SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 751 of 2870

PM-14

PERIODIC MAINTENANCE SERVICE

Timing Belt

16) Install in the reverse order of removal.

2. TURBO MODEL

1) Remove the radiator fan and air conditioner fan.

2) Protect the radiator with cardboard and blanket.

3) Remove the V-belts.

4) Remove the air conditioning compressor drive

belt tensioner.

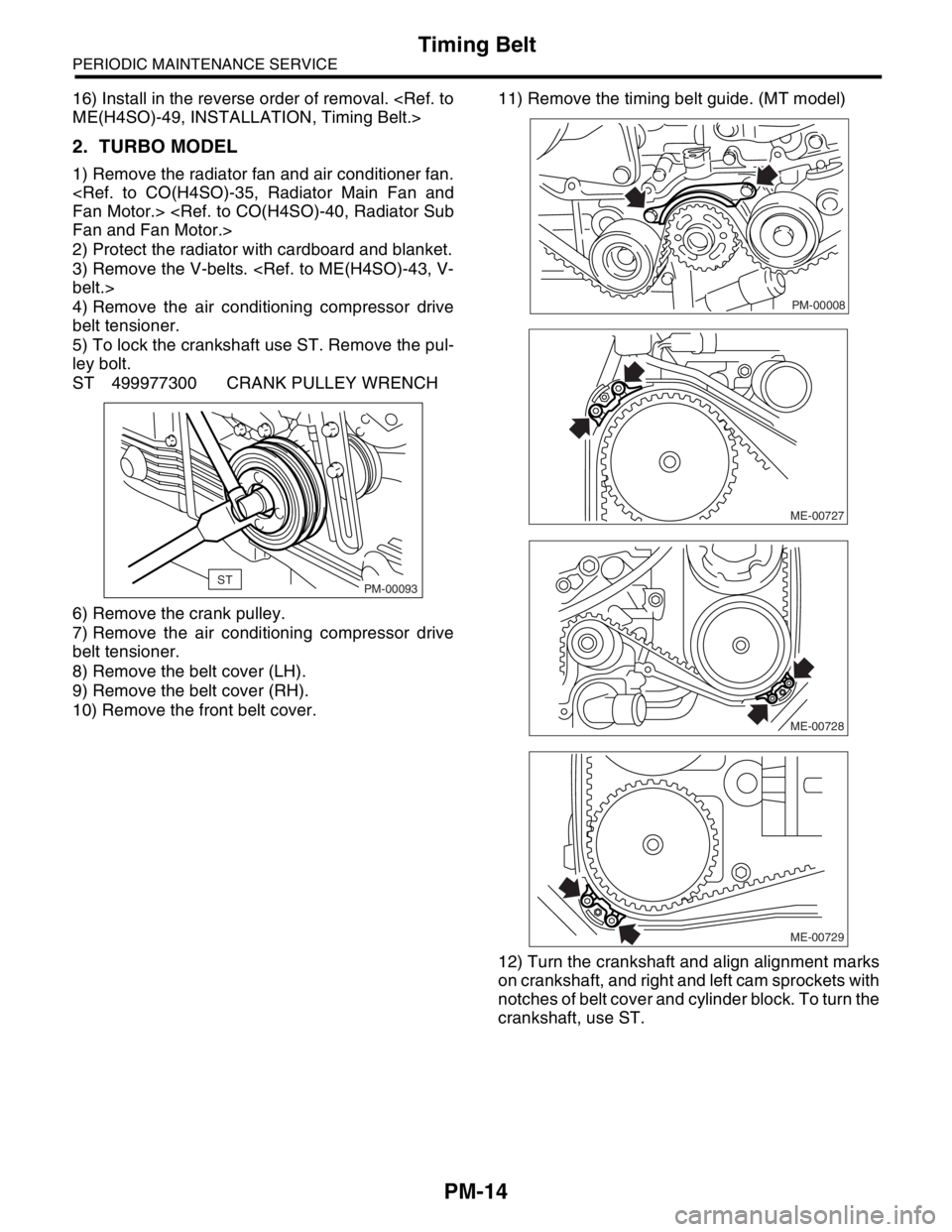

5) To lock the crankshaft use ST. Remove the pul-

ley bolt.

ST 499977300 CRANK PULLEY WRENCH

6) Remove the crank pulley.

7) Remove the air conditioning compressor drive

belt tensioner.

8) Remove the belt cover (LH).

9) Remove the belt cover (RH).

10) Remove the front belt cover.11) Remove the timing belt guide. (MT model)

12) Turn the crankshaft and align alignment marks

on crankshaft, and right and left cam sprockets with

notches of belt cover and cylinder block. To turn the

crankshaft, use ST.

STPM-00093

PM-00008

ME-00727

ME-00728

ME-00729

Page 752 of 2870

PM-15

PERIODIC MAINTENANCE SERVICE

Timing Belt

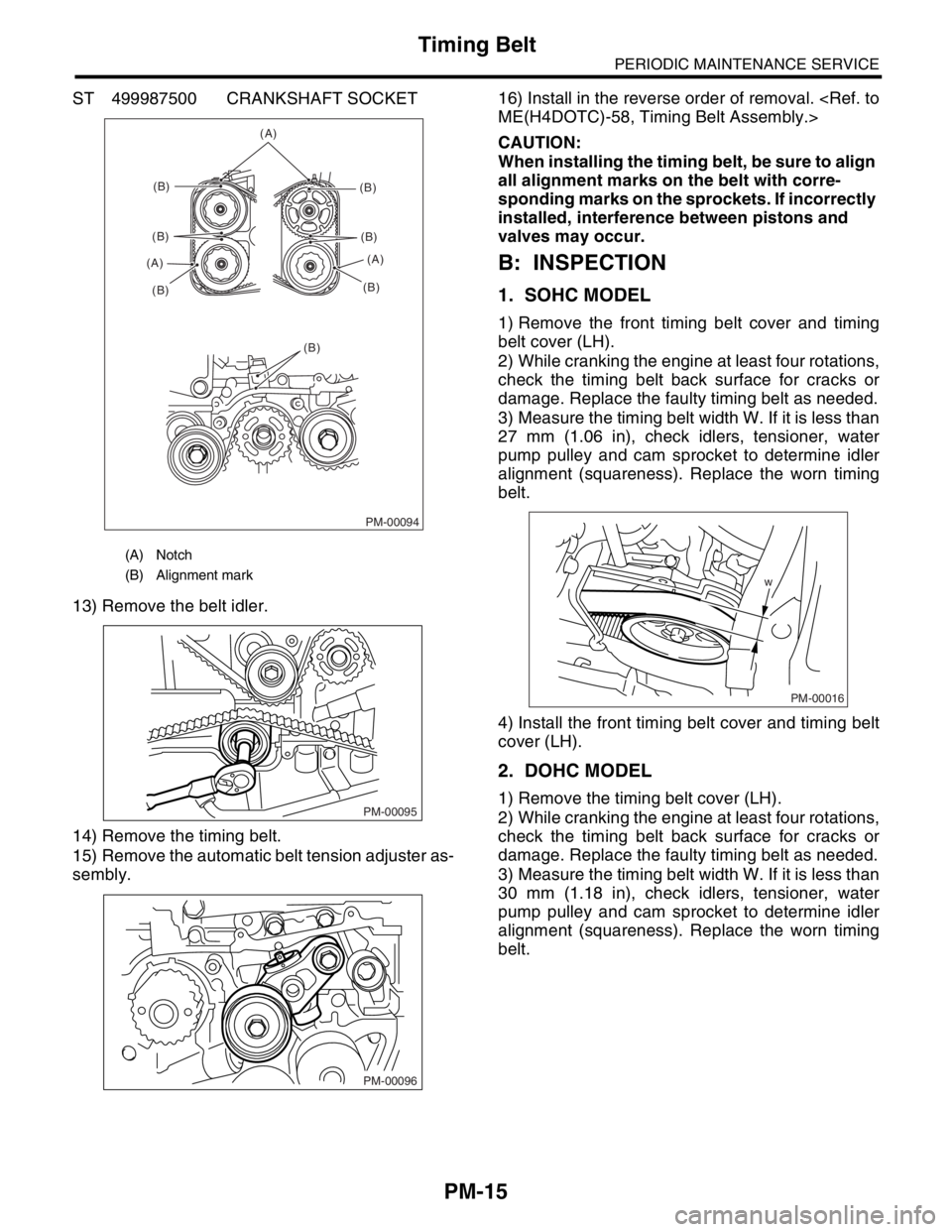

ST 499987500 CRANKSHAFT SOCKET

13) Remove the belt idler.

14) Remove the timing belt.

15) Remove the automatic belt tension adjuster as-

sembly.16) Install in the reverse order of removal.

CAUTION:

When installing the timing belt, be sure to align

all alignment marks on the belt with corre-

sponding marks on the sprockets. If incorrectly

installed, interference between pistons and

valves may occur.

B: INSPECTION

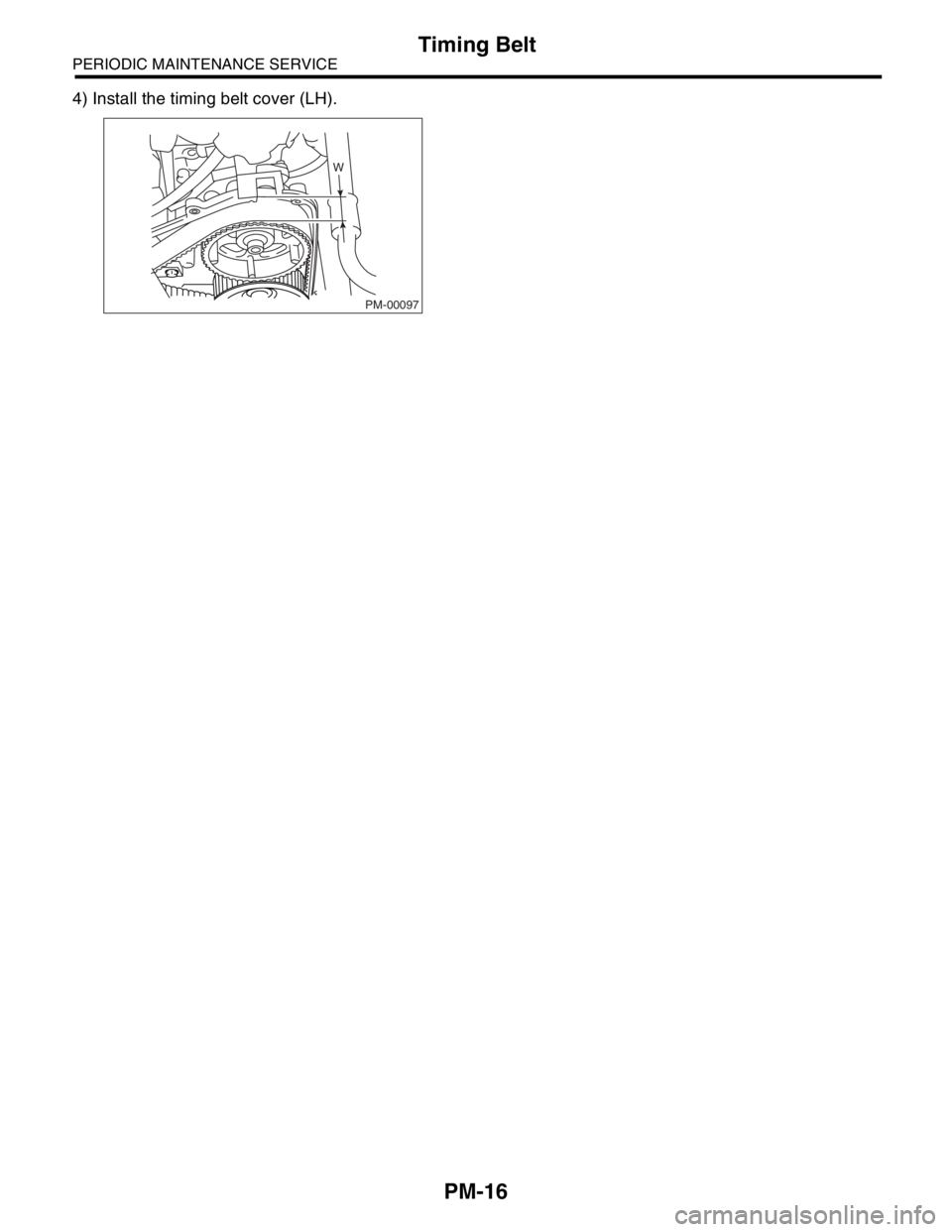

1. SOHC MODEL

1) Remove the front timing belt cover and timing

belt cover (LH).

2) While cranking the engine at least four rotations,

check the timing belt back surface for cracks or

damage. Replace the faulty timing belt as needed.

3) Measure the timing belt width W. If it is less than

27 mm (1.06 in), check idlers, tensioner, water

pump pulley and cam sprocket to determine idler

alignment (squareness). Replace the worn timing

belt.

4) Install the front timing belt cover and timing belt

cover (LH).

2. DOHC MODEL

1) Remove the timing belt cover (LH).

2) While cranking the engine at least four rotations,

check the timing belt back surface for cracks or

damage. Replace the faulty timing belt as needed.

3) Measure the timing belt width W. If it is less than

30 mm (1.18 in), check idlers, tensioner, water

pump pulley and cam sprocket to determine idler

alignment (squareness). Replace the worn timing

belt.

(A) Notch

(B) Alignment mark

PM-00094

(A)

(B)

(B)

(B) (A)(B)

(B)

(B)(A)

(B)

PM-00095

PM-00096

w

PM-00016

Page 753 of 2870

PM-16

PERIODIC MAINTENANCE SERVICE

Timing Belt

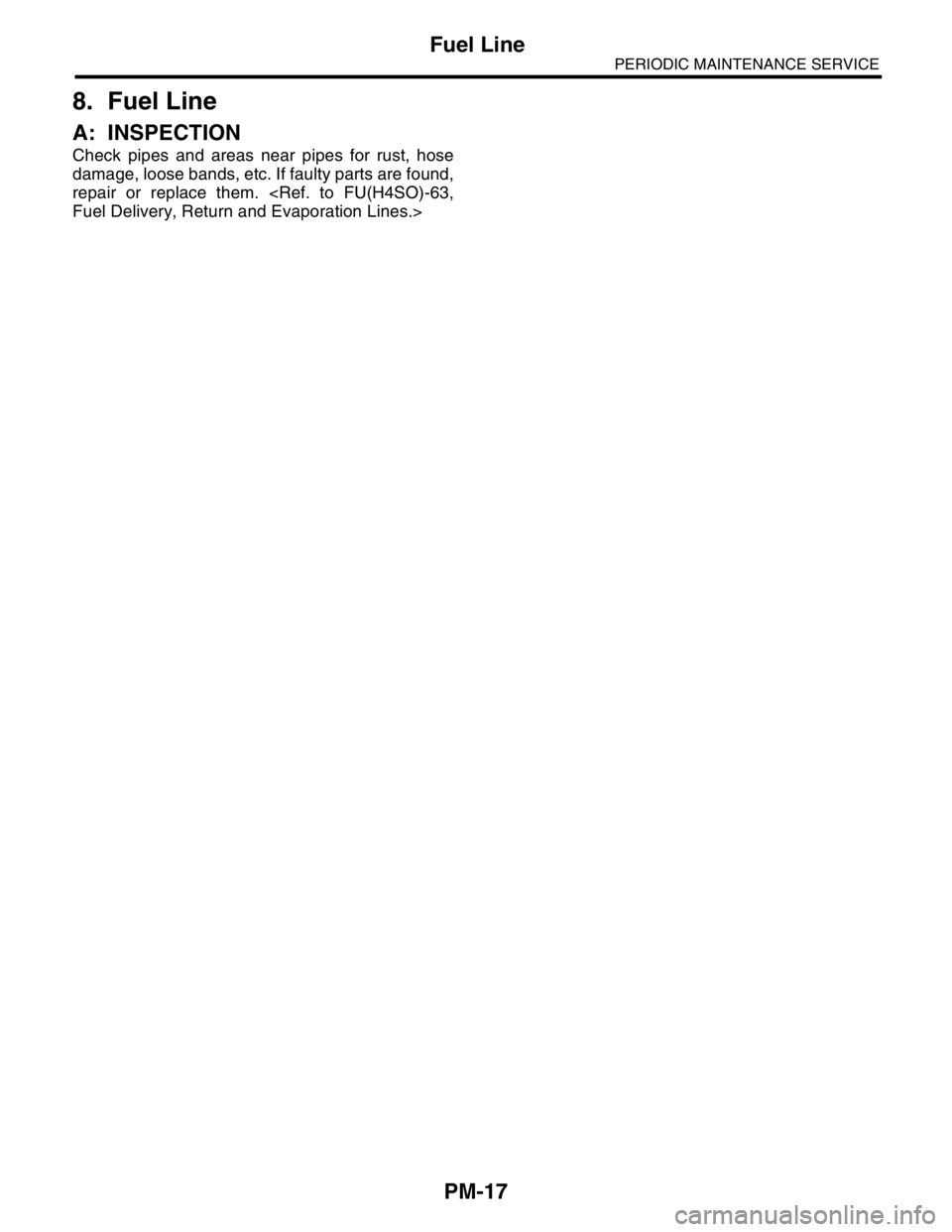

4) Install the timing belt cover (LH).

W

PM-00097

Page 754 of 2870

PM-17

PERIODIC MAINTENANCE SERVICE

Fuel Line

8. Fuel Line

A: INSPECTION

Check pipes and areas near pipes for rust, hose

damage, loose bands, etc. If faulty parts are found,

repair or replace them.

Page 755 of 2870

PM-18

PERIODIC MAINTENANCE SERVICE

Fuel Filter

9. Fuel Filter

A: REPLACEMENT

For fuel filter replacement procedures, refer to “FU”

section.

B: INSPECTION

1) If fuel filter is clogged, or if replacement interval

has been reached, replace it.

2) If water is found in it, shake and expel the water

from inlet port.

Page 756 of 2870

PM-19

PERIODIC MAINTENANCE SERVICE

Air Cleaner Element

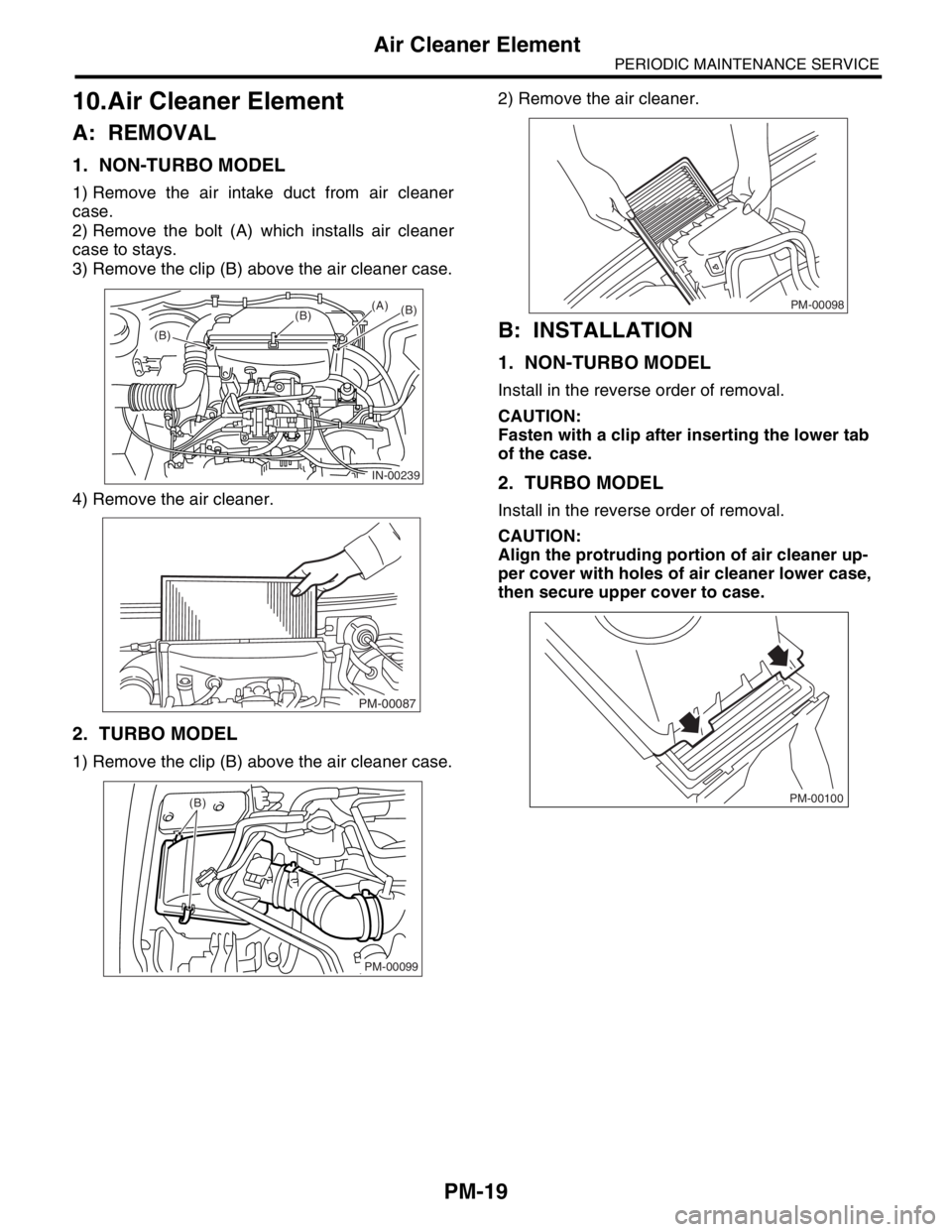

10.Air Cleaner Element

A: REMOVAL

1. NON-TURBO MODEL

1) Remove the air intake duct from air cleaner

case.

2) Remove the bolt (A) which installs air cleaner

case to stays.

3) Remove the clip (B) above the air cleaner case.

4) Remove the air cleaner.

2. TURBO MODEL

1) Remove the clip (B) above the air cleaner case.2) Remove the air cleaner.

B: INSTALLATION

1. NON-TURBO MODEL

Install in the reverse order of removal.

CAUTION:

Fasten with a clip after inserting the lower tab

of the case.

2. TURBO MODEL

Install in the reverse order of removal.

CAUTION:

Align the protruding portion of air cleaner up-

per cover with holes of air cleaner lower case,

then secure upper cover to case.

IN-00239

(B)(B)(B)

(A)

PM-00087

(B)

PM-00099

PM-00098

PM-00100

Page 757 of 2870

PM-20

PERIODIC MAINTENANCE SERVICE

Cooling System

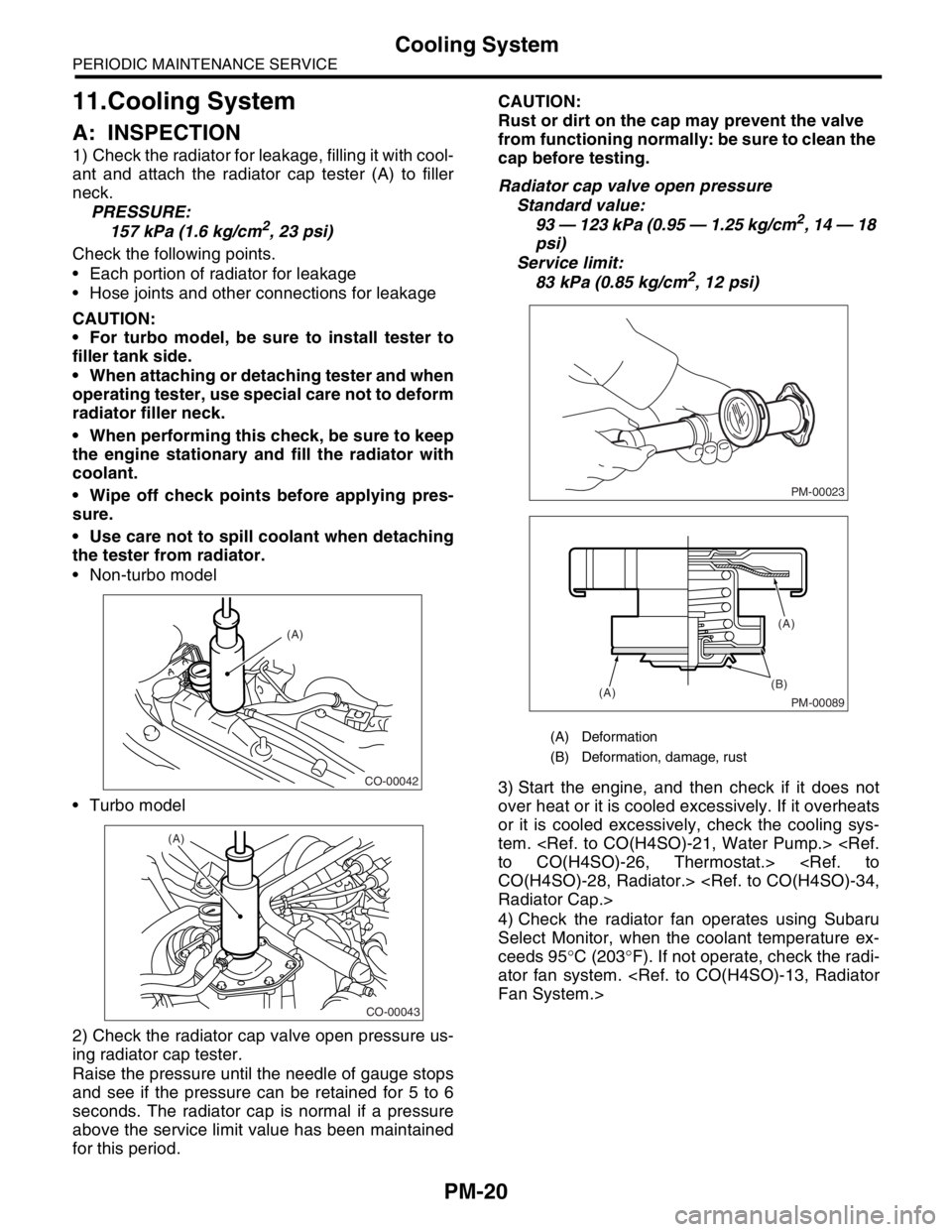

11.Cooling System

A: INSPECTION

1) Check the radiator for leakage, filling it with cool-

ant and attach the radiator cap tester (A) to filler

neck.

PRESSURE:

157 kPa (1.6 kg/cm

2, 23 psi)

Check the following points.

Each portion of radiator for leakage

Hose joints and other connections for leakage

CAUTION:

For turbo model, be sure to install tester to

filler tank side.

When attaching or detaching tester and when

operating tester, use special care not to deform

radiator filler neck.

When performing this check, be sure to keep

the engine stationary and fill the radiator with

coolant.

Wipe off check points before applying pres-

sure.

Use care not to spill coolant when detaching

the tester from radiator.

Non-turbo model

Turbo model

2) Check the radiator cap valve open pressure us-

ing radiator cap tester.

Raise the pressure until the needle of gauge stops

and see if the pressure can be retained for 5 to 6

seconds. The radiator cap is normal if a pressure

above the service limit value has been maintained

for this period.CAUTION:

Rust or dirt on the cap may prevent the valve

from functioning normally: be sure to clean the

cap before testing.

Radiator cap valve open pressure

Standard value:

93 — 123 kPa (0.95 — 1.25 kg/cm2, 14 — 18

psi)

Service limit:

83 kPa (0.85 kg/cm

2, 12 psi)

3) Start the engine, and then check if it does not

over heat or it is cooled excessively. If it overheats

or it is cooled excessively, check the cooling sys-

tem.

4) Check the radiator fan operates using Subaru

Select Monitor, when the coolant temperature ex-

ceeds 95°C (203°F). If not operate, check the radi-

ator fan system.

CO-00042

(A)

CO-00043

(A)

(A) Deformation

(B) Deformation, damage, rust

PM-00023

PM-00089

(B)

(A)(A)

Page 758 of 2870

PM-21

PERIODIC MAINTENANCE SERVICE

Engine Coolant

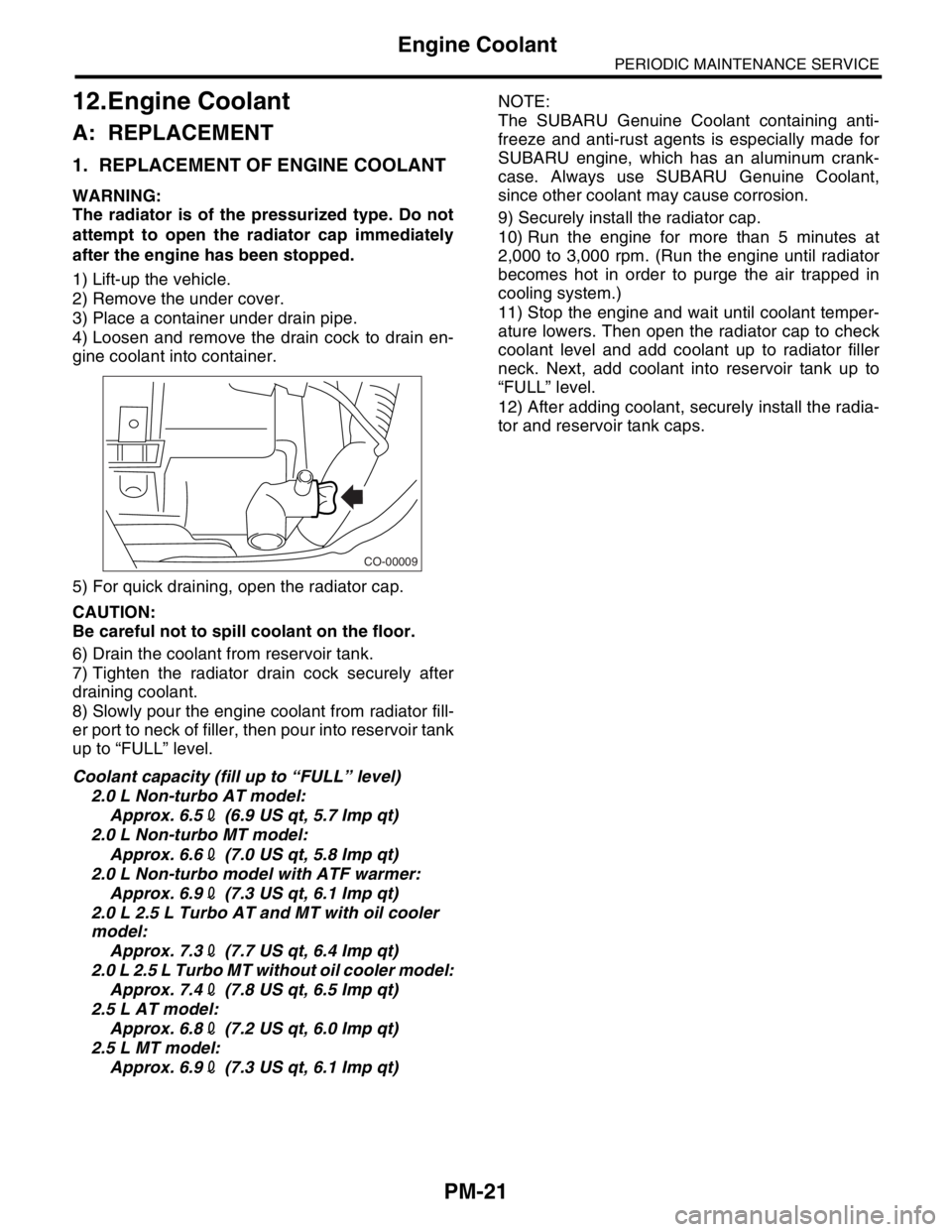

12.Engine Coolant

A: REPLACEMENT

1. REPLACEMENT OF ENGINE COOLANT

WARNING:

The radiator is of the pressurized type. Do not

attempt to open the radiator cap immediately

after the engine has been stopped.

1) Lift-up the vehicle.

2) Remove the under cover.

3) Place a container under drain pipe.

4) Loosen and remove the drain cock to drain en-

gine coolant into container.

5) For quick draining, open the radiator cap.

CAUTION:

Be careful not to spill coolant on the floor.

6) Drain the coolant from reservoir tank.

7) Tighten the radiator drain cock securely after

draining coolant.

8) Slowly pour the engine coolant from radiator fill-

er port to neck of filler, then pour into reservoir tank

up to “FULL” level.

Coolant capacity (fill up to “FULL” level)

2.0 L Non-turbo AT model:

Approx. 6.52 (6.9 US qt, 5.7 Imp qt)

2.0 L Non-turbo MT model:

Approx. 6.62 (7.0 US qt, 5.8 Imp qt)

2.0 L Non-turbo model with ATF warmer:

Approx. 6.92 (7.3 US qt, 6.1 Imp qt)

2.0 L 2.5 L Turbo AT and MT with oil cooler

model:

Approx. 7.32 (7.7 US qt, 6.4 Imp qt)

2.0 L 2.5 L Turbo MT without oil cooler model:

Approx. 7.42 (7.8 US qt, 6.5 Imp qt)

2.5 L AT model:

Approx. 6.82 (7.2 US qt, 6.0 Imp qt)

2.5 L MT model:

Approx. 6.92 (7.3 US qt, 6.1 Imp qt)NOTE:

The SUBARU Genuine Coolant containing anti-

freeze and anti-rust agents is especially made for

SUBARU engine, which has an aluminum crank-

case. Always use SUBARU Genuine Coolant,

since other coolant may cause corrosion.

9) Securely install the radiator cap.

10) Run the engine for more than 5 minutes at

2,000 to 3,000 rpm. (Run the engine until radiator

becomes hot in order to purge the air trapped in

cooling system.)

11) Stop the engine and wait until coolant temper-

ature lowers. Then open the radiator cap to check

coolant level and add coolant up to radiator filler

neck. Next, add coolant into reservoir tank up to

“FULL” level.

12) After adding coolant, securely install the radia-

tor and reservoir tank caps.

CO-00009

Page 759 of 2870

PM-22

PERIODIC MAINTENANCE SERVICE

Engine Coolant

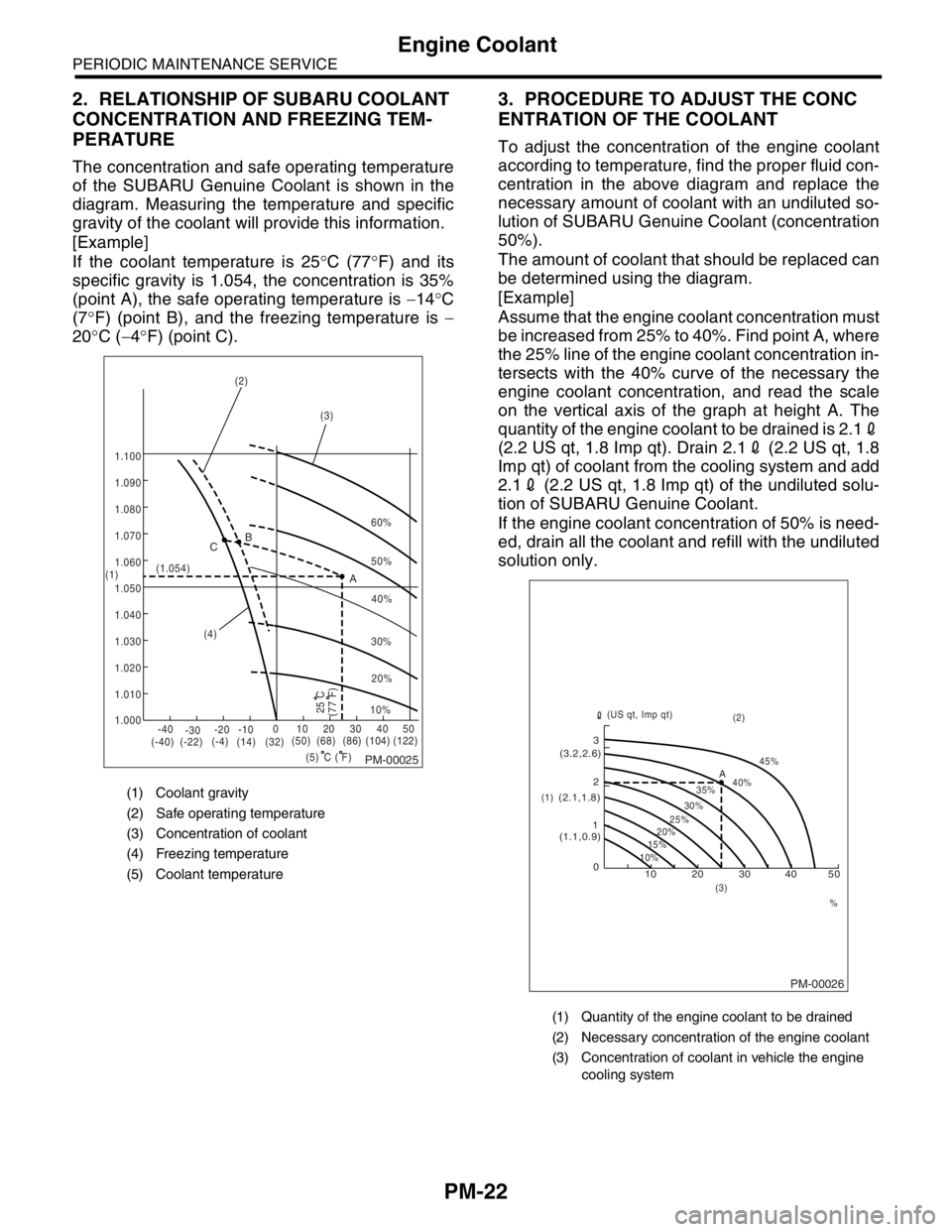

2. RELATIONSHIP OF SUBARU COOLANT

CONCENTRATION AND FREEZING TEM-

PERATURE

The concentration and safe operating temperature

of the SUBARU Genuine Coolant is shown in the

diagram. Measuring the temperature and specific

gravity of the coolant will provide this information.

[Example]

If the coolant temperature is 25°C (77°F) and its

specific gravity is 1.054, the concentration is 35%

(point A), the safe operating temperature is −14°C

(7°F) (point B), and the freezing temperature is −

20°C (−4°F) (point C).

3. PROCEDURE TO ADJUST THE CONC

ENTRATION OF THE COOLANT

To adjust the concentration of the engine coolant

according to temperature, find the proper fluid con-

centration in the above diagram and replace the

necessary amount of coolant with an undiluted so-

lution of SUBARU Genuine Coolant (concentration

50%).

The amount of coolant that should be replaced can

be determined using the diagram.

[Example]

Assume that the engine coolant concentration must

be increased from 25% to 40%. Find point A, where

the 25% line of the engine coolant concentration in-

tersects with the 40% curve of the necessary the

engine coolant concentration, and read the scale

on the vertical axis of the graph at height A. The

quantity of the engine coolant to be drained is 2.12

(2.2 US qt, 1.8 Imp qt). Drain 2.12 (2.2 US qt, 1.8

Imp qt) of coolant from the cooling system and add

2.12 (2.2 US qt, 1.8 Imp qt) of the undiluted solu-

tion of SUBARU Genuine Coolant.

If the engine coolant concentration of 50% is need-

ed, drain all the coolant and refill with the undiluted

solution only.

(1) Coolant gravity

(2) Safe operating temperature

(3) Concentration of coolant

(4) Freezing temperature

(5) Coolant temperature

PM-00025

60%

(1.054)

1.000 1.010 1.020

1.030

1.040

1.050

1.060

1.070 1.080 1.090

1.100

(5) (4)(3) (2)

(1)B

A C

-40

(-40) (-22)(-4)

(14)(32)(50) (68) (86)

( F)(104) (122) -30-20 -1001020304050

(77 F)

50%

40%

30%

20%

25 C10%

C

(1) Quantity of the engine coolant to be drained

(2) Necessary concentration of the engine coolant

(3) Concentration of coolant in vehicle the engine

cooling system

PM-00026

10 0 12 3

(1.1,0.9) (2.1,1.8)(3.2,2.6)

10%15%25%

20%30%35%40%45%

A

20 30 40 50

% (3)(2)

(1)(US qt, Imp qt)

Page 760 of 2870

PM-23

PERIODIC MAINTENANCE SERVICE

Clutch System

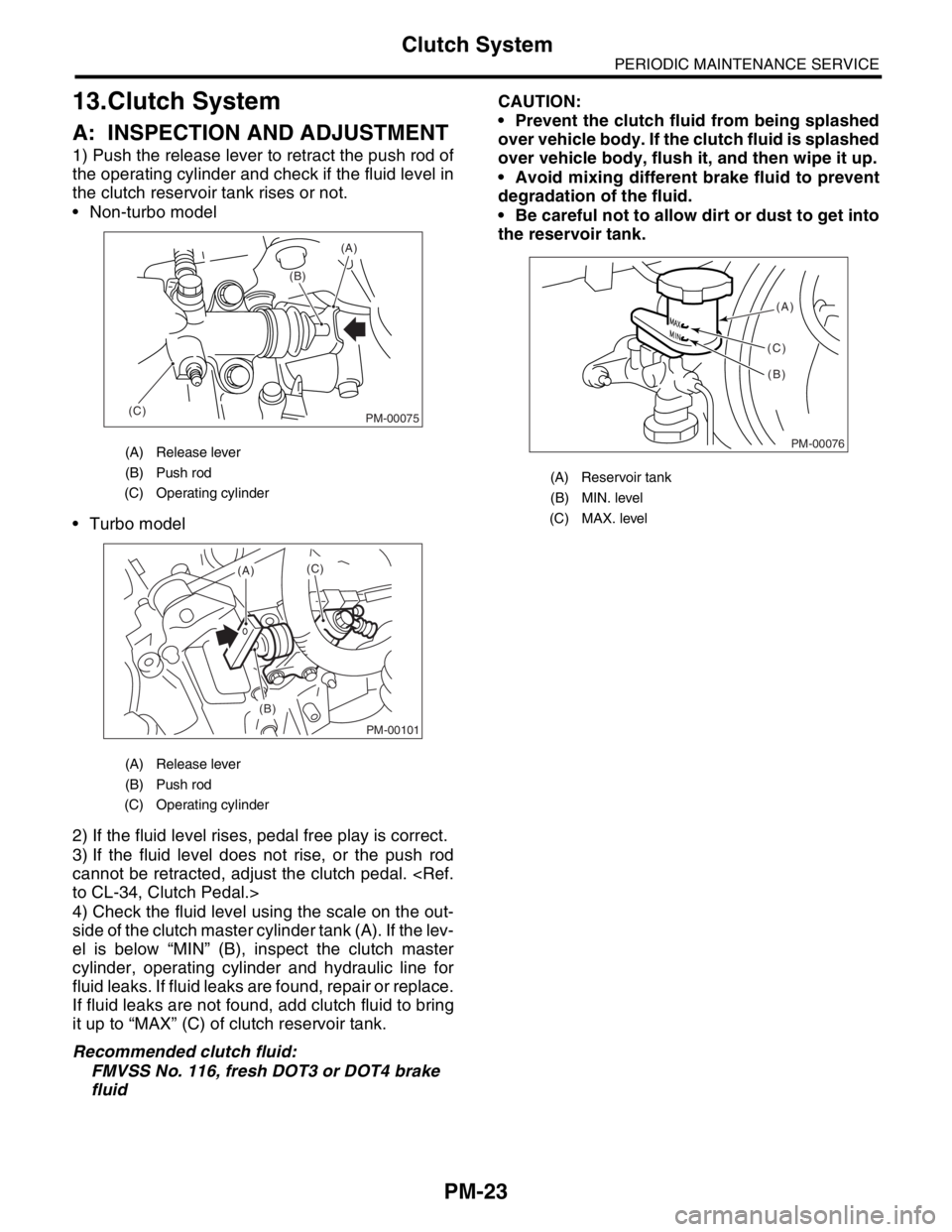

13.Clutch System

A: INSPECTION AND ADJUSTMENT

1) Push the release lever to retract the push rod of

the operating cylinder and check if the fluid level in

the clutch reservoir tank rises or not.

Non-turbo model

Turbo model

2) If the fluid level rises, pedal free play is correct.

3) If the fluid level does not rise, or the push rod

cannot be retracted, adjust the clutch pedal.

4) Check the fluid level using the scale on the out-

side of the clutch master cylinder tank (A). If the lev-

el is below “MIN” (B), inspect the clutch master

cylinder, operating cylinder and hydraulic line for

fluid leaks. If fluid leaks are found, repair or replace.

If fluid leaks are not found, add clutch fluid to bring

it up to “MAX” (C) of clutch reservoir tank.

Recommended clutch fluid:

FMVSS No. 116, fresh DOT3 or DOT4 brake

fluidCAUTION:

Prevent the clutch fluid from being splashed

over vehicle body. If the clutch fluid is splashed

over vehicle body, flush it, and then wipe it up.

Avoid mixing different brake fluid to prevent

degradation of the fluid.

Be careful not to allow dirt or dust to get into

the reservoir tank.

(A) Release lever

(B) Push rod

(C) Operating cylinder

(A) Release lever

(B) Push rod

(C) Operating cylinder

PM-00075

(A)

(C)(B)

PM-00101

(A)

(B)(C)

(A) Reservoir tank

(B) MIN. level

(C) MAX. level

PM-00076

(A)

(B) (C)