SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 931 of 2870

ME(H4SO)-60

MECHANICAL

Camshaft

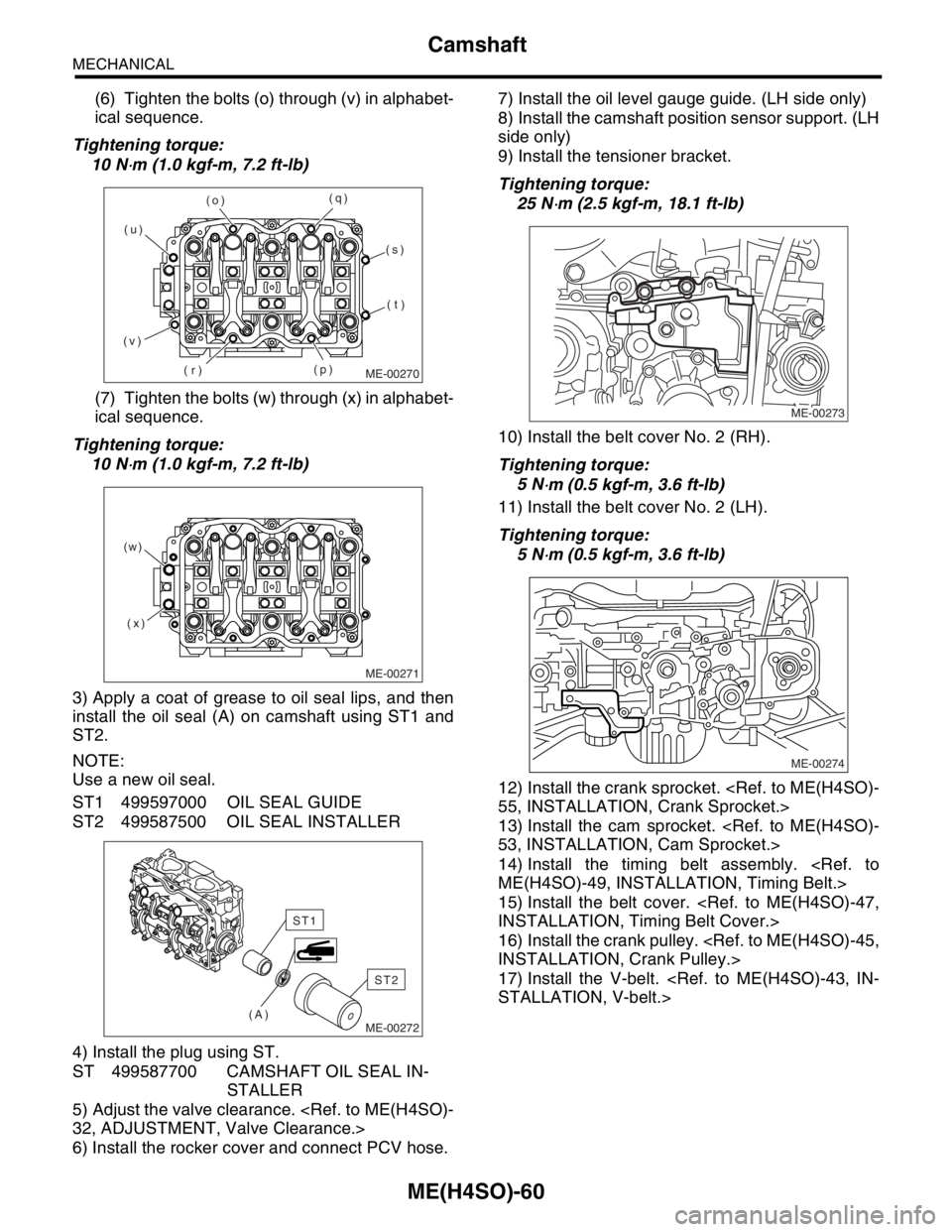

(6) Tighten the bolts (o) through (v) in alphabet-

ical sequence.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

(7) Tighten the bolts (w) through (x) in alphabet-

ical sequence.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

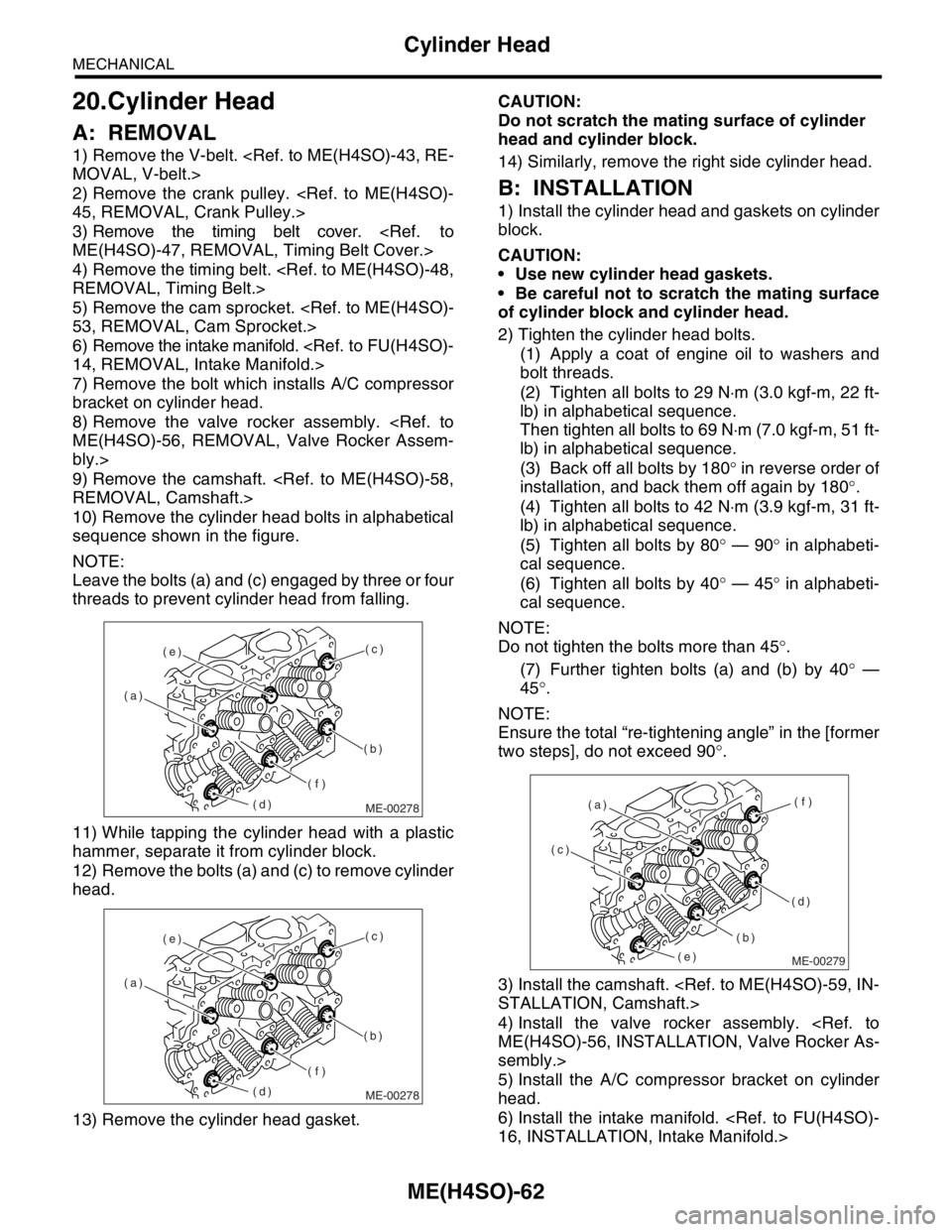

3) Apply a coat of grease to oil seal lips, and then

install the oil seal (A) on camshaft using ST1 and

ST2.

NOTE:

Use a new oil seal.

ST1 499597000 OIL SEAL GUIDE

ST2 499587500 OIL SEAL INSTALLER

4) Install the plug using ST.

ST 499587700 CAMSHAFT OIL SEAL IN-

STALLER

5) Adjust the valve clearance.

6) Install the rocker cover and connect PCV hose.7) Install the oil level gauge guide. (LH side only)

8) Install the camshaft position sensor support. (LH

side only)

9) Install the tensioner bracket.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

10) Install the belt cover No. 2 (RH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

11) Install the belt cover No. 2 (LH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

12) Install the crank sprocket.

13) Install the cam sprocket.

14) Install the timing belt assembly.

15) Install the belt cover.

16) Install the crank pulley.

17) Install the V-belt.

ME-00270

(o)

(r)(q)

(v)(u)

(p)(s)

(t)

ME-00271

(x) (w)

ME-00272(A)

ST2

ST1

ME-00273

ME-00274

Page 932 of 2870

ME(H4SO)-61

MECHANICAL

Camshaft

C: INSPECTION

1. CAMSHAFT

1) Measure the bend, and repair or replace if nec-

essary.

Limit:

0.025 mm (0.0010 in)

2) Check the journal for damage and wear. Re-

place if faulty.

3) Measure the outside diameter of camshaft jour-

nal and inside diameter of cylinder head journal,

and determine the difference between two (= oil

clearance). If the oil clearance exceeds specifica-

tions, replace the camshaft or cylinder head as

necessary.

4) Check the cam face condition; remove the minor

faults by grinding with oil stone. Measure the cam

height H; replace if the limit has been exceeded.

Cam height: HCam base circle diameter A:

IN: 34.00 mm (1.3386 in)

EX: 34.00 mm (1.3386 in)

2. CAMSHAFT SUPPORT

Measure the thrust clearance of camshaft with dial

gauge. If the clearance exceeds the limit, replace

the camshaft support.

Standard:

0.030 — 0.090 mm (0.0012 — 0.0035 in)

Limit:

0.10 mm (0.0039 in)

Unit: mm (in)

Clear-

ance at

journalStandard 0.055 — 0.090 (0.0022 — 0.0035)

Limit 0.10 (0.0039)

Camshaft journal O.D.31.928 — 31.945 (1.2570 —

1.2577)

Journal hole I.D.32.000 — 32.018 (1.2598 —

1.2605)

Model Item Unit: mm (in)

2.0 LIntakeSTD38.732 — 38.832

(1.5249 — 1.528885)

Limit 38.632 (1.5209)

ExhaustSTD39.259 — 39.359

(1.5456 — 1.5496)

Limit 39.157 (1.5416)

2.5 LIntakeSTD39.485 — 39.585

(1.5545 — 1.5585)

Limit 39.385 (1.5506)

ExhaustSTD39.259 — 39.359

(1.5456 — 1.5496)

Limit 39.157 (1.5416)

ME-00275

ME-00276

H

A

ME-00277

Page 933 of 2870

ME(H4SO)-62

MECHANICAL

Cylinder Head

20.Cylinder Head

A: REMOVAL

1) Remove the V-belt.

2) Remove the crank pulley.

3) Remove the timing belt cover.

4) Remove the timing belt.

5) Remove the cam sprocket.

6) Remove the intake manifold.

7) Remove the bolt which installs A/C compressor

bracket on cylinder head.

8) Remove the valve rocker assembly.

bly.>

9) Remove the camshaft.

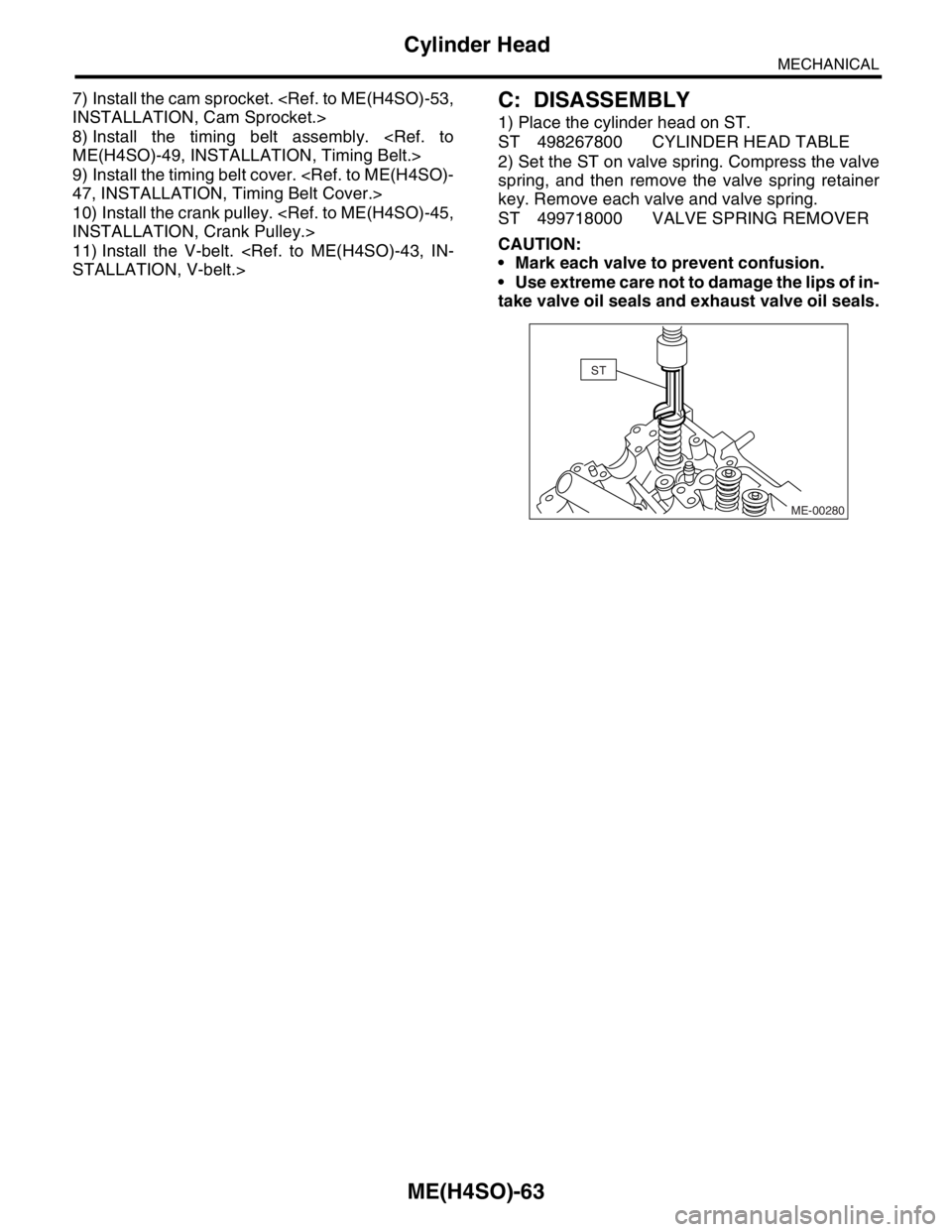

10) Remove the cylinder head bolts in alphabetical

sequence shown in the figure.

NOTE:

Leave the bolts (a) and (c) engaged by three or four

threads to prevent cylinder head from falling.

11) While tapping the cylinder head with a plastic

hammer, separate it from cylinder block.

12) Remove the bolts (a) and (c) to remove cylinder

head.

13) Remove the cylinder head gasket.CAUTION:

Do not scratch the mating surface of cylinder

head and cylinder block.

14) Similarly, remove the right side cylinder head.

B: INSTALLATION

1) Install the cylinder head and gaskets on cylinder

block.

CAUTION:

Use new cylinder head gaskets.

Be careful not to scratch the mating surface

of cylinder block and cylinder head.

2) Tighten the cylinder head bolts.

(1) Apply a coat of engine oil to washers and

bolt threads.

(2) Tighten all bolts to 29 N⋅m (3.0 kgf-m, 22 ft-

lb) in alphabetical sequence.

Then tighten all bolts to 69 N⋅m (7.0 kgf-m, 51 ft-

lb) in alphabetical sequence.

(3) Back off all bolts by 180° in reverse order of

installation, and back them off again by 180°.

(4) Tighten all bolts to 42 N⋅m (3.9 kgf-m, 31 ft-

lb) in alphabetical sequence.

(5) Tighten all bolts by 80° — 90° in alphabeti-

cal sequence.

(6) Tighten all bolts by 40° — 45° in alphabeti-

cal sequence.

NOTE:

Do not tighten the bolts more than 45°.

(7) Further tighten bolts (a) and (b) by 40° —

45°.

NOTE:

Ensure the total “re-tightening angle” in the [former

two steps], do not exceed 90°.

3) Install the camshaft.

4) Install the valve rocker assembly.

sembly.>

5) Install the A/C compressor bracket on cylinder

head.

6) Install the intake manifold.

ME-00278

(c)

(b)

(f)

(d) (a)(e)

ME-00278

(c)

(b)

(f)

(d) (a)(e)

ME-00279

(c)

(b)(f)

(d) (a)

(e)

Page 934 of 2870

ME(H4SO)-63

MECHANICAL

Cylinder Head

7) Install the cam sprocket.

8) Install the timing belt assembly.

9) Install the timing belt cover.

10) Install the crank pulley.

11) Install the V-belt.

1) Place the cylinder head on ST.

ST 498267800 CYLINDER HEAD TABLE

2) Set the ST on valve spring. Compress the valve

spring, and then remove the valve spring retainer

key. Remove each valve and valve spring.

ST 499718000 VALVE SPRING REMOVER

CAUTION:

Mark each valve to prevent confusion.

Use extreme care not to damage the lips of in-

take valve oil seals and exhaust valve oil seals.

ME-00280

ST

Page 935 of 2870

ME(H4SO)-64

MECHANICAL

Cylinder Head

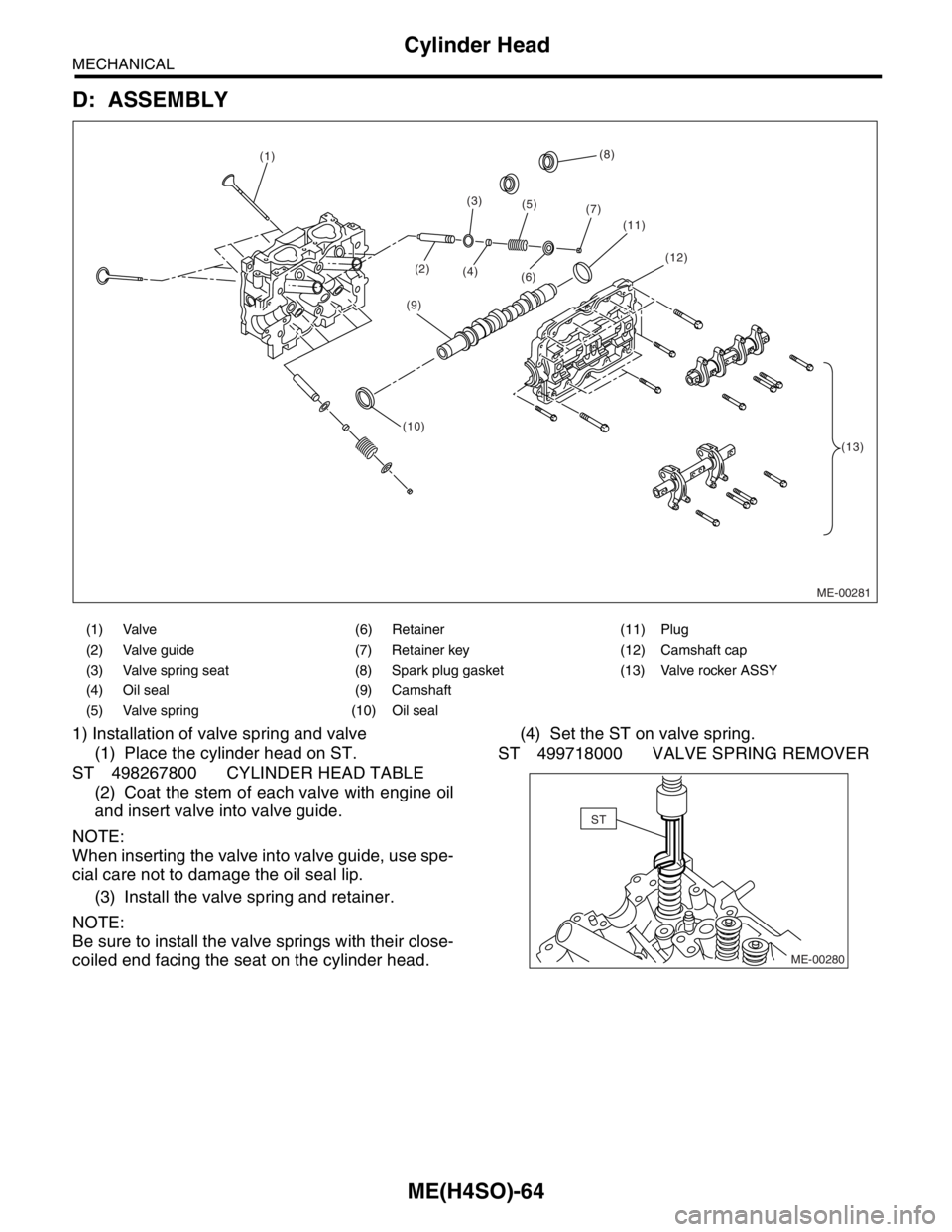

D: ASSEMBLY

1) Installation of valve spring and valve

(1) Place the cylinder head on ST.

ST 498267800 CYLINDER HEAD TABLE

(2) Coat the stem of each valve with engine oil

and insert valve into valve guide.

NOTE:

When inserting the valve into valve guide, use spe-

cial care not to damage the oil seal lip.

(3) Install the valve spring and retainer.

NOTE:

Be sure to install the valve springs with their close-

coiled end facing the seat on the cylinder head.(4) Set the ST on valve spring.

ST 499718000 VALVE SPRING REMOVER

(1) Valve (6) Retainer (11) Plug

(2) Valve guide (7) Retainer key (12) Camshaft cap

(3) Valve spring seat (8) Spark plug gasket (13) Valve rocker ASSY

(4) Oil seal (9) Camshaft

(5) Valve spring (10) Oil seal

ME-00281 (10)(9)(6) (1)

(2)(3)

(4)(5)

(7)(8)

(11)

(13) (12)

ME-00280

ST

Page 936 of 2870

ME(H4SO)-65

MECHANICAL

Cylinder Head

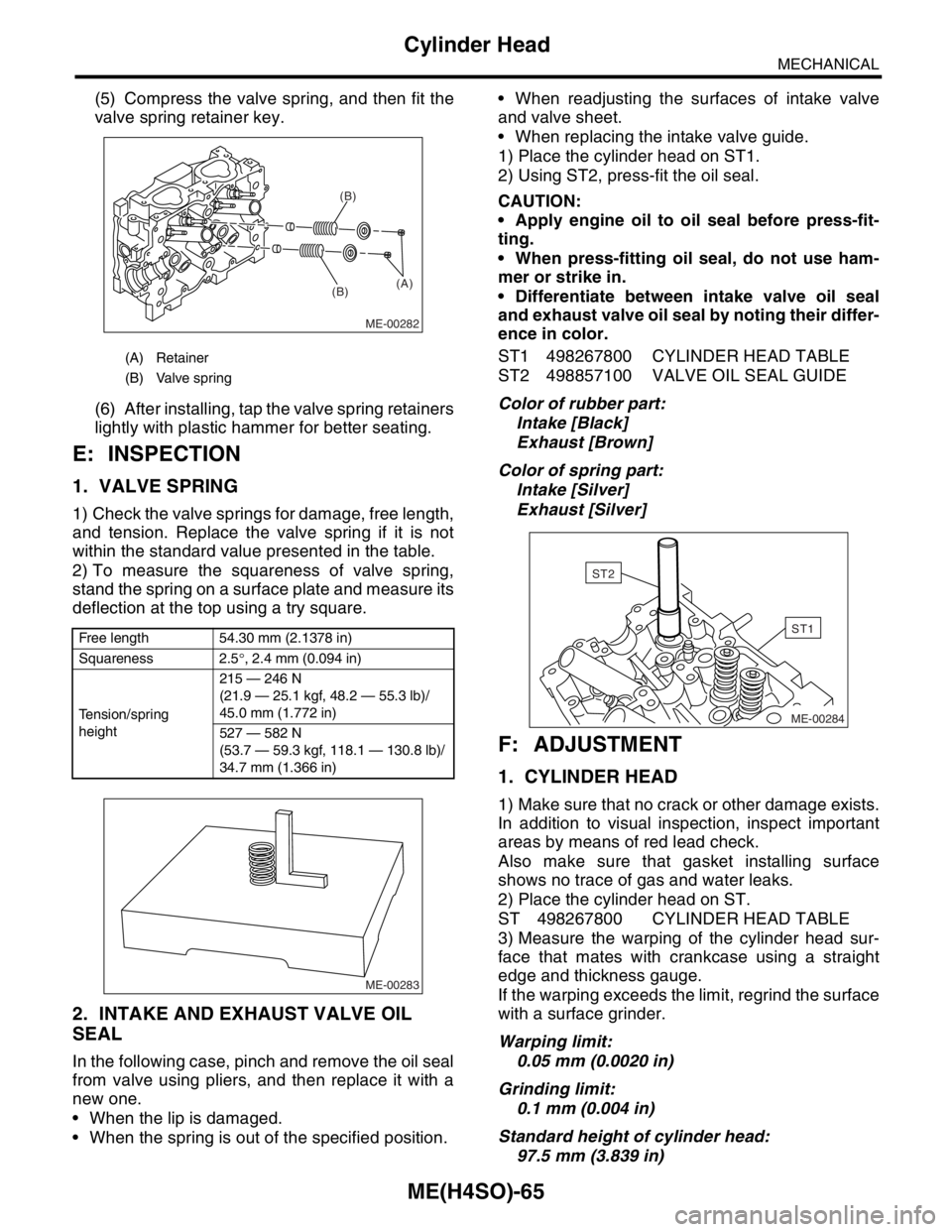

(5) Compress the valve spring, and then fit the

valve spring retainer key.

(6) After installing, tap the valve spring retainers

lightly with plastic hammer for better seating.

E: INSPECTION

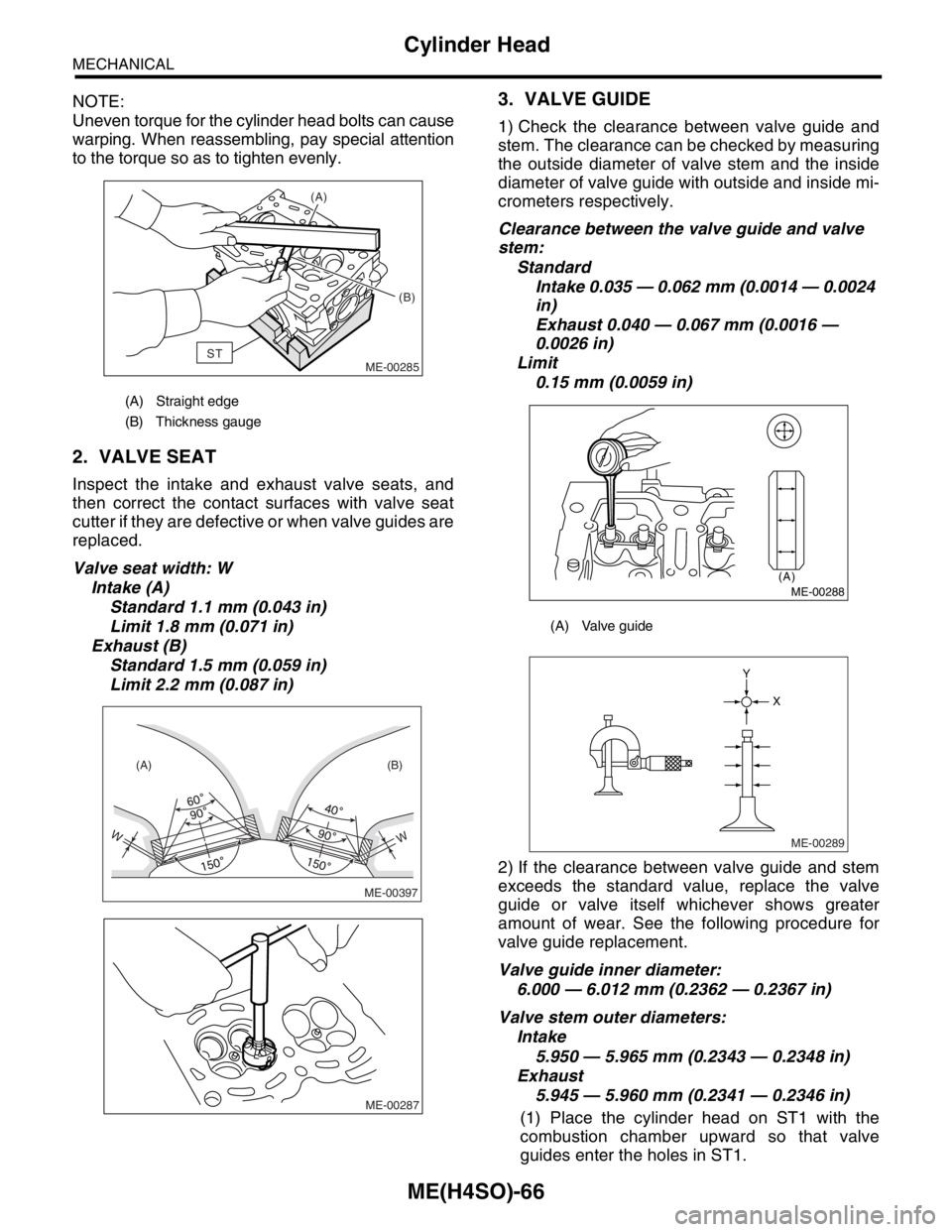

1. VALVE SPRING

1) Check the valve springs for damage, free length,

and tension. Replace the valve spring if it is not

within the standard value presented in the table.

2) To measure the squareness of valve spring,

stand the spring on a surface plate and measure its

deflection at the top using a try square.

2. INTAKE AND EXHAUST VALVE OIL

SEAL

In the following case, pinch and remove the oil seal

from valve using pliers, and then replace it with a

new one.

When the lip is damaged.

When the spring is out of the specified position. When readjusting the surfaces of intake valve

and valve sheet.

When replacing the intake valve guide.

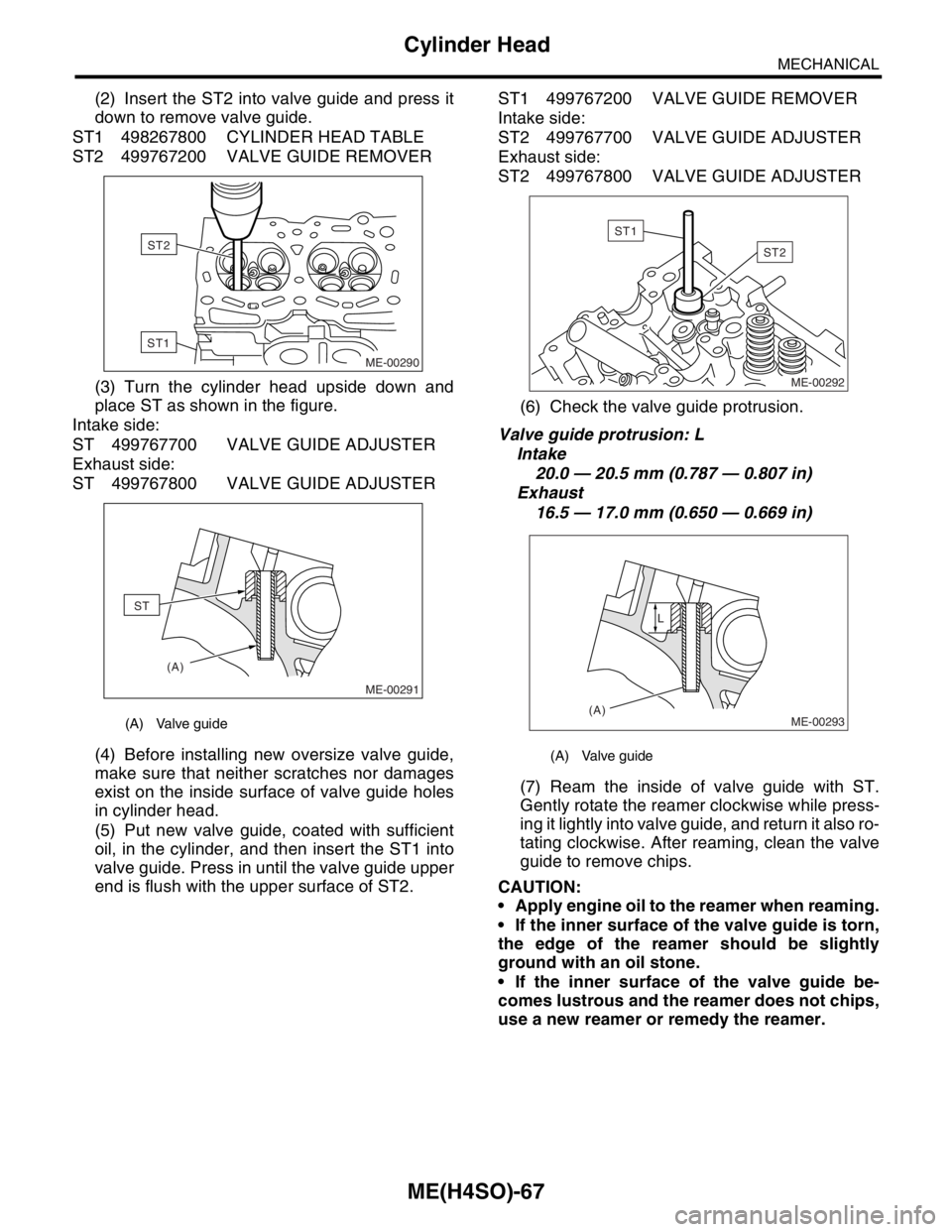

1) Place the cylinder head on ST1.

2) Using ST2, press-fit the oil seal.

CAUTION:

Apply engine oil to oil seal before press-fit-

ting.

When press-fitting oil seal, do not use ham-

mer or strike in.

Differentiate between intake valve oil seal

and exhaust valve oil seal by noting their differ-

ence in color.

ST1 498267800 CYLINDER HEAD TABLE

ST2 498857100 VALVE OIL SEAL GUIDE

Color of rubber part:

Intake [Black]

Exhaust [Brown]

Color of spring part:

Intake [Silver]

Exhaust [Silver]

F: ADJUSTMENT

1. CYLINDER HEAD

1) Make sure that no crack or other damage exists.

In addition to visual inspection, inspect important

areas by means of red lead check.

Also make sure that gasket installing surface

shows no trace of gas and water leaks.

2) Place the cylinder head on ST.

ST 498267800 CYLINDER HEAD TABLE

3) Measure the warping of the cylinder head sur-

face that mates with crankcase using a straight

edge and thickness gauge.

If the warping exceeds the limit, regrind the surface

with a surface grinder.

Warping limit:

0.05 mm (0.0020 in)

Grinding limit:

0.1 mm (0.004 in)

Standard height of cylinder head:

97.5 mm (3.839 in)

(A) Retainer

(B) Valve spring

Free length 54.30 mm (2.1378 in)

Squareness 2.5°, 2.4 mm (0.094 in)

Tension/spring

height215 — 246 N

(21.9 — 25.1 kgf, 48.2 — 55.3 lb)/

45.0 mm (1.772 in)

527 — 582 N

(53.7 — 59.3 kgf, 118.1 — 130.8 lb)/

34.7 mm (1.366 in)

ME-00282

(B)(B)

(A)

ME-00283

ME-00284

ST1

ST2

Page 937 of 2870

ME(H4SO)-66

MECHANICAL

Cylinder Head

NOTE:

Uneven torque for the cylinder head bolts can cause

warping. When reassembling, pay special attention

to the torque so as to tighten evenly.

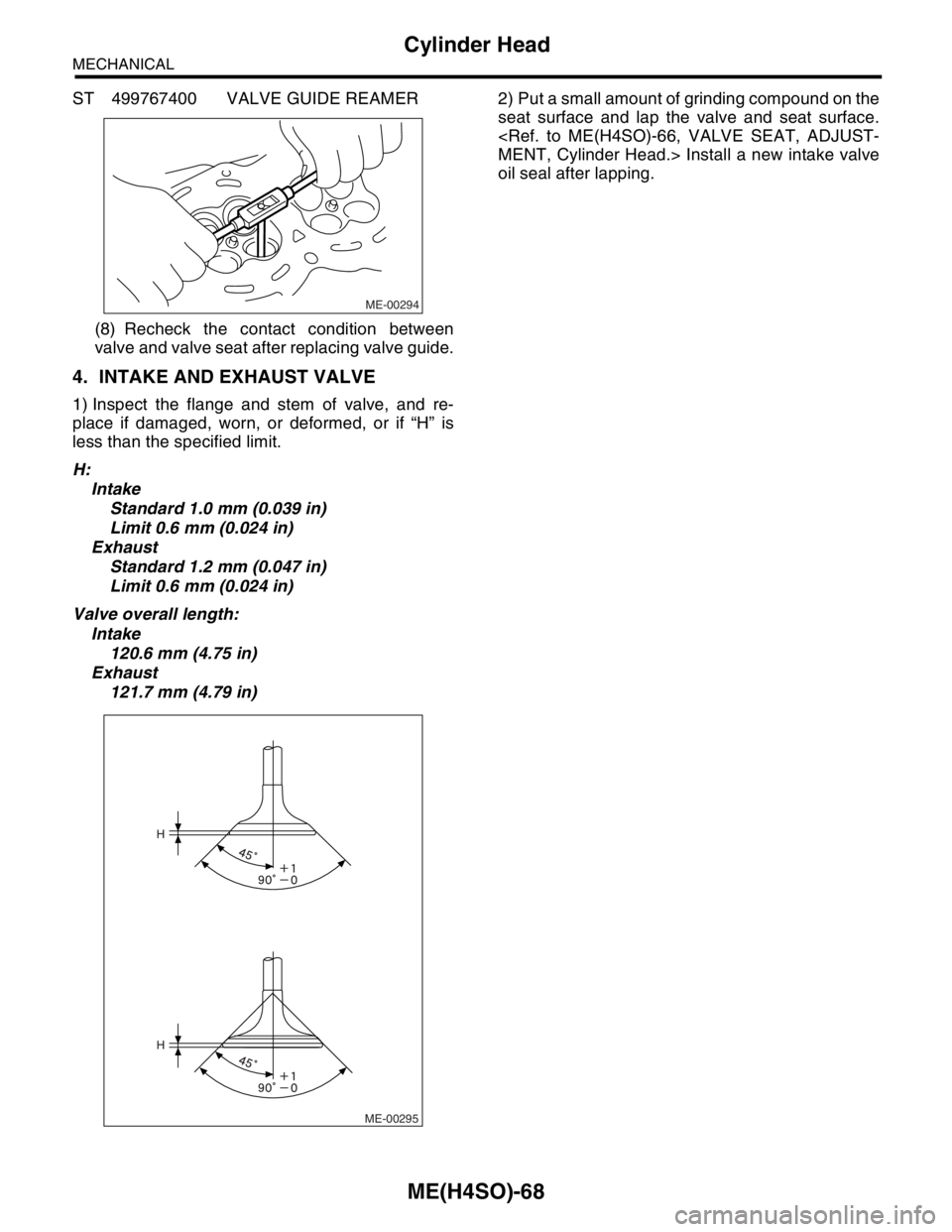

2. VALVE SEAT

Inspect the intake and exhaust valve seats, and

then correct the contact surfaces with valve seat

cutter if they are defective or when valve guides are

replaced.

Valve seat width: W

Intake (A)

Standard 1.1 mm (0.043 in)

Limit 1.8 mm (0.071 in)

Exhaust (B)

Standard 1.5 mm (0.059 in)

Limit 2.2 mm (0.087 in)

3. VALVE GUIDE

1) Check the clearance between valve guide and

stem. The clearance can be checked by measuring

the outside diameter of valve stem and the inside

diameter of valve guide with outside and inside mi-

crometers respectively.

Clearance between the valve guide and valve

stem:

Standard

Intake 0.035 — 0.062 mm (0.0014 — 0.0024

in)

Exhaust 0.040 — 0.067 mm (0.0016 —

0.0026 in)

Limit

0.15 mm (0.0059 in)

2) If the clearance between valve guide and stem

exceeds the standard value, replace the valve

guide or valve itself whichever shows greater

amount of wear. See the following procedure for

valve guide replacement.

Valve guide inner diameter:

6.000 — 6.012 mm (0.2362 — 0.2367 in)

Valve stem outer diameters:

Intake

5.950 — 5.965 mm (0.2343 — 0.2348 in)

Exhaust

5.945 — 5.960 mm (0.2341 — 0.2346 in)

(1) Place the cylinder head on ST1 with the

combustion chamber upward so that valve

guides enter the holes in ST1.

(A) Straight edge

(B) Thickness gauge

ST(A)

(B)

ME-00285

WW

(A) (B)

ME-00397

ME-00287

(A) Valve guide

(A)

ME-00288

ME-00289

X Y

Page 938 of 2870

ME(H4SO)-67

MECHANICAL

Cylinder Head

(2) Insert the ST2 into valve guide and press it

down to remove valve guide.

ST1 498267800 CYLINDER HEAD TABLE

ST2 499767200 VALVE GUIDE REMOVER

(3) Turn the cylinder head upside down and

place ST as shown in the figure.

Intake side:

ST 499767700 VALVE GUIDE ADJUSTER

Exhaust side:

ST 499767800 VALVE GUIDE ADJUSTER

(4) Before installing new oversize valve guide,

make sure that neither scratches nor damages

exist on the inside surface of valve guide holes

in cylinder head.

(5) Put new valve guide, coated with sufficient

oil, in the cylinder, and then insert the ST1 into

valve guide. Press in until the valve guide upper

end is flush with the upper surface of ST2.ST1 499767200 VALVE GUIDE REMOVER

Intake side:

ST2 499767700 VALVE GUIDE ADJUSTER

Exhaust side:

ST2 499767800 VALVE GUIDE ADJUSTER

(6) Check the valve guide protrusion.

Valve guide protrusion: L

Intake

20.0 — 20.5 mm (0.787 — 0.807 in)

Exhaust

16.5 — 17.0 mm (0.650 — 0.669 in)

(7) Ream the inside of valve guide with ST.

Gently rotate the reamer clockwise while press-

ing it lightly into valve guide, and return it also ro-

tating clockwise. After reaming, clean the valve

guide to remove chips.

CAUTION:

Apply engine oil to the reamer when reaming.

If the inner surface of the valve guide is torn,

the edge of the reamer should be slightly

ground with an oil stone.

If the inner surface of the valve guide be-

comes lustrous and the reamer does not chips,

use a new reamer or remedy the reamer.

(A) Valve guide

ME-00290

ST2

ST1

(A)

ME-00291

ST

(A) Valve guide

ST2

ME-00292

ST1

ME-00293(A)L

Page 939 of 2870

ME(H4SO)-68

MECHANICAL

Cylinder Head

ST 499767400 VALVE GUIDE REAMER

(8) Recheck the contact condition between

valve and valve seat after replacing valve guide.

4. INTAKE AND EXHAUST VALVE

1) Inspect the flange and stem of valve, and re-

place if damaged, worn, or deformed, or if “H” is

less than the specified limit.

H:

Intake

Standard 1.0 mm (0.039 in)

Limit 0.6 mm (0.024 in)

Exhaust

Standard 1.2 mm (0.047 in)

Limit 0.6 mm (0.024 in)

Valve overall length:

Intake

120.6 mm (4.75 in)

Exhaust

121.7 mm (4.79 in)2) Put a small amount of grinding compound on the

seat surface and lap the valve and seat surface.

oil seal after lapping.

ME-00294

ME-00295

H

H

Page 940 of 2870

ME(H4SO)-69

MECHANICAL

Cylinder Block

21.Cylinder Block

A: REMOVAL

NOTE:

Before conducting this procedure, drain the engine

oil completely.

1) Remove the intake manifold.

2) Remove the V-belt.

3) Remove the crank pulley.

4) Remove the timing belt cover.

5) Remove the timing belt.

6) Remove the cam sprocket.

7) Remove the crank sprocket.

8) Remove the generator and A/C compressor with

their brackets.

9) Remove the rocker cover.

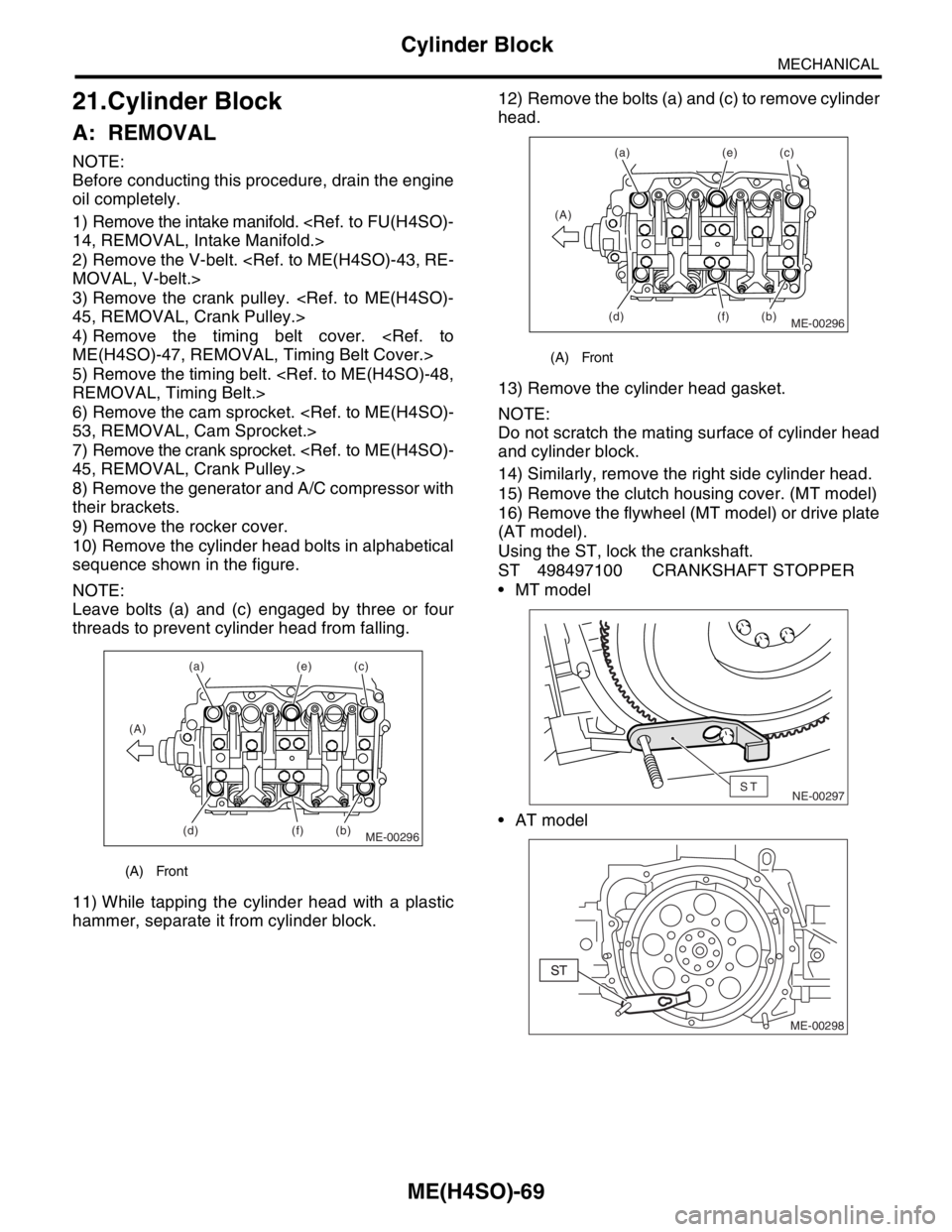

10) Remove the cylinder head bolts in alphabetical

sequence shown in the figure.

NOTE:

Leave bolts (a) and (c) engaged by three or four

threads to prevent cylinder head from falling.

11) While tapping the cylinder head with a plastic

hammer, separate it from cylinder block.12) Remove the bolts (a) and (c) to remove cylinder

head.

13) Remove the cylinder head gasket.

NOTE:

Do not scratch the mating surface of cylinder head

and cylinder block.

14) Similarly, remove the right side cylinder head.

15) Remove the clutch housing cover. (MT model)

16) Remove the flywheel (MT model) or drive plate

(AT model).

Using the ST, lock the crankshaft.

ST 498497100 CRANKSHAFT STOPPER

MT model

AT model

(A) Front

ME-00296

(a)

(b)(c) (e)

(f) (A)

(d)

(A) Front

ME-00296

(a)

(b)(c) (e)

(f) (A)

(d)

NE-00297ST

ME-00298