If the cylinder inner diameter exceeds the

limit after boring and honing, replace the crank-

case.

NOTE:

Immediately after reboring, the cylinder diameter

may differ from its real diameter due to temperature

rise. Thus, pay attention to this when measuring

the cylinder diameter.

Limit of cylinder enlarging (boring):

0.5 mm (0.020 in)

3. PISTON AND PISTON PIN

1) Check the pistons and piston pins for damage,

cracks and wear, Replace if defective.

2) Check the piston ring grooves for wear and dam-

age, Replace if defective.

3) Measure the piston-to-cylinder clearance at

each cylinder.

Block.> If any of the clearances is not within speci-

fication, replace the piston or bore the cylinder to

use an oversize piston.

ME-00172

H

Page 1568 of 2870

ME(H4DOTC)-108

MECHANICAL

Cylinder Block

4) Make sure that the piston pin can be inserted

into the piston pin hole with a thumb at 20°C (68°F).

Replace if defective.

Standard clearance between piston pin and

hole in piston:

Standard

0.004 — 0.008 mm (0.0002 — 0.0003 in)

Limit

0.020 mm (0.0008 in)

5) Check the circlip installation groove on piston for

burr (A). If necessary, remove the burr from groove

so that the piston pin can lightly move.

6) Check the piston pin circlip for distortion, cracks

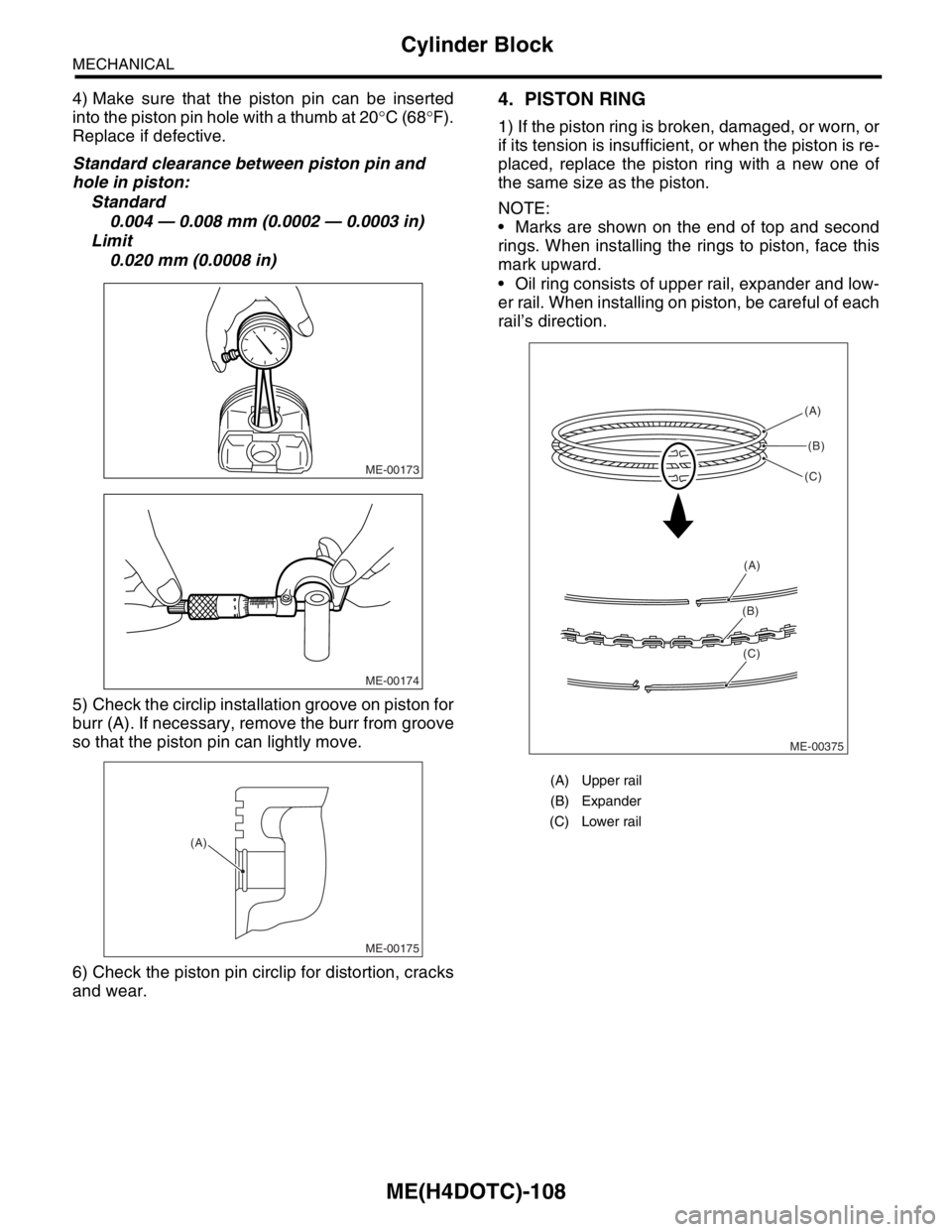

and wear.4. PISTON RING

1) If the piston ring is broken, damaged, or worn, or

if its tension is insufficient, or when the piston is re-

placed, replace the piston ring with a new one of

the same size as the piston.

NOTE:

Marks are shown on the end of top and second

rings. When installing the rings to piston, face this

mark upward.

Oil ring consists of upper rail, expander and low-

er rail. When installing on piston, be careful of each

rail’s direction.

ME-00173

ME-00174

ME-00175

(A)

(A) Upper rail

(B) Expander

(C) Lower rail

ME-00375(A)

(B)

(C)

(A)

(B)

(C)

Page 1569 of 2870

ME(H4DOTC)-109

MECHANICAL

Cylinder Block

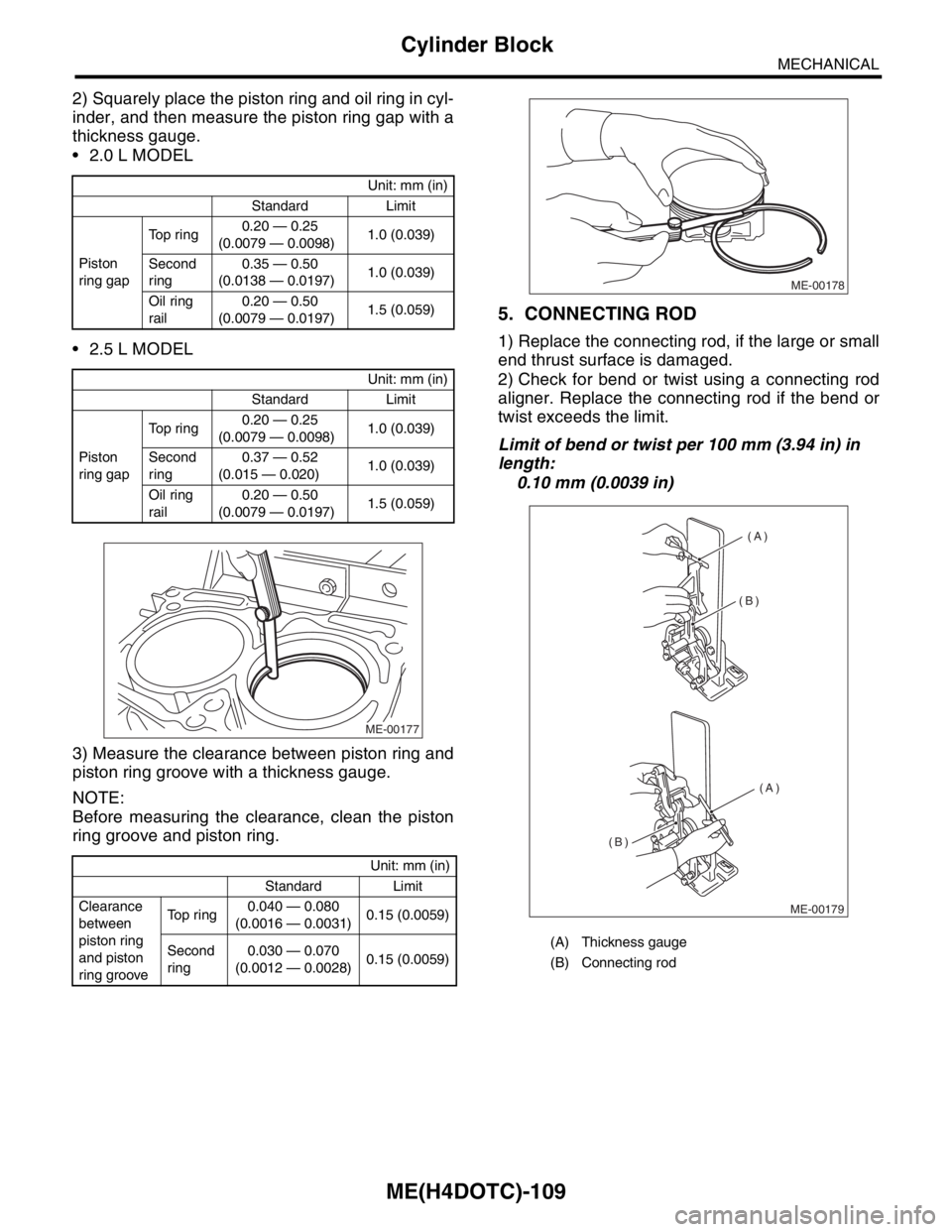

2) Squarely place the piston ring and oil ring in cyl-

inder, and then measure the piston ring gap with a

thickness gauge.

2.0 L MODEL

2.5 L MODEL

3) Measure the clearance between piston ring and

piston ring groove with a thickness gauge.

NOTE:

Before measuring the clearance, clean the piston

ring groove and piston ring.

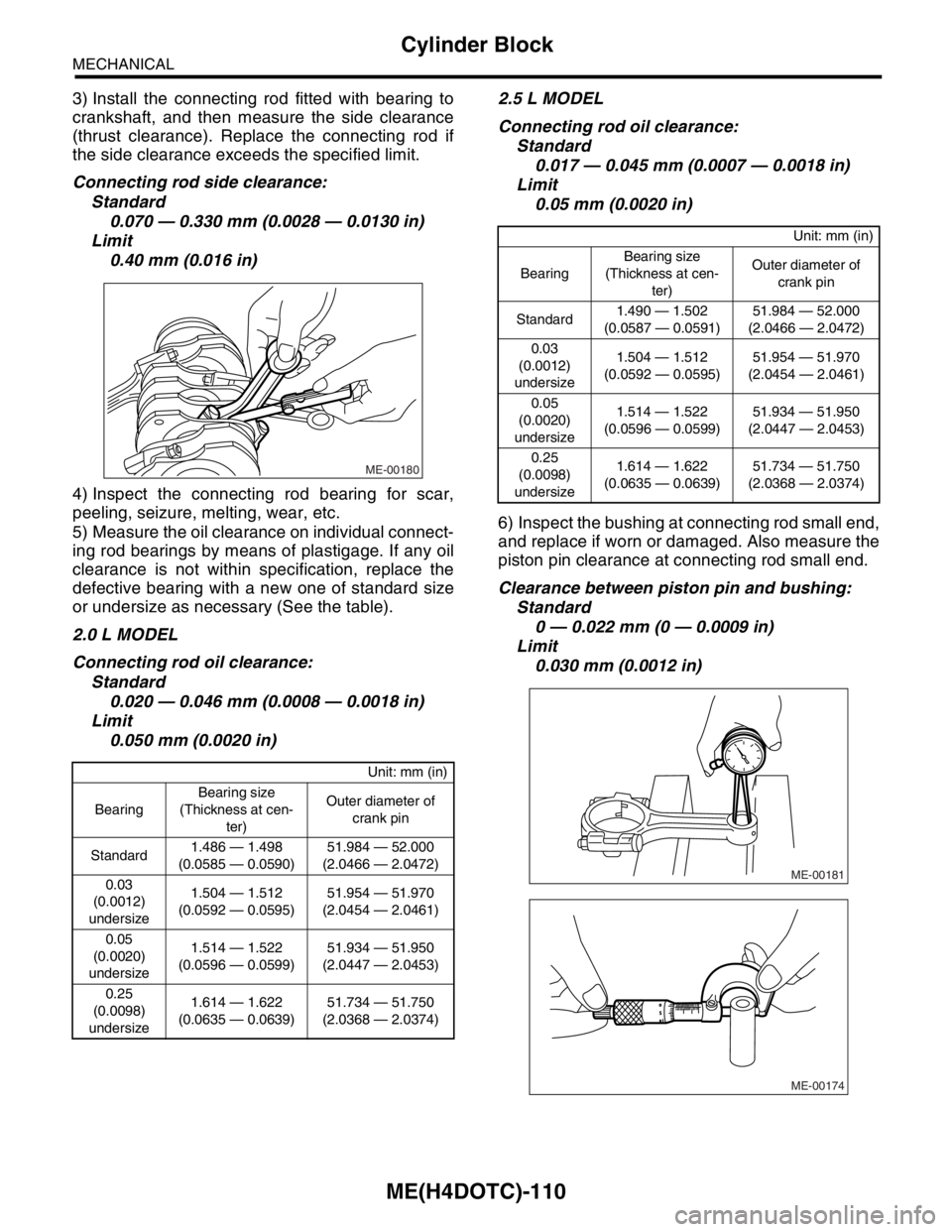

5. CONNECTING ROD

1) Replace the connecting rod, if the large or small

end thrust surface is damaged.

2) Check for bend or twist using a connecting rod

aligner. Replace the connecting rod if the bend or

twist exceeds the limit.

Limit of bend or twist per 100 mm (3.94 in) in

length:

0.10 mm (0.0039 in)

Unit: mm (in)

Standard Limit

Piston

ring gapTop ring0.20 — 0.25

(0.0079 — 0.0098)1.0 (0.039)

Second

ring0.35 — 0.50

(0.0138 — 0.0197)1.0 (0.039)

Oil ring

rail0.20 — 0.50

(0.0079 — 0.0197)1.5 (0.059)

Unit: mm (in)

Standard Limit

Piston

ring gapTop ring0.20 — 0.25

(0.0079 — 0.0098)1.0 (0.039)

Second

ring0.37 — 0.52

(0.015 — 0.020)1.0 (0.039)

Oil ring

rail0.20 — 0.50

(0.0079 — 0.0197)1.5 (0.059)

Unit: mm (in)

Standard Limit

Clearance

between

piston ring

and piston

ring grooveTop ring0.040 — 0.080

(0.0016 — 0.0031)0.15 (0.0059)

Second

ring0.030 — 0.070

(0.0012 — 0.0028)0.15 (0.0059)

ME-00177

(A) Thickness gauge

(B) Connecting rod

ME-00178

(A)

(A) (B)

(B)

ME-00179

Page 1570 of 2870

ME(H4DOTC)-110

MECHANICAL

Cylinder Block

3) Install the connecting rod fitted with bearing to

crankshaft, and then measure the side clearance

(thrust clearance). Replace the connecting rod if

the side clearance exceeds the specified limit.

Connecting rod side clearance:

Standard

0.070 — 0.330 mm (0.0028 — 0.0130 in)

Limit

0.40 mm (0.016 in)

4) Inspect the connecting rod bearing for scar,

peeling, seizure, melting, wear, etc.

5) Measure the oil clearance on individual connect-

ing rod bearings by means of plastigage. If any oil

clearance is not within specification, replace the

defective bearing with a new one of standard size

or undersize as necessary (See the table).

2.0 L MODEL

Connecting rod oil clearance:

Standard

0.020 — 0.046 mm (0.0008 — 0.0018 in)

Limit

0.050 mm (0.0020 in)2.5 L MODEL

Connecting rod oil clearance:

Standard

0.017 — 0.045 mm (0.0007 — 0.0018 in)

Limit

0.05 mm (0.0020 in)

6) Inspect the bushing at connecting rod small end,

and replace if worn or damaged. Also measure the

piston pin clearance at connecting rod small end.

Clearance between piston pin and bushing:

Standard

0 — 0.022 mm (0 — 0.0009 in)

Limit

0.030 mm (0.0012 in)

Unit: mm (in)

BearingBearing size

(Thickness at cen-

ter)Outer diameter of

crank pin

Standard1.486 — 1.498

(0.0585 — 0.0590)51.984 — 52.000

(2.0466 — 2.0472)

0.03

(0.0012)

undersize1.504 — 1.512

(0.0592 — 0.0595)51.954 — 51.970

(2.0454 — 2.0461)

0.05

(0.0020)

undersize1.514 — 1.522

(0.0596 — 0.0599)51.934 — 51.950

(2.0447 — 2.0453)

0.25

(0.0098)

undersize1.614 — 1.622

(0.0635 — 0.0639)51.734 — 51.750

(2.0368 — 2.0374)

ME-00180

Unit: mm (in)

BearingBearing size

(Thickness at cen-

ter)Outer diameter of

crank pin

Standard1.490 — 1.502

(0.0587 — 0.0591)51.984 — 52.000

(2.0466 — 2.0472)

0.03

(0.0012)

undersize1.504 — 1.512

(0.0592 — 0.0595)51.954 — 51.970

(2.0454 — 2.0461)

0.05

(0.0020)

undersize1.514 — 1.522

(0.0596 — 0.0599)51.934 — 51.950

(2.0447 — 2.0453)

0.25

(0.0098)

undersize1.614 — 1.622

(0.0635 — 0.0639)51.734 — 51.750

(2.0368 — 2.0374)

ME-00181

ME-00174