SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 761 of 2870

PM-24

PERIODIC MAINTENANCE SERVICE

Transmission Gear Oil

14.Transmission Gear Oil

A: REPLACEMENT

1. MANUAL TRANSMISSION

1) Drain the gear oil by removing drain plug.

CAUTION:

Before starting work, cool off the transmis-

sion gear oil well.

If transmission gear oil adheres to the ex-

haust pipe, wipe it off completely.

2) Replace the gasket with new one, and then tight-

en it to the specified torque.

Tightening torque:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

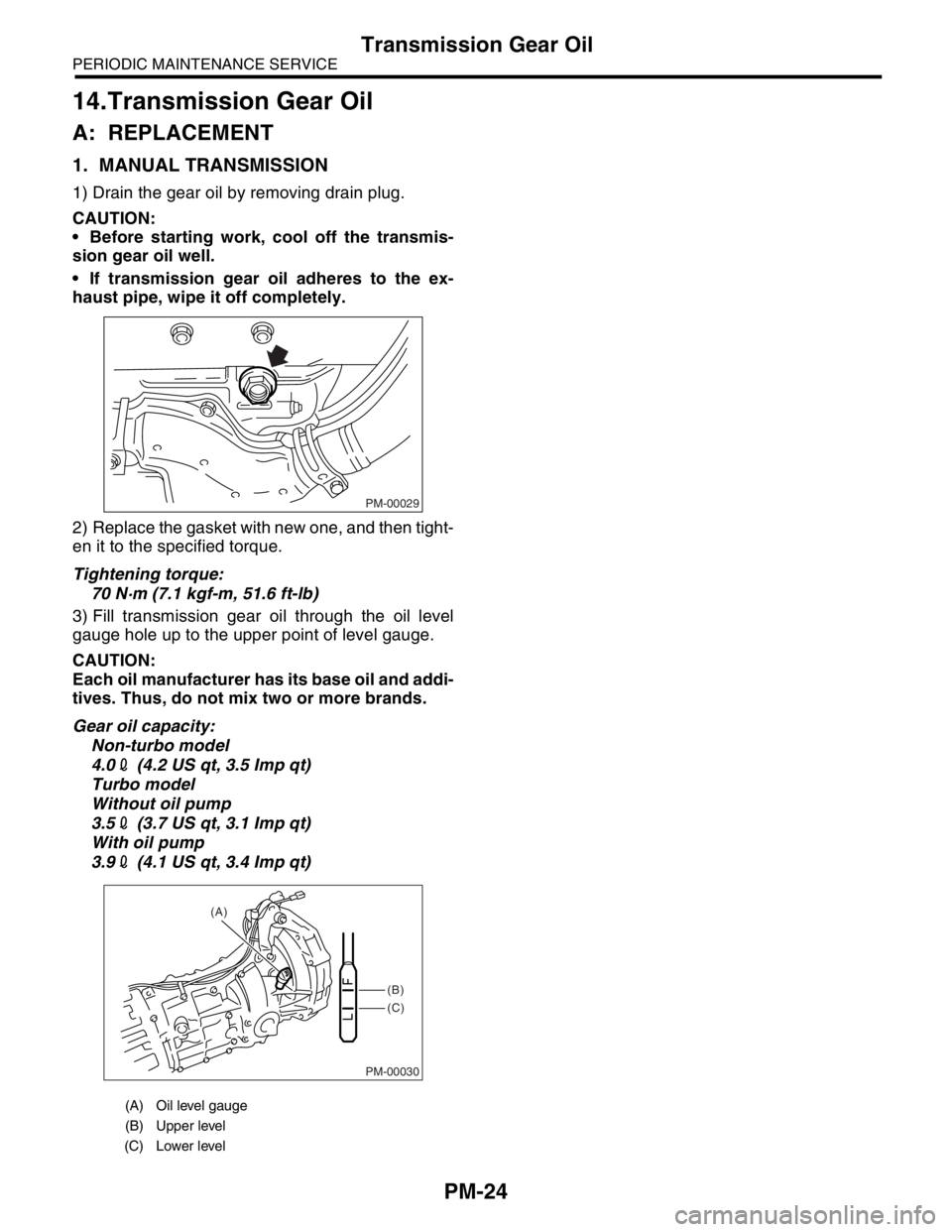

3) Fill transmission gear oil through the oil level

gauge hole up to the upper point of level gauge.

CAUTION:

Each oil manufacturer has its base oil and addi-

tives. Thus, do not mix two or more brands.

Gear oil capacity:

Non-turbo model

4.02 (4.2 US qt, 3.5 Imp qt)

Turbo model

Without oil pump

3.52 (3.7 US qt, 3.1 Imp qt)

With oil pump

3.92 (4.1 US qt, 3.4 Imp qt)

(A) Oil level gauge

(B) Upper level

(C) Lower level

PM-00029

PM-00030

(B)

(C) (A)

Page 762 of 2870

PM-25

PERIODIC MAINTENANCE SERVICE

Hill-holder System

15.Hill-holder System

A: INSPECTION AND ADJUSTMENT

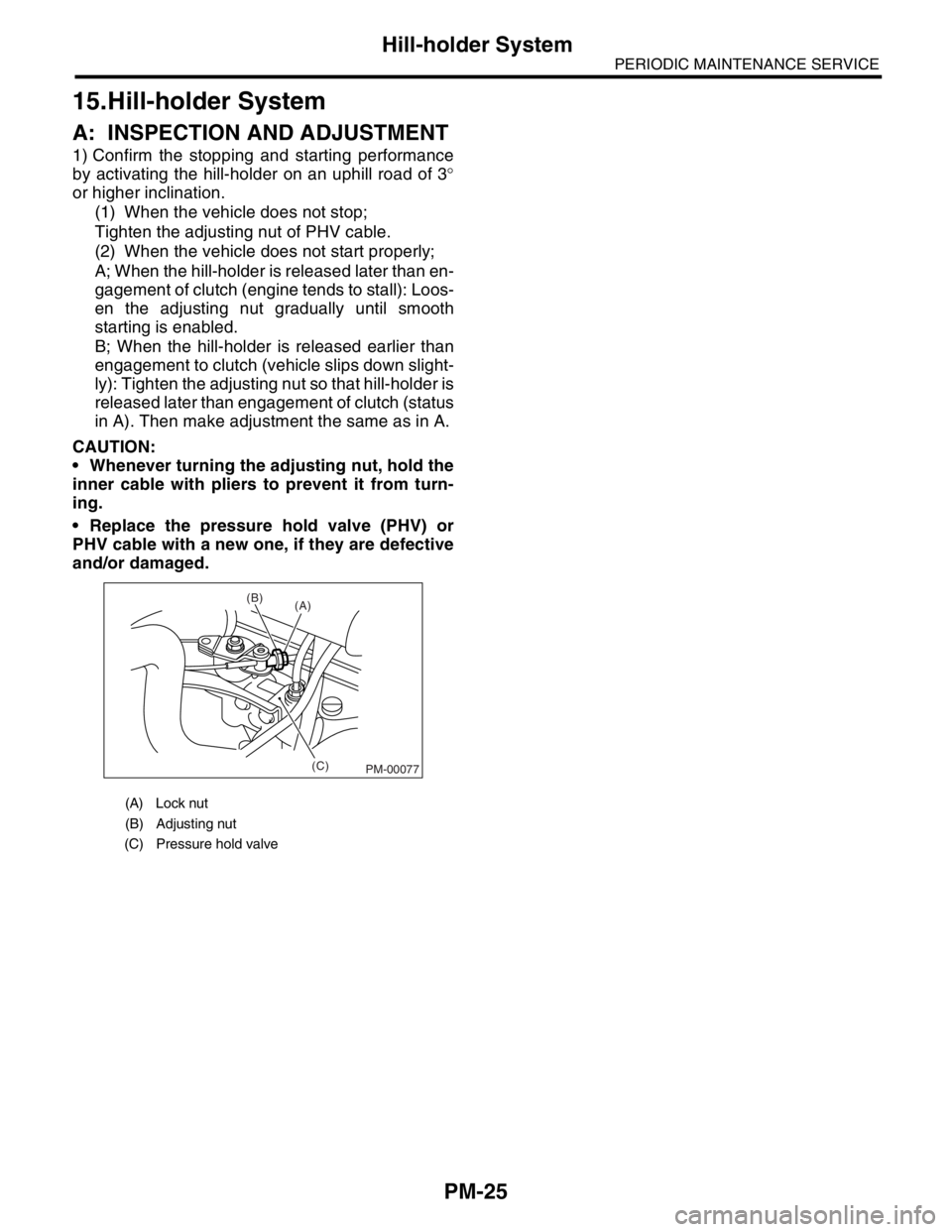

1) Confirm the stopping and starting performance

by activating the hill-holder on an uphill road of 3°

or higher inclination.

(1) When the vehicle does not stop;

Tighten the adjusting nut of PHV cable.

(2) When the vehicle does not start properly;

A; When the hill-holder is released later than en-

gagement of clutch (engine tends to stall): Loos-

en the adjusting nut gradually until smooth

starting is enabled.

B; When the hill-holder is released earlier than

engagement to clutch (vehicle slips down slight-

ly): Tighten the adjusting nut so that hill-holder is

released later than engagement of clutch (status

in A). Then make adjustment the same as in A.

CAUTION:

Whenever turning the adjusting nut, hold the

inner cable with pliers to prevent it from turn-

ing.

Replace the pressure hold valve (PHV) or

PHV cable with a new one, if they are defective

and/or damaged.

(A) Lock nut

(B) Adjusting nut

(C) Pressure hold valve

(C) (B)

(A)

PM-00077

Page 763 of 2870

PM-26

PERIODIC MAINTENANCE SERVICE

ATF

16.ATF

A: INSPECTION

CAUTION:

The level of ATF varies with fluid temperature.

Pay attention to the fluid temperature when

checking ATF level.

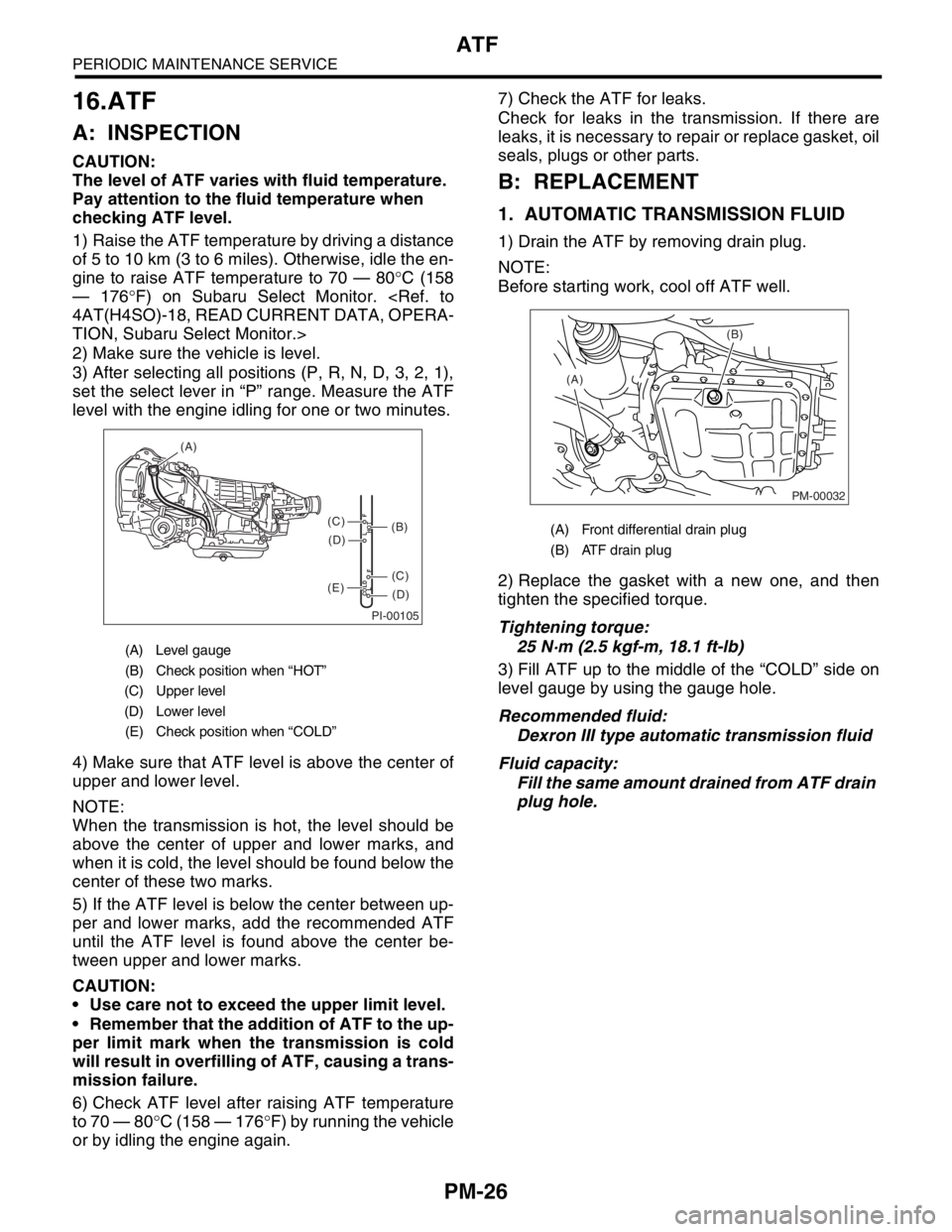

1) Raise the ATF temperature by driving a distance

of 5 to 10 km (3 to 6 miles). Otherwise, idle the en-

gine to raise ATF temperature to 70 — 80°C (158

— 176°F) on Subaru Select Monitor.

TION, Subaru Select Monitor.>

2) Make sure the vehicle is level.

3) After selecting all positions (P, R, N, D, 3, 2, 1),

set the select lever in “P” range. Measure the ATF

level with the engine idling for one or two minutes.

4) Make sure that ATF level is above the center of

upper and lower level.

NOTE:

When the transmission is hot, the level should be

above the center of upper and lower marks, and

when it is cold, the level should be found below the

center of these two marks.

5) If the ATF level is below the center between up-

per and lower marks, add the recommended ATF

until the ATF level is found above the center be-

tween upper and lower marks.

CAUTION:

Use care not to exceed the upper limit level.

Remember that the addition of ATF to the up-

per limit mark when the transmission is cold

will result in overfilling of ATF, causing a trans-

mission failure.

6) Check ATF level after raising ATF temperature

to 70 — 80°C (158 — 176°F) by running the vehicle

or by idling the engine again.7) Check the ATF for leaks.

Check for leaks in the transmission. If there are

leaks, it is necessary to repair or replace gasket, oil

seals, plugs or other parts.

B: REPLACEMENT

1. AUTOMATIC TRANSMISSION FLUID

1) Drain the ATF by removing drain plug.

NOTE:

Before starting work, cool off ATF well.

2) Replace the gasket with a new one, and then

tighten the specified torque.

Tightening torque:

25 N·m (2.5 kgf-m, 18.1 ft-lb)

3) Fill ATF up to the middle of the “COLD” side on

level gauge by using the gauge hole.

Recommended fluid:

Dexron III type automatic transmission fluid

Fluid capacity:

Fill the same amount drained from ATF drain

plug hole.

(A) Level gauge

(B) Check position when “HOT”

(C) Upper level

(D) Lower level

(E) Check position when “COLD”

PI-00105

COLD

LFHOT LF

(A)

(C)

(D)

(C)

(D)

(E)

(B)(A) Front differential drain plug

(B) ATF drain plug

PM-00032

(B)

(A)

Page 764 of 2870

PM-27

PERIODIC MAINTENANCE SERVICE

ATF

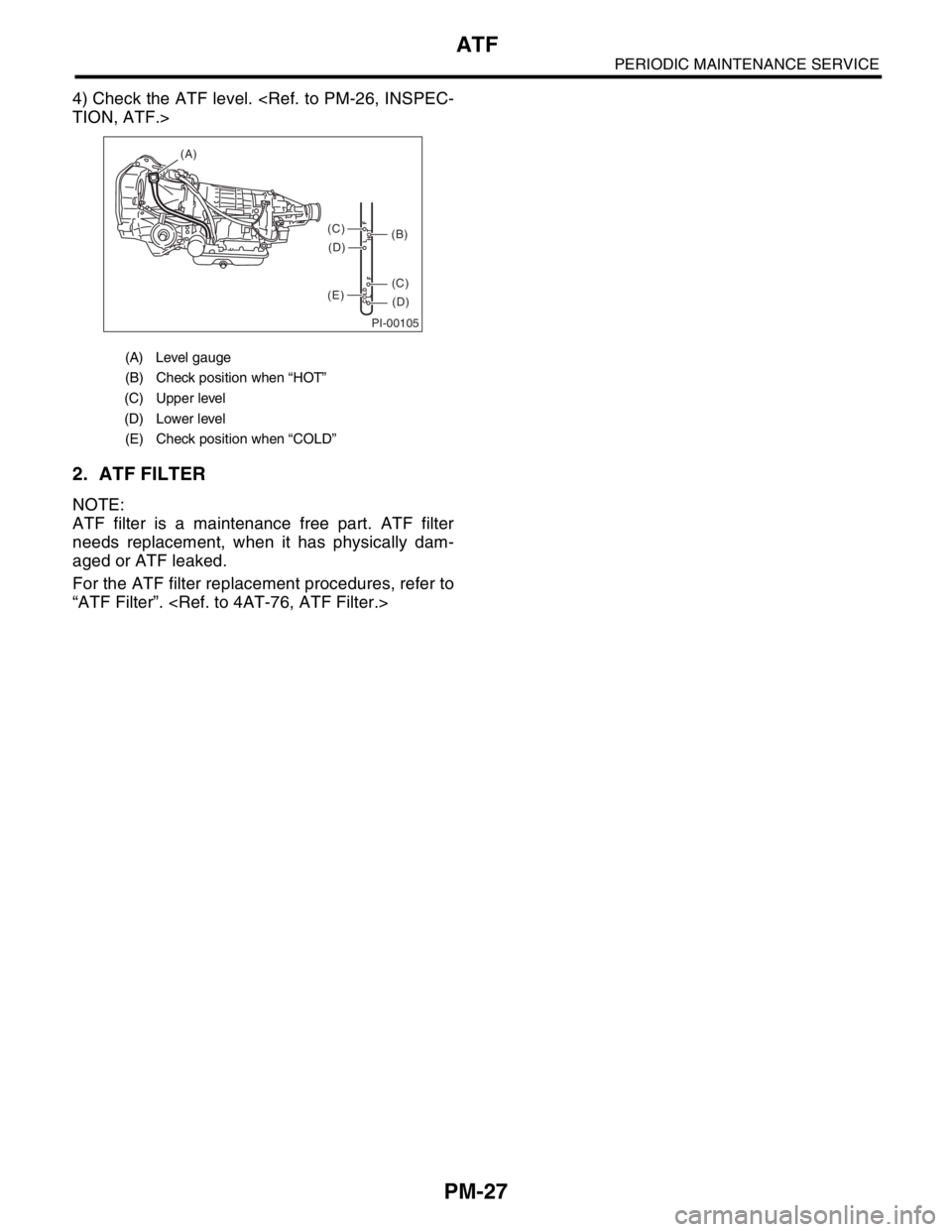

4) Check the ATF level.

2. ATF FILTER

NOTE:

ATF filter is a maintenance free part. ATF filter

needs replacement, when it has physically dam-

aged or ATF leaked.

For the ATF filter replacement procedures, refer to

“ATF Filter”.

(A) Level gauge

(B) Check position when “HOT”

(C) Upper level

(D) Lower level

(E) Check position when “COLD”

PI-00105

COLD

LFHOT LF

(A)

(C)

(D)

(C)

(D)

(E)

(B)

Page 765 of 2870

PM-28

PERIODIC MAINTENANCE SERVICE

Front & Rear Differential Oil

17.Front & Rear Differential Oil

A: REPLACEMENT

1. FRONT DIFFERENTIAL (MT MODEL)

For MT model, manual transmission oil works as

differential oil to lubricate differential. Refer to

“Transmission Oil”.

2. FRONT DIFFERENTIAL (AT MODEL)

1) Drain the differential gear oil by removing drain

plug using TORX® T70.

CAUTION:

Before starting work, cool off differential gear

oil well.

If front differential gear oil adheres to the ex-

haust pipe, wipe it off completely.

2) Replace the gasket with a new one, and then

tighten the drain plug to specified torque.

Tightening torque:

Aluminum gasket:

44 N·m (4.5 kgf-m, 32.5 ft-lb)

Copper gasket:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

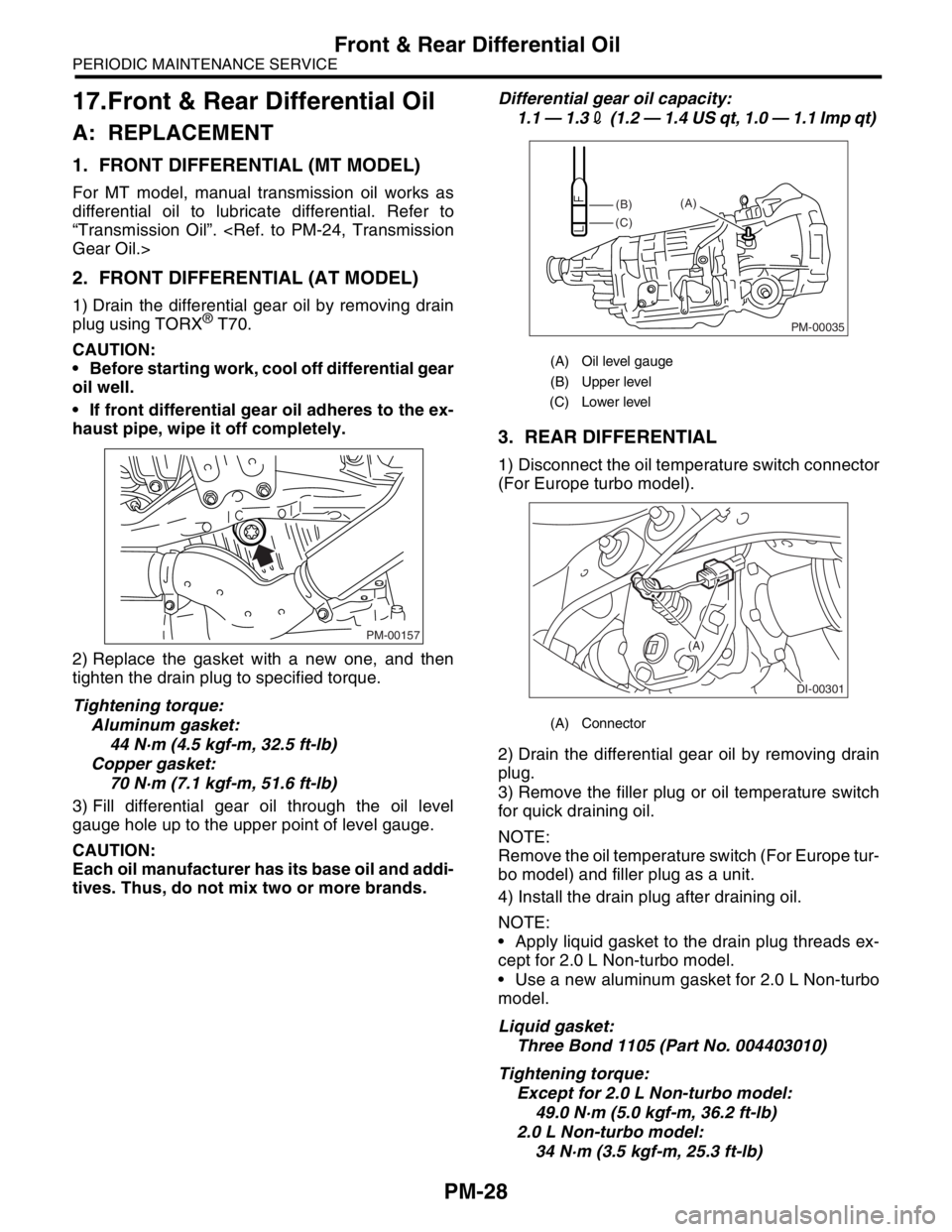

3) Fill differential gear oil through the oil level

gauge hole up to the upper point of level gauge.

CAUTION:

Each oil manufacturer has its base oil and addi-

tives. Thus, do not mix two or more brands.Differential gear oil capacity:

1.1 — 1.32 (1.2 — 1.4 US qt, 1.0 — 1.1 Imp qt)

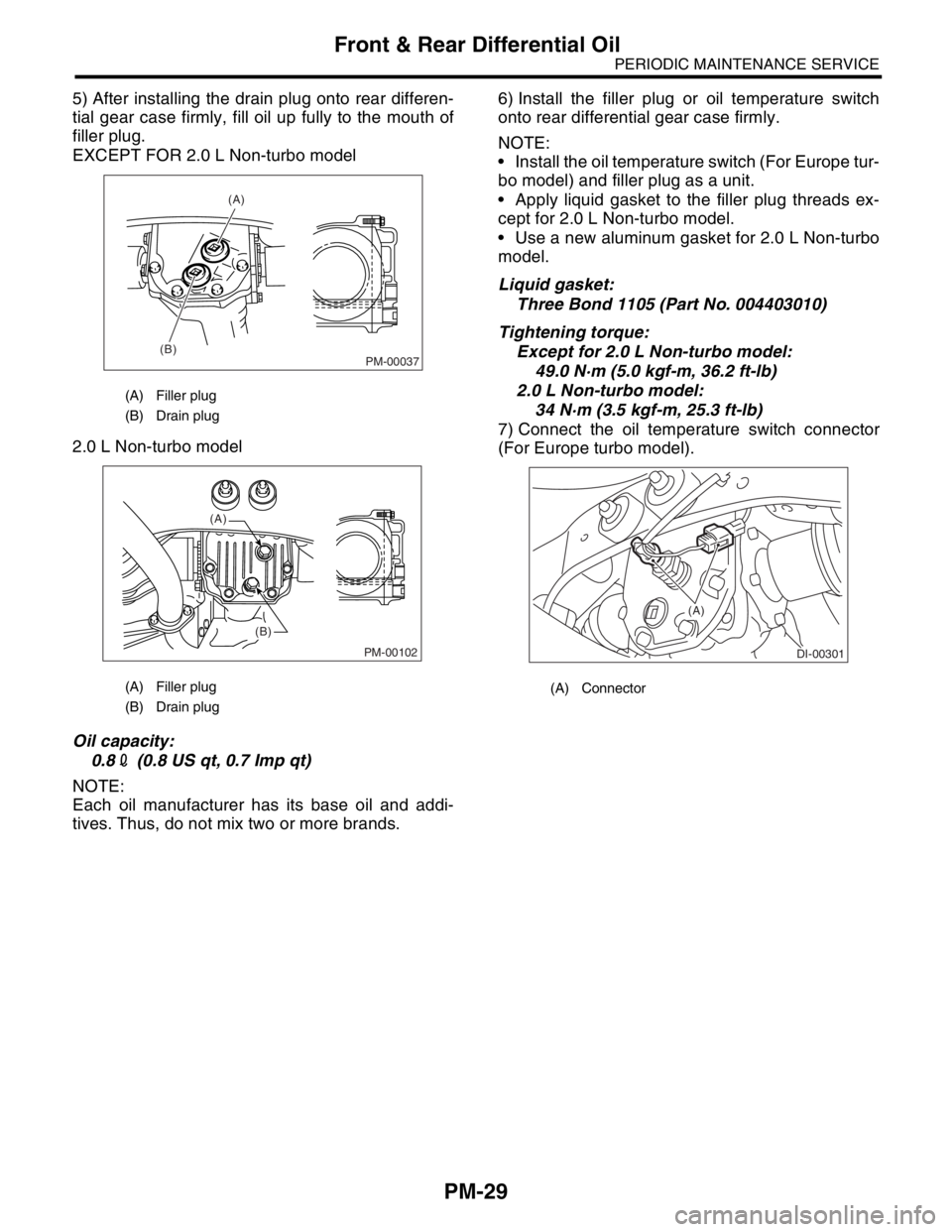

3. REAR DIFFERENTIAL

1) Disconnect the oil temperature switch connector

(For Europe turbo model).

2) Drain the differential gear oil by removing drain

plug.

3) Remove the filler plug or oil temperature switch

for quick draining oil.

NOTE:

Remove the oil temperature switch (For Europe tur-

bo model) and filler plug as a unit.

4) Install the drain plug after draining oil.

NOTE:

Apply liquid gasket to the drain plug threads ex-

cept for 2.0 L Non-turbo model.

Use a new aluminum gasket for 2.0 L Non-turbo

model.

Liquid gasket:

Three Bond 1105 (Part No. 004403010)

Tightening torque:

Except for 2.0 L Non-turbo model:

49.0 N·m (5.0 kgf-m, 36.2 ft-lb)

2.0 L Non-turbo model:

34 N·m (3.5 kgf-m, 25.3 ft-lb)

PM-00157

(A) Oil level gauge

(B) Upper level

(C) Lower level

(A) Connector

PM-00035

(B)

(C)(A)

DI-00301

(A)

Page 766 of 2870

PM-29

PERIODIC MAINTENANCE SERVICE

Front & Rear Differential Oil

5) After installing the drain plug onto rear differen-

tial gear case firmly, fill oil up fully to the mouth of

filler plug.

EXCEPT FOR 2.0 L Non-turbo model

2.0 L Non-turbo model

Oil capacity:

0.82 (0.8 US qt, 0.7 Imp qt)

NOTE:

Each oil manufacturer has its base oil and addi-

tives. Thus, do not mix two or more brands.6) Install the filler plug or oil temperature switch

onto rear differential gear case firmly.

NOTE:

Install the oil temperature switch (For Europe tur-

bo model) and filler plug as a unit.

Apply liquid gasket to the filler plug threads ex-

cept for 2.0 L Non-turbo model.

Use a new aluminum gasket for 2.0 L Non-turbo

model.

Liquid gasket:

Three Bond 1105 (Part No. 004403010)

Tightening torque:

Except for 2.0 L Non-turbo model:

49.0 N·m (5.0 kgf-m, 36.2 ft-lb)

2.0 L Non-turbo model:

34 N·m (3.5 kgf-m, 25.3 ft-lb)

7) Connect the oil temperature switch connector

(For Europe turbo model).

(A) Filler plug

(B) Drain plug

(A) Filler plug

(B) Drain plug

PM-00037

(A)

(B)

PM-00102

(A)

(B)

(A) Connector

DI-00301

(A)

Page 767 of 2870

PM-30

PERIODIC MAINTENANCE SERVICE

Brake Line

18.Brake Line

A: INSPECTION

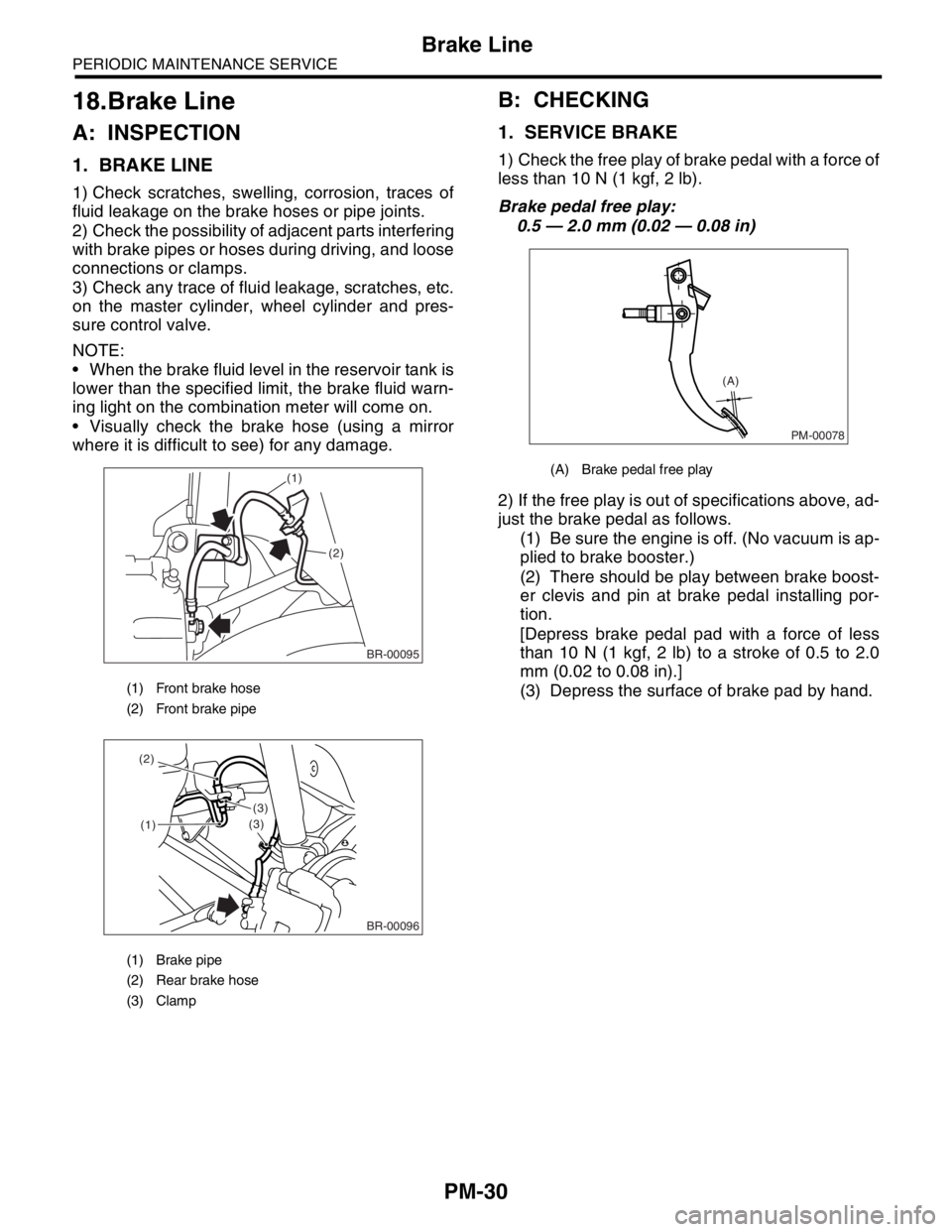

1. BRAKE LINE

1) Check scratches, swelling, corrosion, traces of

fluid leakage on the brake hoses or pipe joints.

2) Check the possibility of adjacent parts interfering

with brake pipes or hoses during driving, and loose

connections or clamps.

3) Check any trace of fluid leakage, scratches, etc.

on the master cylinder, wheel cylinder and pres-

sure control valve.

NOTE:

When the brake fluid level in the reservoir tank is

lower than the specified limit, the brake fluid warn-

ing light on the combination meter will come on.

Visually check the brake hose (using a mirror

where it is difficult to see) for any damage.

B: CHECKING

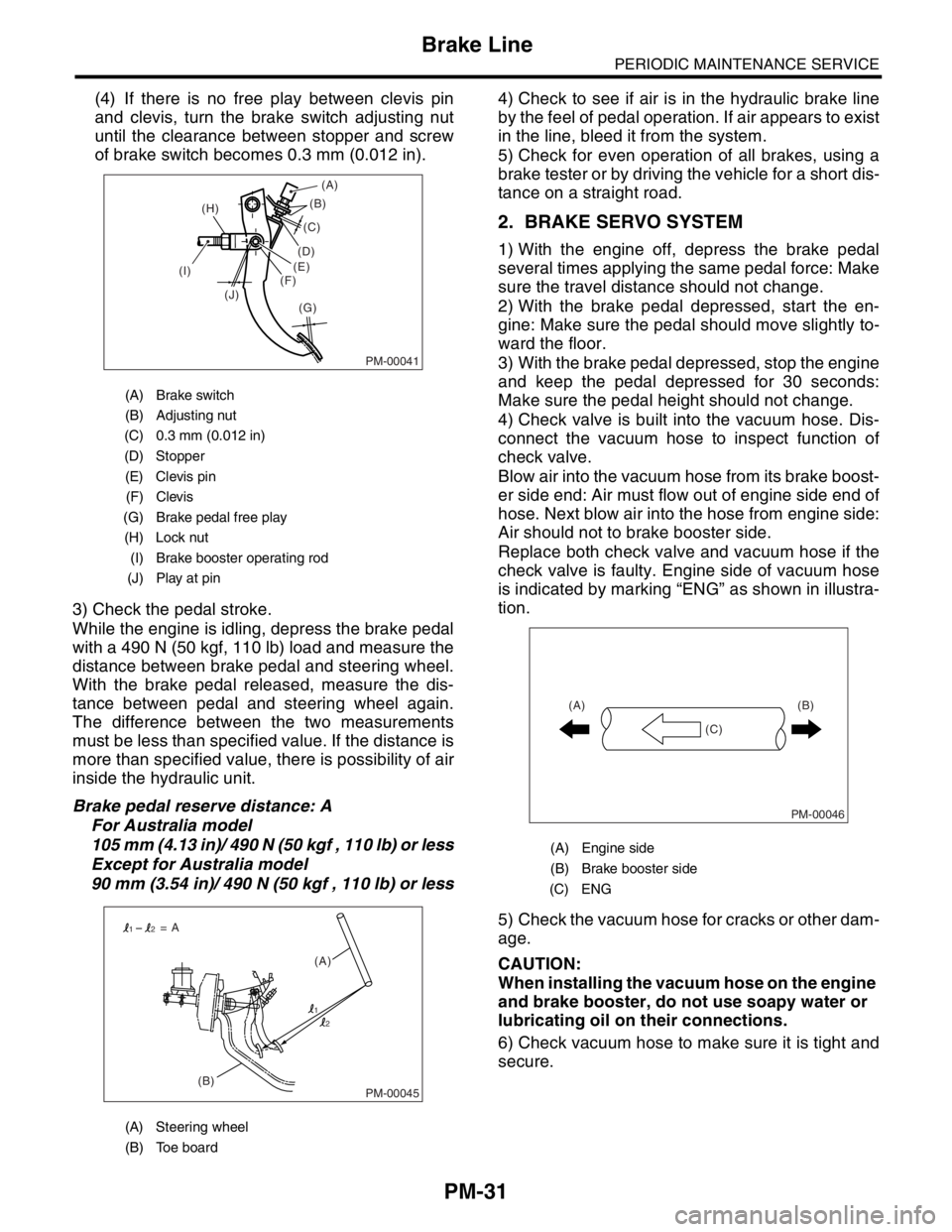

1. SERVICE BRAKE

1) Check the free play of brake pedal with a force of

less than 10 N (1 kgf, 2 lb).

Brake pedal free play:

0.5 — 2.0 mm (0.02 — 0.08 in)

2) If the free play is out of specifications above, ad-

just the brake pedal as follows.

(1) Be sure the engine is off. (No vacuum is ap-

plied to brake booster.)

(2) There should be play between brake boost-

er clevis and pin at brake pedal installing por-

tion.

[Depress brake pedal pad with a force of less

than 10 N (1 kgf, 2 lb) to a stroke of 0.5 to 2.0

mm (0.02 to 0.08 in).]

(3) Depress the surface of brake pad by hand.

(1) Front brake hose

(2) Front brake pipe

(1) Brake pipe

(2) Rear brake hose

(3) Clamp

BR-00095

(1)

(2)

(1)

(3)

(3) (2)

BR-00096

(A) Brake pedal free play

PM-00078

(A)

Page 768 of 2870

PM-31

PERIODIC MAINTENANCE SERVICE

Brake Line

(4) If there is no free play between clevis pin

and clevis, turn the brake switch adjusting nut

until the clearance between stopper and screw

of brake switch becomes 0.3 mm (0.012 in).

3) Check the pedal stroke.

While the engine is idling, depress the brake pedal

with a 490 N (50 kgf, 110 lb) load and measure the

distance between brake pedal and steering wheel.

With the brake pedal released, measure the dis-

tance between pedal and steering wheel again.

The difference between the two measurements

must be less than specified value. If the distance is

more than specified value, there is possibility of air

inside the hydraulic unit.

Brake pedal reserve distance: A

For Australia model

105 mm (4.13 in)/ 490 N (50 kgf , 110 lb) or less

Except for Australia model

90 mm (3.54 in)/ 490 N (50 kgf , 110 lb) or less4) Check to see if air is in the hydraulic brake line

by the feel of pedal operation. If air appears to exist

in the line, bleed it from the system.

5) Check for even operation of all brakes, using a

brake tester or by driving the vehicle for a short dis-

tance on a straight road.

2. BRAKE SERVO SYSTEM

1) With the engine off, depress the brake pedal

several times applying the same pedal force: Make

sure the travel distance should not change.

2) With the brake pedal depressed, start the en-

gine: Make sure the pedal should move slightly to-

ward the floor.

3) With the brake pedal depressed, stop the engine

and keep the pedal depressed for 30 seconds:

Make sure the pedal height should not change.

4) Check valve is built into the vacuum hose. Dis-

connect the vacuum hose to inspect function of

check valve.

Blow air into the vacuum hose from its brake boost-

er side end: Air must flow out of engine side end of

hose. Next blow air into the hose from engine side:

Air should not to brake booster side.

Replace both check valve and vacuum hose if the

check valve is faulty. Engine side of vacuum hose

is indicated by marking “ENG” as shown in illustra-

tion.

5) Check the vacuum hose for cracks or other dam-

age.

CAUTION:

When installing the vacuum hose on the engine

and brake booster, do not use soapy water or

lubricating oil on their connections.

6) Check vacuum hose to make sure it is tight and

secure.

(A) Brake switch

(B) Adjusting nut

(C) 0.3 mm (0.012 in)

(D) Stopper

(E) Clevis pin

(F) Clevis

(G) Brake pedal free play

(H) Lock nut

(I) Brake booster operating rod

(J) Play at pin

(A) Steering wheel

(B) Toe board

PM-00041

(B)

(G) (H)

(I)

(J)(C)

(D)

(E)

(F)(A)

PM-00045(B)(A) = A

1

12

2

(A) Engine side

(B) Brake booster side

(C) ENG

PM-00046

(B)

(C) (A)

Page 769 of 2870

PM-32

PERIODIC MAINTENANCE SERVICE

Brake Fluid

19.Brake Fluid

A: REPLACEMENT

1) Lift-up the vehicle.

2) Remove both front and rear wheels.

3) Draw out the brake fluid from master cylinder

with syringe.

4) Refill the reservoir tank with recommended

brake fluid.

Recommended brake fluid:

FMVSS No. 116, fresh DOT3 or DOT4 brake

fluid

CAUTION:

Avoid mixing different brands of brake fluid

to prevent degrading the quality of the fluid.

Be careful not to allow dirt or dust to get into

the reservoir tank.

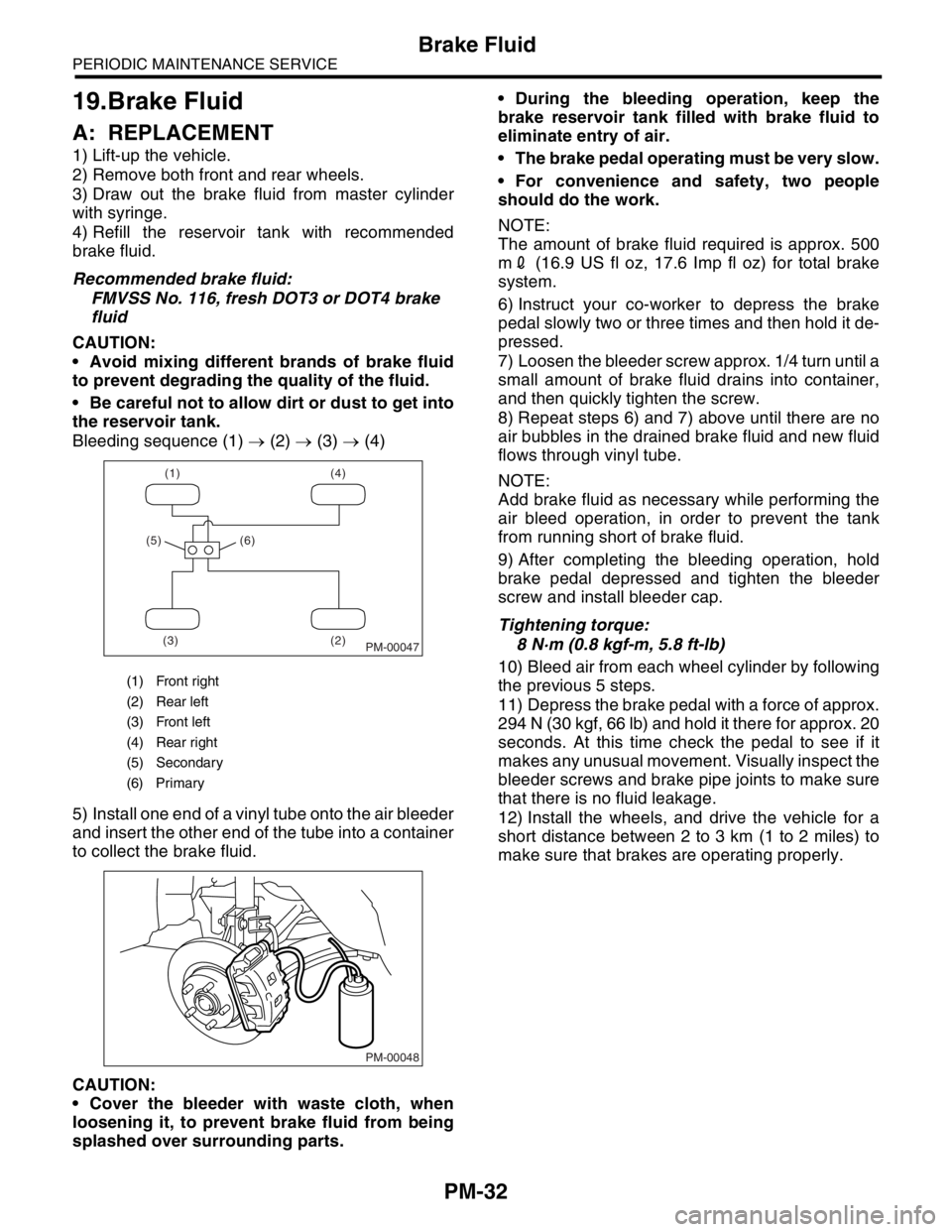

Bleeding sequence (1) → (2) → (3) → (4)

5) Install one end of a vinyl tube onto the air bleeder

and insert the other end of the tube into a container

to collect the brake fluid.

CAUTION:

Cover the bleeder with waste cloth, when

loosening it, to prevent brake fluid from being

splashed over surrounding parts. During the bleeding operation, keep the

brake reservoir tank filled with brake fluid to

eliminate entry of air.

The brake pedal operating must be very slow.

For convenience and safety, two people

should do the work.

NOTE:

The amount of brake fluid required is approx. 500

m2 (16.9 US fl oz, 17.6 Imp fl oz) for total brake

system.

6) Instruct your co-worker to depress the brake

pedal slowly two or three times and then hold it de-

pressed.

7) Loosen the bleeder screw approx. 1/4 turn until a

small amount of brake fluid drains into container,

and then quickly tighten the screw.

8) Repeat steps 6) and 7) above until there are no

air bubbles in the drained brake fluid and new fluid

flows through vinyl tube.

NOTE:

Add brake fluid as necessary while performing the

air bleed operation, in order to prevent the tank

from running short of brake fluid.

9) After completing the bleeding operation, hold

brake pedal depressed and tighten the bleeder

screw and install bleeder cap.

Tightening torque:

8 N·m (0.8 kgf-m, 5.8 ft-lb)

10) Bleed air from each wheel cylinder by following

the previous 5 steps.

11) Depress the brake pedal with a force of approx.

294 N (30 kgf, 66 lb) and hold it there for approx. 20

seconds. At this time check the pedal to see if it

makes any unusual movement. Visually inspect the

bleeder screws and brake pipe joints to make sure

that there is no fluid leakage.

12) Install the wheels, and drive the vehicle for a

short distance between 2 to 3 km (1 to 2 miles) to

make sure that brakes are operating properly.

(1) Front right

(2) Rear left

(3) Front left

(4) Rear right

(5) Secondary

(6) Primary

(1) (4)

(2) (3) (5) (6)

PM-00047

PM-00048

Page 770 of 2870

PM-33

PERIODIC MAINTENANCE SERVICE

Disc Brake Pads and Discs

20.Disc Brake Pads and Discs

A: INSPECTION

1. DISC BRAKE PAD AND DISC

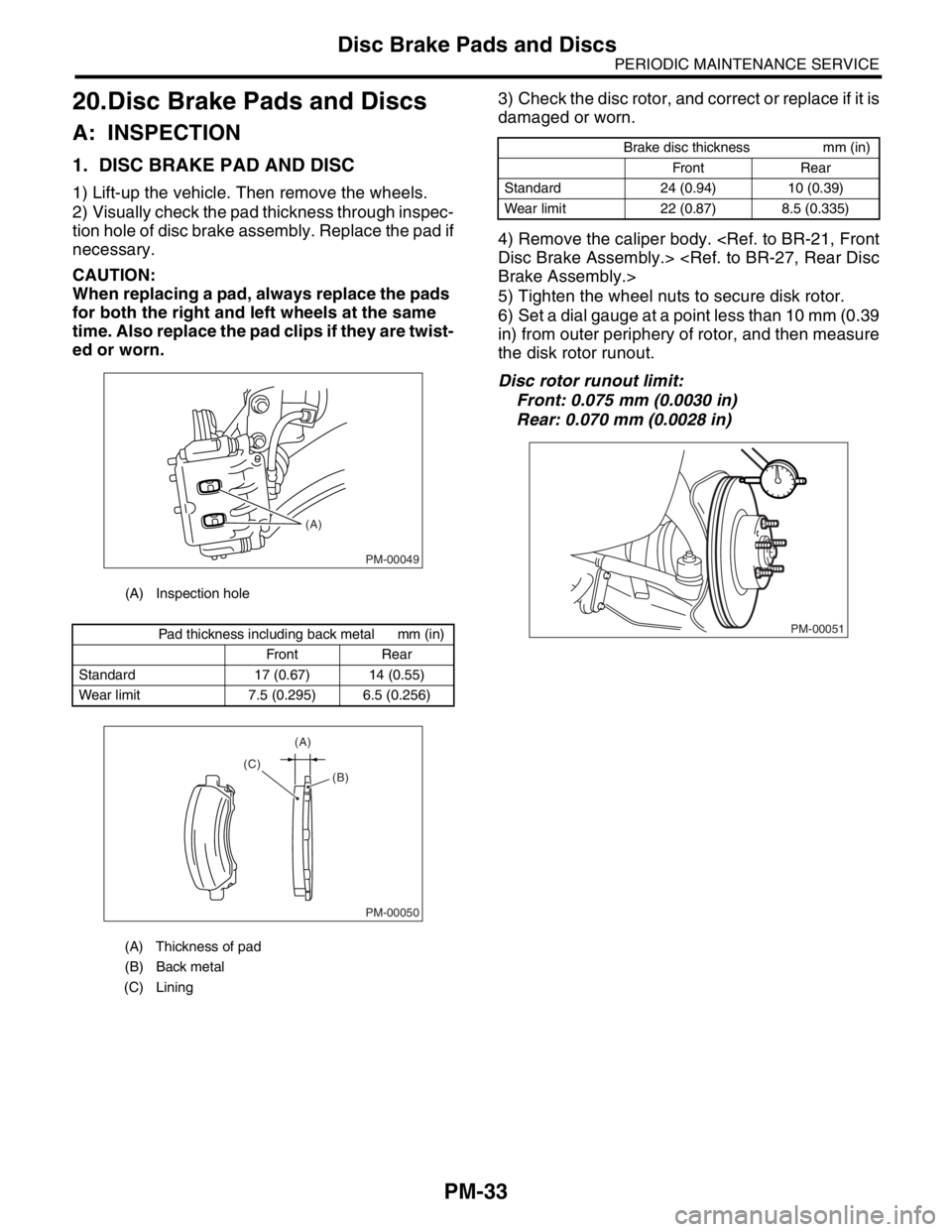

1) Lift-up the vehicle. Then remove the wheels.

2) Visually check the pad thickness through inspec-

tion hole of disc brake assembly. Replace the pad if

necessary.

CAUTION:

When replacing a pad, always replace the pads

for both the right and left wheels at the same

time. Also replace the pad clips if they are twist-

ed or worn.3) Check the disc rotor, and correct or replace if it is

damaged or worn.

4) Remove the caliper body.

5) Tighten the wheel nuts to secure disk rotor.

6) Set a dial gauge at a point less than 10 mm (0.39

in) from outer periphery of rotor, and then measure

the disk rotor runout.

Disc rotor runout limit:

Front: 0.075 mm (0.0030 in)

Rear: 0.070 mm (0.0028 in)

(A) Inspection hole

Pad thickness including back metal mm (in)

Front Rear

Standard 17 (0.67) 14 (0.55)

Wear limit 7.5 (0.295) 6.5 (0.256)

(A) Thickness of pad

(B) Back metal

(C) Lining

PM-00049

(A)

PM-00050

(A)

(C)

(B)

Brake disc thickness mm (in)

Front Rear

Standard 24 (0.94) 10 (0.39)

Wear limit 22 (0.87) 8.5 (0.335)

PM-00051