sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1592 of 2453

FU(H6DO)-31

Rear Oxygen Sensor

FUEL INJECTION (FUEL SYSTEMS)

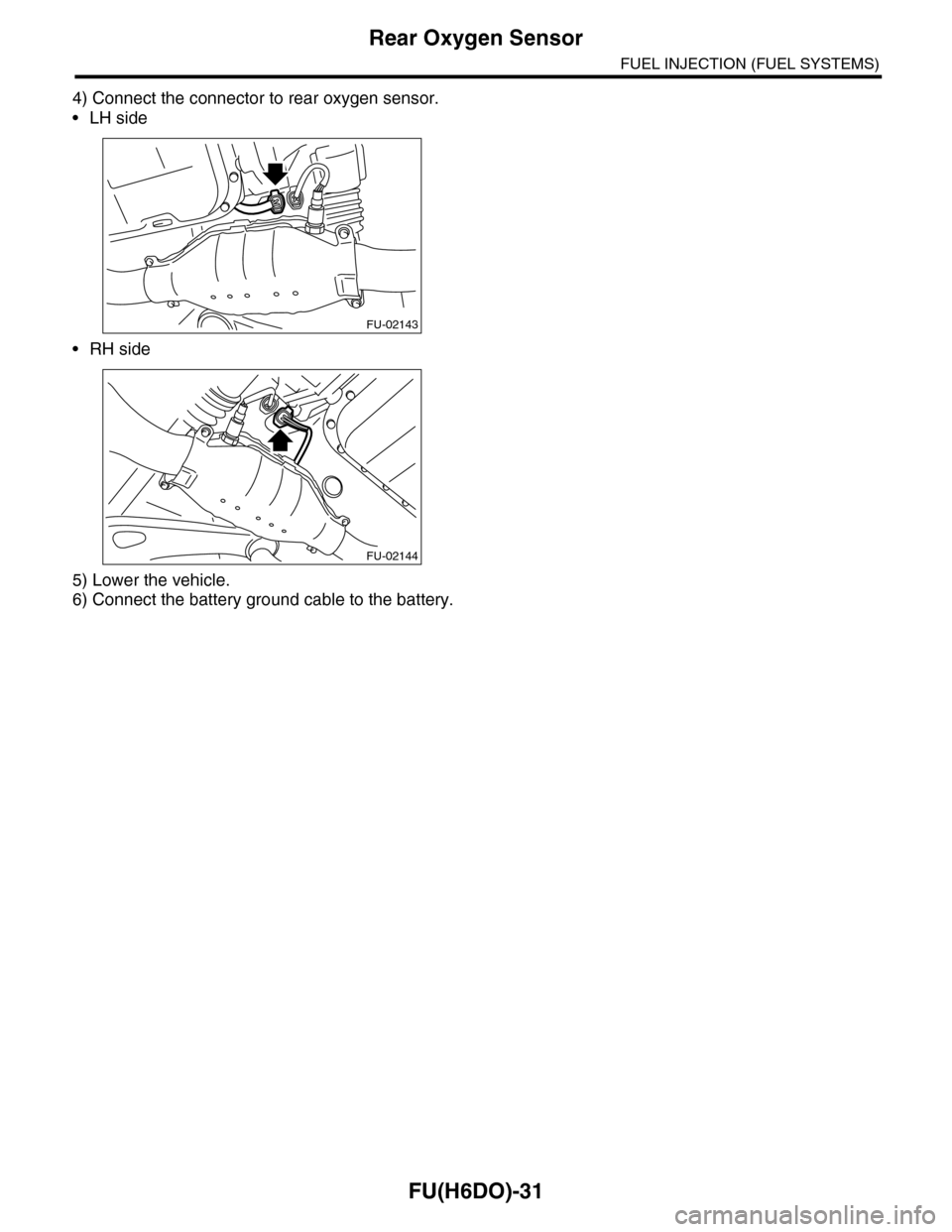

4) Connect the connector to rear oxygen sensor.

•LH side

•RH side

5) Lower the vehicle.

6) Connect the battery ground cable to the battery.

FU-02143

FU-02144

Page 1599 of 2453

FU(H6DO)-38

Fuel Tank

FUEL INJECTION (FUEL SYSTEMS)

22.Fuel Tank

A: REMOVAL

WARNING:

•Place “NO FIRE” signs near the working area.

•Be careful not to spill fuel on the floor.

1) Set the vehicle on a lift.

2) Release the fuel pressure.

DURE, Fuel.>

3) Disconnect the ground cable from battery.

4) Drain fuel from fuel tank.

5) Remove the second seat.

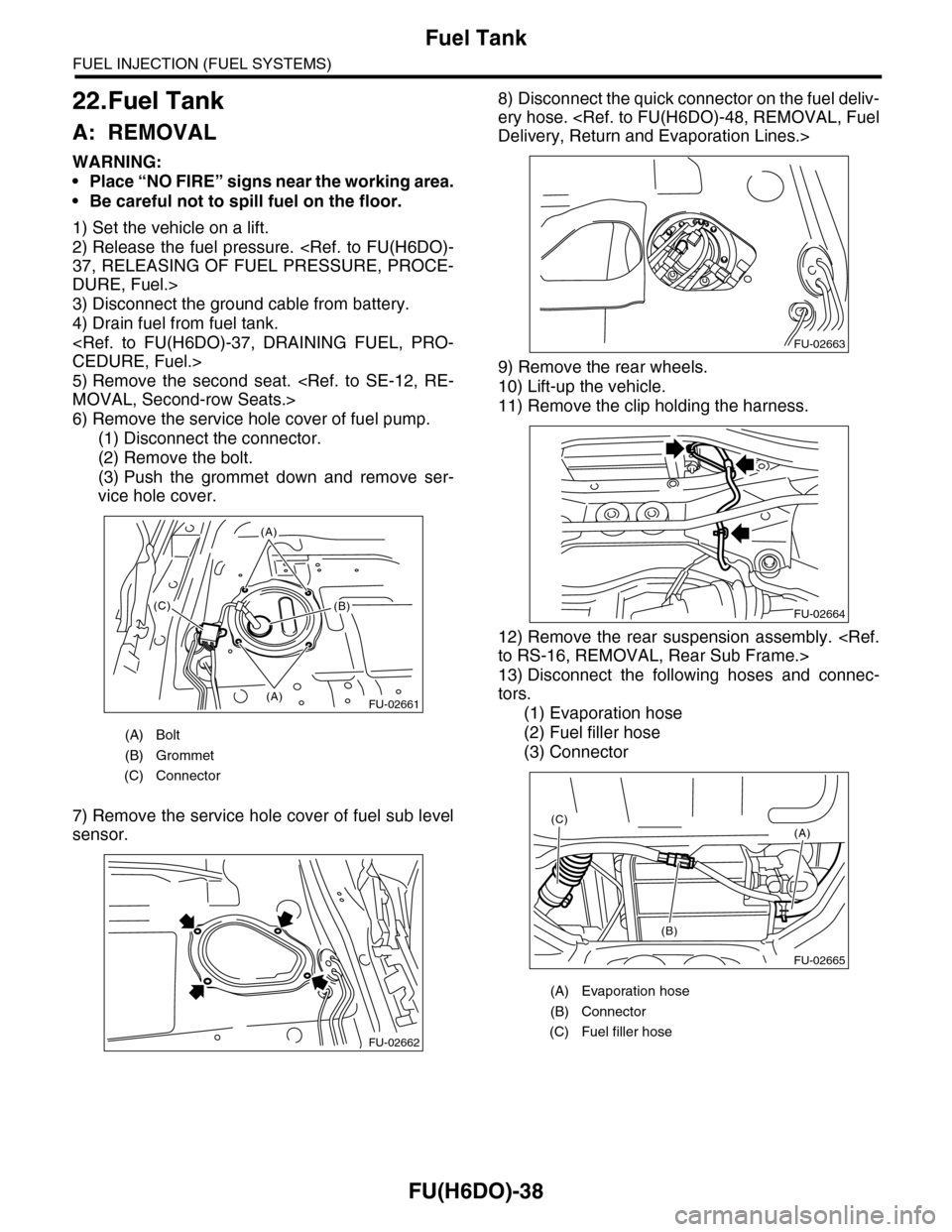

6) Remove the service hole cover of fuel pump.

(1) Disconnect the connector.

(2) Remove the bolt.

(3) Push the grommet down and remove ser-

vice hole cover.

7) Remove the service hole cover of fuel sub level

sensor.

8) Disconnect the quick connector on the fuel deliv-

ery hose.

9) Remove the rear wheels.

10) Lift-up the vehicle.

11) Remove the clip holding the harness.

12) Remove the rear suspension assembly.

13) Disconnect the following hoses and connec-

tors.

(1) Evaporation hose

(2) Fuel filler hose

(3) Connector

(A) Bolt

(B) Grommet

(C) Connector

FU-02661(A)

(A)

(B)(C)

FU-02662

(A) Evaporation hose

(B) Connector

(C) Fuel filler hose

FU-02663

FU-02664

FU-02665

(A)

(B)

(C)

Page 1600 of 2453

FU(H6DO)-39

Fuel Tank

FUEL INJECTION (FUEL SYSTEMS)

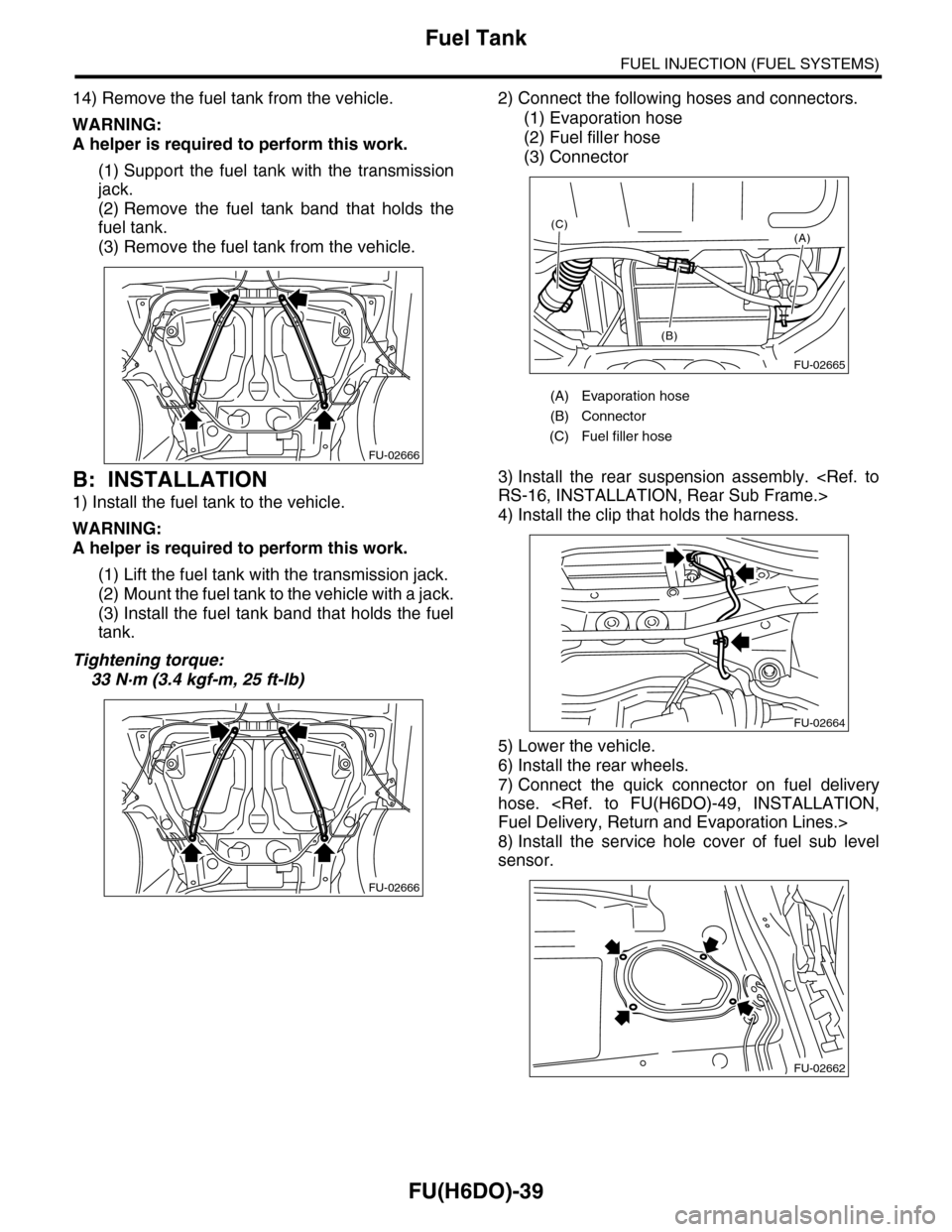

14) Remove the fuel tank from the vehicle.

WARNING:

A helper is required to perform this work.

(1) Support the fuel tank with the transmission

jack.

(2) Remove the fuel tank band that holds the

fuel tank.

(3) Remove the fuel tank from the vehicle.

B: INSTALLATION

1) Install the fuel tank to the vehicle.

WARNING:

A helper is required to perform this work.

(1) Lift the fuel tank with the transmission jack.

(2) Mount the fuel tank to the vehicle with a jack.

(3) Install the fuel tank band that holds the fuel

tank.

Tightening torque:

33 N·m (3.4 kgf-m, 25 ft-lb)

2) Connect the following hoses and connectors.

(1) Evaporation hose

(2) Fuel filler hose

(3) Connector

3) Install the rear suspension assembly.

4) Install the clip that holds the harness.

5) Lower the vehicle.

6) Install the rear wheels.

7) Connect the quick connector on fuel delivery

hose.

8) Install the service hole cover of fuel sub level

sensor.

FU-02666

FU-02666

(A) Evaporation hose

(B) Connector

(C) Fuel filler hose

FU-02665

(A)

(B)

(C)

FU-02664

FU-02662

Page 1604 of 2453

FU(H6DO)-43

Fuel Pump

FUEL INJECTION (FUEL SYSTEMS)

24.Fuel Pump

A: REMOVAL

WARNING:

•Place “NO FIRE” signs near the working area.

•Be careful not to spill fuel on the floor.

NOTE:

Fuel pump assembly consists of fuel pump and fuel

level sensor.

1) Release the fuel pressure.

DURE, Fuel.>

2) Drain fuel.

3) Remove the second seat.

4) Remove the service hole cover.

5) Disconnect the connector from fuel pump.

6) Disconnect the quick connector, and then dis-

connect the fuel delivery hose, return hose and jet

pump hose.

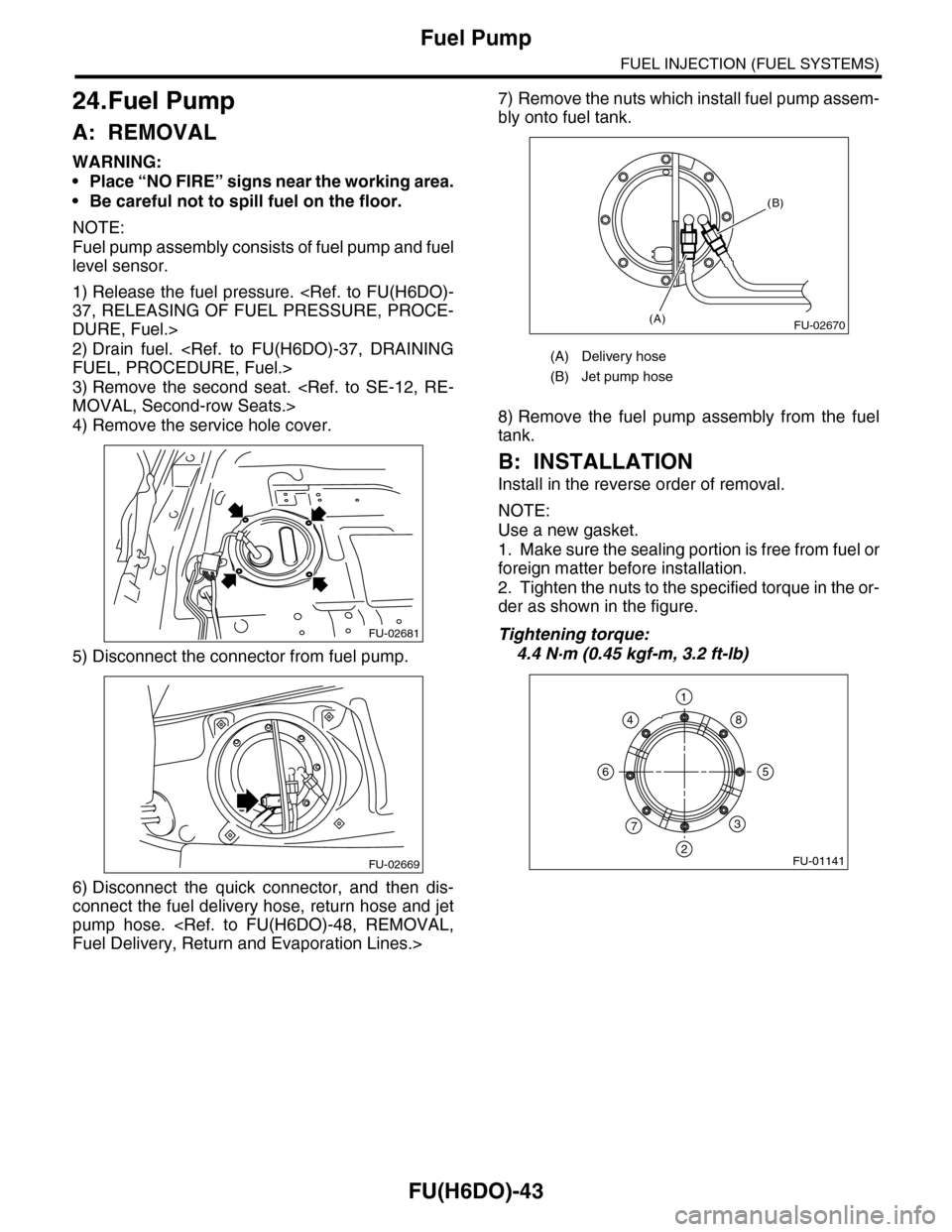

7) Remove the nuts which install fuel pump assem-

bly onto fuel tank.

8) Remove the fuel pump assembly from the fuel

tank.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Use a new gasket.

1. Make sure the sealing portion is free from fuel or

foreign matter before installation.

2. Tighten the nuts to the specified torque in the or-

der as shown in the figure.

Tightening torque:

4.4 N·m (0.45 kgf-m, 3.2 ft-lb)

FU-02681

FU-02669

(A) Delivery hose

(B) Jet pump hose

FU-02670(A)

(B)

FU-01141

1

2

3

4

56

7

8

Page 1606 of 2453

FU(H6DO)-45

Fuel Level Sensor

FUEL INJECTION (FUEL SYSTEMS)

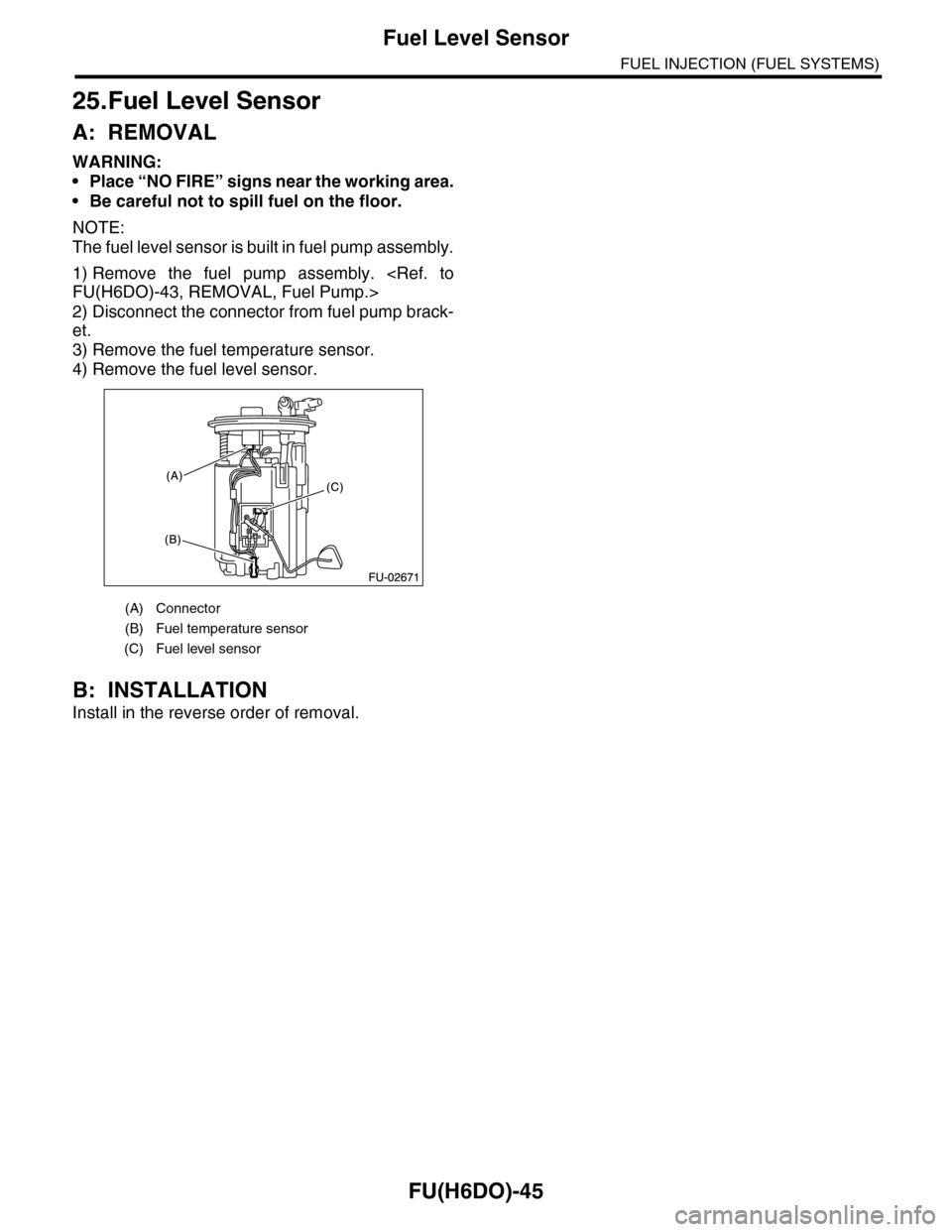

25.Fuel Level Sensor

A: REMOVAL

WARNING:

•Place “NO FIRE” signs near the working area.

•Be careful not to spill fuel on the floor.

NOTE:

The fuel level sensor is built in fuel pump assembly.

1) Remove the fuel pump assembly.

2) Disconnect the connector from fuel pump brack-

et.

3) Remove the fuel temperature sensor.

4) Remove the fuel level sensor.

B: INSTALLATION

Install in the reverse order of removal.

(A) Connector

(B) Fuel temperature sensor

(C) Fuel level sensor

Page 1607 of 2453

FU(H6DO)-46

Fuel Sub Level Sensor

FUEL INJECTION (FUEL SYSTEMS)

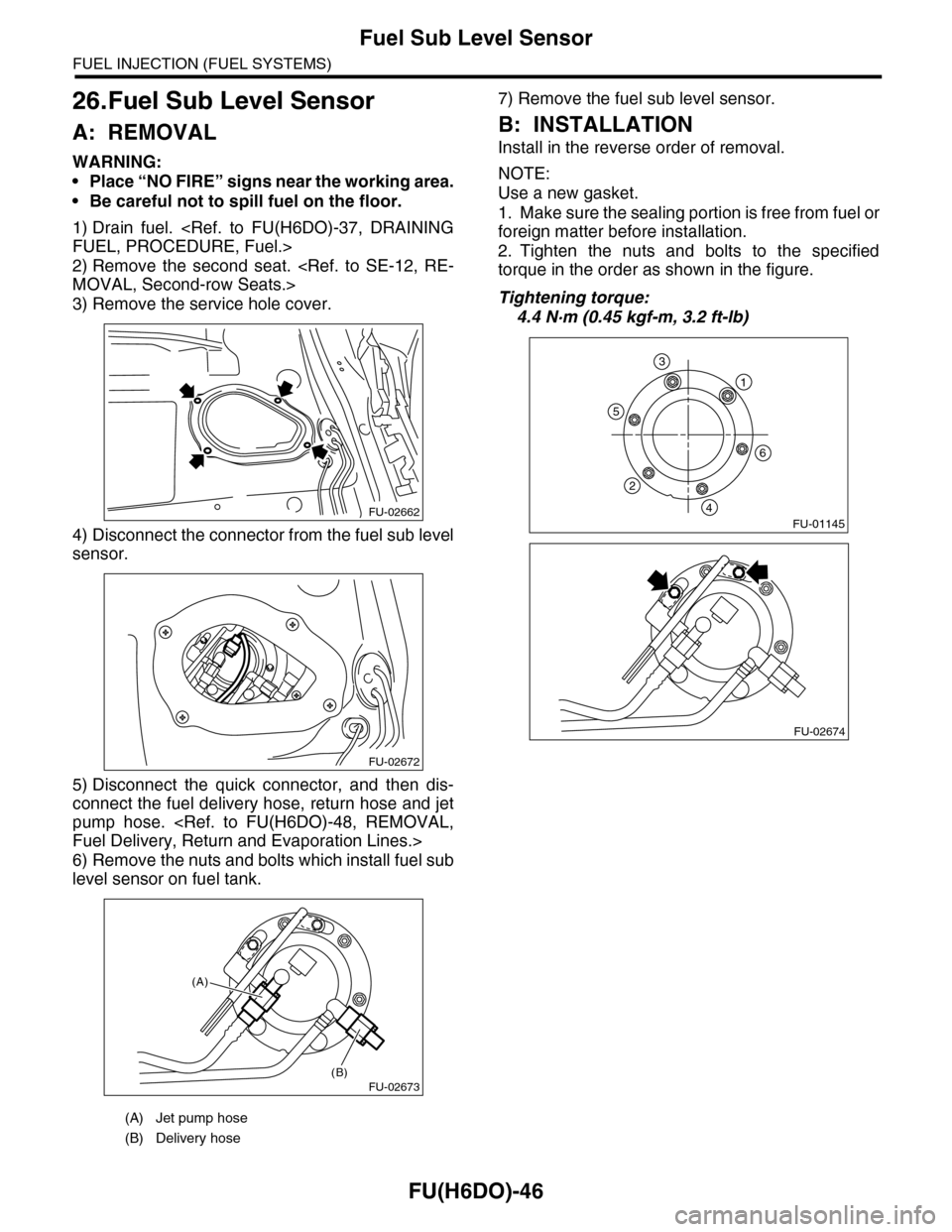

26.Fuel Sub Level Sensor

A: REMOVAL

WARNING:

•Place “NO FIRE” signs near the working area.

•Be careful not to spill fuel on the floor.

1) Drain fuel.

2) Remove the second seat.

3) Remove the service hole cover.

4) Disconnect the connector from the fuel sub level

sensor.

5) Disconnect the quick connector, and then dis-

connect the fuel delivery hose, return hose and jet

pump hose.

6) Remove the nuts and bolts which install fuel sub

level sensor on fuel tank.

7) Remove the fuel sub level sensor.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Use a new gasket.

1. Make sure the sealing portion is free from fuel or

foreign matter before installation.

2. Tighten the nuts and bolts to the specified

torque in the order as shown in the figure.

Tightening torque:

4.4 N·m (0.45 kgf-m, 3.2 ft-lb)

(A) Jet pump hose

(B) Delivery hose

FU-02662

FU-02672

FU-02673(B)

(A)

FU-01145

1

6

5

2

4

3

FU-02674

Page 1612 of 2453

FU(H6DO)-51

Fuel System Trouble in General

FUEL INJECTION (FUEL SYSTEMS)

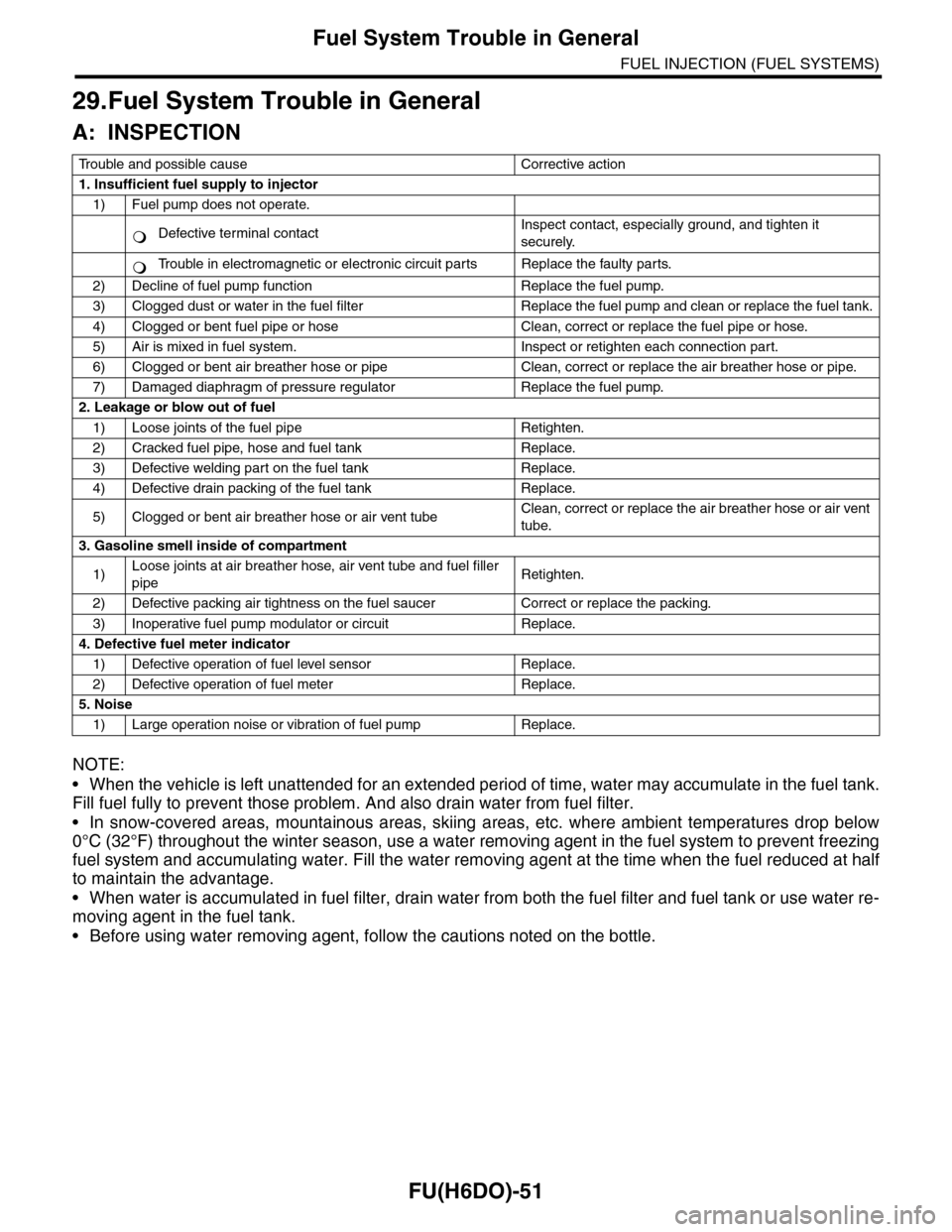

29.Fuel System Trouble in General

A: INSPECTION

NOTE:

•When the vehicle is left unattended for an extended period of time, water may accumulate in the fuel tank.

Fill fuel fully to prevent those problem. And also drain water from fuel filter.

•In snow-covered areas, mountainous areas, skiing areas, etc. where ambient temperatures drop below

0°C (32°F) throughout the winter season, use a water removing agent in the fuel system to prevent freezing

fuel system and accumulating water. Fill the water removing agent at the time when the fuel reduced at half

to maintain the advantage.

•When water is accumulated in fuel filter, drain water from both the fuel filter and fuel tank or use water re-

moving agent in the fuel tank.

•Before using water removing agent, follow the cautions noted on the bottle.

Tr o u b l e a n d p o s s i b l e c a u s e C o r r e c t i v e a c t i o n

1. Insufficient fuel supply to injector

1) Fuel pump does not operate.

Defective terminal contactInspect contact, especially ground, and tighten it

securely.

Tr o u b l e i n e l e c t r o m a g n e t i c o r e l e c t r o n i c c i r c u i t p a r t s R e p l a c e t h e f a u l t y p a r t s .

2) Decline of fuel pump function Replace the fuel pump.

3) Clogged dust or water in the fuel filter Replace the fuel pump and clean or replace the fuel tank.

4) Clogged or bent fuel pipe or hose Clean, correct or replace the fuel pipe or hose.

5) Air is mixed in fuel system. Inspect or retighten each connection part.

6) Clogged or bent air breather hose or pipe Clean, correct or replace the air breather hose or pipe.

7) Damaged diaphragm of pressure regulator Replace the fuel pump.

2. Leakage or blow out of fuel

1) Loose joints of the fuel pipe Retighten.

2) Cracked fuel pipe, hose and fuel tank Replace.

3) Defective welding part on the fuel tank Replace.

4) Defective drain packing of the fuel tank Replace.

5) Clogged or bent air breather hose or air vent tubeClean, correct or replace the air breather hose or air vent

tube.

3. Gasoline smell inside of compartment

1)Loose joints at air breather hose, air vent tube and fuel filler

pipeRetighten.

2) Defective packing air tightness on the fuel saucer Correct or replace the packing.

3) Inoperative fuel pump modulator or circuit Replace.

4. Defective fuel meter indicator

1) Defective operation of fuel level sensor Replace.

2) Defective operation of fuel meter Replace.

5. Noise

1) Large operation noise or vibration of fuel pump Replace.

�

Page 1614 of 2453

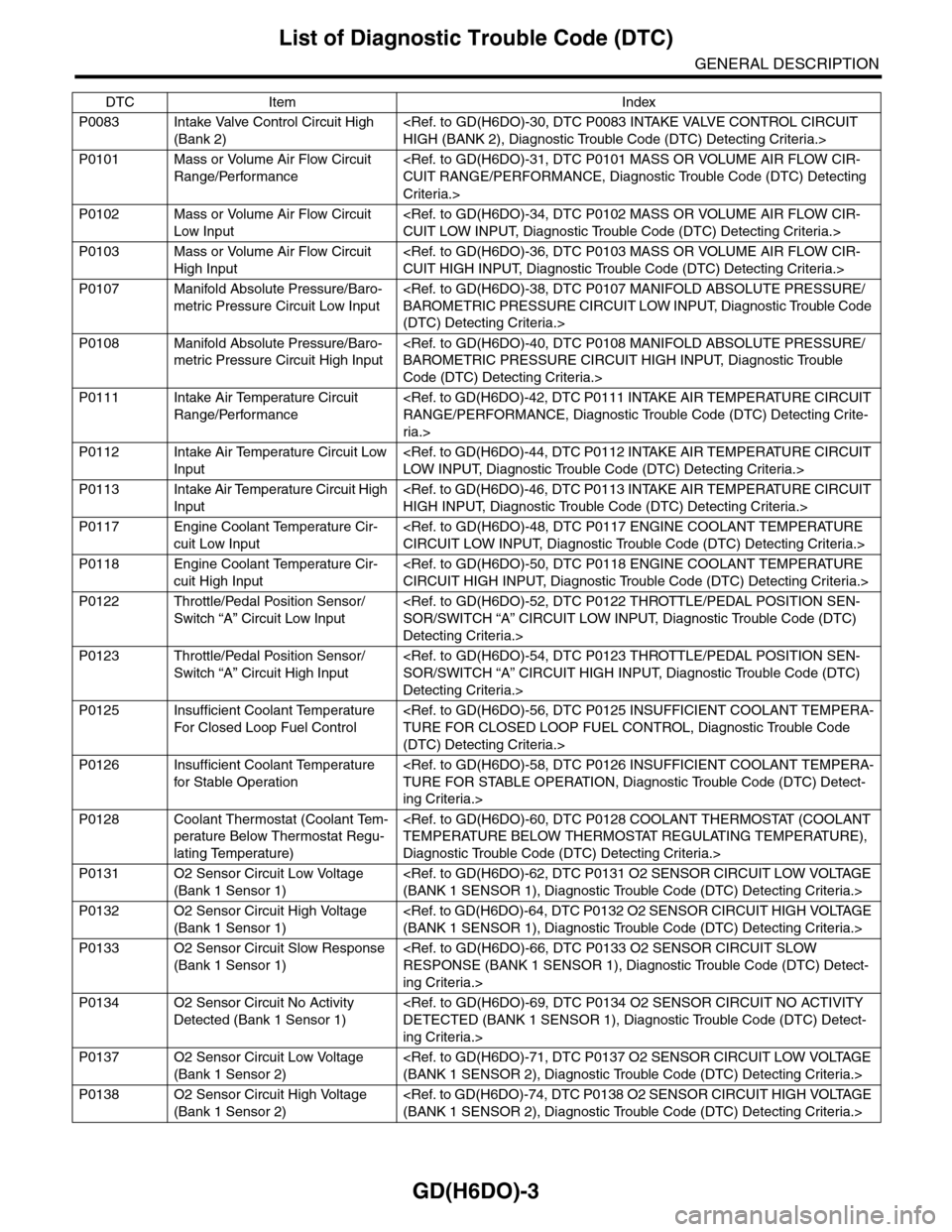

GD(H6DO)-2

List of Diagnostic Trouble Code (DTC)

GENERAL DESCRIPTION

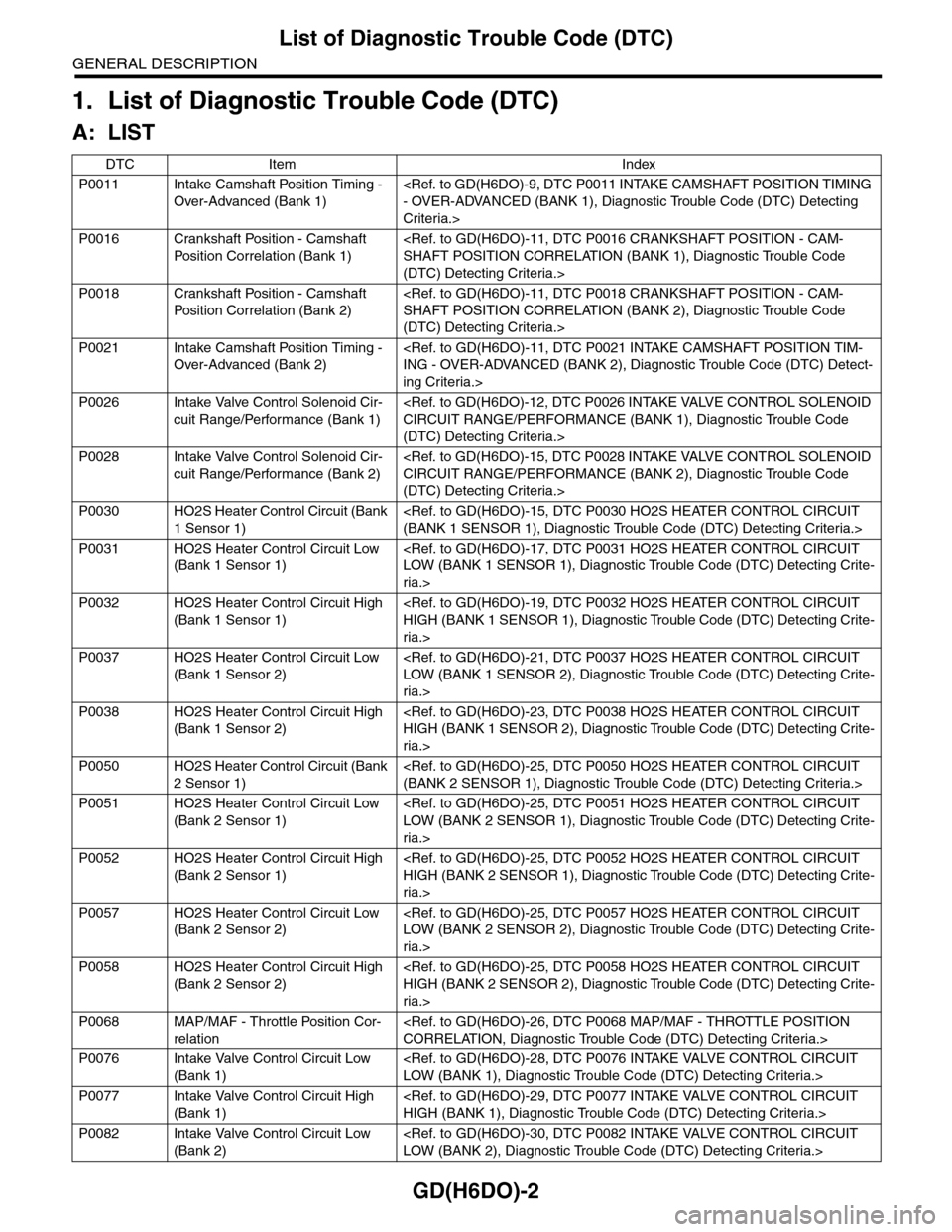

1. List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Item Index

P0011 Intake Camshaft Position Timing -

Over-Advanced (Bank 1)

Criteria.>

P0016 Crankshaft Position - Camshaft

Pos it i o n C o r r el a ti o n ( B a nk 1)

(DTC) Detecting Criteria.>

P0018 Crankshaft Position - Camshaft

Pos it i o n C o r r el a ti o n ( B a nk 2)

(DTC) Detecting Criteria.>

P0021 Intake Camshaft Position Timing -

Over-Advanced (Bank 2)

ing Criteria.>

P0026 Intake Valve Control Solenoid Cir-

cuit Range/Performance (Bank 1)

(DTC) Detecting Criteria.>

P0028 Intake Valve Control Solenoid Cir-

cuit Range/Performance (Bank 2)

(DTC) Detecting Criteria.>

P0030 HO2S Heater Control Circuit (Bank

1 Sensor 1)

P0031 HO2S Heater Control Circuit Low

(Bank 1 Sensor 1)

ria.>

P0032 HO2S Heater Control Circuit High

(Bank 1 Sensor 1)

ria.>

P0037 HO2S Heater Control Circuit Low

(Bank 1 Sensor 2)

ria.>

P0038 HO2S Heater Control Circuit High

(Bank 1 Sensor 2)

ria.>

P0050 HO2S Heater Control Circuit (Bank

2 Sensor 1)

P0051 HO2S Heater Control Circuit Low

(Bank 2 Sensor 1)

ria.>

P0052 HO2S Heater Control Circuit High

(Bank 2 Sensor 1)

ria.>

P0057 HO2S Heater Control Circuit Low

(Bank 2 Sensor 2)

ria.>

P0058 HO2S Heater Control Circuit High

(Bank 2 Sensor 2)

ria.>

P0068 MAP/MAF - Throttle Position Cor-

relation

P0076 Intake Valve Control Circuit Low

(Bank 1)

P0077 Intake Valve Control Circuit High

(Bank 1)

P0082 Intake Valve Control Circuit Low

(Bank 2)

Page 1615 of 2453

GD(H6DO)-3

List of Diagnostic Trouble Code (DTC)

GENERAL DESCRIPTION

P0083 Intake Valve Control Circuit High

(Bank 2)

P0101 Mass or Volume Air Flow Circuit

Range/Performance

Criteria.>

P0102 Mass or Volume Air Flow Circuit

Low Input

P0103 Mass or Volume Air Flow Circuit

High Input

P0107 Manifold Absolute Pressure/Baro-

metric Pressure Circuit Low Input

(DTC) Detecting Criteria.>

P0108 Manifold Absolute Pressure/Baro-

metric Pressure Circuit High Input

Code (DTC) Detecting Criteria.>

P0111 Intake Air Temperature Circuit

Range/Performance

ria.>

P0112 Intake Air Temperature Circuit Low

Input

P0113 Intake Air Temperature Circuit High

Input

P0117 Engine Coolant Temperature Cir-

cuit Low Input

P0118 Engine Coolant Temperature Cir-

cuit High Input

P0122 Throttle/Pedal Position Sensor/

Switch “A” Circuit Low Input

Detecting Criteria.>

P0123 Throttle/Pedal Position Sensor/

Switch “A” Circuit High Input

Detecting Criteria.>

P0125 Insufficient Coolant Temperature

For Closed Loop Fuel Control

(DTC) Detecting Criteria.>

P0126 Insufficient Coolant Temperature

for Stable Operation

ing Criteria.>

P0128 Coolant Thermostat (Coolant Tem-

perature Below Thermostat Regu-

lating Temperature)

Diagnostic Trouble Code (DTC) Detecting Criteria.>

P0131 O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 1)

P0132 O2 Sensor Circuit High Voltage

(Bank 1 Sensor 1)

P0133 O2 Sensor Circuit Slow Response

(Bank 1 Sensor 1)

ing Criteria.>

P0134 O2 Sensor Circuit No Activity

Detected (Bank 1 Sensor 1)

ing Criteria.>

P0137 O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 2)

P0138 O2 Sensor Circuit High Voltage

(Bank 1 Sensor 2)

DTC Item Index

Page 1616 of 2453

GD(H6DO)-4

List of Diagnostic Trouble Code (DTC)

GENERAL DESCRIPTION

P0139 O2 Sensor Circuit Slow Response

(Bank 1 Sensor 2)

ing Criteria.>

P0140 O2 Sensor Circuit No Activity

Detected (Bank 1 Sensor 2)

ing Criteria.>

P0151 O2 Sensor Circuit Low Voltage

(Bank 2 Sensor 1)

P0152 O2 Sensor Circuit High Voltage

(Bank 2 Sensor 1)

P0153 O2 Sensor Circuit Slow Response

(Bank 2 Sensor 1)

ing Criteria.>

P0154 O2 Sensor Circuit No Activity

Detected (Bank 2 Sensor 1)

ing Criteria.>

P0157 O2 Sensor Circuit Low Voltage

(Bank 2 Sensor 2)

P0158 O2 Sensor Circuit High Voltage

(Bank 2 Sensor 2)

P0159 O2 Sensor Circuit Slow Response

(Bank 2 Sensor 2)

ing Criteria.>

P0160 O2 Sensor Circuit No Activity

Detected (Bank 2 Sensor 2)

ing Criteria.>

P0171 System Too Lean (Bank 1)

P0172 System Too Rich (Bank 1)

P0174 System Too Lean (Bank 2)

P0175 System Too Rich (Bank 2)

P0181 Fuel Temperature Sensor “A” Cir-

cuit Range/Performance

ing Criteria.>

P0182 Fuel Temperature Sensor “A” Cir-

cuit Low Input

P0183 Fuel Temperature Sensor “A” Cir-

cuit High Input

P0196 Engine Oil Temperature Sensor

Circuit Range/Performance

Detecting Criteria.>

P0197 Engine Oil Temperature Sensor

Circuit Low

P0198 Engine Oil Temperature Sensor

Circuit High

P0222 Throttle/Pedal Position Sensor/

Switch “B” Circuit Low Input

Detecting Criteria.>

P0223 Throttle/Pedal Position Sensor/

Switch “B” Circuit High Input

Detecting Criteria.>

P0230 Fuel Pump Primary Circuit

DTC Item Index