SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 2801 of 2870

5MT-88

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

8) Select one to three shims from the next table for

the value determined as described above and take

a shim thickness which is closest to the indicated

value.

9) Install the differential assembly.

10) Set the transmission main shaft assembly and

drive pinion assembly in position. (So there is no

clearance between the two when moved all the way

to the front). Inspect the suitable 1st-2nd, 3rd-4th

and 5th shifter fork so that coupling sleeve and re-

verse driven gear are positioned in the center of

their synchronizing mechanisms.

11) Install the transmission case.

12) Install the transfer case with extension case as-

sembly.

13) Install the manual transmission assembly to ve-

hicle.

NOTE:

Attach a cloth to the end of driven shaft (on the fric-

tional side of thrust needle bearing) during disas-

sembly or reassembly to prevent damage.

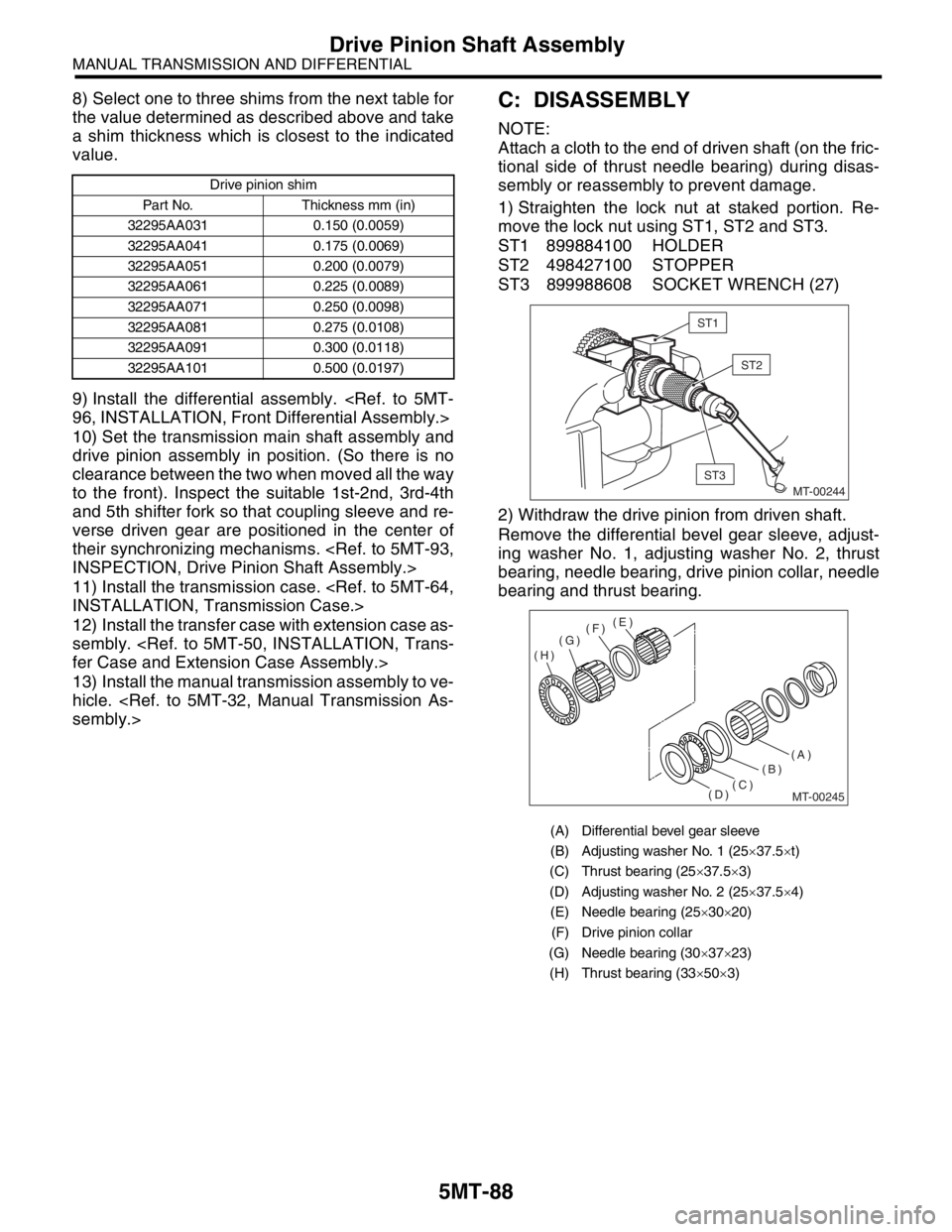

1) Straighten the lock nut at staked portion. Re-

move the lock nut using ST1, ST2 and ST3.

ST1 899884100 HOLDER

ST2 498427100 STOPPER

ST3 899988608 SOCKET WRENCH (27)

2) Withdraw the drive pinion from driven shaft.

Remove the differential bevel gear sleeve, adjust-

ing washer No. 1, adjusting washer No. 2, thrust

bearing, needle bearing, drive pinion collar, needle

bearing and thrust bearing.

Drive pinion shim

Part No. Thickness mm (in)

32295AA031 0.150 (0.0059)

32295AA041 0.175 (0.0069)

32295AA051 0.200 (0.0079)

32295AA061 0.225 (0.0089)

32295AA071 0.250 (0.0098)

32295AA081 0.275 (0.0108)

32295AA091 0.300 (0.0118)

32295AA101 0.500 (0.0197)

(A) Differential bevel gear sleeve

(B) Adjusting washer No. 1 (25×37.5×t)

(C) Thrust bearing (25×37.5×3)

(D) Adjusting washer No. 2 (25×37.5×4)

(E) Needle bearing (25×30×20)

(F) Drive pinion collar

(G) Needle bearing (30×37×23)

(H) Thrust bearing (33×50×3)

ST1

ST2

MT-00244

ST3

MT-00245

(B)

(D)(C)(A) (F)

(H)(G)(E)

Page 2802 of 2870

5MT-89

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

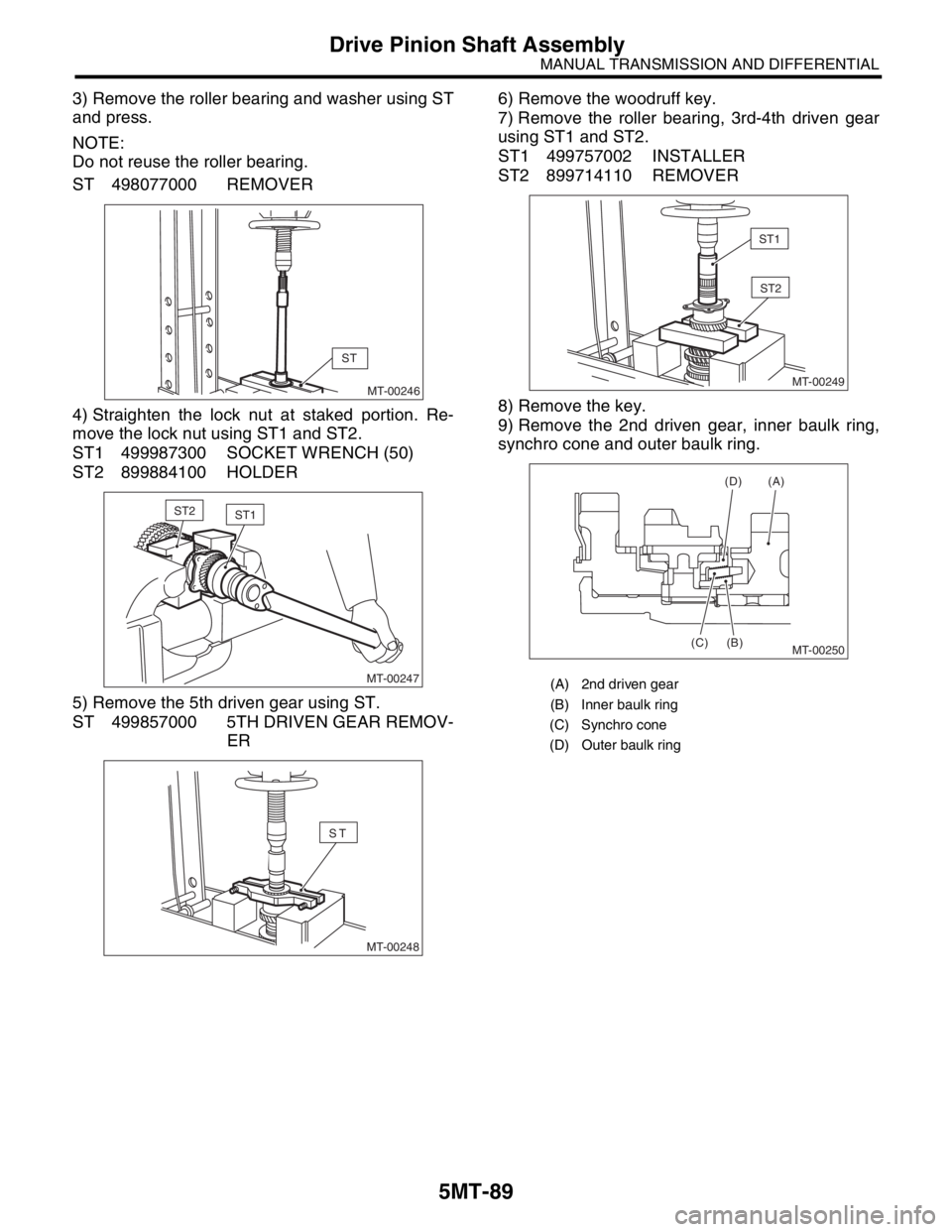

3) Remove the roller bearing and washer using ST

and press.

NOTE:

Do not reuse the roller bearing.

ST 498077000 REMOVER

4) Straighten the lock nut at staked portion. Re-

move the lock nut using ST1 and ST2.

ST1 499987300 SOCKET WRENCH (50)

ST2 899884100 HOLDER

5) Remove the 5th driven gear using ST.

ST 499857000 5TH DRIVEN GEAR REMOV-

ER6) Remove the woodruff key.

7) Remove the roller bearing, 3rd-4th driven gear

using ST1 and ST2.

ST1 499757002 INSTALLER

ST2 899714110 REMOVER

8) Remove the key.

9) Remove the 2nd driven gear, inner baulk ring,

synchro cone and outer baulk ring.

MT-00246

ST

MT-00247

ST1ST2

MT-00248

ST

(A) 2nd driven gear

(B) Inner baulk ring

(C) Synchro cone

(D) Outer baulk ring

MT-00249

ST1

ST2

MT-00250

(A)

(B) (C)(D)

Page 2803 of 2870

5MT-90

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

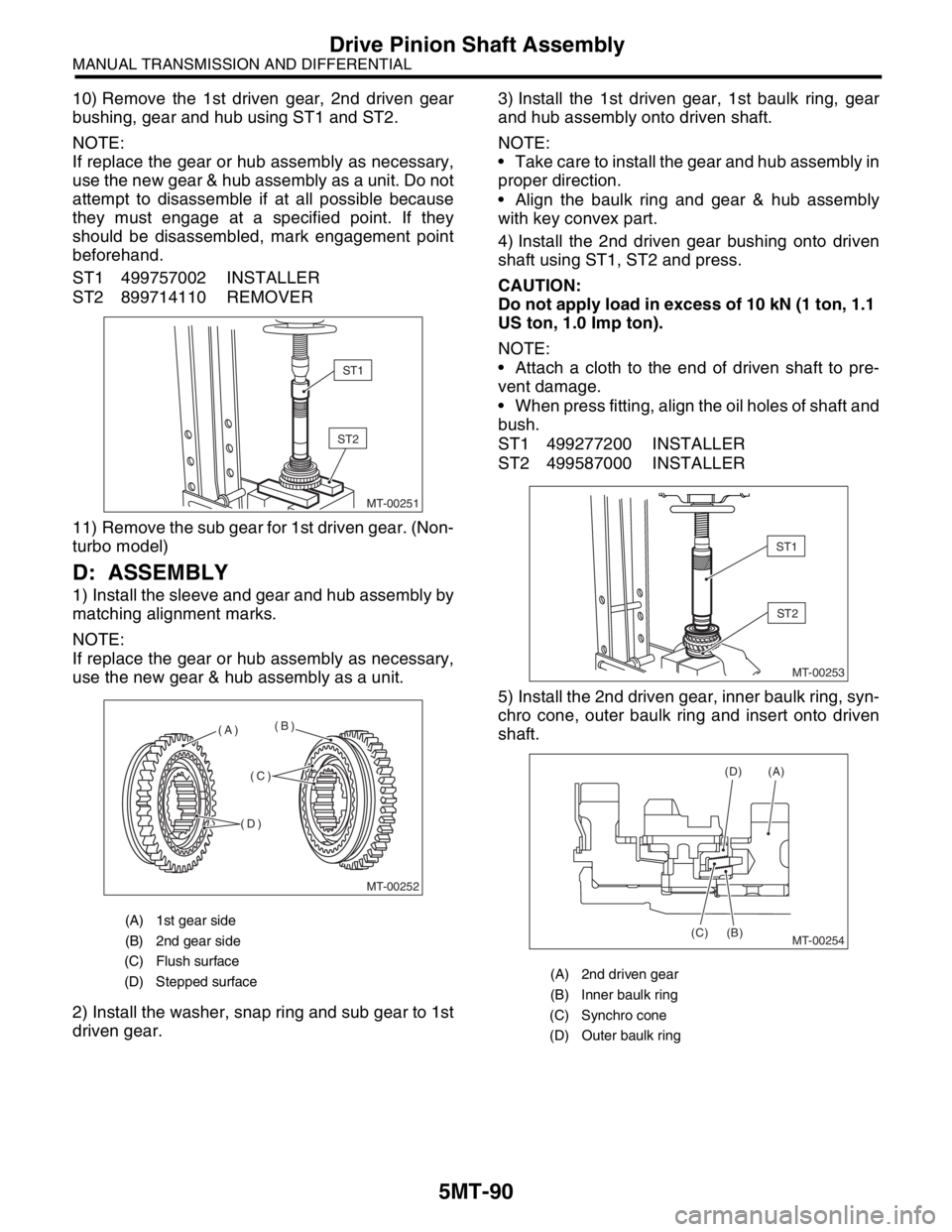

10) Remove the 1st driven gear, 2nd driven gear

bushing, gear and hub using ST1 and ST2.

NOTE:

If replace the gear or hub assembly as necessary,

use the new gear & hub assembly as a unit. Do not

attempt to disassemble if at all possible because

they must engage at a specified point. If they

should be disassembled, mark engagement point

beforehand.

ST1 499757002 INSTALLER

ST2 899714110 REMOVER

11) Remove the sub gear for 1st driven gear. (Non-

turbo model)

D: ASSEMBLY

1) Install the sleeve and gear and hub assembly by

matching alignment marks.

NOTE:

If replace the gear or hub assembly as necessary,

use the new gear & hub assembly as a unit.

2) Install the washer, snap ring and sub gear to 1st

driven gear.3) Install the 1st driven gear, 1st baulk ring, gear

and hub assembly onto driven shaft.

NOTE:

Take care to install the gear and hub assembly in

proper direction.

Align the baulk ring and gear & hub assembly

with key convex part.

4) Install the 2nd driven gear bushing onto driven

shaft using ST1, ST2 and press.

CAUTION:

Do not apply load in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton).

NOTE:

Attach a cloth to the end of driven shaft to pre-

vent damage.

When press fitting, align the oil holes of shaft and

bush.

ST1 499277200 INSTALLER

ST2 499587000 INSTALLER

5) Install the 2nd driven gear, inner baulk ring, syn-

chro cone, outer baulk ring and insert onto driven

shaft.

(A) 1st gear side

(B) 2nd gear side

(C) Flush surface

(D) Stepped surface

MT-00251

ST1

ST2

MT-00252

(B)

(A)

(C)

(D)

(A) 2nd driven gear

(B) Inner baulk ring

(C) Synchro cone

(D) Outer baulk ring

MT-00253

ST1

ST2

MT-00254

(A)

(B) (C)(D)

Page 2804 of 2870

5MT-91

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

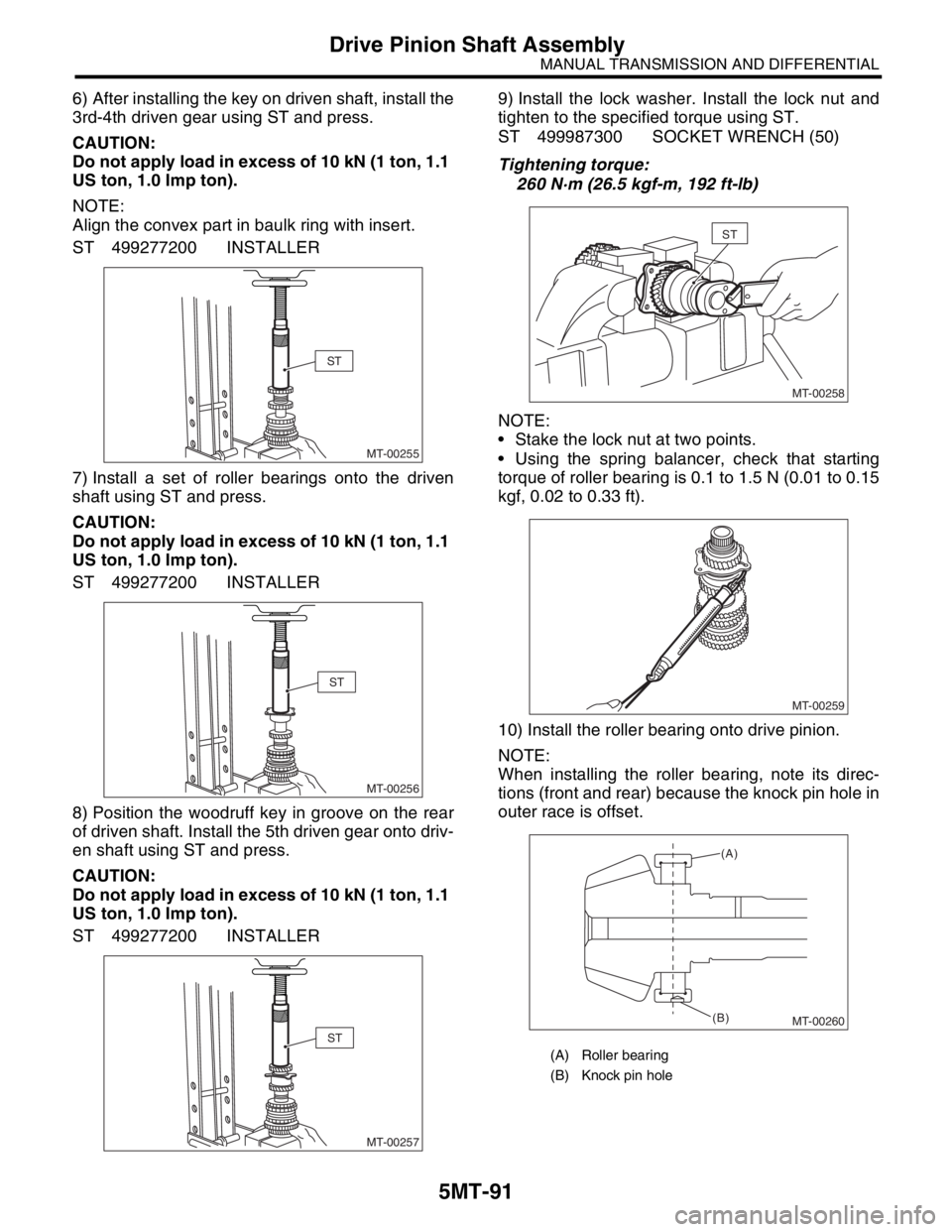

6) After installing the key on driven shaft, install the

3rd-4th driven gear using ST and press.

CAUTION:

Do not apply load in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton).

NOTE:

Align the convex part in baulk ring with insert.

ST 499277200 INSTALLER

7) Install a set of roller bearings onto the driven

shaft using ST and press.

CAUTION:

Do not apply load in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton).

ST 499277200 INSTALLER

8) Position the woodruff key in groove on the rear

of driven shaft. Install the 5th driven gear onto driv-

en shaft using ST and press.

CAUTION:

Do not apply load in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton).

ST 499277200 INSTALLER9) Install the lock washer. Install the lock nut and

tighten to the specified torque using ST.

ST 499987300 SOCKET WRENCH (50)

Tightening torque:

260 N·m (26.5 kgf-m, 192 ft-lb)

NOTE:

Stake the lock nut at two points.

Using the spring balancer, check that starting

torque of roller bearing is 0.1 to 1.5 N (0.01 to 0.15

kgf, 0.02 to 0.33 ft).

10) Install the roller bearing onto drive pinion.

NOTE:

When installing the roller bearing, note its direc-

tions (front and rear) because the knock pin hole in

outer race is offset.

MT-00255

ST

MT-00256

ST

MT-00257

ST

(A) Roller bearing

(B) Knock pin hole

MT-00258

ST

MT-00259

MT-00260

(A)

(B)

Page 2805 of 2870

5MT-92

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

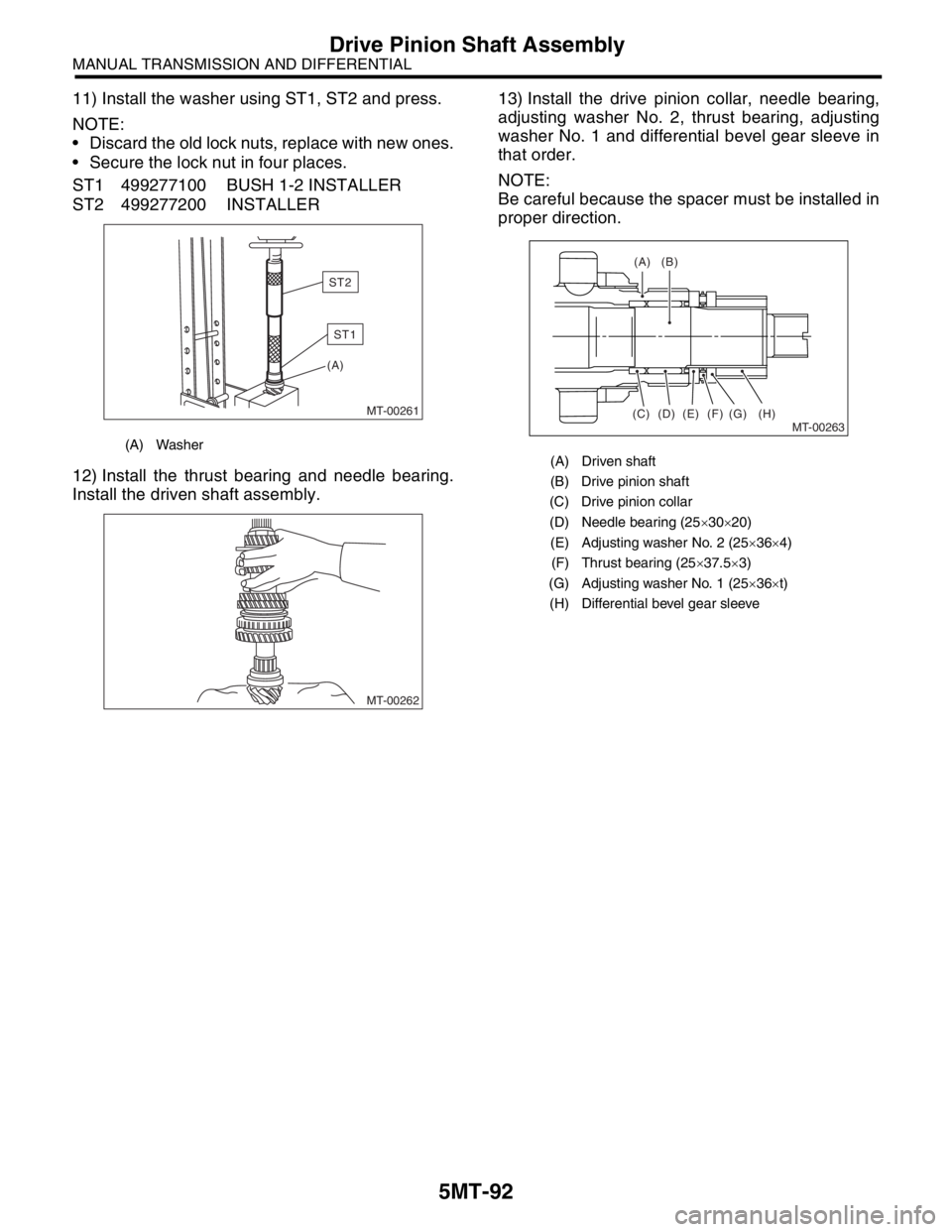

11) Install the washer using ST1, ST2 and press.

NOTE:

Discard the old lock nuts, replace with new ones.

Secure the lock nut in four places.

ST1 499277100 BUSH 1-2 INSTALLER

ST2 499277200 INSTALLER

12) Install the thrust bearing and needle bearing.

Install the driven shaft assembly.13) Install the drive pinion collar, needle bearing,

adjusting washer No. 2, thrust bearing, adjusting

washer No. 1 and differential bevel gear sleeve in

that order.

NOTE:

Be careful because the spacer must be installed in

proper direction.

(A) Washer

MT-00261

(A)

ST1

ST2

MT-00262

(A) Driven shaft

(B) Drive pinion shaft

(C) Drive pinion collar

(D) Needle bearing (25×30×20)

(E) Adjusting washer No. 2 (25×36×4)

(F) Thrust bearing (25×37.5×3)

(G) Adjusting washer No. 1 (25×36×t)

(H) Differential bevel gear sleeve

MT-00263

(A) (B)

(C) (D) (E) (F) (G) (H)

Page 2806 of 2870

5MT-93

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

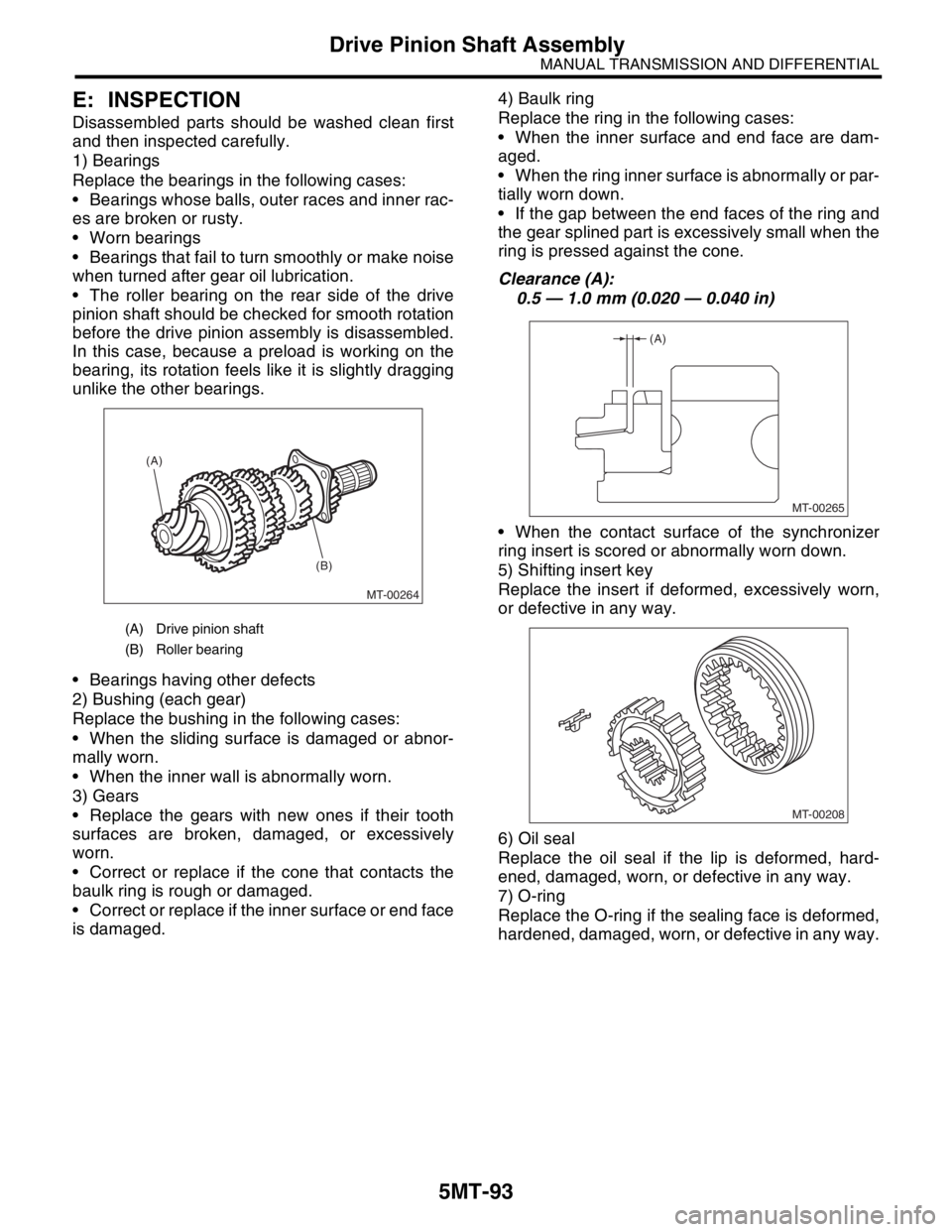

E: INSPECTION

Disassembled parts should be washed clean first

and then inspected carefully.

1) Bearings

Replace the bearings in the following cases:

Bearings whose balls, outer races and inner rac-

es are broken or rusty.

Worn bearings

Bearings that fail to turn smoothly or make noise

when turned after gear oil lubrication.

The roller bearing on the rear side of the drive

pinion shaft should be checked for smooth rotation

before the drive pinion assembly is disassembled.

In this case, because a preload is working on the

bearing, its rotation feels like it is slightly dragging

unlike the other bearings.

Bearings having other defects

2) Bushing (each gear)

Replace the bushing in the following cases:

When the sliding surface is damaged or abnor-

mally worn.

When the inner wall is abnormally worn.

3) Gears

Replace the gears with new ones if their tooth

surfaces are broken, damaged, or excessively

worn.

Correct or replace if the cone that contacts the

baulk ring is rough or damaged.

Correct or replace if the inner surface or end face

is damaged.4) Baulk ring

Replace the ring in the following cases:

When the inner surface and end face are dam-

aged.

When the ring inner surface is abnormally or par-

tially worn down.

If the gap between the end faces of the ring and

the gear splined part is excessively small when the

ring is pressed against the cone.

Clearance (A):

0.5 — 1.0 mm (0.020 — 0.040 in)

When the contact surface of the synchronizer

ring insert is scored or abnormally worn down.

5) Shifting insert key

Replace the insert if deformed, excessively worn,

or defective in any way.

6) Oil seal

Replace the oil seal if the lip is deformed, hard-

ened, damaged, worn, or defective in any way.

7) O-ring

Replace the O-ring if the sealing face is deformed,

hardened, damaged, worn, or defective in any way.

(A) Drive pinion shaft

(B) Roller bearing

MT-00264

(A)

(B)

MT-00265

(A)

MT-00208

Page 2807 of 2870

5MT-94

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

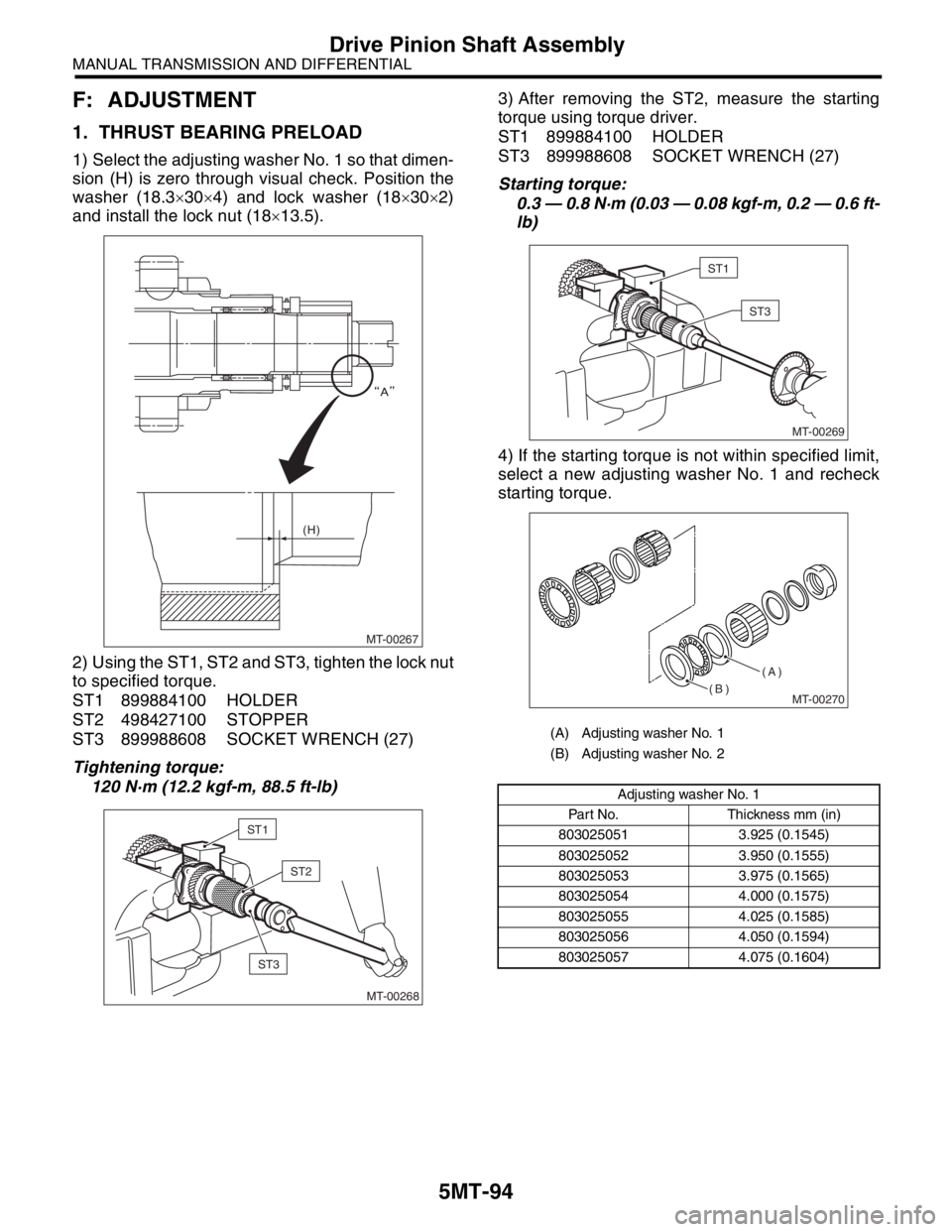

F: ADJUSTMENT

1. THRUST BEARING PRELOAD

1) Select the adjusting washer No. 1 so that dimen-

sion (H) is zero through visual check. Position the

washer (18.3×30×4) and lock washer (18×30×2)

and install the lock nut (18×13.5).

2) Using the ST1, ST2 and ST3, tighten the lock nut

to specified torque.

ST1 899884100 HOLDER

ST2 498427100 STOPPER

ST3 899988608 SOCKET WRENCH (27)

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb) 3) After removing the ST2, measure the starting

torque using torque driver.

ST1 899884100 HOLDER

ST3 899988608 SOCKET WRENCH (27)

Starting torque:

0.3 — 0.8 N·m (0.03 — 0.08 kgf-m, 0.2 — 0.6 ft-

lb)

4) If the starting torque is not within specified limit,

select a new adjusting washer No. 1 and recheck

starting torque.

MT-00267 (H)

MT-00268

ST1

ST2

ST3

(A) Adjusting washer No. 1

(B) Adjusting washer No. 2

Adjusting washer No. 1

Part No. Thickness mm (in)

803025051 3.925 (0.1545)

803025052 3.950 (0.1555)

803025053 3.975 (0.1565)

803025054 4.000 (0.1575)

803025055 4.025 (0.1585)

803025056 4.050 (0.1594)

803025057 4.075 (0.1604)

MT-00269

ST1

ST3

MT-00270

(A)

(B)

Page 2808 of 2870

5MT-95

MANUAL TRANSMISSION AND DIFFERENTIAL

Drive Pinion Shaft Assembly

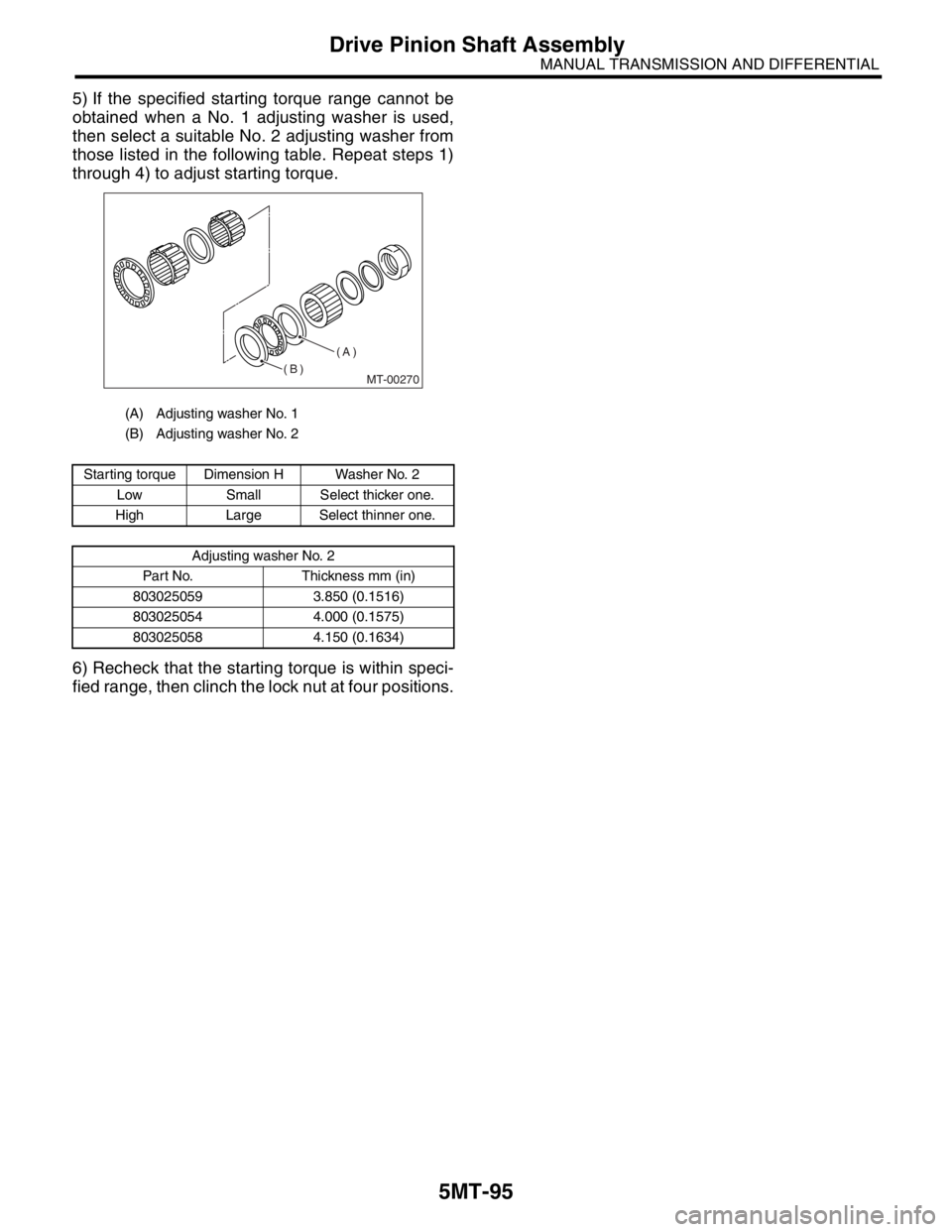

5) If the specified starting torque range cannot be

obtained when a No. 1 adjusting washer is used,

then select a suitable No. 2 adjusting washer from

those listed in the following table. Repeat steps 1)

through 4) to adjust starting torque.

6) Recheck that the starting torque is within speci-

fied range, then clinch the lock nut at four positions.

(A) Adjusting washer No. 1

(B) Adjusting washer No. 2

Starting torque Dimension H Washer No. 2

Low Small Select thicker one.

High Large Select thinner one.

Adjusting washer No. 2

Part No. Thickness mm (in)

803025059 3.850 (0.1516)

803025054 4.000 (0.1575)

803025058 4.150 (0.1634)

MT-00270

(A)

(B)

Page 2809 of 2870

5MT-96

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

21.Front Differential Assembly

A: REMOVAL

1) Remove the manual transmission assembly

from vehicle.

2) Remove the transfer case with extension case

assembly.

3) Remove the transmission case.

4) Remove the drive pinion shaft assembly.

bly.>

5) Remove the main shaft assembly.

Single-range model

Dual-range model

6) Remove the differential assembly.

NOTE:

Be careful not to confuse the right and left roller

bearing outer races.

Be careful not to damage the retainer oil seal.

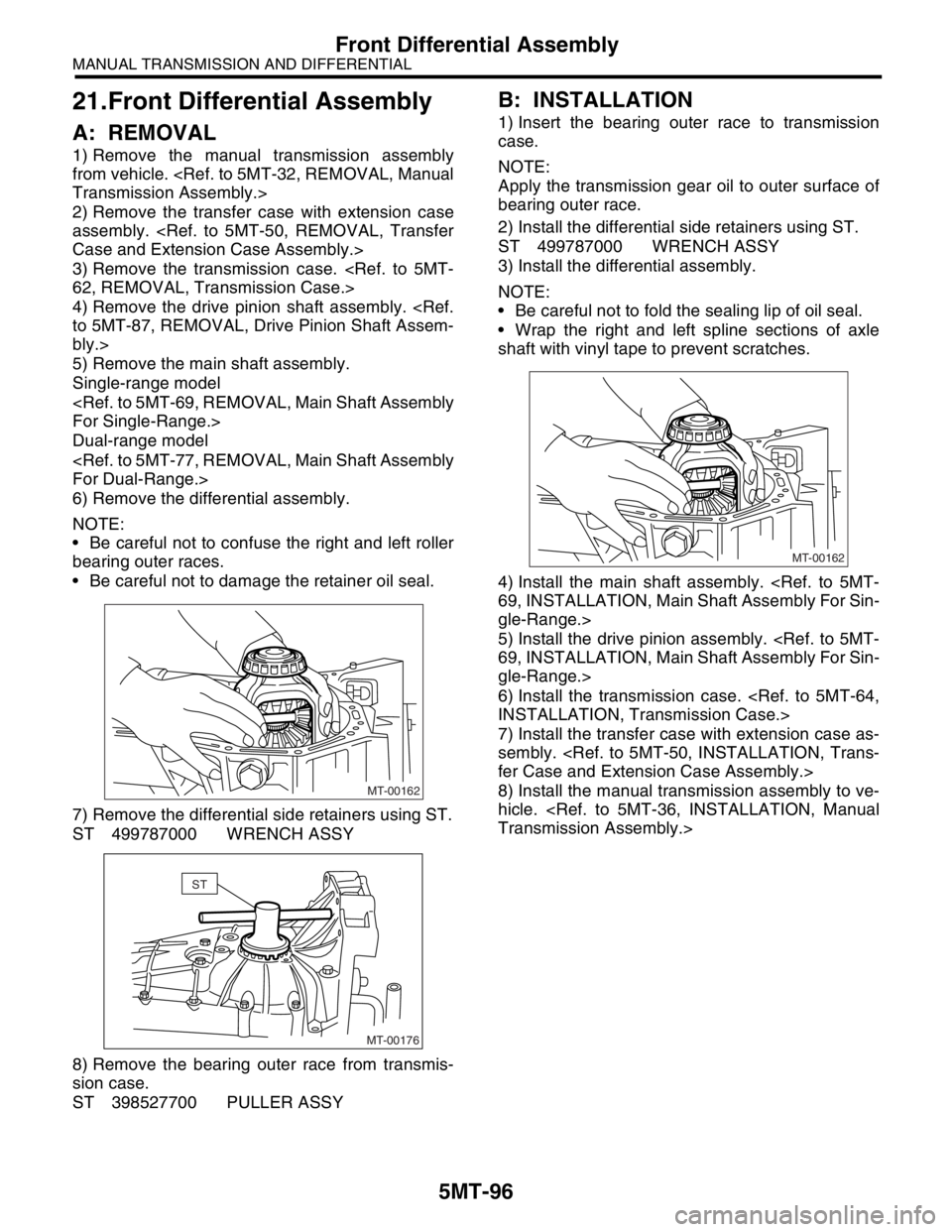

7) Remove the differential side retainers using ST.

ST 499787000 WRENCH ASSY

8) Remove the bearing outer race from transmis-

sion case.

ST 398527700 PULLER ASSY

B: INSTALLATION

1) Insert the bearing outer race to transmission

case.

NOTE:

Apply the transmission gear oil to outer surface of

bearing outer race.

2) Install the differential side retainers using ST.

ST 499787000 WRENCH ASSY

3) Install the differential assembly.

NOTE:

Be careful not to fold the sealing lip of oil seal.

Wrap the right and left spline sections of axle

shaft with vinyl tape to prevent scratches.

4) Install the main shaft assembly.

gle-Range.>

5) Install the drive pinion assembly.

gle-Range.>

6) Install the transmission case.

7) Install the transfer case with extension case as-

sembly.

8) Install the manual transmission assembly to ve-

hicle.

MT-00162

MT-00176

ST

MT-00162

Page 2810 of 2870

5MT-97

MANUAL TRANSMISSION AND DIFFERENTIAL

Front Differential Assembly

C: DISASSEMBLY

1. DIFFERENTIAL CASE ASSEMBLY

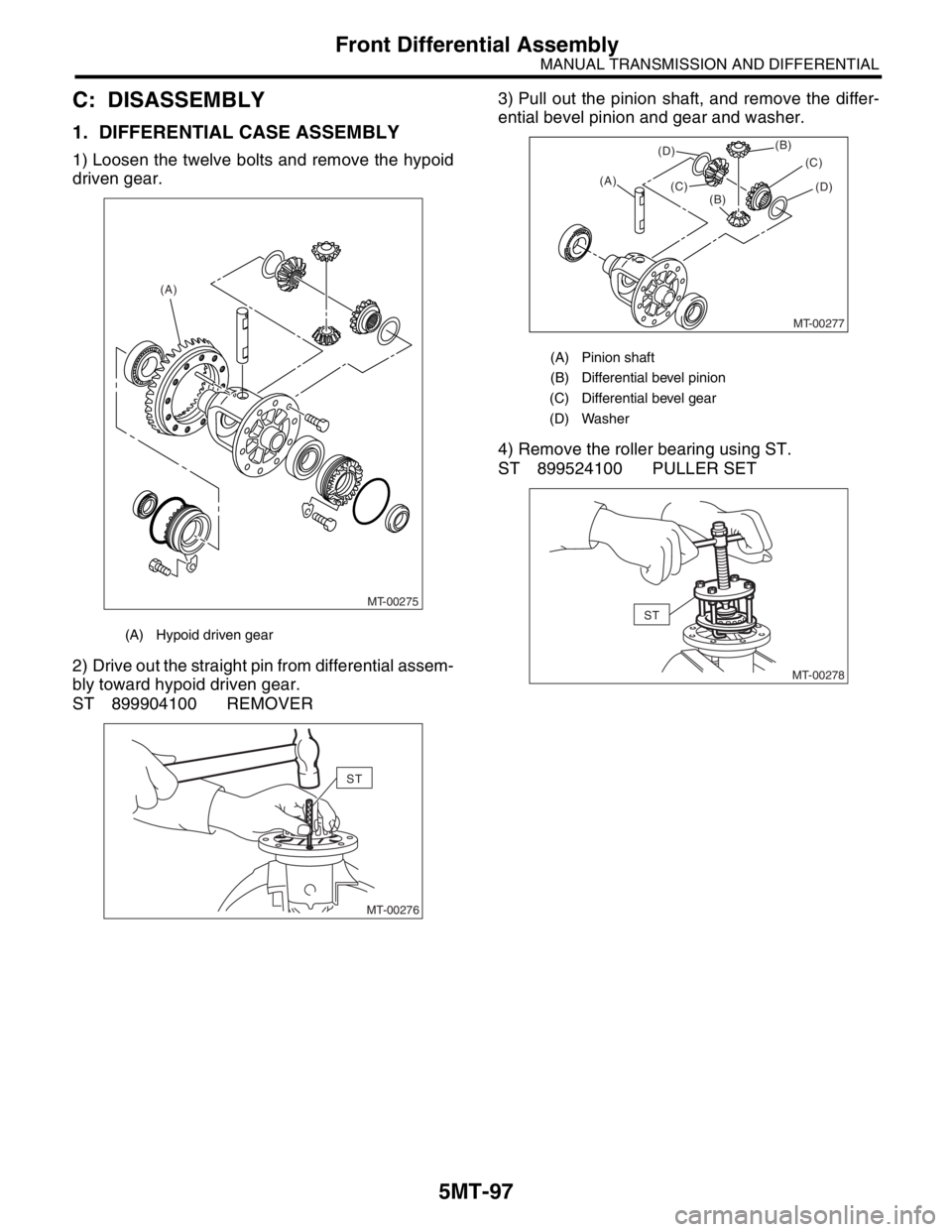

1) Loosen the twelve bolts and remove the hypoid

driven gear.

2) Drive out the straight pin from differential assem-

bly toward hypoid driven gear.

ST 899904100 REMOVER3) Pull out the pinion shaft, and remove the differ-

ential bevel pinion and gear and washer.

4) Remove the roller bearing using ST.

ST 899524100 PULLER SET

(A) Hypoid driven gear

(A)

MT-00275

MT-00276

ST

(A) Pinion shaft

(B) Differential bevel pinion

(C) Differential bevel gear

(D) Washer

MT-00277

(A)

(D)

(D)

(C)

(C)

(B)

(B)

MT-00278

ST