SUBARU LEGACY 1999 Service Repair Manual

Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 381 of 1456

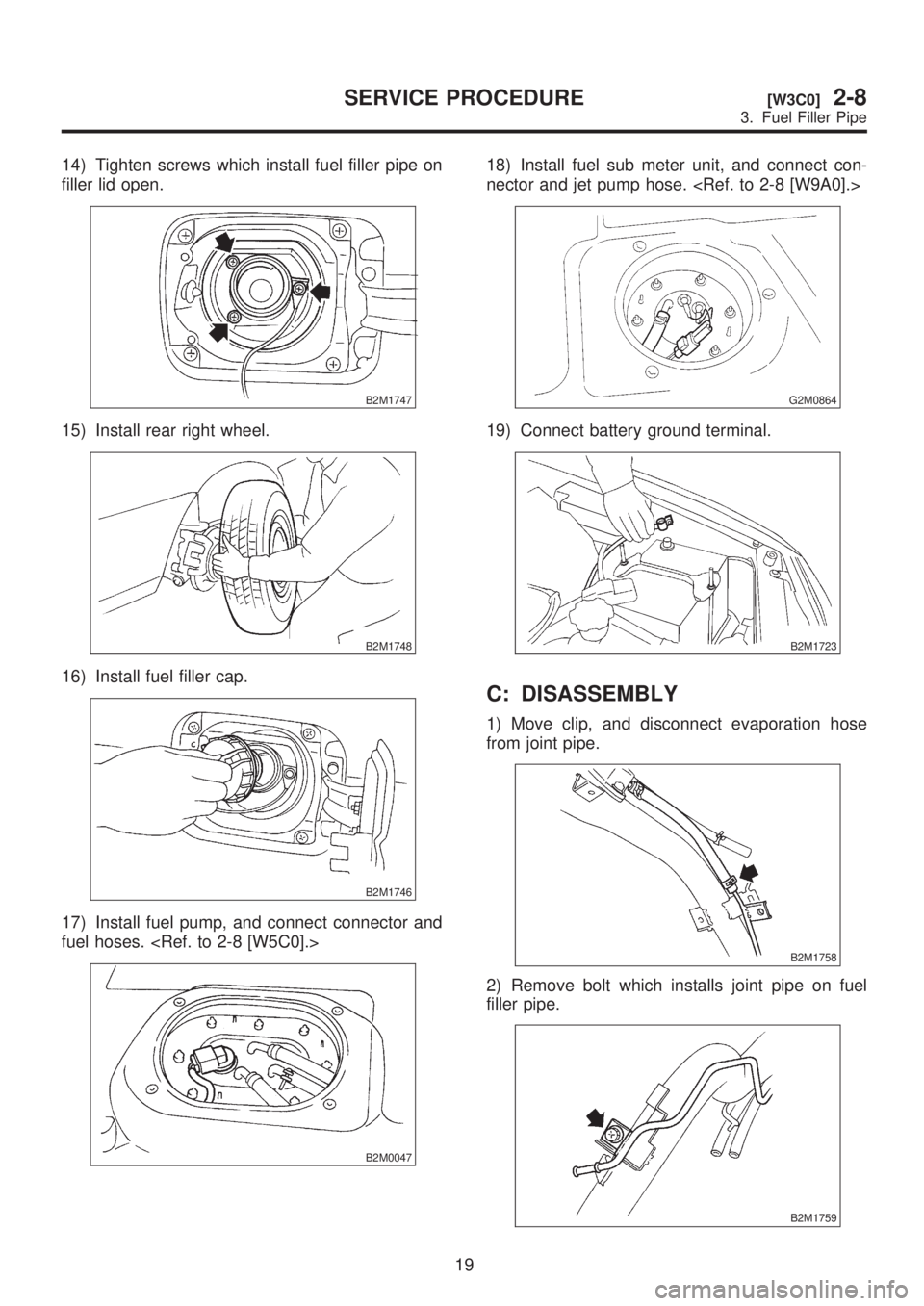

14) Tighten screws which install fuel filler pipe on

filler lid open.

B2M1747

15) Install rear right wheel.

B2M1748

16) Install fuel filler cap.

B2M1746

17) Install fuel pump, and connect connector and

fuel hoses.

B2M0047

18) Install fuel sub meter unit, and connect con-

nector and jet pump hose.

G2M0864

19) Connect battery ground terminal.

B2M1723

C: DISASSEMBLY

1) Move clip, and disconnect evaporation hose

from joint pipe.

B2M1758

2) Remove bolt which installs joint pipe on fuel

filler pipe.

B2M1759

19

[W3C0]2-8SERVICE PROCEDURE

3. Fuel Filler Pipe

Page 382 of 1456

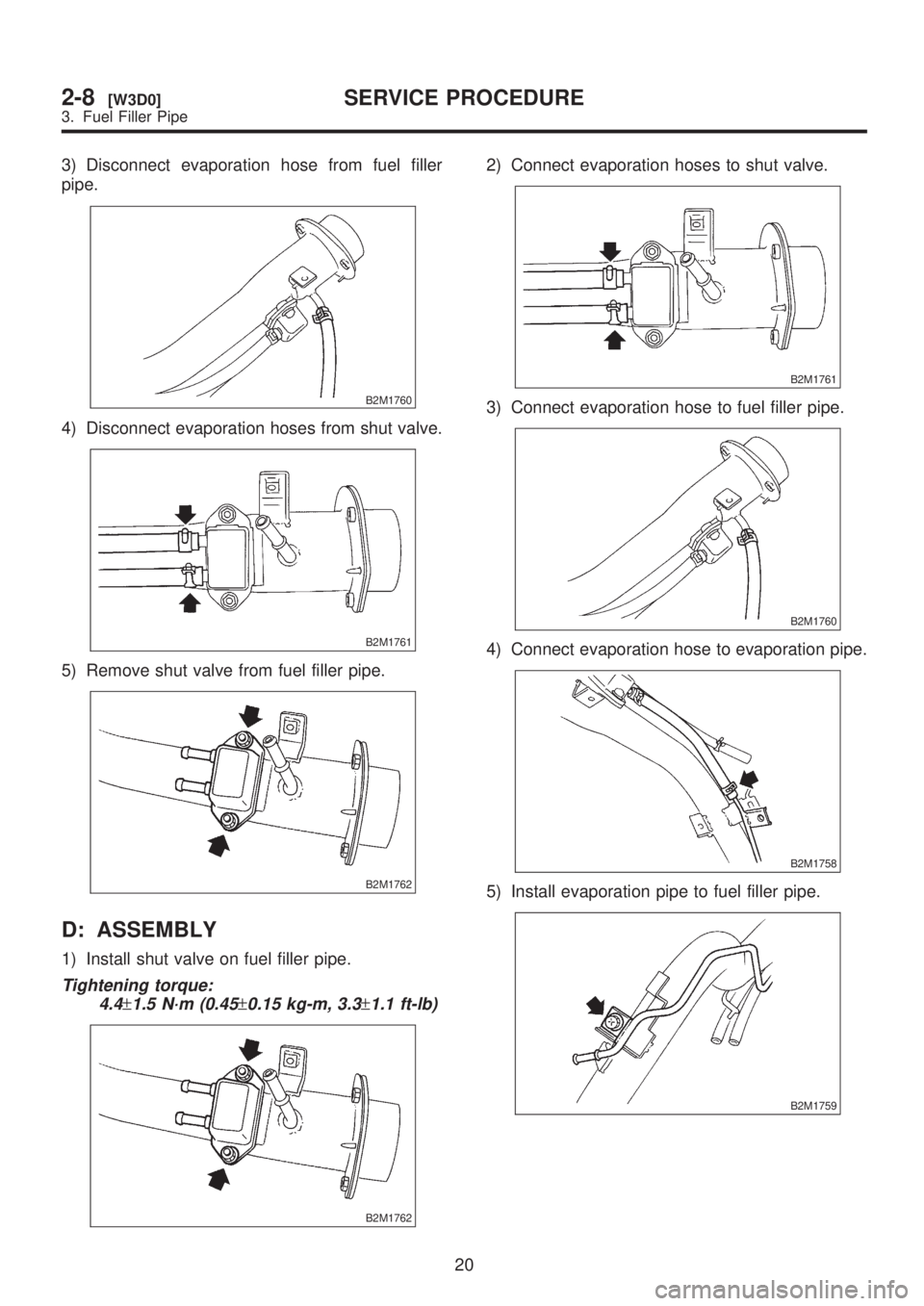

3) Disconnect evaporation hose from fuel filler

pipe.

B2M1760

4) Disconnect evaporation hoses from shut valve.

B2M1761

5) Remove shut valve from fuel filler pipe.

B2M1762

D: ASSEMBLY

1) Install shut valve on fuel filler pipe.

Tightening torque:

4.4

±1.5 N´m (0.45±0.15 kg-m, 3.3±1.1 ft-lb)

B2M1762

2) Connect evaporation hoses to shut valve.

B2M1761

3) Connect evaporation hose to fuel filler pipe.

B2M1760

4) Connect evaporation hose to evaporation pipe.

B2M1758

5) Install evaporation pipe to fuel filler pipe.

B2M1759

20

2-8[W3D0]SERVICE PROCEDURE

3. Fuel Filler Pipe

Page 383 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 4. Fuel Filter

A: REMOVAL

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Disconnect fuel delivery hoses from fuel filter.

S2M0195

3) Remove filter from holder.

B: INSPECTION

1) Check the inside of SUBARU LEGACY 1999 Service Repair Manual 4. Fuel Filter

A: REMOVAL

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Disconnect fuel delivery hoses from fuel filter.

S2M0195

3) Remove filter from holder.

B: INSPECTION

1) Check the inside of](/img/17/57435/w960_57435-382.png)

4. Fuel Filter

A: REMOVAL

1) Release fuel pressure.

2) Disconnect fuel delivery hoses from fuel filter.

S2M0195

3) Remove filter from holder.

B: INSPECTION

1) Check the inside of fuel filter for dirt and water

sediment.

2) If it is clogged, or if replacement interval has

been reached, replace it.

3) If water is found in it, shake and expel the water

from inlet port.

C: INSTALLATION

CAUTION:

IIf fuel hoses are damaged at the connecting

portion, replace it with a new one.

IIf clamps are badly damaged, replace with

new ones.

1) Installation is in the reverse order of removal.

2) Tighten hose clamp screws.

Tightening torque:

1.0+0.5/þ0N´m (0.1+0.05/þ0kg-m, 0.7+0.4/þ0ft-lb)

S2M0195

5. Fuel Pump

A: REMOVAL

1) Release fuel pressure.

2) Disconnect fuel delivery hose (A), return hose

(B) and jet pump hose (C) (AWD model only).

B2M0048B

3) Remove nuts which install fuel pump assembly

onto fuel tank.

G2M0343

4) Take off fuel pump from fuel tank.

G2M0344

21

[W5A0]2-8SERVICE PROCEDURE

5. Fuel Pump

Page 384 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 4. Fuel Filter

A: REMOVAL

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Disconnect fuel delivery hoses from fuel filter.

S2M0195

3) Remove filter from holder.

B: INSPECTION

1) Check the inside of SUBARU LEGACY 1999 Service Repair Manual 4. Fuel Filter

A: REMOVAL

1) Release fuel pressure. <Ref. to 2-8 [W1B0].>

2) Disconnect fuel delivery hoses from fuel filter.

S2M0195

3) Remove filter from holder.

B: INSPECTION

1) Check the inside of](/img/17/57435/w960_57435-383.png)

4. Fuel Filter

A: REMOVAL

1) Release fuel pressure.

2) Disconnect fuel delivery hoses from fuel filter.

S2M0195

3) Remove filter from holder.

B: INSPECTION

1) Check the inside of fuel filter for dirt and water

sediment.

2) If it is clogged, or if replacement interval has

been reached, replace it.

3) If water is found in it, shake and expel the water

from inlet port.

C: INSTALLATION

CAUTION:

IIf fuel hoses are damaged at the connecting

portion, replace it with a new one.

IIf clamps are badly damaged, replace with

new ones.

1) Installation is in the reverse order of removal.

2) Tighten hose clamp screws.

Tightening torque:

1.0+0.5/þ0N´m (0.1+0.05/þ0kg-m, 0.7+0.4/þ0ft-lb)

S2M0195

5. Fuel Pump

A: REMOVAL

1) Release fuel pressure.

2) Disconnect fuel delivery hose (A), return hose

(B) and jet pump hose (C) (AWD model only).

B2M0048B

3) Remove nuts which install fuel pump assembly

onto fuel tank.

G2M0343

4) Take off fuel pump from fuel tank.

G2M0344

21

[W5A0]2-8SERVICE PROCEDURE

5. Fuel Pump

Page 385 of 1456

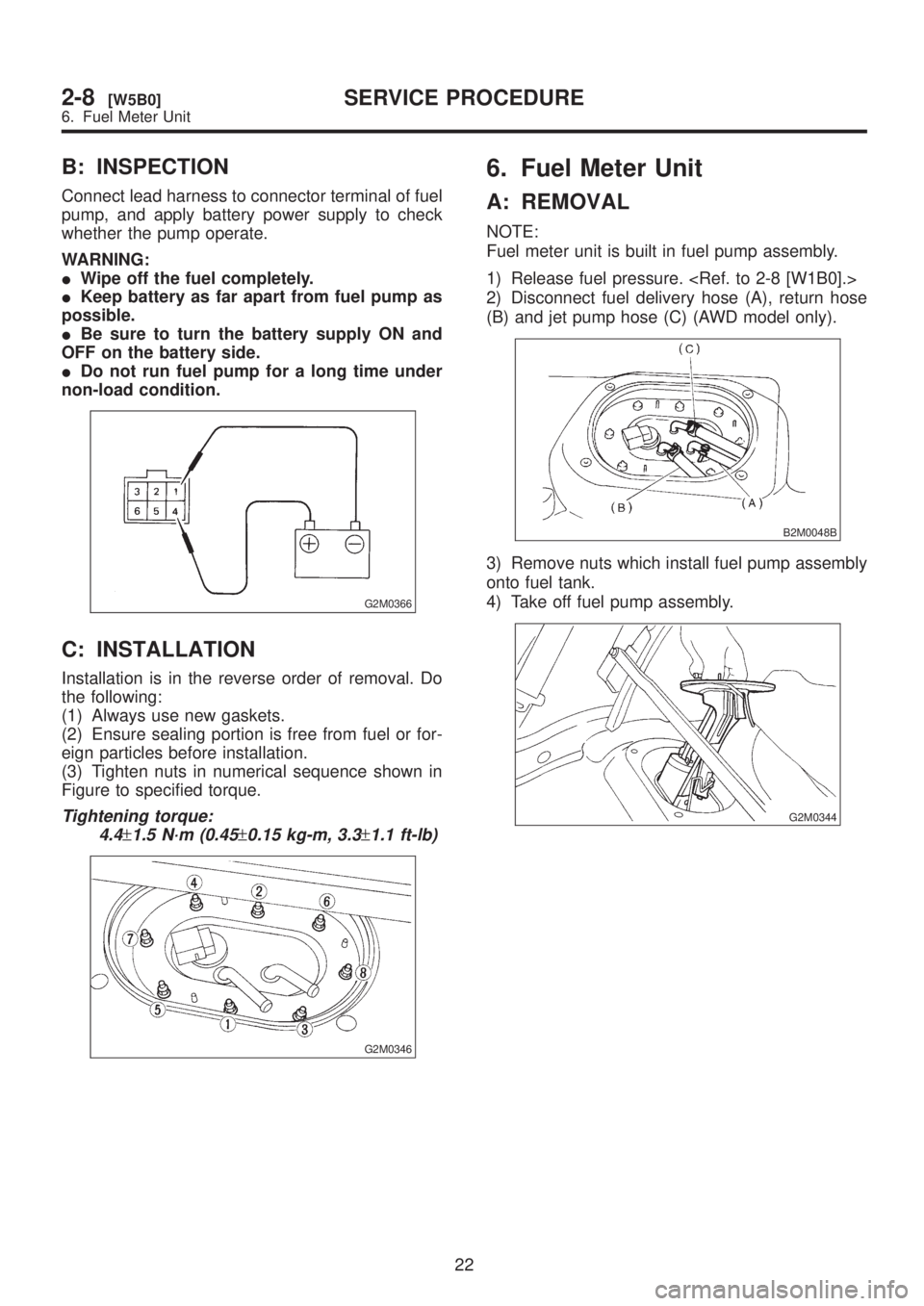

B: INSPECTION

Connect lead harness to connector terminal of fuel

pump, and apply battery power supply to check

whether the pump operate.

WARNING:

IWipe off the fuel completely.

IKeep battery as far apart from fuel pump as

possible.

IBe sure to turn the battery supply ON and

OFF on the battery side.

IDo not run fuel pump for a long time under

non-load condition.

G2M0366

C: INSTALLATION

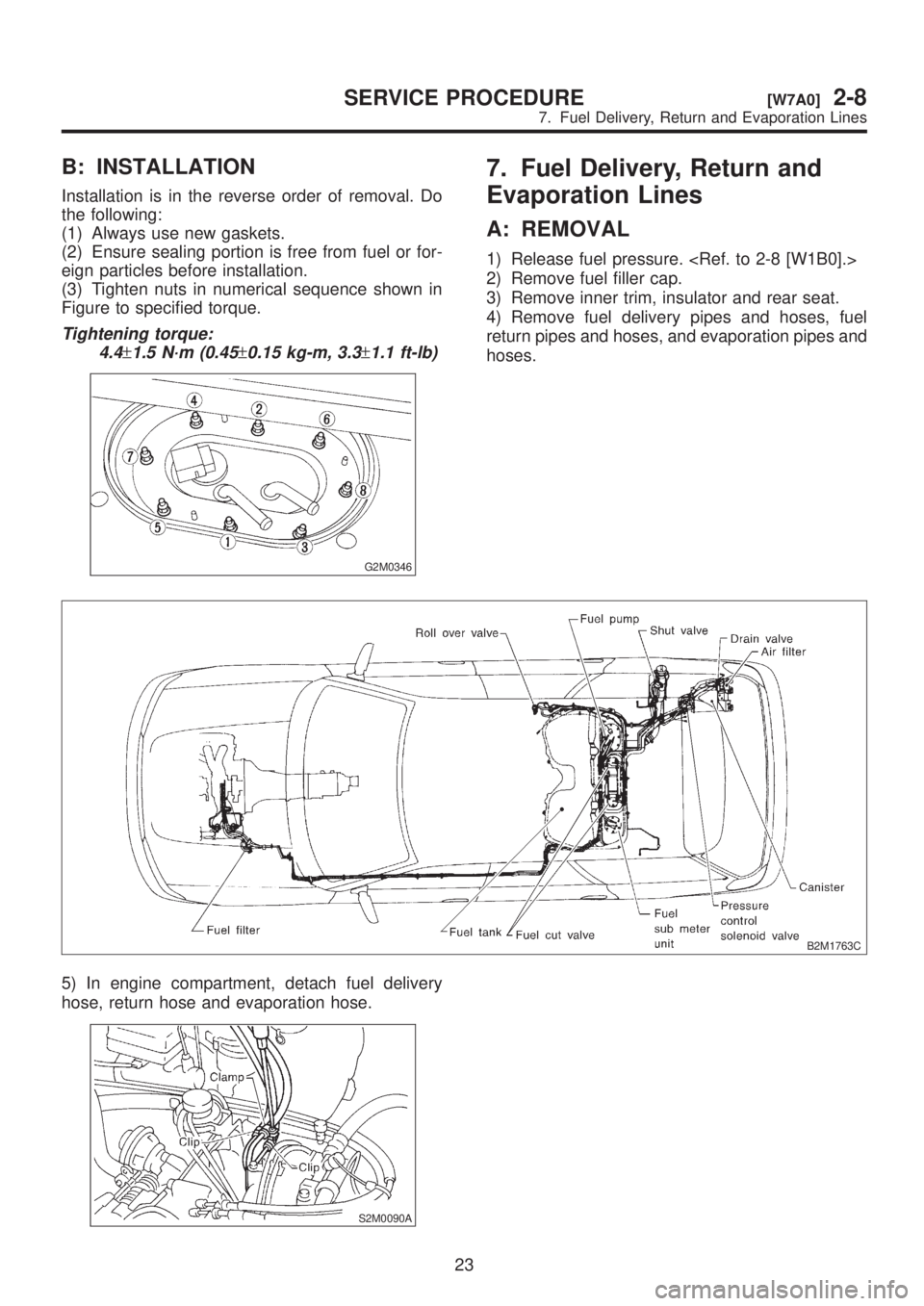

Installation is in the reverse order of removal. Do

the following:

(1) Always use new gaskets.

(2) Ensure sealing portion is free from fuel or for-

eign particles before installation.

(3) Tighten nuts in numerical sequence shown in

Figure to specified torque.

Tightening torque:

4.4

±1.5 N´m (0.45±0.15 kg-m, 3.3±1.1 ft-lb)

G2M0346

6. Fuel Meter Unit

A: REMOVAL

NOTE:

Fuel meter unit is built in fuel pump assembly.

1) Release fuel pressure.

2) Disconnect fuel delivery hose (A), return hose

(B) and jet pump hose (C) (AWD model only).

B2M0048B

3) Remove nuts which install fuel pump assembly

onto fuel tank.

4) Take off fuel pump assembly.

G2M0344

22

2-8[W5B0]SERVICE PROCEDURE

6. Fuel Meter Unit

Page 386 of 1456

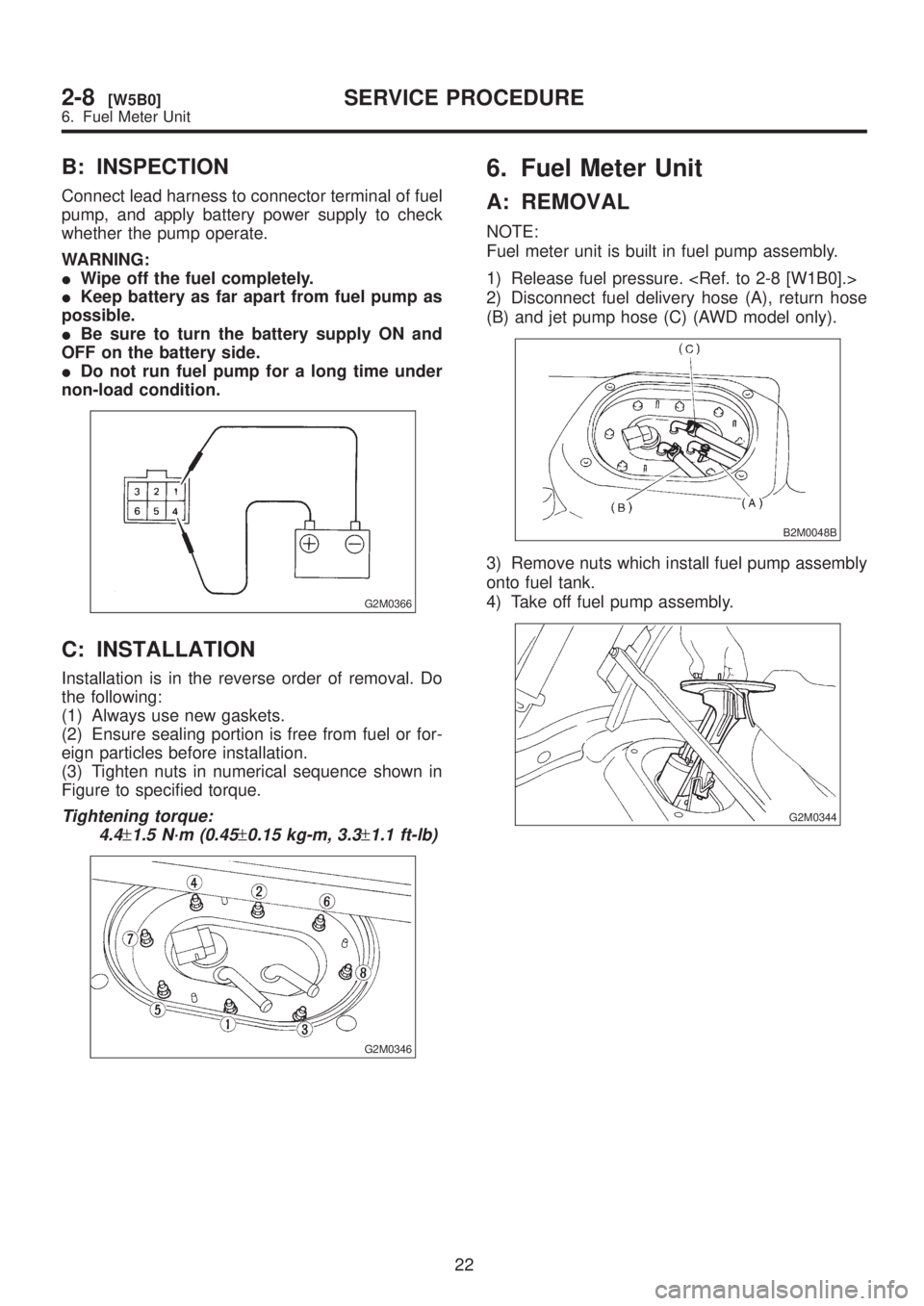

B: INSPECTION

Connect lead harness to connector terminal of fuel

pump, and apply battery power supply to check

whether the pump operate.

WARNING:

IWipe off the fuel completely.

IKeep battery as far apart from fuel pump as

possible.

IBe sure to turn the battery supply ON and

OFF on the battery side.

IDo not run fuel pump for a long time under

non-load condition.

G2M0366

C: INSTALLATION

Installation is in the reverse order of removal. Do

the following:

(1) Always use new gaskets.

(2) Ensure sealing portion is free from fuel or for-

eign particles before installation.

(3) Tighten nuts in numerical sequence shown in

Figure to specified torque.

Tightening torque:

4.4

±1.5 N´m (0.45±0.15 kg-m, 3.3±1.1 ft-lb)

G2M0346

6. Fuel Meter Unit

A: REMOVAL

NOTE:

Fuel meter unit is built in fuel pump assembly.

1) Release fuel pressure.

2) Disconnect fuel delivery hose (A), return hose

(B) and jet pump hose (C) (AWD model only).

B2M0048B

3) Remove nuts which install fuel pump assembly

onto fuel tank.

4) Take off fuel pump assembly.

G2M0344

22

2-8[W5B0]SERVICE PROCEDURE

6. Fuel Meter Unit

Page 387 of 1456

B: INSTALLATION

Installation is in the reverse order of removal. Do

the following:

(1) Always use new gaskets.

(2) Ensure sealing portion is free from fuel or for-

eign particles before installation.

(3) Tighten nuts in numerical sequence shown in

Figure to specified torque.

Tightening torque:

4.4

±1.5 N´m (0.45±0.15 kg-m, 3.3±1.1 ft-lb)

G2M0346

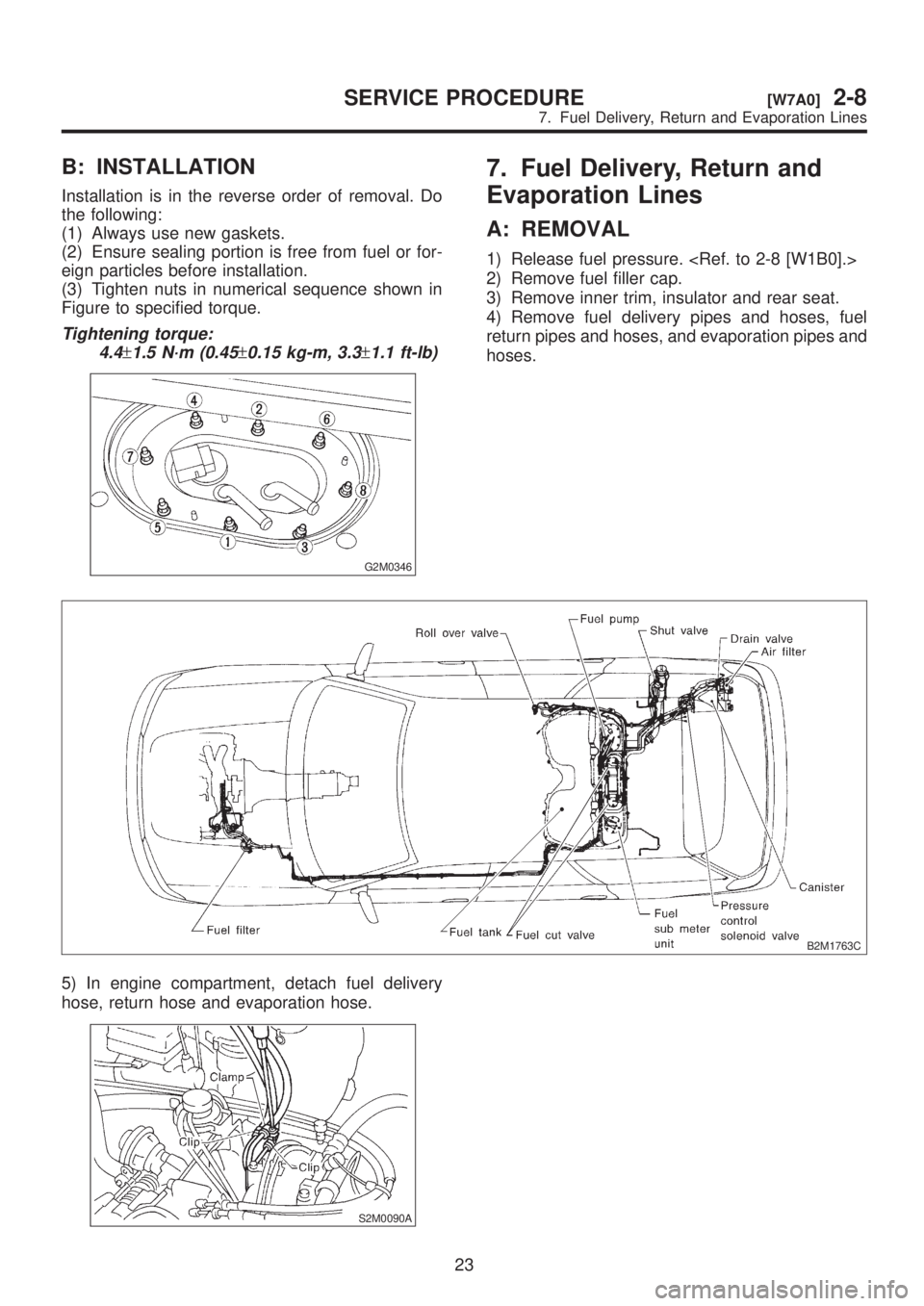

7. Fuel Delivery, Return and

Evaporation Lines

A: REMOVAL

1) Release fuel pressure.

2) Remove fuel filler cap.

3) Remove inner trim, insulator and rear seat.

4) Remove fuel delivery pipes and hoses, fuel

return pipes and hoses, and evaporation pipes and

hoses.

B2M1763C

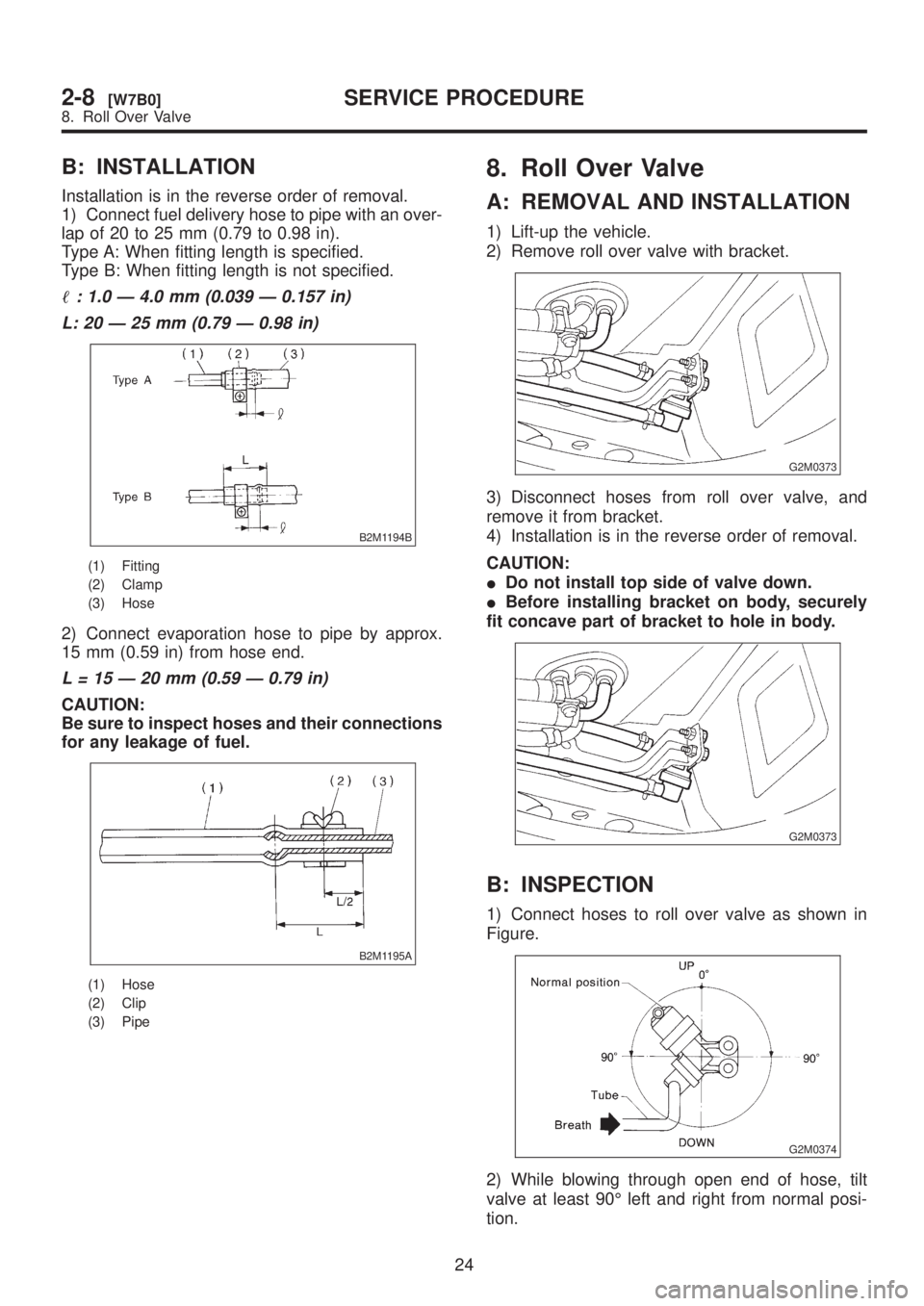

5) In engine compartment, detach fuel delivery

hose, return hose and evaporation hose.

S2M0090A

23

[W7A0]2-8SERVICE PROCEDURE

7. Fuel Delivery, Return and Evaporation Lines

Page 388 of 1456

B: INSTALLATION

Installation is in the reverse order of removal. Do

the following:

(1) Always use new gaskets.

(2) Ensure sealing portion is free from fuel or for-

eign particles before installation.

(3) Tighten nuts in numerical sequence shown in

Figure to specified torque.

Tightening torque:

4.4

±1.5 N´m (0.45±0.15 kg-m, 3.3±1.1 ft-lb)

G2M0346

7. Fuel Delivery, Return and

Evaporation Lines

A: REMOVAL

1) Release fuel pressure.

2) Remove fuel filler cap.

3) Remove inner trim, insulator and rear seat.

4) Remove fuel delivery pipes and hoses, fuel

return pipes and hoses, and evaporation pipes and

hoses.

B2M1763C

5) In engine compartment, detach fuel delivery

hose, return hose and evaporation hose.

S2M0090A

23

[W7A0]2-8SERVICE PROCEDURE

7. Fuel Delivery, Return and Evaporation Lines

Page 389 of 1456

B: INSTALLATION

Installation is in the reverse order of removal.

1) Connect fuel delivery hose to pipe with an over-

lap of 20 to 25 mm (0.79 to 0.98 in).

Type A: When fitting length is specified.

Type B: When fitting length is not specified.

: 1.0 Ð 4.0 mm (0.039 Ð 0.157 in)

L: 20 Ð 25 mm (0.79 Ð 0.98 in)

B2M1194B

(1) Fitting

(2) Clamp

(3) Hose

2) Connect evaporation hose to pipe by approx.

15 mm (0.59 in) from hose end.

L = 15 Ð 20 mm (0.59 Ð 0.79 in)

CAUTION:

Be sure to inspect hoses and their connections

for any leakage of fuel.

B2M1195A

(1) Hose

(2) Clip

(3) Pipe

8. Roll Over Valve

A: REMOVAL AND INSTALLATION

1) Lift-up the vehicle.

2) Remove roll over valve with bracket.

G2M0373

3) Disconnect hoses from roll over valve, and

remove it from bracket.

4) Installation is in the reverse order of removal.

CAUTION:

IDo not install top side of valve down.

IBefore installing bracket on body, securely

fit concave part of bracket to hole in body.

G2M0373

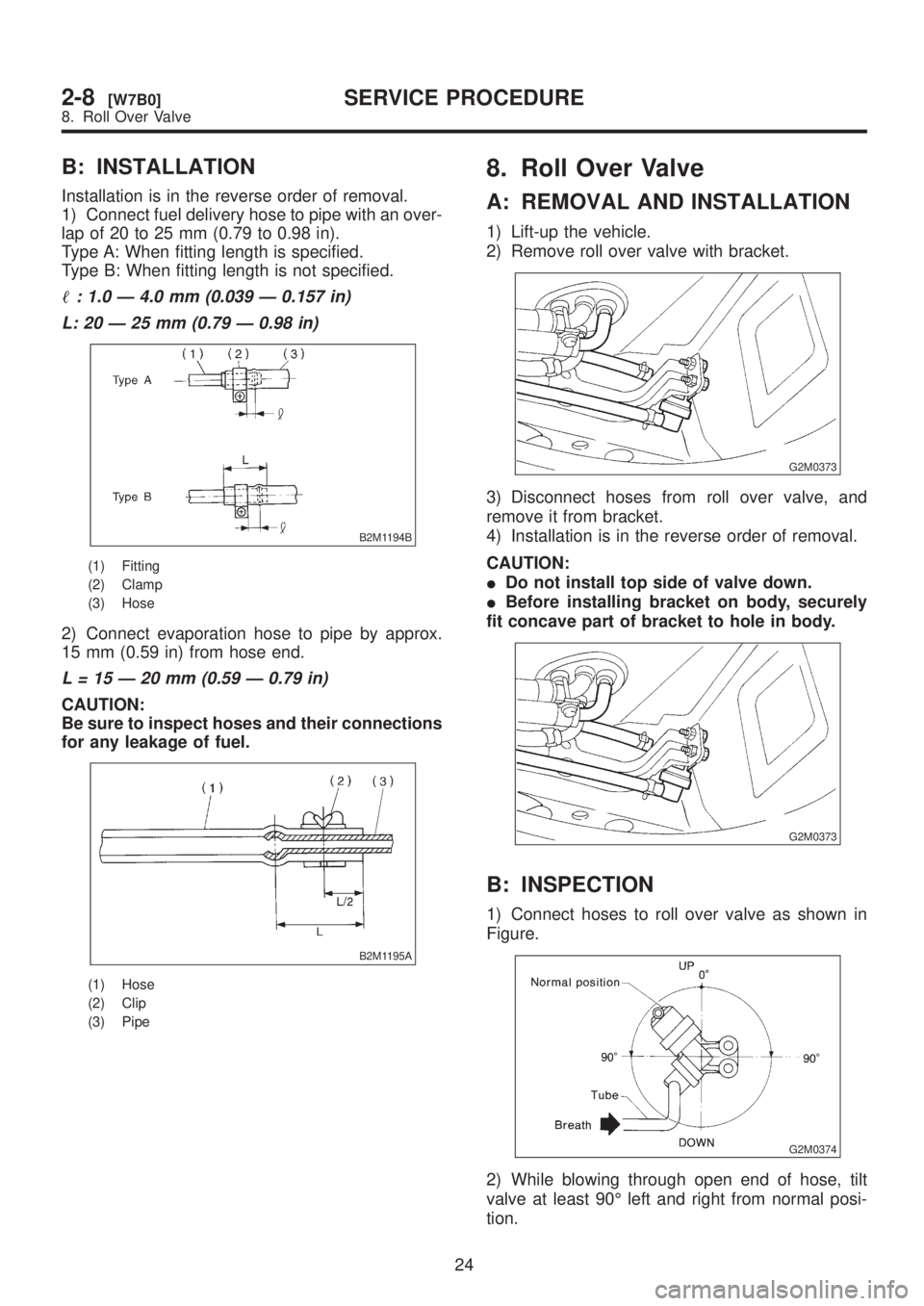

B: INSPECTION

1) Connect hoses to roll over valve as shown in

Figure.

G2M0374

2) While blowing through open end of hose, tilt

valve at least 90É left and right from normal posi-

tion.

24

2-8[W7B0]SERVICE PROCEDURE

8. Roll Over Valve

Page 390 of 1456

B: INSTALLATION

Installation is in the reverse order of removal.

1) Connect fuel delivery hose to pipe with an over-

lap of 20 to 25 mm (0.79 to 0.98 in).

Type A: When fitting length is specified.

Type B: When fitting length is not specified.

: 1.0 Ð 4.0 mm (0.039 Ð 0.157 in)

L: 20 Ð 25 mm (0.79 Ð 0.98 in)

B2M1194B

(1) Fitting

(2) Clamp

(3) Hose

2) Connect evaporation hose to pipe by approx.

15 mm (0.59 in) from hose end.

L = 15 Ð 20 mm (0.59 Ð 0.79 in)

CAUTION:

Be sure to inspect hoses and their connections

for any leakage of fuel.

B2M1195A

(1) Hose

(2) Clip

(3) Pipe

8. Roll Over Valve

A: REMOVAL AND INSTALLATION

1) Lift-up the vehicle.

2) Remove roll over valve with bracket.

G2M0373

3) Disconnect hoses from roll over valve, and

remove it from bracket.

4) Installation is in the reverse order of removal.

CAUTION:

IDo not install top side of valve down.

IBefore installing bracket on body, securely

fit concave part of bracket to hole in body.

G2M0373

B: INSPECTION

1) Connect hoses to roll over valve as shown in

Figure.

G2M0374

2) While blowing through open end of hose, tilt

valve at least 90É left and right from normal posi-

tion.

24

2-8[W7B0]SERVICE PROCEDURE

8. Roll Over Valve