SUZUKI GRAND VITARA 1987 Service Manual Online

Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 81 of 962

Fig. 3-5-26

Cylinder Block

l Distortion of gasketed surface:

Using a straightedge and a thickness gauge,

check gasketed surface for distortion and, if

result exceeds specified limit, correct it.

StandardLimitI

IFlatness0.03 mm0.06 mm

(0.0012 in.)(0.0024 in.)I

Fig. 3-5-27

l Cylinder bore:

1) Inspect cylinder walls for scratches, roughness,

or ridges which indicate excessive wear. If

cylinder bore is very rough or deeply scratch-

ed, or ridged, rebore cylinder and use oversize

piston.

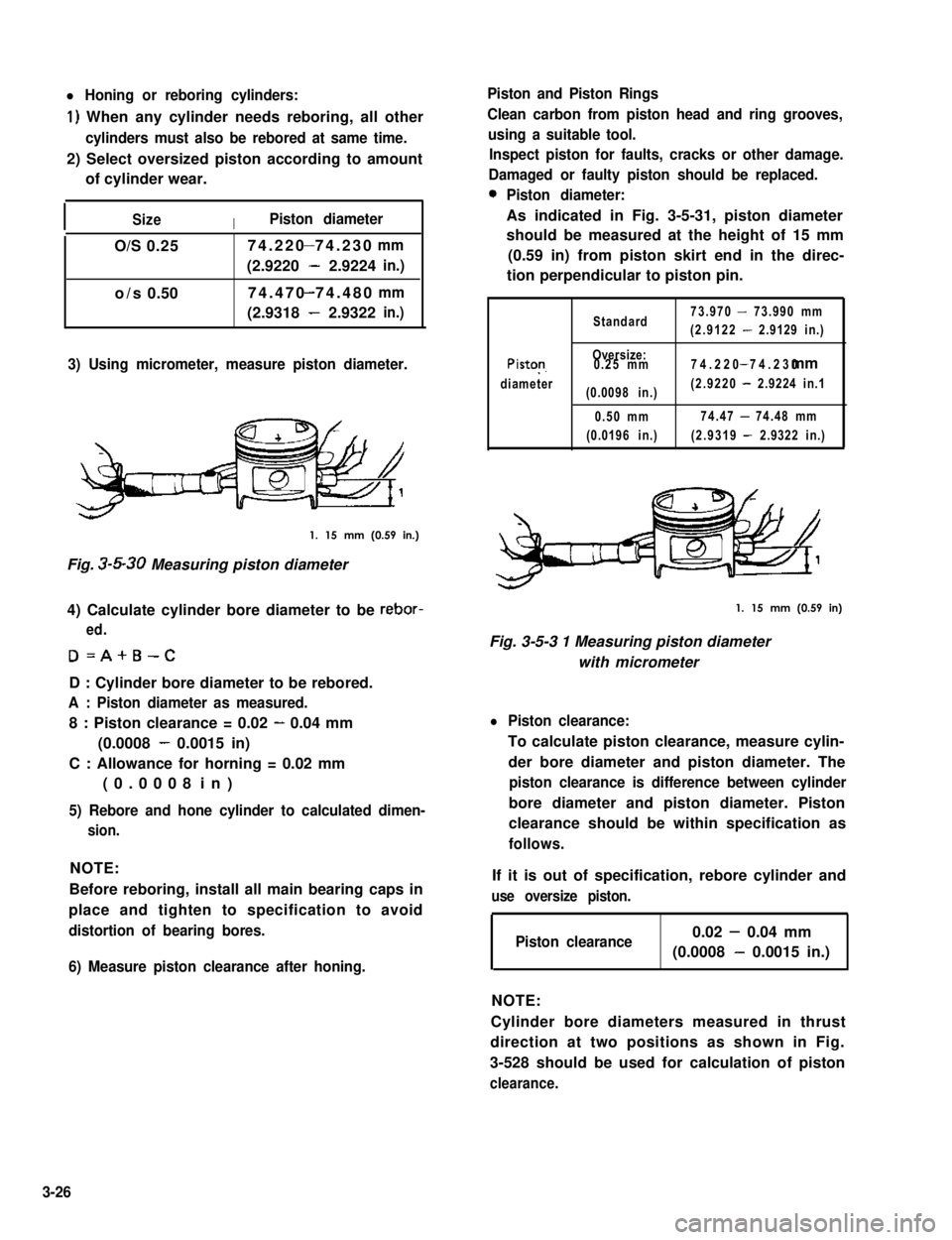

2) Using a cylinder gauge, measure cylinder bore

in thrust and axial directions at two positions

as shown in Fig. 3-5-28.

If any of the following conditions exists,

rebore cylinder.

l Cylinder bore dia. exceeds its limit.

l Difference of measurements at two positions

exceeds taper limit.

l Difference between thrust and axial measure-

ments exceeds out-of-round limit.

NOTE:

If any one of four cylinders has to be rebored,

rebore all four to the same next oversize. This is

necessary for the sake of uniformity and balance.

1. 50mm (1.96in.j

2. 95 mm (3.74 in.)

Fig. 3-5-28 Positions to be measured

Fig. 3-5-29 Measuring cylinder bore with

cylinder gauge

3-25

Page 82 of 962

l Honing or reboring cylinders:

1) When any cylinder needs reboring, all other

cylinders must also be rebored at same time.

2) Select oversized piston according to amount

of cylinder wear.

ISizeIPiston diameter

O/S0.2574.220 74.230-mm

(2.9220 - 2.9224in.)

74.470 74.480-o/s0.50mm

(2.9318 - 2.9322in.)

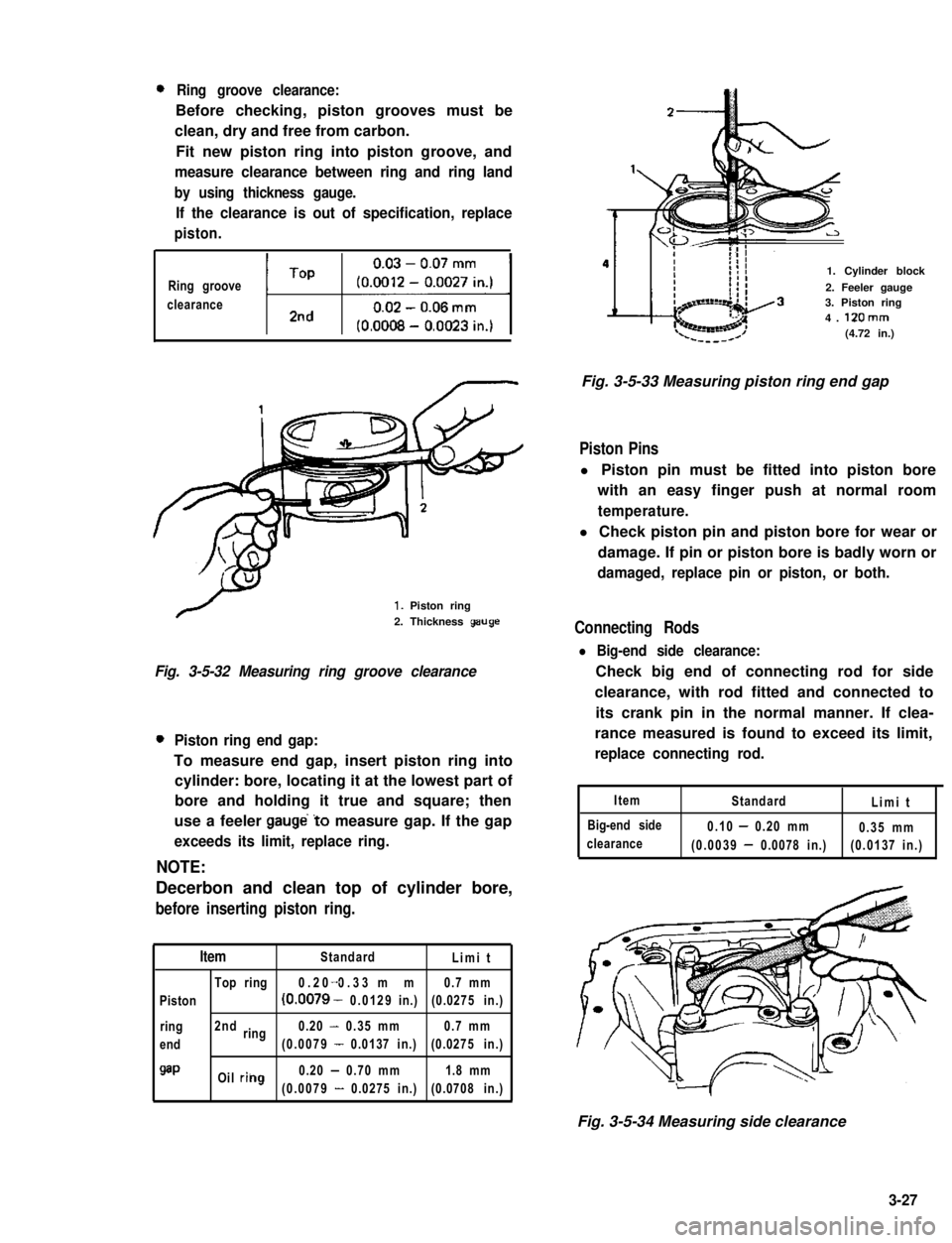

3) Using micrometer, measure piston diameter.

1. 15 mm (0.59 in.)

Fig. 3-5-30 Measuring piston diameter

4) Calculate cylinder bore diameter to be rebor-

ed.

D=A+B-C

D : Cylinder bore diameter to be rebored.

A : Piston diameter as measured.

8 : Piston clearance = 0.02 - 0.04 mm

(0.0008 - 0.0015 in)

C : Allowance for horning = 0.02 mm

(0.0008 in)

5) Rebore and hone cylinder to calculated dimen-

sion.

NOTE:

Before reboring, install all main bearing caps in

place and tighten to specification to avoid

distortion of bearing bores.

6) Measure piston clearance after honing.

Piston and Piston Rings

Clean carbon from piston head and ring grooves,

using a suitable tool.

Inspect piston for faults, cracks or other damage.

Damaged or faulty piston should be replaced.

0Piston diameter:

As indicated in Fig. 3-5-31, piston diameter

should be measured at the height of 15 mm

(0.59 in) from piston skirt end in the direc-

tion perpendicular to piston pin.

Standard73.970 - 73.990 mm

(2.9122 - 2.9129 in.)

Piston

diameter

Oversize:0.25 mm

(0.0098 in.)

0.50 mm

(0.0196 in.)

74.220 74.230- mm

(2.9220 - 2.9224 in.1

74.47 - 74.48 mm

(2.9319 - 2.9322 in.)

1. 15 mm (0.59 in)

Fig. 3-5-3 1 Measuring piston diameter

with micrometer

l Piston clearance:

To calculate piston clearance, measure cylin-

der bore diameter and piston diameter. The

piston clearance is difference between cylinder

bore diameter and piston diameter. Piston

clearance should be within specification as

follows.

If it is out of specification, rebore cylinder and

use oversize piston.

Piston clearance0.02 - 0.04 mm

(0.0008 - 0.0015 in.)

NOTE:

Cylinder bore diameters measured in thrust

direction at two positions as shown in Fig.

3-528 should be used for calculation of piston

clearance.

3-26

Page 83 of 962

0Ring groove clearance:

Before checking, piston grooves must be

clean, dry and free from carbon.

Fit new piston ring into piston groove, and

measure clearance between ring and ring land

by using thickness gauge.

If the clearance is out of specification, replace

piston.

Ring groove

clearanceti1

1. Piston ring

2. Thickness geuge

Fig. 3-5-32 Measuring ring groove clearance

0Piston ring end gap:

To measure end gap, insert piston ring into

cylinder: bore, locating it at the lowest part of

bore and holding it true and square; then

use a feeler gauge’to measure gap. If the gap

exceeds its limit, replace ring.

NOTE:

Decerbon and clean top of cylinder bore,

before inserting piston ring.

ItemStandardLimit

Top ring0.20 0.33 mm-0.7 mm

Piston(0.0079 - 0.0129in.)(0.0275 in.)

ring2ndring0.20 - 0.35 mm0.7 mm

end(0.0079 - 0.0137 in.)(0.0275 in.)

QaPOil riilg0.20 - 0.70 mm1.8 mm

(0.0079 - 0.0275 in.)(0.0708 in.)

1. Cylinder block

2. Feeler gauge3. Piston ring4. 12Omm(4.72 in.)

Fig. 3-5-33 Measuring piston ring end gap

Piston Pins

l Piston pin must be fitted into piston bore

with an easy finger push at normal room

temperature.

l Check piston pin and piston bore for wear or

damage. If pin or piston bore is badly worn or

damaged, replace pin or piston, or both.

Connecting Rods

l Big-end side clearance:

Check big end of connecting rod for side

clearance, with rod fitted and connected to

its crank pin in the normal manner. If clea-

rance measured is found to exceed its limit,

replace connecting rod.

Item

Big-end side

clearance

StandardLimit

0.10 - 0.20 mm0.35 mm

(0.0039 - 0.0078 in.)(0.0137 in.)

Fig. 3-5-34 Measuring side clearance

3-27

Page 84 of 962

l Connecting rod alignment:

Mount connecting rod on aligner to check

it for bow and twist and, if either limit is

exceeded, replace it.

Limit on bow0.05 mm (0.0020 in.)

ILimit on twist) 0.10 mm (0.0039 in.) 1

Crank Pin and Connecting Rod Bearings

l Inspect crank pin for uneven wear or damage.

Measure crank pin for out-of-round or taper

with a micrometer. If crank pin is damaged,

or out-of-round or taper is out of limit,

replace crankshaft or regrind crank pin to

undersize and use undersize bearing.

I

Connecting

rod bearing sizeCrank pin diameterI

IStandard41.982 - 42.000 mm

(1.6529 - 1.6535 in.)I

0.25 mm (0.0098 in.)41.732 - 41.750 mm

undersize(1.6430 - 1.6437 in.)

Out-of-round and

taper limit0.01 mm (0.0004 in.)

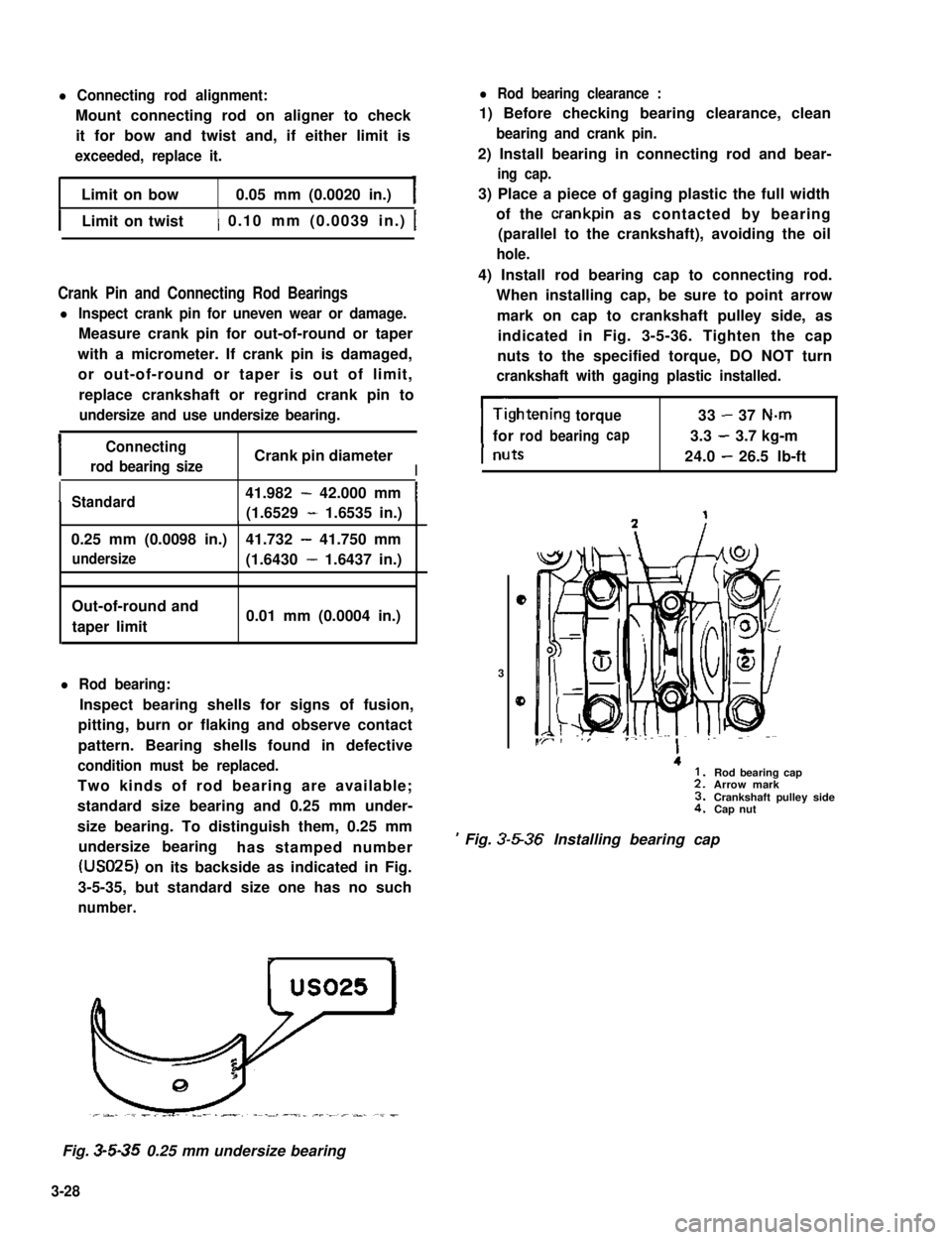

l Rod bearing:

Inspect bearing shells for signs of fusion,

pitting, burn or flaking and observe contact

pattern. Bearing shells found in defective

condition must be replaced.

Two kinds of rod bearing are available;

standard size bearing and 0.25 mm under-

size bearing. To distinguish them, 0.25 mm

undersize bearinghas stamped number

(USO25) on its backside as indicated in Fig.

3-5-35, but standard size one has no such

number.

l Rod bearing clearance :

1) Before checking bearing clearance, clean

bearing and crank pin.

2) Install bearing in connecting rod and bear-

ing cap.

3) Place a piece of gaging plastic the full width

of the crankpin as contacted by bearing

(parallel to the crankshaft), avoiding the oil

hole.

4) Install rod bearing cap to connecting rod.

When installing cap, be sure to point arrow

mark on cap to crankshaft pulley side, as

indicated in Fig. 3-5-36. Tighten the cap

nuts to the specified torque, DO NOT turn

crankshaft with gaging plastic installed.

torque33-37 N-m

forrodbearingcap3.3-3.7 kg-m

24.0-26.5 lb-ft

e

3

0

.

’ Fig. 3-5-36 Installing bearing cap

Rod bearing capArrow markCrankshaft pulley sideCap nut

Fig. 3-5-35 0.25 mm undersize bearing

3-28

Page 85 of 962

Fig. 3-5-19 Contactpattern @ uniform in width

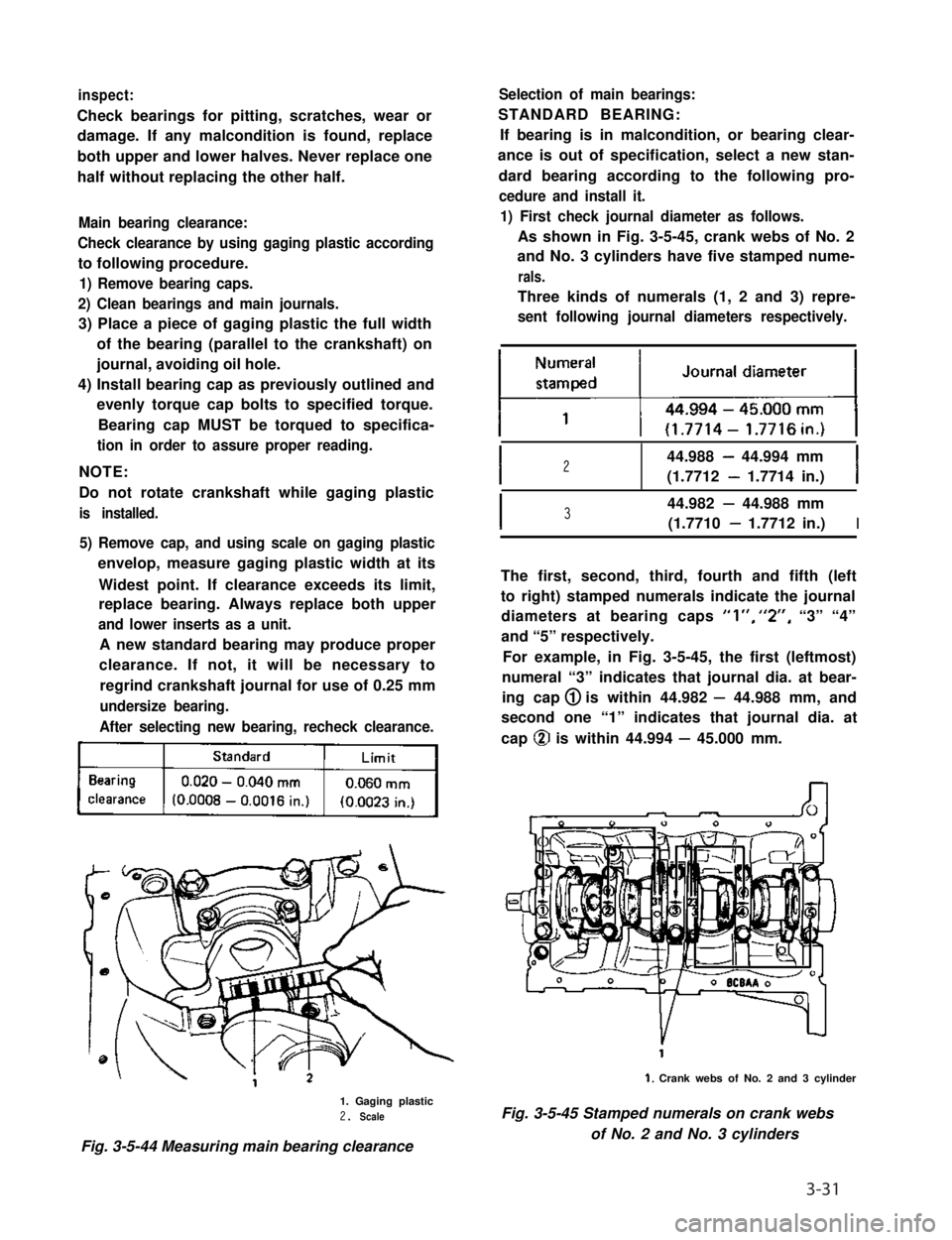

Valve Springs

l Referring to the criterion-data given below,

check to be sure that each spring is in sound

condition, free of any evidence of breakage or

weakening. Remember, weakenedvalve springs

can be the cause of chatter, not to mention

the possibility of reducing power output due

to gas leakage caused by decreased seating

Valve springfor 41.5 mmfor 41.5 mm

preload(54.7 - 64.3 lb/(50.2 lb/

1.63 in.)1.63 in.)

Fig. 3-5-21 Measuring spring preload

l Spring squareness:

Use a square and surface plate to check each

spring for squareness in terms of clearance

between the end of valve spring and square.

Valve springs found to exhibit a larger clea-

rance than specified limit must be replaced.

Valve springs

squareness limit2.0 mm (0.079 in.)

Fig. 3-5-22 Measuring spring squareness

Fig. 3-5-20 Measuring free length of spring

3-23

Page 86 of 962

c5) Remove cap and using scale on gaging bIastic

envelope, measure gaging plastic width at

the widest point.

If the clearance exceeds its limit, use a new

standard size bearing and remeasure clea-

rance.

1. Gaging plastic2. Scale

Fig. 3-5-37 Measuring rod bearing clearance

6) If clearance can not be brought to within

limit even by using a new standard size bear-

ing, regrind crankpin to the undersizeand use

0.25 mm undersize bearing.

Crankshaft

l Crankshaft runout:

Using a dial gauge, measure runout at center

journal. Rotate crankshaft slowly. If runout

exceeds limit, replace crankshaft.

Limit on runout0.06 mm (0.0023 in.)

l Crankshaft thrust play :

Measure this play with crankshaft set in

cylinder block in the normal manner, that is,

with thrust bearing fitted and journal bearing

caps installed. Tighten bearing cap bolts to

specified torque.

Use a dial gauge to read displacement in axial

(thrust) direction of crankshaft.

If the limit is exceeded, replace thrust bearing

with new standard one or oversize one to

obtain standard thrust play.

ItemStandardLimit

Crankshaft0.11 - 0.31 mm0.38 mm

thrust play(0.0044 - 0.0122 in.)(0.0149 in.)

-.Thickness of

crankshaft

thrust bearing

1, Thrust bearing

Fig. 3-5-39 Thrust bearings

Fig. 3-5-38 Measuring runou t

3-29

Page 87 of 962

Crankshaft Main (Journal) Bearings

General informations:

l Service main bearings are available in standard-

size and 0.25 mm (0.0098 in) undersize, and

each of them has 5 kinds of bearings differ-

ing in tolerance.

l The upper half of bearing has oil groove as

indicated in Fig. 3~5-42. Install this half with

oil groove to cylinder block.

Fig. 3-5-40 Measuring thrust play of crankshaft

l Out-of-round and taper (uneven wear):

An unevenly worn crankshaft journal shows

up as a difference in diameter at a cross

section or along its length (or both). This

difference, if any, is to be determined from

micrometer readings.

If any of journals is badly damaged or if the

amount of uneven wear in the sense explained

above exceeds its limit, regrind or replace the

crankshaft.

I

Limit on out-of-round

and taper0.01 mm (0.0004 in.)

Fig. 3-5-4 1 Checking uneven wear

1. Cylinder block2. Upper half of bearing

3. Oil groove

Fig. 3-5-42 Upper half of bearing installation

l On each main bearing cap, arrow mark and

number are embossed as indicated in Fig.

3-5-43.

When installing each bearing cap to cylinder

block, point arrow mark toward crankshaft

pulley side and install each cap from crank-

shaft pulley side to flywheel side in ascending

order of numbers @,a, 0, @ and 0. Tigh-

ten cap bolts to specified torque.

3

2. Flywheel side

Fig. 3-5-43 Bearing caps ins talla tion

3-30

Page 88 of 962

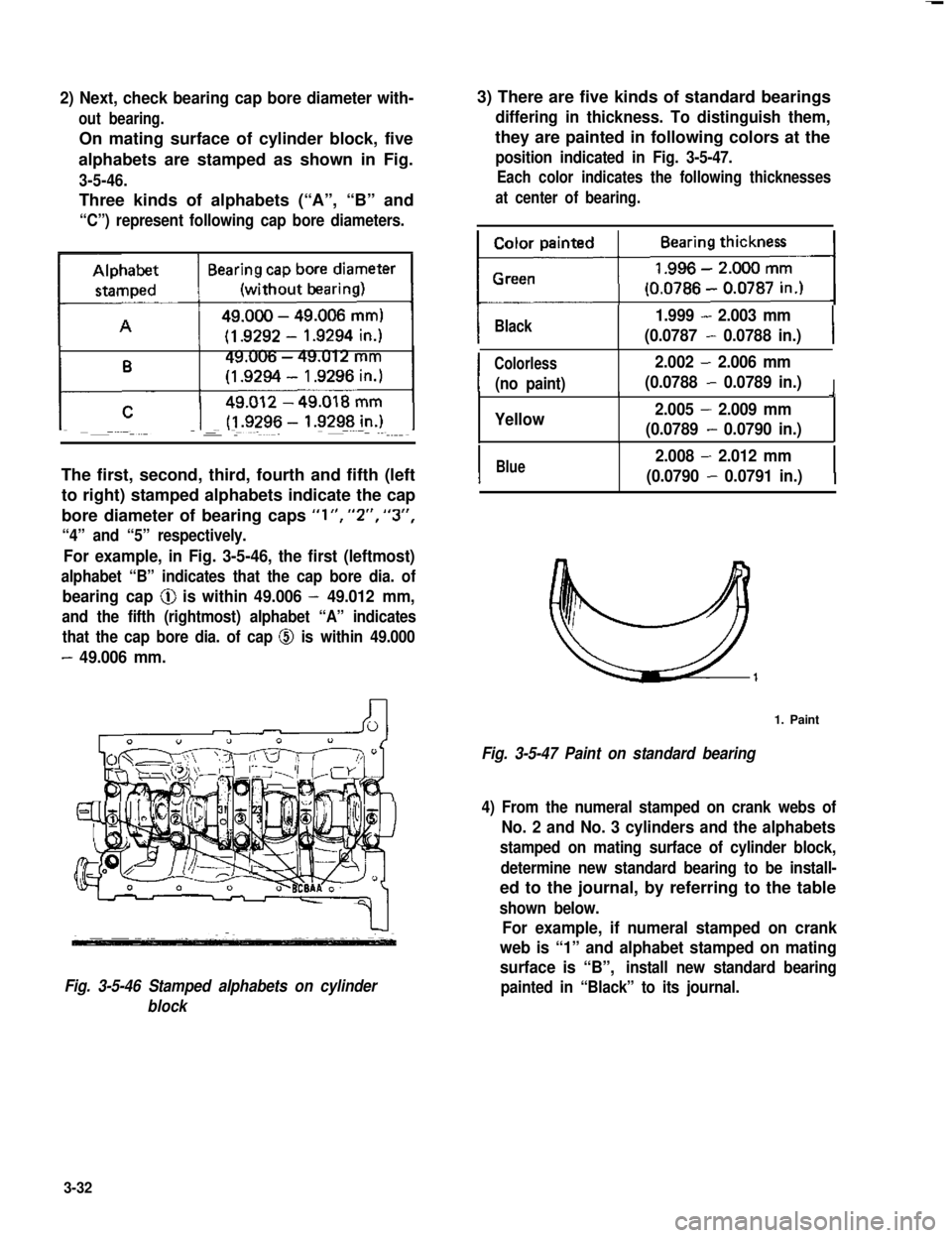

inspect:

Check bearings for pitting, scratches, wear or

damage. If any malcondition is found, replace

both upper and lower halves. Never replace one

half without replacing the other half.

Main bearing clearance:

Check clearance by using gaging plastic according

to following procedure.

1) Remove bearing caps.

2) Clean bearings and main journals.

3) Place a piece of gaging plastic the full width

of the bearing (parallel to the crankshaft) on

journal, avoiding oil hole.

4) Install bearing cap as previously outlined and

evenly torque cap bolts to specified torque.

Bearing cap MUST be torqued to specifica-

tion in order to assure proper reading.

NOTE:

Do not rotate crankshaft while gaging plastic

is installed.

5) Remove cap, and using scale on gaging plastic

envelop, measure gaging plastic width at its

Widest point. If clearance exceeds its limit,

replace bearing. Always replace both upper

and lower inserts as a unit.

A new standard bearing may produce proper

clearance. If not, it will be necessary to

regrind crankshaft journal for use of 0.25 mm

undersize bearing.

After selecting new bearing, recheck clearance.

kj

1. Gaging plastic2. Scale

Fig. 3-5-44 Measuring main bearing clearance

Selection of main bearings:

STANDARD BEARING:

If bearing is in malcondition, or bearing clear-

ance is out of specification, select a new stan-

dard bearing according to the following pro-

cedure and install it.

1) First check journal diameter as follows.

As shown in Fig. 3-5-45, crank webs of No. 2

and No. 3 cylinders have five stamped nume-

rals.

Three kinds of numerals (1, 2 and 3) repre-

sent following journal diameters respectively.

I244.988 - 44.994 mm

(1.7712 - 1.7714 in.)I

I344.982 - 44.988 mm

(1.7710 - 1.7712 in.)I

The first, second, third, fourth and fifth (left

to right) stamped numerals indicate the journal

diameters at bearing caps “l”, “2”, “3” “4”

and “5” respectively.

For example, in Fig. 3-5-45, the first (leftmost)

numeral “3” indicates that journal dia. at bear-

ing cap 1 is within 44.982 - 44.988 mm, and

second one “1” indicates that journal dia. at

cap @ is within 44.994 - 45.000 mm.

1. Crank webs of No. 2 and 3 cylinder

Fig. 3-5-45 Stamped numerals on crank webs

of No. 2 and No. 3 cylinders

3-31

Page 89 of 962

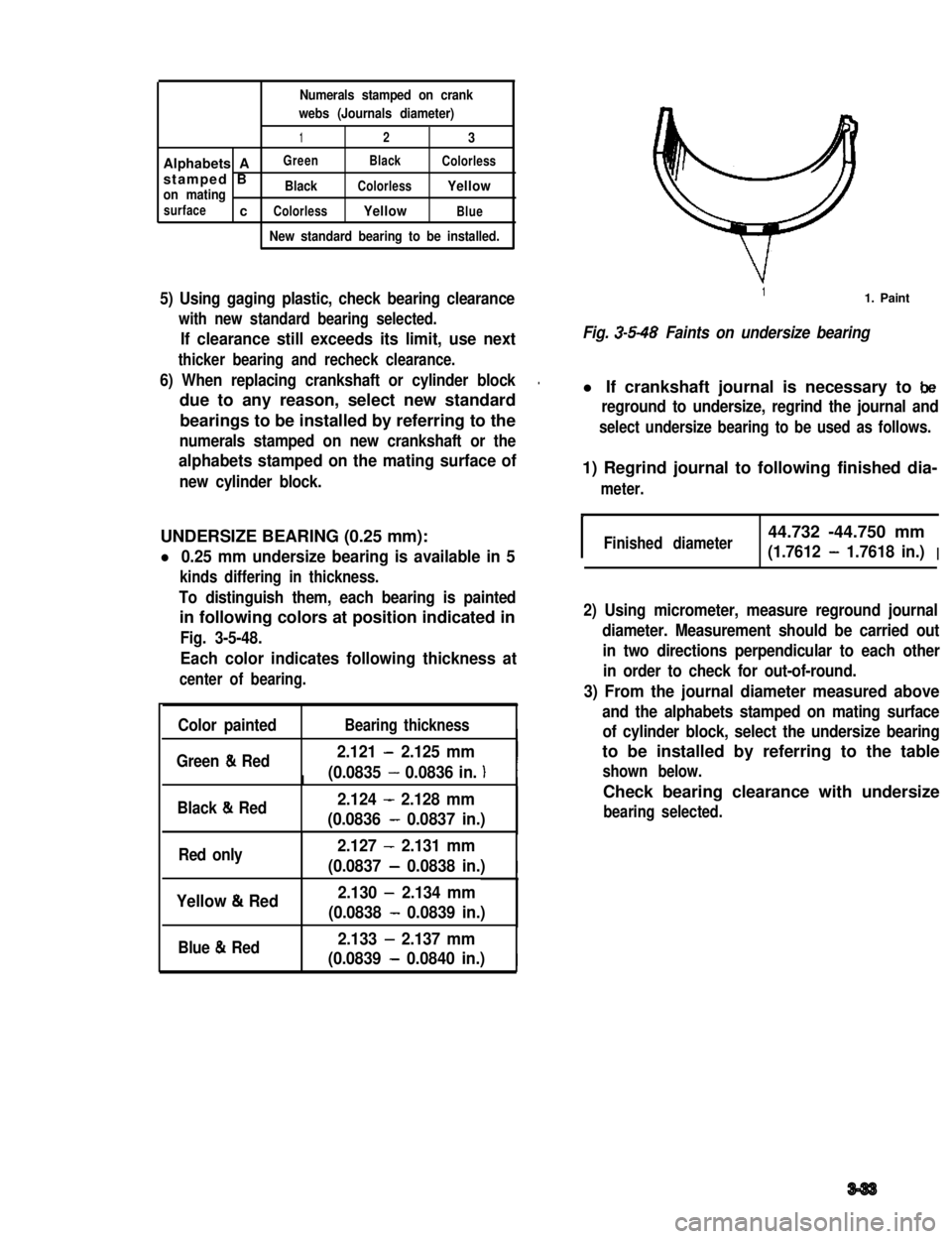

2) Next, check bearing cap bore diameter with-

out bearing.

On mating surface of cylinder block, five

alphabets are stamped as shown in Fig.

3-5-46.

Three kinds of alphabets (“A”, “B” and

“C”) represent following cap bore diameters.

The first, second, third, fourth and fifth (left

to right) stamped alphabets indicate the cap

bore diameter of bearing caps “l”, “2”, “3”,

“4” and “5” respectively.

For example, in Fig. 3-5-46, the first (leftmost)

alphabet “B” indicates that the cap bore dia. of

bearing cap @ is within 49.006 - 49.012 mm,

and the fifth (rightmost) alphabet “A” indicates

that the cap bore dia. of cap @ is within 49.000

- 49.006 mm.

Fig. 3-5-46 Stamped alphabets on cylinder

block

3) There are five kinds of standard bearings

differing in thickness. To distinguish them,

they are painted in following colors at the

position indicated in Fig. 3-5-47.

Each color indicates the following thicknesses

at center of bearing.

IBlack1.999 - 2.003 mm

(0.0787 - 0.0788 in.)I

I

Colorless2.002 - 2.006 mm

(no paint)(0.0788 - 0.0789 in.)I9

Yellow2.005 - 2.009 mm

(0.0789 - 0.0790 in.)

IBlue2.008 - 2.012 mm

(0.0790 - 0.0791 in.)I

1. Paint

Fig. 3-5-47 Paint on standard bearing

4) From the numeral stamped on crank webs of

No. 2 and No. 3 cylinders and the alphabets

stamped on mating surface of cylinder block,

determine new standard bearing to be install-

ed to the journal, by referring to the table

shown below.

For example, if numeral stamped on crank

web is “1” and alphabet stamped on mating

surface is “B”,install new standard bearing

painted in “Black” to its journal.

3-32

Page 90 of 962

Numerals stamped on crank

webs (Journals diameter)

123

Alphabets AGreenBlackColorless

stamped Bon matingBlackColorlessYellow

surfacecColorlessYellowBlue

New standard bearing to be installed.

5) Using gaging plastic, check bearing clearance

with new standard bearing selected.

If clearance still exceeds its limit, use next

thicker bearing and recheck clearance.

6) When replacing crankshaft or cylinder block.

due to any reason, select new standard

bearings to be installed by referring to the

numerals stamped on new crankshaft or the

alphabets stamped on the mating surface of

new cylinder block.

UNDERSIZE BEARING (0.25 mm):

l 0.25 mm undersize bearing is available in 5

kinds differing in thickness.

To distinguish them, each bearing is painted

in following colors at position indicated in

Fig. 3-5-48.

Each color indicates following thickness at

center of bearing.

Color paintedBearing thicknessI

Green & Red2.121 - 2.125 mm

(0.0835 - 0.0836 in. )III

Black & Red2.124 - 2.128 mm

(0.0836 - 0.0837 in.)

Red only2.127 - 2.131 mm

(0.0837 - 0.0838 in.)I

Yellow & Red2.130 - 2.134 mm

(0.0838 - 0.0839 in.)

Blue & Red2.133 - 2.137 mm

(0.0839 - 0.0840 in.)I

11. Paint

Fig. 3-5-48 Faints on undersize bearing

l If crankshaft journal is necessary to be

reground to undersize, regrind the journal and

select undersize bearing to be used as follows.

1) Regrind journal to following finished dia-

meter.

IFinished diameter44.732 -44.750 mm

(1.7612 - 1.7618 in.)I

2) Using micrometer, measure reground journal

diameter. Measurement should be carried out

in two directions perpendicular to each other

in order to check for out-of-round.

3) From the journal diameter measured above

and the alphabets stamped on mating surface

of cylinder block, select the undersize bearing

to be installed by referring to the table

shown below.

Check bearing clearance with undersize

bearing selected.

3-33