TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: air condition, engine oil, headlight aiming, child lock, weight, fuel, fuse diagram

Page 401 of 2389

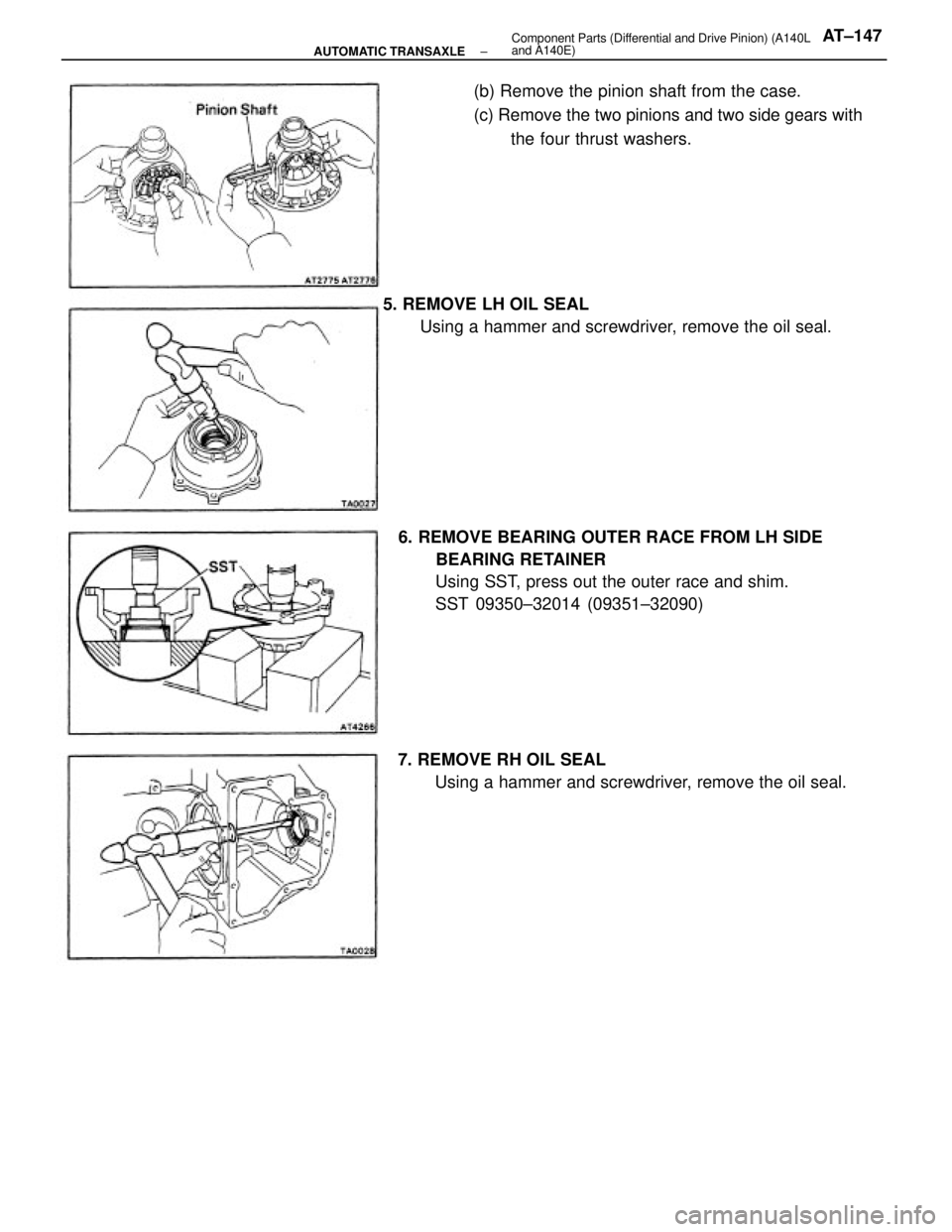

3. CHECK SIDE GEAR BACKLASH

Using a dial gauge, measure the backlash of each side

gear while holding one pinion toward the case.

Standard backlash:

0.05 ± 0.20 mm (0.0020 ± 0.0079 in.) 2. REMOVE SIDE BEARINGS

Fasten SST under the bearing above the cutouts on the

speedometer drive gear. Remove the bearing from the case.

SST 09502±10012

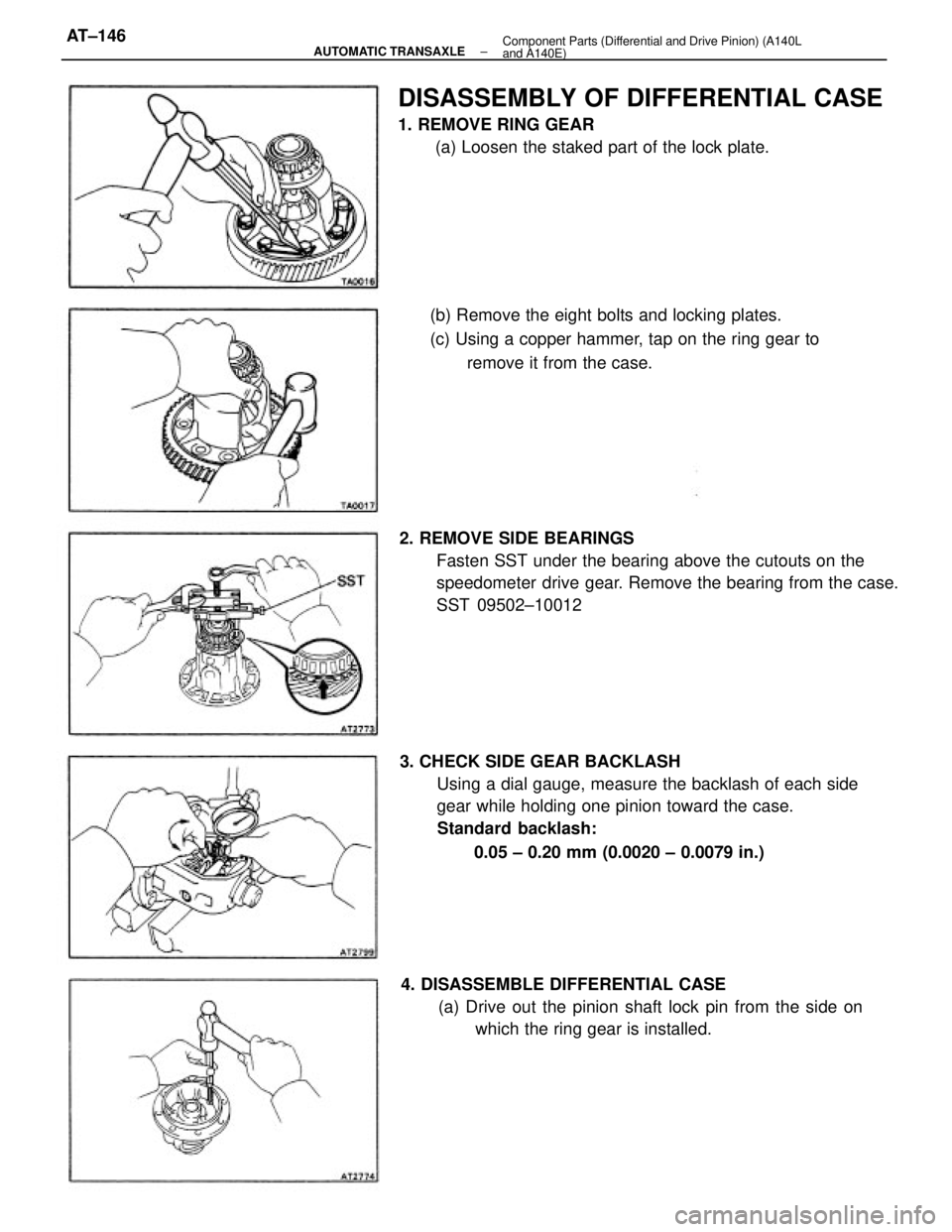

DISASSEMBLY OF DIFFERENTIAL CASE

1. REMOVE RING GEAR

(a) Loosen the staked part of the lock plate.

4. DISASSEMBLE DIFFERENTIAL CASE

(a) Drive out the pinion shaft lock pin from the side on

which the ring gear is installed. (b) Remove the eight bolts and locking plates.

(c) Using a copper hammer, tap on the ring gear to

remove it from the case.

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±146

Page 402 of 2389

6. REMOVE BEARING OUTER RACE FROM LH SIDE

BEARING RETAINER

Using SST, press out the outer race and shim.

SST 09350±32014 (09351±32090)(b) Remove the pinion shaft from the case.

(c) Remove the two pinions and two side gears with

the four thrust washers.

5. REMOVE LH OIL SEAL

Using a hammer and screwdriver, remove the oil seal.

7. REMOVE RH OIL SEAL

Using a hammer and screwdriver, remove the oil seal.

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±147

Page 403 of 2389

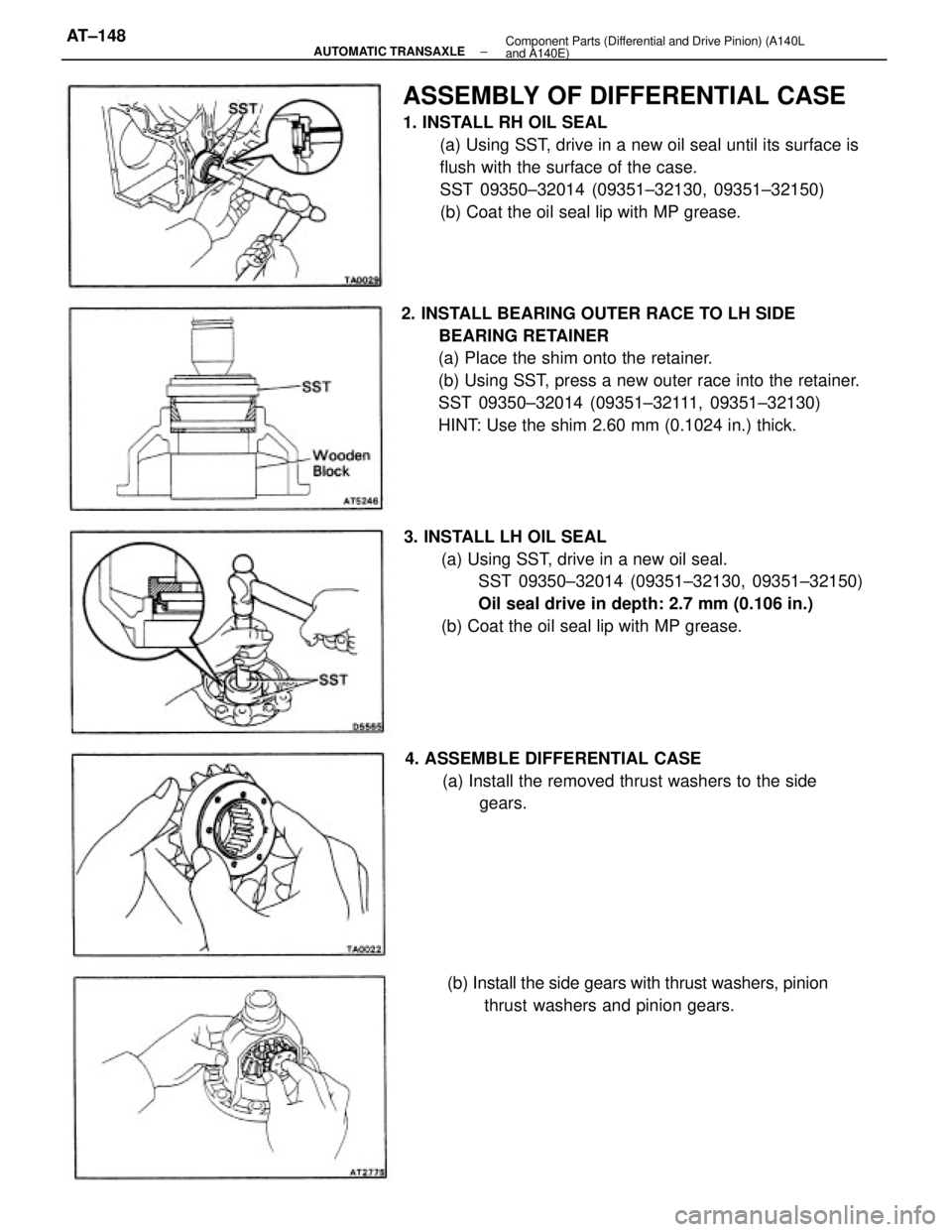

ASSEMBLY OF DIFFERENTIAL CASE

1. INSTALL RH OIL SEAL

(a) Using SST, drive in a new oil seal until its surface is

flush with the surface of the case.

SST 09350±32014 (09351±32130, 09351±32150)

(b) Coat the oil seal lip with MP grease.

2. INSTALL BEARING OUTER RACE TO LH SIDE

BEARING RETAINER

(a) Place the shim onto the retainer.

(b) Using SST, press a new outer race into the retainer.

SST 09350±32014 (09351±32111, 09351±32130)

HINT: Use the shim 2.60 mm (0.1024 in.) thick.

3. INSTALL LH OIL SEAL

(a) Using SST, drive in a new oil seal.

SST 09350±32014 (09351±32130, 09351±32150)

Oil seal drive in depth: 2.7 mm (0.106 in.)

(b) Coat the oil seal lip with MP grease.

4. ASSEMBLE DIFFERENTIAL CASE

(a) Install the removed thrust washers to the side

gears.

(b) Install the side gears with thrust washers, pinion

thrust washers and pinion gears.

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±148

Page 404 of 2389

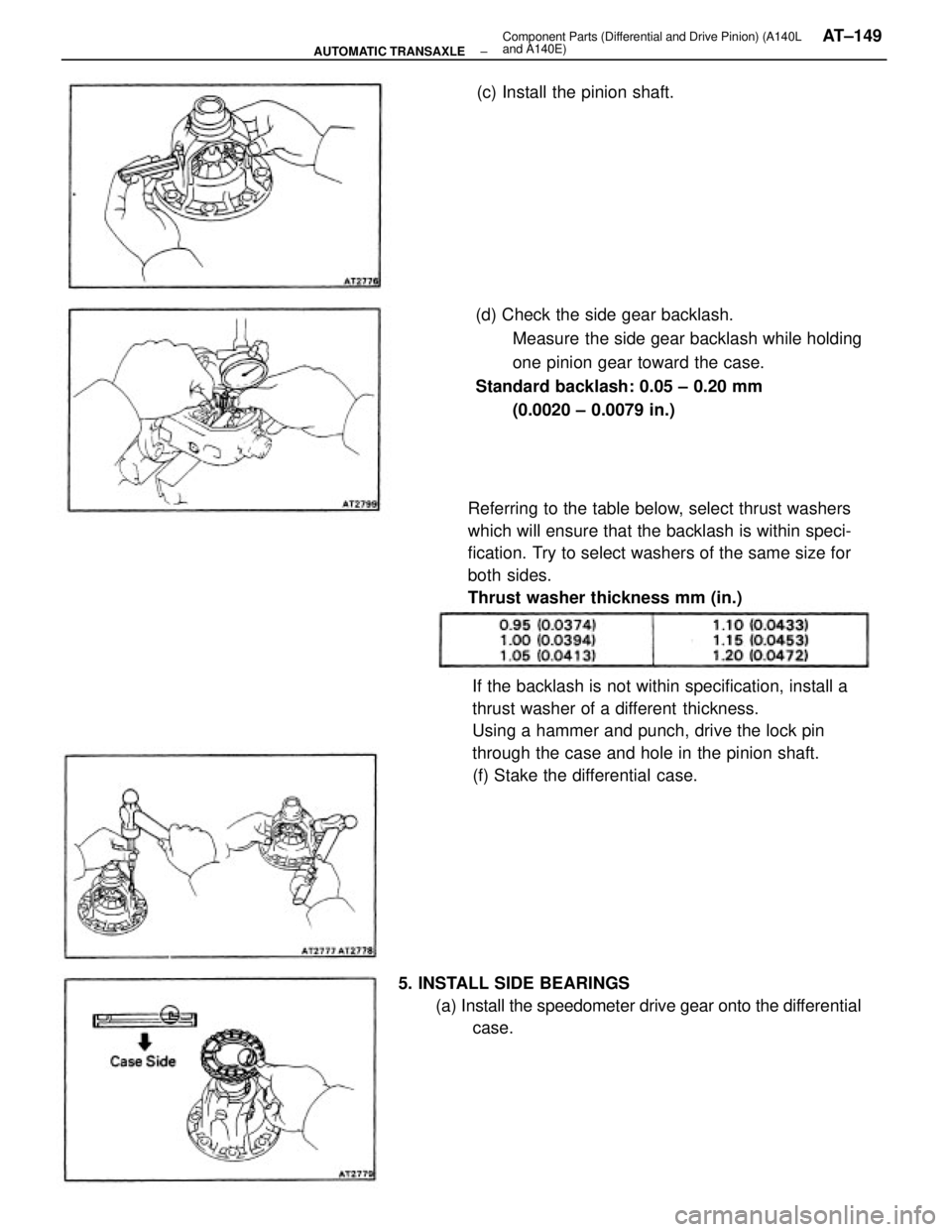

If the backlash is not within specification, install a

thrust washer of a different thickness.

Using a hammer and punch, drive the lock pin

through the case and hole in the pinion shaft.

(f) Stake the differential case.(d) Check the side gear backlash.

Measure the side gear backlash while holding

one pinion gear toward the case.

Standard backlash: 0.05 ± 0.20 mm

(0.0020 ± 0.0079 in.)

Referring to the table below, select thrust washers

which will ensure that the backlash is within speci-

fication. Try to select washers of the same size for

both sides.

Thrust washer thickness mm (in.)

5. INSTALL SIDE BEARINGS

(a) Install the speedometer drive gear onto the differential

case.(c) Install the pinion shaft.

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±149

Page 405 of 2389

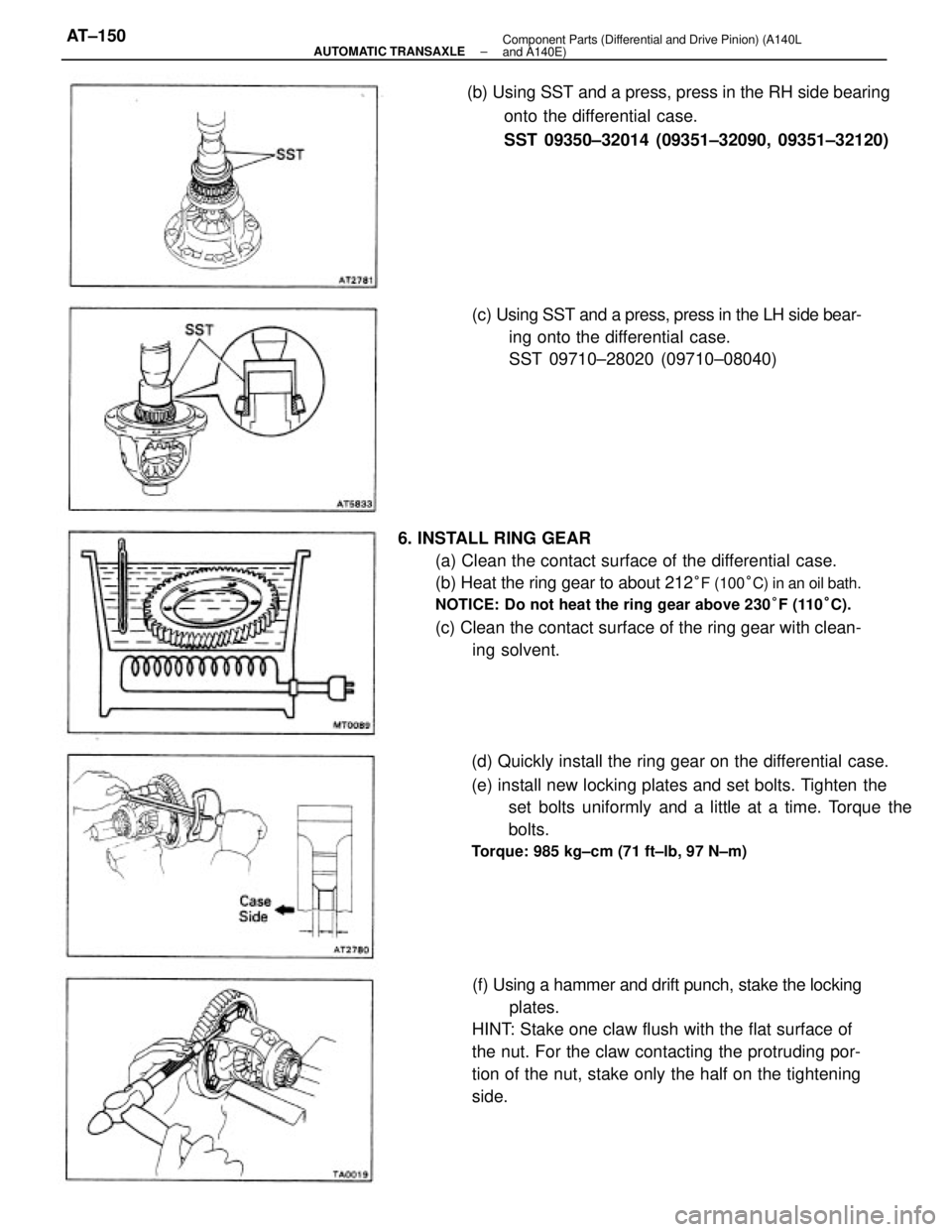

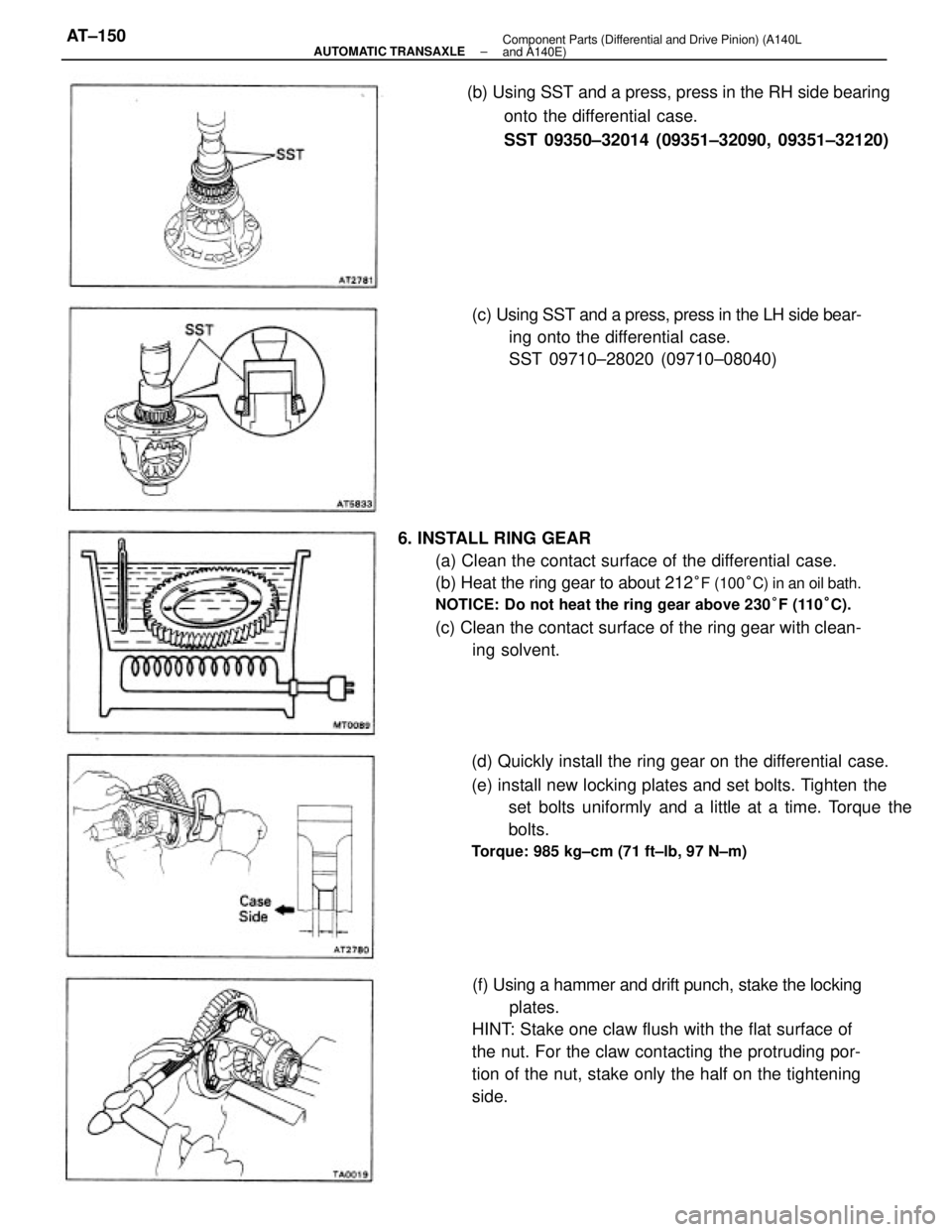

6. INSTALL RING GEAR

(a) Clean the contact surface of the differential case.

(b) Heat the ring gear to about 212

°F (100°C) in an oil bath.

NOTICE: Do not heat the ring gear above 230°F (110°C).

(c) Clean the contact surface of the ring gear with clean-

ing solvent.

(d) Quickly install the ring gear on the differential case.

(e) install new locking plates and set bolts. Tighten the

set bolts uniformly and a little at a time. Torque the

bolts.

Torque: 985 kg±cm (71 ft±lb, 97 N±m)

(f) Using a hammer and drift punch, stake the locking

plates.

HINT: Stake one claw flush with the flat surface of

the nut. For the claw contacting the protruding por-

tion of the nut, stake only the half on the tightening

side. (b) Using SST and a press, press in the RH side bearing

onto the differential case.

SST 09350±32014 (09351±32090, 09351±32120)

(c) Using SST and a press, press in the LH side bear-

ing onto the differential case.

SST 09710±28020 (09710±08040)

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±150

Page 406 of 2389

ASSEMBLY OF DRIVE PINION SHAFT

COMPONENTS

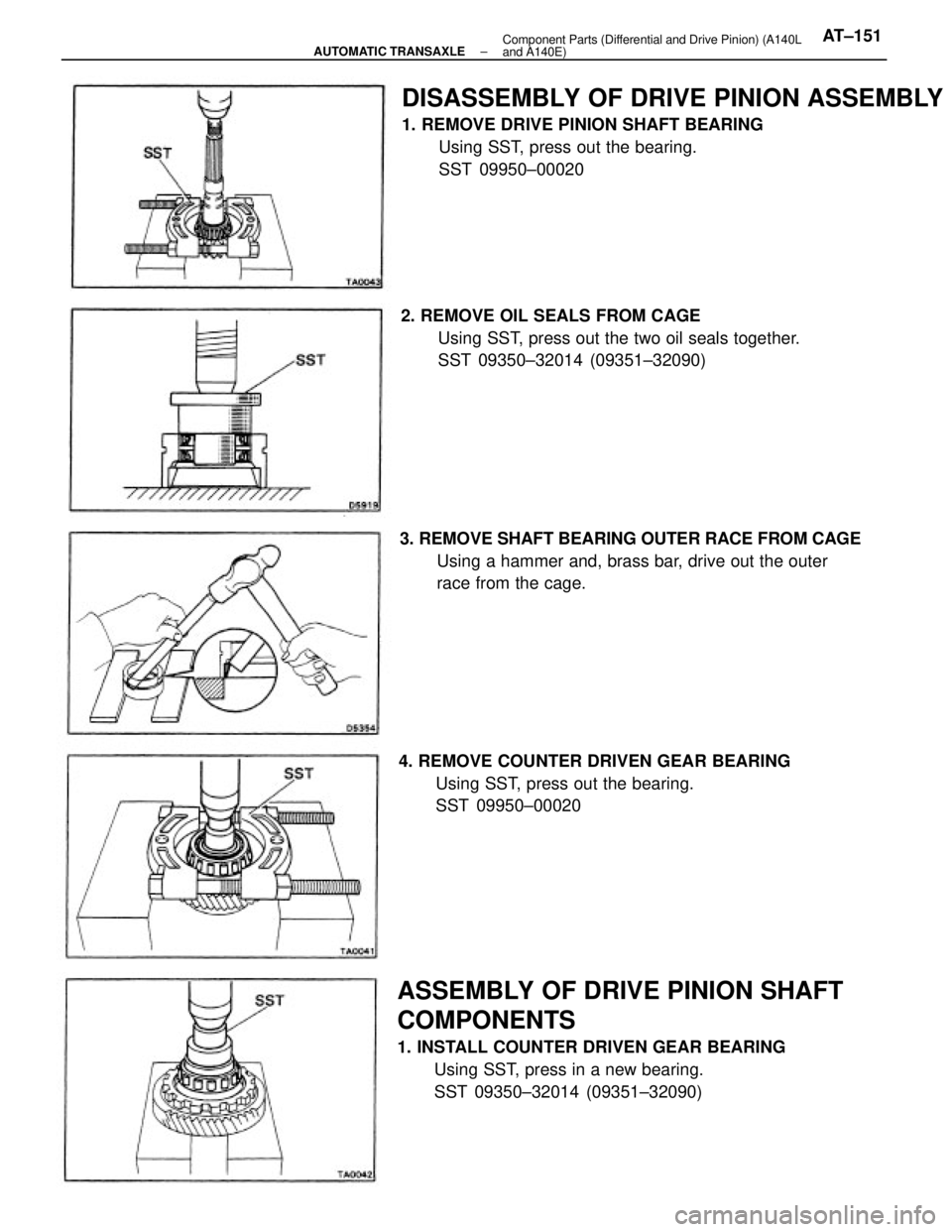

1. INSTALL COUNTER DRIVEN GEAR BEARING

Using SST, press in a new bearing.

SST 09350±32014 (09351±32090)

DISASSEMBLY OF DRIVE PINION ASSEMBLY

1. REMOVE DRIVE PINION SHAFT BEARING

Using SST, press out the bearing.

SST 09950±00020

3. REMOVE SHAFT BEARING OUTER RACE FROM CAGE

Using a hammer and, brass bar, drive out the outer

race from the cage. 2. REMOVE OIL SEALS FROM CAGE

Using SST, press out the two oil seals together.

SST 09350±32014 (09351±32090)

4. REMOVE COUNTER DRIVEN GEAR BEARING

Using SST, press out the bearing.

SST 09950±00020

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±151

Page 407 of 2389

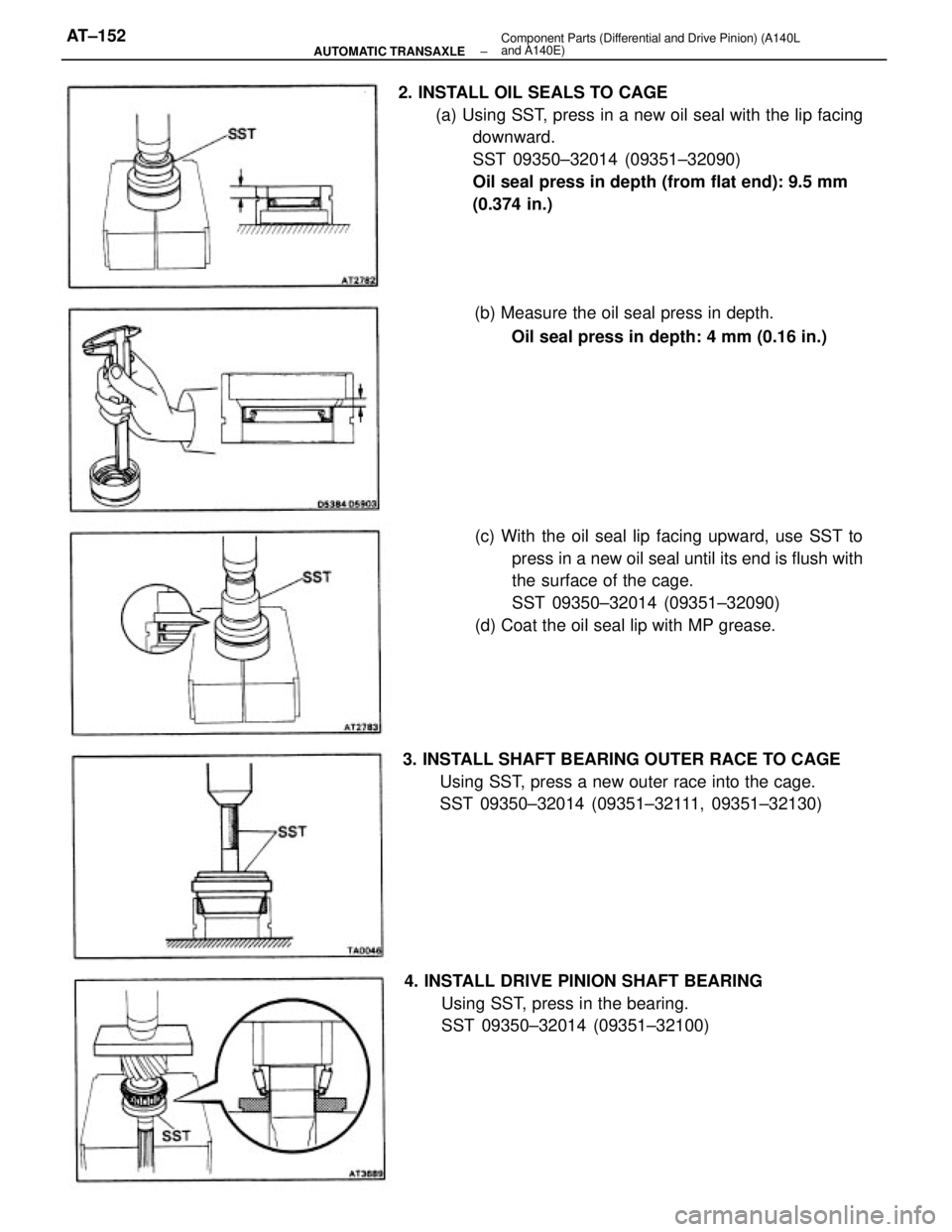

2. INSTALL OIL SEALS TO CAGE

(a) Using SST, press in a new oil seal with the lip facing

downward.

SST 09350±32014 (09351±32090)

Oil seal press in depth (from flat end): 9.5 mm

(0.374 in.)

(c) With the oil seal lip facing upward, use SST to

press in a new oil seal until its end is flush with

the surface of the cage.

SST 09350±32014 (09351±32090)

(d) Coat the oil seal lip with MP grease.

3. INSTALL SHAFT BEARING OUTER RACE TO CAGE

Using SST, press a new outer race into the cage.

SST 09350±32014 (09351±32111, 09351±32130)

4. INSTALL DRIVE PINION SHAFT BEARING

Using SST, press in the bearing.

SST 09350±32014 (09351±32100)(b) Measure the oil seal press in depth.

Oil seal press in depth: 4 mm (0.16 in.)

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±152

Page 408 of 2389

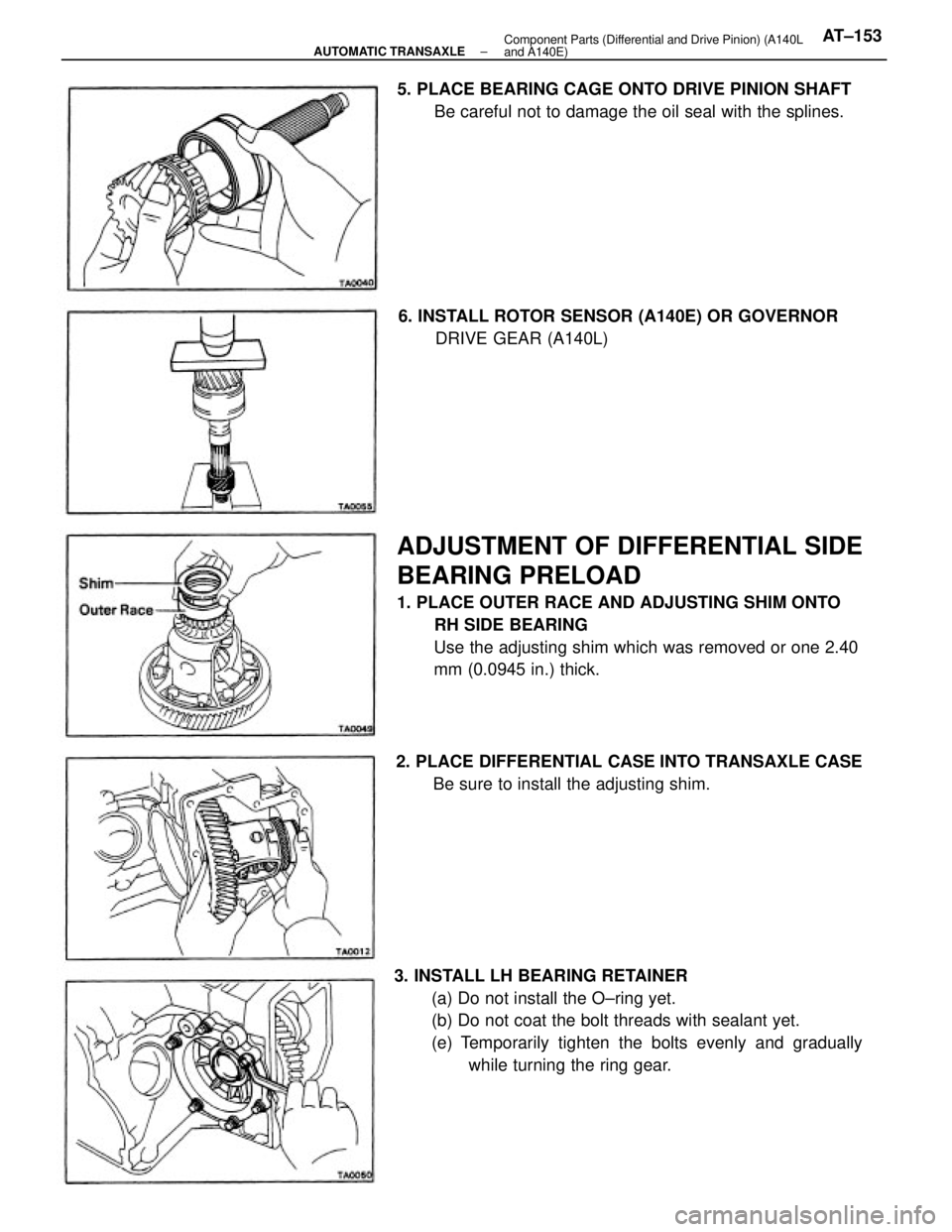

3. INSTALL LH BEARING RETAINER

(a) Do not install the O±ring yet.

(b) Do not coat the bolt threads with sealant yet.

(e) Temporarily tighten the bolts evenly and gradually

while turning the ring gear.

ADJUSTMENT OF DIFFERENTIAL SIDE

BEARING PRELOAD

1. PLACE OUTER RACE AND ADJUSTING SHIM ONTO

RH SIDE BEARING

Use the adjusting shim which was removed or one 2.40

mm (0.0945 in.) thick. 5. PLACE BEARING CAGE ONTO DRIVE PINION SHAFT

Be careful not to damage the oil seal with the splines.

2. PLACE DIFFERENTIAL CASE INTO TRANSAXLE CASE

Be sure to install the adjusting shim. 6. INSTALL ROTOR SENSOR (A140E) OR GOVERNOR

DRIVE GEAR (A140L)

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±153

Page 409 of 2389

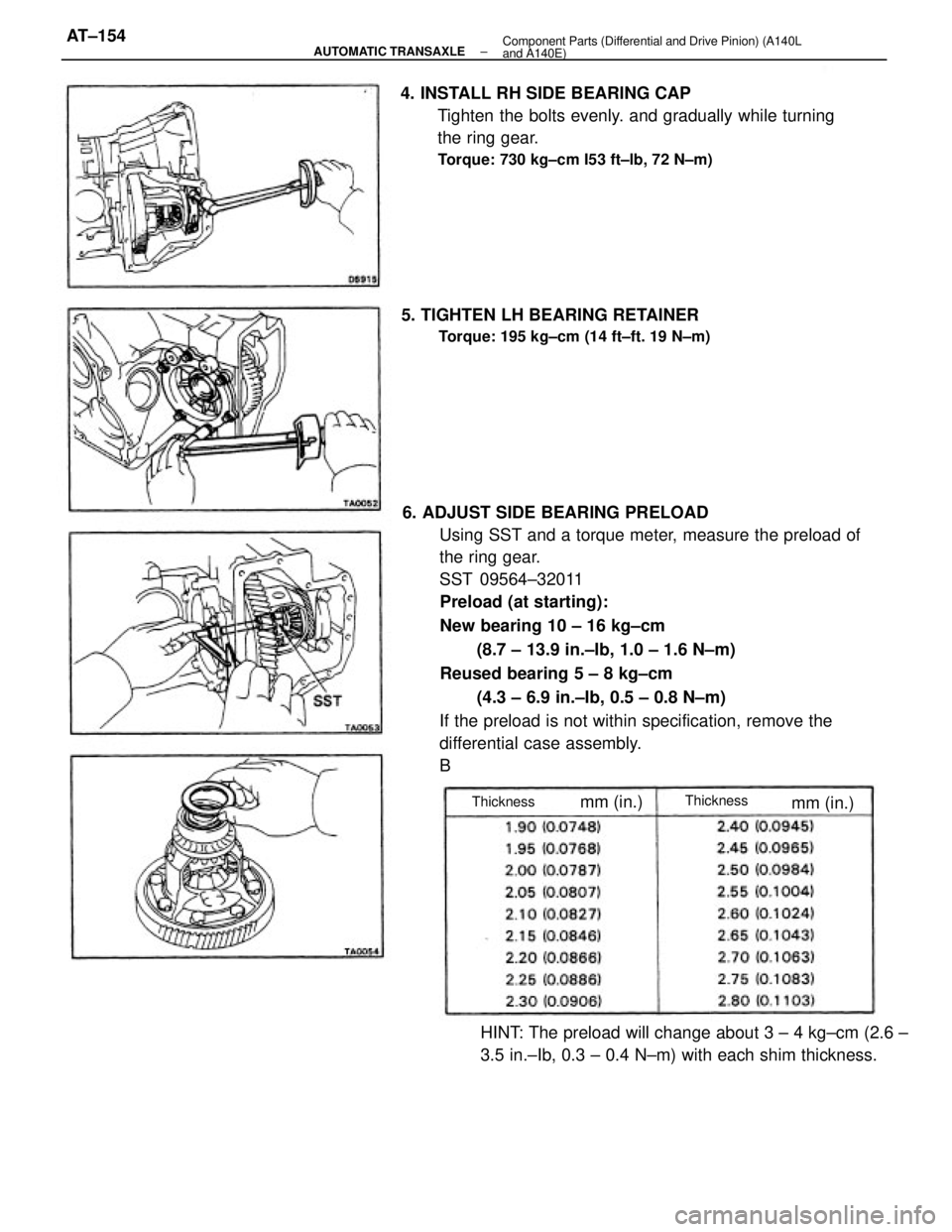

6. ADJUST SIDE BEARING PRELOAD

Using SST and a torque meter, measure the preload of

the ring gear.

SST 09564±32011

Preload (at starting):

New bearing 10 ± 16 kg±cm

(8.7 ± 13.9 in.±Ib, 1.0 ± 1.6 N±m)

Reused bearing 5 ± 8 kg±cm

(4.3 ± 6.9 in.±Ib, 0.5 ± 0.8 N±m)

If the preload is not within specification, remove the

differential case assembly.

B 4. INSTALL RH SIDE BEARING CAP

Tighten the bolts evenly. and gradually while turning

the ring gear.

Torque: 730 kg±cm I53 ft±lb, 72 N±m)

HINT: The preload will change about 3 ± 4 kg±cm (2.6 ±

3.5 in.±Ib, 0.3 ± 0.4 N±m) with each shim thickness. 5. TIGHTEN LH BEARING RETAINER

Torque: 195 kg±cm (14 ft±ft. 19 N±m)

Thickness

Thicknessmm (in.)

mm (in.)

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±154

Page 410 of 2389

7. REMOVE DIFFERENTIAL CASE AND COMPONENT

PARTS

If the preload is adjusted within specification, remove

the bearing retainer, differential case, RH side bearing

and shim.

Be careful not to lose the adjusted shim.

± AUTOMATIC TRANSAXLEComponent Parts (Differential and Drive Pinion) (A140L

and A140E)AT±155

Trending: headlight bulb, headlight aiming, door lock, washer fluid, boot, mileage, service interval