SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

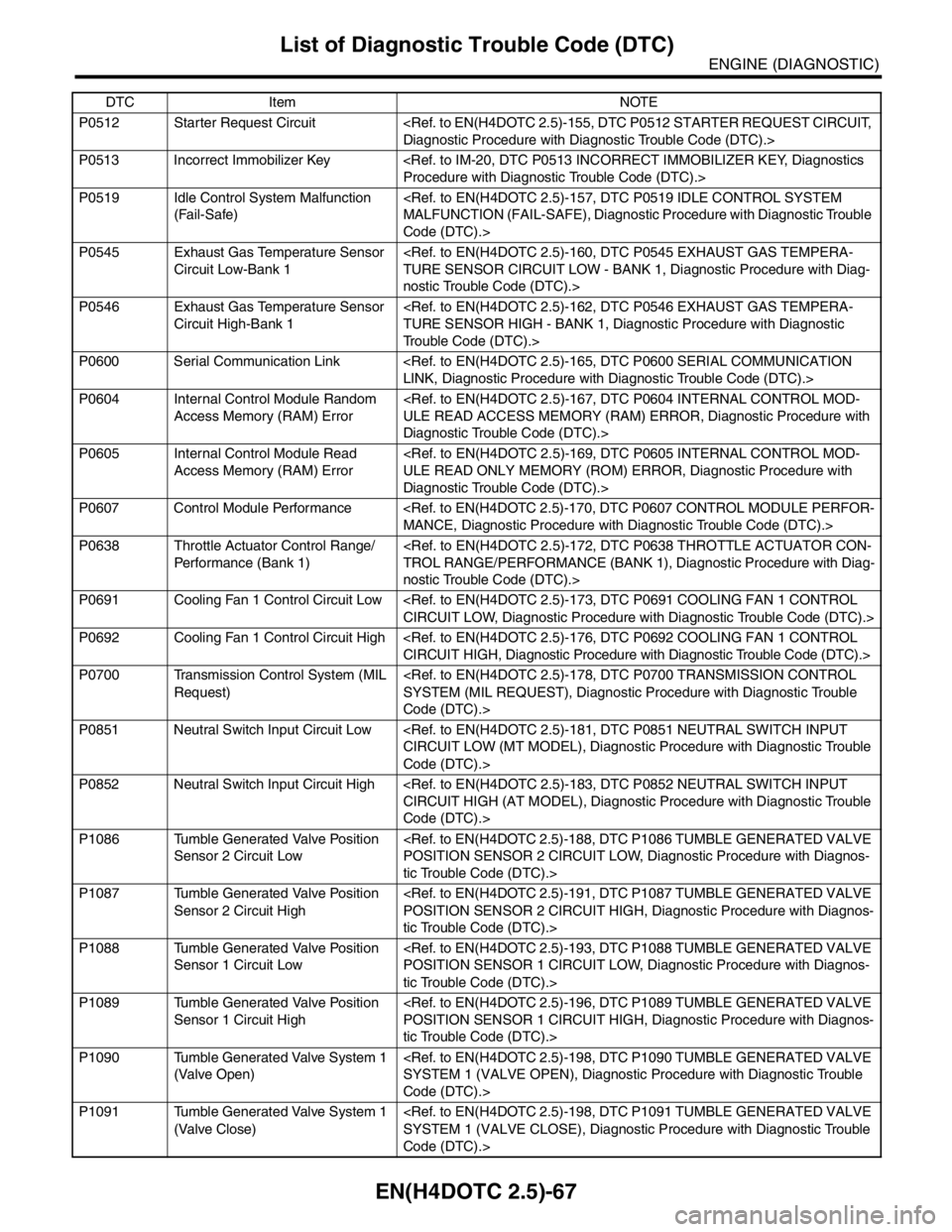

Page 2091 of 2870

EN(H4DOTC 2.5)-67

ENGINE (DIAGNOSTIC)

List of Diagnostic Trouble Code (DTC)

P0512 Starter Request Circuit

P0513 Incorrect Immobilizer Key

P0519 Idle Control System Malfunction

(Fail-Safe)

Code (DTC).>

P0545 Exhaust Gas Temperature Sensor

Circuit Low-Bank 1

nostic Trouble Code (DTC).>

P0546 Exhaust Gas Temperature Sensor

Circuit High-Bank 1

Trouble Code (DTC).>

P0600 Serial Communication Link

P0604 Internal Control Module Random

Access Memory (RAM) Error

Diagnostic Trouble Code (DTC).>

P0605 Internal Control Module Read

Access Memory (RAM) Error

Diagnostic Trouble Code (DTC).>

P0607 Control Module Performance

P0638 Throttle Actuator Control Range/

Performance (Bank 1)

nostic Trouble Code (DTC).>

P0691 Cooling Fan 1 Control Circuit Low

P0692 Cooling Fan 1 Control Circuit High

P0700 Transmission Control System (MIL

Request)

Code (DTC).>

P0851 Neutral Switch Input Circuit Low

Code (DTC).>

P0852 Neutral Switch Input Circuit High

Code (DTC).>

P1086 Tumble Generated Valve Position

Sensor 2 Circuit Low

tic Trouble Code (DTC).>

P1087 Tumble Generated Valve Position

Sensor 2 Circuit High

tic Trouble Code (DTC).>

P1088 Tumble Generated Valve Position

Sensor 1 Circuit Low

tic Trouble Code (DTC).>

P1089 Tumble Generated Valve Position

Sensor 1 Circuit High

tic Trouble Code (DTC).>

P1090 Tumble Generated Valve System 1

(Valve Open)

Code (DTC).>

P1091 Tumble Generated Valve System 1

(Valve Close)

Code (DTC).> DTC Item NOTE

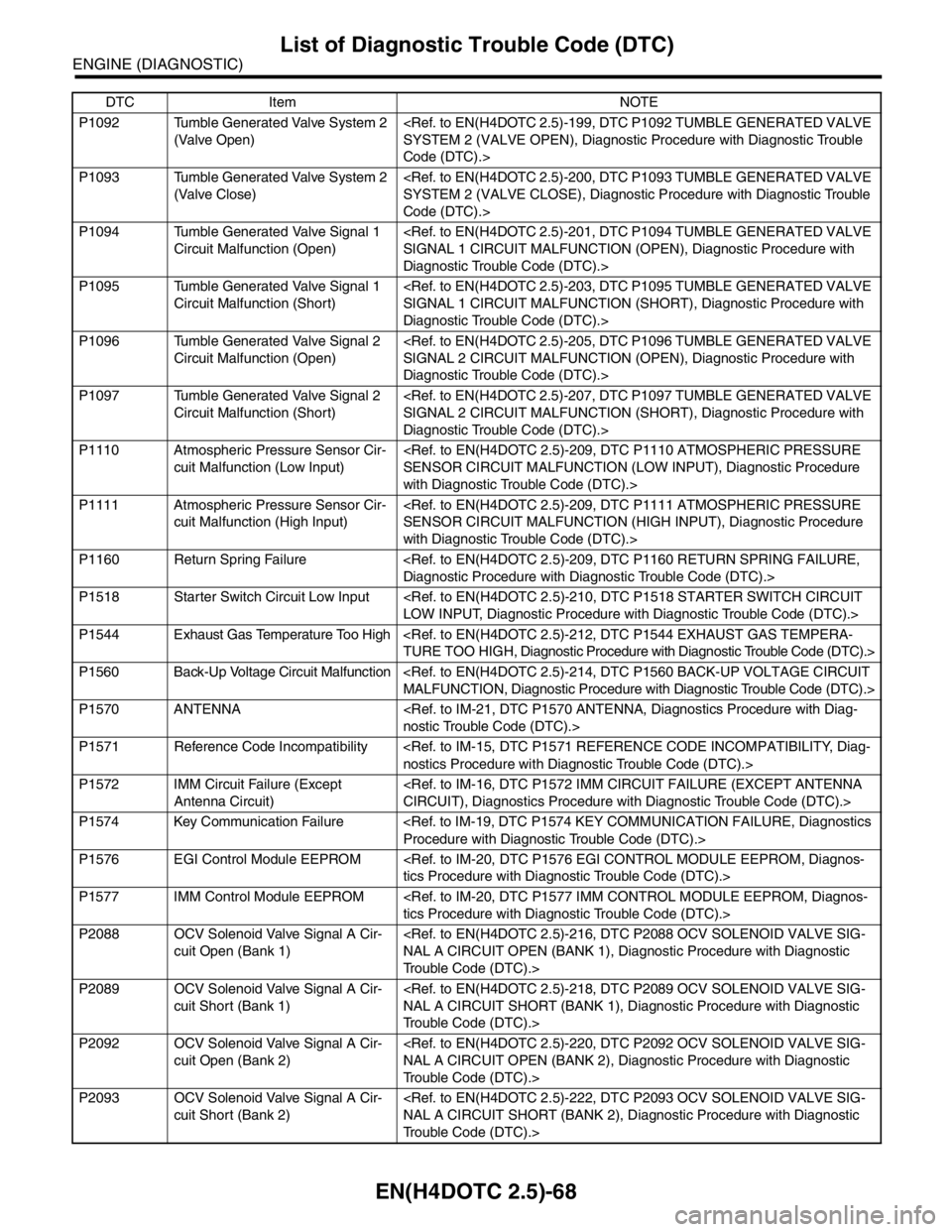

Page 2092 of 2870

EN(H4DOTC 2.5)-68

ENGINE (DIAGNOSTIC)

List of Diagnostic Trouble Code (DTC)

P1092 Tumble Generated Valve System 2

(Valve Open)

Code (DTC).>

P1093 Tumble Generated Valve System 2

(Valve Close)

Code (DTC).>

P1094 Tumble Generated Valve Signal 1

Circuit Malfunction (Open)

Diagnostic Trouble Code (DTC).>

P1095 Tumble Generated Valve Signal 1

Circuit Malfunction (Short)

Diagnostic Trouble Code (DTC).>

P1096 Tumble Generated Valve Signal 2

Circuit Malfunction (Open)

Diagnostic Trouble Code (DTC).>

P1097 Tumble Generated Valve Signal 2

Circuit Malfunction (Short)

Diagnostic Trouble Code (DTC).>

P1110 Atmospheric Pressure Sensor Cir-

cuit Malfunction (Low Input)

with Diagnostic Trouble Code (DTC).>

P1111 Atmospheric Pressure Sensor Cir-

cuit Malfunction (High Input)

with Diagnostic Trouble Code (DTC).>

P1160 Return Spring Failure

P1518 Starter Switch Circuit Low Input

P1544 Exhaust Gas Temperature Too High

P1560 Back-Up Voltage Circuit Malfunction

P1570 ANTENNA

P1571 Reference Code Incompatibility

P1572 IMM Circuit Failure (Except

Antenna Circuit)

P1574 Key Communication Failure

P1576 EGI Control Module EEPROM

P1577 IMM Control Module EEPROM

P2088 OCV Solenoid Valve Signal A Cir-

cuit Open (Bank 1)

Trouble Code (DTC).>

P2089 OCV Solenoid Valve Signal A Cir-

cuit Short (Bank 1)

Trouble Code (DTC).>

P2092 OCV Solenoid Valve Signal A Cir-

cuit Open (Bank 2)

Trouble Code (DTC).>

P2093 OCV Solenoid Valve Signal A Cir-

cuit Short (Bank 2)

Trouble Code (DTC).> DTC Item NOTE

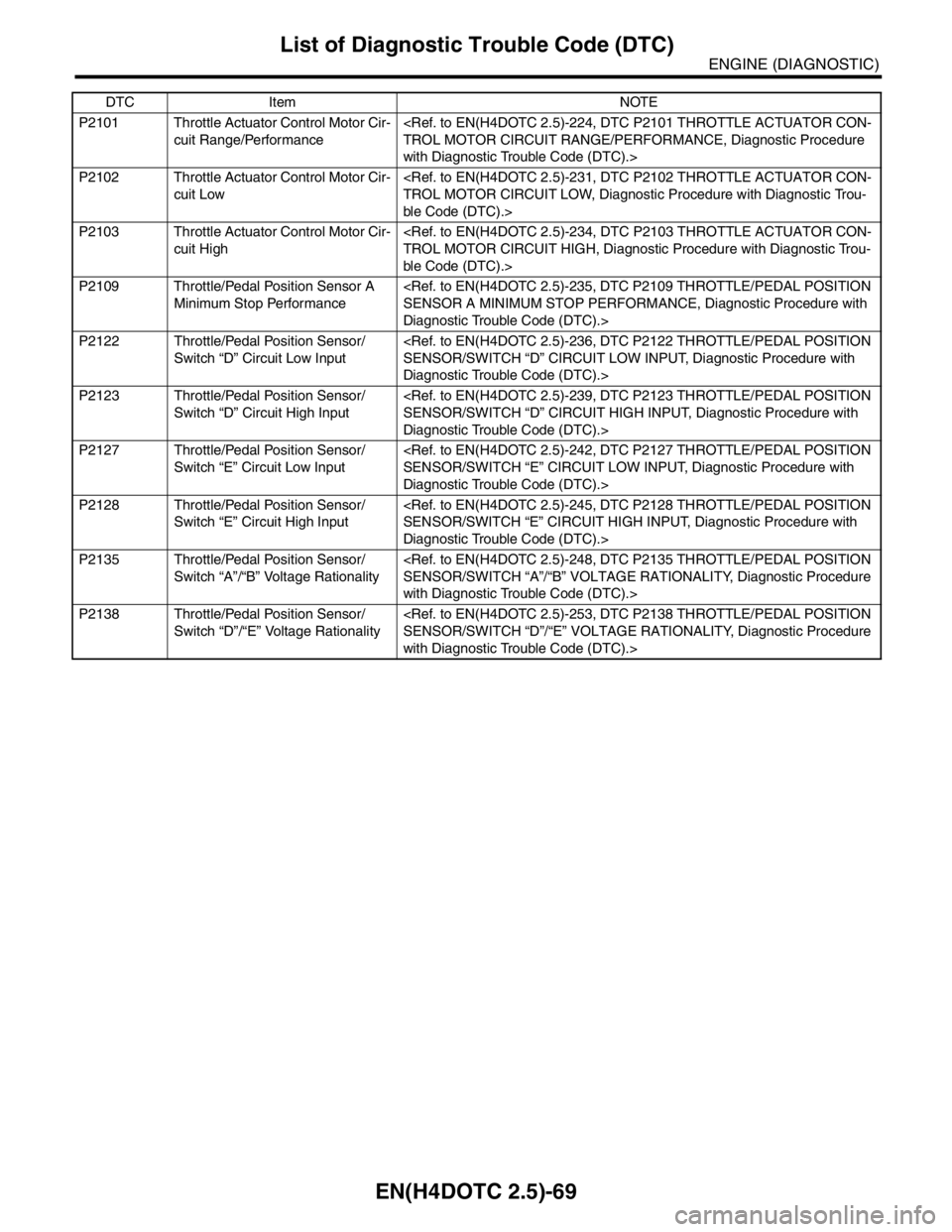

Page 2093 of 2870

EN(H4DOTC 2.5)-69

ENGINE (DIAGNOSTIC)

List of Diagnostic Trouble Code (DTC)

P2101 Throttle Actuator Control Motor Cir-

cuit Range/Performance

with Diagnostic Trouble Code (DTC).>

P2102 Throttle Actuator Control Motor Cir-

cuit Low

ble Code (DTC).>

P2103 Throttle Actuator Control Motor Cir-

cuit High

ble Code (DTC).>

P2109 Throttle/Pedal Position Sensor A

Minimum Stop Performance

Diagnostic Trouble Code (DTC).>

P2122 Throttle/Pedal Position Sensor/

Switch “D” Circuit Low Input

Diagnostic Trouble Code (DTC).>

P2123 Throttle/Pedal Position Sensor/

Switch “D” Circuit High Input

Diagnostic Trouble Code (DTC).>

P2127 Throttle/Pedal Position Sensor/

Switch “E” Circuit Low Input

Diagnostic Trouble Code (DTC).>

P2128 Throttle/Pedal Position Sensor/

Switch “E” Circuit High Input

Diagnostic Trouble Code (DTC).>

P2135 Throttle/Pedal Position Sensor/

Switch “A”/“B” Voltage Rationality

with Diagnostic Trouble Code (DTC).>

P2138 Throttle/Pedal Position Sensor/

Switch “D”/“E” Voltage Rationality

with Diagnostic Trouble Code (DTC).> DTC Item NOTE

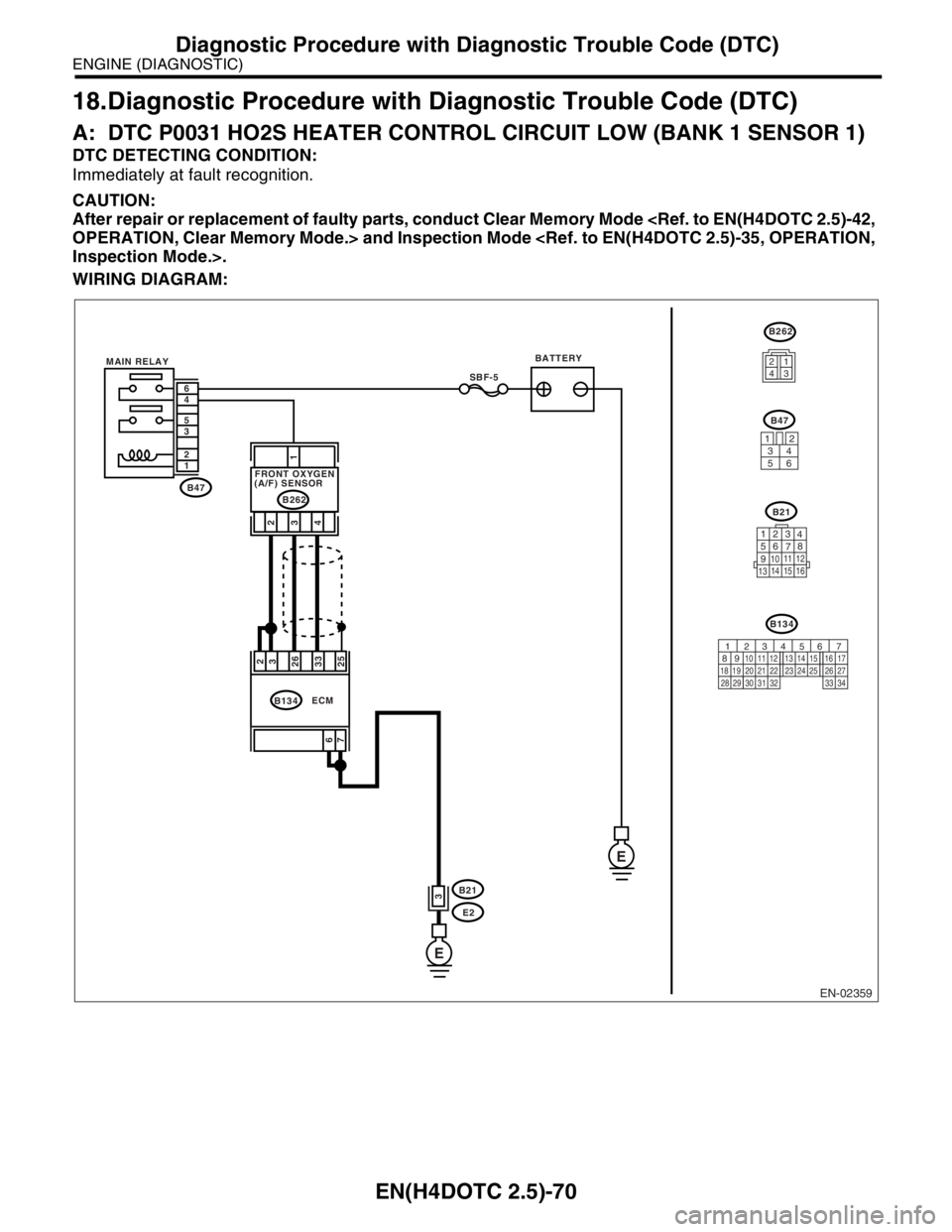

Page 2094 of 2870

EN(H4DOTC 2.5)-70

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

18.Diagnostic Procedure with Diagnostic Trouble Code (DTC)

A: DTC P0031 HO2S HEATER CONTROL CIRCUIT LOW (BANK 1 SENSOR 1)

DTC DETECTING CONDITION:

Immediately at fault recognition.

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02359

SBF-5

B47 1 2 3 5 4 6

E

E

B21

E236

72

3

26

33

25

ECM

B134

1

3 2

4

B262

34 12

56

123

4

56

78

9

1011 12

1314 15 16

B21 B47 B262

B134

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

MAIN RELAY1234BATTERY

FRONT OXYGEN

(A/F) SENSOR

Page 2095 of 2870

EN(H4DOTC 2.5)-71

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

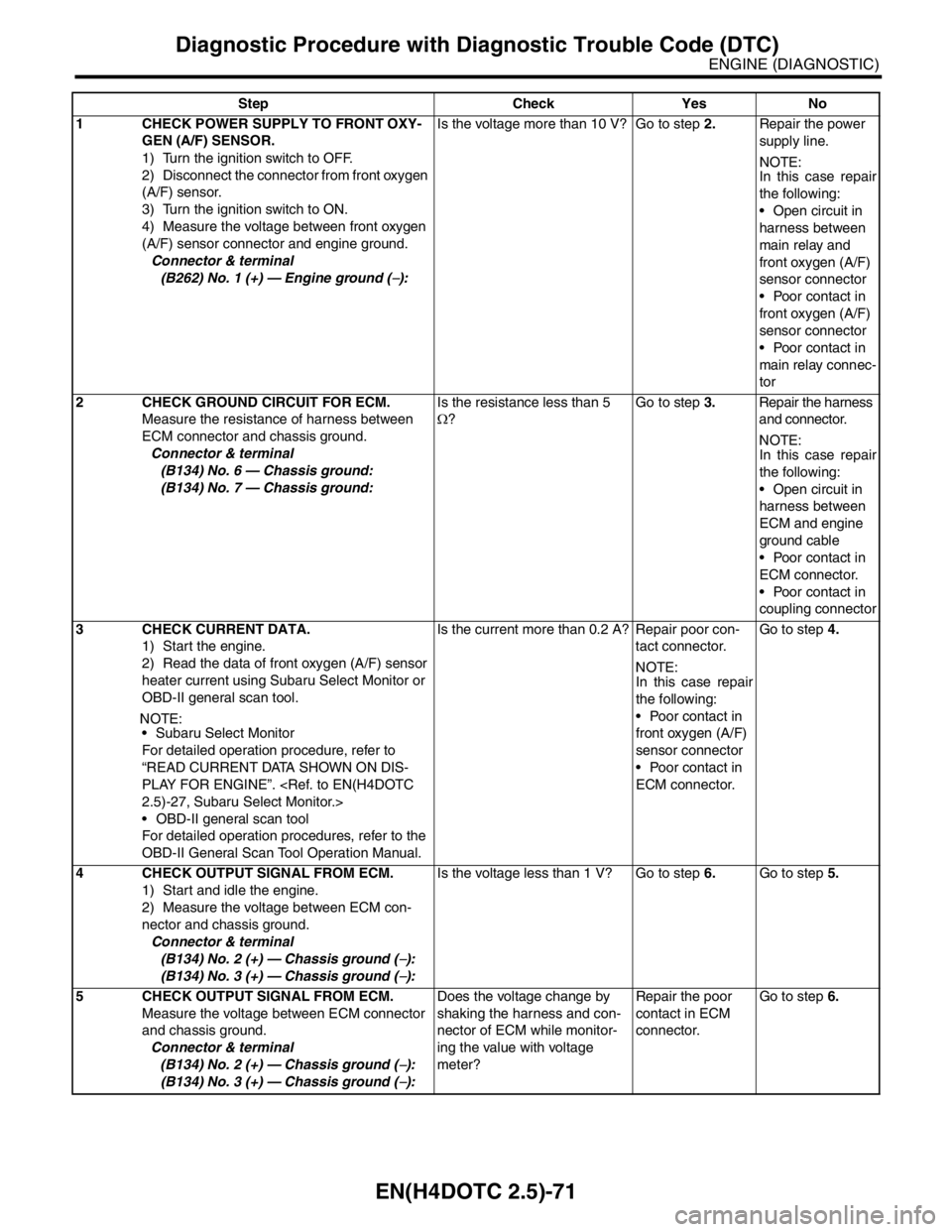

Step Check Yes No

1 CHECK POWER SUPPLY TO FRONT OXY-

GEN (A/F) SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from front oxygen

(A/F) sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between front oxygen

(A/F) sensor connector and engine ground.

Connector & terminal

(B262) No. 1 (+) — Engine ground (

−):Is the voltage more than 10 V? Go to step 2.Repair the power

supply line.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

main relay and

front oxygen (A/F)

sensor connector

Poor contact in

front oxygen (A/F)

sensor connector

Poor contact in

main relay connec-

tor

2 CHECK GROUND CIRCUIT FOR ECM.

Measure the resistance of harness between

ECM connector and chassis ground.

Connector & terminal

(B134) No. 6 — Chassis ground:

(B134) No. 7 — Chassis ground:Is the resistance less than 5

Ω?Go to step 3.Repair the harness

and connector.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

ECM and engine

ground cable

Poor contact in

ECM connector.

Poor contact in

coupling connector

3 CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of front oxygen (A/F) sensor

heater current using Subaru Select Monitor or

OBD-II general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Is the current more than 0.2 A? Repair poor con-

tact connector.

N

OTE:

In this case repair

the following:

Poor contact in

front oxygen (A/F)

sensor connector

Poor contact in

ECM connector.Go to step 4.

4 CHECK OUTPUT SIGNAL FROM ECM.

1) Start and idle the engine.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B134) No. 2 (+) — Chassis ground (

−):

(B134) No. 3 (+) — Chassis ground (

−):Is the voltage less than 1 V? Go to step 6.Go to step 5.

5 CHECK OUTPUT SIGNAL FROM ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B134) No. 2 (+) — Chassis ground (

−):

(B134) No. 3 (+) — Chassis ground (

−):Does the voltage change by

shaking the harness and con-

nector of ECM while monitor-

ing the value with voltage

meter?Repair the poor

contact in ECM

connector.Go to step 6.

Page 2096 of 2870

EN(H4DOTC 2.5)-72

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

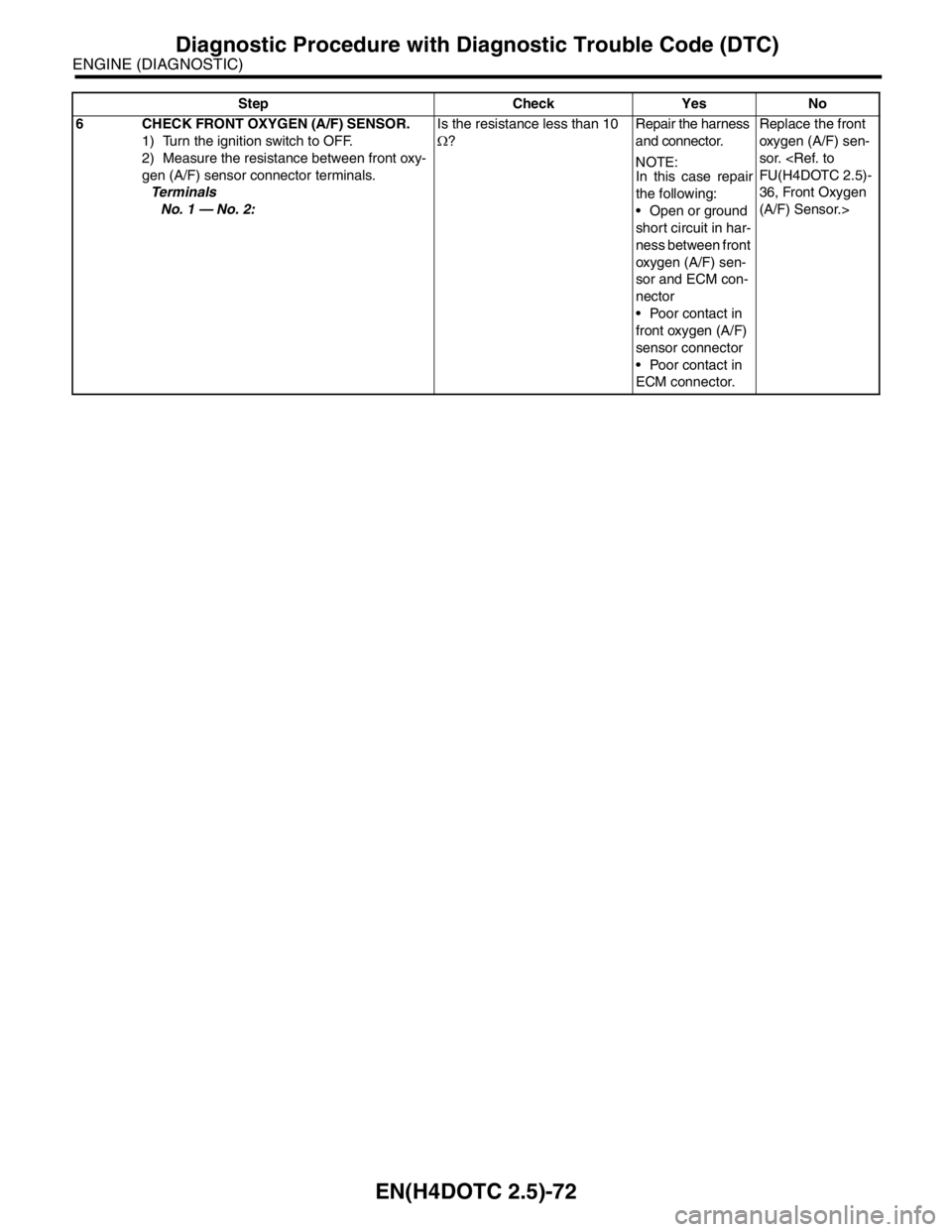

6 CHECK FRONT OXYGEN (A/F) SENSOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between front oxy-

gen (A/F) sensor connector terminals.

Te r m i n a l s

No. 1 — No. 2:Is the resistance less than 10

Ω?Repair the harness

and connector.

N

OTE:

In this case repair

the following:

Open or ground

short circuit in har-

ness between front

oxygen (A/F) sen-

sor and ECM con-

nector

Poor contact in

front oxygen (A/F)

sensor connector

Poor contact in

ECM connector.Replace the front

oxygen (A/F) sen-

sor.

36, Front Oxygen

(A/F) Sensor.> Step Check Yes No

Page 2097 of 2870

EN(H4DOTC 2.5)-73

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

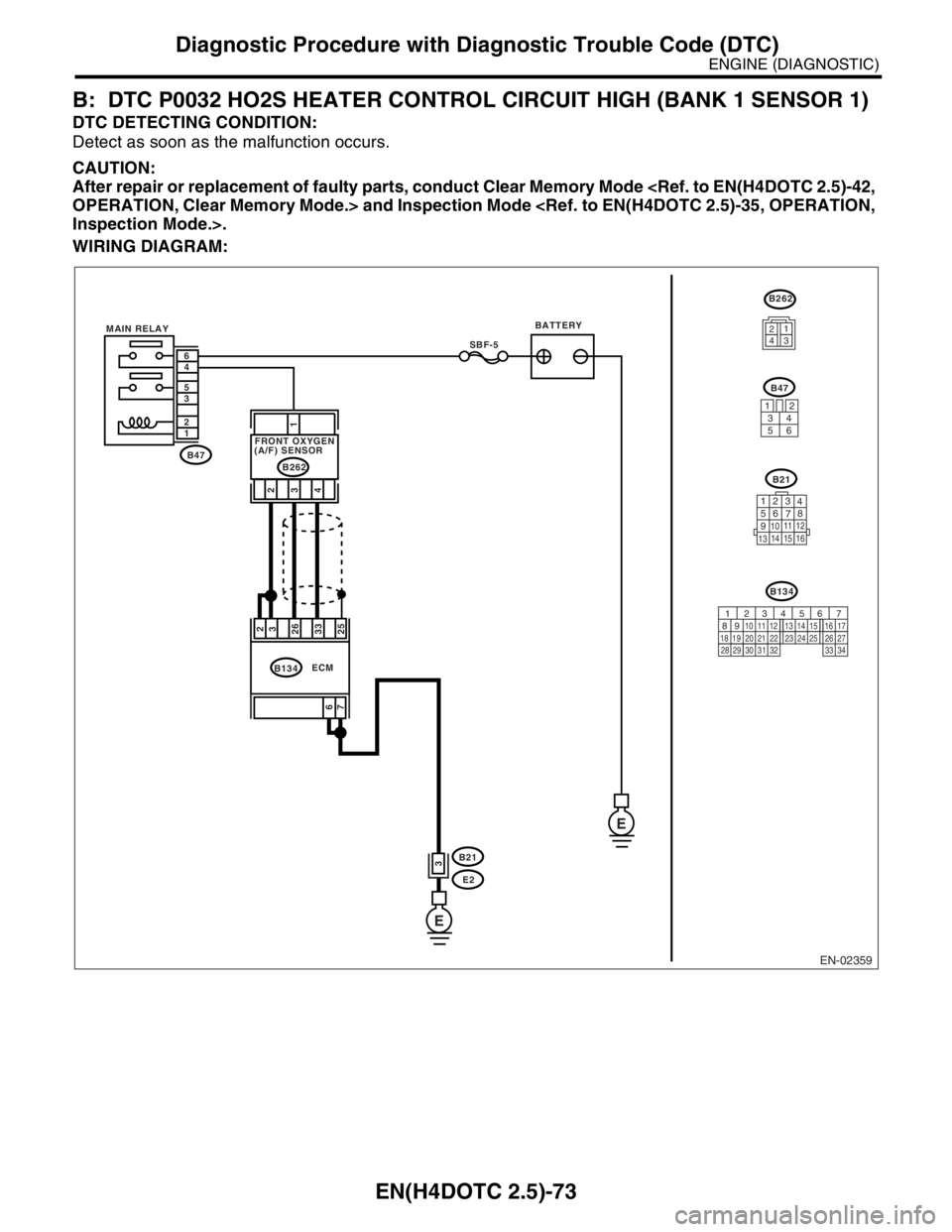

B: DTC P0032 HO2S HEATER CONTROL CIRCUIT HIGH (BANK 1 SENSOR 1)

DTC DETECTING CONDITION:

Detect as soon as the malfunction occurs.

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02359

SBF-5

B47 1 2 3 5 4 6

E

E

B21

E236

72

3

26

33

25

ECM

B134

1

3 2

4

B262

34 12

56

123

4

56

78

9

1011 12

1314 15 16

B21 B47 B262

B134

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

MAIN RELAY1234BATTERY

FRONT OXYGEN

(A/F) SENSOR

Page 2098 of 2870

EN(H4DOTC 2.5)-74

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

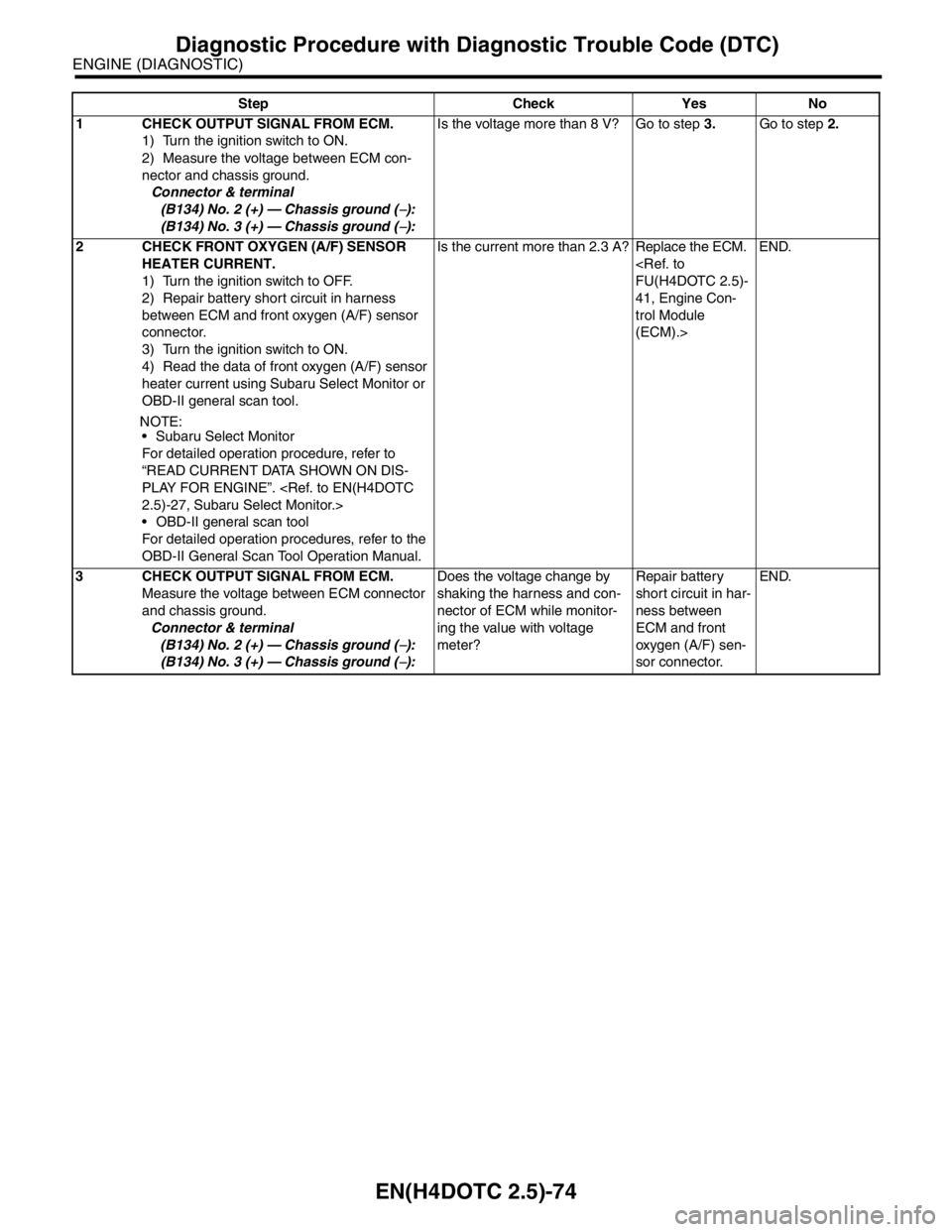

Step Check Yes No

1 CHECK OUTPUT SIGNAL FROM ECM.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B134) No. 2 (+) — Chassis ground (

−):

(B134) No. 3 (+) — Chassis ground (

−):Is the voltage more than 8 V? Go to step 3.Go to step 2.

2 CHECK FRONT OXYGEN (A/F) SENSOR

HEATER CURRENT.

1) Turn the ignition switch to OFF.

2) Repair battery short circuit in harness

between ECM and front oxygen (A/F) sensor

connector.

3) Turn the ignition switch to ON.

4) Read the data of front oxygen (A/F) sensor

heater current using Subaru Select Monitor or

OBD-II general scan tool.

N

OTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Is the current more than 2.3 A? Replace the ECM.

41, Engine Con-

trol Module

(ECM).>END.

3 CHECK OUTPUT SIGNAL FROM ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B134) No. 2 (+) — Chassis ground (

−):

(B134) No. 3 (+) — Chassis ground (

−):Does the voltage change by

shaking the harness and con-

nector of ECM while monitor-

ing the value with voltage

meter?Repair battery

short circuit in har-

ness between

ECM and front

oxygen (A/F) sen-

sor connector.END.

Page 2099 of 2870

EN(H4DOTC 2.5)-75

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

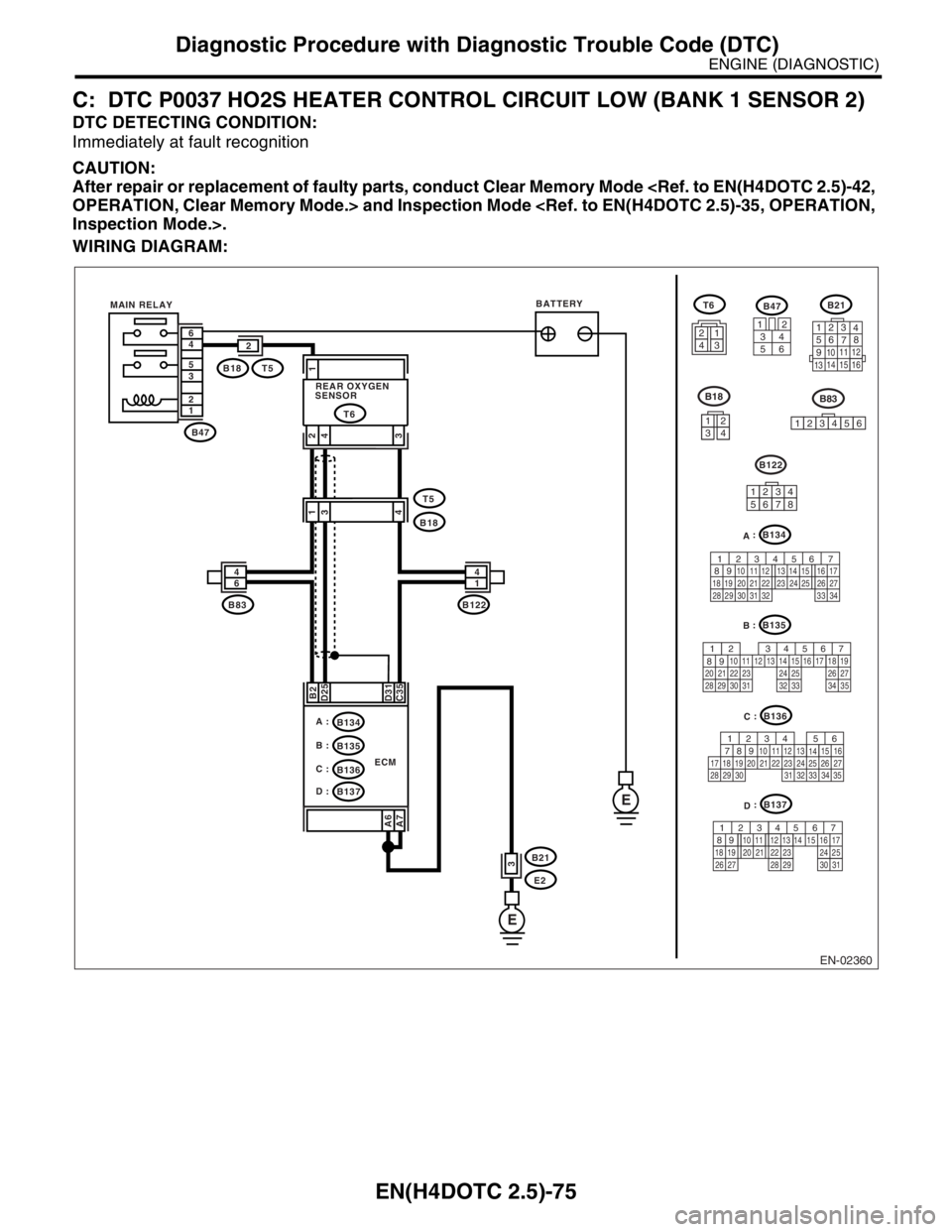

C: DTC P0037 HO2S HEATER CONTROL CIRCUIT LOW (BANK 1 SENSOR 2)

DTC DETECTING CONDITION:

Immediately at fault recognition

CAUTION:

After repair or replacement of faulty parts, conduct Clear Memory Mode

WIRING DIAGRAM:

EN-02360

B122 B47 1 2 3 5 4 6

E

E

B21

E23

4

1

B122

34 12

56123

4

56

78

9

1011 12

1314 15 16

: B134

: B135B21

B47 T6

: B136 T6

A6

A7B2

D25

D31

C35

C : B :

D :

4

6

B83A

B

C

B136

B137 B135 B134 A :

: B137

D

56 7

82 1

94 310

24 22 23 25 11 12 13 14 15

26 27

2816 17

18 19 20 21

33 34 29

32 30 31

56

782 1

94 310

24 22 23 2511 12 13

1415

26 27

2816

17 18 19 20 21

33 34 29

32 30

31 35

567

82 1

94 310

24 22 23 2511 12 13 14 15

26 27

2816 17 18 19

20 21

29 30 31 32 33 34 35

567

82 1

94 310

22 23 11 12 13 14 15

24 25

2616 17

18 19 20 21

27 28 29 30 31

ECM MAIN RELAYBATTERY

REAR OXYGEN

SENSOR

12345678

B18 T52

B18

T5

B18

1234

B83

1

23456

1234

3 1

4

1

2

4

3

Page 2100 of 2870

EN(H4DOTC 2.5)-76

ENGINE (DIAGNOSTIC)

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

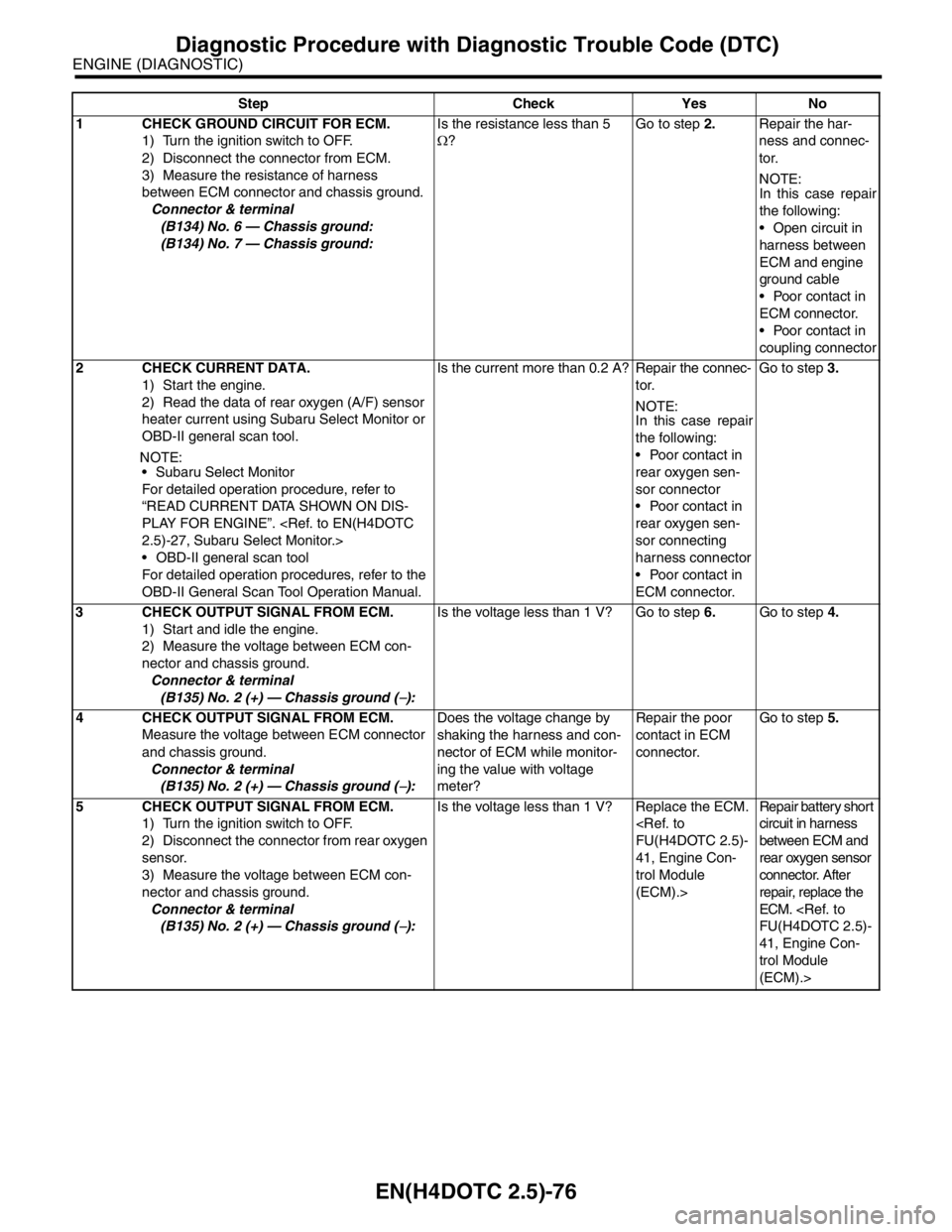

Step Check Yes No

1 CHECK GROUND CIRCUIT FOR ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Measure the resistance of harness

between ECM connector and chassis ground.

Connector & terminal

(B134) No. 6 — Chassis ground:

(B134) No. 7 — Chassis ground:Is the resistance less than 5

Ω?Go to step 2.Repair the har-

ness and connec-

tor.

N

OTE:

In this case repair

the following:

Open circuit in

harness between

ECM and engine

ground cable

Poor contact in

ECM connector.

Poor contact in

coupling connector

2 CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of rear oxygen (A/F) sensor

heater current using Subaru Select Monitor or

OBD-II general scan tool.

NOTE:

Subaru Select Monitor

For detailed operation procedure, refer to

“READ CURRENT DATA SHOWN ON DIS-

PLAY FOR ENGINE”.

OBD-II general scan tool

For detailed operation procedures, refer to the

OBD-II General Scan Tool Operation Manual.Is the current more than 0.2 A? Repair the connec-

tor.

NOTE:

In this case repair

the following:

Poor contact in

rear oxygen sen-

sor connector

Poor contact in

rear oxygen sen-

sor connecting

harness connector

Poor contact in

ECM connector.Go to step 3.

3 CHECK OUTPUT SIGNAL FROM ECM.

1) Start and idle the engine.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B135) No. 2 (+) — Chassis ground (

−):Is the voltage less than 1 V? Go to step 6.Go to step 4.

4 CHECK OUTPUT SIGNAL FROM ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B135) No. 2 (+) — Chassis ground (

−):Does the voltage change by

shaking the harness and con-

nector of ECM while monitor-

ing the value with voltage

meter?Repair the poor

contact in ECM

connector.Go to step 5.

5 CHECK OUTPUT SIGNAL FROM ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from rear oxygen

sensor.

3) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B135) No. 2 (+) — Chassis ground (

−):Is the voltage less than 1 V? Replace the ECM.

41, Engine Con-

trol Module

(ECM).>Repair battery short

circuit in harness

between ECM and

rear oxygen sensor

connector. After

repair, replace the

ECM.

41, Engine Con-

trol Module

(ECM).>