TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: air filter, jump cable, panel, sensor, ground clearance, trunk release, door lock

Page 1971 of 2389

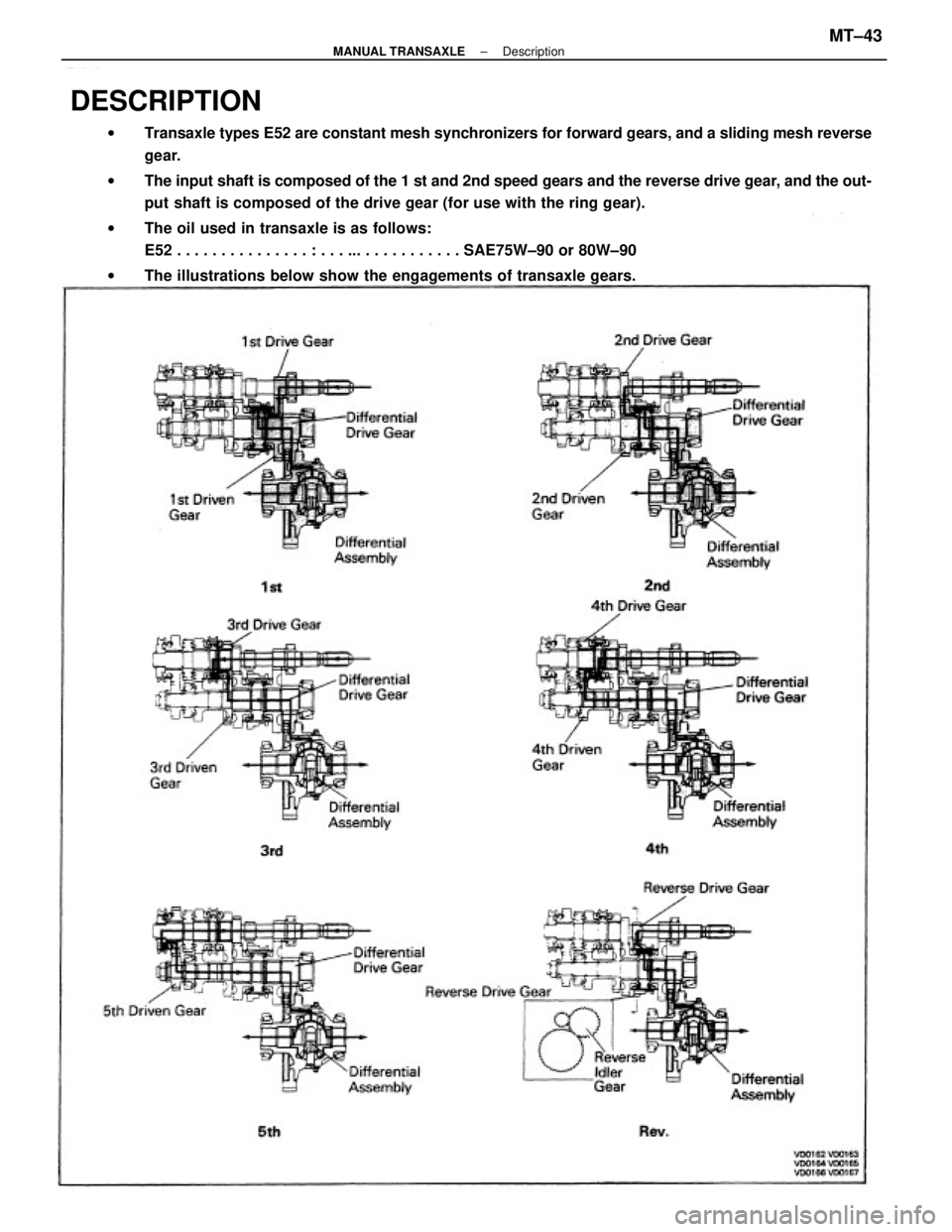

DESCRIPTION

wTransaxle types E52 are constant mesh synchronizers for forward gears, and a sliding mesh reverse

gear.

wThe input shaft is composed of the 1 st and 2nd speed gears and the reverse drive gear, and the out-

put shaft is composed of the drive gear (for use with the ring gear).

wThe oil used in transaxle is as follows:

E52 . . . . . . . . . . . . . . . : . . . ... . . . . . . . . . . . SAE75W±90 or 80W±90

wThe illustrations below show the engagements of transaxle gears.

± MANUAL TRANSAXLEDescriptionMT±43

Page 1972 of 2389

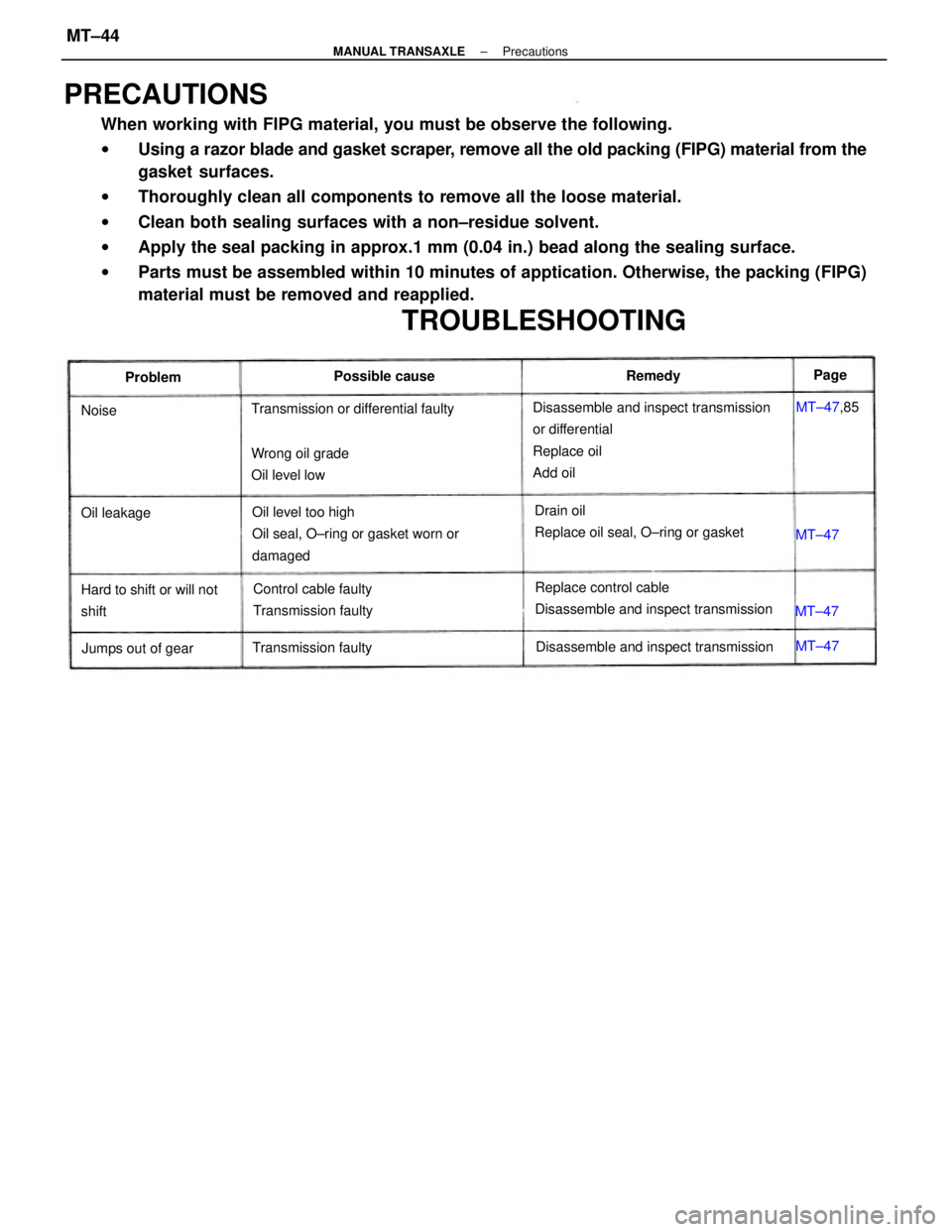

PRECAUTIONS

When working with FIPG material, you must be observe the following.

wUsing a razor blade and gasket scraper, remove all the old packing (FIPG) material from the

gasket surfaces.

wThoroughly clean all components to remove all the loose material.

wClean both sealing surfaces with a non±residue solvent.

wApply the seal packing in approx.1 mm (0.04 in.) bead along the sealing surface.

wParts must be assembled within 10 minutes of apptication. Otherwise, the packing (FIPG)

material must be removed and reapplied.

Disassemble and inspect transmission

or differential

Replace oil

Add oil

Oil level too high

Oil seal, O±ring or gasket worn or

damaged

Replace control cable

Disassemble and inspect transmission Drain oil

Replace oil seal, O±ring or gasket

TROUBLESHOOTING

Control cable faulty

Transmission faulty

Disassemble and inspect transmission Transmission or differential faulty

Hard to shift or will not

shiftWrong oil grade

Oil level low

Transmission faulty

Jumps out of gearPossible cause

Oil leakageMT±47,85 ProblemRemedy

MT±47 MT±47MT±47 NoisePage

± MANUAL TRANSAXLEPrecautionsMT±44

Page 1973 of 2389

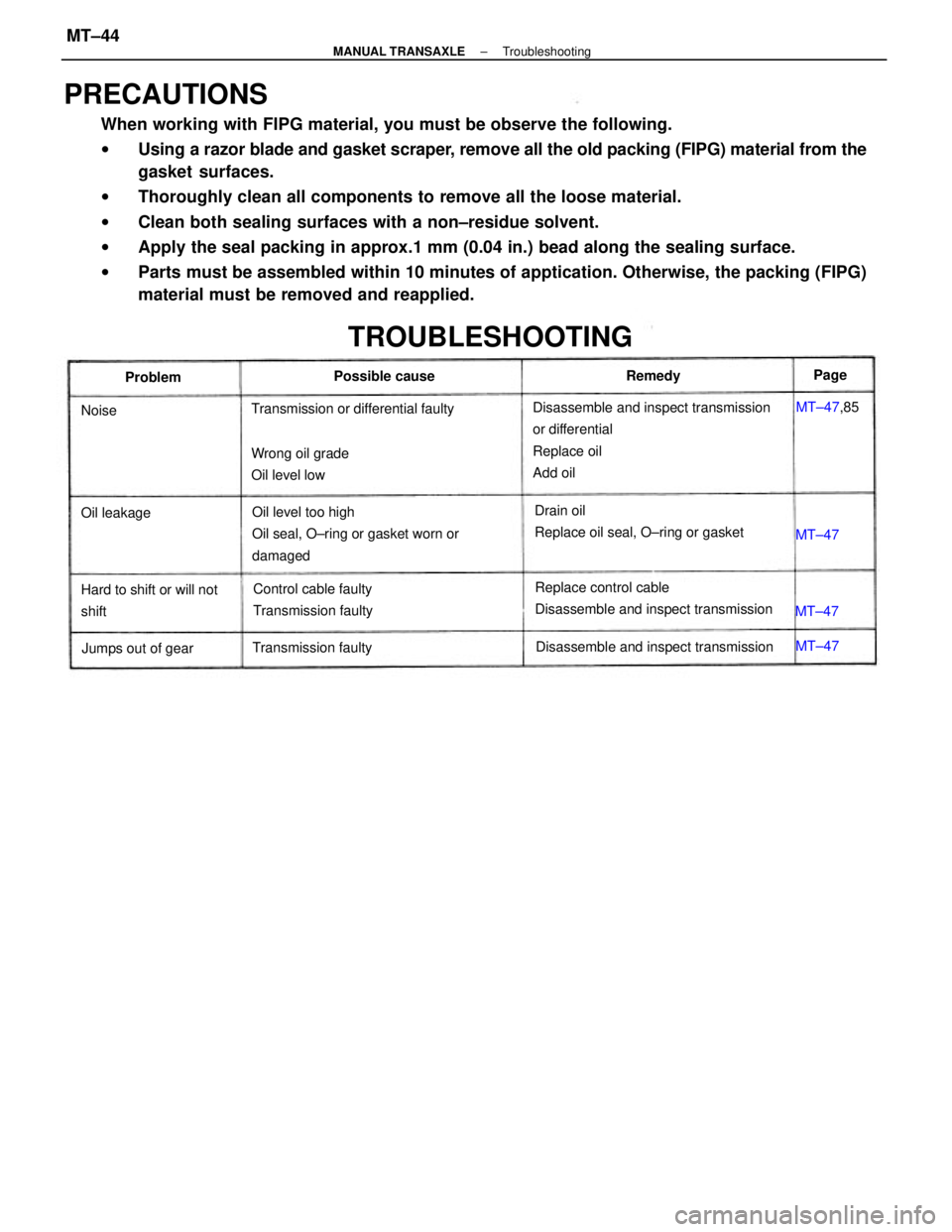

PRECAUTIONS

When working with FIPG material, you must be observe the following.

wUsing a razor blade and gasket scraper, remove all the old packing (FIPG) material from the

gasket surfaces.

wThoroughly clean all components to remove all the loose material.

wClean both sealing surfaces with a non±residue solvent.

wApply the seal packing in approx.1 mm (0.04 in.) bead along the sealing surface.

wParts must be assembled within 10 minutes of apptication. Otherwise, the packing (FIPG)

material must be removed and reapplied.

Disassemble and inspect transmission

or differential

Replace oil

Add oil

Oil level too high

Oil seal, O±ring or gasket worn or

damaged

Replace control cable

Disassemble and inspect transmission Drain oil

Replace oil seal, O±ring or gasket

TROUBLESHOOTING

Control cable faulty

Transmission faulty

Disassemble and inspect transmission Transmission or differential faulty

Hard to shift or will not

shiftWrong oil grade

Oil level low

Transmission faulty

Jumps out of gearPossible cause

Oil leakageMT±47,85 ProblemRemedy

MT±47 MT±47MT±47 NoisePage

± MANUAL TRANSAXLETroubleshootingMT±44

Page 1974 of 2389

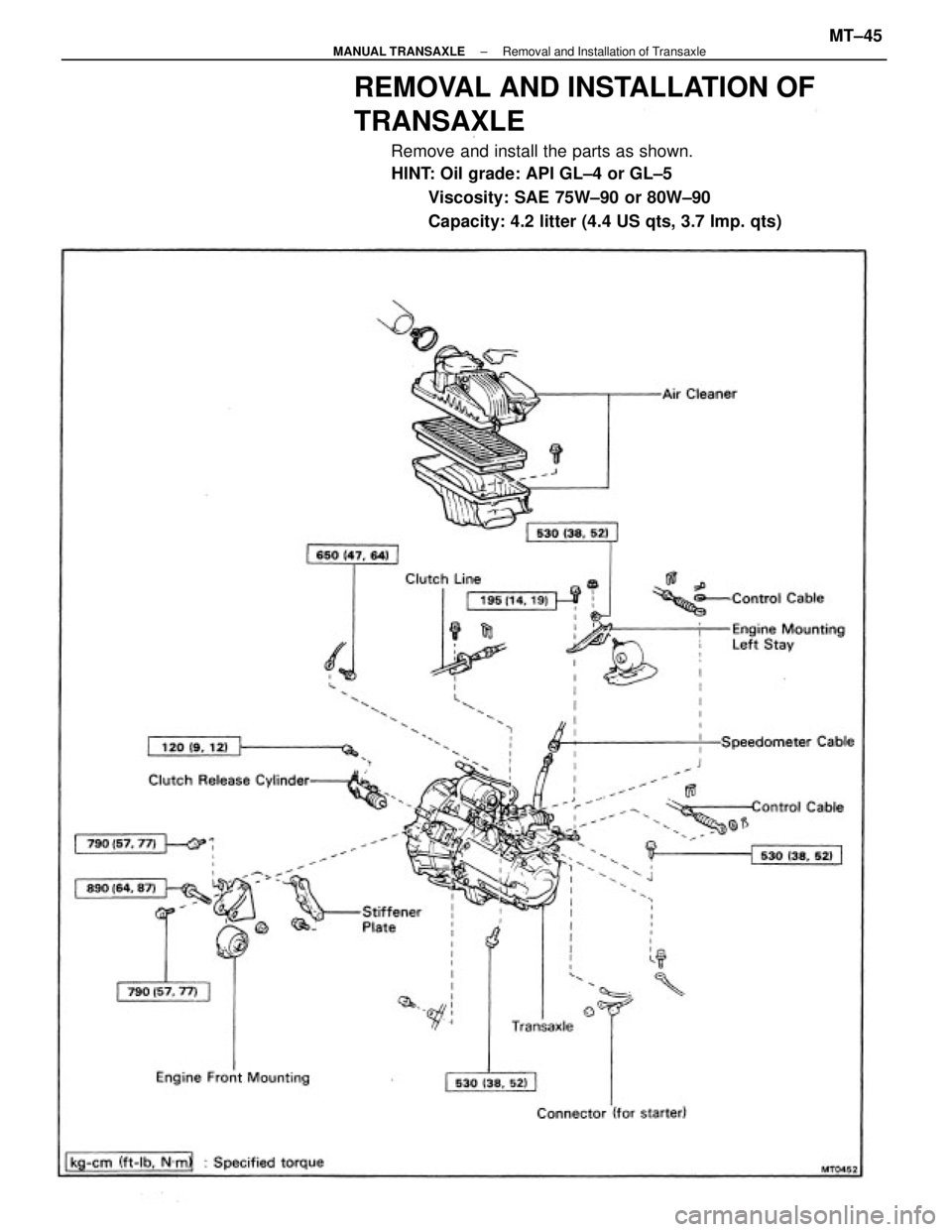

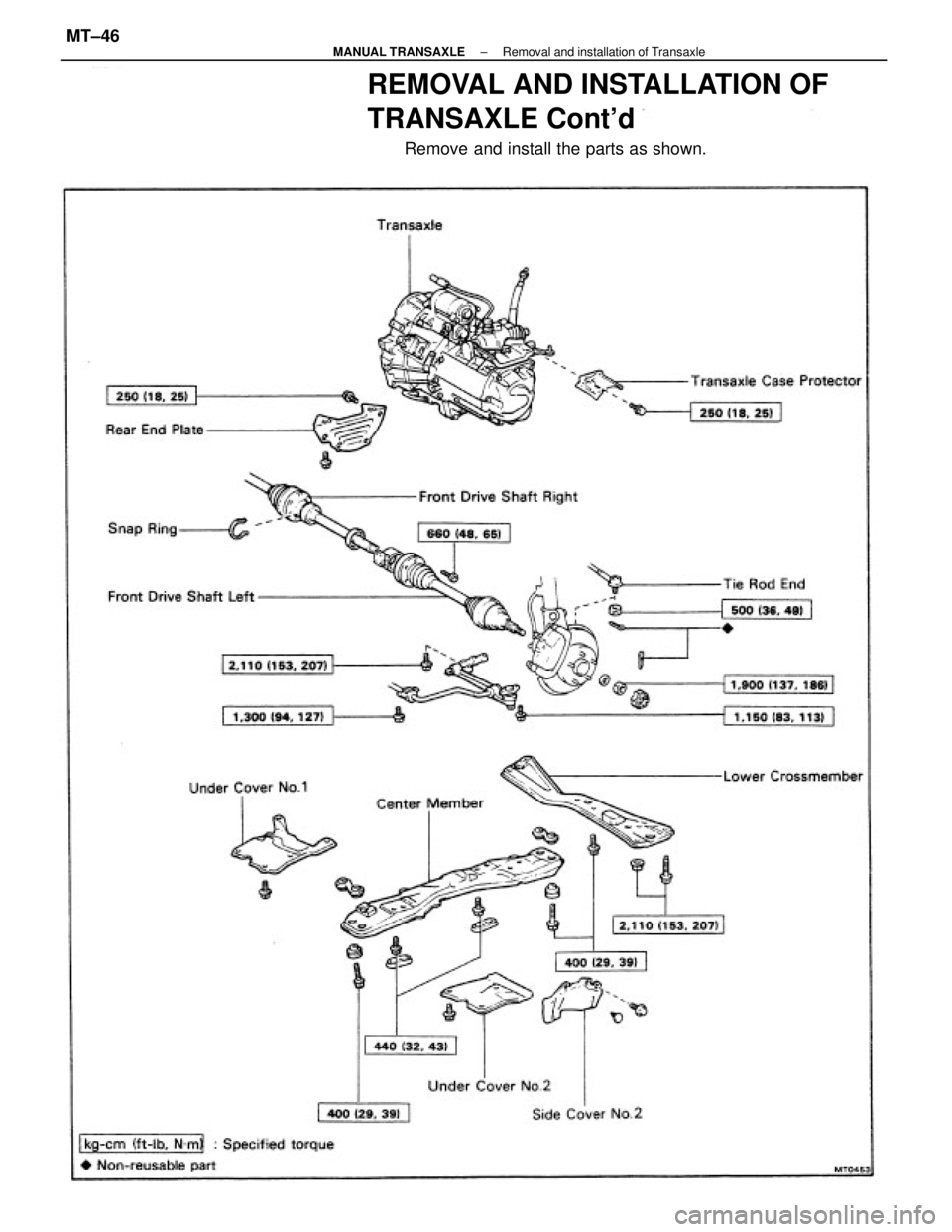

REMOVAL AND INSTALLATION OF

TRANSAXLE

Remove and install the parts as shown.

HINT: Oil grade: API GL±4 or GL±5

Viscosity: SAE 75W±90 or 80W±90

Capacity: 4.2 litter (4.4 US qts, 3.7 Imp. qts)

± MANUAL TRANSAXLERemoval and Installation of TransaxleMT±45

Page 1975 of 2389

REMOVAL AND INSTALLATION OF

TRANSAXLE Cont'd

Remove and install the parts as shown.

± MANUAL TRANSAXLERemoval and installation of TransaxleMT±46

Page 1976 of 2389

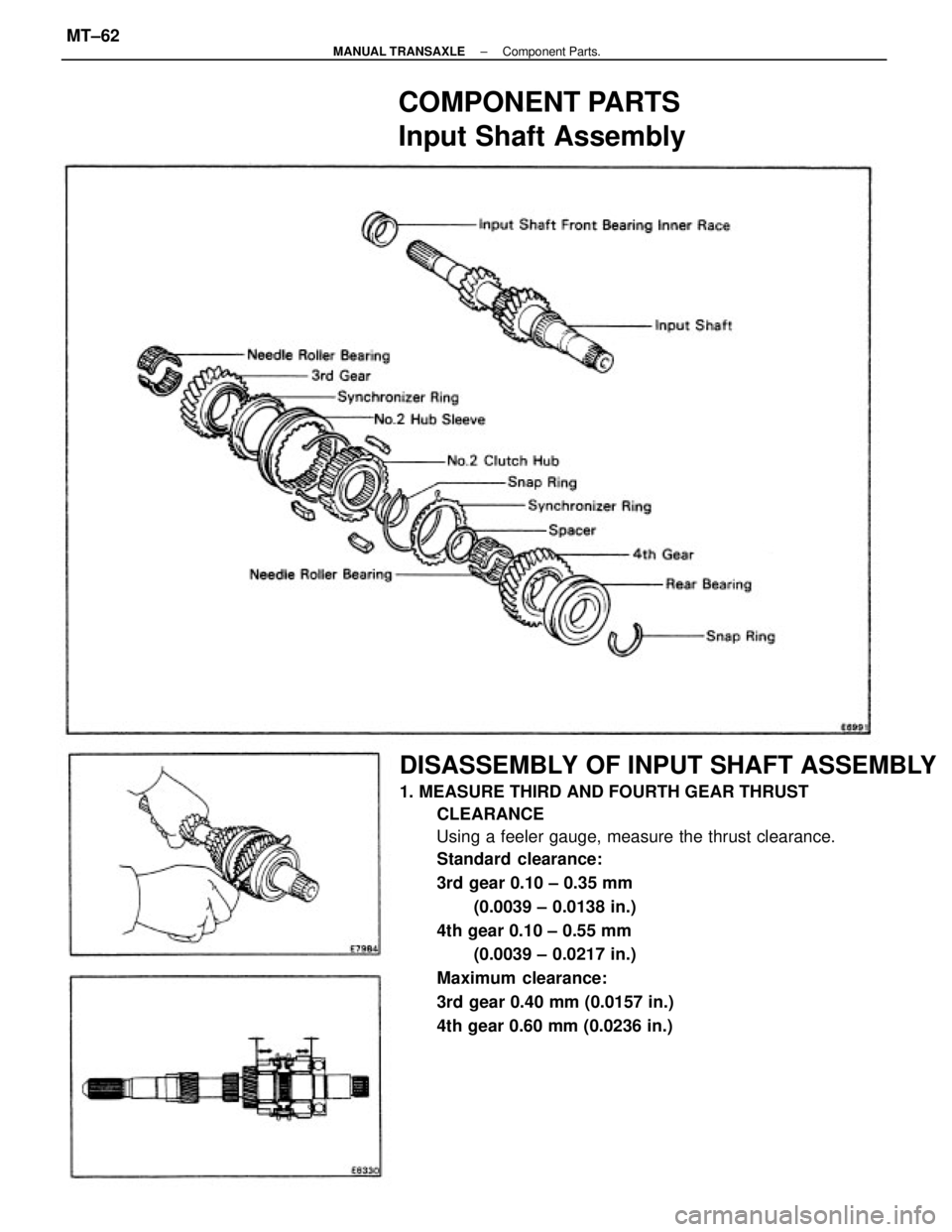

DISASSEMBLY OF INPUT SHAFT ASSEMBLY

1. MEASURE THIRD AND FOURTH GEAR THRUST

CLEARANCE

Using a feeler gauge, measure the thrust clearance.

Standard clearance:

3rd gear 0.10 ± 0.35 mm

(0.0039 ± 0.0138 in.)

4th gear 0.10 ± 0.55 mm

(0.0039 ± 0.0217 in.)

Maximum clearance:

3rd gear 0.40 mm (0.0157 in.)

4th gear 0.60 mm (0.0236 in.)

COMPONENT PARTS

Input Shaft Assembly

± MANUAL TRANSAXLEComponent Parts.MT±62

Page 1977 of 2389

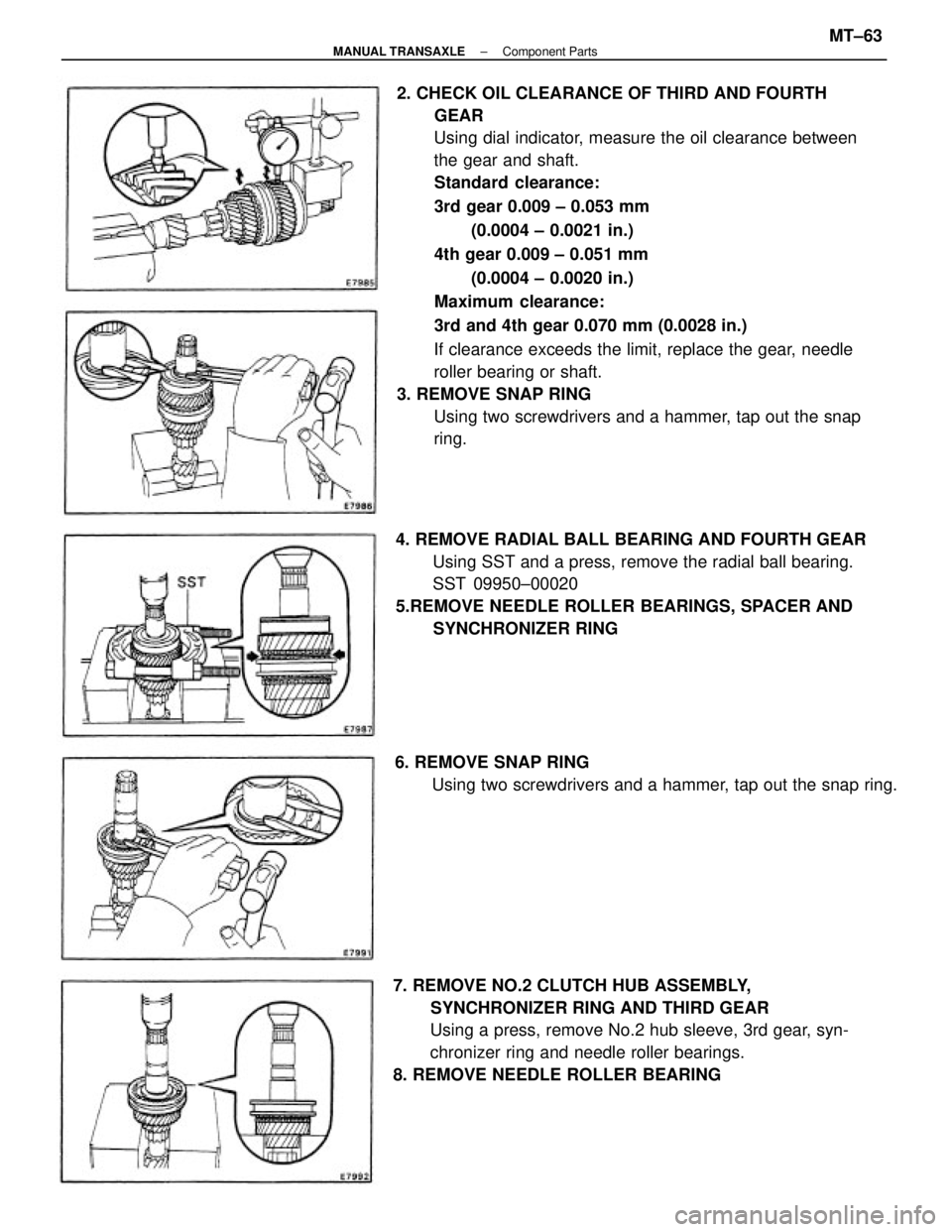

2. CHECK OIL CLEARANCE OF THIRD AND FOURTH

GEAR

Using dial indicator, measure the oil clearance between

the gear and shaft.

Standard clearance:

3rd gear 0.009 ± 0.053 mm

(0.0004 ± 0.0021 in.)

4th gear 0.009 ± 0.051 mm

(0.0004 ± 0.0020 in.)

Maximum clearance:

3rd and 4th gear 0.070 mm (0.0028 in.)

If clearance exceeds the limit, replace the gear, needle

roller bearing or shaft.

3. REMOVE SNAP RING

Using two screwdrivers and a hammer, tap out the snap

ring.

4. REMOVE RADIAL BALL BEARING AND FOURTH GEAR

Using SST and a press, remove the radial ball bearing.

SST 09950±00020

5.REMOVE NEEDLE ROLLER BEARINGS, SPACER AND

SYNCHRONIZER RING

7. REMOVE NO.2 CLUTCH HUB ASSEMBLY,

SYNCHRONIZER RING AND THIRD GEAR

Using a press, remove No.2 hub sleeve, 3rd gear, syn-

chronizer ring and needle roller bearings.

8. REMOVE NEEDLE ROLLER BEARING6. REMOVE SNAP RING

Using two screwdrivers and a hammer, tap out the snap ring.

± MANUAL TRANSAXLEComponent PartsMT±63

Page 1978 of 2389

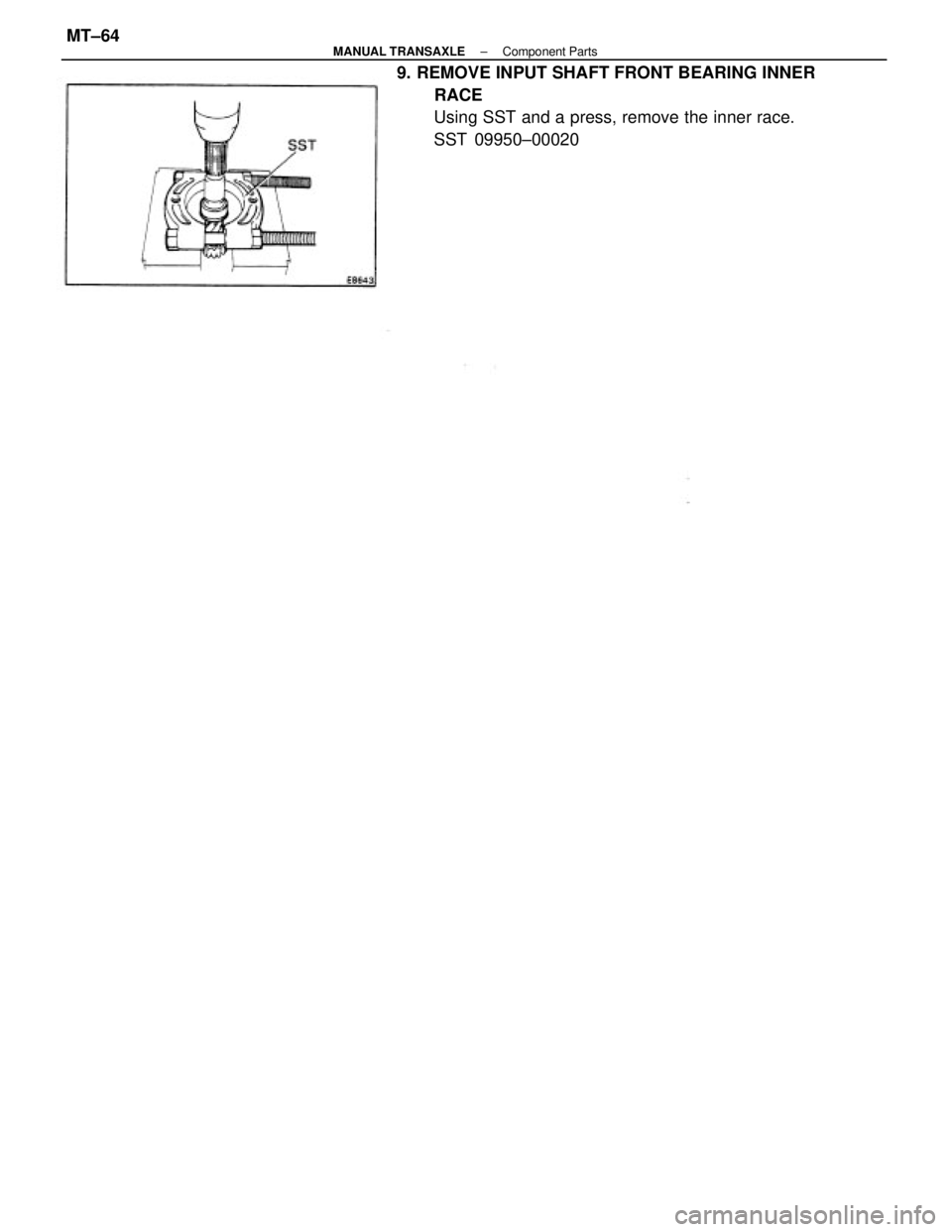

9. REMOVE INPUT SHAFT FRONT BEARING INNER

RACE

Using SST and a press, remove the inner race.

SST 09950±00020

± MANUAL TRANSAXLEComponent PartsMT±64

Page 1979 of 2389

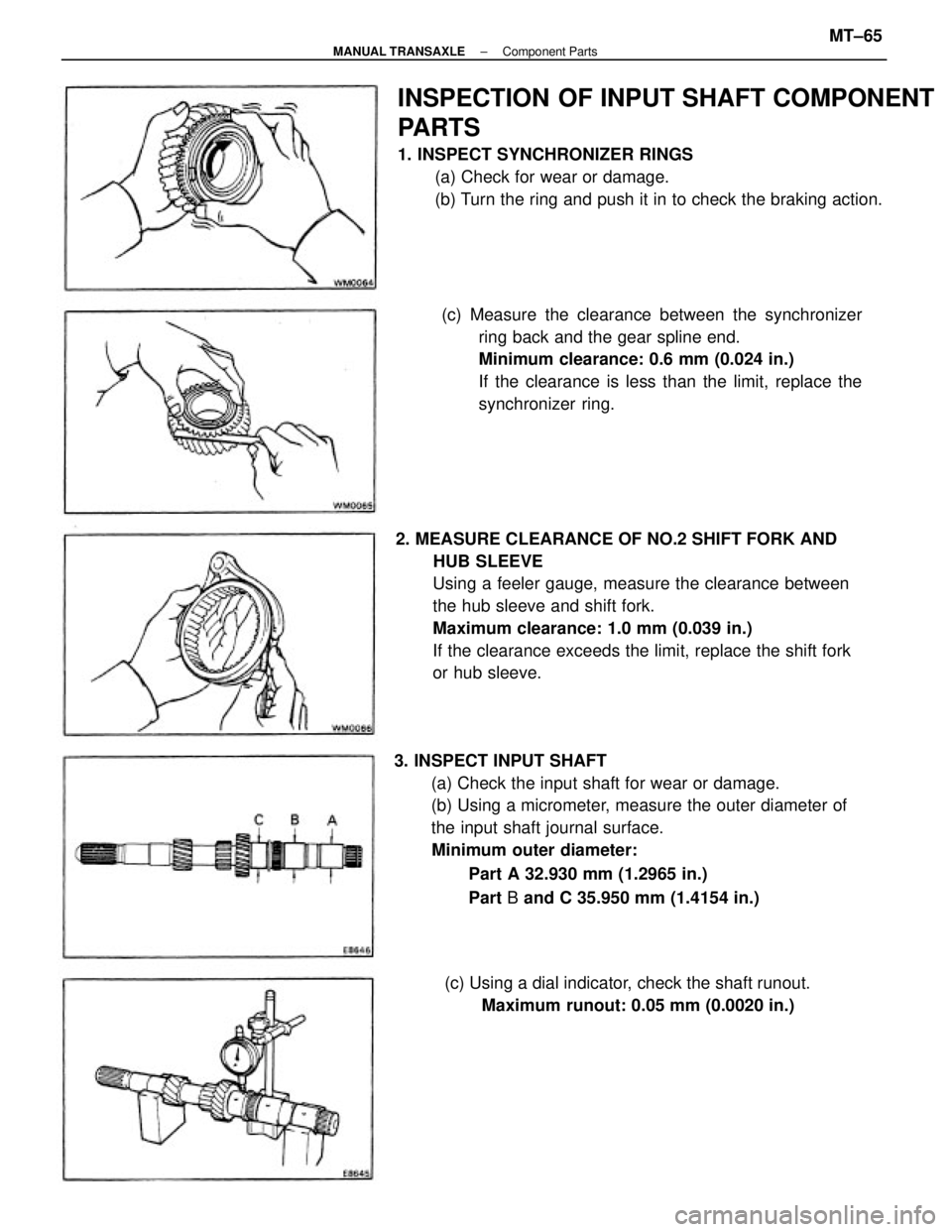

3. INSPECT INPUT SHAFT

(a) Check the input shaft for wear or damage.

(b) Using a micrometer, measure the outer diameter of

the input shaft journal surface.

Minimum outer diameter:

Part A 32.930 mm (1.2965 in.)

Part B and C 35.950 mm (1.4154 in.) 2. MEASURE CLEARANCE OF NO.2 SHIFT FORK AND

HUB SLEEVE

Using a feeler gauge, measure the clearance between

the hub sleeve and shift fork.

Maximum clearance: 1.0 mm (0.039 in.)

If the clearance exceeds the limit, replace the shift fork

or hub sleeve.

INSPECTION OF INPUT SHAFT COMPONENT

PARTS

1. INSPECT SYNCHRONIZER RINGS

(a) Check for wear or damage.

(b) Turn the ring and push it in to check the braking action.

(c) Measure the clearance between the synchronizer

ring back and the gear spline end.

Minimum clearance: 0.6 mm (0.024 in.)

If the clearance is less than the limit, replace the

synchronizer ring.

(c) Using a dial indicator, check the shaft runout.

Maximum runout: 0.05 mm (0.0020 in.)

± MANUAL TRANSAXLEComponent PartsMT±65

Page 1980 of 2389

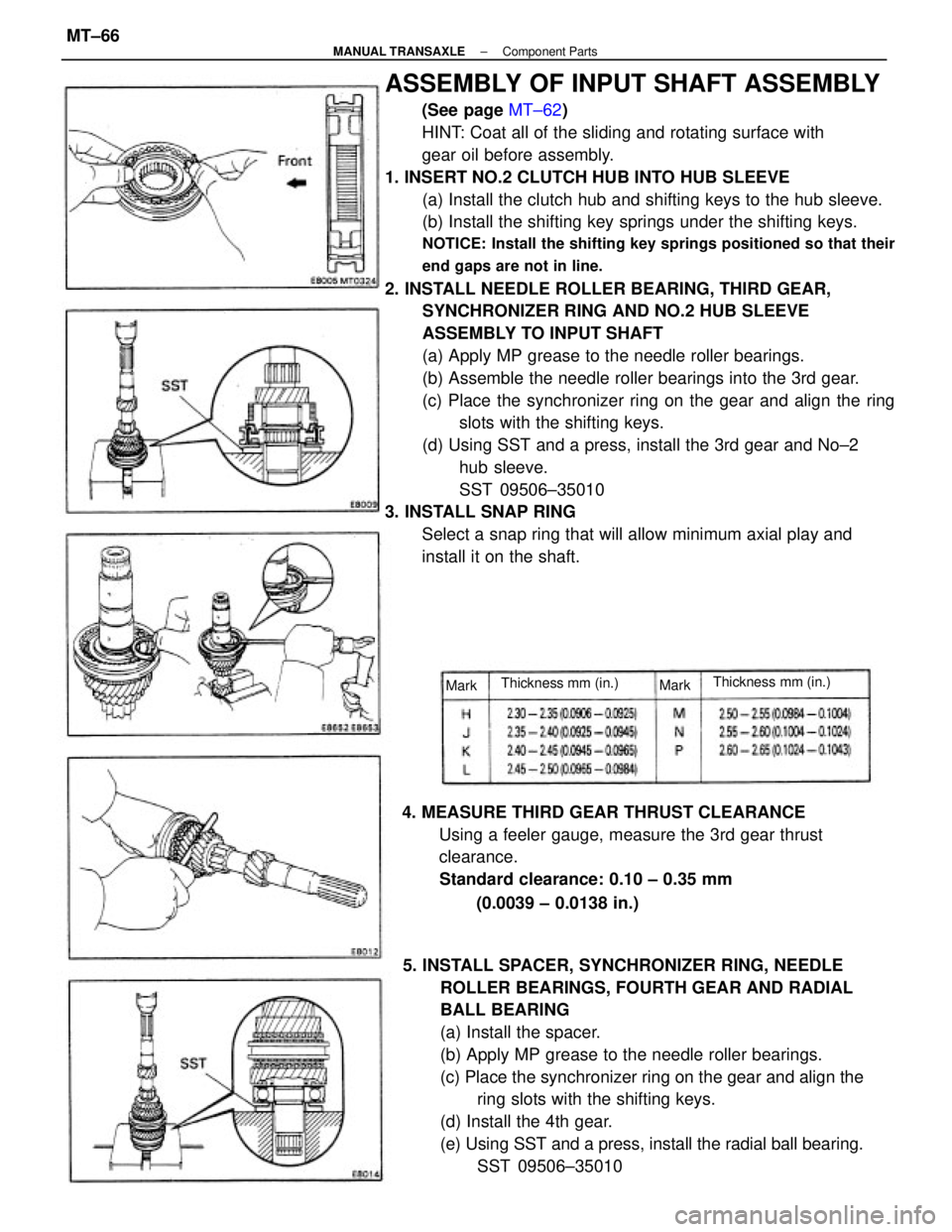

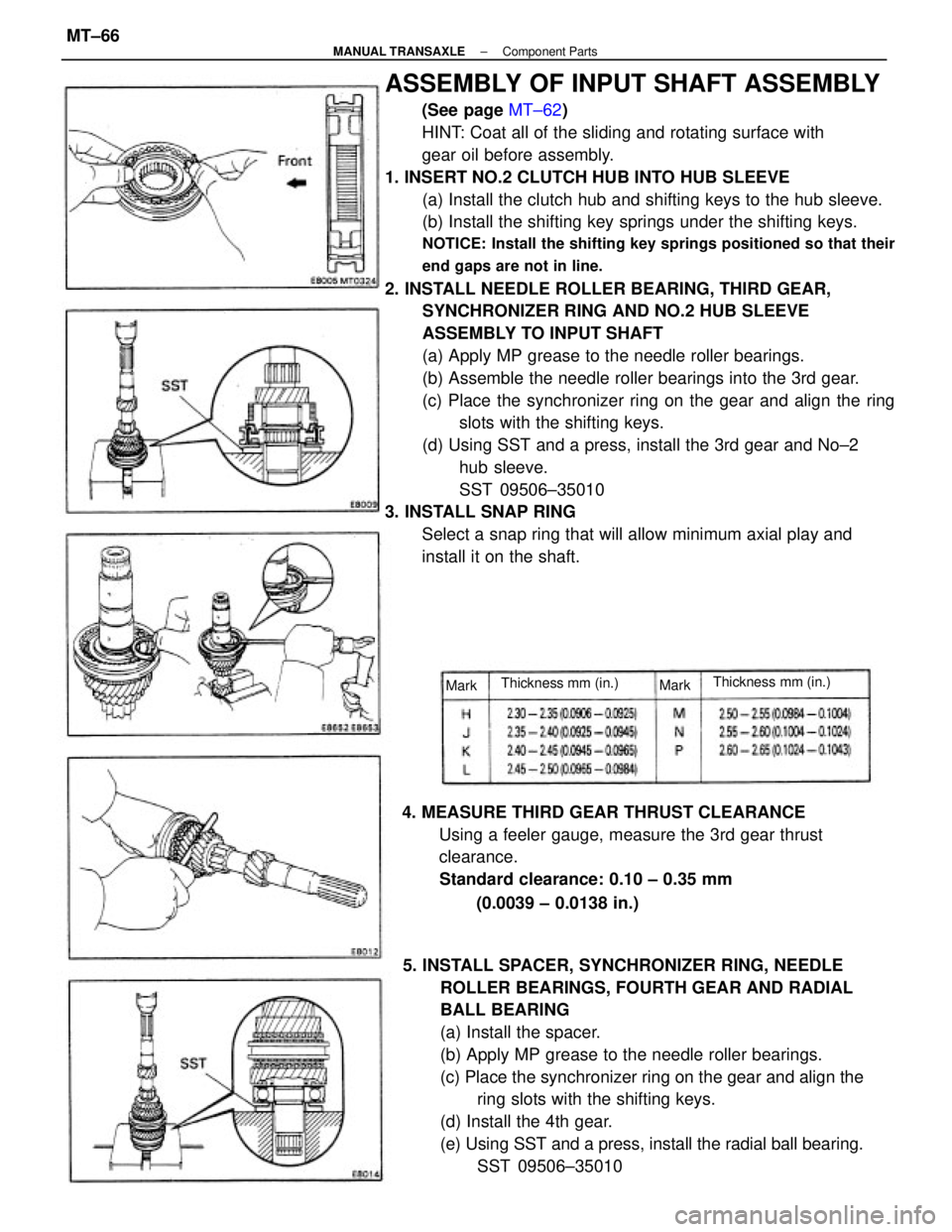

ASSEMBLY OF INPUT SHAFT ASSEMBLY

(See page MT±62)

HINT: Coat all of the sliding and rotating surface with

gear oil before assembly.

1. INSERT NO.2 CLUTCH HUB INTO HUB SLEEVE

(a) Install the clutch hub and shifting keys to the hub sleeve.

(b) Install the shifting key springs under the shifting keys.

NOTICE: Install the shifting key springs positioned so that their

end gaps are not in line.

2. INSTALL NEEDLE ROLLER BEARING, THIRD GEAR,

SYNCHRONIZER RING AND NO.2 HUB SLEEVE

ASSEMBLY TO INPUT SHAFT

(a) Apply MP grease to the needle roller bearings.

(b) Assemble the needle roller bearings into the 3rd gear.

(c) Place the synchronizer ring on the gear and align the ring

slots with the shifting keys.

(d) Using SST and a press, install the 3rd gear and No±2

hub sleeve.

SST 09506±35010

3. INSTALL SNAP RING

Select a snap ring that will allow minimum axial play and

install it on the shaft.

5. INSTALL SPACER, SYNCHRONIZER RING, NEEDLE

ROLLER BEARINGS, FOURTH GEAR AND RADIAL

BALL BEARING

(a) Install the spacer.

(b) Apply MP grease to the needle roller bearings.

(c) Place the synchronizer ring on the gear and align the

ring slots with the shifting keys.

(d) Install the 4th gear.

(e) Using SST and a press, install the radial ball bearing.

SST 09506±35010 4. MEASURE THIRD GEAR THRUST CLEARANCE

Using a feeler gauge, measure the 3rd gear thrust

clearance.

Standard clearance: 0.10 ± 0.35 mm

(0.0039 ± 0.0138 in.)

Thickness mm (in.)

Thickness mm (in.)

MarkMark

± MANUAL TRANSAXLEComponent PartsMT±66

Trending: tire size, battery capacity, trunk release, ECO mode, air bleeding, roof rack, brake