SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 901 of 2870

ME(H4SO)-32

MECHANICAL

Valve Clearance

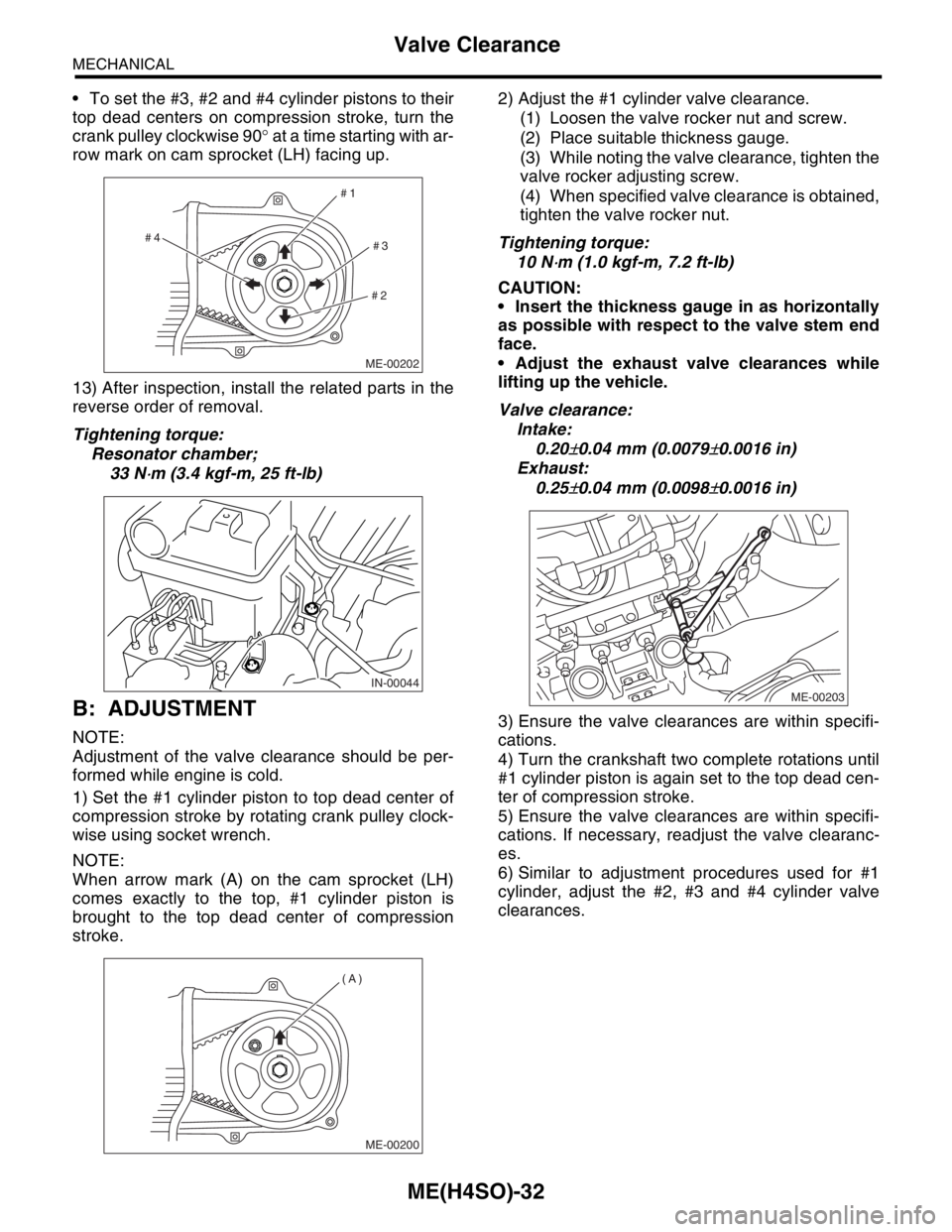

To set the #3, #2 and #4 cylinder pistons to their

top dead centers on compression stroke, turn the

crank pulley clockwise 90° at a time starting with ar-

row mark on cam sprocket (LH) facing up.

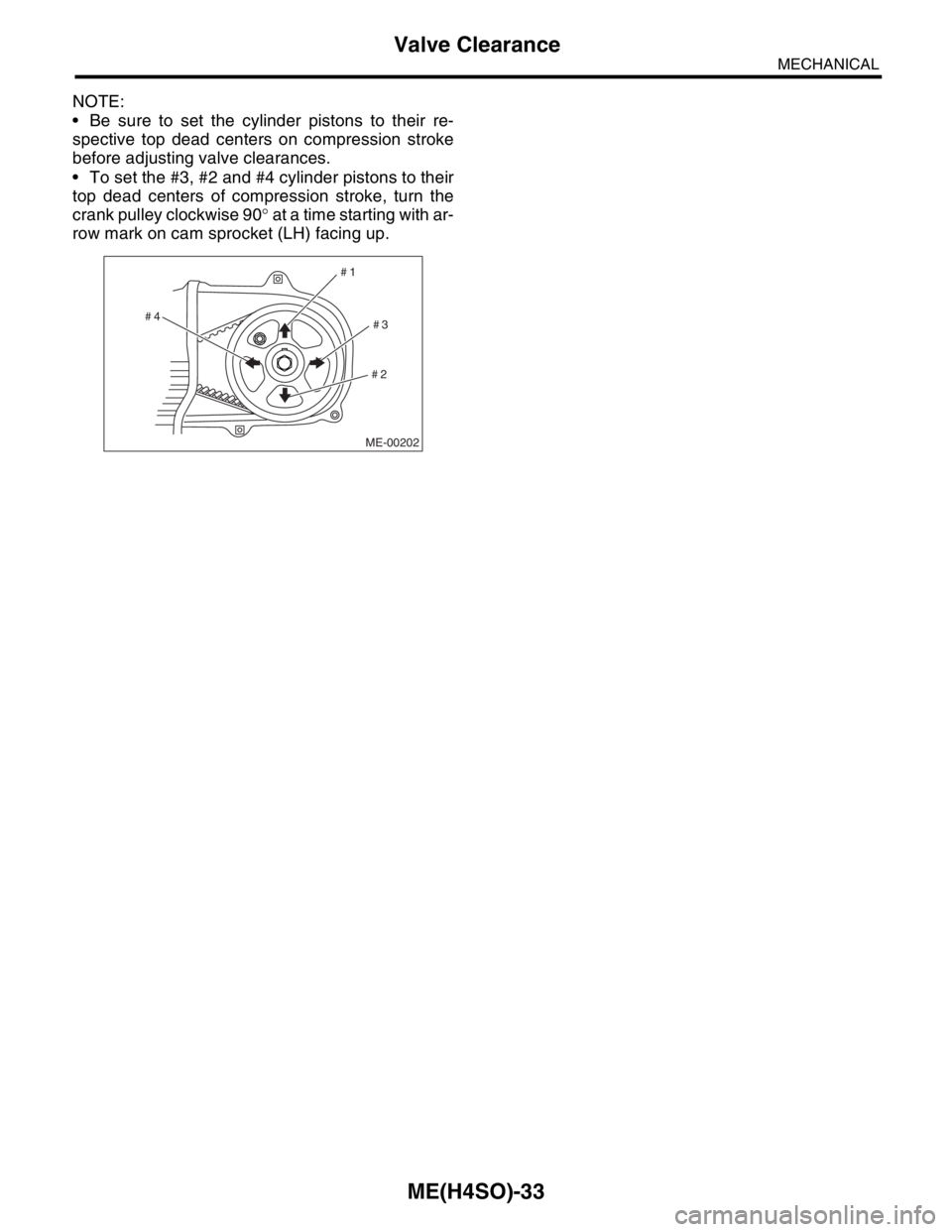

13) After inspection, install the related parts in the

reverse order of removal.

Tightening torque:

Resonator chamber;

33 N

⋅m (3.4 kgf-m, 25 ft-lb)

B: ADJUSTMENT

NOTE:

Adjustment of the valve clearance should be per-

formed while engine is cold.

1) Set the #1 cylinder piston to top dead center of

compression stroke by rotating crank pulley clock-

wise using socket wrench.

NOTE:

When arrow mark (A) on the cam sprocket (LH)

comes exactly to the top, #1 cylinder piston is

brought to the top dead center of compression

stroke.2) Adjust the #1 cylinder valve clearance.

(1) Loosen the valve rocker nut and screw.

(2) Place suitable thickness gauge.

(3) While noting the valve clearance, tighten the

valve rocker adjusting screw.

(4) When specified valve clearance is obtained,

tighten the valve rocker nut.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

CAUTION:

Insert the thickness gauge in as horizontally

as possible with respect to the valve stem end

face.

Adjust the exhaust valve clearances while

lifting up the vehicle.

Valve clearance:

Intake:

0.20

±0.04 mm (0.0079±0.0016 in)

Exhaust:

0.25

±0.04 mm (0.0098±0.0016 in)

3) Ensure the valve clearances are within specifi-

cations.

4) Turn the crankshaft two complete rotations until

#1 cylinder piston is again set to the top dead cen-

ter of compression stroke.

5) Ensure the valve clearances are within specifi-

cations. If necessary, readjust the valve clearanc-

es.

6) Similar to adjustment procedures used for #1

cylinder, adjust the #2, #3 and #4 cylinder valve

clearances.

ME-00202

#1

#2#3 #4

IN-00044

ME-00200

(A)

ME-00203

Page 902 of 2870

ME(H4SO)-33

MECHANICAL

Valve Clearance

NOTE:

Be sure to set the cylinder pistons to their re-

spective top dead centers on compression stroke

before adjusting valve clearances.

To set the #3, #2 and #4 cylinder pistons to their

top dead centers of compression stroke, turn the

crank pulley clockwise 90° at a time starting with ar-

row mark on cam sprocket (LH) facing up.

ME-00202

#1

#2#3 #4

Page 903 of 2870

ME(H4SO)-34

MECHANICAL

Engine Assembly

9. Engine Assembly

A: REMOVAL

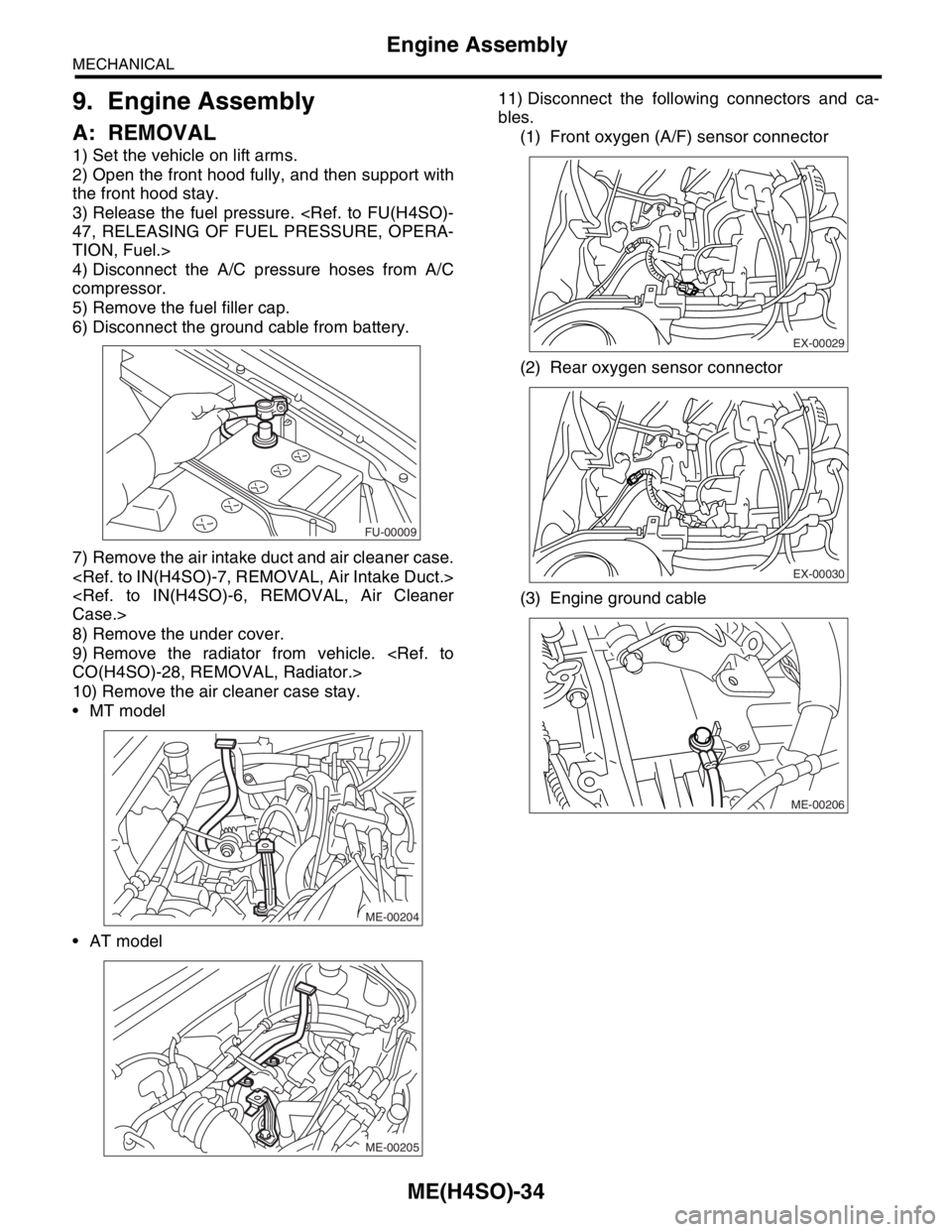

1) Set the vehicle on lift arms.

2) Open the front hood fully, and then support with

the front hood stay.

3) Release the fuel pressure.

TION, Fuel.>

4) Disconnect the A/C pressure hoses from A/C

compressor.

5) Remove the fuel filler cap.

6) Disconnect the ground cable from battery.

7) Remove the air intake duct and air cleaner case.

8) Remove the under cover.

9) Remove the radiator from vehicle.

10) Remove the air cleaner case stay.

MT model

AT model11) Disconnect the following connectors and ca-

bles.

(1) Front oxygen (A/F) sensor connector

(2) Rear oxygen sensor connector

(3) Engine ground cable

FU-00009

ME-00204

ME-00205

EX-00029

EX-00030

ME-00206

Page 904 of 2870

ME(H4SO)-35

MECHANICAL

Engine Assembly

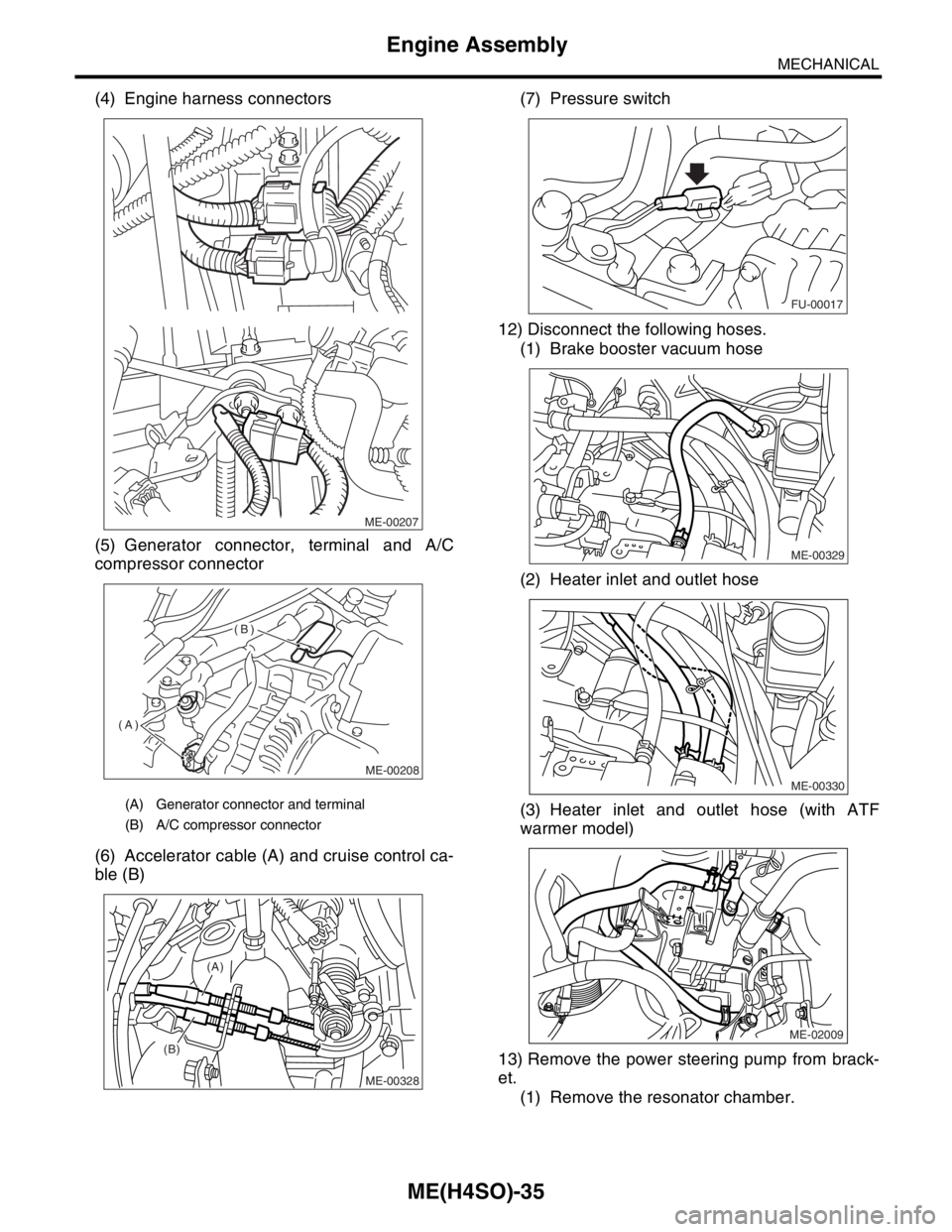

(4) Engine harness connectors

(5) Generator connector, terminal and A/C

compressor connector

(6) Accelerator cable (A) and cruise control ca-

ble (B)(7) Pressure switch

12) Disconnect the following hoses.

(1) Brake booster vacuum hose

(2) Heater inlet and outlet hose

(3) Heater inlet and outlet hose (with ATF

warmer model)

13) Remove the power steering pump from brack-

et.

(1) Remove the resonator chamber.

(A) Generator connector and terminal

(B) A/C compressor connector

ME-00207

ME-00208

(A)

(B)

(B)(A)

ME-00328

FU-00017

ME-00329

ME-00330

ME-02009

Page 905 of 2870

ME(H4SO)-36

MECHANICAL

Engine Assembly

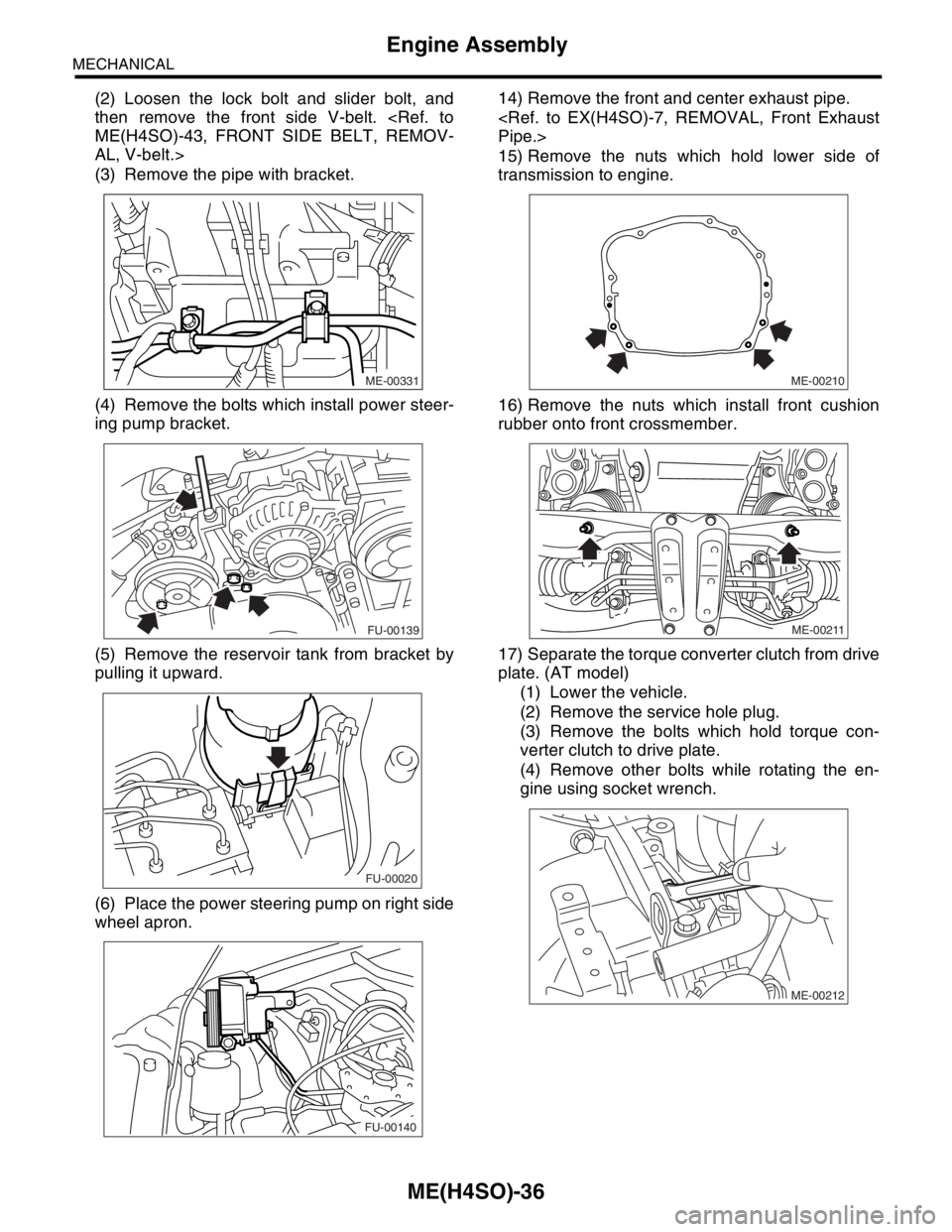

(2) Loosen the lock bolt and slider bolt, and

then remove the front side V-belt.

AL, V-belt.>

(3) Remove the pipe with bracket.

(4) Remove the bolts which install power steer-

ing pump bracket.

(5) Remove the reservoir tank from bracket by

pulling it upward.

(6) Place the power steering pump on right side

wheel apron.14) Remove the front and center exhaust pipe.

15) Remove the nuts which hold lower side of

transmission to engine.

16) Remove the nuts which install front cushion

rubber onto front crossmember.

17) Separate the torque converter clutch from drive

plate. (AT model)

(1) Lower the vehicle.

(2) Remove the service hole plug.

(3) Remove the bolts which hold torque con-

verter clutch to drive plate.

(4) Remove other bolts while rotating the en-

gine using socket wrench.

ME-00331

FU-00139

FU-00020

FU-00140ME-00210

ME-00211

ME-00212

Page 906 of 2870

ME(H4SO)-37

MECHANICAL

Engine Assembly

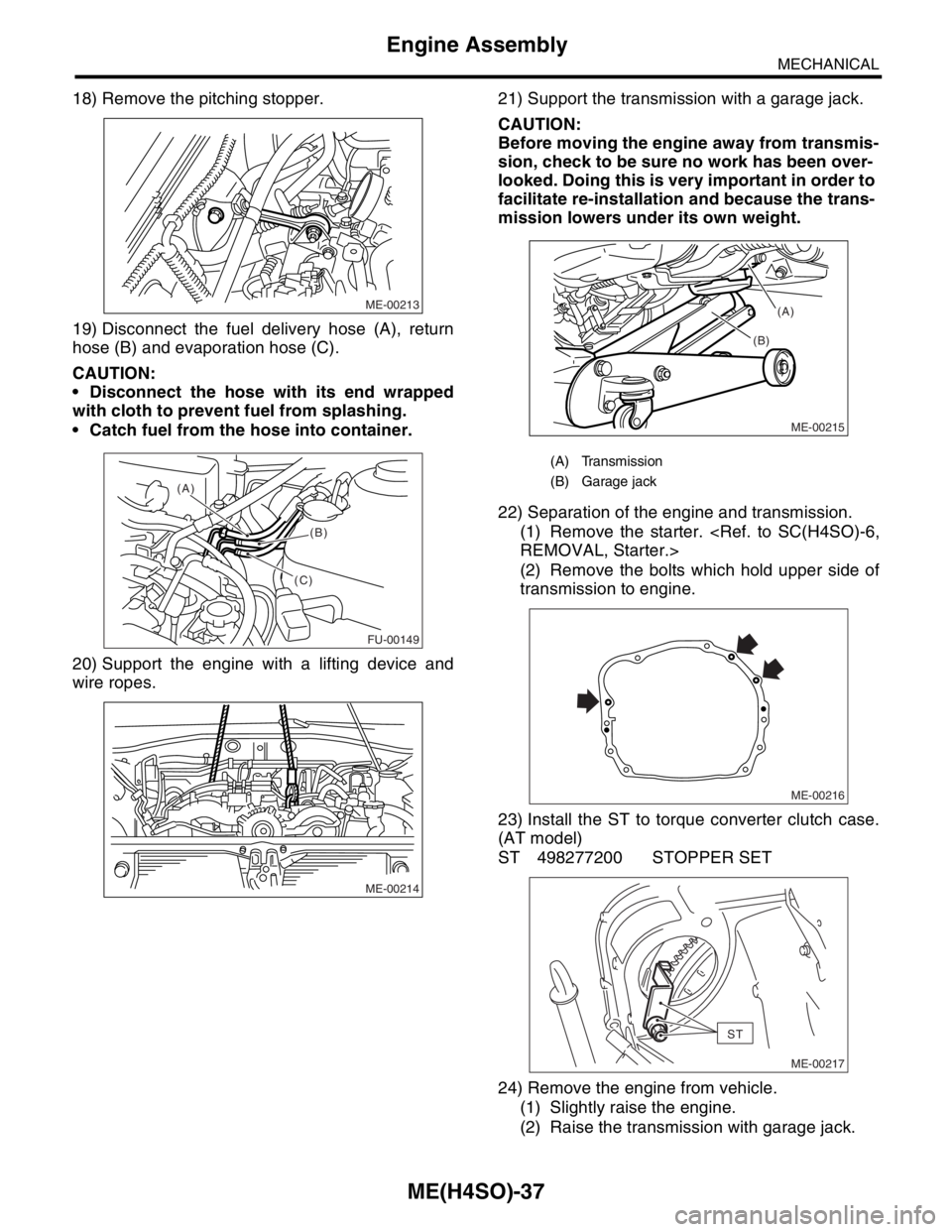

18) Remove the pitching stopper.

19) Disconnect the fuel delivery hose (A), return

hose (B) and evaporation hose (C).

CAUTION:

Disconnect the hose with its end wrapped

with cloth to prevent fuel from splashing.

Catch fuel from the hose into container.

20) Support the engine with a lifting device and

wire ropes.21) Support the transmission with a garage jack.

CAUTION:

Before moving the engine away from transmis-

sion, check to be sure no work has been over-

looked. Doing this is very important in order to

facilitate re-installation and because the trans-

mission lowers under its own weight.

22) Separation of the engine and transmission.

(1) Remove the starter.

(2) Remove the bolts which hold upper side of

transmission to engine.

23) Install the ST to torque converter clutch case.

(AT model)

ST 498277200 STOPPER SET

24) Remove the engine from vehicle.

(1) Slightly raise the engine.

(2) Raise the transmission with garage jack.

ME-00213

FU-00149

(A)

(B)

(C)

ME-00214

(A) Transmission

(B) Garage jack

ME-00215

(B)(A)

ME-00216

ST

ME-00217

Page 907 of 2870

ME(H4SO)-38

MECHANICAL

Engine Assembly

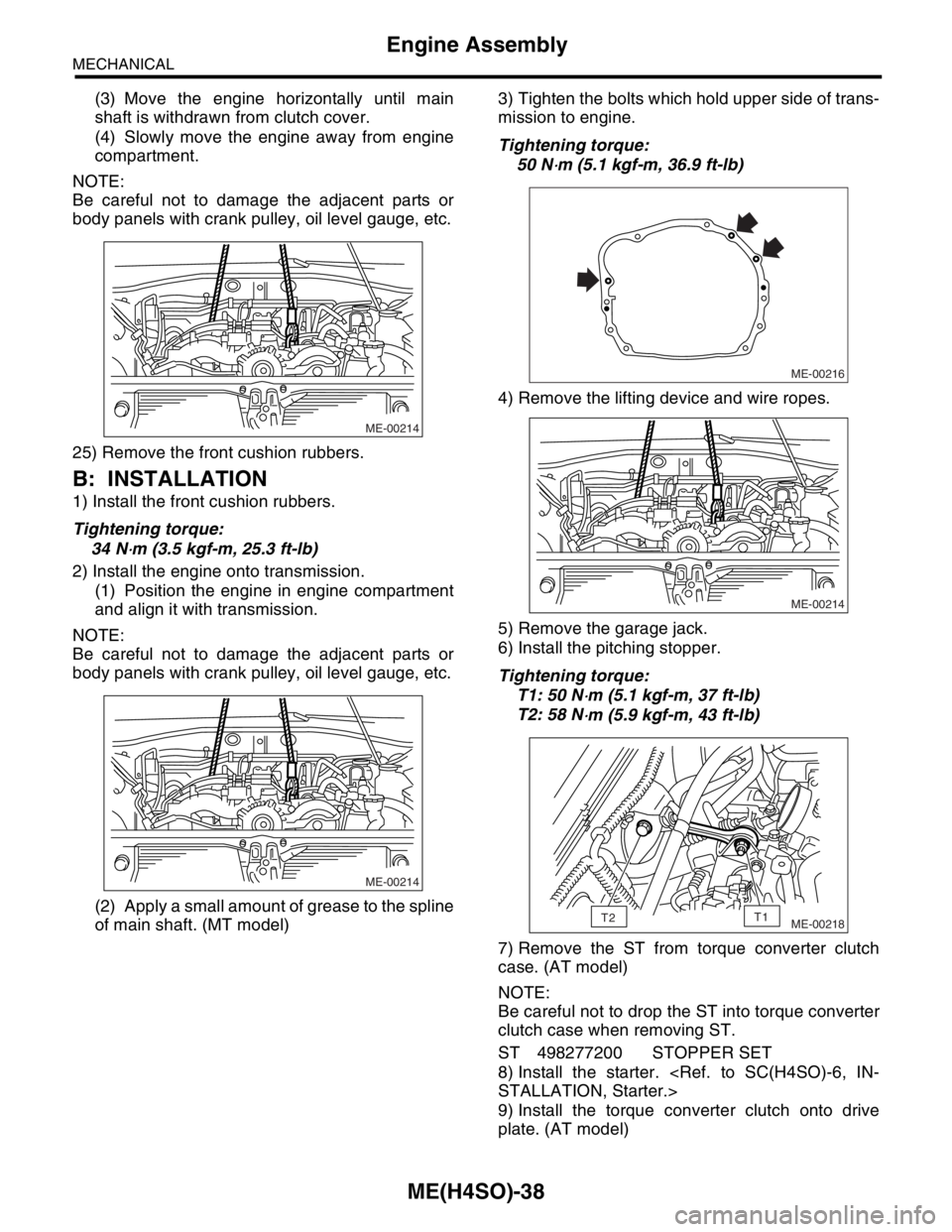

(3) Move the engine horizontally until main

shaft is withdrawn from clutch cover.

(4) Slowly move the engine away from engine

compartment.

NOTE:

Be careful not to damage the adjacent parts or

body panels with crank pulley, oil level gauge, etc.

25) Remove the front cushion rubbers.

B: INSTALLATION

1) Install the front cushion rubbers.

Tightening torque:

34 N

⋅m (3.5 kgf-m, 25.3 ft-lb)

2) Install the engine onto transmission.

(1) Position the engine in engine compartment

and align it with transmission.

NOTE:

Be careful not to damage the adjacent parts or

body panels with crank pulley, oil level gauge, etc.

(2) Apply a small amount of grease to the spline

of main shaft. (MT model)3) Tighten the bolts which hold upper side of trans-

mission to engine.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 36.9 ft-lb)

4) Remove the lifting device and wire ropes.

5) Remove the garage jack.

6) Install the pitching stopper.

Tightening torque:

T1: 50 N

⋅m (5.1 kgf-m, 37 ft-lb)

T2: 58 N

⋅m (5.9 kgf-m, 43 ft-lb)

7) Remove the ST from torque converter clutch

case. (AT model)

NOTE:

Be careful not to drop the ST into torque converter

clutch case when removing ST.

ST 498277200 STOPPER SET

8) Install the starter.

9) Install the torque converter clutch onto drive

plate. (AT model)

ME-00214

ME-00214

ME-00216

ME-00214

ME-00218T2T1

Page 908 of 2870

ME(H4SO)-39

MECHANICAL

Engine Assembly

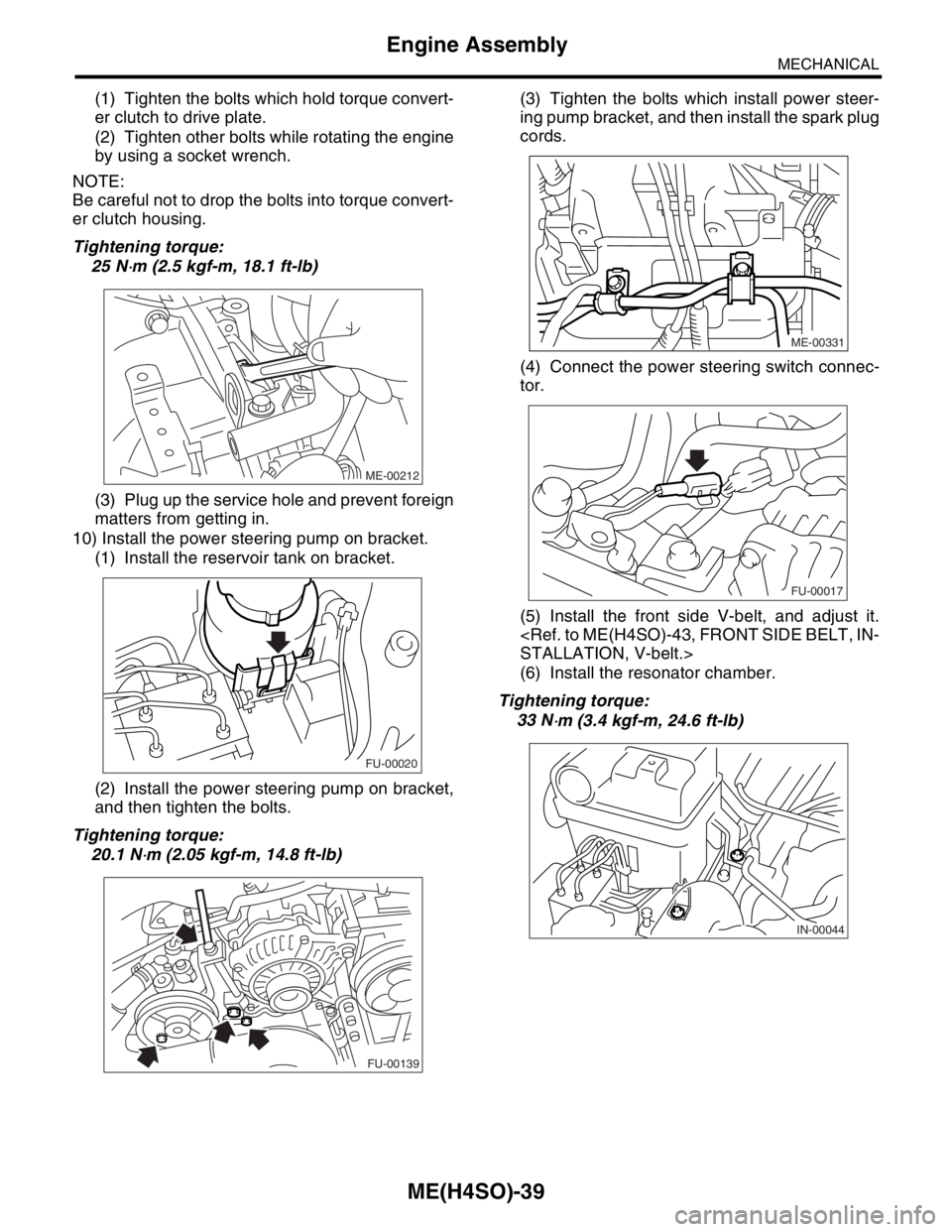

(1) Tighten the bolts which hold torque convert-

er clutch to drive plate.

(2) Tighten other bolts while rotating the engine

by using a socket wrench.

NOTE:

Be careful not to drop the bolts into torque convert-

er clutch housing.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(3) Plug up the service hole and prevent foreign

matters from getting in.

10) Install the power steering pump on bracket.

(1) Install the reservoir tank on bracket.

(2) Install the power steering pump on bracket,

and then tighten the bolts.

Tightening torque:

20.1 N

⋅m (2.05 kgf-m, 14.8 ft-lb)(3) Tighten the bolts which install power steer-

ing pump bracket, and then install the spark plug

cords.

(4) Connect the power steering switch connec-

tor.

(5) Install the front side V-belt, and adjust it.

(6) Install the resonator chamber.

Tightening torque:

33 N

⋅m (3.4 kgf-m, 24.6 ft-lb)

ME-00212

FU-00020

FU-00139

ME-00331

FU-00017

IN-00044

Page 909 of 2870

ME(H4SO)-40

MECHANICAL

Engine Assembly

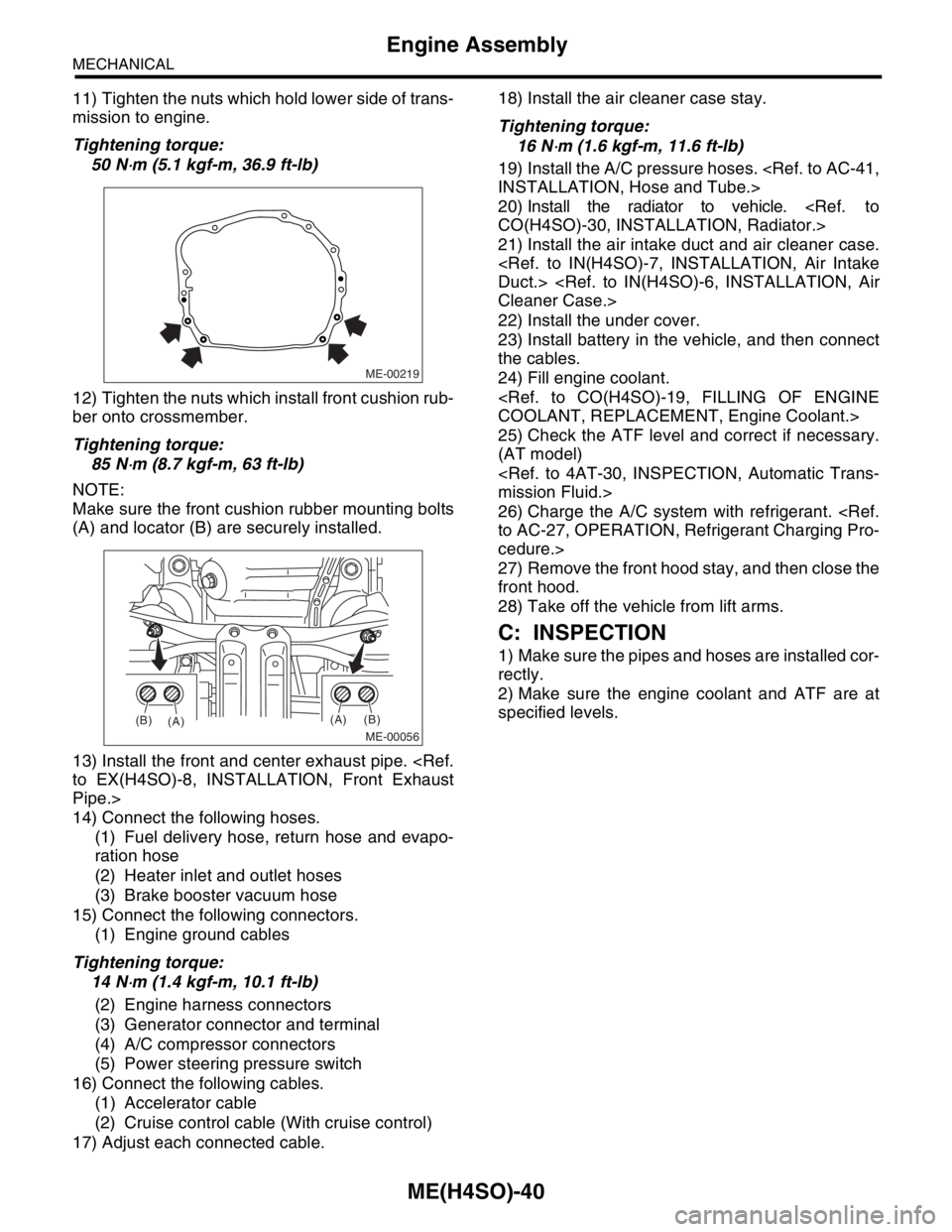

11) Tighten the nuts which hold lower side of trans-

mission to engine.

Tightening torque:

50 N

⋅m (5.1 kgf-m, 36.9 ft-lb)

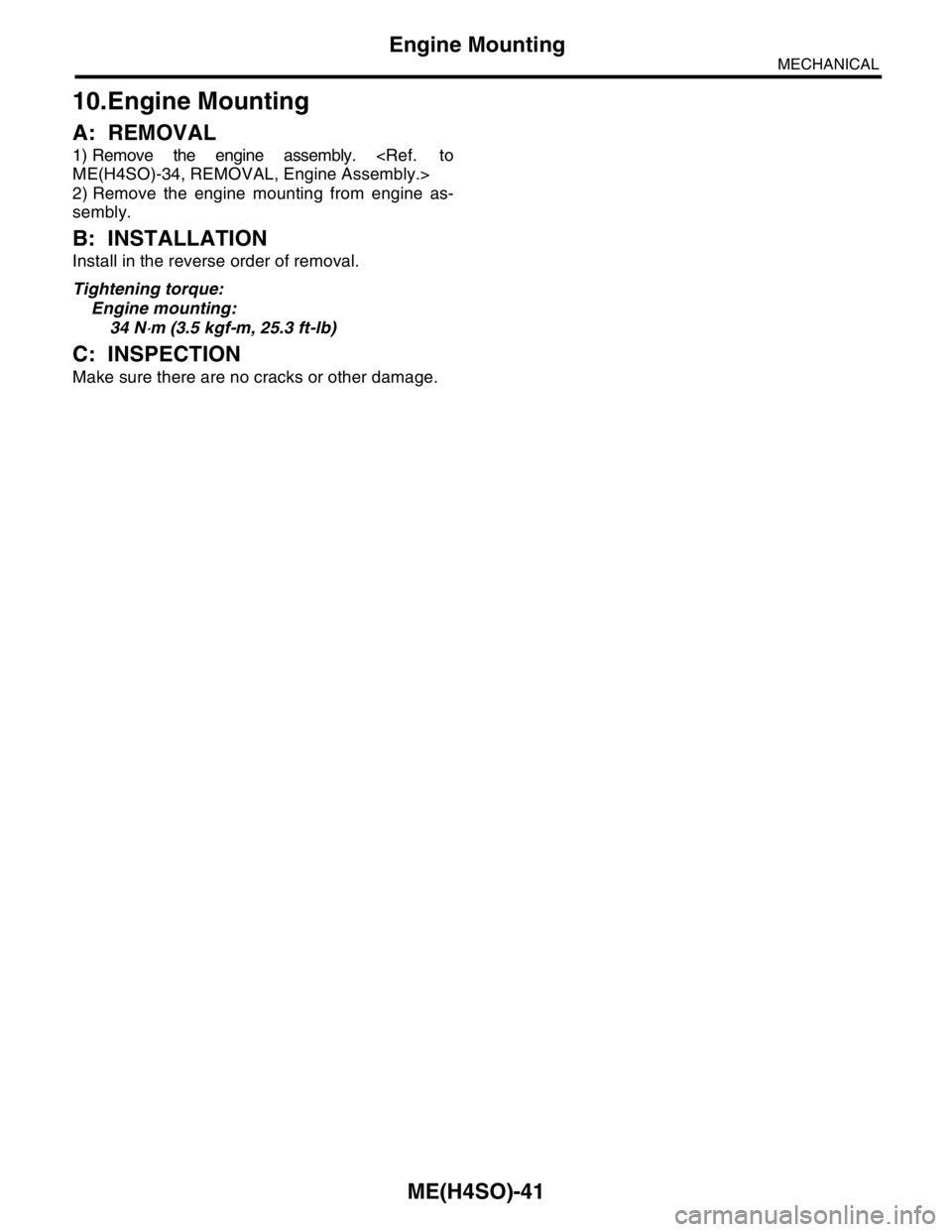

12) Tighten the nuts which install front cushion rub-

ber onto crossmember.

Tightening torque:

85 N

⋅m (8.7 kgf-m, 63 ft-lb)

NOTE:

Make sure the front cushion rubber mounting bolts

(A) and locator (B) are securely installed.

13) Install the front and center exhaust pipe.

Pipe.>

14) Connect the following hoses.

(1) Fuel delivery hose, return hose and evapo-

ration hose

(2) Heater inlet and outlet hoses

(3) Brake booster vacuum hose

15) Connect the following connectors.

(1) Engine ground cables

Tightening torque:

14 N

⋅m (1.4 kgf-m, 10.1 ft-lb)

(2) Engine harness connectors

(3) Generator connector and terminal

(4) A/C compressor connectors

(5) Power steering pressure switch

16) Connect the following cables.

(1) Accelerator cable

(2) Cruise control cable (With cruise control)

17) Adjust each connected cable.18) Install the air cleaner case stay.

Tightening torque:

16 N

⋅m (1.6 kgf-m, 11.6 ft-lb)

19) Install the A/C pressure hoses.

20) Install the radiator to vehicle.

21) Install the air intake duct and air cleaner case.

22) Install the under cover.

23) Install battery in the vehicle, and then connect

the cables.

24) Fill engine coolant.

25) Check the ATF level and correct if necessary.

(AT model)

26) Charge the A/C system with refrigerant.

cedure.>

27) Remove the front hood stay, and then close the

front hood.

28) Take off the vehicle from lift arms.

C: INSPECTION

1) Make sure the pipes and hoses are installed cor-

rectly.

2) Make sure the engine coolant and ATF are at

specified levels.

ME-00219

ME-00056

(A)

(A)(B)

(B)

Page 910 of 2870

ME(H4SO)-41

MECHANICAL

Engine Mounting

10.Engine Mounting

A: REMOVAL

1) Remove the engine assembly.

2) Remove the engine mounting from engine as-

sembly.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Engine mounting:

34 N

⋅m (3.5 kgf-m, 25.3 ft-lb)

C: INSPECTION

Make sure there are no cracks or other damage.