SUBARU TRIBECA 2009 1.G Service Workshop Manual

TRIBECA 2009 1.G

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/7322/w960_7322-0.png

SUBARU TRIBECA 2009 1.G Service Workshop Manual

Page 1579 of 2453

FU(H6DO)-18

Crankshaft Position Sensor

FUEL INJECTION (FUEL SYSTEMS)

5. Crankshaft Position Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

IN(H6DO)-6, REMOVAL, Air Intake Chamber.>

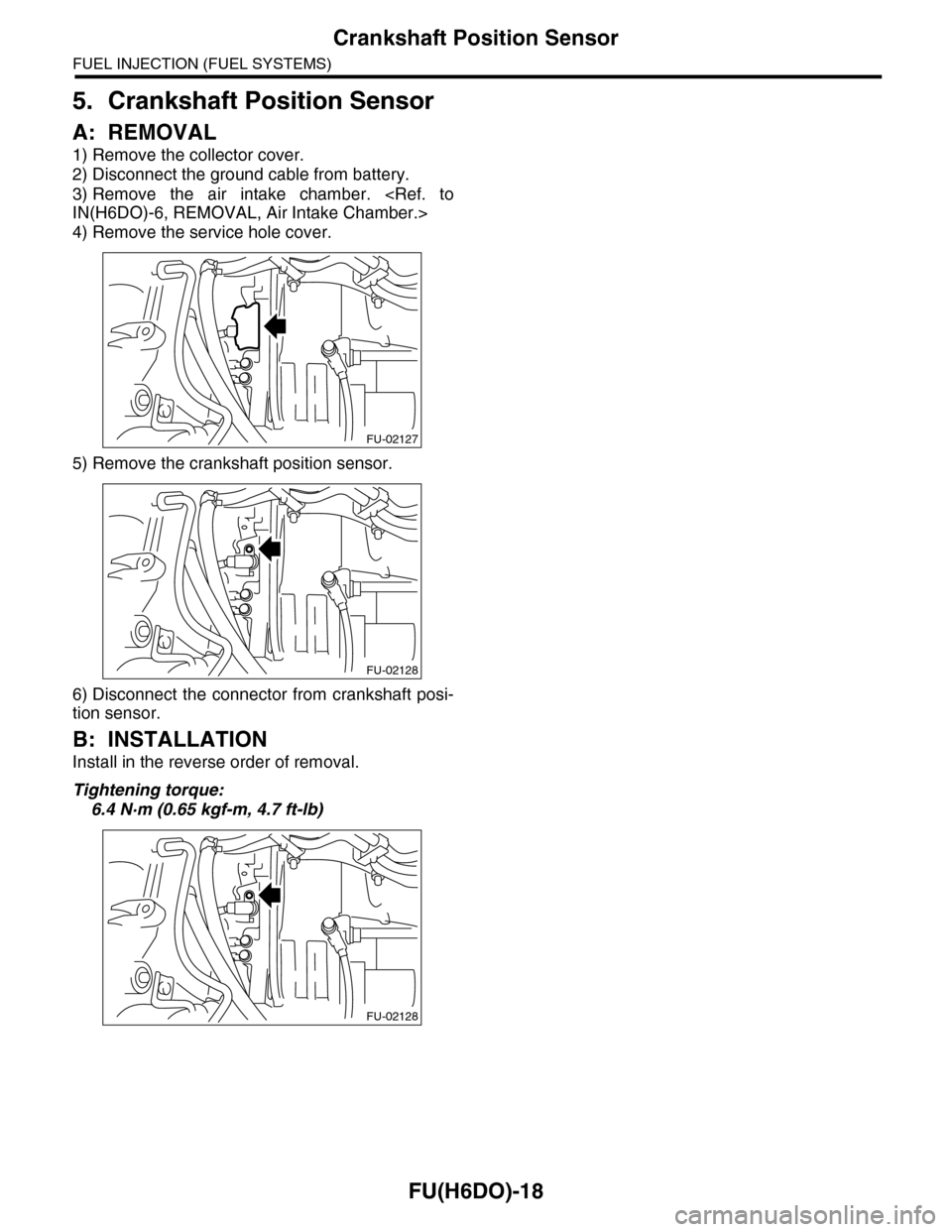

4) Remove the service hole cover.

5) Remove the crankshaft position sensor.

6) Disconnect the connector from crankshaft posi-

tion sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

FU-02127

FU-02128

FU-02128

Page 1580 of 2453

FU(H6DO)-19

Camshaft Position Sensor

FUEL INJECTION (FUEL SYSTEMS)

6. Camshaft Position Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the generator harness from fuel pipe

protector LH.

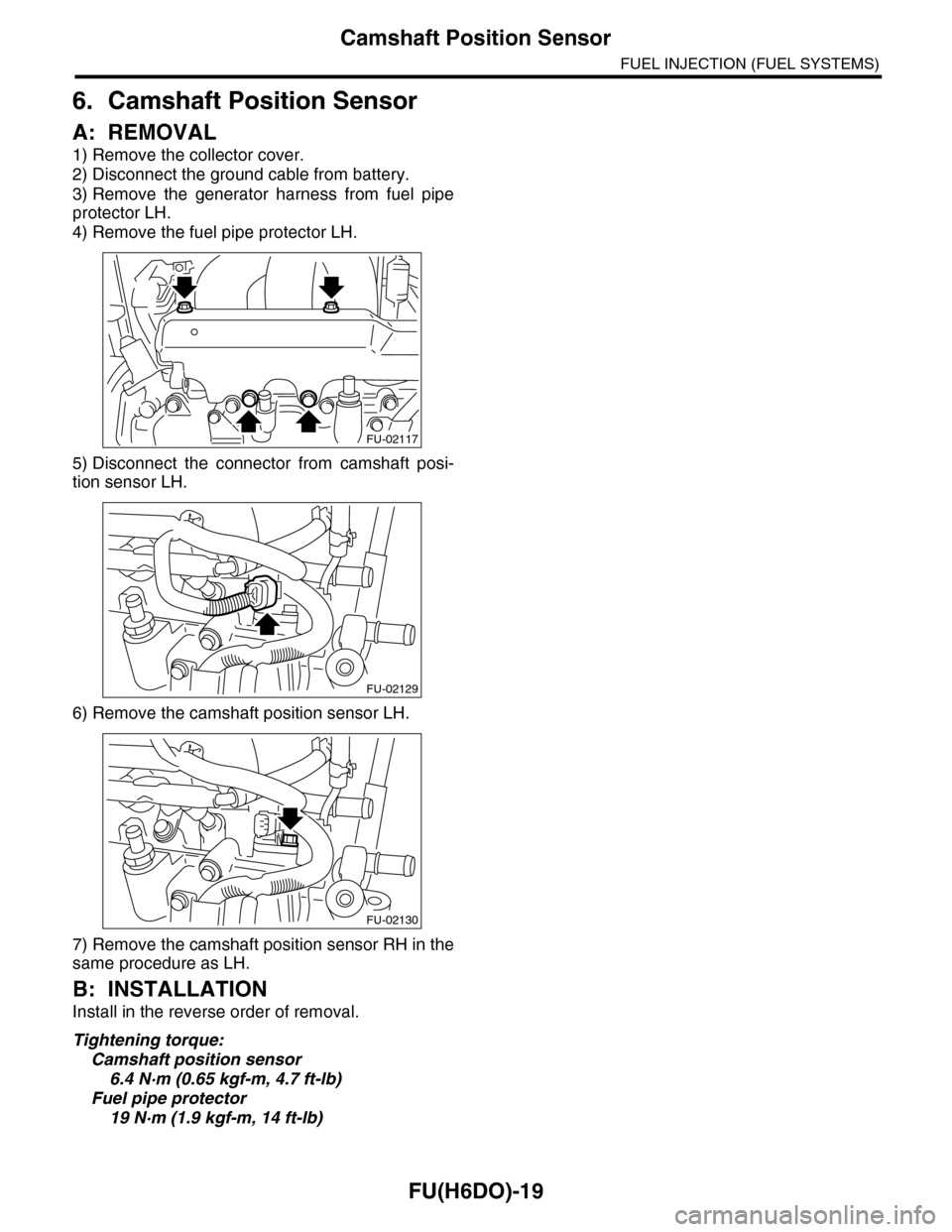

4) Remove the fuel pipe protector LH.

5) Disconnect the connector from camshaft posi-

tion sensor LH.

6) Remove the camshaft position sensor LH.

7) Remove the camshaft position sensor RH in the

same procedure as LH.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

Camshaft position sensor

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

Fuel pipe protector

19 N·m (1.9 kgf-m, 14 ft-lb)

FU-02117

FU-02129

FU-02130

Page 1581 of 2453

FU(H6DO)-20

Knock Sensor

FUEL INJECTION (FUEL SYSTEMS)

7. Knock Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the intake manifold.

fold.>

4) Disconnect the knock sensor connector.

5) Remove the knock sensor from cylinder block.

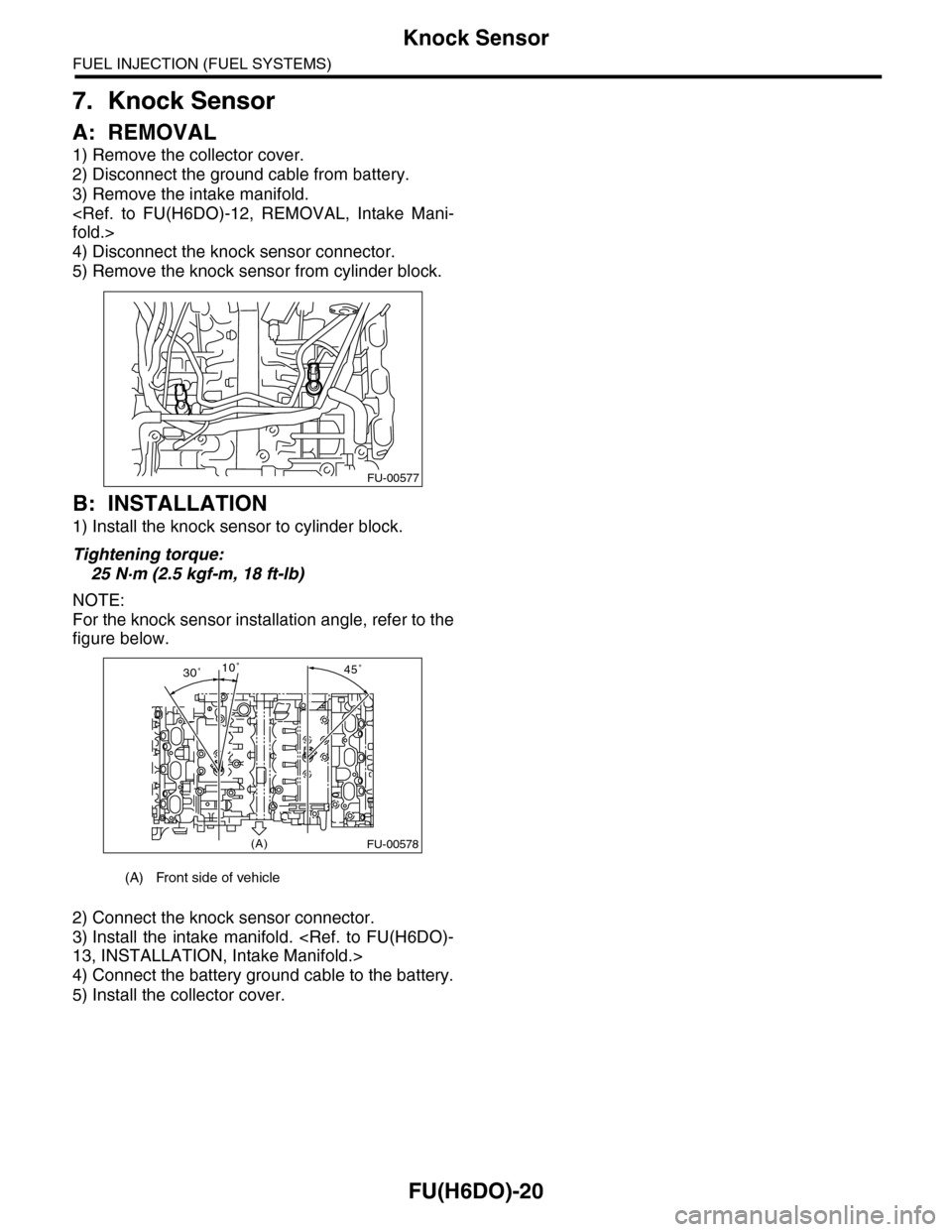

B: INSTALLATION

1) Install the knock sensor to cylinder block.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

NOTE:

For the knock sensor installation angle, refer to the

figure below.

2) Connect the knock sensor connector.

3) Install the intake manifold.

13, INSTALLATION, Intake Manifold.>

4) Connect the battery ground cable to the battery.

5) Install the collector cover.

(A) Front side of vehicle

FU-00577

45˚30˚10˚

(A)FU-00578

Page 1582 of 2453

FU(H6DO)-21

Throttle Position Sensor

FUEL INJECTION (FUEL SYSTEMS)

8. Throttle Position Sensor

A: SPECIFICATION

Throttle body is a non-disassembled part, so do not

remove the throttle position sensor from throttle

body.

Refer to “Throttle Body” for removal and installation

procedure.

Throttle Body.>

LATION, Throttle Body.>

Page 1583 of 2453

FU(H6DO)-22

Manifold Absolute Pressure Sensor

FUEL INJECTION (FUEL SYSTEMS)

9. Manifold Absolute Pressure

Sensor

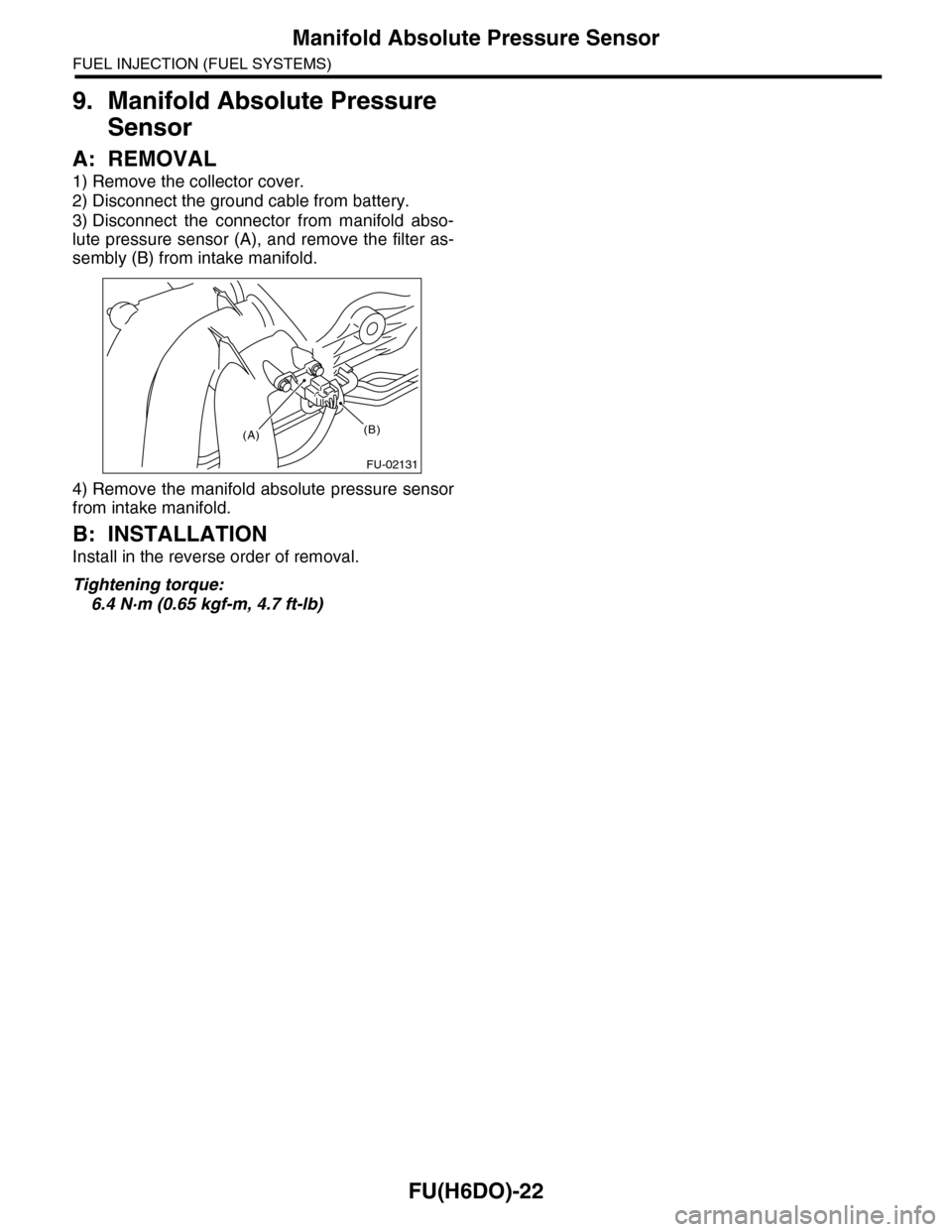

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Disconnect the connector from manifold abso-

lute pressure sensor (A), and remove the filter as-

sembly (B) from intake manifold.

4) Remove the manifold absolute pressure sensor

from intake manifold.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

FU-02131

(B)(A)

Page 1584 of 2453

FU(H6DO)-23

Mass Air Flow and Intake Air Temperature Sensor

FUEL INJECTION (FUEL SYSTEMS)

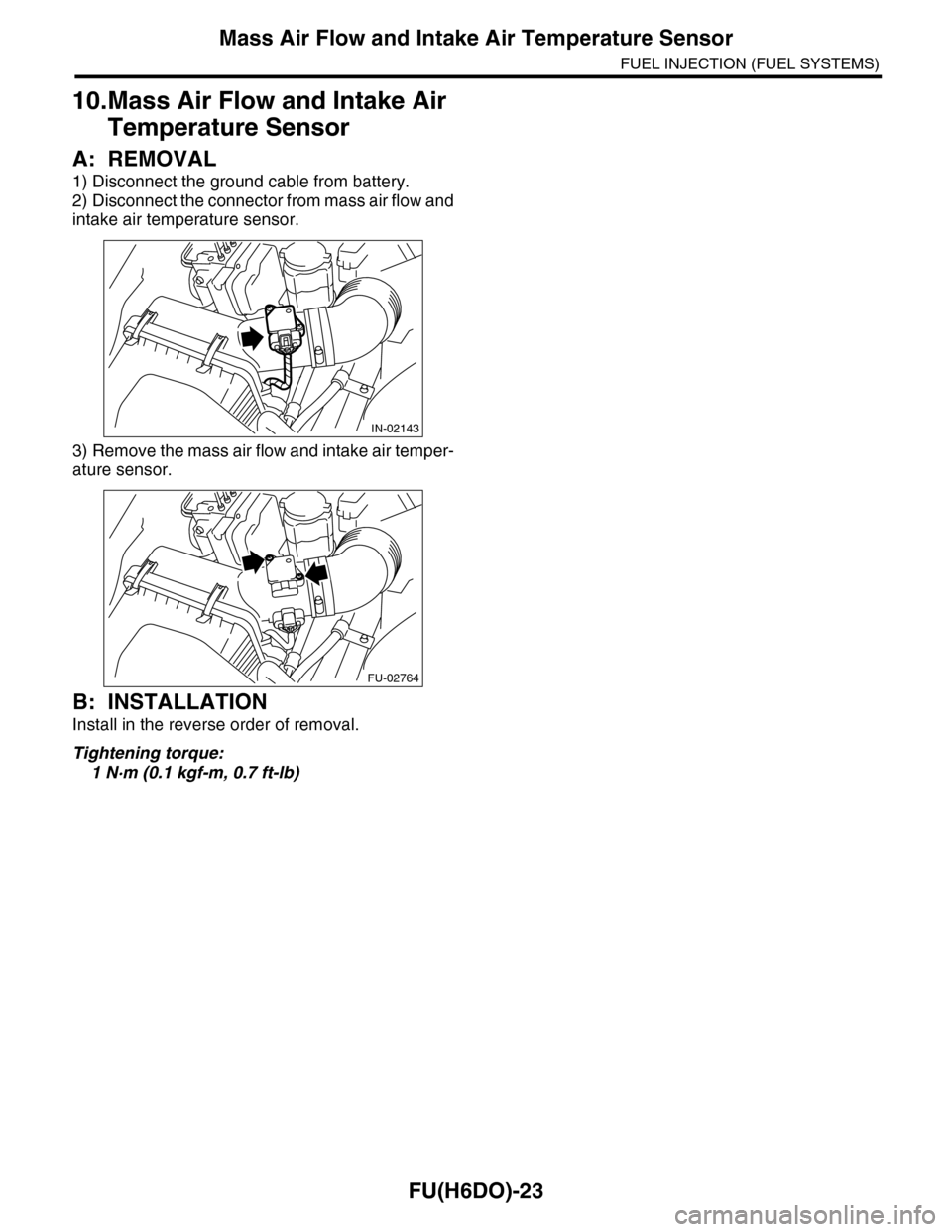

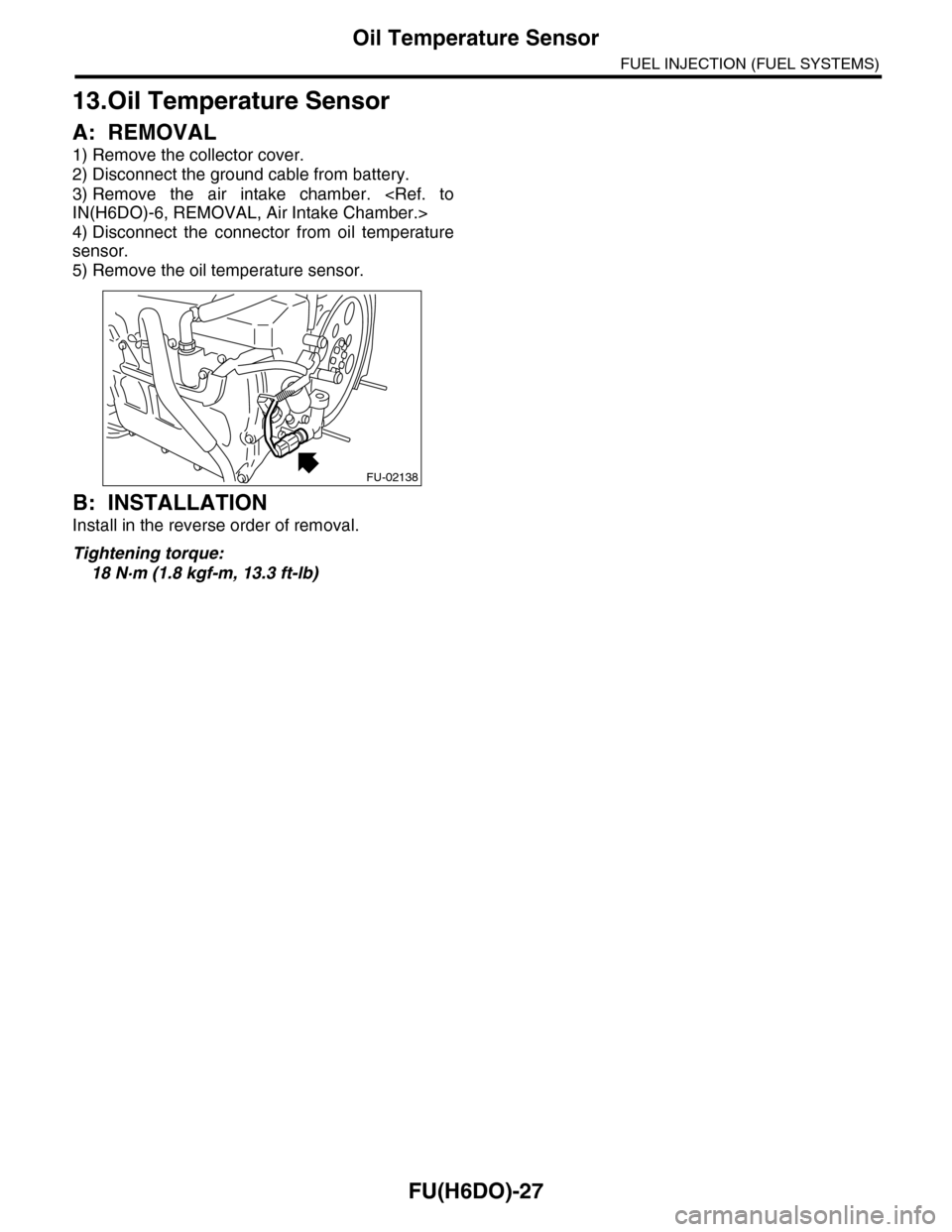

10.Mass Air Flow and Intake Air

Temperature Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Disconnect the connector from mass air flow and

intake air temperature sensor.

3) Remove the mass air flow and intake air temper-

ature sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

1 N·m (0.1 kgf-m, 0.7 ft-lb)

IN-02143

FU-02764

Page 1588 of 2453

FU(H6DO)-27

Oil Temperature Sensor

FUEL INJECTION (FUEL SYSTEMS)

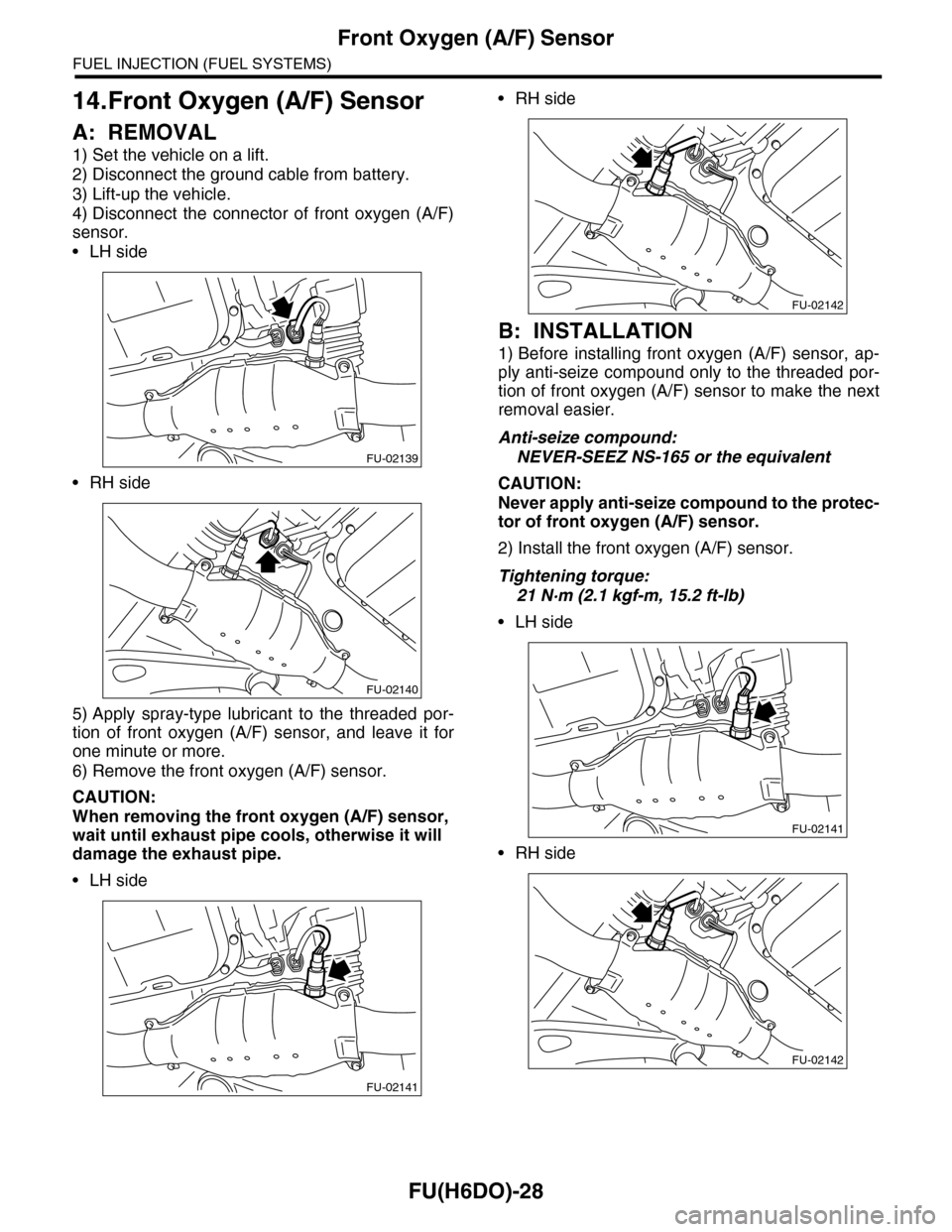

13.Oil Temperature Sensor

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air intake chamber.

IN(H6DO)-6, REMOVAL, Air Intake Chamber.>

4) Disconnect the connector from oil temperature

sensor.

5) Remove the oil temperature sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

FU-02138

Page 1589 of 2453

FU(H6DO)-28

Front Oxygen (A/F) Sensor

FUEL INJECTION (FUEL SYSTEMS)

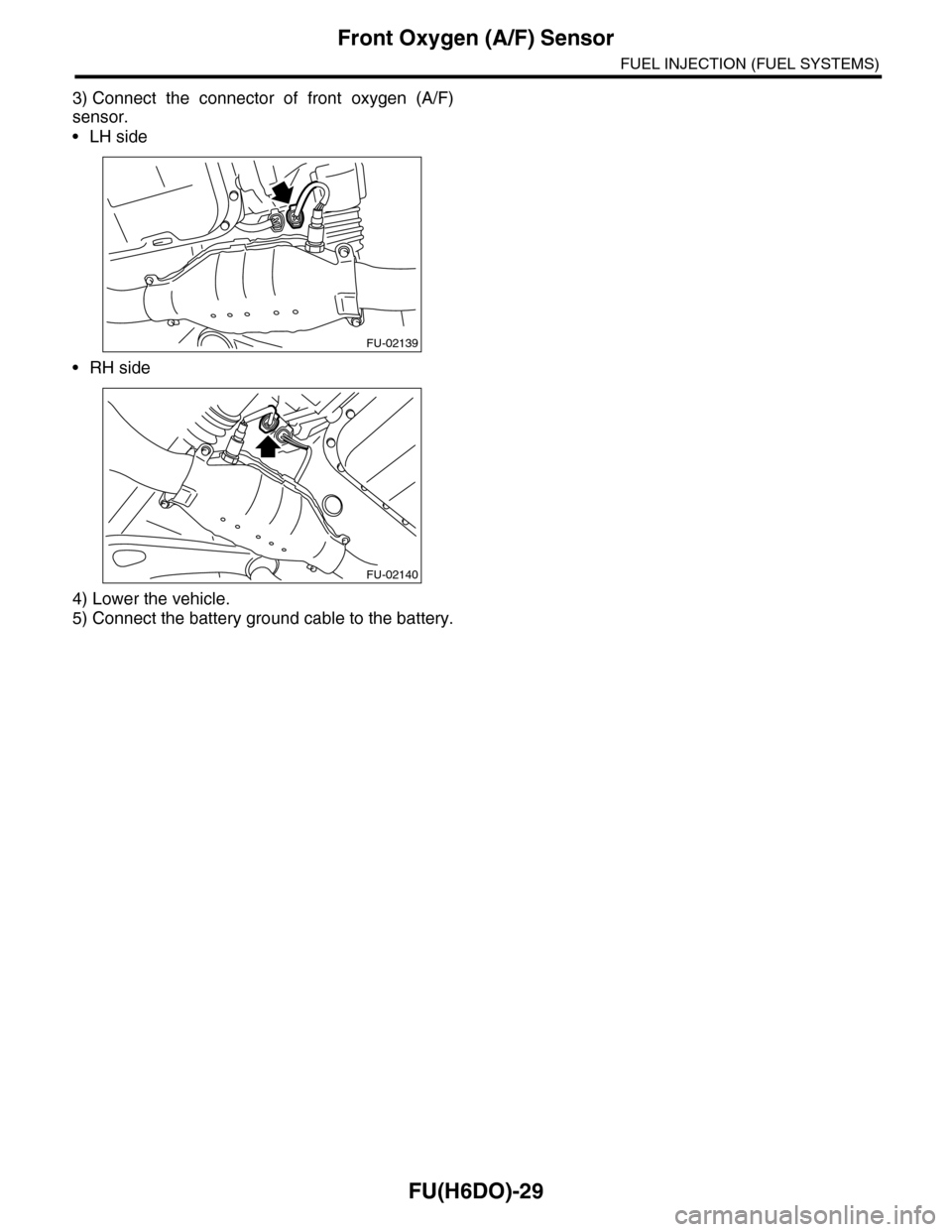

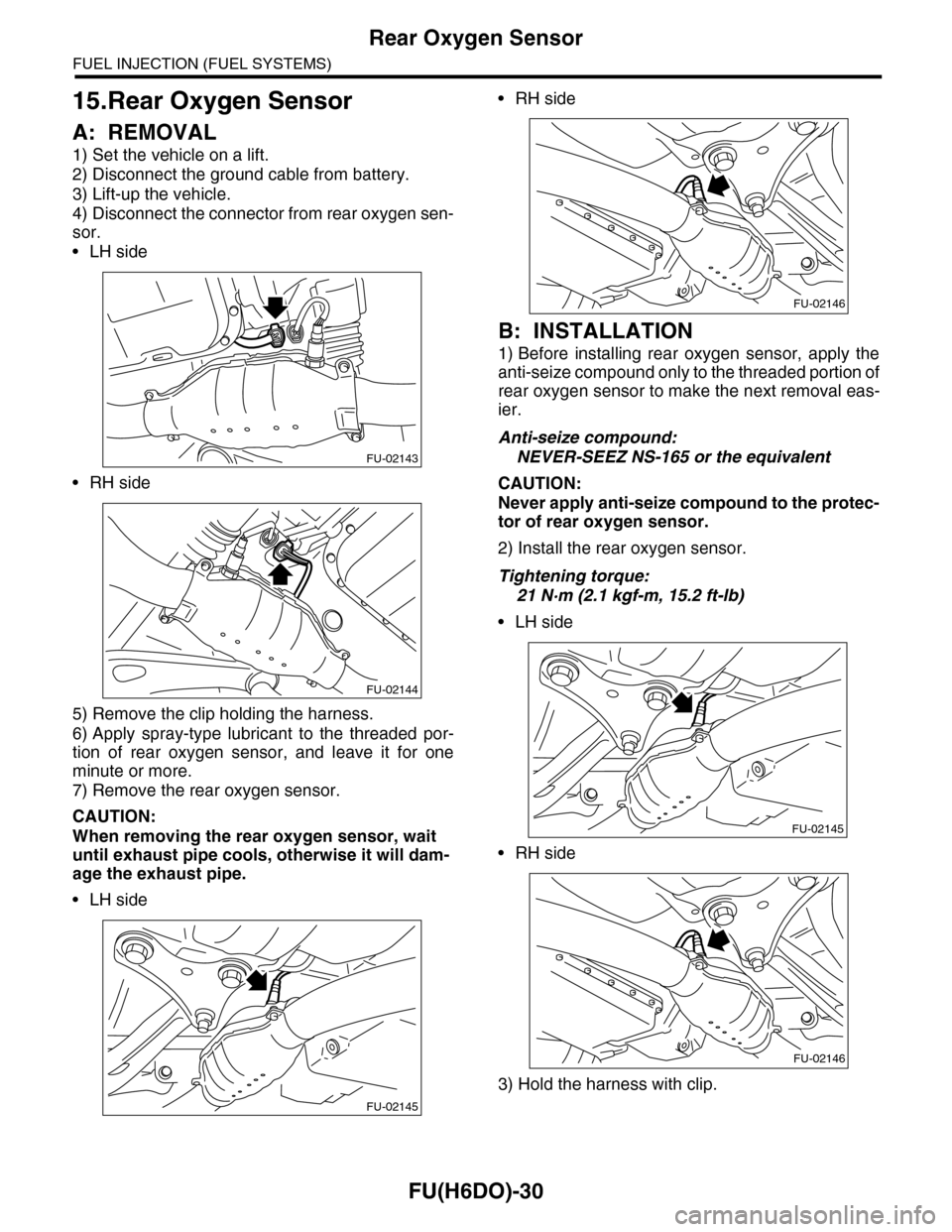

14.Front Oxygen (A/F) Sensor

A: REMOVAL

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Lift-up the vehicle.

4) Disconnect the connector of front oxygen (A/F)

sensor.

•LH side

•RH side

5) Apply spray-type lubricant to the threaded por-

tion of front oxygen (A/F) sensor, and leave it for

one minute or more.

6) Remove the front oxygen (A/F) sensor.

CAUTION:

When removing the front oxygen (A/F) sensor,

wait until exhaust pipe cools, otherwise it will

damage the exhaust pipe.

•LH side

•RH side

B: INSTALLATION

1) Before installing front oxygen (A/F) sensor, ap-

ply anti-seize compound only to the threaded por-

tion of front oxygen (A/F) sensor to make the next

removal easier.

Anti-seize compound:

NEVER-SEEZ NS-165 or the equivalent

CAUTION:

Never apply anti-seize compound to the protec-

tor of front oxygen (A/F) sensor.

2) Install the front oxygen (A/F) sensor.

Tightening torque:

21 N·m (2.1 kgf-m, 15.2 ft-lb)

•LH side

•RH side

FU-02139

FU-02140

FU-02141

FU-02142

FU-02141

FU-02142

Page 1590 of 2453

FU(H6DO)-29

Front Oxygen (A/F) Sensor

FUEL INJECTION (FUEL SYSTEMS)

3) Connect the connector of front oxygen (A/F)

sensor.

•LH side

•RH side

4) Lower the vehicle.

5) Connect the battery ground cable to the battery.

FU-02139

FU-02140

Page 1591 of 2453

FU(H6DO)-30

Rear Oxygen Sensor

FUEL INJECTION (FUEL SYSTEMS)

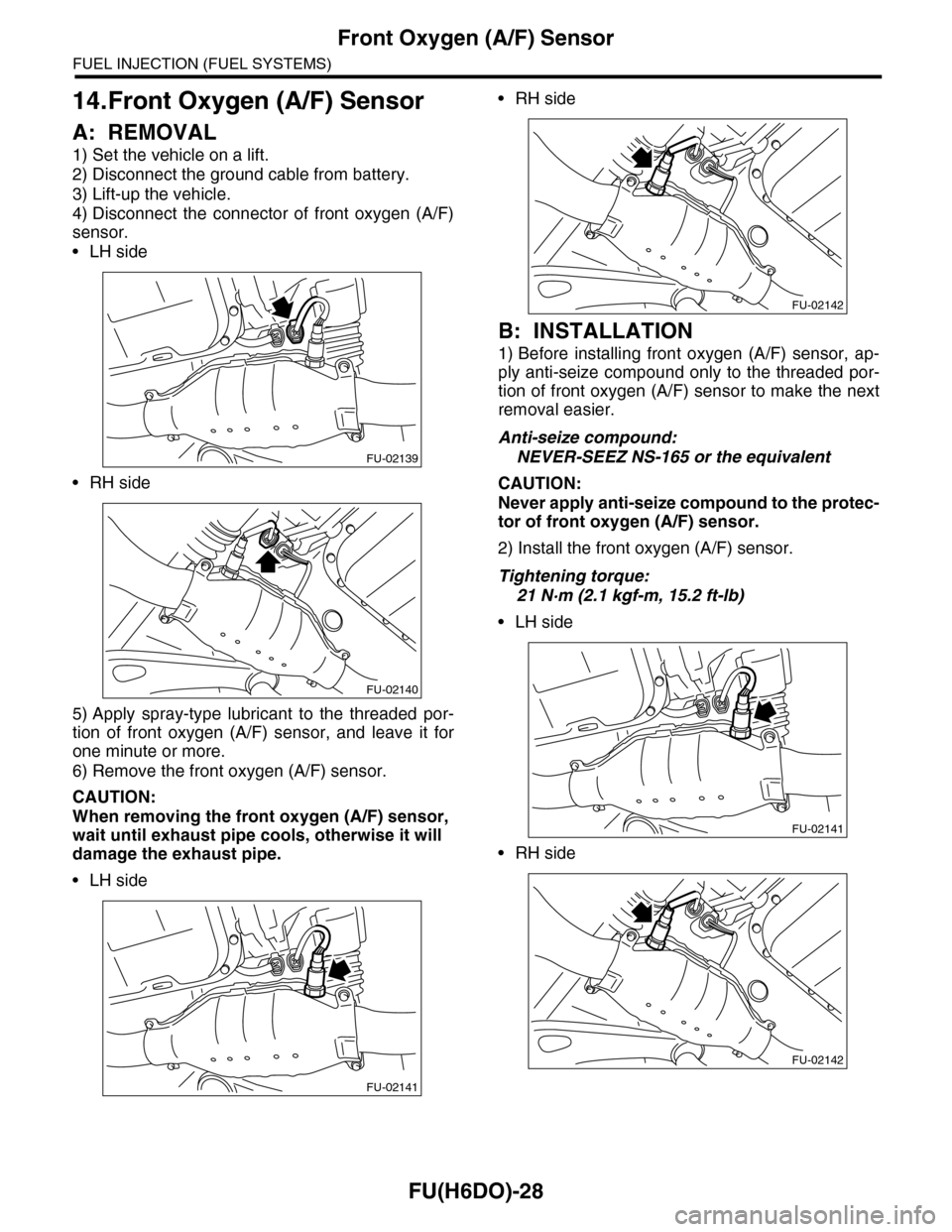

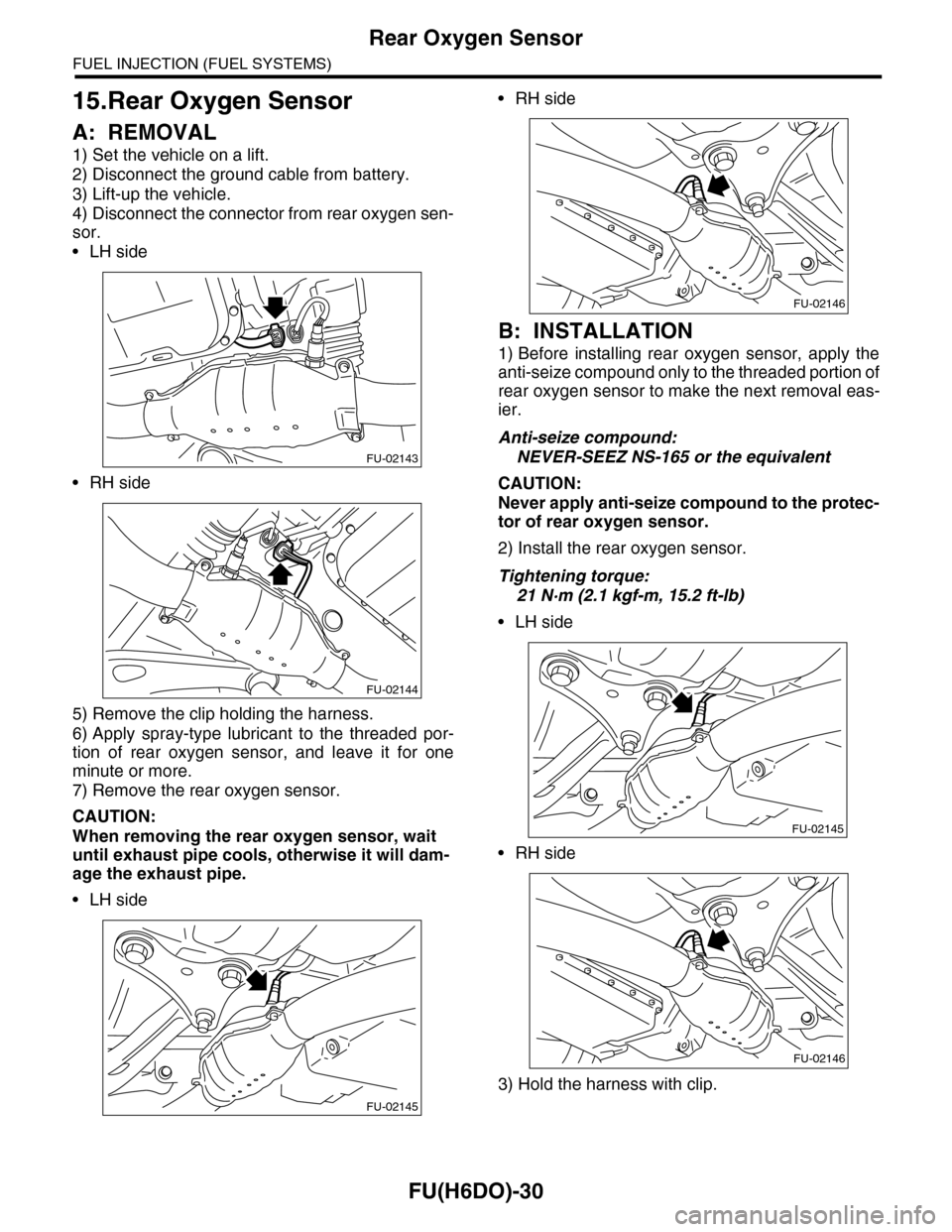

15.Rear Oxygen Sensor

A: REMOVAL

1) Set the vehicle on a lift.

2) Disconnect the ground cable from battery.

3) Lift-up the vehicle.

4) Disconnect the connector from rear oxygen sen-

sor.

•LH side

•RH side

5) Remove the clip holding the harness.

6) Apply spray-type lubricant to the threaded por-

tion of rear oxygen sensor, and leave it for one

minute or more.

7) Remove the rear oxygen sensor.

CAUTION:

When removing the rear oxygen sensor, wait

until exhaust pipe cools, otherwise it will dam-

age the exhaust pipe.

•LH side

•RH side

B: INSTALLATION

1) Before installing rear oxygen sensor, apply the

anti-seize compound only to the threaded portion of

rear oxygen sensor to make the next removal eas-

ier.

Anti-seize compound:

NEVER-SEEZ NS-165 or the equivalent

CAUTION:

Never apply anti-seize compound to the protec-

tor of rear oxygen sensor.

2) Install the rear oxygen sensor.

Tightening torque:

21 N·m (2.1 kgf-m, 15.2 ft-lb)

•LH side

•RH side

3) Hold the harness with clip.

FU-02143

FU-02144

FU-02145

FU-02146

FU-02145

FU-02146