SUBARU FORESTER 2004 Service Repair Manual

Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 941 of 2870

ME(H4SO)-70

MECHANICAL

Cylinder Block

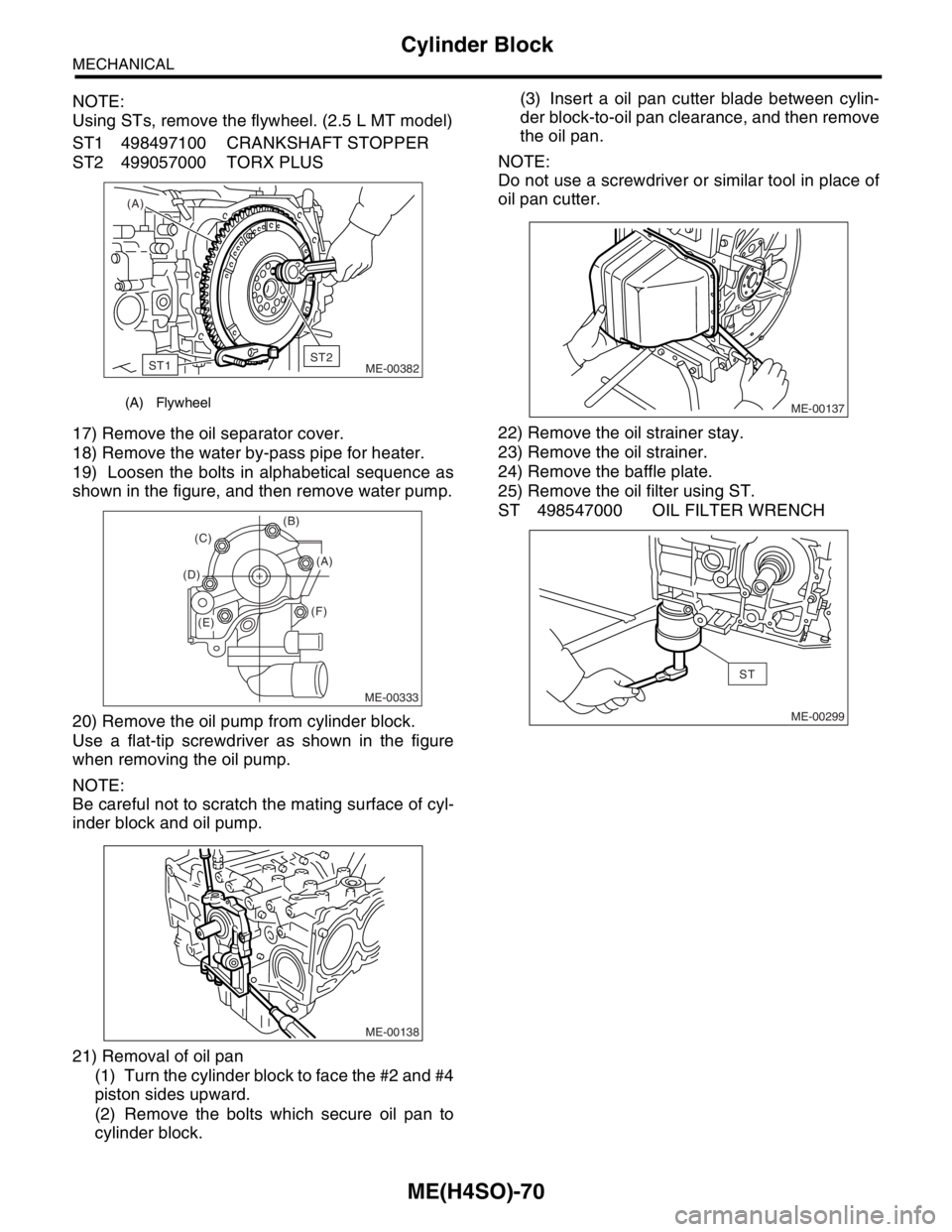

NOTE:

Using STs, remove the flywheel. (2.5 L MT model)

ST1 498497100 CRANKSHAFT STOPPER

ST2 499057000 TORX PLUS

17) Remove the oil separator cover.

18) Remove the water by-pass pipe for heater.

19) Loosen the bolts in alphabetical sequence as

shown in the figure, and then remove water pump.

20) Remove the oil pump from cylinder block.

Use a flat-tip screwdriver as shown in the figure

when removing the oil pump.

NOTE:

Be careful not to scratch the mating surface of cyl-

inder block and oil pump.

21) Removal of oil pan

(1) Turn the cylinder block to face the #2 and #4

piston sides upward.

(2) Remove the bolts which secure oil pan to

cylinder block.(3) Insert a oil pan cutter blade between cylin-

der block-to-oil pan clearance, and then remove

the oil pan.

NOTE:

Do not use a screwdriver or similar tool in place of

oil pan cutter.

22) Remove the oil strainer stay.

23) Remove the oil strainer.

24) Remove the baffle plate.

25) Remove the oil filter using ST.

ST 498547000 OIL FILTER WRENCH

(A) Flywheel

(A)

ME-00382

ST1ST2

ME-00333

(B)

(F) (D)(C)

(A)

(E)

ME-00138

ME-00137

ME-00299

ST

Page 942 of 2870

![SUBARU FORESTER 2004 Service Repair Manual ME(H4SO)-71

MECHANICAL

Cylinder Block

26) Remove the water pipe.

27) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].28) Rotate the crankshaft to bring #1 a SUBARU FORESTER 2004 Service Repair Manual ME(H4SO)-71

MECHANICAL

Cylinder Block

26) Remove the water pipe.

27) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].28) Rotate the crankshaft to bring #1 a](/img/17/57426/w960_57426-941.png)

ME(H4SO)-71

MECHANICAL

Cylinder Block

26) Remove the water pipe.

27) Remove the service hole cover and service

hole plugs using hexagon wrench [14 mm (0.55

in)].28) Rotate the crankshaft to bring #1 and #2 pis-

tons to bottom dead center position, and then re-

move the piston snap ring through service hole of

#1 and #2 cylinders using needle nose plier.

ME-00300

(1) Service hole plug (3) Snap ring (5) Service hole cover

(2) Gasket (4) Piston pin (6) O-ring

ME-00139

(3)

(4) (2)(1)

(3)

(4)

(5)

(6)

(2)(3)

(2)

(1)(3)(4)

(4)

(1)

ME-00140

ME-00141

Page 943 of 2870

ME(H4SO)-72

MECHANICAL

Cylinder Block

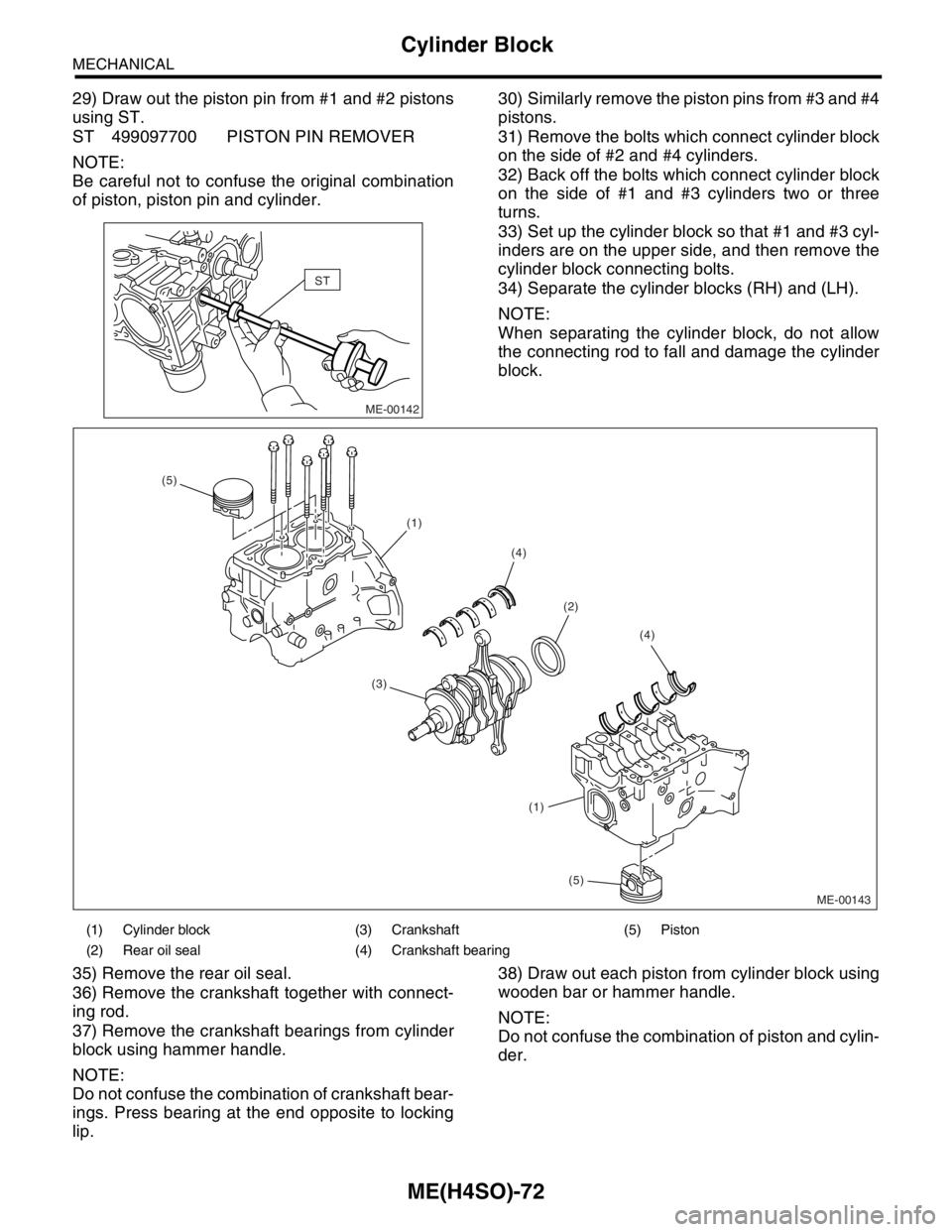

29) Draw out the piston pin from #1 and #2 pistons

using ST.

ST 499097700 PISTON PIN REMOVER

NOTE:

Be careful not to confuse the original combination

of piston, piston pin and cylinder.30) Similarly remove the piston pins from #3 and #4

pistons.

31) Remove the bolts which connect cylinder block

on the side of #2 and #4 cylinders.

32) Back off the bolts which connect cylinder block

on the side of #1 and #3 cylinders two or three

turns.

33) Set up the cylinder block so that #1 and #3 cyl-

inders are on the upper side, and then remove the

cylinder block connecting bolts.

34) Separate the cylinder blocks (RH) and (LH).

NOTE:

When separating the cylinder block, do not allow

the connecting rod to fall and damage the cylinder

block.

35) Remove the rear oil seal.

36) Remove the crankshaft together with connect-

ing rod.

37) Remove the crankshaft bearings from cylinder

block using hammer handle.

NOTE:

Do not confuse the combination of crankshaft bear-

ings. Press bearing at the end opposite to locking

lip.38) Draw out each piston from cylinder block using

wooden bar or hammer handle.

NOTE:

Do not confuse the combination of piston and cylin-

der.

ME-00142

ST

(1) Cylinder block (3) Crankshaft (5) Piston

(2) Rear oil seal (4) Crankshaft bearing

ME-00143

(2)

(3)(4)

(4) (5)

(5) (1) (1)

Page 944 of 2870

ME(H4SO)-73

MECHANICAL

Cylinder Block

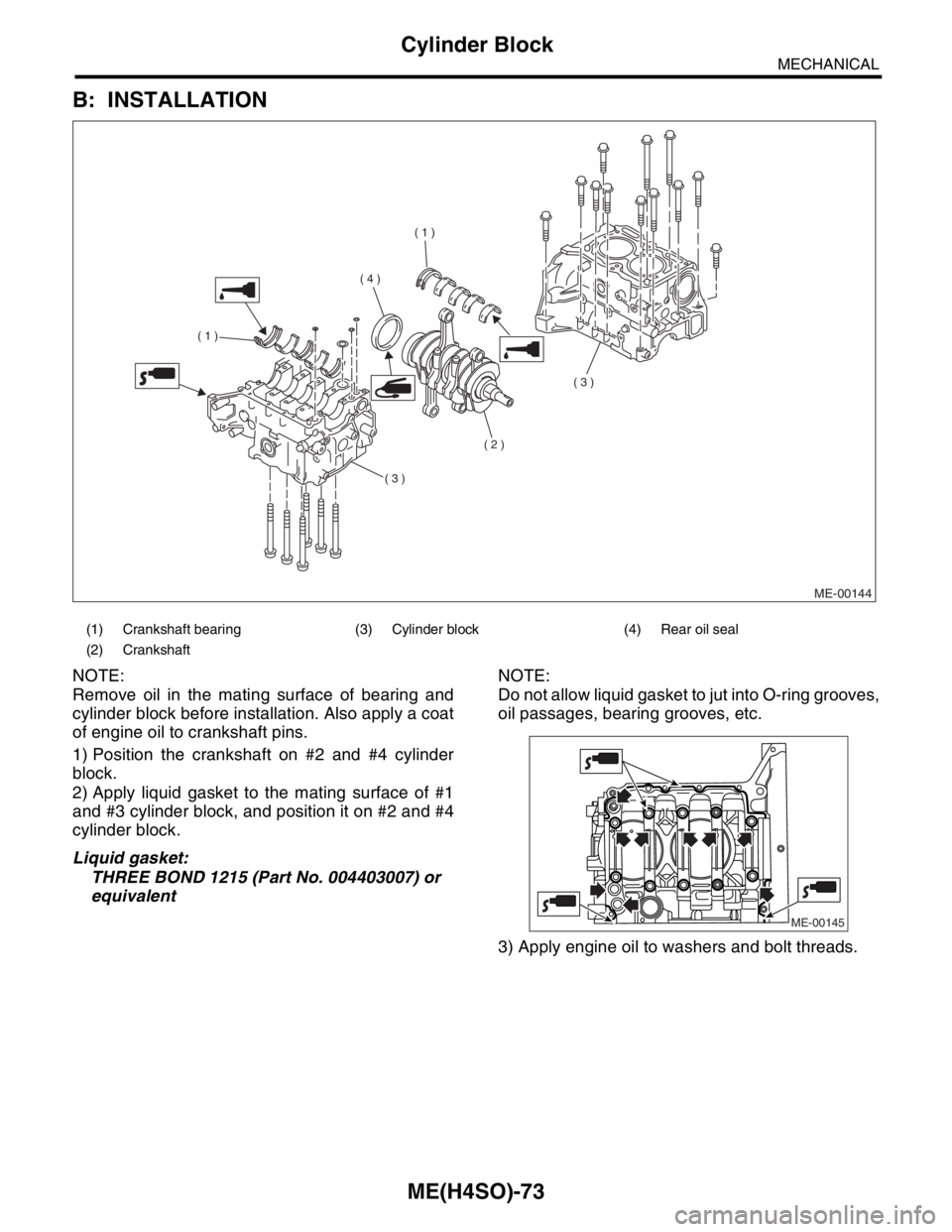

B: INSTALLATION

NOTE:

Remove oil in the mating surface of bearing and

cylinder block before installation. Also apply a coat

of engine oil to crankshaft pins.

1) Position the crankshaft on #2 and #4 cylinder

block.

2) Apply liquid gasket to the mating surface of #1

and #3 cylinder block, and position it on #2 and #4

cylinder block.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007) or

equivalentNOTE:

Do not allow liquid gasket to jut into O-ring grooves,

oil passages, bearing grooves, etc.

3) Apply engine oil to washers and bolt threads.

(1) Crankshaft bearing (3) Cylinder block (4) Rear oil seal

(2) Crankshaft

ME-00144

( 1 )

( 1 )

( 2 )

( 3 )

( 3 )

( 4 )

ME-00145

Page 945 of 2870

ME(H4SO)-74

MECHANICAL

Cylinder Block

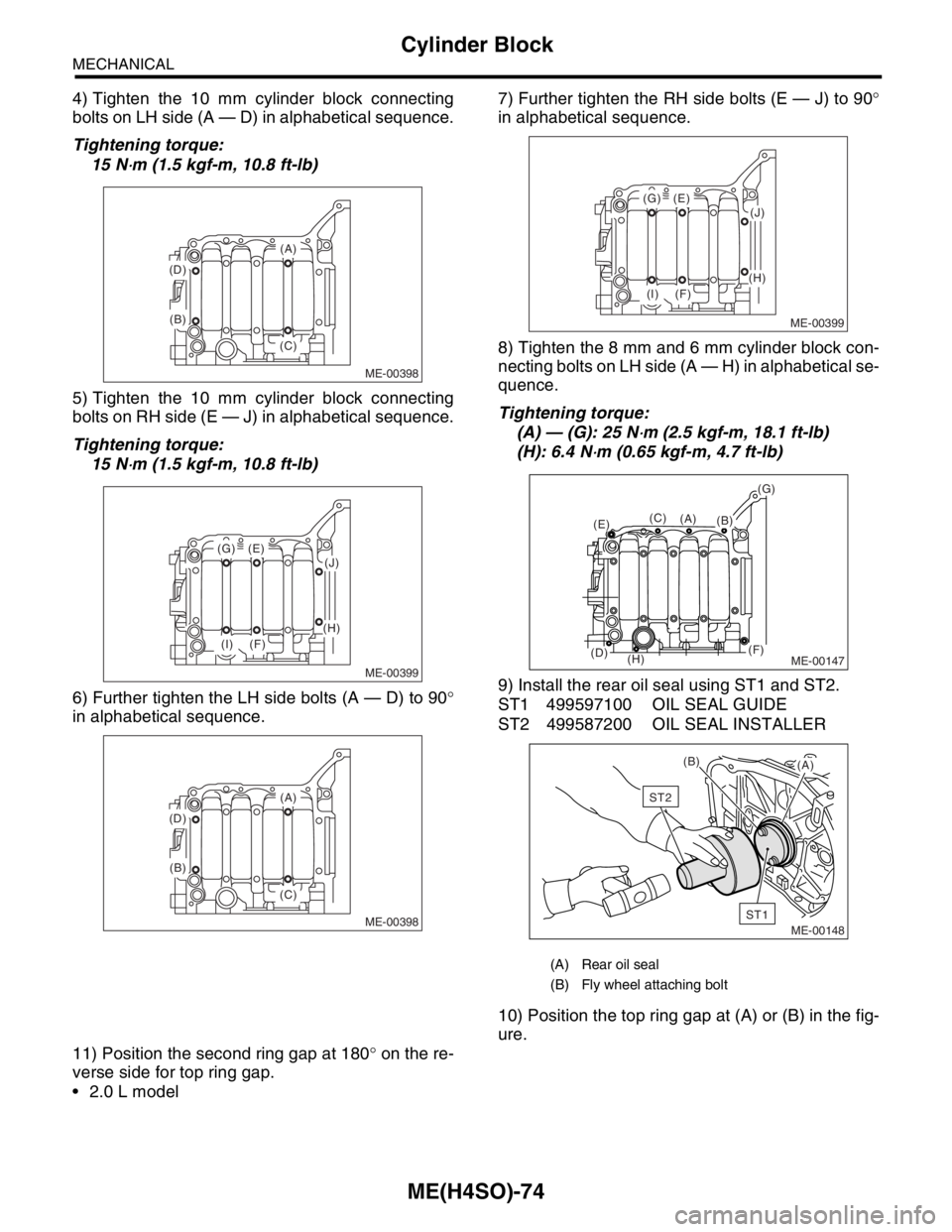

4) Tighten the 10 mm cylinder block connecting

bolts on LH side (A — D) in alphabetical sequence.

Tightening torque:

15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

5) Tighten the 10 mm cylinder block connecting

bolts on RH side (E — J) in alphabetical sequence.

Tightening torque:

15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

6) Further tighten the LH side bolts (A — D) to 90°

in alphabetical sequence.7) Further tighten the RH side bolts (E — J) to 90°

in alphabetical sequence.

8) Tighten the 8 mm and 6 mm cylinder block con-

necting bolts on LH side (A — H) in alphabetical se-

quence.

Tightening torque:

(A) — (G): 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(H): 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

9) Install the rear oil seal using ST1 and ST2.

ST1 499597100 OIL SEAL GUIDE

ST2 499587200 OIL SEAL INSTALLER

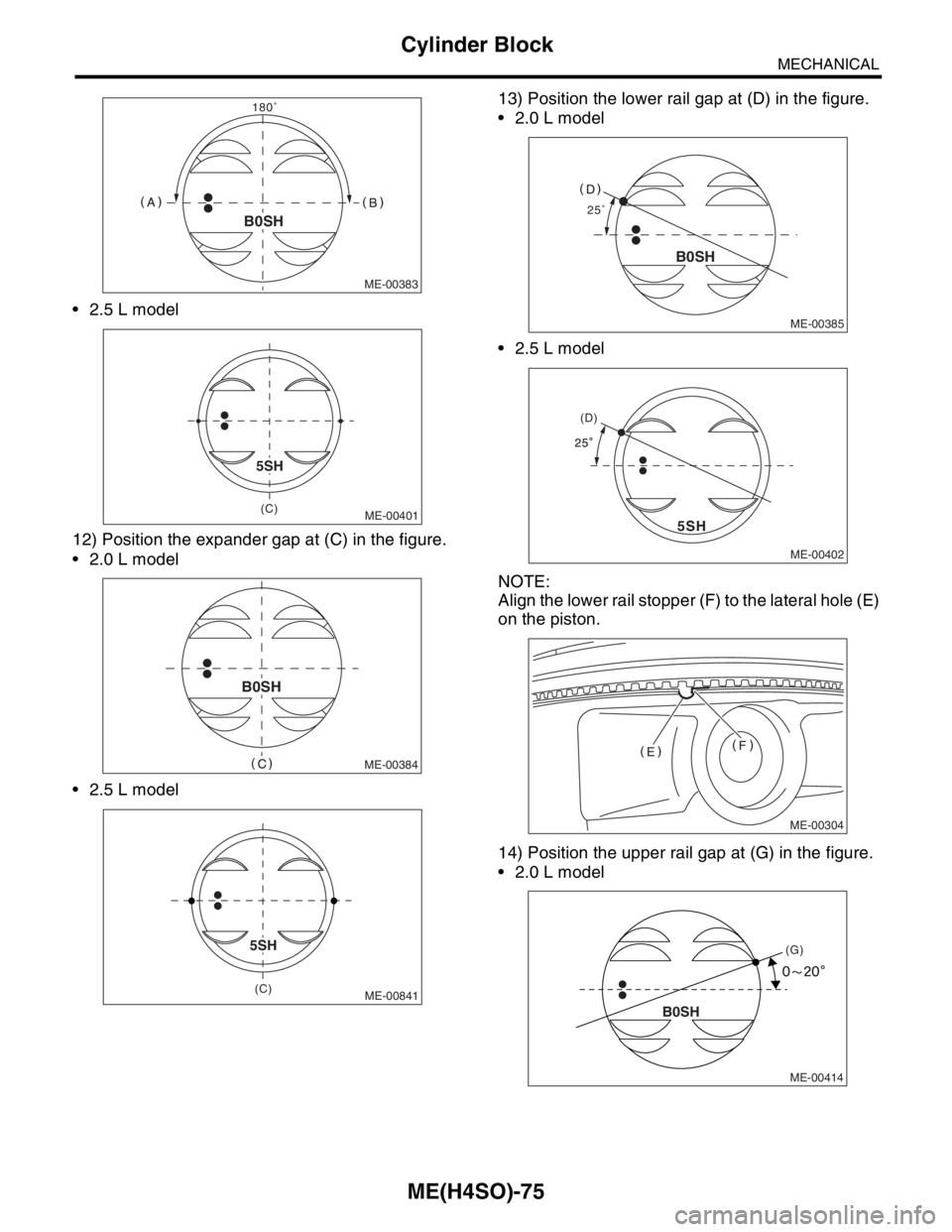

10) Position the top ring gap at (A) or (B) in the fig-

ure.

11) Position the second ring gap at 180° on the re-

verse side for top ring gap.

2.0 L model

ME-00398

(A)

(B)

(C) (D)

ME-00399

(E)(G)

(F)(I)

(J)

(H)

ME-00398

(A)

(B)

(C) (D)

(A) Rear oil seal

(B) Fly wheel attaching bolt

ME-00399

(E)(G)

(F)(I)

(J)

(H)

ME-00147

(B)(C)

(D)

(E)

(F)

(G)

(H)

(A)

ME-00148

ST1

ST2

(B)

(A)

Page 946 of 2870

ME(H4SO)-75

MECHANICAL

Cylinder Block

2.5 L model

12) Position the expander gap at (C) in the figure.

2.0 L model

2.5 L model13) Position the lower rail gap at (D) in the figure.

2.0 L model

2.5 L model

NOTE:

Align the lower rail stopper (F) to the lateral hole (E)

on the piston.

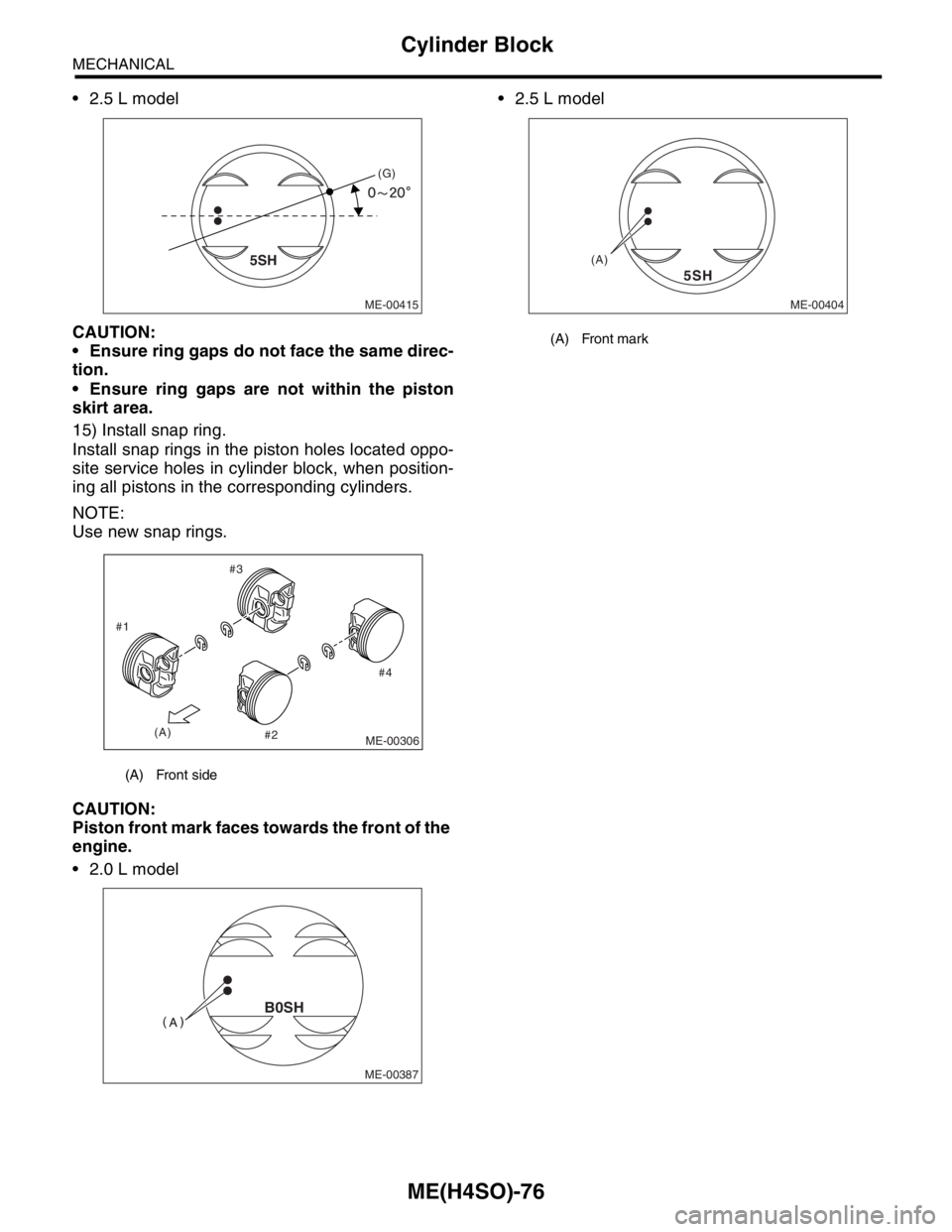

14) Position the upper rail gap at (G) in the figure.

2.0 L model

ME-00383

180�

B0SH

ME-00401(C)

5SH

ME-00384

B0SH

ME-00841

5SH

(C)ME-00385

25�

B0SH

ME-00402

(D)

5SH

ME-00304

(G)

B0SH

ME-00414

Page 947 of 2870

ME(H4SO)-76

MECHANICAL

Cylinder Block

2.5 L model

CAUTION:

Ensure ring gaps do not face the same direc-

tion.

Ensure ring gaps are not within the piston

skirt area.

15) Install snap ring.

Install snap rings in the piston holes located oppo-

site service holes in cylinder block, when position-

ing all pistons in the corresponding cylinders.

NOTE:

Use new snap rings.

CAUTION:

Piston front mark faces towards the front of the

engine.

2.0 L model 2.5 L model

(A) Front side

ME-00415

5SH

(G)

ME-00306

#4 #3

#2 #1

(A)

ME-00387

B0SH

(A) Front mark

ME-00404

5SH

(A)

Page 948 of 2870

ME(H4SO)-77

MECHANICAL

Cylinder Block

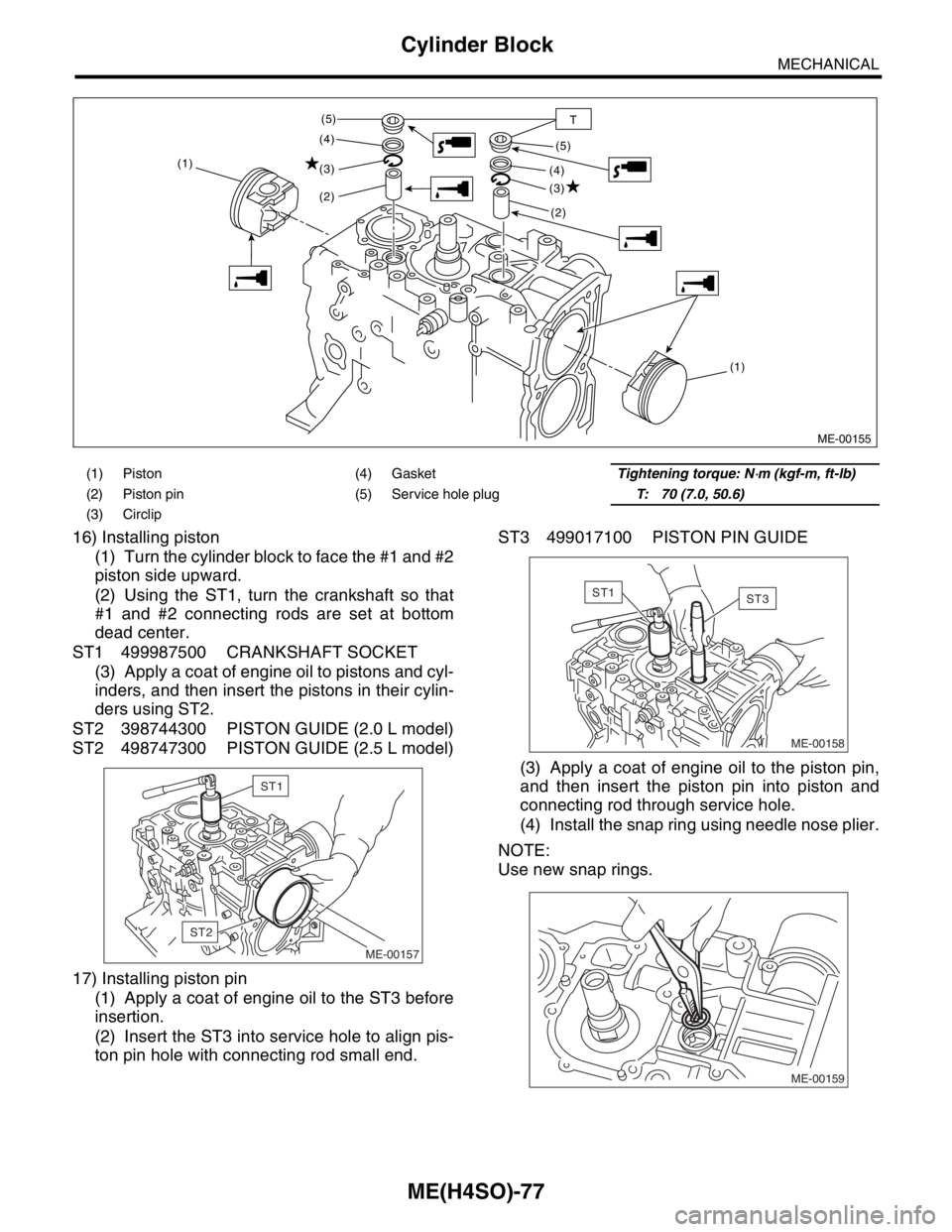

16) Installing piston

(1) Turn the cylinder block to face the #1 and #2

piston side upward.

(2) Using the ST1, turn the crankshaft so that

#1 and #2 connecting rods are set at bottom

dead center.

ST1 499987500 CRANKSHAFT SOCKET

(3) Apply a coat of engine oil to pistons and cyl-

inders, and then insert the pistons in their cylin-

ders using ST2.

ST2 398744300 PISTON GUIDE (2.0 L model)

ST2 498747300 PISTON GUIDE (2.5 L model)

17) Installing piston pin

(1) Apply a coat of engine oil to the ST3 before

insertion.

(2) Insert the ST3 into service hole to align pis-

ton pin hole with connecting rod small end.ST3 499017100 PISTON PIN GUIDE

(3) Apply a coat of engine oil to the piston pin,

and then insert the piston pin into piston and

connecting rod through service hole.

(4) Install the snap ring using needle nose plier.

NOTE:

Use new snap rings.

(1) Piston (4) GasketTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (5) Service hole plugT: 70 (7.0, 50.6)

(3) Circlip

ME-00155

(1) (1)

(2)

(2) (3)

(3) (4)

(4) (5)

(5)

T

ME-00157

ST2

ST1

ME-00158

ST1ST3

ME-00159

Page 949 of 2870

ME(H4SO)-78

MECHANICAL

Cylinder Block

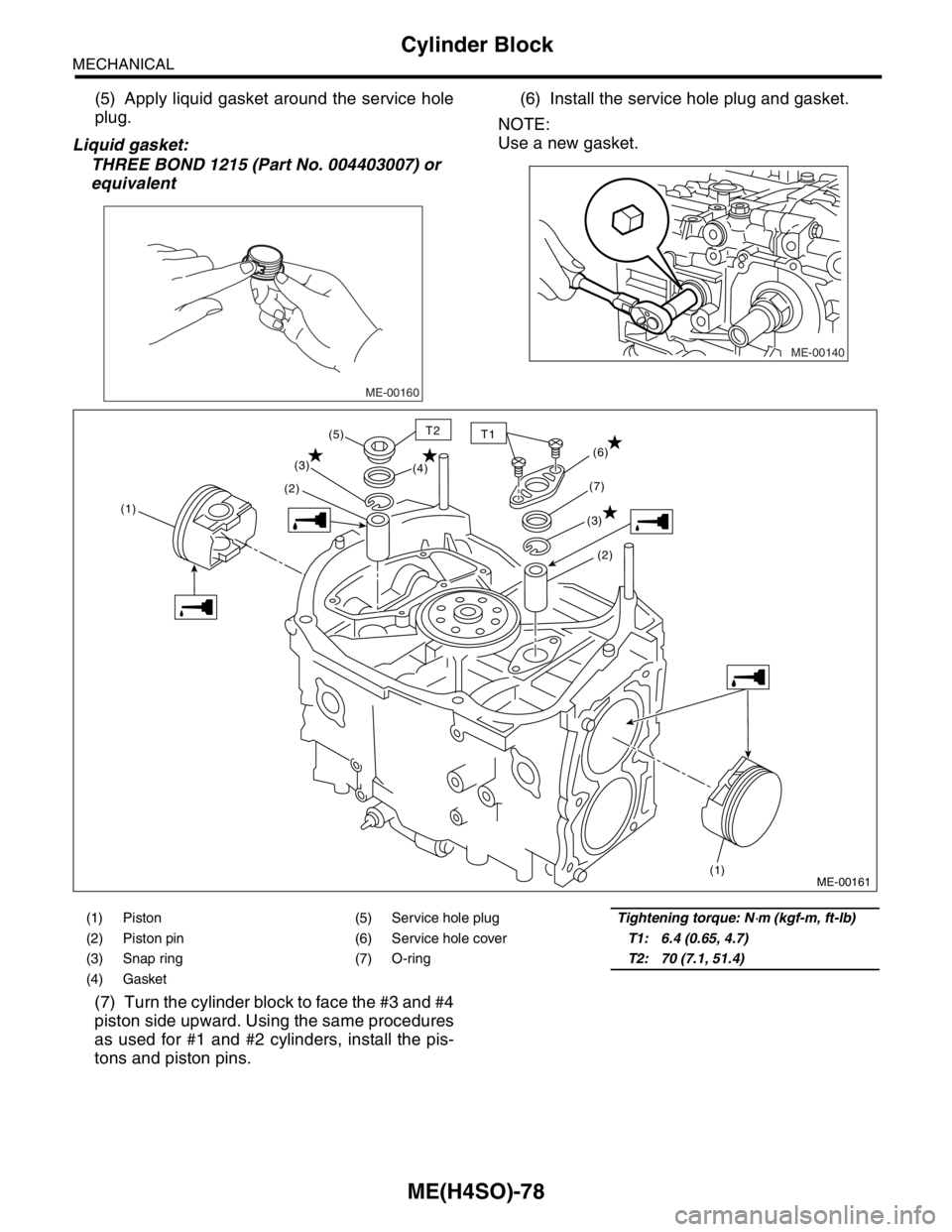

(5) Apply liquid gasket around the service hole

plug.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007) or

equivalent(6) Install the service hole plug and gasket.

NOTE:

Use a new gasket.

(7) Turn the cylinder block to face the #3 and #4

piston side upward. Using the same procedures

as used for #1 and #2 cylinders, install the pis-

tons and piston pins.

ME-00160

ME-00140

(1) Piston (5) Service hole plugTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (6) Service hole coverT1: 6.4 (0.65, 4.7)

(3) Snap ring (7) O-ringT2: 70 (7.1, 51.4)

(4) Gasket

(1)(2)(3)

(1)

(2) (6)

(3)(7) (4) (5)

ME-00161

T2T1

Page 950 of 2870

ME(H4SO)-79

MECHANICAL

Cylinder Block

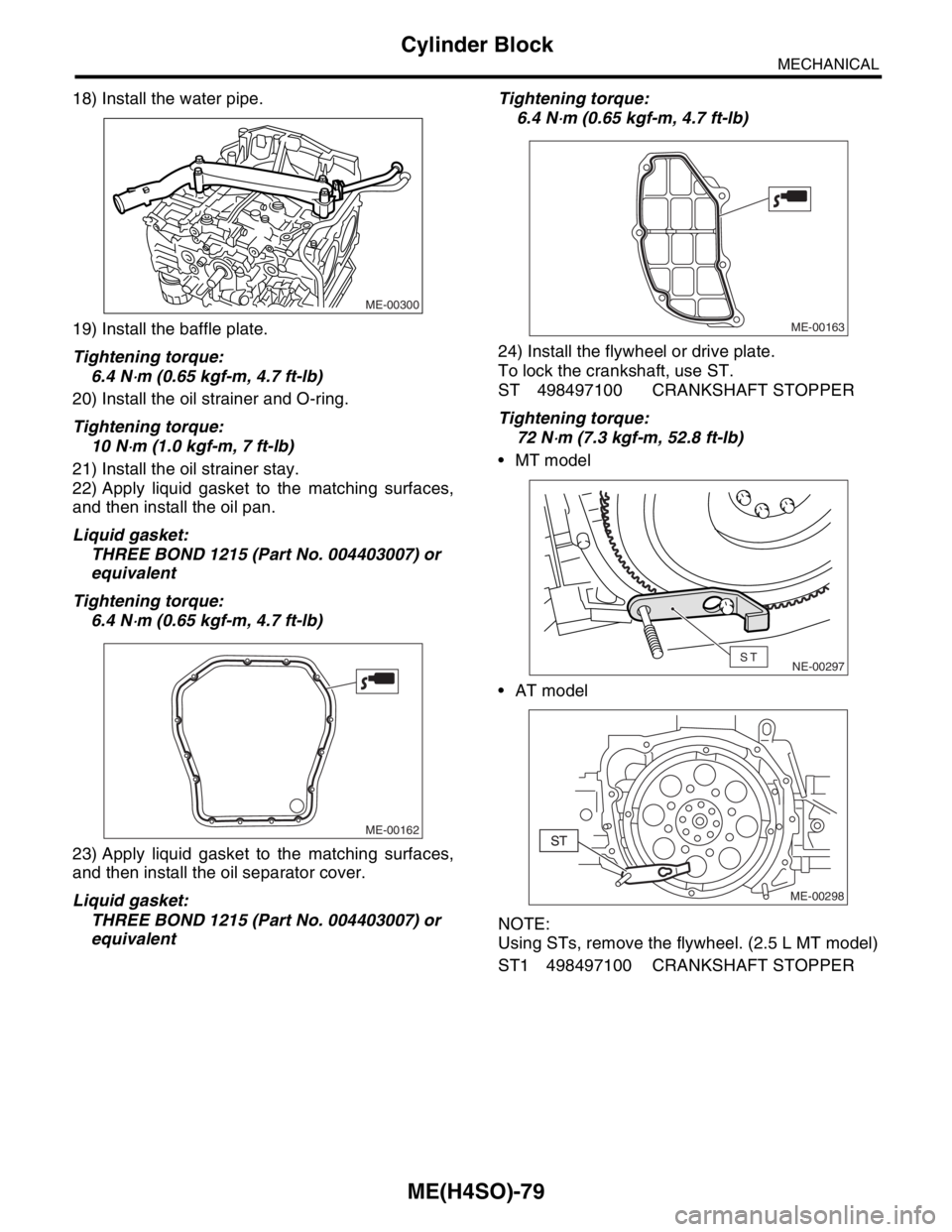

18) Install the water pipe.

19) Install the baffle plate.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

20) Install the oil strainer and O-ring.

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7 ft-lb)

21) Install the oil strainer stay.

22) Apply liquid gasket to the matching surfaces,

and then install the oil pan.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007) or

equivalent

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

23) Apply liquid gasket to the matching surfaces,

and then install the oil separator cover.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007) or

equivalentTightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

24) Install the flywheel or drive plate.

To lock the crankshaft, use ST.

ST 498497100 CRANKSHAFT STOPPER

Tightening torque:

72 N

⋅m (7.3 kgf-m, 52.8 ft-lb)

MT model

AT model

NOTE:

Using STs, remove the flywheel. (2.5 L MT model)

ST1 498497100 CRANKSHAFT STOPPER

ME-00300

ME-00162

ME-00163

NE-00297ST

ME-00298