SUZUKI GRAND VITARA 1999 2.G Owners Manual

Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 511 of 656

8-2 BODY ELECTRICAL SYSTEM

General Description

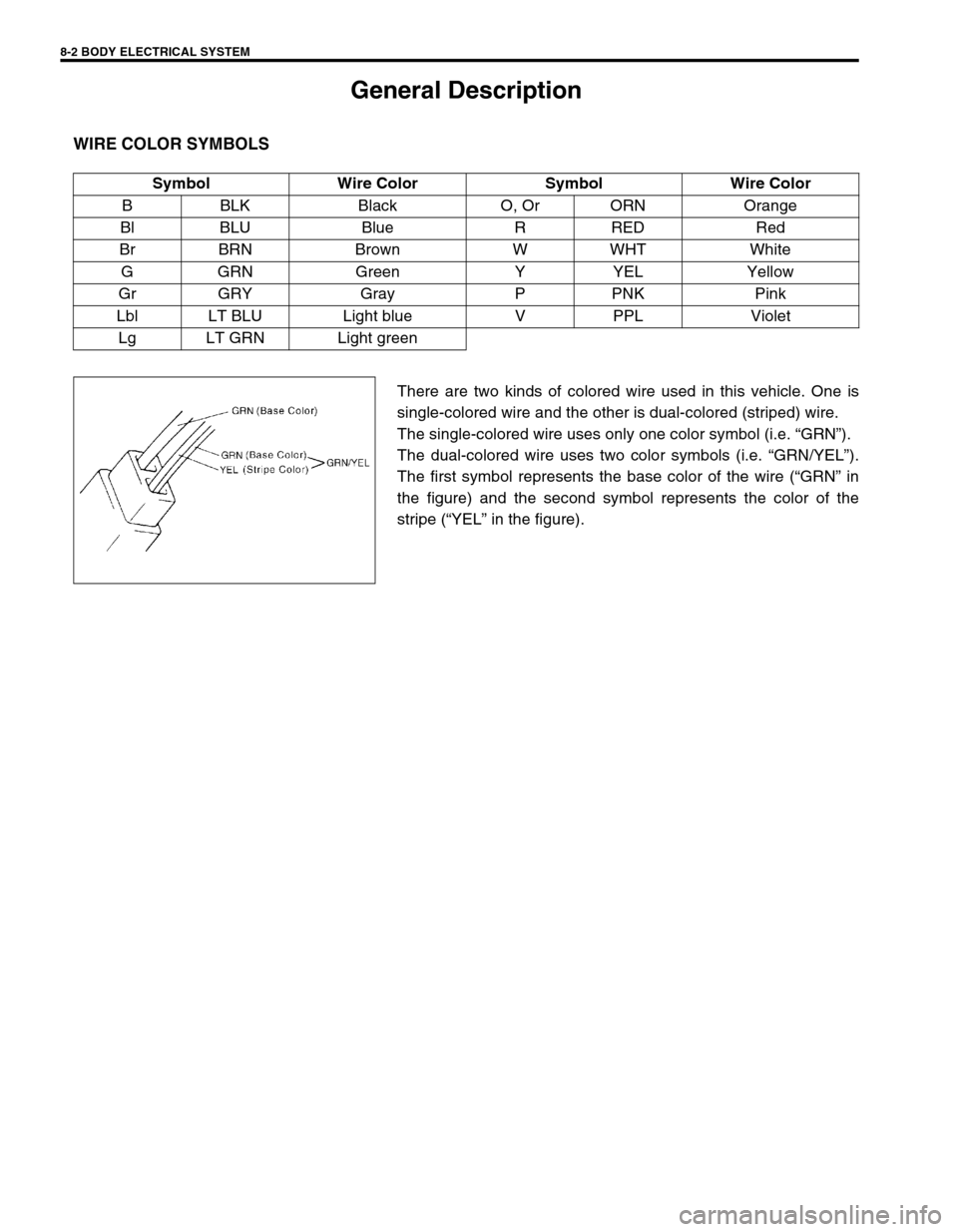

WIRE COLOR SYMBOLS

There are two kinds of colored wire used in this vehicle. One is

single-colored wire and the other is dual-colored (striped) wire.

The single-colored wire uses only one color symbol (i.e. “GRN”).

The dual-colored wire uses two color symbols (i.e. “GRN/YEL”).

The first symbol represents the base color of the wire (“GRN” in

the figure) and the second symbol represents the color of the

stripe (“YEL” in the figure). Symbol Wire Color Symbol Wire Color

B BLK Black O, Or ORN Orange

Bl BLU Blue R RED Red

Br BRN Brown W WHT White

GGRN Green Y YEL Yellow

Gr GRY Gray P PNK Pink

Lbl LT BLU Light blue V PPL Violet

Lg LT GRN Light green

Page 512 of 656

INSTRUMENTATION/DRIVER INFORMATION 8C-1

8C

SECTION 8C

INSTRUMENTATION/DRIVER INFORMATION

CONTENTS

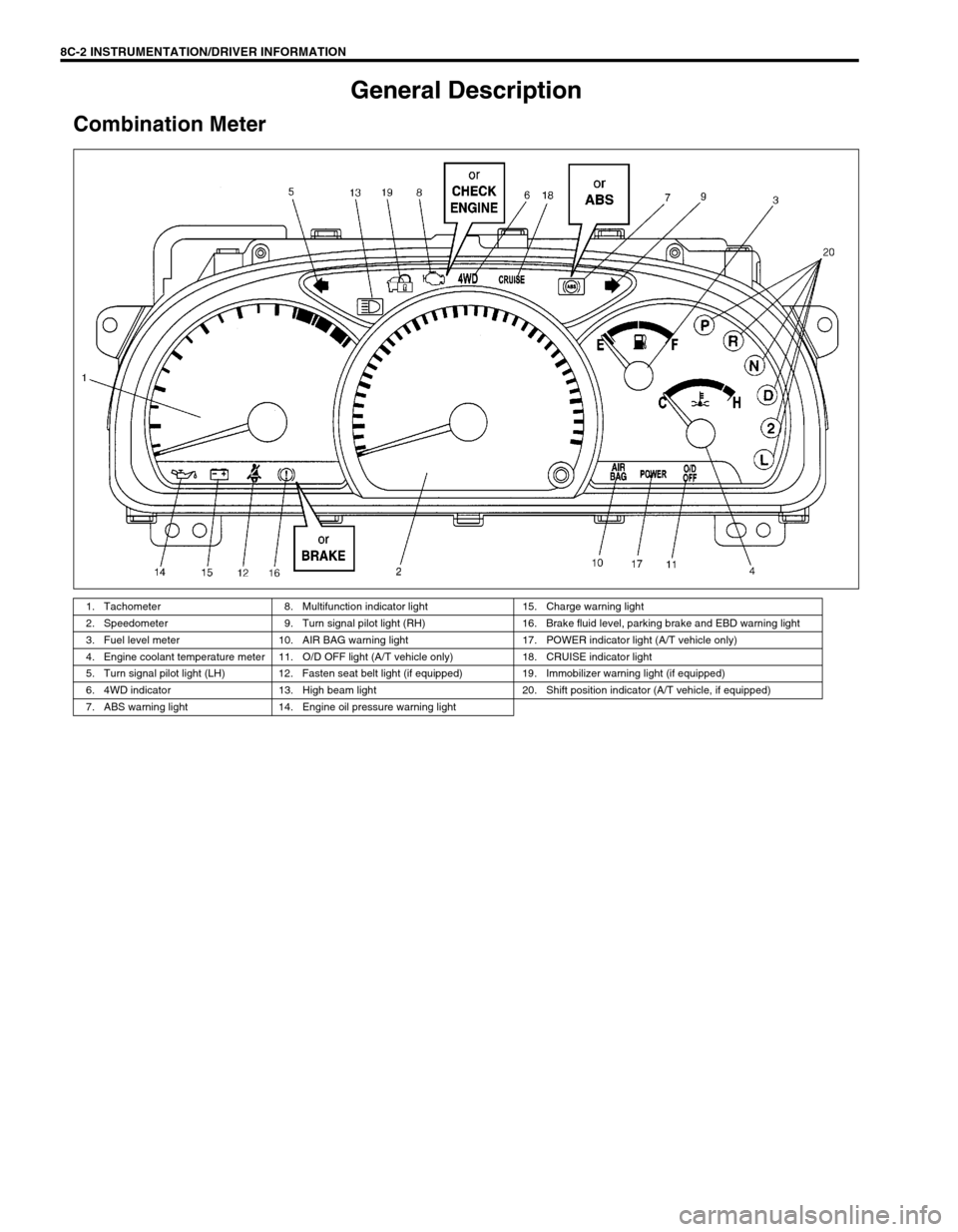

General Description ........................................8C-2

Combination Meter ........................................8C-2

On-vehicle Service ..........................................8C-4

Fuel Meter/Fuel Gauge Unit ..........................8C-4

Fuel level sensor (sender gauge) ..............8C-4

Engine Coolant Temperature (ECT) Meter

and Sensor ....................................................8C-5Engine coolant temperature sensor .......... 8C-5

Oil Pressure Light ......................................... 8C-5

Oil pressure switch .................................... 8C-5

Brake Warning Light ..................................... 8C-5

Brake fluid level switch .............................. 8C-5

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Manual

mentioned in the FOREWORD of this manual.

Page 513 of 656

8C-2 INSTRUMENTATION/DRIVER INFORMATION

General Description

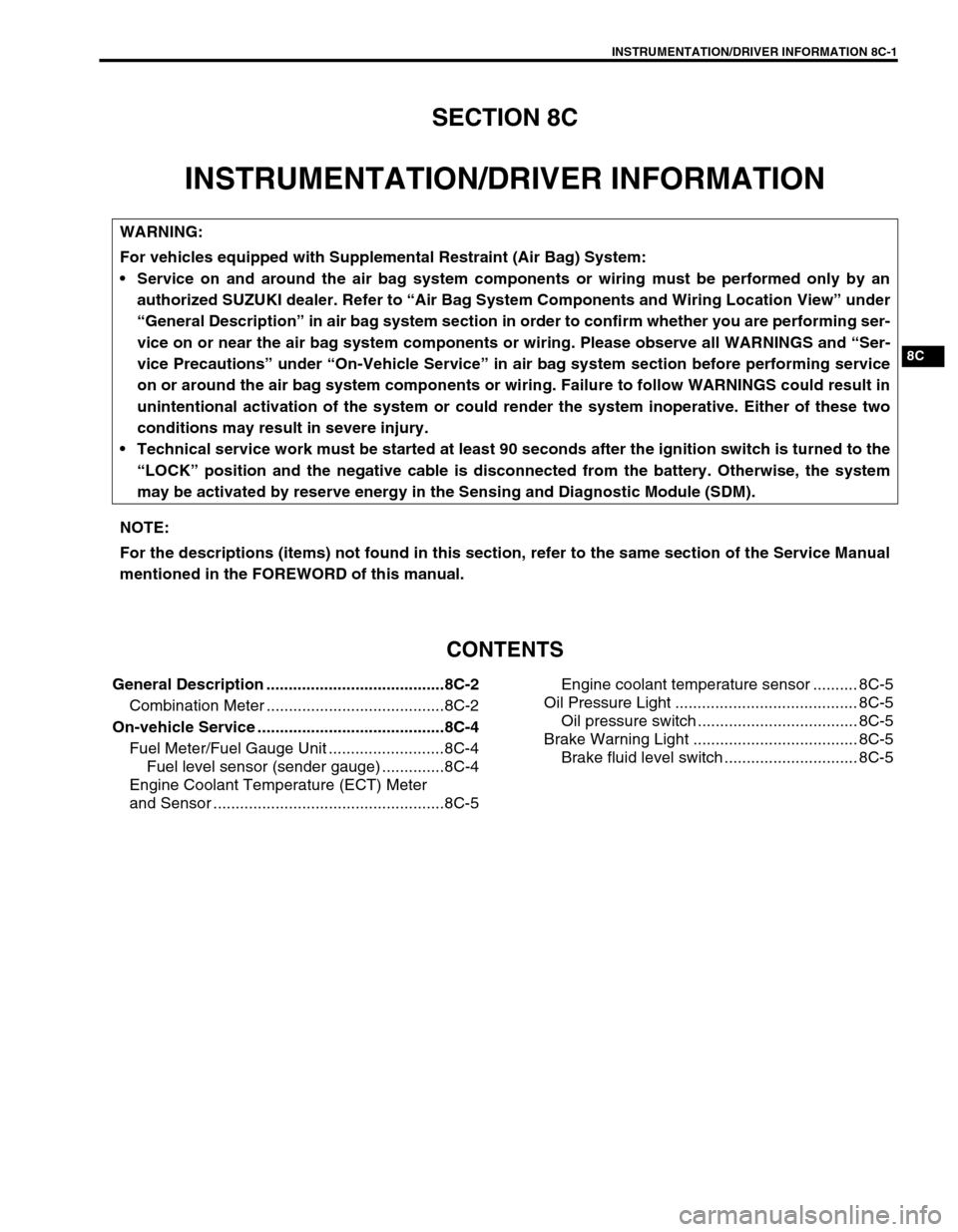

Combination Meter

1. Tachometer 8. Multifunction indicator light 15. Charge warning light

2. Speedometer 9. Turn signal pilot light (RH) 16. Brake fluid level, parking brake and EBD warning light

3. Fuel level meter 10. AIR BAG warning light 17. POWER indicator light (A/T vehicle only)

4. Engine coolant temperature meter 11. O/D OFF light (A/T vehicle only) 18. CRUISE indicator light

5. Turn signal pilot light (LH) 12. Fasten seat belt light (if equipped) 19. Immobilizer warning light (if equipped)

6. 4WD indicator 13. High beam light 20. Shift position indicator (A/T vehicle, if equipped)

7. ABS warning light 14. Engine oil pressure warning light

Page 514 of 656

![SUZUKI GRAND VITARA 1999 2.G Owners Manual INSTRUMENTATION/DRIVER INFORMATION 8C-3

COMBINATION METER INTERNAL CIRCUITS

COMBINATION METER COUPLERS

[A] : Coupler A [B] : Coupler B [C] : Coupler C

1. To Cruise control module (if equipped) GRY/YE SUZUKI GRAND VITARA 1999 2.G Owners Manual INSTRUMENTATION/DRIVER INFORMATION 8C-3

COMBINATION METER INTERNAL CIRCUITS

COMBINATION METER COUPLERS

[A] : Coupler A [B] : Coupler B [C] : Coupler C

1. To Cruise control module (if equipped) GRY/YE](/img/20/7583/w960_7583-513.png)

INSTRUMENTATION/DRIVER INFORMATION 8C-3

COMBINATION METER INTERNAL CIRCUITS

COMBINATION METER COUPLERS

[A] : Coupler A [B] : Coupler B [C] : Coupler C

1. To Cruise control module (if equipped) GRY/YEL 1. To door switch (drive side) BLK/BLU 1. To ground BLK

2. Blank–2. To transmission range switch

(A/T vehicle only, if equipped) LGRN/BLU 2. To ECM (PCM for A/T vehicle) BRN

3. To ignition switch BLK/WHT 3. To transmission range switch

(A/T vehicle only, if equipped) 2GRN/ORN 3. To ignition switch PPL/RED

4. Blank–4. To transmission range switch

(A/T vehicle only, if equipped) DYEL/GRN 4. To brake fluid level switch RED/BLK

5. To ABS control module (if equipped) BLU/ORN 5. To transmission range switch

(A/T vehicle only, if equipped) NORN/BLU 5. To parking brake switch PPL

6. To PCM (A/T vehicle only) GRY/BLU 6. To transmission range switch

(A/T vehicle only, if equipped) PORN/GRN 6. To seat belt switch GRY/RED

7. To ABS control module (if equipped) BRN 7. To transmission range switch

(A/T vehicle only, if equipped) RRED 7. To generator WHT/RED

8. To VSS BLU/YEL 8. To illumination control module RED/GRN 8. To engine oil pressure switch YEL/BLK

9. To combination switch GRN/RED 9. To PCM (A/T vehicle only) WHT/BLK 9. To combination switch RED/YEL

10. To air bag SDM BLU 10. To ECT sensor YEL/WHT 10. To ignition switch BLU/RED

11. To main fuse WHT/BLU 11. To fuel level gauge BLU/WHT

12. To fuse box WHT 12. To ground BLU/YEL

13. To combination switch RED 13. To combination switch GRN/YEL

14. To immobilizer control module

(if equipped)PPL

15. To ECM (PCM for A/T vehicle) PPL/YEL

16. To ECM (PCM for A/T vehicle) ORN/BLK

P R N D 2 LCRUISEPOWER4WDSPEED

METERTACHO

METERFUEL

METERTEMP.

METER

A-11

A-13 A-8 B-12 B-11 C-8 A-15 A-6 A-1 B-9 A-16 A-14 C-7 C-1 A-10 C-3 C-4 C-5 A-7 A-5 B-8 B-1B-10 C-2 A-12 A-3B-13 B-2 B-3 B-4 B-5 B- B-6 C-9 C-10 A-9ABS circuit EBD circuit Air bag circuit

or ABS or BRAKE

if equipped

or CHECK

ENGINE

NOTE:

Terminal arrangement of coupler viewed from harness side.

Page 515 of 656

8C-4 INSTRUMENTATION/DRIVER INFORMATION

On-vehicle Service

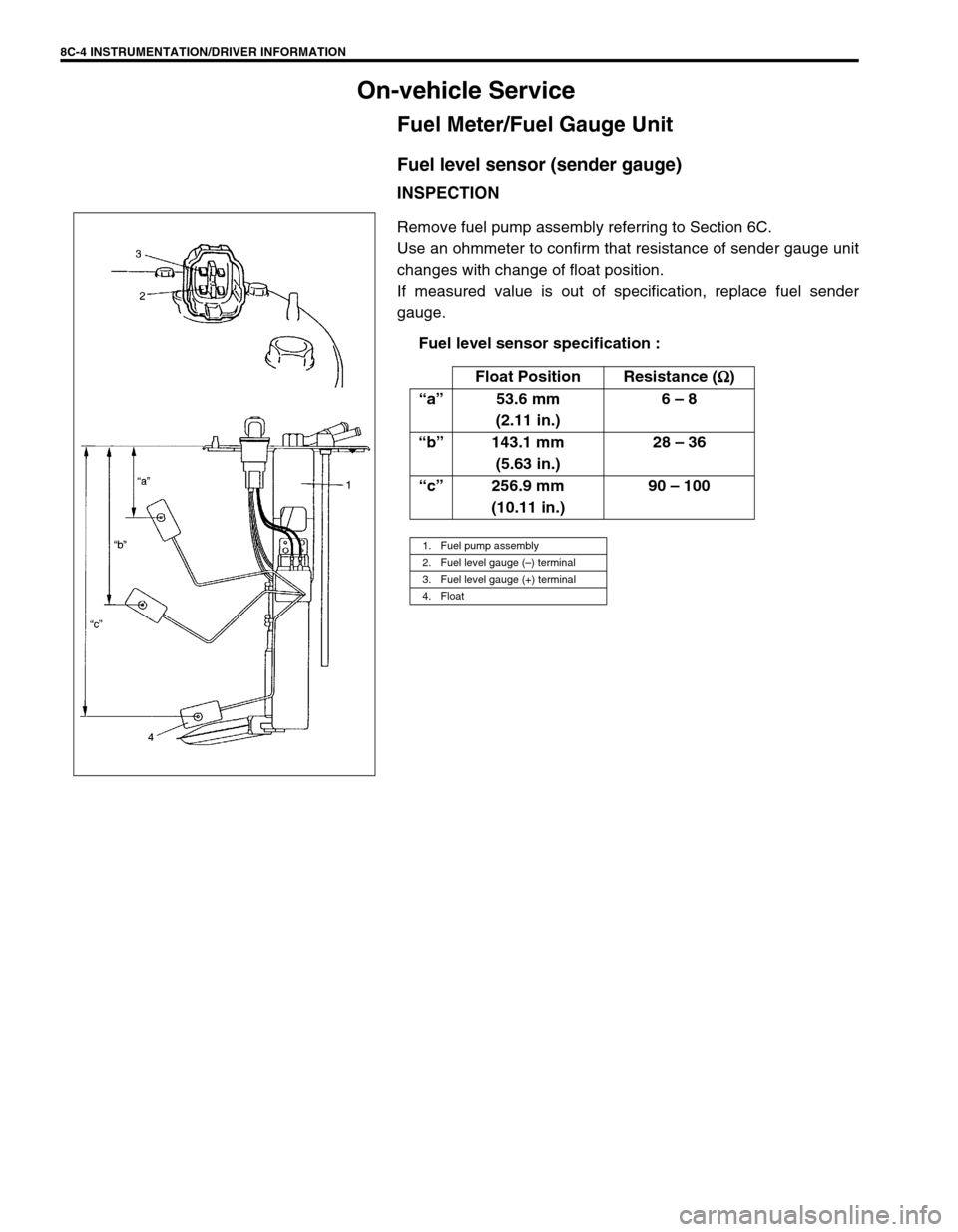

Fuel Meter/Fuel Gauge Unit

Fuel level sensor (sender gauge)

INSPECTION

Remove fuel pump assembly referring to Section 6C.

Use an ohmmeter to confirm that resistance of sender gauge unit

changes with change of float position.

If measured value is out of specification, replace fuel sender

gauge.

Fuel level sensor specification :

Float Position Resistance (Ω

ΩΩ Ω)

“a”53.6 mm

(2.11 in.)6 – 8

“b”143.1 mm

(5.63 in.)28 – 36

“c”256.9 mm

(10.11 in.)90 – 100

1. Fuel pump assembly

2. Fuel level gauge (–) terminal

3. Fuel level gauge (+) terminal

4. Float

Page 516 of 656

INSTRUMENTATION/DRIVER INFORMATION 8C-5

Engine Coolant Temperature (ECT) Meter and

Sensor

Engine coolant temperature sensor

REMOVAL AND INSTALLATION

Refer to “ECT SENSOR” in Section 6E2.

Oil Pressure Light

Oil pressure switch

REMOVAL AND INSTALLATION

Refer to “OIL PRESSURE CHECK” in Section 6A2.

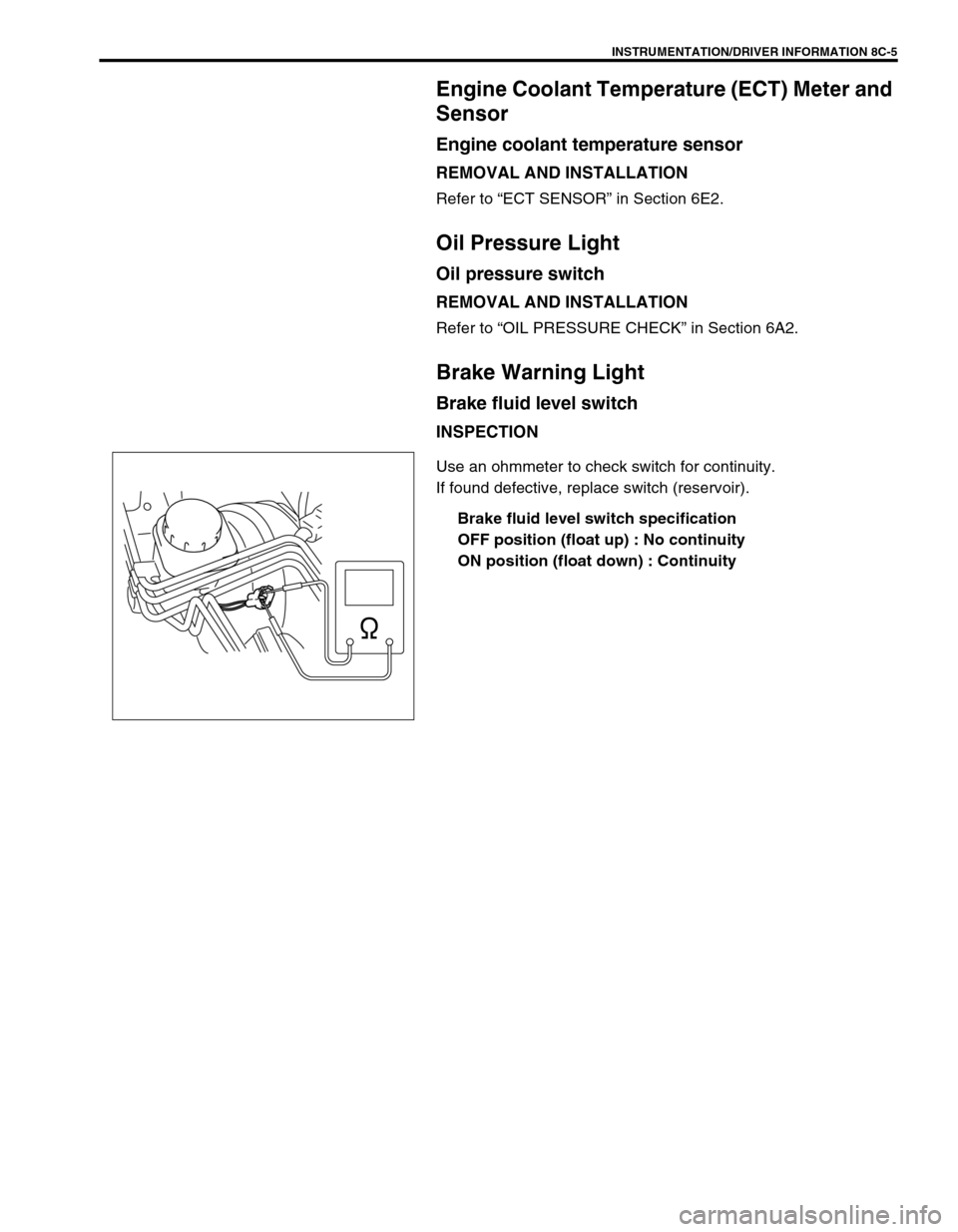

Brake Warning Light

Brake fluid level switch

INSPECTION

Use an ohmmeter to check switch for continuity.

If found defective, replace switch (reservoir).

Brake fluid level switch specification

OFF position (float up) : No continuity

ON position (float down) : Continuity

Page 517 of 656

8C-6 INSTRUMENTATION/DRIVER INFORMATION

Page 518 of 656

WINDOWS, MIRRORS, SECURITY AND LOCKS 8D-1

8D

SECTION 8D

WINDOWS, MIRRORS, SECURITY AND LOCKS

CONTENTS

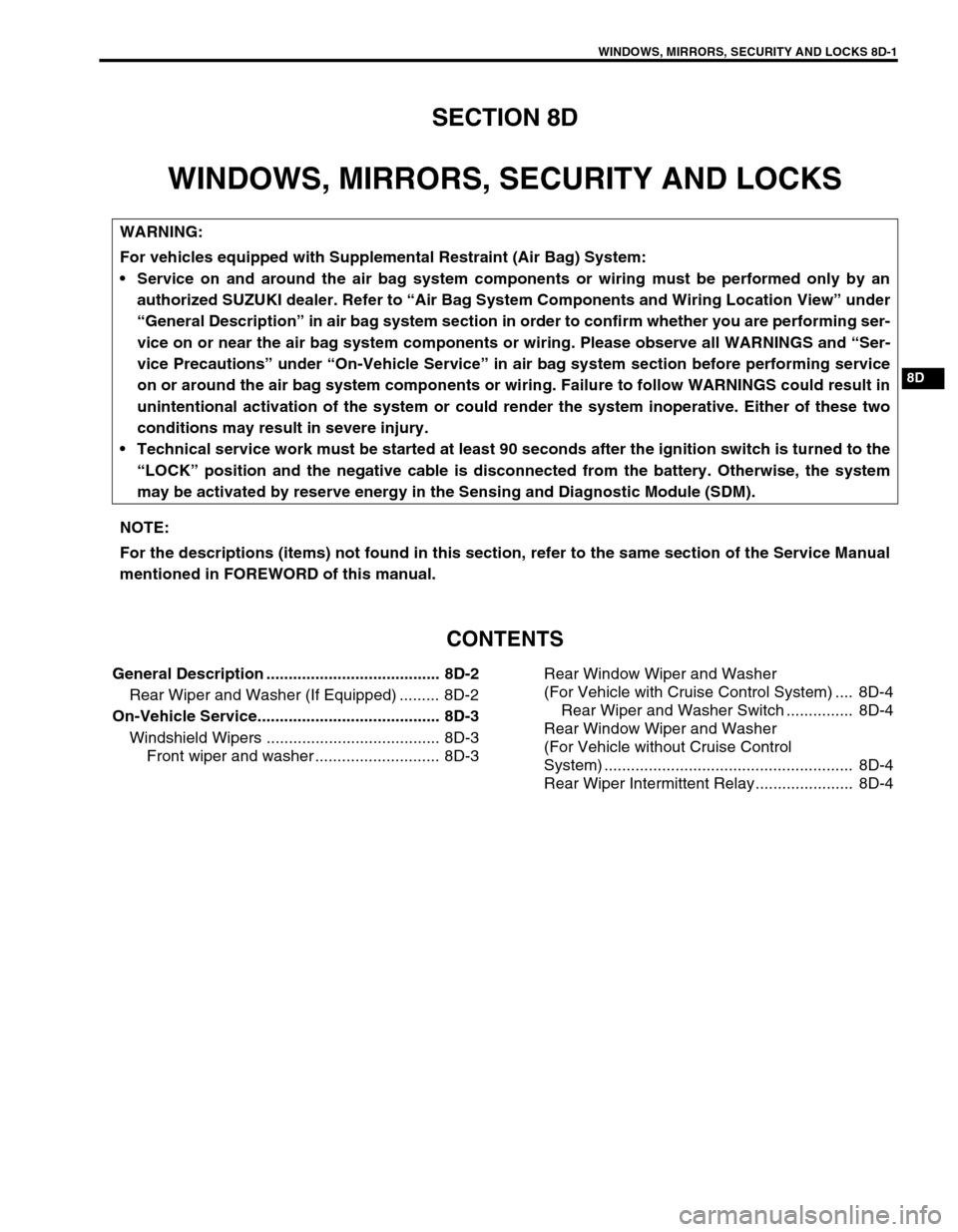

General Description ....................................... 8D-2

Rear Wiper and Washer (If Equipped) ......... 8D-2

On-Vehicle Service......................................... 8D-3

Windshield Wipers ....................................... 8D-3

Front wiper and washer ............................ 8D-3Rear Window Wiper and Washer

(For Vehicle with Cruise Control System) .... 8D-4

Rear Wiper and Washer Switch ............... 8D-4

Rear Window Wiper and Washer

(For Vehicle without Cruise Control

System) ........................................................ 8D-4

Rear Wiper Intermittent Relay...................... 8D-4

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Manual

mentioned in FOREWORD of this manual.

Page 519 of 656

8D-2 WINDOWS, MIRRORS, SECURITY AND LOCKS

General Description

Rear Wiper and Washer (If Equipped)

Page 520 of 656

WINDOWS, MIRRORS, SECURITY AND LOCKS 8D-3

On-Vehicle Service

Windshield Wipers

Front wiper and washer

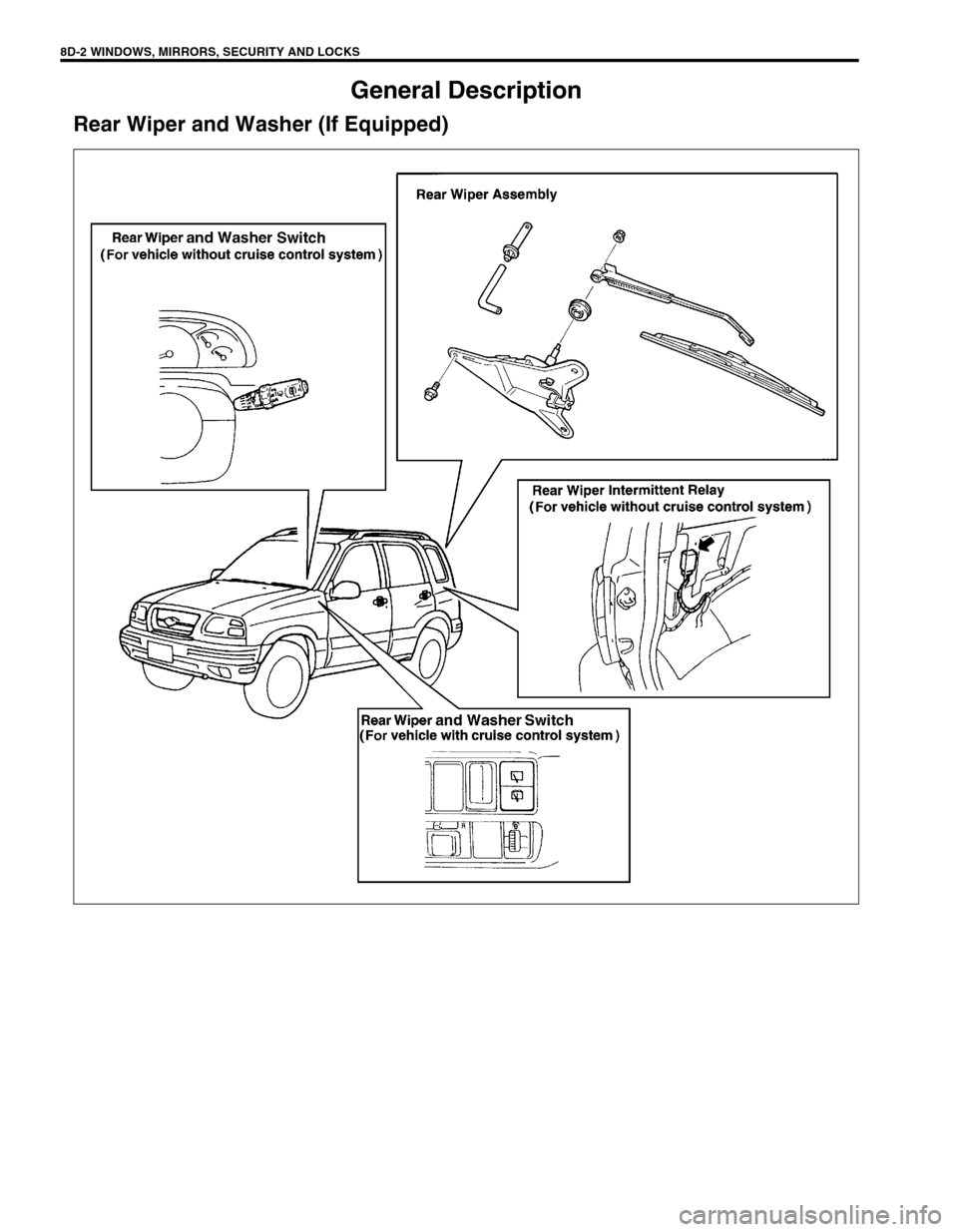

Wiper motor

•As shown in the figure, use a 12 V battery to connect its (+)

terminal to terminal “A”, and its (–) terminal to “Black” lead

wire (2).

If motor (1) rotates at a low revolution speed of 45 to 55 rpm,

it is proper. For high speed check, connect battery (+) termi-

nal to terminal “B”, and its (–) terminal to “Black” lead wire

(2). If motor rotates at a high revolution speed of 67 to 83

rpm, it is proper.

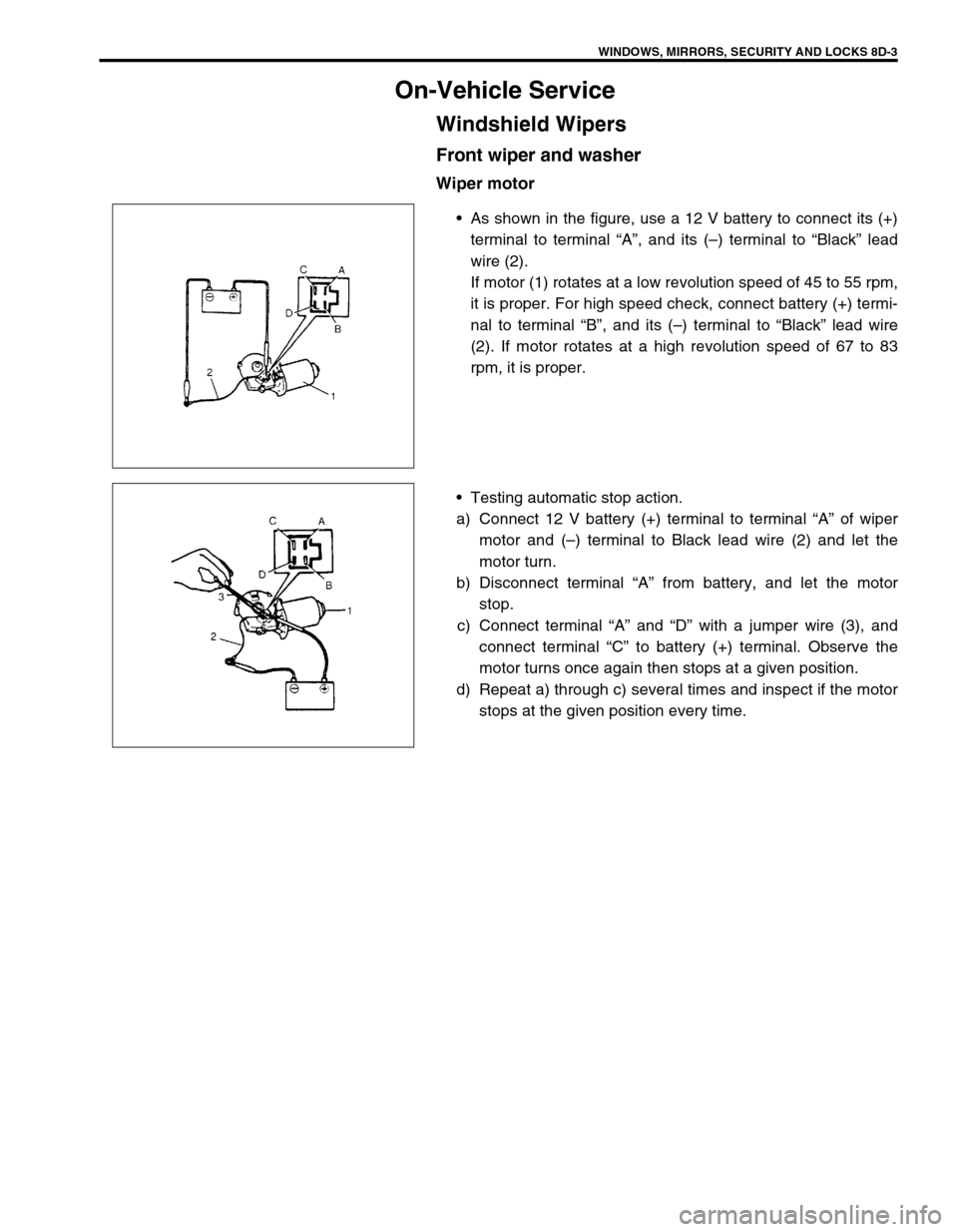

•Testing automatic stop action.

a) Connect 12 V battery (+) terminal to terminal “A” of wiper

motor and (–) terminal to Black lead wire (2) and let the

motor turn.

b) Disconnect terminal “A” from battery, and let the motor

stop.

c) Connect terminal “A” and “D” with a jumper wire (3), and

connect terminal “C” to battery (+) terminal. Observe the

motor turns once again then stops at a given position.

d) Repeat a) through c) several times and inspect if the motor

stops at the given position every time.