SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2281 of 2453

CS-29

AT Shift Lock Solenoid and “P” Range Switch

CONTROL SYSTEMS

5. AT Shift Lock Solenoid and

“P” Range Switch

A: REMOVAL

NOTE:

For removal of the mode change switch and the

shift button switch, refer to the section on Select

Levers.

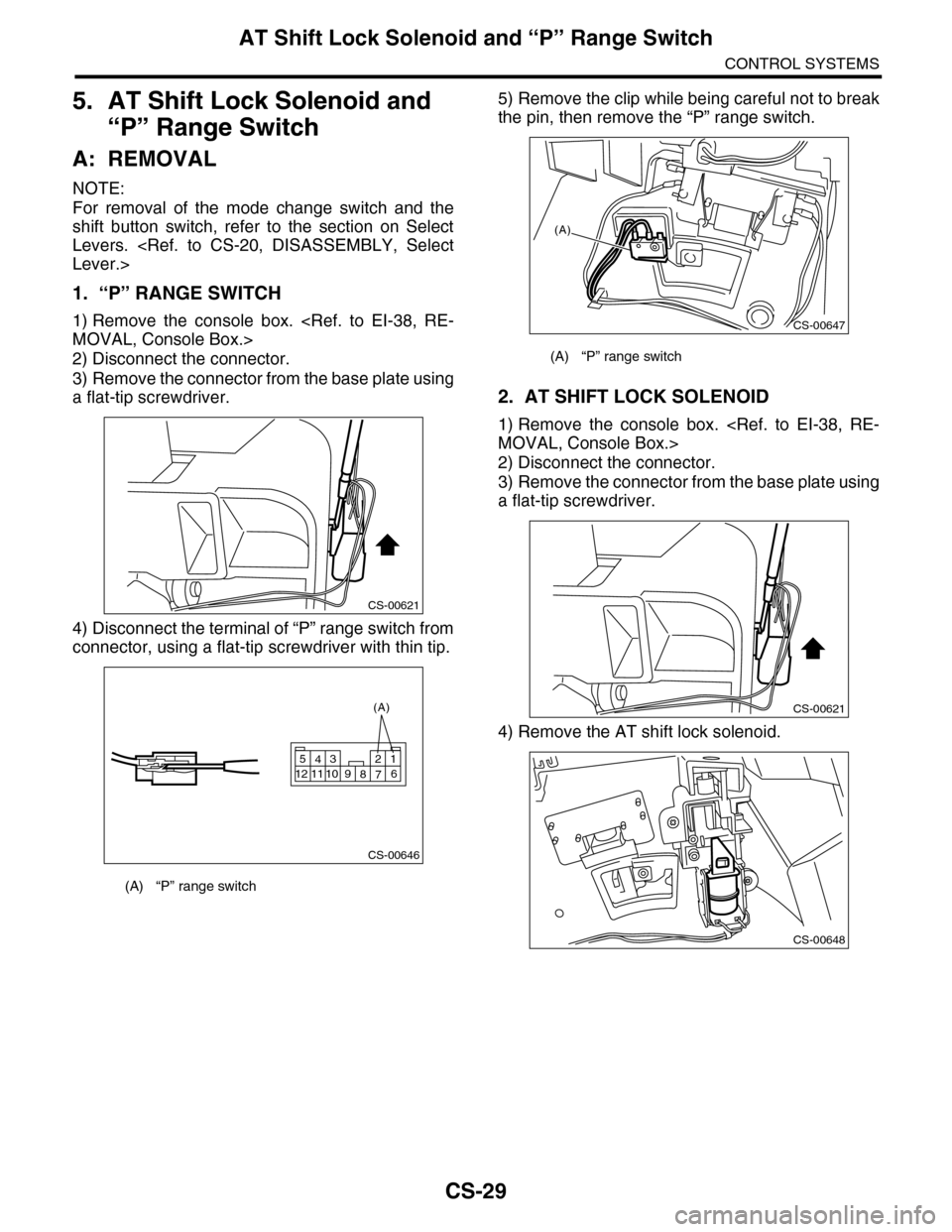

1. “P” RANGE SWITCH

1) Remove the console box.

2) Disconnect the connector.

3) Remove the connector from the base plate using

a flat-tip screwdriver.

4) Disconnect the terminal of “P” range switch from

connector, using a flat-tip screwdriver with thin tip.

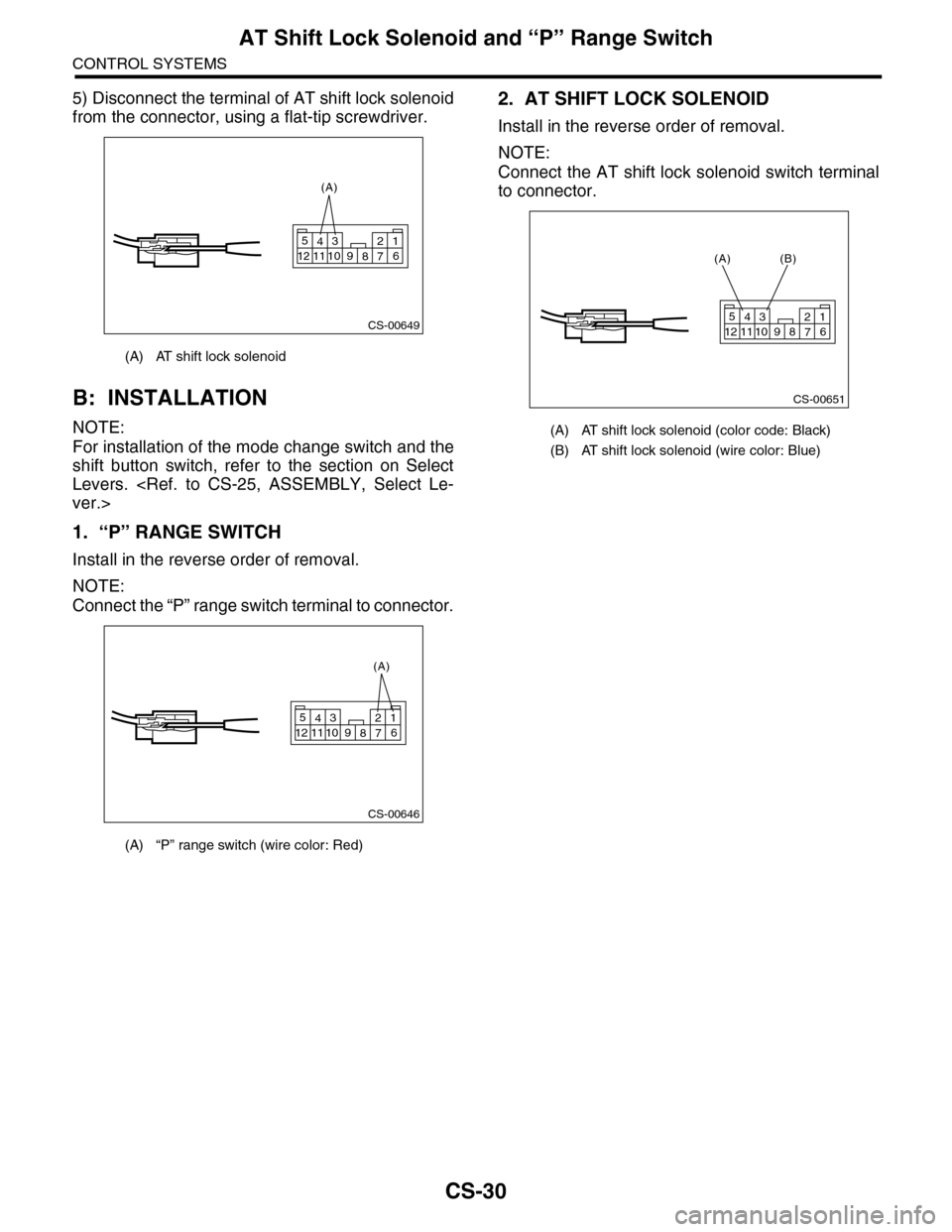

5) Remove the clip while being careful not to break

the pin, then remove the “P” range switch.

2. AT SHIFT LOCK SOLENOID

1) Remove the console box.

2) Disconnect the connector.

3) Remove the connector from the base plate using

a flat-tip screwdriver.

4) Remove the AT shift lock solenoid.

(A) “P” range switch

CS-00621

CS-00646

5432112 11 10 9876

(A)

(A) “P” range switch

CS-00647

(A)

CS-00621

CS-00648

Page 2282 of 2453

CS-30

AT Shift Lock Solenoid and “P” Range Switch

CONTROL SYSTEMS

5) Disconnect the terminal of AT shift lock solenoid

from the connector, using a flat-tip screwdriver.

B: INSTALLATION

NOTE:

For installation of the mode change switch and the

shift button switch, refer to the section on Select

Levers.

1. “P” RANGE SWITCH

Install in the reverse order of removal.

NOTE:

Connect the “P” range switch terminal to connector.

2. AT SHIFT LOCK SOLENOID

Install in the reverse order of removal.

NOTE:

Connect the AT shift lock solenoid switch terminal

to connector.

(A) AT shift lock solenoid

(A) “P” range switch (wire color: Red)

CS-00649

5432112 11 10 9876

(A)

CS-00646

5432112 11 10 9876

(A)

(A) AT shift lock solenoid (color code: Black)

(B) AT shift lock solenoid (wire color: Blue)

CS-00651

5432112 11 10 9876

(A) (B)

Page 2283 of 2453

CS-31

AT Shift Lock Solenoid and “P” Range Switch

CONTROL SYSTEMS

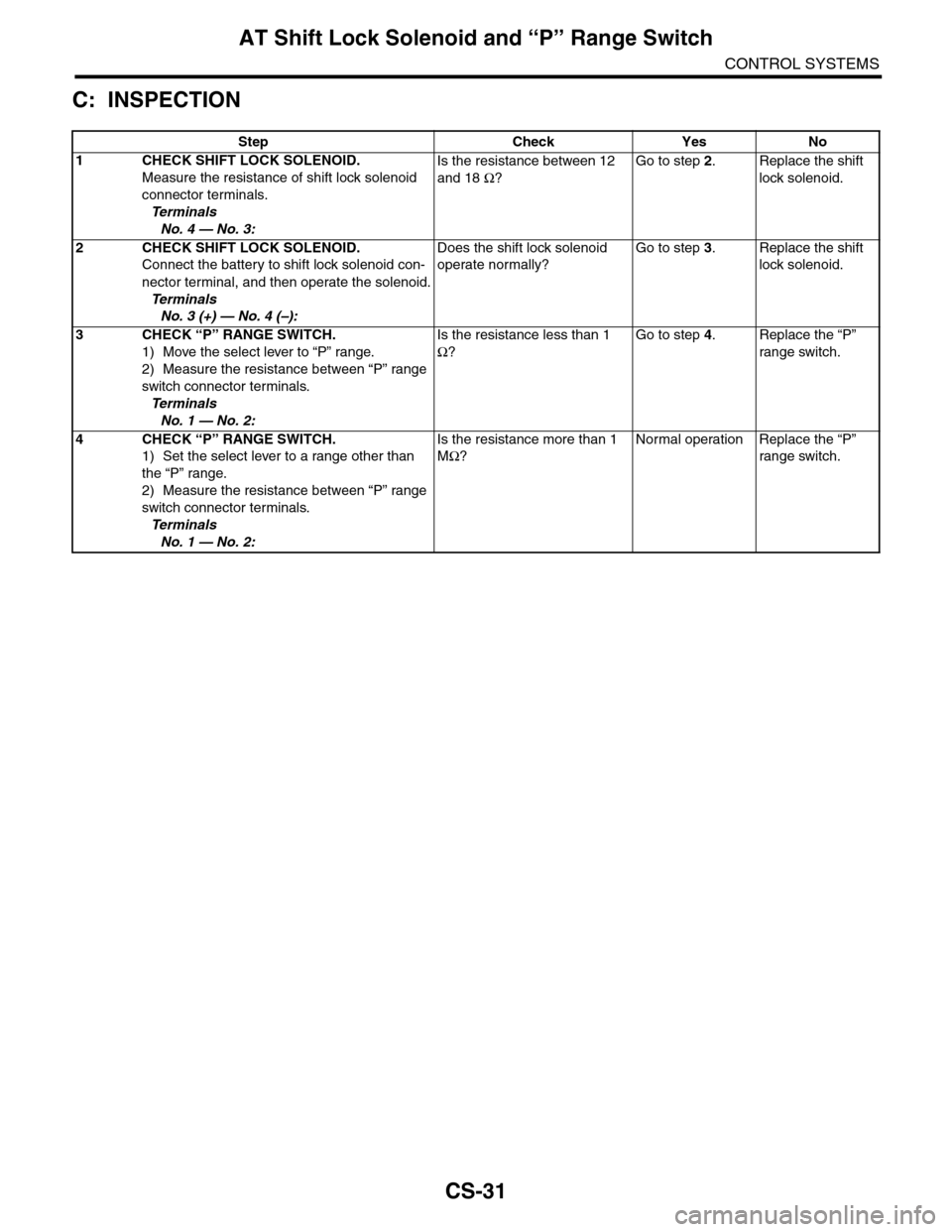

C: INSPECTION

Step Check Yes No

1CHECK SHIFT LOCK SOLENOID.

Measure the resistance of shift lock solenoid

connector terminals.

Te r m i n a l s

No. 4 — No. 3:

Is the resistance between 12

and 18 Ω?

Go to step 2.Replace the shift

lock solenoid.

2CHECK SHIFT LOCK SOLENOID.

Connect the battery to shift lock solenoid con-

nector terminal, and then operate the solenoid.

Te r m i n a l s

No. 3 (+) — No. 4 (–):

Does the shift lock solenoid

operate normally?

Go to step 3.Replace the shift

lock solenoid.

3CHECK “P” RANGE SWITCH.

1) Move the select lever to “P” range.

2) Measure the resistance between “P” range

switch connector terminals.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance less than 1

Ω?

Go to step 4.Replace the “P”

range switch.

4CHECK “P” RANGE SWITCH.

1) Set the select lever to a range other than

the “P” range.

2) Measure the resistance between “P” range

switch connector terminals.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance more than 1

MΩ?

Normal operation Replace the “P”

range switch.

Page 2284 of 2453

CS-32

Body Integrated Unit

CONTROL SYSTEMS

6. Body Integrated Unit

A: NOTE

Refer to “Body Integrated Unit” for removal and in-

stallation procedure.

Page 2285 of 2453

CS-33

General Diagnostic Table

CONTROL SYSTEMS

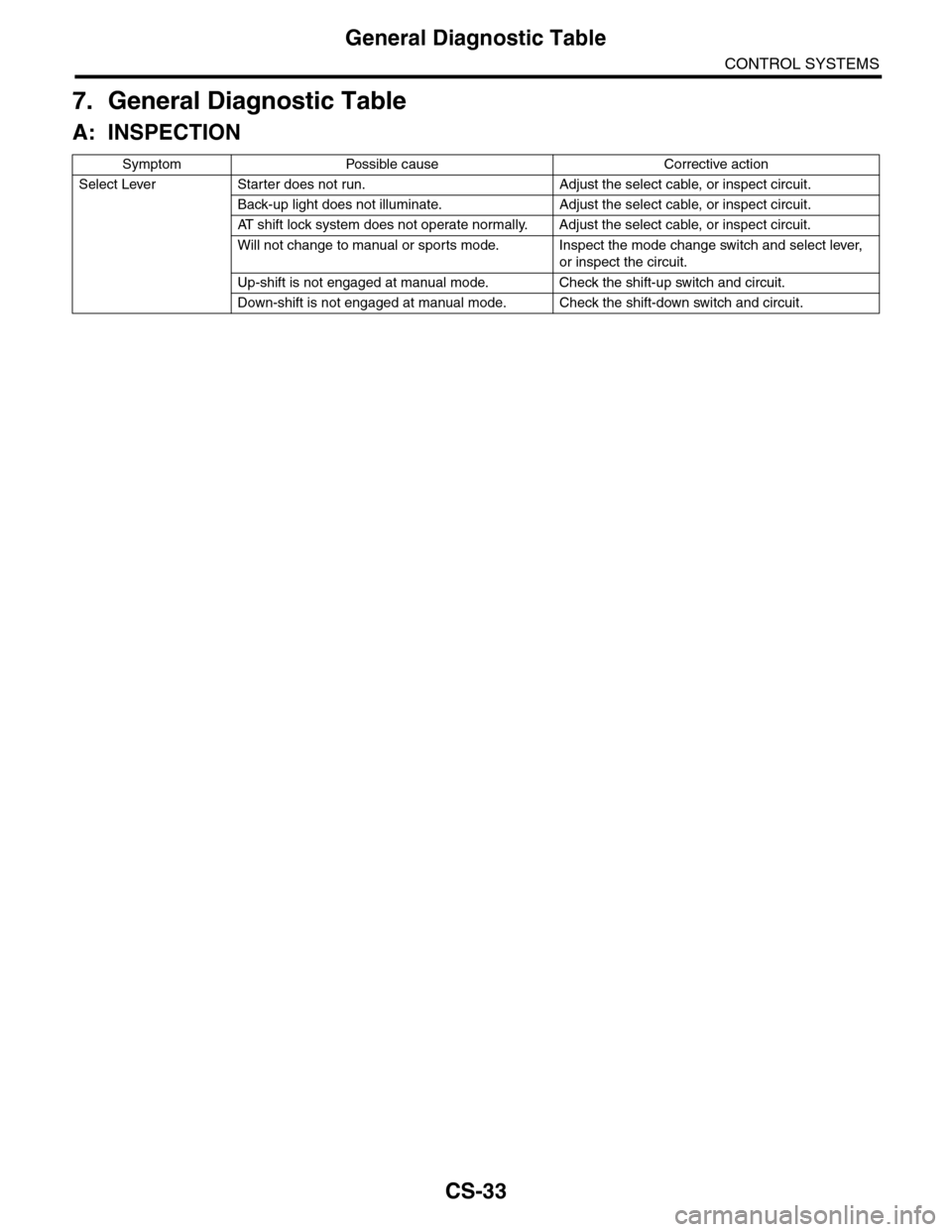

7. General Diagnostic Table

A: INSPECTION

Symptom Possible cause Corrective action

Select Lever Starter does not run. Adjust the select cable, or inspect circuit.

Back-up light does not illuminate. Adjust the select cable, or inspect circuit.

AT s h i f t l o c k s y s t e m d o e s n o t o p e r a t e n o r m a l l y. A d j u s t t h e s e l e c t c a b l e , o r i n s p e c t c i r c u i t .

Will not change to manual or sports mode. Inspect the mode change switch and select lever,

or inspect the circuit.

Up-shift is not engaged at manual mode. Check the shift-up switch and circuit.

Down-shift is not engaged at manual mode. Check the shift-down switch and circuit.

Page 2286 of 2453

CS-34

General Diagnostic Table

CONTROL SYSTEMS

Page 2287 of 2453

WI-3

Basic Diagnostic Procedure

WIRING SYSTEM

1. Basic Diagnostic Procedure

A: BASIC PROCEDURES

1. GENERAL DESCRIPTION

The most important purpose of diagnostics is to

quickly determine which part is malfunctioning, to

save time and labor.

2. IDENTIFICATION OF TROUBLE SYMP-

TOM

Determine what the problem is based on the symp-

tom.

3. PROBABLE CAUSE OF TROUBLE

Look at the wiring diagram and check the system’s

circuit. Then check the switch, relay, fuse, ground,

etc.

4. LOCATION AND REPAIR OF TROUBLE

1) Using the diagnostics, narrow down the causes.

2) If necessary, use a voltmeter, ohmmeter, etc.

3) Before replacing certain component parts

(switch, relay, etc.), check the power supply,

ground, for open wiring harness, poor connectors,

etc. If no problem is encountered, check the com-

ponent parts.

5. SYSTEM OPERATION CHECK

After repairing, ensure that the system operates

properly.

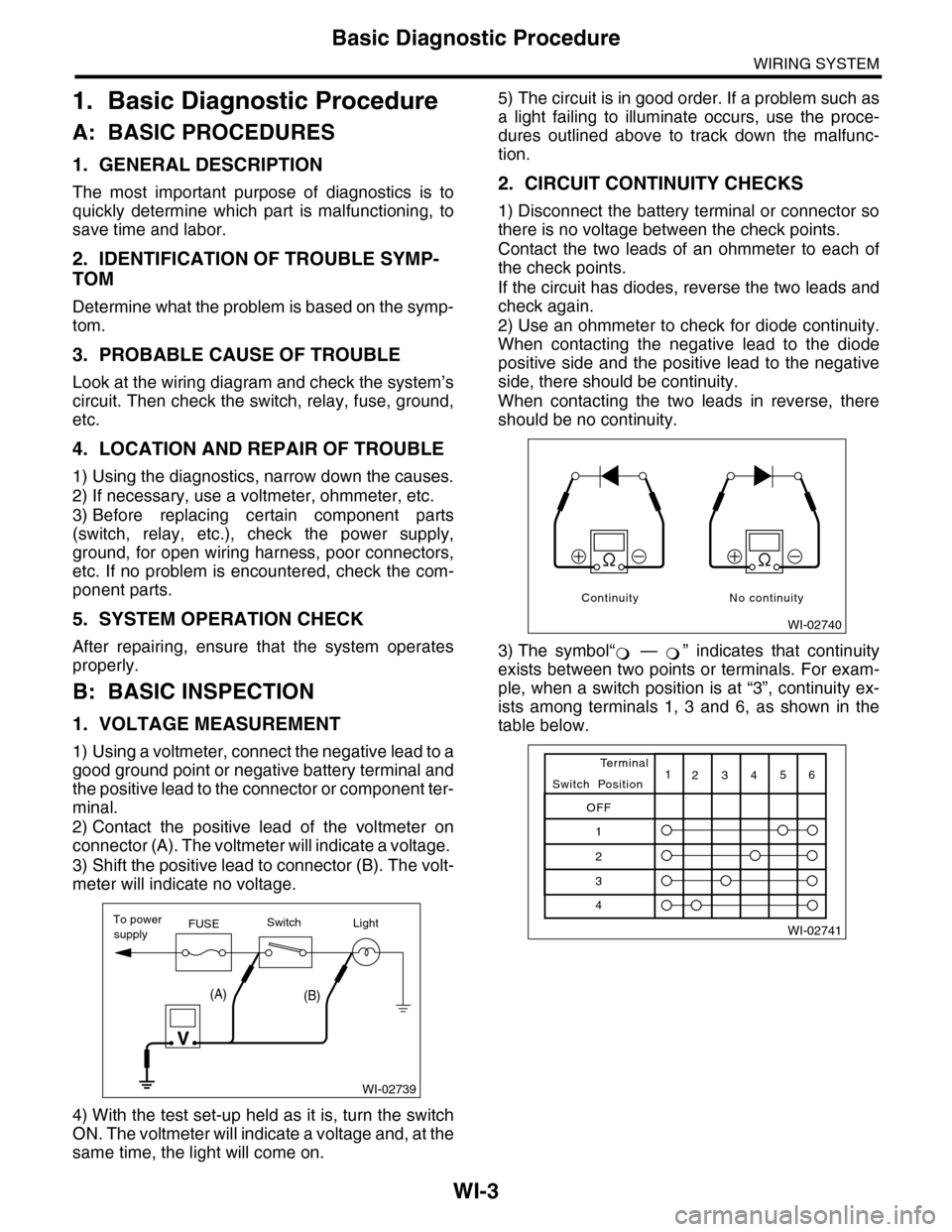

B: BASIC INSPECTION

1. VOLTAGE MEASUREMENT

1) Using a voltmeter, connect the negative lead to a

good ground point or negative battery terminal and

the positive lead to the connector or component ter-

minal.

2) Contact the positive lead of the voltmeter on

connector (A). The voltmeter will indicate a voltage.

3) Shift the positive lead to connector (B). The volt-

meter will indicate no voltage.

4) With the test set-up held as it is, turn the switch

ON. The voltmeter will indicate a voltage and, at the

same time, the light will come on.

5) The circuit is in good order. If a problem such as

a light failing to illuminate occurs, use the proce-

dures outlined above to track down the malfunc-

tion.

2. CIRCUIT CONTINUITY CHECKS

1) Disconnect the battery terminal or connector so

there is no voltage between the check points.

Contact the two leads of an ohmmeter to each of

the check points.

If the circuit has diodes, reverse the two leads and

check again.

2) Use an ohmmeter to check for diode continuity.

When contacting the negative lead to the diode

positive side and the positive lead to the negative

side, there should be continuity.

When contacting the two leads in reverse, there

should be no continuity.

3) The symbol“ — ” indicates that continuity

exists between two points or terminals. For exam-

ple, when a switch position is at “3”, continuity ex-

ists among terminals 1, 3 and 6, as shown in the

table below.

WI-02739

To powerFUSEsupplySwitchLight

V

(A)(B)

WI-02740

Continuity No continuity

�

Page 2288 of 2453

WI-4

Basic Diagnostic Procedure

WIRING SYSTEM

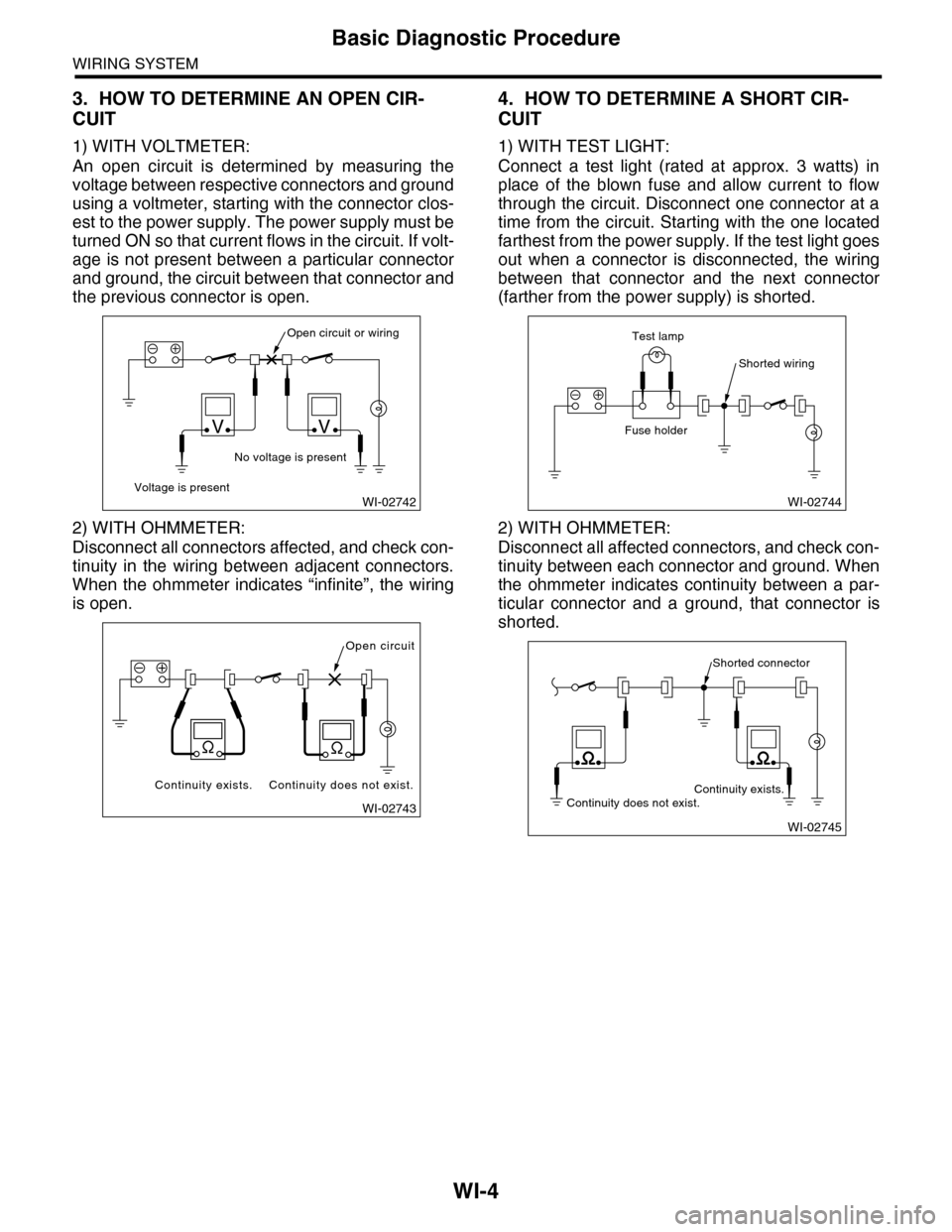

3. HOW TO DETERMINE AN OPEN CIR-

CUIT

1) WITH VOLTMETER:

An open circuit is determined by measuring the

voltage between respective connectors and ground

using a voltmeter, starting with the connector clos-

est to the power supply. The power supply must be

turned ON so that current flows in the circuit. If volt-

age is not present between a particular connector

and ground, the circuit between that connector and

the previous connector is open.

2) WITH OHMMETER:

Disconnect all connectors affected, and check con-

tinuity in the wiring between adjacent connectors.

When the ohmmeter indicates “infinite”, the wiring

is open.

4. HOW TO DETERMINE A SHORT CIR-

CUIT

1) WITH TEST LIGHT:

Connect a test light (rated at approx. 3 watts) in

place of the blown fuse and allow current to flow

through the circuit. Disconnect one connector at a

time from the circuit. Starting with the one located

farthest from the power supply. If the test light goes

out when a connector is disconnected, the wiring

between that connector and the next connector

(farther from the power supply) is shorted.

2) WITH OHMMETER:

Disconnect all affected connectors, and check con-

tinuity between each connector and ground. When

the ohmmeter indicates continuity between a par-

ticular connector and a ground, that connector is

shorted.

WI-02742

Open circuit or wiring

No voltage is present

Voltage is present

VV

WI-02743

Open circuit

Continuity does not exist.Continuity exists.

WI-02744

Shorted wiring

Test lamp

Fuse holder

WI-02745

Shorted connector

Continuity does not exist.Continuity exists.

Page 2289 of 2453

WI-5

Basic Diagnostic Procedure

WIRING SYSTEM

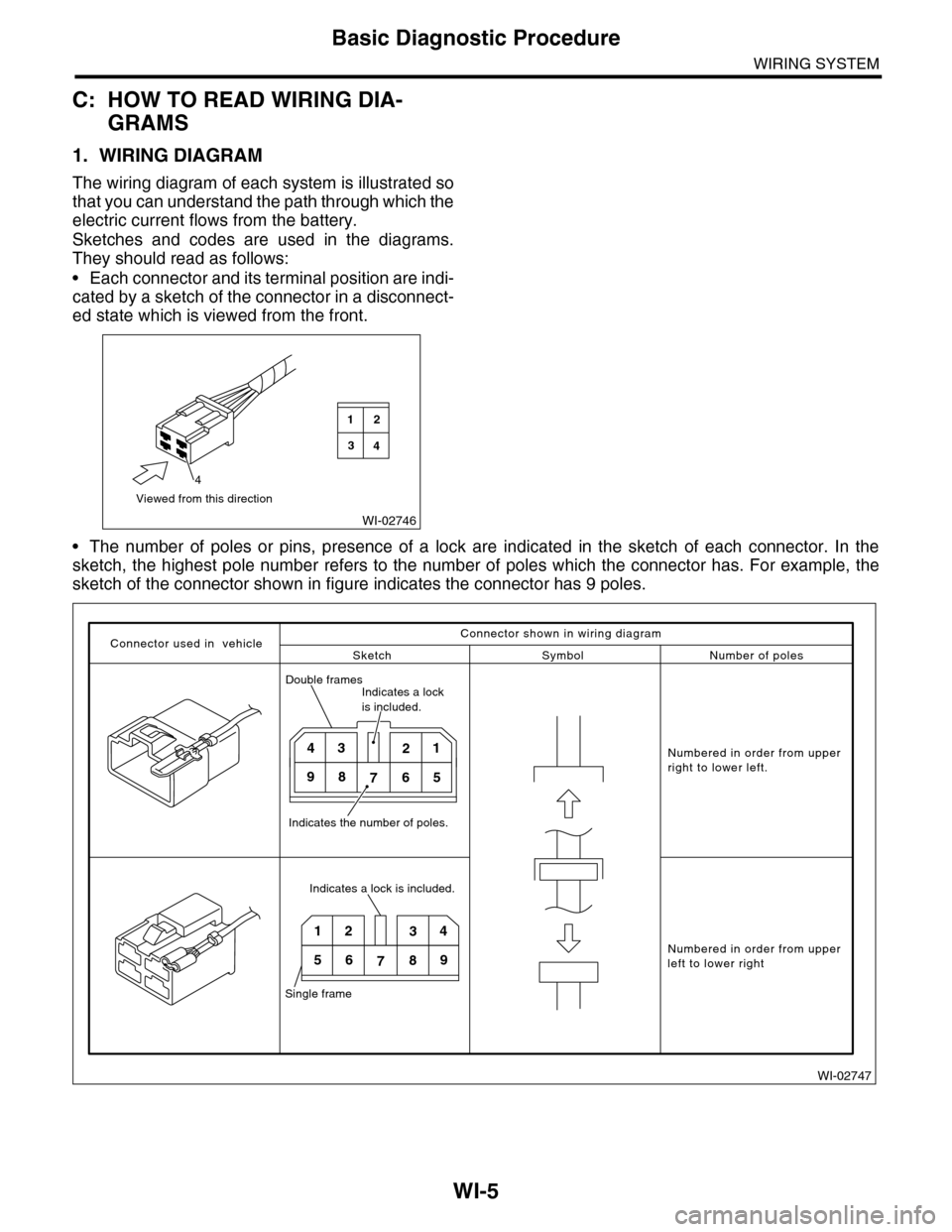

C: HOW TO READ WIRING DIA-

GRAMS

1. WIRING DIAGRAM

The wiring diagram of each system is illustrated so

that you can understand the path through which the

electric current flows from the battery.

Sketches and codes are used in the diagrams.

They should read as follows:

•Each connector and its terminal position are indi-

cated by a sketch of the connector in a disconnect-

ed state which is viewed from the front.

•The number of poles or pins, presence of a lock are indicated in the sketch of each connector. In the

sketch, the highest pole number refers to the number of poles which the connector has. For example, the

sketch of the connector shown in figure indicates the connector has 9 poles.

WI-02746

Viewed from this direction

4

2

4

1

3

WI-02747

Connector used in vehicleSketch Symbol Number of poles

Numbered in order from upperright to lower left.

Numbered in order from upperleft to lower right

Connector shown in wiring diagram

Double framesIndicates a lock is included.

Indicates the number of poles.

4321

98765

Indicates a lock is included.

Single frame

1234

56789

Page 2290 of 2453

WI-6

Basic Diagnostic Procedure

WIRING SYSTEM

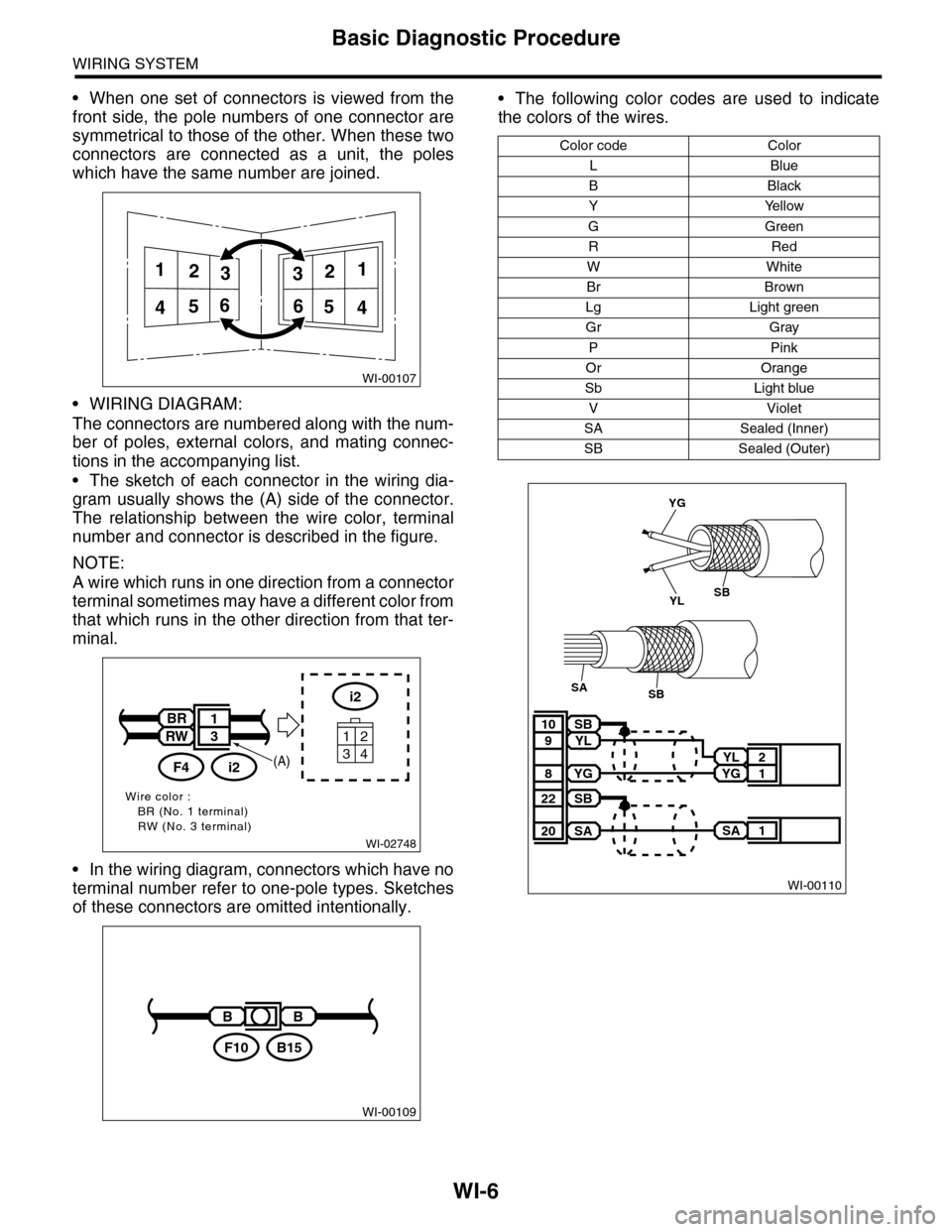

•When one set of connectors is viewed from the

front side, the pole numbers of one connector are

symmetrical to those of the other. When these two

connectors are connected as a unit, the poles

which have the same number are joined.

•WIRING DIAGRAM:

The connectors are numbered along with the num-

ber of poles, external colors, and mating connec-

tions in the accompanying list.

•The sketch of each connector in the wiring dia-

gram usually shows the (A) side of the connector.

The relationship between the wire color, terminal

number and connector is described in the figure.

NOTE:

A wire which runs in one direction from a connector

terminal sometimes may have a different color from

that which runs in the other direction from that ter-

minal.

•In the wiring diagram, connectors which have no

terminal number refer to one-pole types. Sketches

of these connectors are omitted intentionally.

•The following color codes are used to indicate

the colors of the wires.

WI-00107

112233

445566

WI-02748

Wire color :BR (No. 1 terminal)RW (No. 3 terminal)

i2

34

12

BR

RW

i2F4

1

3

(A)

WI-00109

BB

B15F10

Color code Color

LBlue

BBlack

YYellow

GGreen

RRed

WWhite

Br Brown

Lg Light green

Gr Gray

PPink

Or Orange

Sb Light blue

VViolet

SA Sealed (Inner)

SB Sealed (Outer)

WI-00110

YL 2

YG 1

SB10

YL9

YG8

SA 1

SB22

SA20

YG

YLSB

SBSA