TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: automatic transmission, headlight bulb, transmission oil, gas type, compression ratio, buttons, gas mileage

Page 2011 of 2389

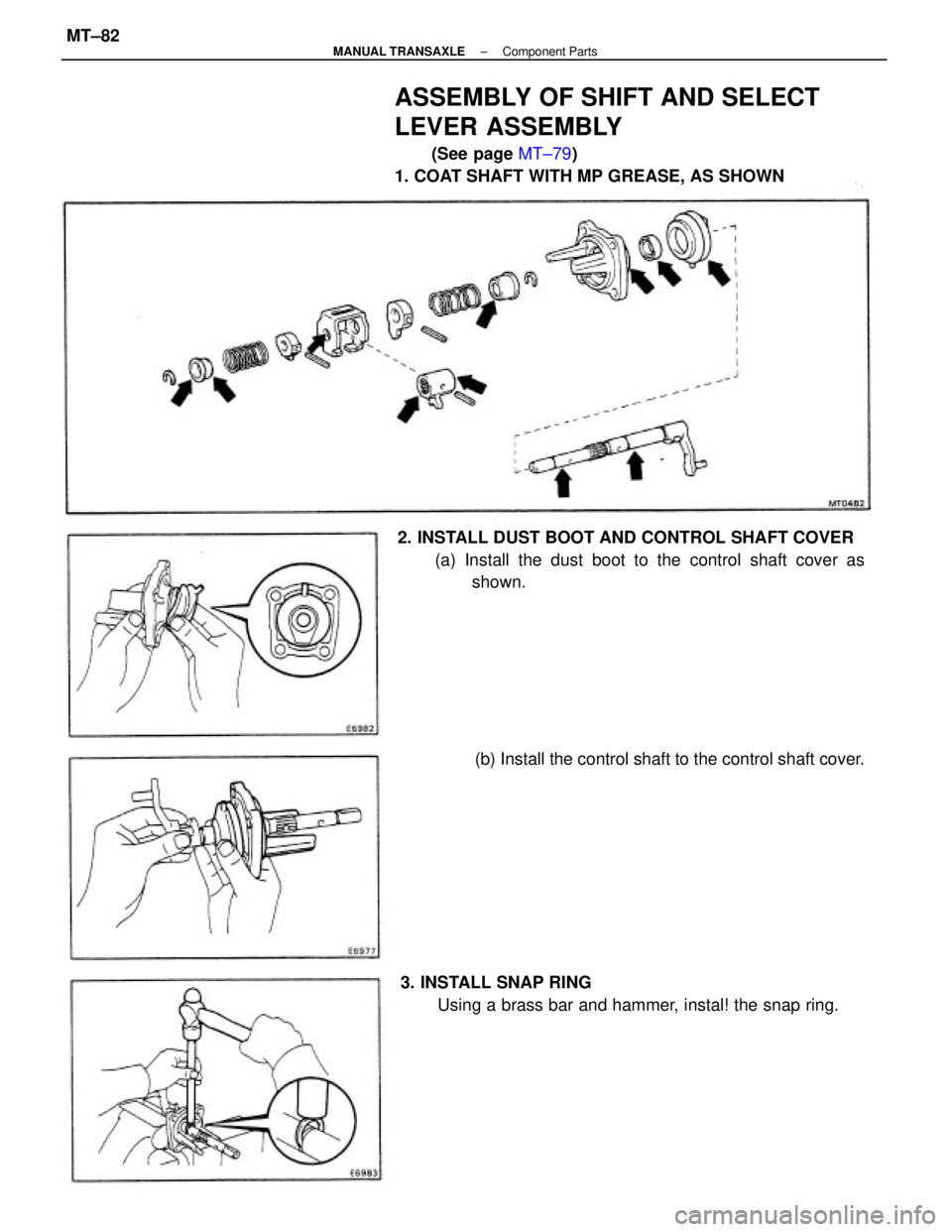

ASSEMBLY OF SHIFT AND SELECT

LEVER ASSEMBLY

(See page MT±79)

1. COAT SHAFT WITH MP GREASE, AS SHOWN

2. INSTALL DUST BOOT AND CONTROL SHAFT COVER

(a) Install the dust boot to the control shaft cover as

shown.

3. INSTALL SNAP RING

Using a brass bar and hammer, instal! the snap ring.(b) Install the control shaft to the control shaft cover.

± MANUAL TRANSAXLEComponent PartsMT±82

Page 2012 of 2389

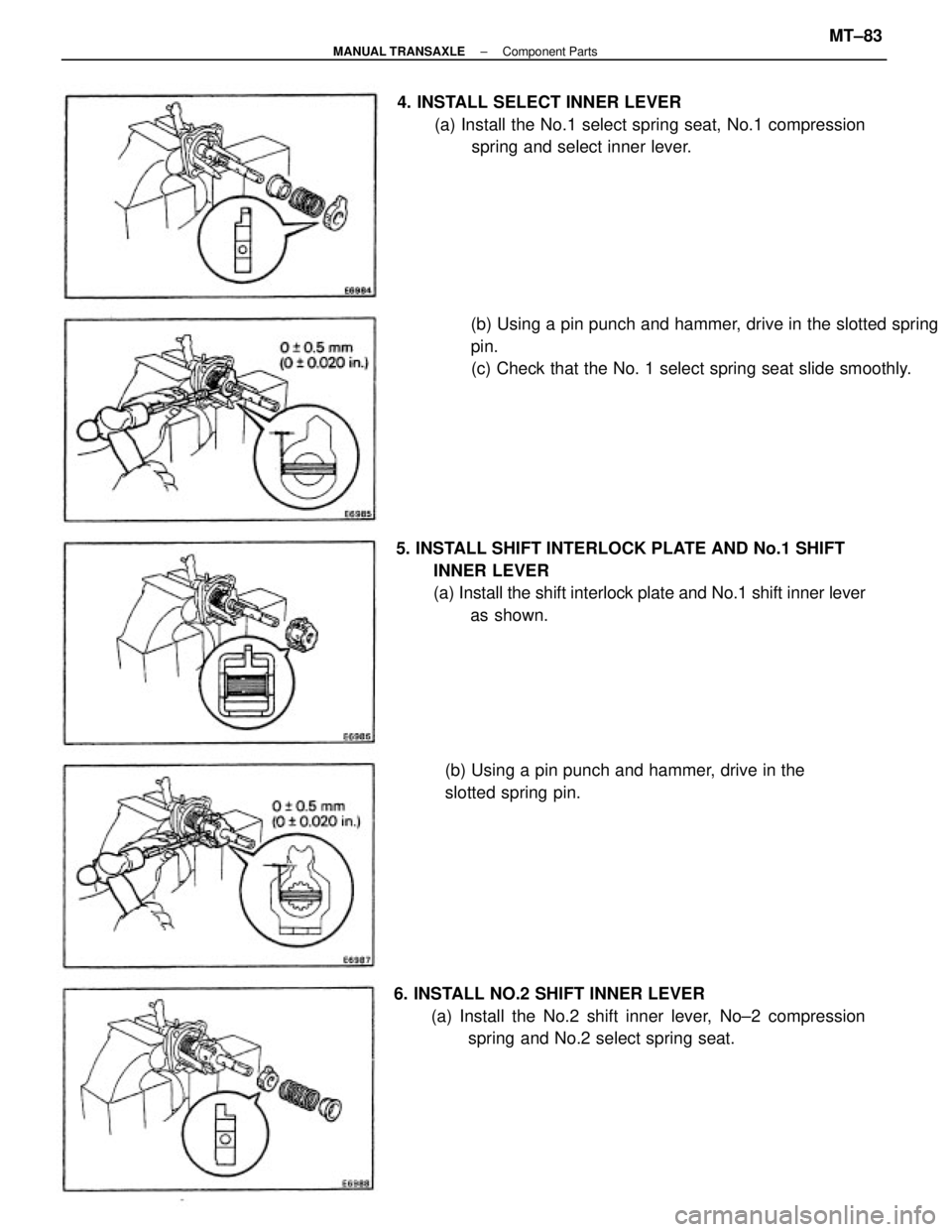

5. INSTALL SHIFT INTERLOCK PLATE AND No.1 SHIFT

INNER LEVER

(a) Install the shift interlock plate and No.1 shift inner lever

as shown.(b) Using a pin punch and hammer, drive in the slotted spring

pin.

(c) Check that the No. 1 select spring seat slide smoothly. 4. INSTALL SELECT INNER LEVER

(a) Install the No.1 select spring seat, No.1 compression

spring and select inner lever.

6. INSTALL NO.2 SHIFT INNER LEVER

(a) Install the No.2 shift inner lever, No±2 compression

spring and No.2 select spring seat. (b) Using a pin punch and hammer, drive in the

slotted spring pin.

± MANUAL TRANSAXLEComponent PartsMT±83

Page 2013 of 2389

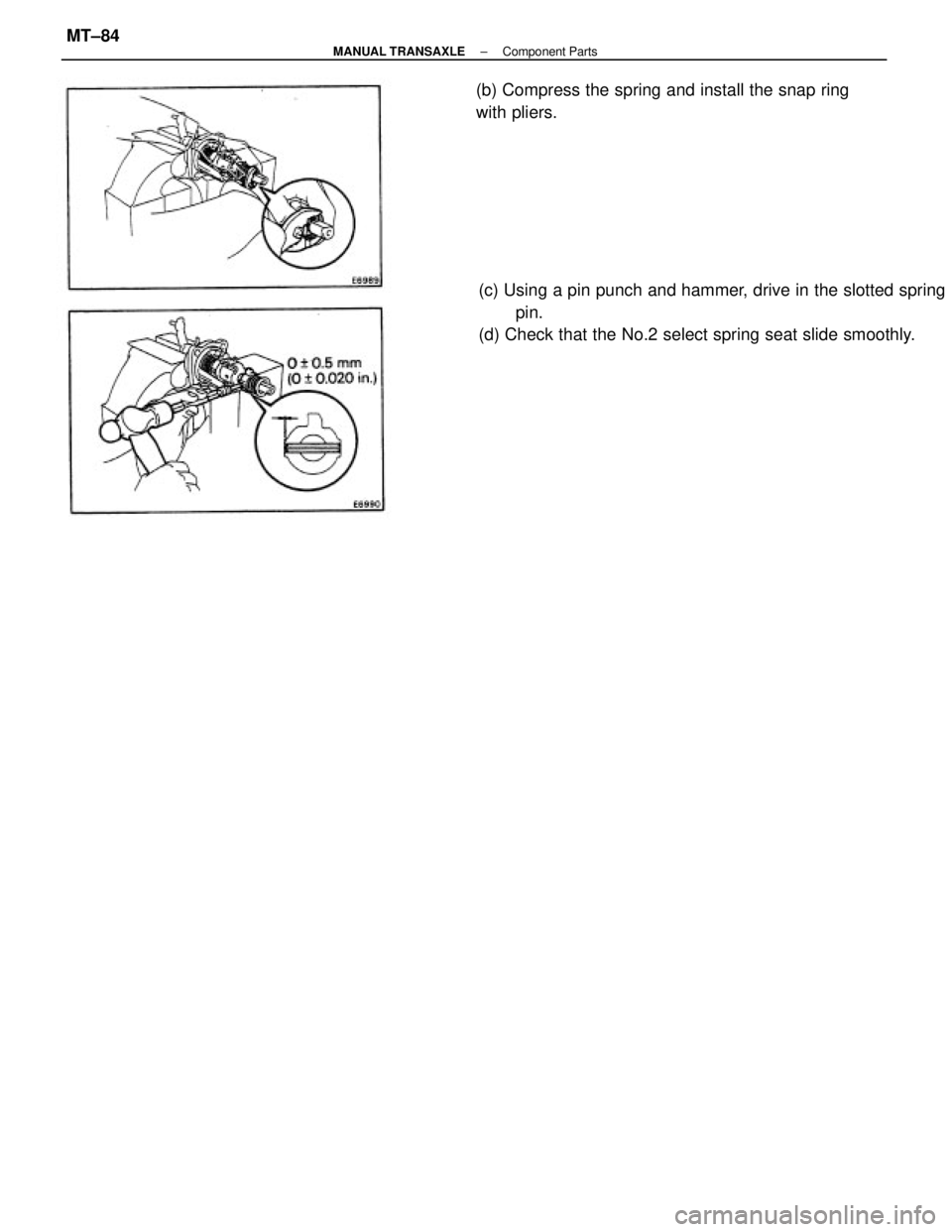

(c) Using a pin punch and hammer, drive in the slotted spring

pin.

(d) Check that the No.2 select spring seat slide smoothly. (b) Compress the spring and install the snap ring

with pliers.

± MANUAL TRANSAXLEComponent PartsMT±84

Page 2014 of 2389

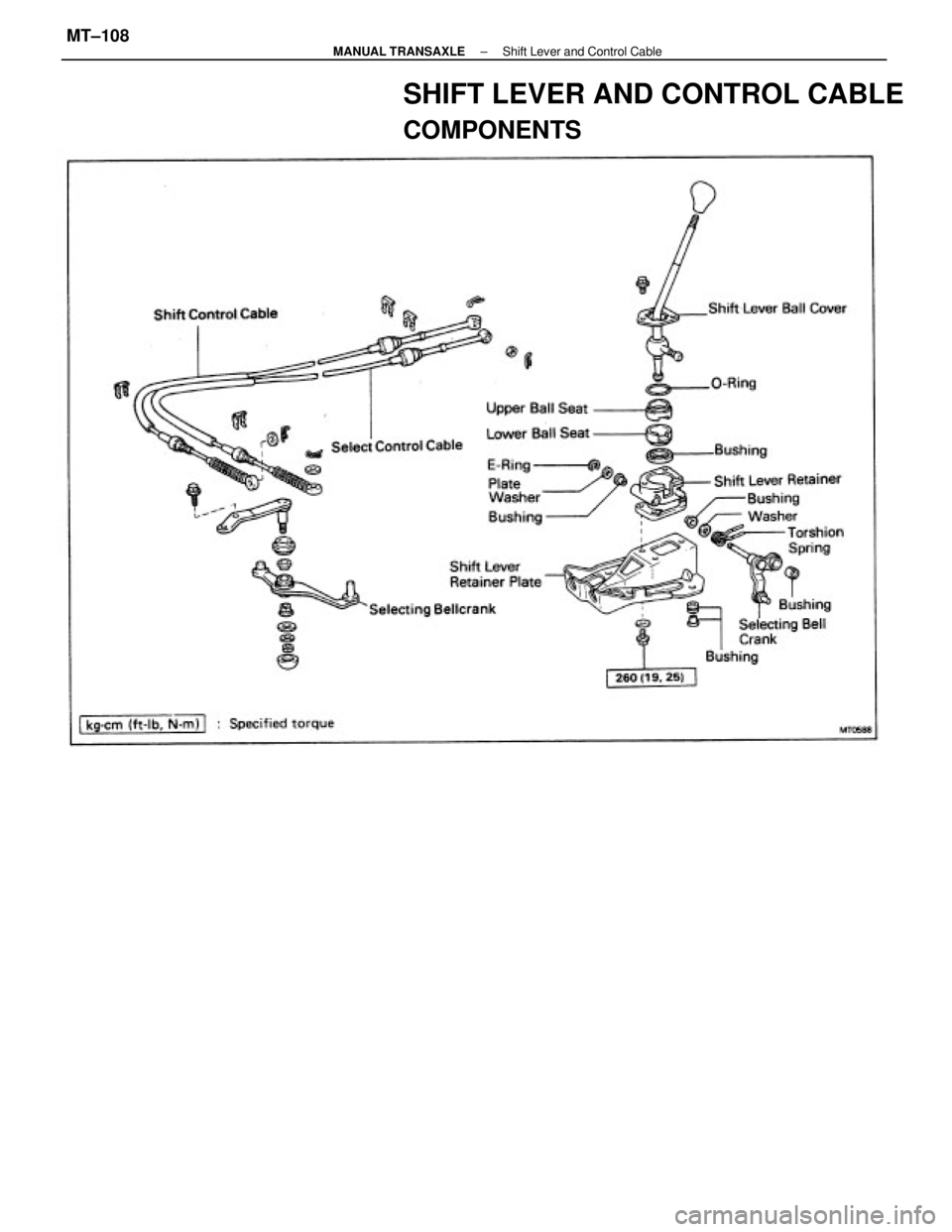

SHIFT LEVER AND CONTROL CABLE

COMPONENTS

± MANUAL TRANSAXLEShift Lever and Control CableMT±108

Page 2015 of 2389

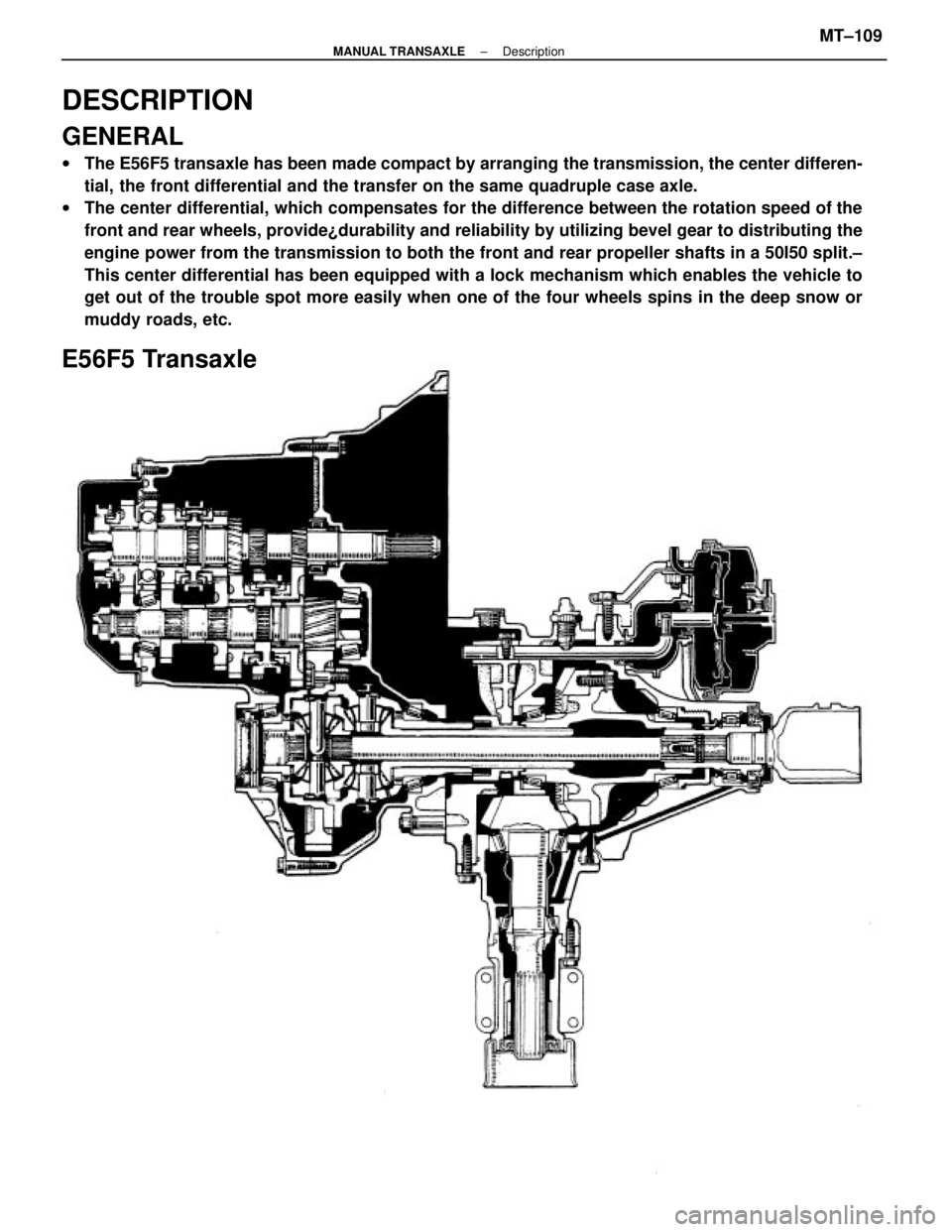

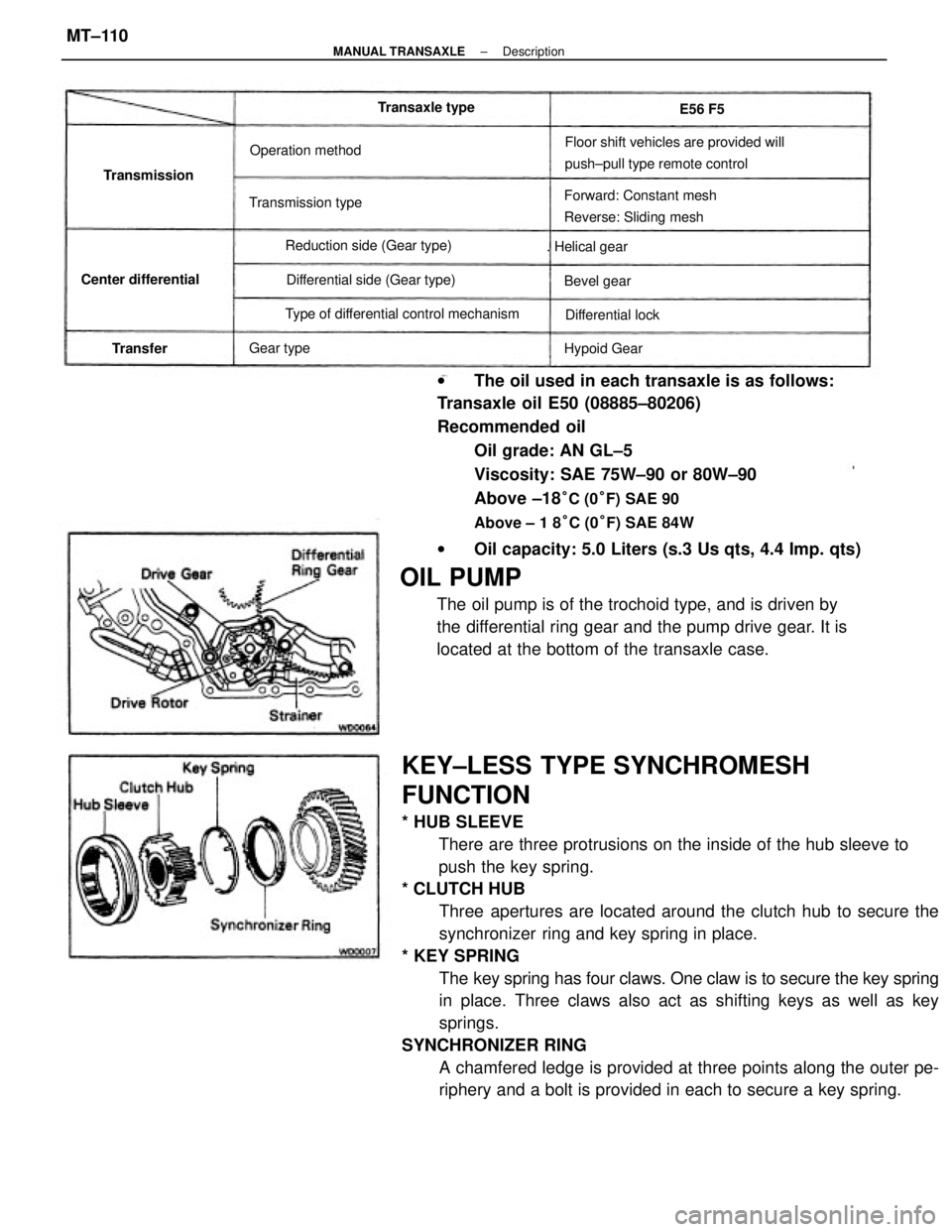

DESCRIPTION

GENERAL

wThe E56F5 transaxle has been made compact by arranging the transmission, the center differen-

tial, the front differential and the transfer on the same quadruple case axle.

wThe center differential, which compensates for the difference between the rotation speed of the

front and rear wheels, provide¿durability and reliability by utilizing bevel gear to distributing the

engine power from the transmission to both the front and rear propeller shafts in a 50I50 split.±

This center differential has been equipped with a lock mechanism which enables the vehicle to

get out of the trouble spot more easily when one of the four wheels spins in the deep snow or

muddy roads, etc.

E56F5 Transaxle

± MANUAL TRANSAXLEDescriptionMT±109

Page 2016 of 2389

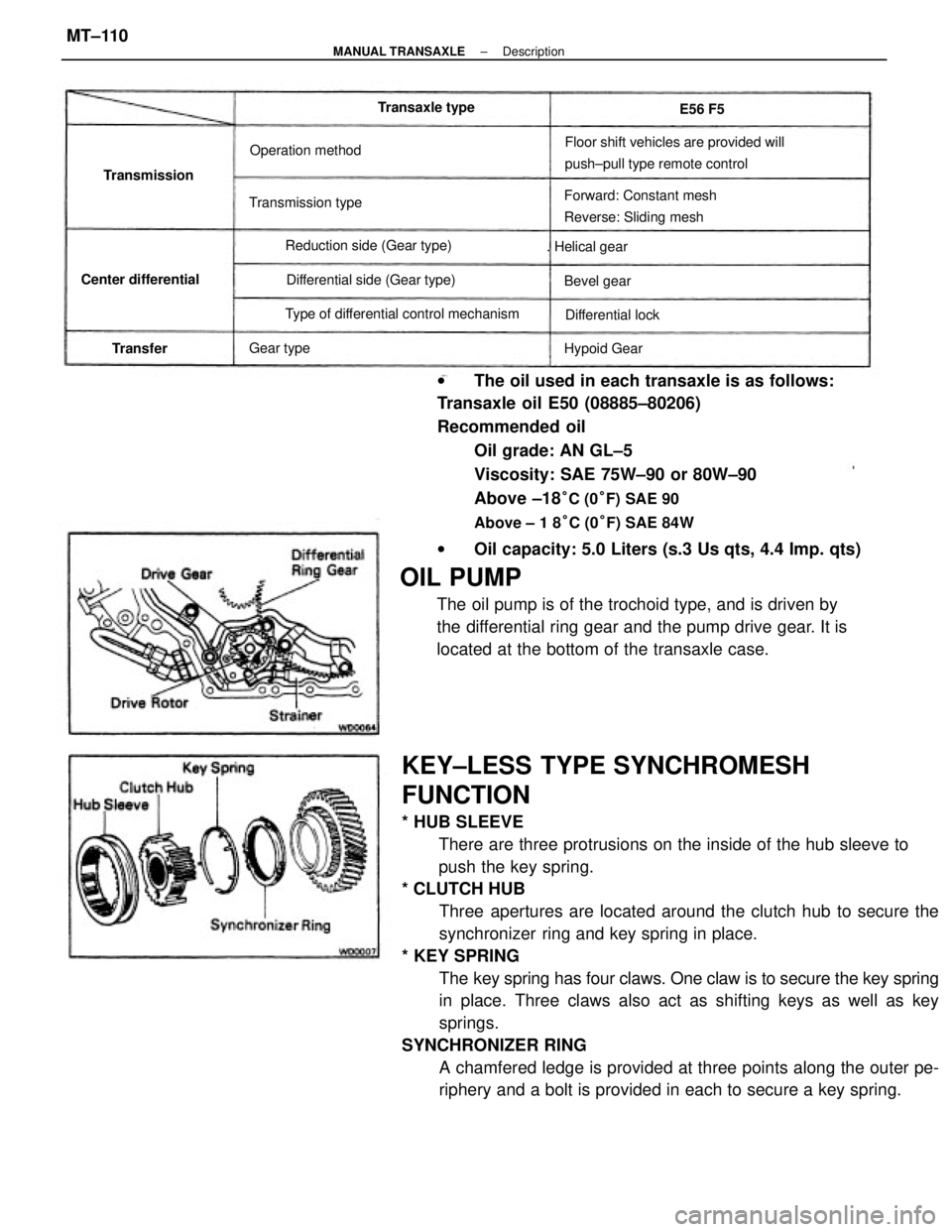

KEY±LESS TYPE SYNCHROMESH

FUNCTION

* HUB SLEEVE

There are three protrusions on the inside of the hub sleeve to

push the key spring.

* CLUTCH HUB

Three apertures are located around the clutch hub to secure the

synchronizer ring and key spring in place.

* KEY SPRING

The key spring has four claws. One claw is to secure the key spring

in place. Three claws also act as shifting keys as well as key

springs.

SYNCHRONIZER RING

A chamfered ledge is provided at three points along the outer pe-

riphery and a bolt is provided in each to secure a key spring. wThe oil used in each transaxle is as follows:

Transaxle oil E50 (08885±80206)

Recommended oil

Oil grade: AN GL±5

Viscosity: SAE 75W±90 or 80W±90

Above ±18

°C (0°F) SAE 90

Above ± 1 8°C (0°F) SAE 84W

wOil capacity: 5.0 Liters (s.3 Us qts, 4.4 Imp. qts)

OIL PUMP

The oil pump is of the trochoid type, and is driven by

the differential ring gear and the pump drive gear. It is

located at the bottom of the transaxle case.

Floor shift vehicles are provided will

push±pull type remote control

Forward: Constant mesh

Reverse: Sliding mesh

Type of differential control mechanismDifferential side (Gear type) Reduction side (Gear type) Transmission typeOperation method

Center differential. Helical gear

Differential lock Transaxle type

Hypoid Gear Transmission

Bevel gear

Gear type

TransferE56 F5

± MANUAL TRANSAXLEDescriptionMT±110

Page 2017 of 2389

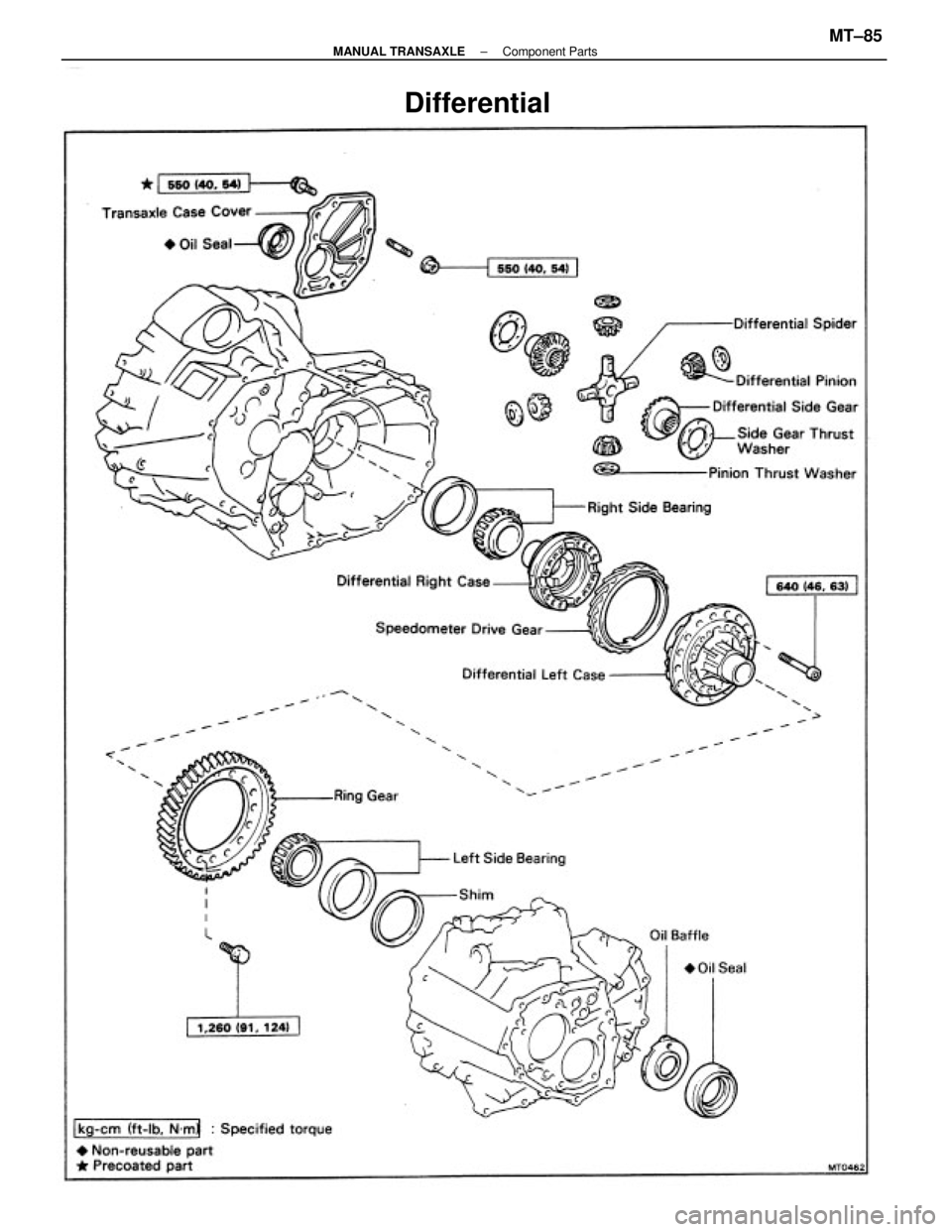

Differential

± MANUAL TRANSAXLEComponent PartsMT±85

Page 2018 of 2389

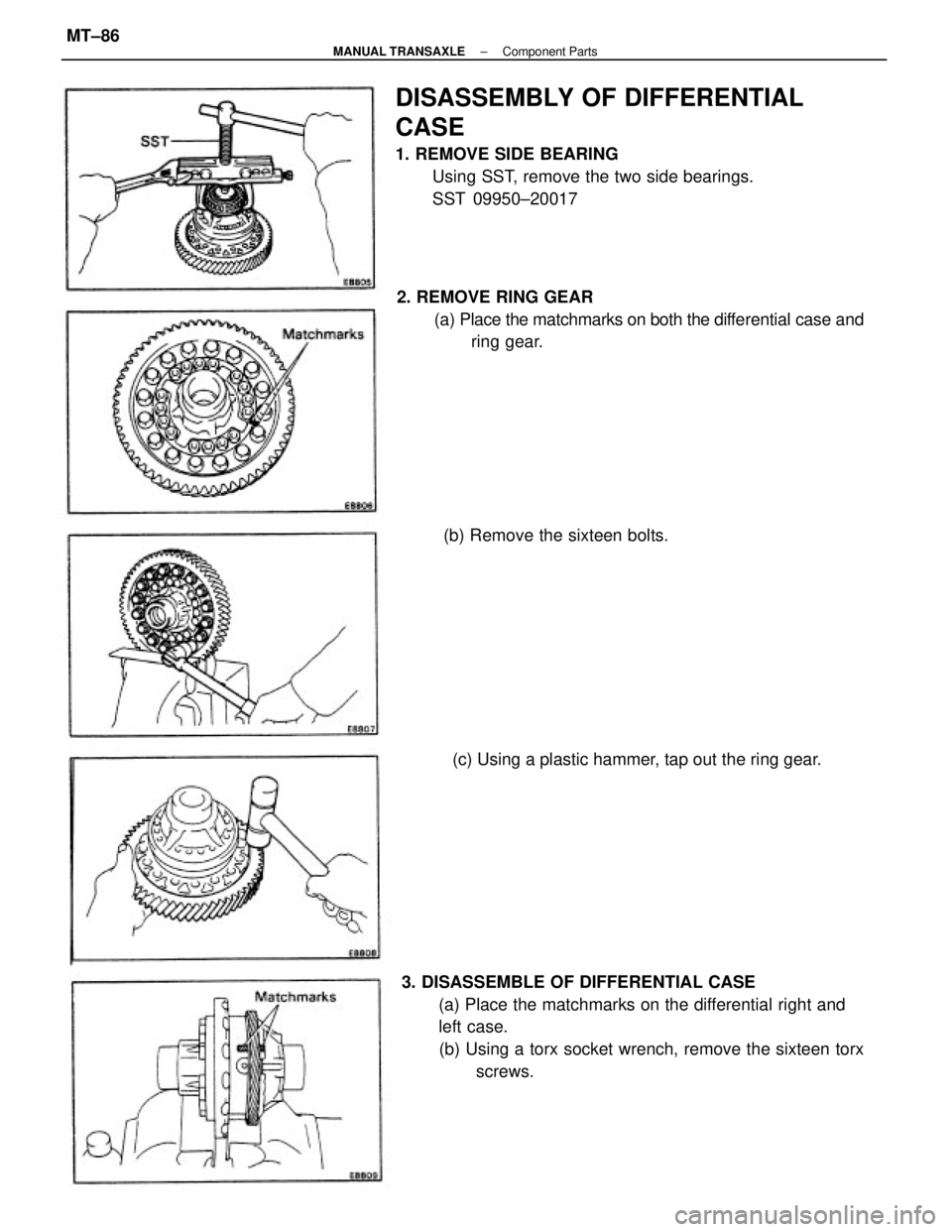

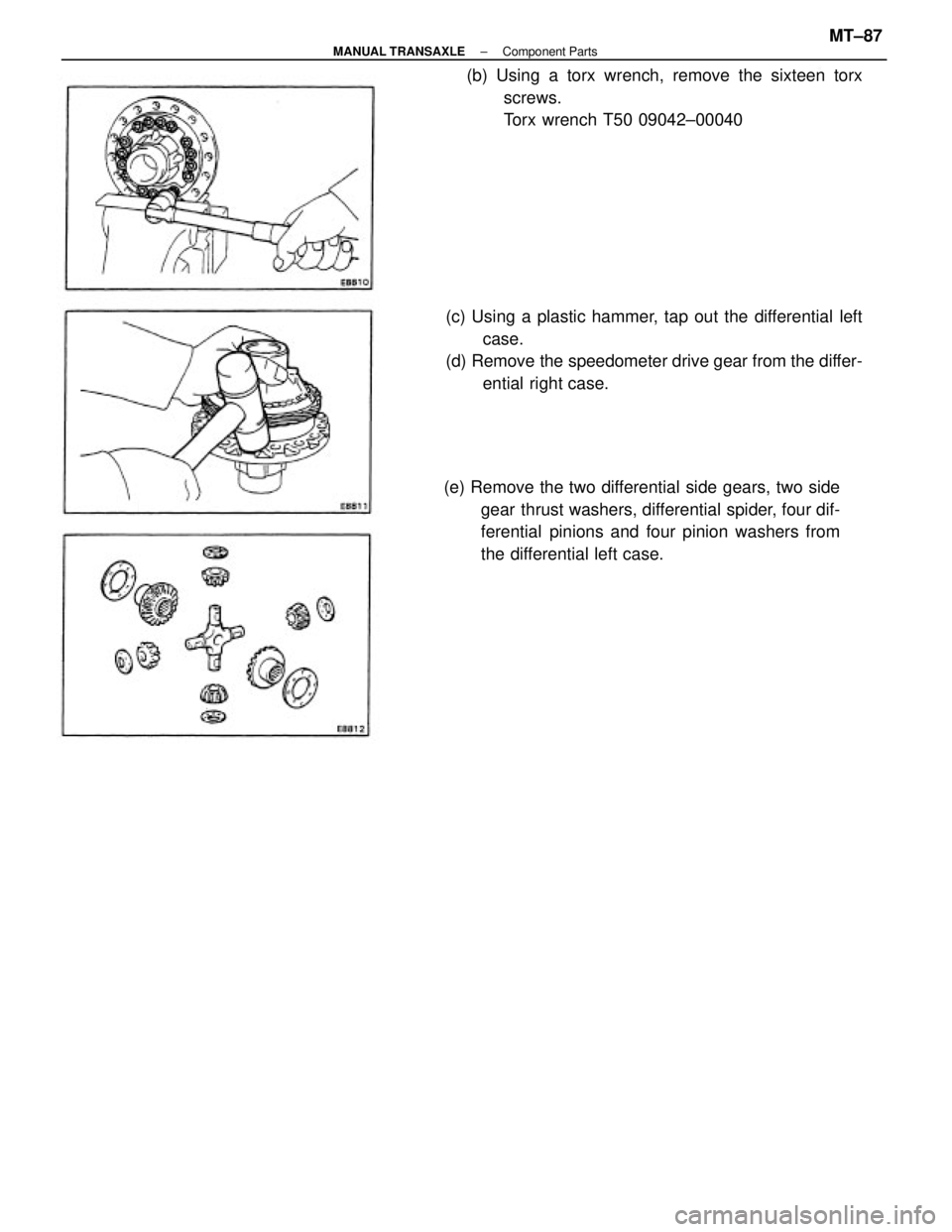

3. DISASSEMBLE OF DIFFERENTIAL CASE

(a) Place the matchmarks on the differential right and

left case.

(b) Using a torx socket wrench, remove the sixteen torx

screws. 2. REMOVE RING GEAR

(a) Place the matchmarks on both the differential case and

ring gear.

DISASSEMBLY OF DIFFERENTIAL

CASE

1. REMOVE SIDE BEARING

Using SST, remove the two side bearings.

SST 09950±20017

(c) Using a plastic hammer, tap out the ring gear. (b) Remove the sixteen bolts.

± MANUAL TRANSAXLEComponent PartsMT±86

Page 2019 of 2389

(e) Remove the two differential side gears, two side

gear thrust washers, differential spider, four dif-

ferential pinions and four pinion washers from

the differential left case. (c) Using a plastic hammer, tap out the differential left

case.

(d) Remove the speedometer drive gear from the differ-

ential right case. (b) Using a torx wrench, remove the sixteen torx

screws.

Torx wrench T50 09042±00040

± MANUAL TRANSAXLEComponent PartsMT±87

Page 2020 of 2389

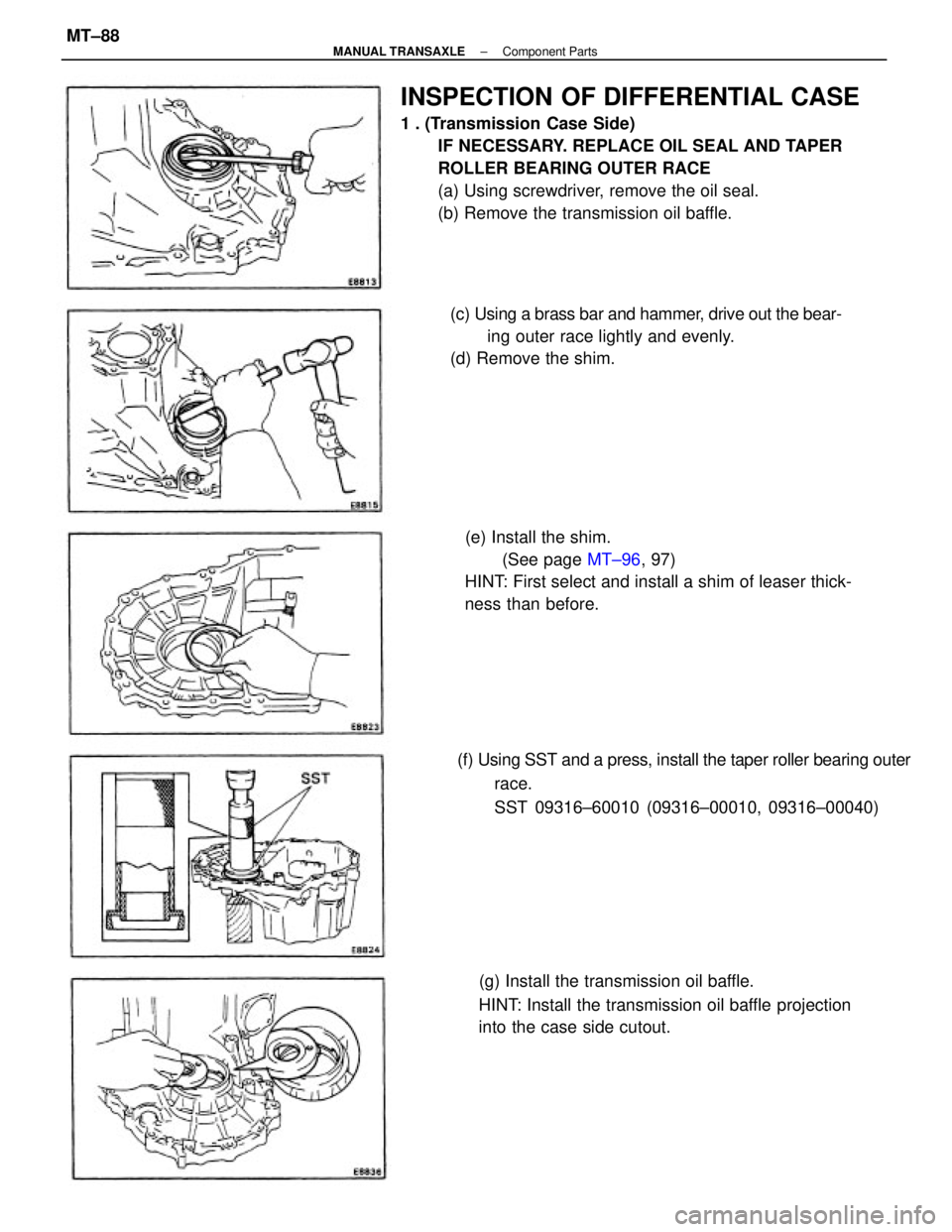

INSPECTION OF DIFFERENTIAL CASE

1 . (Transmission Case Side)

IF NECESSARY. REPLACE OIL SEAL AND TAPER

ROLLER BEARING OUTER RACE

(a) Using screwdriver, remove the oil seal.

(b) Remove the transmission oil baffle.

(e) Install the shim.

(See page MT±96, 97)

HINT: First select and install a shim of leaser thick-

ness than before.

(g) Install the transmission oil baffle.

HINT: Install the transmission oil baffle projection

into the case side cutout. (f) Using SST and a press, install the taper roller bearing outer

race.

SST 09316±60010 (09316±00010, 09316±00040) (c) Using a brass bar and hammer, drive out the bear-

ing outer race lightly and evenly.

(d) Remove the shim.

± MANUAL TRANSAXLEComponent PartsMT±88

Trending: spark plugs, rear view mirror, ABS, hood open, heating, service reset, rims