SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 921 of 2870

ME(H4SO)-52

MECHANICAL

Timing Belt

2. AUTOMATIC BELT TENSION ADJUST-

ER

1) Visually check oil seals for leaks, and rod ends

for abnormal wear or scratches. If necessary, re-

place faulty parts.

2) Check that the adjuster rod does not move when

a pressure of 294 N (30 kgf, 66 lb) is applied to it.

This is to check adjuster rod stiffness.

3) If the adjuster rod is not stiff and moves freely

when applying 294 N (30 kgf, 66 lb), check it using

the following procedures:

(1) Slowly press the adjuster rod down to the

end surface of the cylinder. Repeat this motion 2

or 3 times.

(2) With the adjuster rod moved all the way up,

apply a pressure of 294 N (30 kgf, 66 lb) to it.

Check adjuster rod stiffness.

(3) If the adjuster rod is not stiff and moves

down, replace the automatic belt tension adjust-

er assembly with a new one.

CAUTION:

Always use a vertical type pressing tool to

move the adjuster rod down.

Do not use a lateral type vise.

Push the adjuster rod vertically.

Press-in the adjuster rod gradually taking

more than 3 minutes.

Do not allow press pressure to exceed 9,807

N (1,000 kgf, 2,205 lb).

Press the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

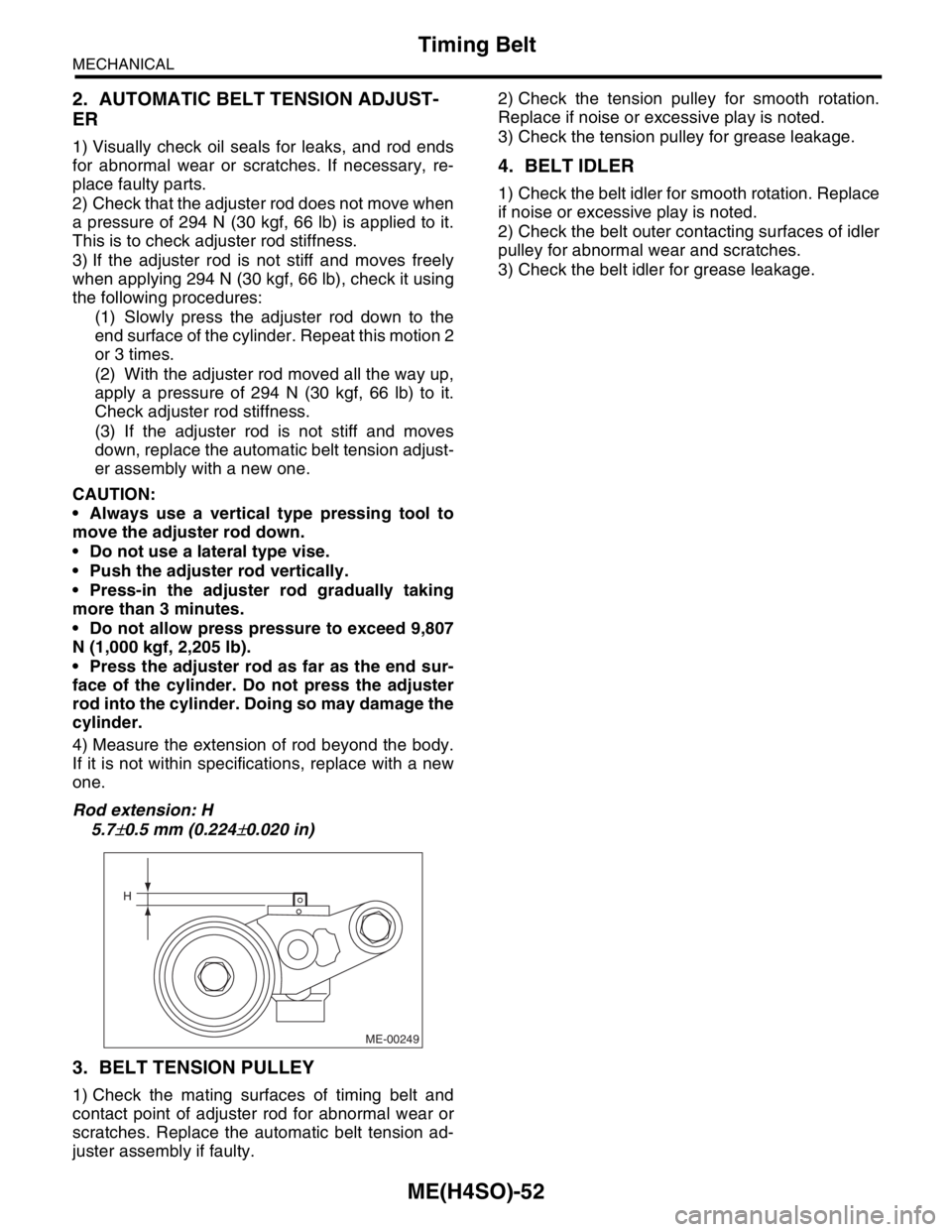

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

5.7

±0.5 mm (0.224±0.020 in)

3. BELT TENSION PULLEY

1) Check the mating surfaces of timing belt and

contact point of adjuster rod for abnormal wear or

scratches. Replace the automatic belt tension ad-

juster assembly if faulty.2) Check the tension pulley for smooth rotation.

Replace if noise or excessive play is noted.

3) Check the tension pulley for grease leakage.

4. BELT IDLER

1) Check the belt idler for smooth rotation. Replace

if noise or excessive play is noted.

2) Check the belt outer contacting surfaces of idler

pulley for abnormal wear and scratches.

3) Check the belt idler for grease leakage.

ME-00249

H

Page 922 of 2870

FUJI HEAVY INDUSTRIES LTD. G8080GE2

2004 FORESTER SERVICE MANUAL QUICK REFERENCE INDEX

ENGINE SECTION 1

This service manual has been prepared

to provide SUBARU service personnel

with the necessary information and data

for the correct maintenance and repair

of SUBARU vehicles.

This manual includes the procedures

for maintenance, disassembling, reas-

sembling, inspection and adjustment of

components and diagnostics for guid-

ance of experienced mechanics.

Please peruse and utilize this manual

fully to ensure complete repair work for

satisfying our customers by keeping

their vehicle in optimum condition.

When replacement of parts during

repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi-

cations contained in this manual are

based on the latest product information

available at the time of publication

approval.FUEL INJECTION (FUEL SYSTEM) FU(H4SO)

EMISSION CONTROL

(AUX. EMISSION CONTROL DEVICE)EC(H4SO)

INTAKE (INDUCTION) IN(H4SO)

MECHANICAL ME(H4SO)

EXHAUST EX(H4SO)

COOLING CO(H4SO)

LUBRICATION LU(H4SO)

SPEED CONTROL SYSTEM SP(H4SO)

IGNITION IG(H4SO)

STARTING/CHARGING SYSTEM SC(H4SO)

ENGINE (DIAGNOSTIC) EN(H4SO)

Page 923 of 2870

MECHANICAL

ME(H4SO)

Page

1. General Description ....................................................................................2

2. Compression .............................................................................................25

3. Idle Speed .................................................................................................26

4. Ignition Timing ...........................................................................................27

5. Intake Manifold Vacuum............................................................................28

6. Engine Oil Pressure ..................................................................................29

7. Fuel Pressure ............................................................................................30

8. Valve Clearance ........................................................................................31

9. Engine Assembly ......................................................................................34

10. Engine Mounting .......................................................................................41

11. Preparation for Overhaul ...........................................................................42

12. V-belt .........................................................................................................43

13. Crank Pulley ..............................................................................................45

14. Timing Belt Cover......................................................................................47

15. Timing Belt ................................................................................................48

16. Cam Sprocket ...........................................................................................53

17. Crank Sprocket .........................................................................................55

18. Valve Rocker Assembly ............................................................................56

19. Camshaft ...................................................................................................58

20. Cylinder Head ...........................................................................................62

21. Cylinder Block ...........................................................................................69

22. Engine Trouble in General ........................................................................91

23. Engine Noise .............................................................................................96

Page 924 of 2870

ME(H4SO)-53

MECHANICAL

Cam Sprocket

16.Cam Sprocket

A: REMOVAL

1. REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the belt cover.

4) Remove the timing belt assembly.

5) Remove the camshaft position sensor.

Sensor.>

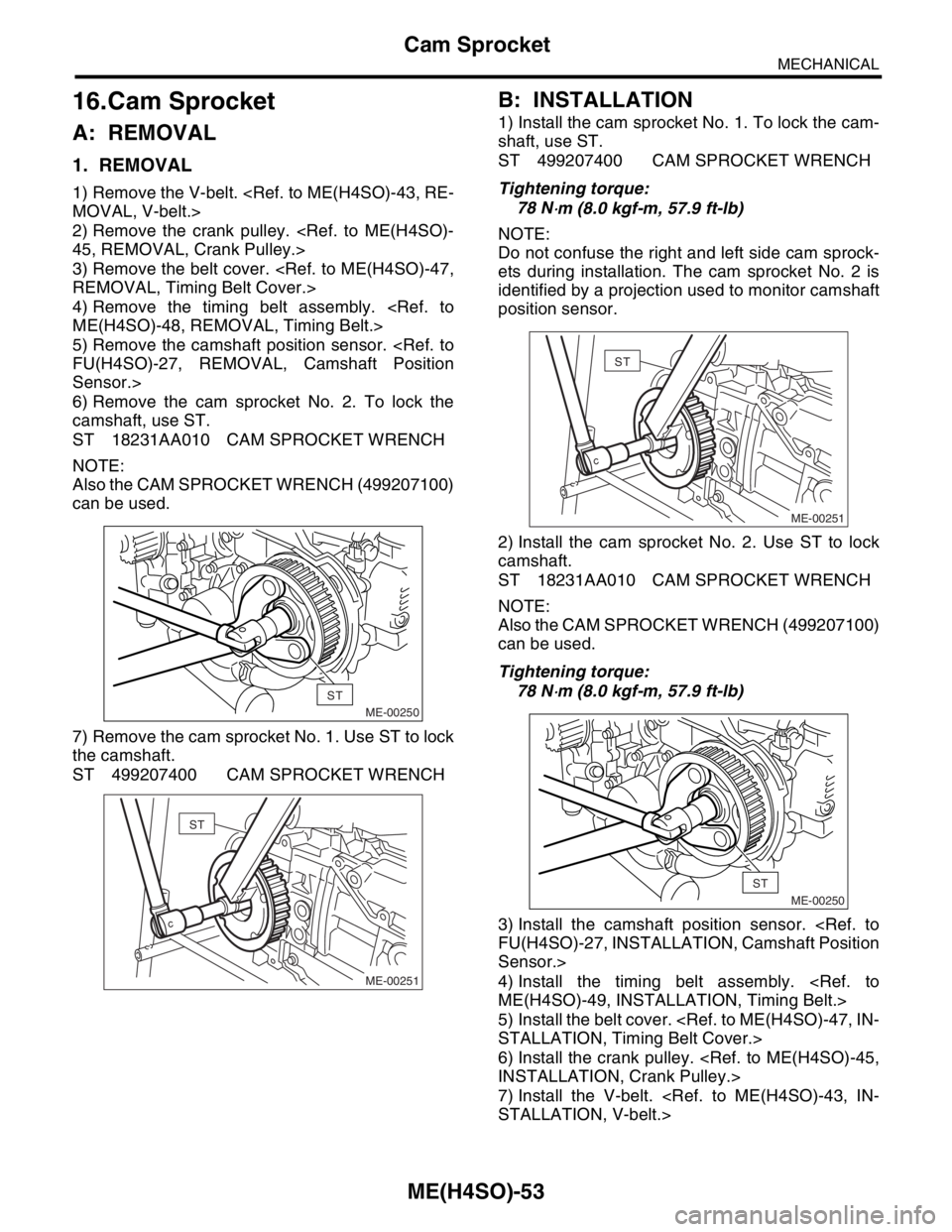

6) Remove the cam sprocket No. 2. To lock the

camshaft, use ST.

ST 18231AA010 CAM SPROCKET WRENCH

NOTE:

Also the CAM SPROCKET WRENCH (499207100)

can be used.

7) Remove the cam sprocket No. 1. Use ST to lock

the camshaft.

ST 499207400 CAM SPROCKET WRENCH

B: INSTALLATION

1) Install the cam sprocket No. 1. To lock the cam-

shaft, use ST.

ST 499207400 CAM SPROCKET WRENCH

Tightening torque:

78 N

⋅m (8.0 kgf-m, 57.9 ft-lb)

NOTE:

Do not confuse the right and left side cam sprock-

ets during installation. The cam sprocket No. 2 is

identified by a projection used to monitor camshaft

position sensor.

2) Install the cam sprocket No. 2. Use ST to lock

camshaft.

ST 18231AA010 CAM SPROCKET WRENCH

NOTE:

Also the CAM SPROCKET WRENCH (499207100)

can be used.

Tightening torque:

78 N

⋅m (8.0 kgf-m, 57.9 ft-lb)

3) Install the camshaft position sensor.

Sensor.>

4) Install the timing belt assembly.

5) Install the belt cover.

6) Install the crank pulley.

7) Install the V-belt.

ME-00250

ST

ME-00251

ST

ME-00251

ST

ME-00250

ST

Page 925 of 2870

ME(H4SO)-54

MECHANICAL

Cam Sprocket

C: INSPECTION

1) Check the cam sprocket teeth for abnormal wear

and scratches.

2) Make sure there is no free play between cam

sprocket and key.

3) Check the cam sprocket notch for sensor for

damage and contamination of foreign matter.

Page 926 of 2870

ME(H4SO)-55

MECHANICAL

Crank Sprocket

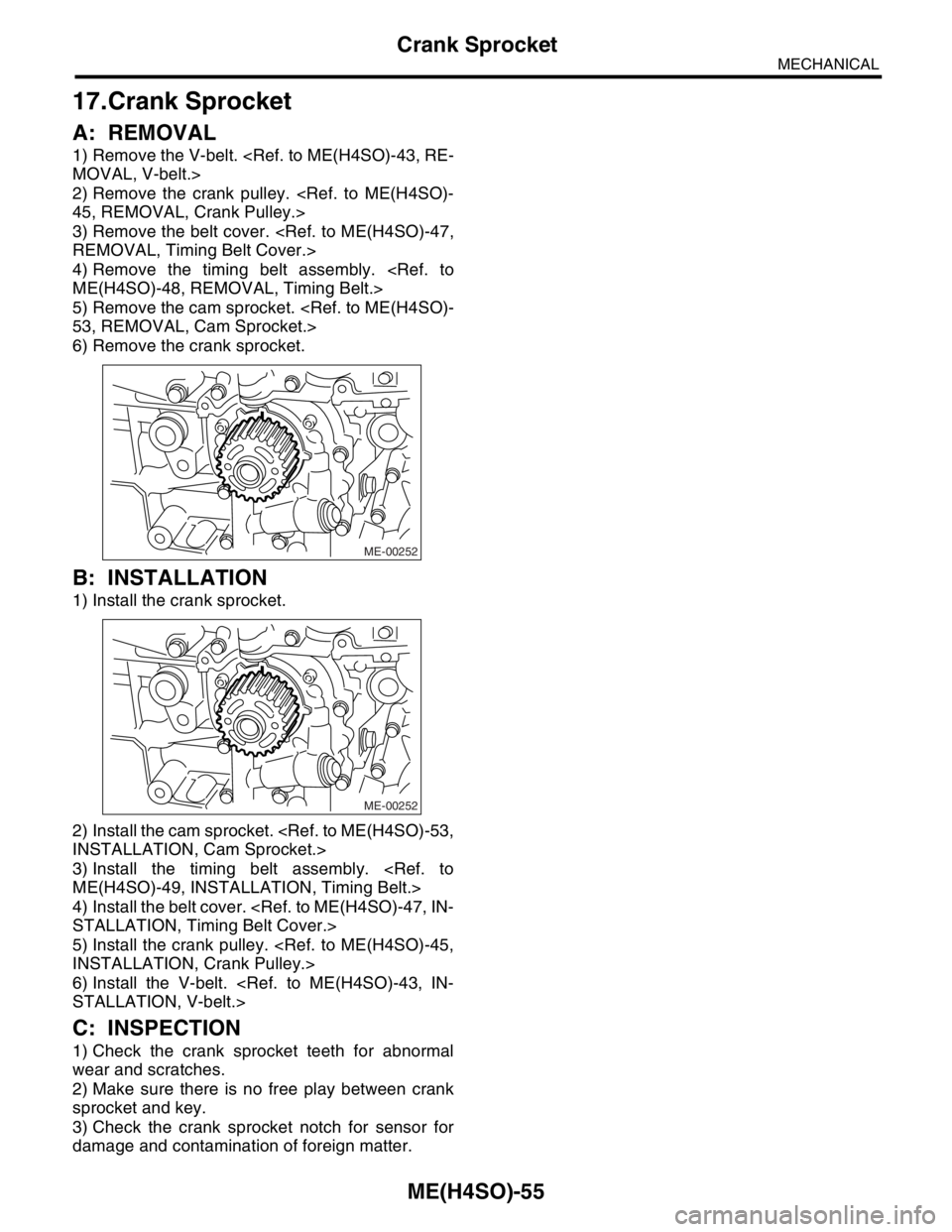

17.Crank Sprocket

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the belt cover.

4) Remove the timing belt assembly.

5) Remove the cam sprocket.

6) Remove the crank sprocket.

B: INSTALLATION

1) Install the crank sprocket.

2) Install the cam sprocket.

3) Install the timing belt assembly.

4) Install the belt cover.

5) Install the crank pulley.

6) Install the V-belt.

C: INSPECTION

1) Check the crank sprocket teeth for abnormal

wear and scratches.

2) Make sure there is no free play between crank

sprocket and key.

3) Check the crank sprocket notch for sensor for

damage and contamination of foreign matter.

ME-00252

ME-00252

Page 927 of 2870

ME(H4SO)-56

MECHANICAL

Valve Rocker Assembly

18.Valve Rocker Assembly

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the belt cover.

4) Remove the timing belt assembly.

5) Remove the cam sprocket.

6) Disconnect the PCV hose and remove rocker

cover.

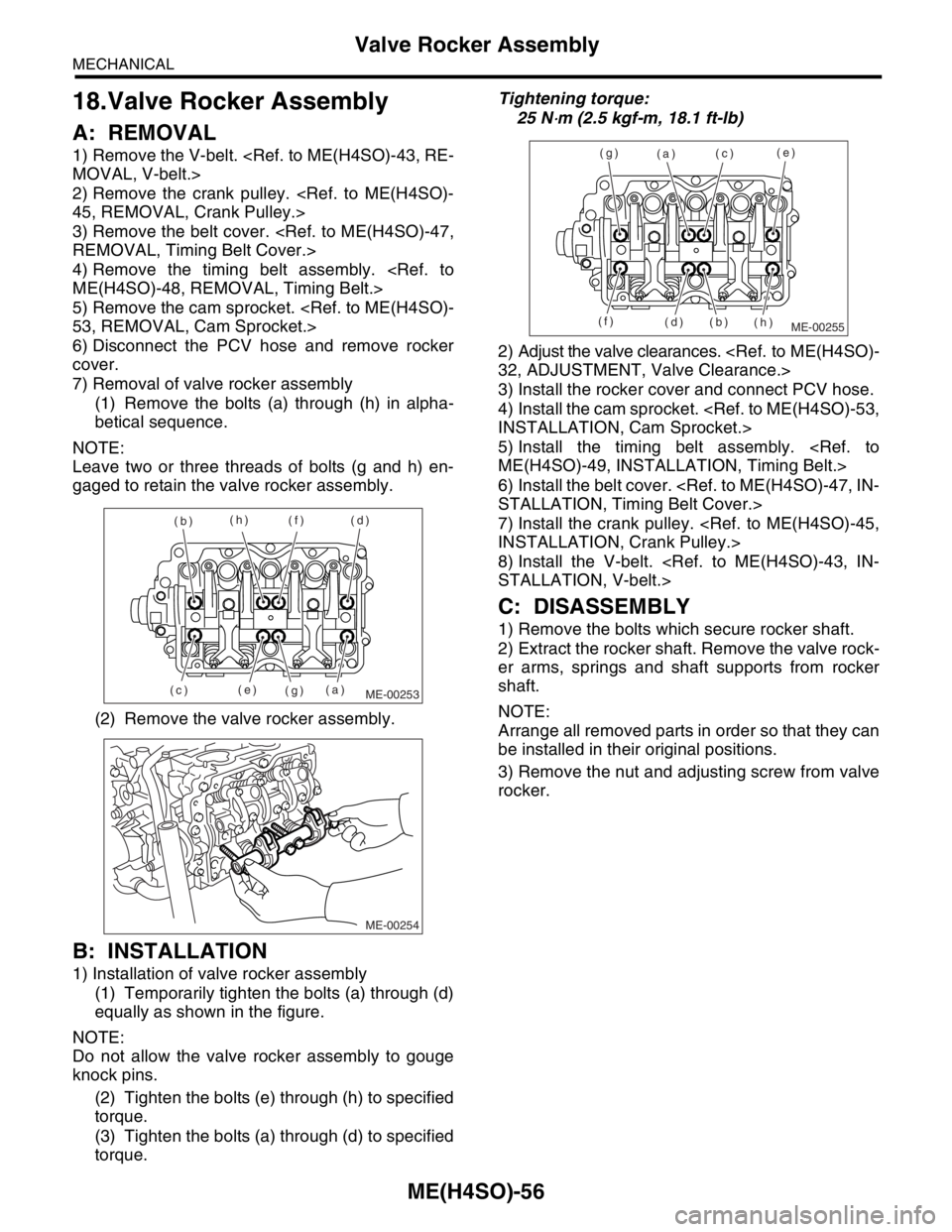

7) Removal of valve rocker assembly

(1) Remove the bolts (a) through (h) in alpha-

betical sequence.

NOTE:

Leave two or three threads of bolts (g and h) en-

gaged to retain the valve rocker assembly.

(2) Remove the valve rocker assembly.

B: INSTALLATION

1) Installation of valve rocker assembly

(1) Temporarily tighten the bolts (a) through (d)

equally as shown in the figure.

NOTE:

Do not allow the valve rocker assembly to gouge

knock pins.

(2) Tighten the bolts (e) through (h) to specified

torque.

(3) Tighten the bolts (a) through (d) to specified

torque.Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

2) Adjust the valve clearances.

3) Install the rocker cover and connect PCV hose.

4) Install the cam sprocket.

5) Install the timing belt assembly.

6) Install the belt cover.

7) Install the crank pulley.

8) Install the V-belt.

C: DISASSEMBLY

1) Remove the bolts which secure rocker shaft.

2) Extract the rocker shaft. Remove the valve rock-

er arms, springs and shaft supports from rocker

shaft.

NOTE:

Arrange all removed parts in order so that they can

be installed in their original positions.

3) Remove the nut and adjusting screw from valve

rocker.

ME-00253(a) (b)

(c)(d)

(e)(f)

(g) (h)

ME-00254

ME-00255

(a)

(b)(c)

(d)(e)

(f)(g)

(h)

Page 928 of 2870

ME(H4SO)-57

MECHANICAL

Valve Rocker Assembly

D: ASSEMBLY

1) Install the adjusting screw and nut to valve rock-

er.

2) Arrange the valve rocker arms, springs and shaft

supports in assembly order and insert valve rocker

shaft.

Tightening torque (Shaft supports installing

bolts):

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

NOTE:

Valve rocker arms, rocker shaft and shaft supports

have identification marks. Ensure the parts with

same markings are properly assembled.

3) Install the valve rocker shaft securing bolts.

E: INSPECTION

1. VALVE ROCKER ARM AND ROCKER

SHAFT

1) Measure the inside diameter of valve rocker arm

and outside diameter of valve rocker shaft, and de-

termine the difference between the two (= oil clear-

ance).

Clearance between arm and shaft:

Standard

0.020 — 0.054 mm (0.0008 — 0.0021 in)

Limit

0.10 mm (0.0039 in)2) If oil clearance exceeds the limit, replace the

valve rocker arm or shaft, whichever shows greater

amount of wear.

Rocker arm inside diameter:

22.020 — 22.041 mm (0.8669 — 0.8678 in)

Rocker shaft diameter:

21.987 — 22.000 mm (0.8656 — 0.8661 in)

3) If cam or valve contact surface of valve rocker

arm is worn or dented excessively, replace the

valve rocker arm.

4) Check that the valve rocker arm roller rotates

smoothly. If not, replace the valve rocker arm.

ME-00256

ME-00257

Page 929 of 2870

ME(H4SO)-58

MECHANICAL

Camshaft

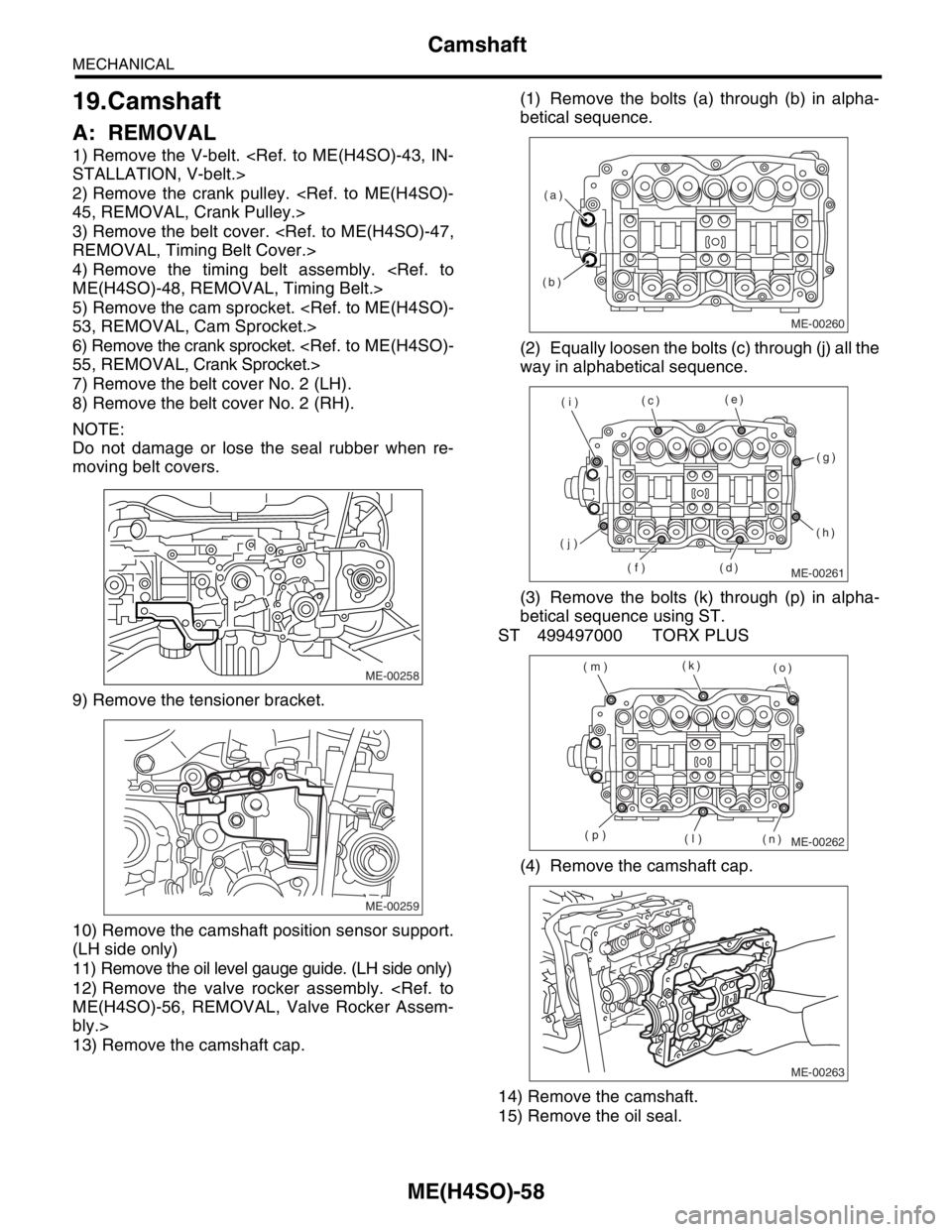

19.Camshaft

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the belt cover.

4) Remove the timing belt assembly.

5) Remove the cam sprocket.

6) Remove the crank sprocket.

7) Remove the belt cover No. 2 (LH).

8) Remove the belt cover No. 2 (RH).

NOTE:

Do not damage or lose the seal rubber when re-

moving belt covers.

9) Remove the tensioner bracket.

10) Remove the camshaft position sensor support.

(LH side only)

11) Remove the oil level gauge guide. (LH side only)

12) Remove the valve rocker assembly.

bly.>

13) Remove the camshaft cap.(1) Remove the bolts (a) through (b) in alpha-

betical sequence.

(2) Equally loosen the bolts (c) through (j) all the

way in alphabetical sequence.

(3) Remove the bolts (k) through (p) in alpha-

betical sequence using ST.

ST 499497000 TORX PLUS

(4) Remove the camshaft cap.

14) Remove the camshaft.

15) Remove the oil seal.

ME-00258

ME-00259

ME-00260

(b)(a)

ME-00261

(c)(e)

(g)

(h)

(d) (f) (j)(i)

ME-00262

(k)

(o)

(n) (l) (p) (m)

ME-00263

Page 930 of 2870

ME(H4SO)-59

MECHANICAL

Camshaft

16) Remove the plug from rear side of camshaft.

CAUTION:

Do not remove the oil seal unless necessary.

Do not scratch the journal surface when re-

moving oil seal.

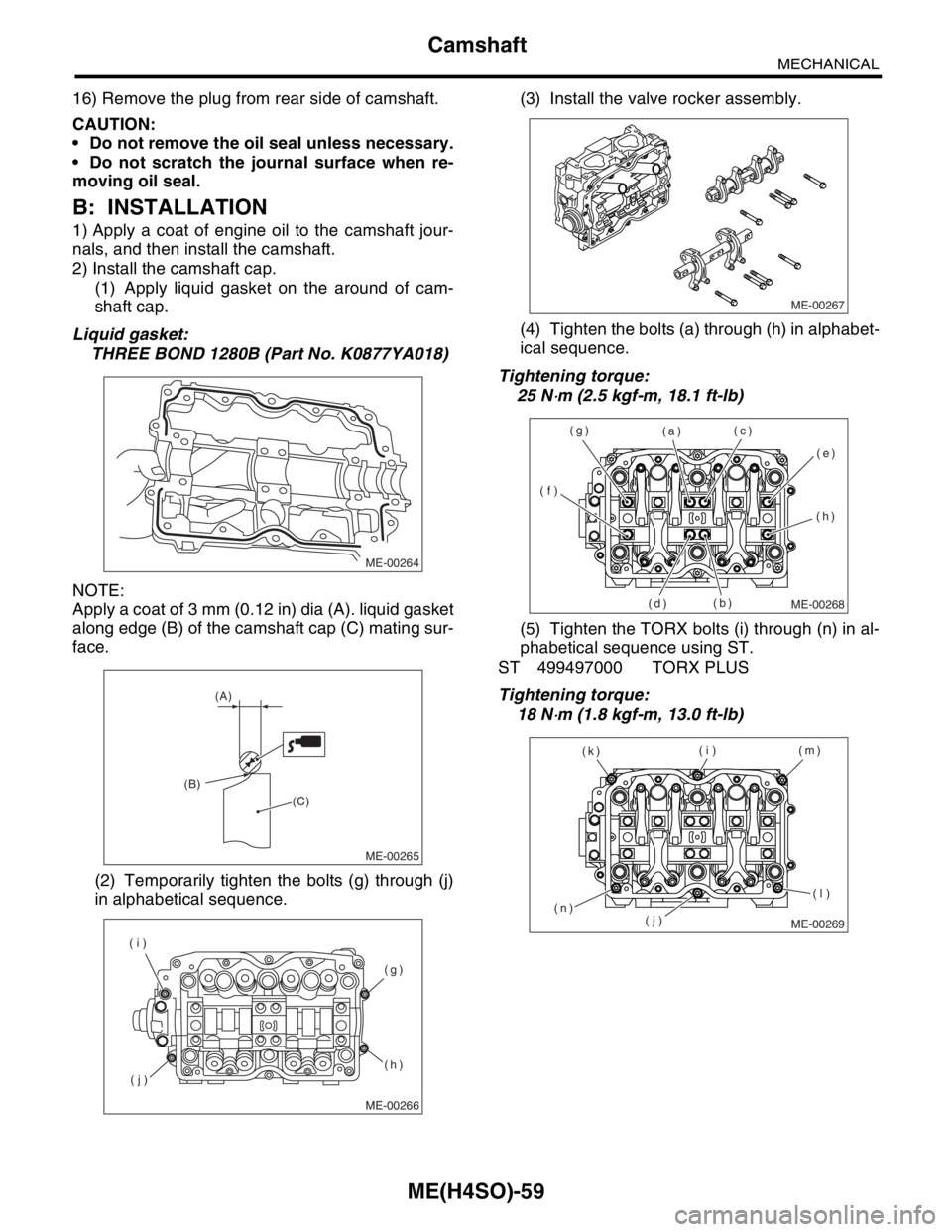

B: INSTALLATION

1) Apply a coat of engine oil to the camshaft jour-

nals, and then install the camshaft.

2) Install the camshaft cap.

(1) Apply liquid gasket on the around of cam-

shaft cap.

Liquid gasket:

THREE BOND 1280B (Part No. K0877YA018)

NOTE:

Apply a coat of 3 mm (0.12 in) dia (A). liquid gasket

along edge (B) of the camshaft cap (C) mating sur-

face.

(2) Temporarily tighten the bolts (g) through (j)

in alphabetical sequence.(3) Install the valve rocker assembly.

(4) Tighten the bolts (a) through (h) in alphabet-

ical sequence.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(5) Tighten the TORX bolts (i) through (n) in al-

phabetical sequence using ST.

ST 499497000 TORX PLUS

Tightening torque:

18 N

⋅m (1.8 kgf-m, 13.0 ft-lb)

ME-00264

ME-00265

(A)

(B)

(C)

ME-00266

(g)

(h)

(j) (i)

ME-00267

ME-00268

(a)

(b)(c)

(d)(e)

(f)(g)

(h)

ME-00269

(i)

(j)(m)

(n)(k)

(l)