SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1571 of 2870

ME(H4DOTC)-111

MECHANICAL

Cylinder Block

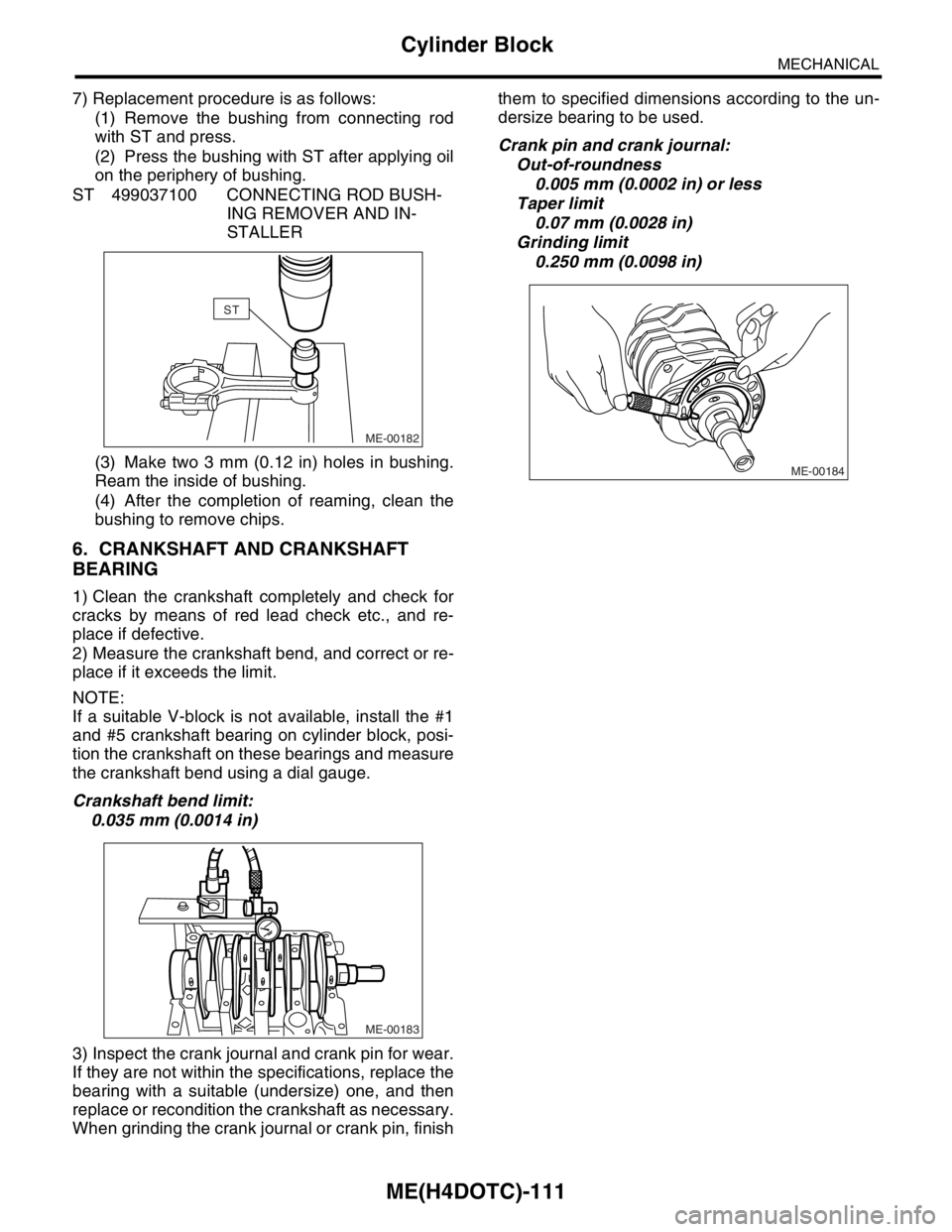

7) Replacement procedure is as follows:

(1) Remove the bushing from connecting rod

with ST and press.

(2) Press the bushing with ST after applying oil

on the periphery of bushing.

ST 499037100 CONNECTING ROD BUSH-

ING REMOVER AND IN-

STALLER

(3) Make two 3 mm (0.12 in) holes in bushing.

Ream the inside of bushing.

(4) After the completion of reaming, clean the

bushing to remove chips.

6. CRANKSHAFT AND CRANKSHAFT

BEARING

1) Clean the crankshaft completely and check for

cracks by means of red lead check etc., and re-

place if defective.

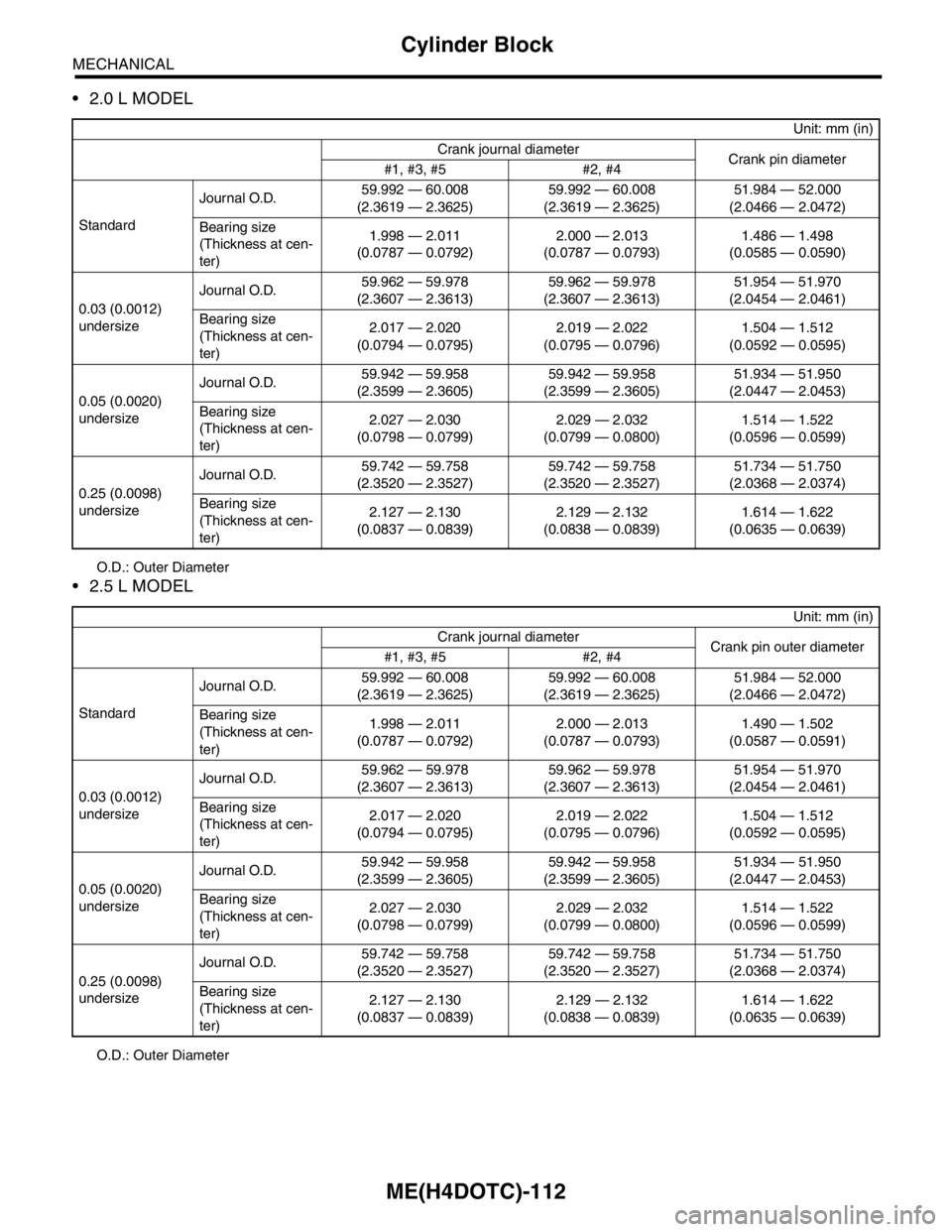

2) Measure the crankshaft bend, and correct or re-

place if it exceeds the limit.

NOTE:

If a suitable V-block is not available, install the #1

and #5 crankshaft bearing on cylinder block, posi-

tion the crankshaft on these bearings and measure

the crankshaft bend using a dial gauge.

Crankshaft bend limit:

0.035 mm (0.0014 in)

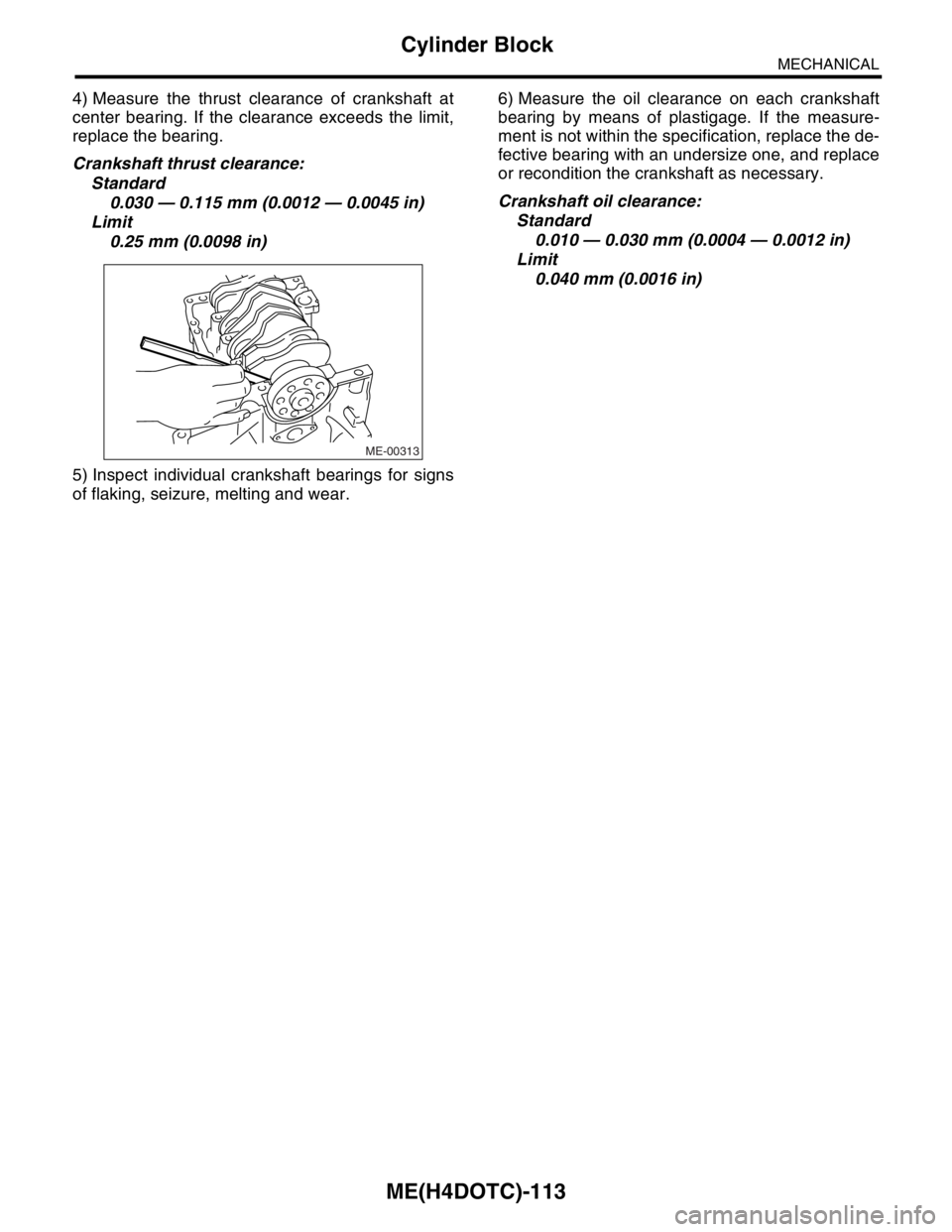

3) Inspect the crank journal and crank pin for wear.

If they are not within the specifications, replace the

bearing with a suitable (undersize) one, and then

replace or recondition the crankshaft as necessary.

When grinding the crank journal or crank pin, finishthem to specified dimensions according to the un-

dersize bearing to be used.

Crank pin and crank journal:

Out-of-roundness

0.005 mm (0.0002 in) or less

Taper limit

0.07 mm (0.0028 in)

Grinding limit

0.250 mm (0.0098 in)

ME-00182

ST

ME-00183

ME-00184

Page 1572 of 2870

ME(H4DOTC)-112

MECHANICAL

Cylinder Block

2.0 L MODEL

O.D.: Outer Diameter

2.5 L MODEL

O.D.: Outer DiameterUnit: mm (in)

Crank journal diameter

Crank pin diameter

#1, #3, #5 #2, #4

StandardJournal O.D.59.992 — 60.008

(2.3619 — 2.3625)59.992 — 60.008

(2.3619 — 2.3625)51.984 — 52.000

(2.0466 — 2.0472)

Bearing size

(Thickness at cen-

ter)1.998 — 2.011

(0.0787 — 0.0792)2.000 — 2.013

(0.0787 — 0.0793)1.486 — 1.498

(0.0585 — 0.0590)

0.03 (0.0012)

undersizeJournal O.D.59.962 — 59.978

(2.3607 — 2.3613)59.962 — 59.978

(2.3607 — 2.3613)51.954 — 51.970

(2.0454 — 2.0461)

Bearing size

(Thickness at cen-

ter)2.017 — 2.020

(0.0794 — 0.0795)2.019 — 2.022

(0.0795 — 0.0796)1.504 — 1.512

(0.0592 — 0.0595)

0.05 (0.0020)

undersizeJournal O.D.59.942 — 59.958

(2.3599 — 2.3605)59.942 — 59.958

(2.3599 — 2.3605)51.934 — 51.950

(2.0447 — 2.0453)

Bearing size

(Thickness at cen-

ter)2.027 — 2.030

(0.0798 — 0.0799)2.029 — 2.032

(0.0799 — 0.0800)1.514 — 1.522

(0.0596 — 0.0599)

0.25 (0.0098)

undersizeJournal O.D.59.742 — 59.758

(2.3520 — 2.3527)59.742 — 59.758

(2.3520 — 2.3527)51.734 — 51.750

(2.0368 — 2.0374)

Bearing size

(Thickness at cen-

ter)2.127 — 2.130

(0.0837 — 0.0839)2.129 — 2.132

(0.0838 — 0.0839)1.614 — 1.622

(0.0635 — 0.0639)

Unit: mm (in)

Crank journal diameter

Crank pin outer diameter

#1, #3, #5 #2, #4

StandardJournal O.D.59.992 — 60.008

(2.3619 — 2.3625)59.992 — 60.008

(2.3619 — 2.3625)51.984 — 52.000

(2.0466 — 2.0472)

Bearing size

(Thickness at cen-

ter)1.998 — 2.011

(0.0787 — 0.0792)2.000 — 2.013

(0.0787 — 0.0793)1.490 — 1.502

(0.0587 — 0.0591)

0.03 (0.0012)

undersizeJournal O.D.59.962 — 59.978

(2.3607 — 2.3613)59.962 — 59.978

(2.3607 — 2.3613)51.954 — 51.970

(2.0454 — 2.0461)

Bearing size

(Thickness at cen-

ter)2.017 — 2.020

(0.0794 — 0.0795)2.019 — 2.022

(0.0795 — 0.0796)1.504 — 1.512

(0.0592 — 0.0595)

0.05 (0.0020)

undersizeJournal O.D.59.942 — 59.958

(2.3599 — 2.3605)59.942 — 59.958

(2.3599 — 2.3605)51.934 — 51.950

(2.0447 — 2.0453)

Bearing size

(Thickness at cen-

ter)2.027 — 2.030

(0.0798 — 0.0799)2.029 — 2.032

(0.0799 — 0.0800)1.514 — 1.522

(0.0596 — 0.0599)

0.25 (0.0098)

undersizeJournal O.D.59.742 — 59.758

(2.3520 — 2.3527)59.742 — 59.758

(2.3520 — 2.3527)51.734 — 51.750

(2.0368 — 2.0374)

Bearing size

(Thickness at cen-

ter)2.127 — 2.130

(0.0837 — 0.0839)2.129 — 2.132

(0.0838 — 0.0839)1.614 — 1.622

(0.0635 — 0.0639)

Page 1573 of 2870

ME(H4DOTC)-113

MECHANICAL

Cylinder Block

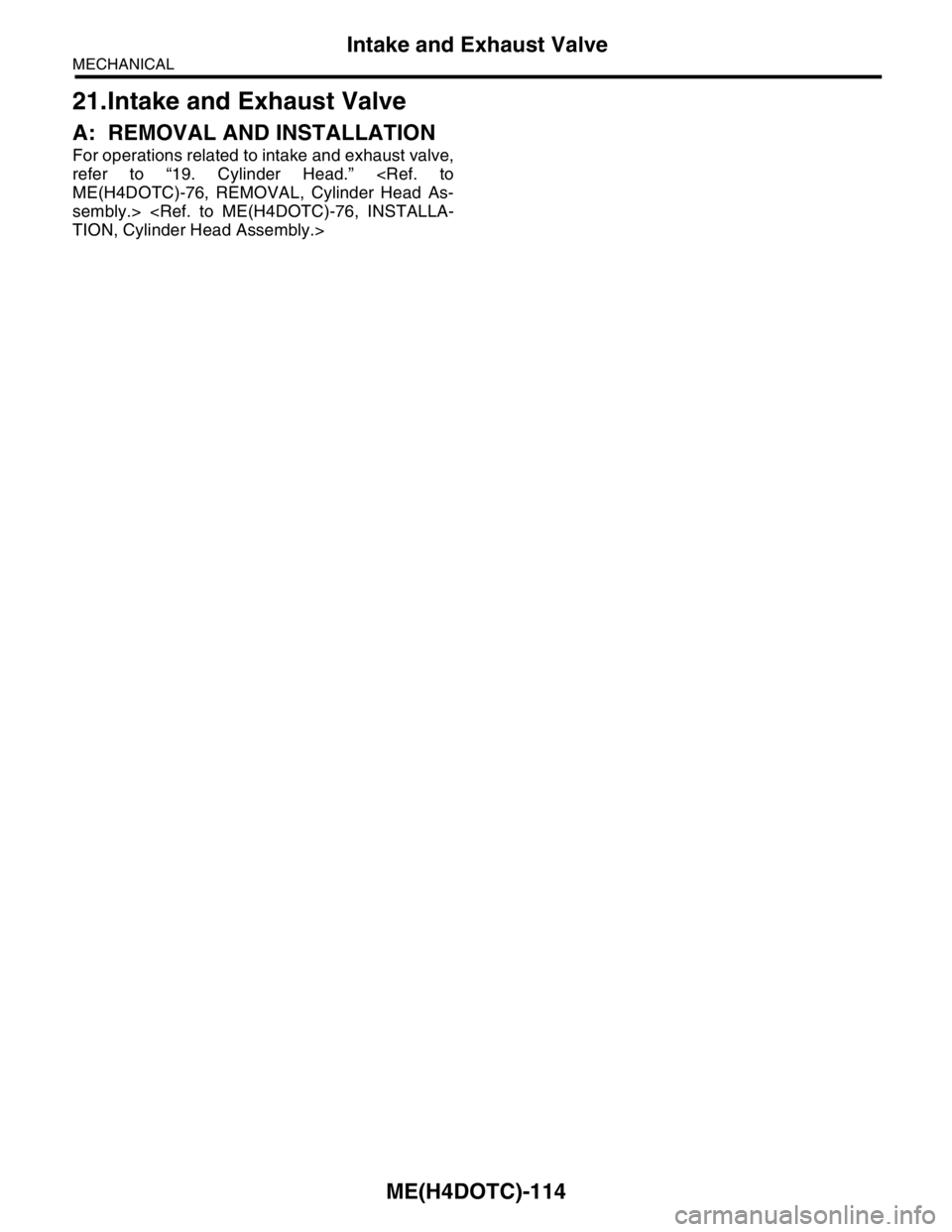

4) Measure the thrust clearance of crankshaft at

center bearing. If the clearance exceeds the limit,

replace the bearing.

Crankshaft thrust clearance:

Standard

0.030 — 0.115 mm (0.0012 — 0.0045 in)

Limit

0.25 mm (0.0098 in)

5) Inspect individual crankshaft bearings for signs

of flaking, seizure, melting and wear.6) Measure the oil clearance on each crankshaft

bearing by means of plastigage. If the measure-

ment is not within the specification, replace the de-

fective bearing with an undersize one, and replace

or recondition the crankshaft as necessary.

Crankshaft oil clearance:

Standard

0.010 — 0.030 mm (0.0004 — 0.0012 in)

Limit

0.040 mm (0.0016 in)

ME-00313

Page 1574 of 2870

ME(H4DOTC)-114

MECHANICAL

Intake and Exhaust Valve

21.Intake and Exhaust Valve

A: REMOVAL AND INSTALLATION

For operations related to intake and exhaust valve,

refer to “19. Cylinder Head.”

sembly.>

Page 1575 of 2870

ME(H4DOTC)-115

MECHANICAL

Piston

22.Piston

A: REMOVAL AND INSTALLATION

For operations related to piston, refer to “20. Cylin-

der Block.”

Page 1576 of 2870

ME(H4DOTC)-116

MECHANICAL

Connecting Rod

23.Connecting Rod

A: REMOVAL AND INSTALLATION

For operations related to connecting rod, refer to

“20. Cylinder Block.”

Block.>

Page 1577 of 2870

ME(H4DOTC)-117

MECHANICAL

Crankshaft

24.Crankshaft

A: REMOVAL AND INSTALLATION

For operations related to crankshaft, refer to “20.

Cylinder Block.”

Page 1578 of 2870

ME(H4DOTC)-118

MECHANICAL

Engine Trouble in General

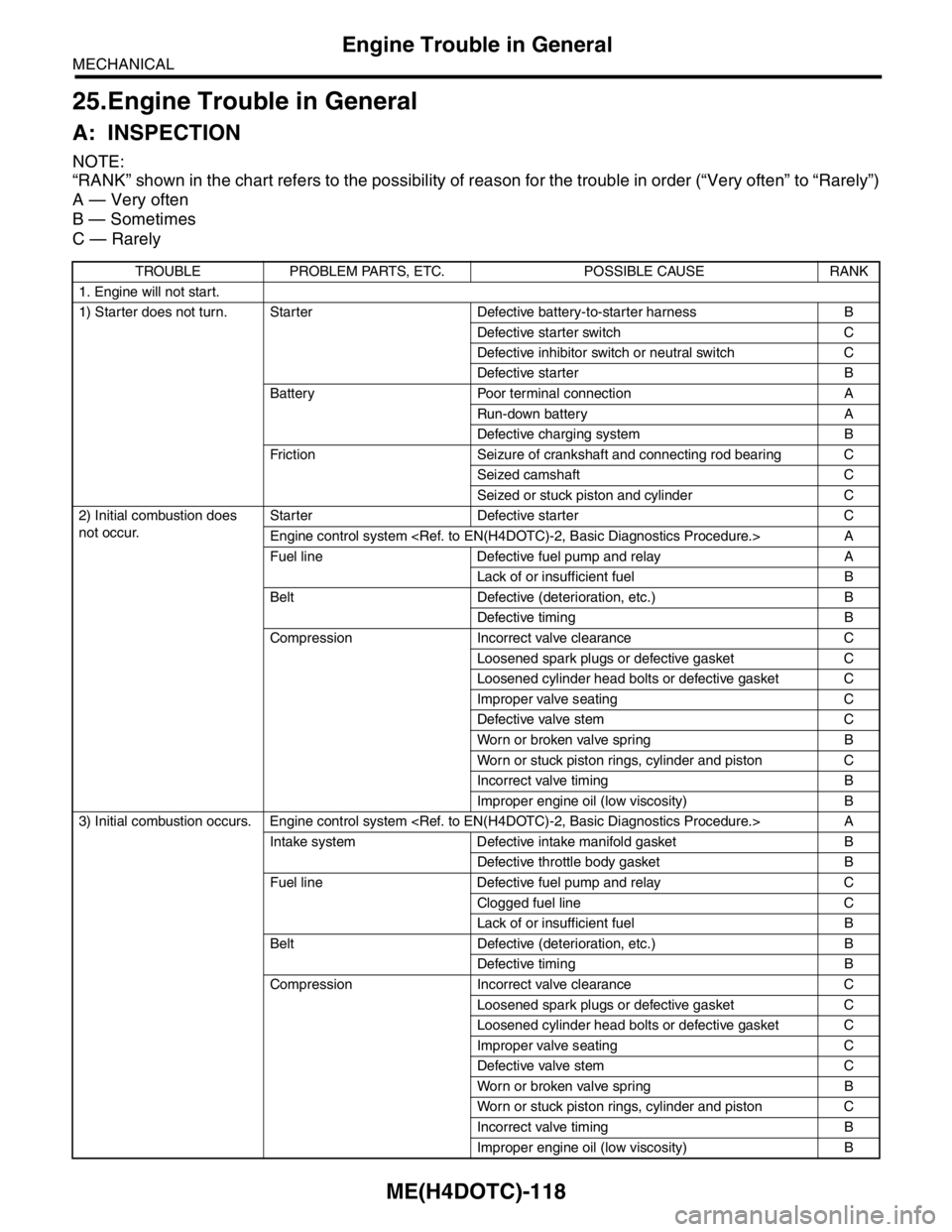

25.Engine Trouble in General

A: INSPECTION

NOTE:

“RANK” shown in the chart refers to the possibility of reason for the trouble in order (“Very often” to “Rarely”)

A — Very often

B — Sometimes

C — Rarely

TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

1. Engine will not start.

1) Starter does not turn. Starter Defective battery-to-starter harness B

Defective starter switch C

Defective inhibitor switch or neutral switch C

Defective starter B

Battery Poor terminal connection A

Run-down battery A

Defective charging system B

Friction Seizure of crankshaft and connecting rod bearing C

Seized camshaft C

Seized or stuck piston and cylinder C

2) Initial combustion does

not occur. Starter Defective starter C

Engine control system

Fuel line Defective fuel pump and relay A

Lack of or insufficient fuel B

Belt Defective (deterioration, etc.) B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating C

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

3) Initial combustion occurs. Engine control system

Intake system Defective intake manifold gasket B

Defective throttle body gasket B

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Belt Defective (deterioration, etc.) B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating C

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

Page 1579 of 2870

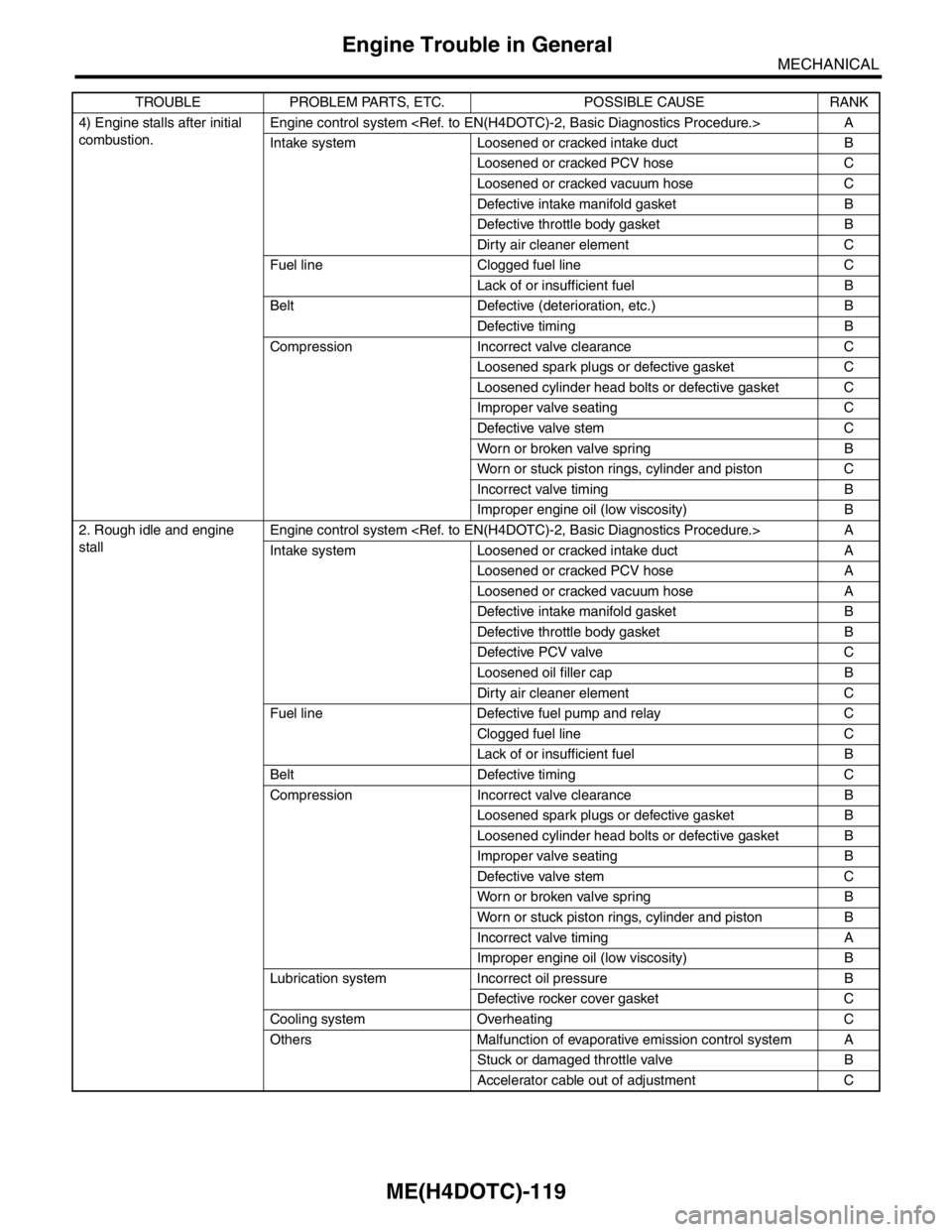

ME(H4DOTC)-119

MECHANICAL

Engine Trouble in General

4) Engine stalls after initial

combustion. Engine control system

Intake system Loosened or cracked intake duct B

Loosened or cracked PCV hose C

Loosened or cracked vacuum hose C

Defective intake manifold gasket B

Defective throttle body gasket B

Dirty air cleaner element C

Fuel line Clogged fuel line C

Lack of or insufficient fuel B

Belt Defective (deterioration, etc.) B

Defective timing B

Compression Incorrect valve clearance C

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating C

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing B

Improper engine oil (low viscosity) B

2. Rough idle and engine

stallEngine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve C

Loosened oil filler cap B

Dirty air cleaner element C

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Belt Defective timing C

Compression Incorrect valve clearance B

Loosened spark plugs or defective gasket B

Loosened cylinder head bolts or defective gasket B

Improper valve seating B

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston B

Incorrect valve timing A

Improper engine oil (low viscosity) B

Lubrication system Incorrect oil pressure B

Defective rocker cover gasket C

Cooling system Overheating C

Others Malfunction of evaporative emission control system A

Stuck or damaged throttle valve B

Accelerator cable out of adjustment C TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK

Page 1580 of 2870

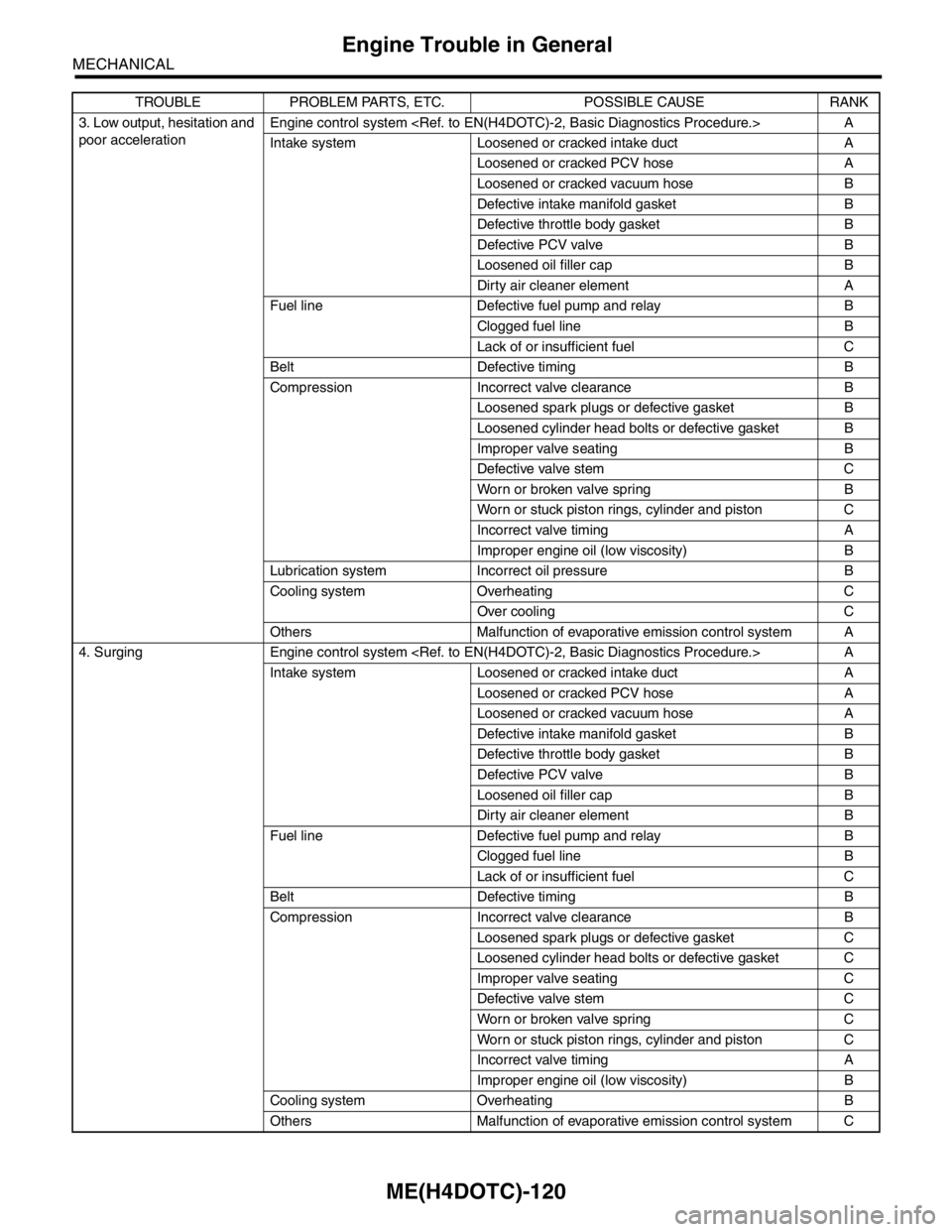

ME(H4DOTC)-120

MECHANICAL

Engine Trouble in General

3. Low output, hesitation and

poor accelerationEngine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose B

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element A

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Belt Defective timing B

Compression Incorrect valve clearance B

Loosened spark plugs or defective gasket B

Loosened cylinder head bolts or defective gasket B

Improper valve seating B

Defective valve stem C

Worn or broken valve spring B

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Lubrication system Incorrect oil pressure B

Cooling system Overheating C

Over cooling C

Others Malfunction of evaporative emission control system A

4. Surging Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element B

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Belt Defective timing B

Compression Incorrect valve clearance B

Loosened spark plugs or defective gasket C

Loosened cylinder head bolts or defective gasket C

Improper valve seating C

Defective valve stem C

Worn or broken valve spring C

Worn or stuck piston rings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Cooling system Overheating B

Others Malfunction of evaporative emission control system C TROUBLE PROBLEM PARTS, ETC. POSSIBLE CAUSE RANK