Torque SUZUKI SWIFT 2000 1.G RG413 Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 290 of 698

BRAKES 5-17

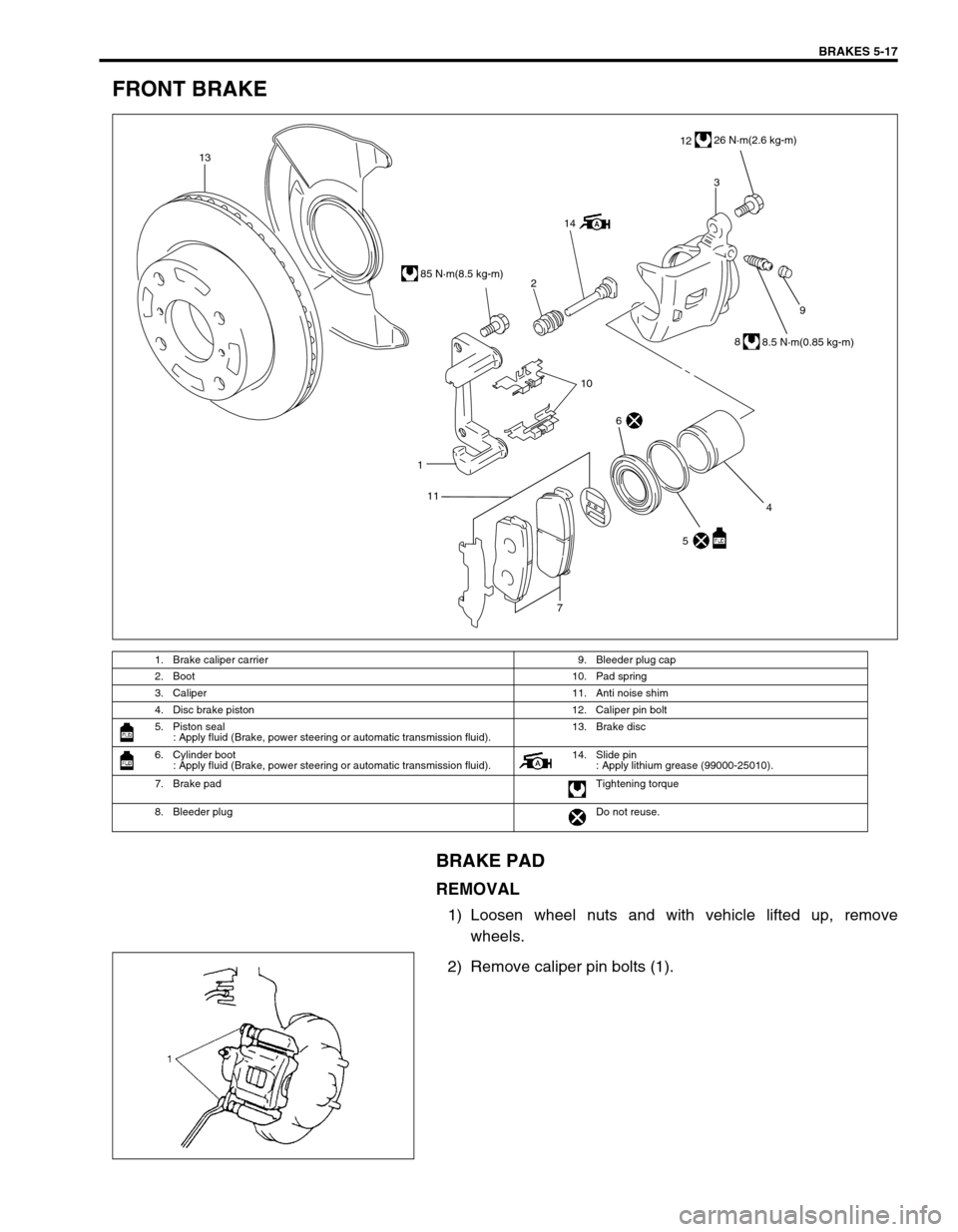

FRONT BRAKE

BRAKE PAD

REMOVAL

1) Loosen wheel nuts and with vehicle lifted up, remove

wheels.

2) Remove caliper pin bolts (1).

1. Brake caliper carrier 9. Bleeder plug cap

2. Boot 10. Pad spring

3. Caliper 11. Anti noise shim

4. Disc brake piston 12. Caliper pin bolt

5. Piston seal

: Apply fluid (Brake, power steering or automatic transmission fluid).13. Brake disc

6. Cylinder boot

: Apply fluid (Brake, power steering or automatic transmission fluid).14. Slide pin

: Apply lithium grease (99000-25010).

7. Brake pad Tightening torque

8. Bleeder plugDo not reuse.

9

1

7

13

2

143

1226 N·m(2.6 kg-m)

85 N·m(8.5 kg-m)

8

8.5 N·m(0.85 kg-m)

10

5 4

6

11

Page 291 of 698

5-18 BRAKES

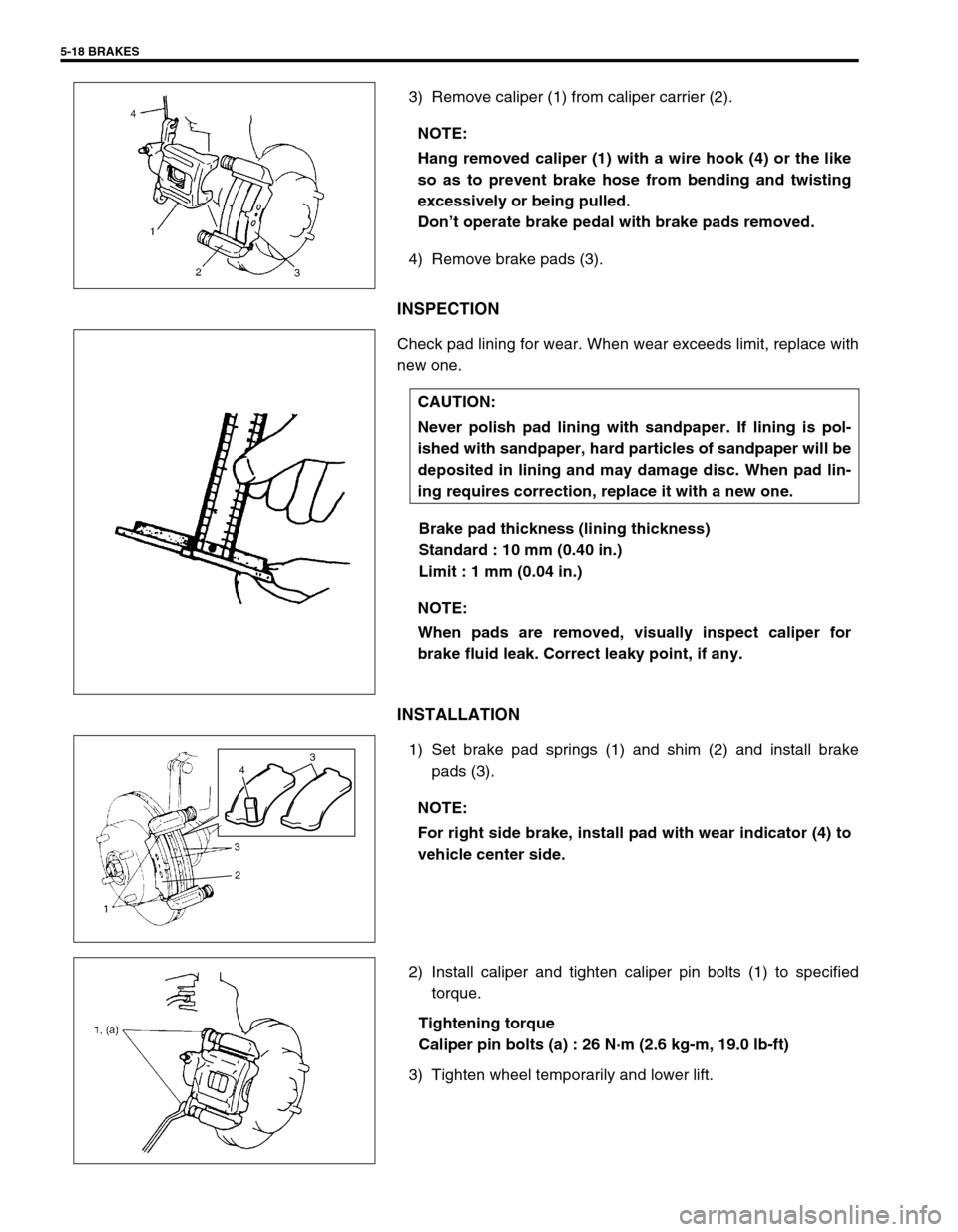

3) Remove caliper (1) from caliper carrier (2).

4) Remove brake pads (3).

INSPECTION

Check pad lining for wear. When wear exceeds limit, replace with

new one.

Brake pad thickness (lining thickness)

Standard : 10 mm (0.40 in.)

Limit : 1 mm (0.04 in.)

INSTALLATION

1) Set brake pad springs (1) and shim (2) and install brake

pads (3).

2) Install caliper and tighten caliper pin bolts (1) to specified

torque.

Tightening torque

Caliper pin bolts (a) : 26 N·m (2.6 kg-m, 19.0 lb-ft)

3) Tighten wheel temporarily and lower lift.NOTE:

Hang removed caliper (1) with a wire hook (4) or the like

so as to prevent brake hose from bending and twisting

excessively or being pulled.

Don’t operate brake pedal with brake pads removed.

CAUTION:

Never polish pad lining with sandpaper. If lining is pol-

ished with sandpaper, hard particles of sandpaper will be

deposited in lining and may damage disc. When pad lin-

ing requires correction, replace it with a new one.

NOTE:

When pads are removed, visually inspect caliper for

brake fluid leak. Correct leaky point, if any.

NOTE:

For right side brake, install pad with wear indicator (4) to

vehicle center side.

3

4

2

3

1

Page 292 of 698

BRAKES 5-19

4) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts (a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

5) After completion of installation, check for brake effective-

ness.

CALIPER ASSEMBLY

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove E-ring (1).

3) Loosen flexible hose joint bolt (1) a little at caliper.

4) Remove caliper pin bolts (1).

5) Remove caliper from caliper carrier.

6) Disconnect flexible hose from caliper using care not to twist

it. As this will allow brake fluid to flow out of flexible hose,

have a container ready beforehand.

CAUTION:

Be careful not to twist flexible hose while loosening the

bolt.

Page 295 of 698

5-22 BRAKES

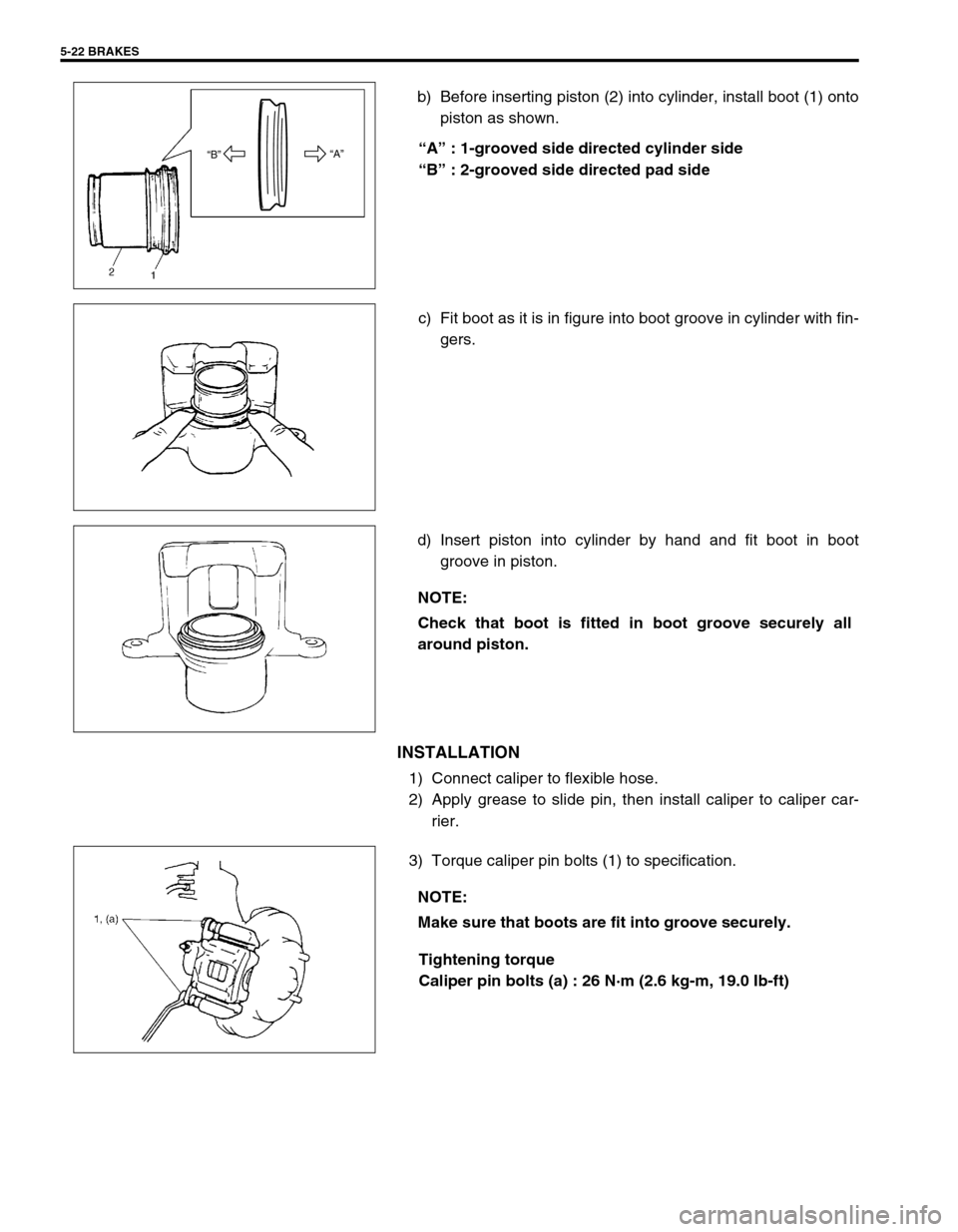

b) Before inserting piston (2) into cylinder, install boot (1) onto

piston as shown.

“A” : 1-grooved side directed cylinder side

“B” : 2-grooved side directed pad side

c) Fit boot as it is in figure into boot groove in cylinder with fin-

gers.

d) Insert piston into cylinder by hand and fit boot in boot

groove in piston.

INSTALLATION

1) Connect caliper to flexible hose.

2) Apply grease to slide pin, then install caliper to caliper car-

rier.

3) Torque caliper pin bolts (1) to specification.

Tightening torque

Caliper pin bolts (a) : 26 N·m (2.6 kg-m, 19.0 Ib-ft)

“A”

“B”

NOTE:

Check that boot is fitted in boot groove securely all

around piston.

NOTE:

Make sure that boots are fit into groove securely.

Page 296 of 698

BRAKES 5-23

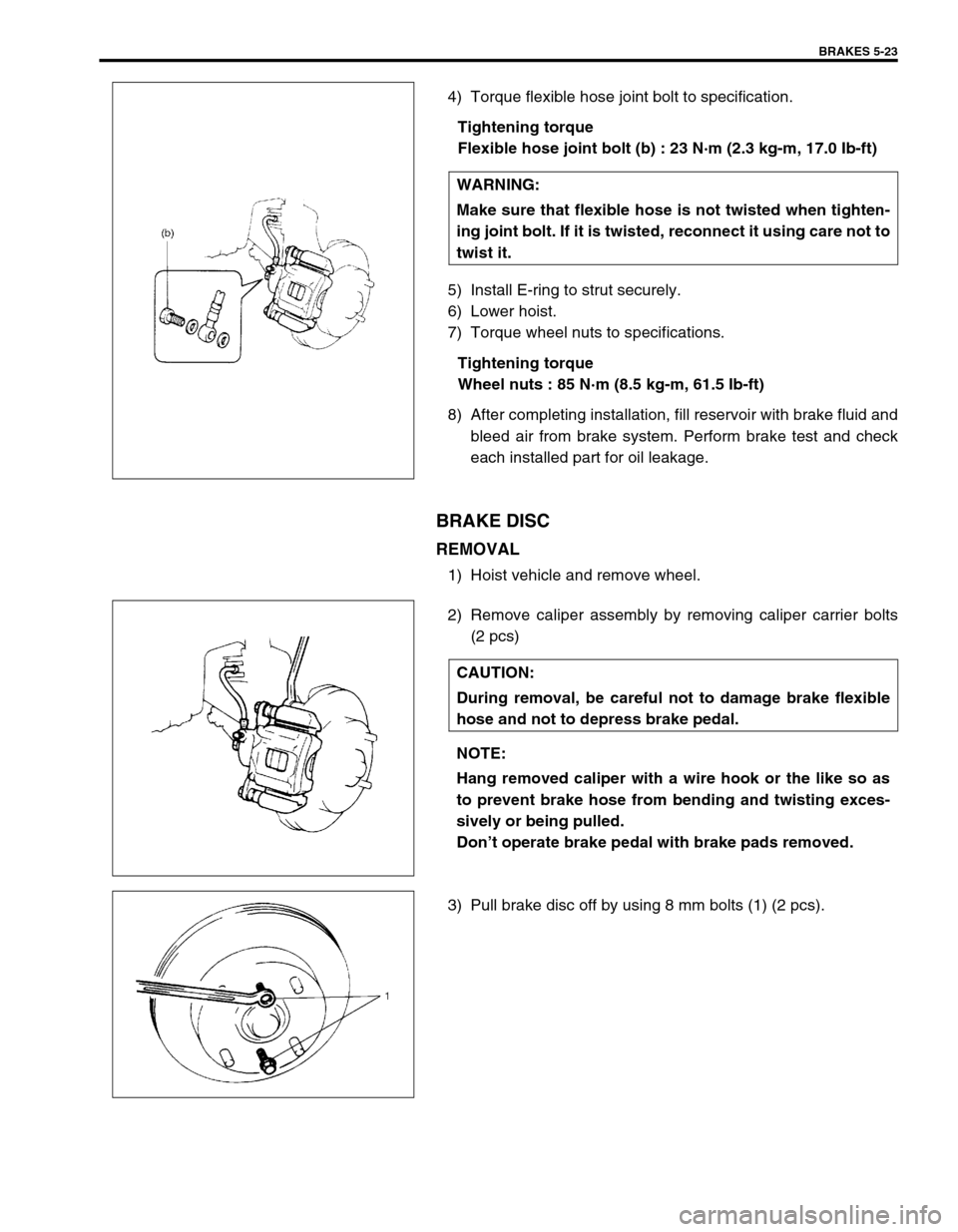

4) Torque flexible hose joint bolt to specification.

Tightening torque

Flexible hose joint bolt (b) : 23 N·m (2.3 kg-m, 17.0 Ib-ft)

5) Install E-ring to strut securely.

6) Lower hoist.

7) Torque wheel nuts to specifications.

Tightening torque

Wheel nuts : 85 N·m (8.5 kg-m, 61.5 Ib-ft)

8) After completing installation, fill reservoir with brake fluid and

bleed air from brake system. Perform brake test and check

each installed part for oil leakage.

BRAKE DISC

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper carrier bolts

(2 pcs)

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs).WARNING:

Make sure that flexible hose is not twisted when tighten-

ing joint bolt. If it is twisted, reconnect it using care not to

twist it.

CAUTION:

During removal, be careful not to damage brake flexible

hose and not to depress brake pedal.

NOTE:

Hang removed caliper with a wire hook or the like so as

to prevent brake hose from bending and twisting exces-

sively or being pulled.

Don’t operate brake pedal with brake pads removed.

Page 297 of 698

5-24 BRAKES

INSPECTION

Using magnetic stand and with dial gauge positioned at

about 10 mm (0.39 in.) inward from periphery of disc, mea-

sure deflection of disc.

If limit value is exceeded, replace correct or replace.

Disc deflection

Limit : 0.10 mm (0.004 in.) max.

Special tool

(A) : 09900-20606

(B) : 09900-20701

Using micrometer, measure thickness of brake disc.

If limit value is exceeded, replace brake disc.

Brake disc thickness

Standard : 17.0 mm (0.67 in.)

Limit : 15.0 mm (0.59 in.)

INSTALLATION

1) Install disc to wheel hub.

2) Install caliper assembly to steering knuckle.

3) Torque caliper carrier bolts to specification.

Tightening torque

Caliper carrier bolts (a) : 85 N·m (8.5 kg-m, 61.5 Ib-ft)

4) Torque front wheel nuts to specification.

Tightening torque

Wheel nuts (b) : 85 N·m (8.5 kg-m, 61.5 Ib-ft)

5) Upon completion of installation, perform brake test.

Page 298 of 698

BRAKES 5-25

REAR BRAKE

1. Brake back plate

: Apply water tight sealant (99000-31090) to joint seam of brake back plate and rear axle 9. Bleeder plug

2. Brake shoe10. Bleeder plug cap

3. Push nut 11. Parking lever spring

4. Shoe hold down spring12. Parking brake shoe lever

5. Shoe return upper spring 13. Brake Drum

6. Shoe hold down pin 14. Spindle nut (For 2WD vehicle only)

: Calk spindle nut after tightening

7. Brake strutTightening torque

8. Wheel cylinder

: Apply brake fluid to piston cup Do not reuse.

Page 301 of 698

5-28 BRAKES

INSTALLATION

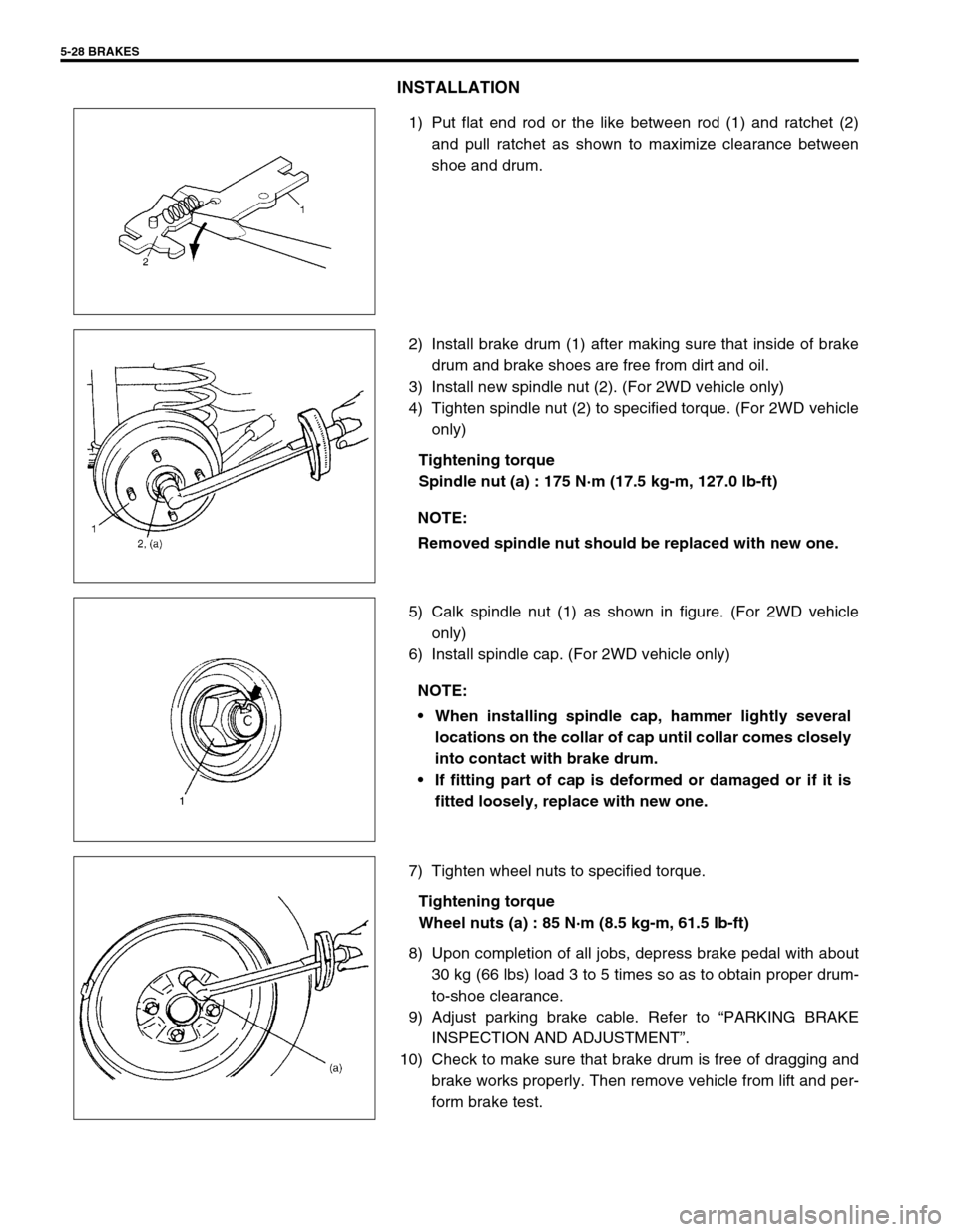

1) Put flat end rod or the like between rod (1) and ratchet (2)

and pull ratchet as shown to maximize clearance between

shoe and drum.

2) Install brake drum (1) after making sure that inside of brake

drum and brake shoes are free from dirt and oil.

3) Install new spindle nut (2). (For 2WD vehicle only)

4) Tighten spindle nut (2) to specified torque. (For 2WD vehicle

only)

Tightening torque

Spindle nut (a) : 175 N·m (17.5 kg-m, 127.0 lb-ft)

5) Calk spindle nut (1) as shown in figure. (For 2WD vehicle

only)

6) Install spindle cap. (For 2WD vehicle only)

7) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts (a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

8) Upon completion of all jobs, depress brake pedal with about

30 kg (66 lbs) load 3 to 5 times so as to obtain proper drum-

to-shoe clearance.

9) Adjust parking brake cable. Refer to “PARKING BRAKE

INSPECTION AND ADJUSTMENT”.

10) Check to make sure that brake drum is free of dragging and

brake works properly. Then remove vehicle from lift and per-

form brake test.

NOTE:

Removed spindle nut should be replaced with new one.

NOTE:

When installing spindle cap, hammer lightly several

locations on the collar of cap until collar comes closely

into contact with brake drum.

If fitting part of cap is deformed or damaged or if it is

fitted loosely, replace with new one.

Page 304 of 698

BRAKES 5-31

INSTALLATION

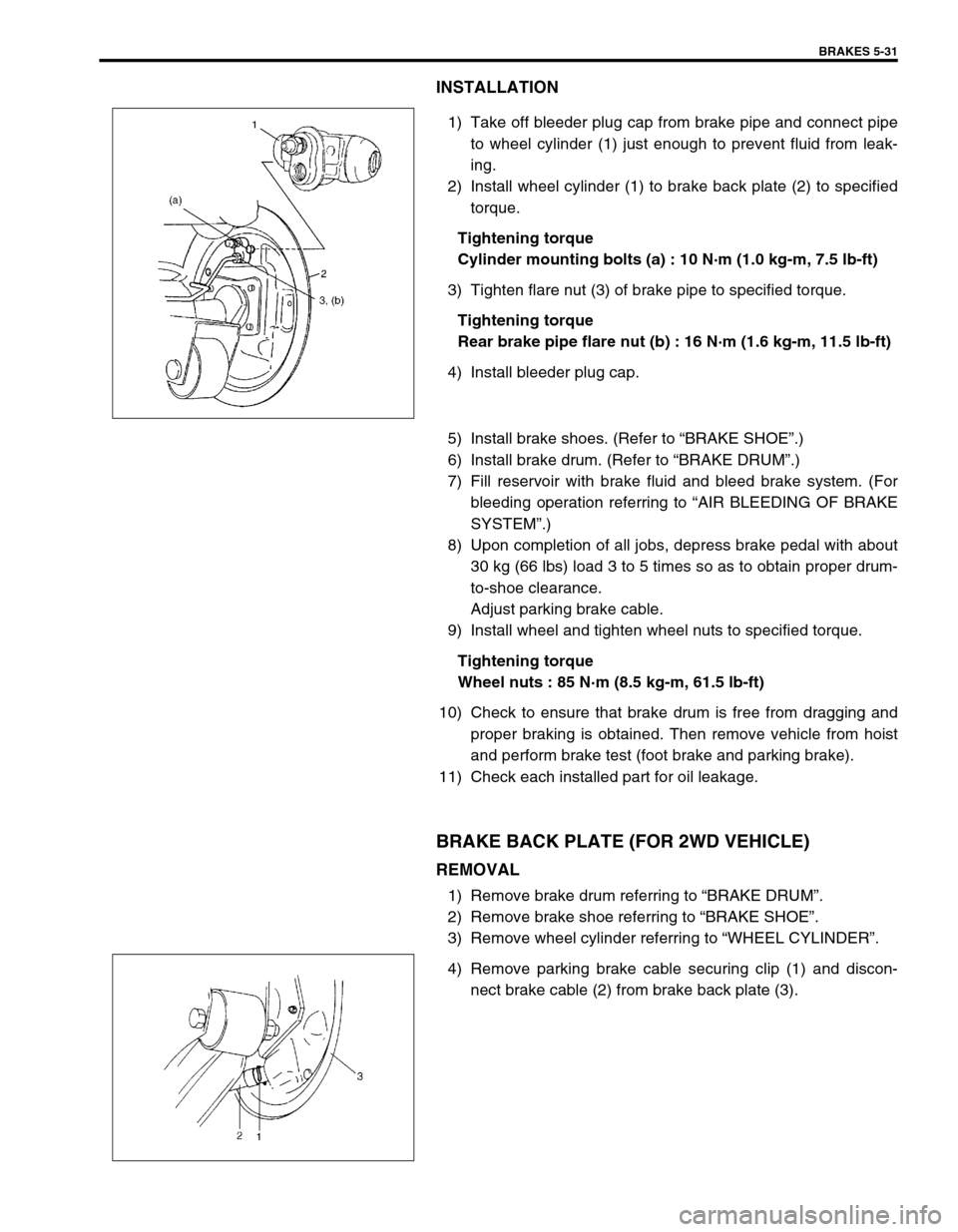

1) Take off bleeder plug cap from brake pipe and connect pipe

to wheel cylinder (1) just enough to prevent fluid from leak-

ing.

2) Install wheel cylinder (1) to brake back plate (2) to specified

torque.

Tightening torque

Cylinder mounting bolts (a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

3) Tighten flare nut (3) of brake pipe to specified torque.

Tightening torque

Rear brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

4) Install bleeder plug cap.

5) Install brake shoes. (Refer to “BRAKE SHOE”.)

6) Install brake drum. (Refer to “BRAKE DRUM”.)

7) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation referring to “AIR BLEEDING OF BRAKE

SYSTEM”.)

8) Upon completion of all jobs, depress brake pedal with about

30 kg (66 lbs) load 3 to 5 times so as to obtain proper drum-

to-shoe clearance.

Adjust parking brake cable.

9) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts : 85 N·m (8.5 kg-m, 61.5 lb-ft)

10) Check to ensure that brake drum is free from dragging and

proper braking is obtained. Then remove vehicle from hoist

and perform brake test (foot brake and parking brake).

11) Check each installed part for oil leakage.

BRAKE BACK PLATE (FOR 2WD VEHICLE)

REMOVAL

1) Remove brake drum referring to “BRAKE DRUM”.

2) Remove brake shoe referring to “BRAKE SHOE”.

3) Remove wheel cylinder referring to “WHEEL CYLINDER”.

4) Remove parking brake cable securing clip (1) and discon-

nect brake cable (2) from brake back plate (3).

Page 305 of 698

5-32 BRAKES

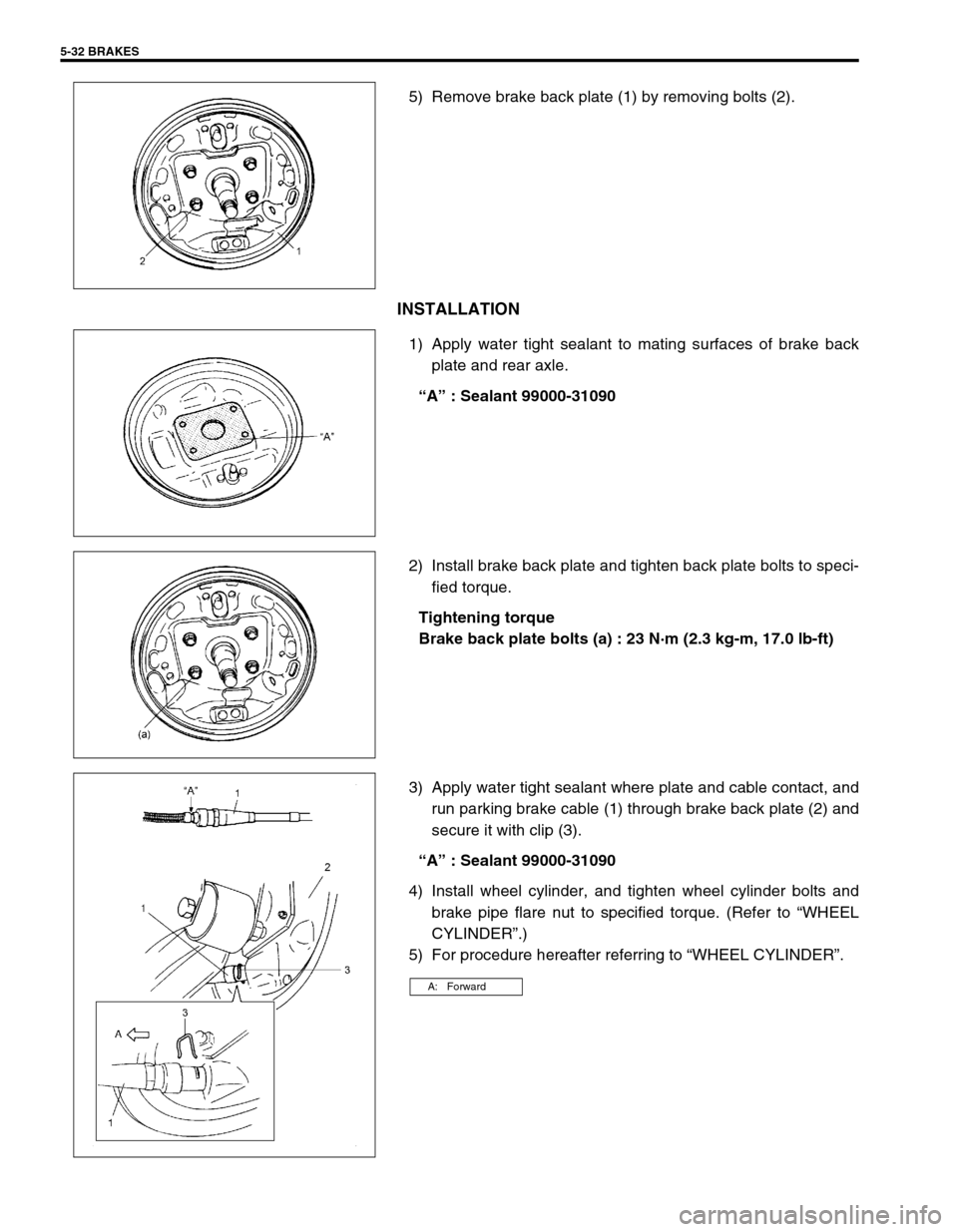

5) Remove brake back plate (1) by removing bolts (2).

INSTALLATION

1) Apply water tight sealant to mating surfaces of brake back

plate and rear axle.

“A” : Sealant 99000-31090

2) Install brake back plate and tighten back plate bolts to speci-

fied torque.

Tightening torque

Brake back plate bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

3) Apply water tight sealant where plate and cable contact, and

run parking brake cable (1) through brake back plate (2) and

secure it with clip (3).

“A” : Sealant 99000-31090

4) Install wheel cylinder, and tighten wheel cylinder bolts and

brake pipe flare nut to specified torque. (Refer to “WHEEL

CYLINDER”.)

5) For procedure hereafter referring to “WHEEL CYLINDER”.

A: Forward