TOYOTA CAMRY V20 1986 Service Information

CAMRY V20 1986

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57449/w960_57449-0.png

TOYOTA CAMRY V20 1986 Service Information

Trending: turn signal, radiator cap, interior, seats, air conditioning, air conditioning relay, seat adjustment

Page 741 of 2389

BODY DIMENSIONS

General Information

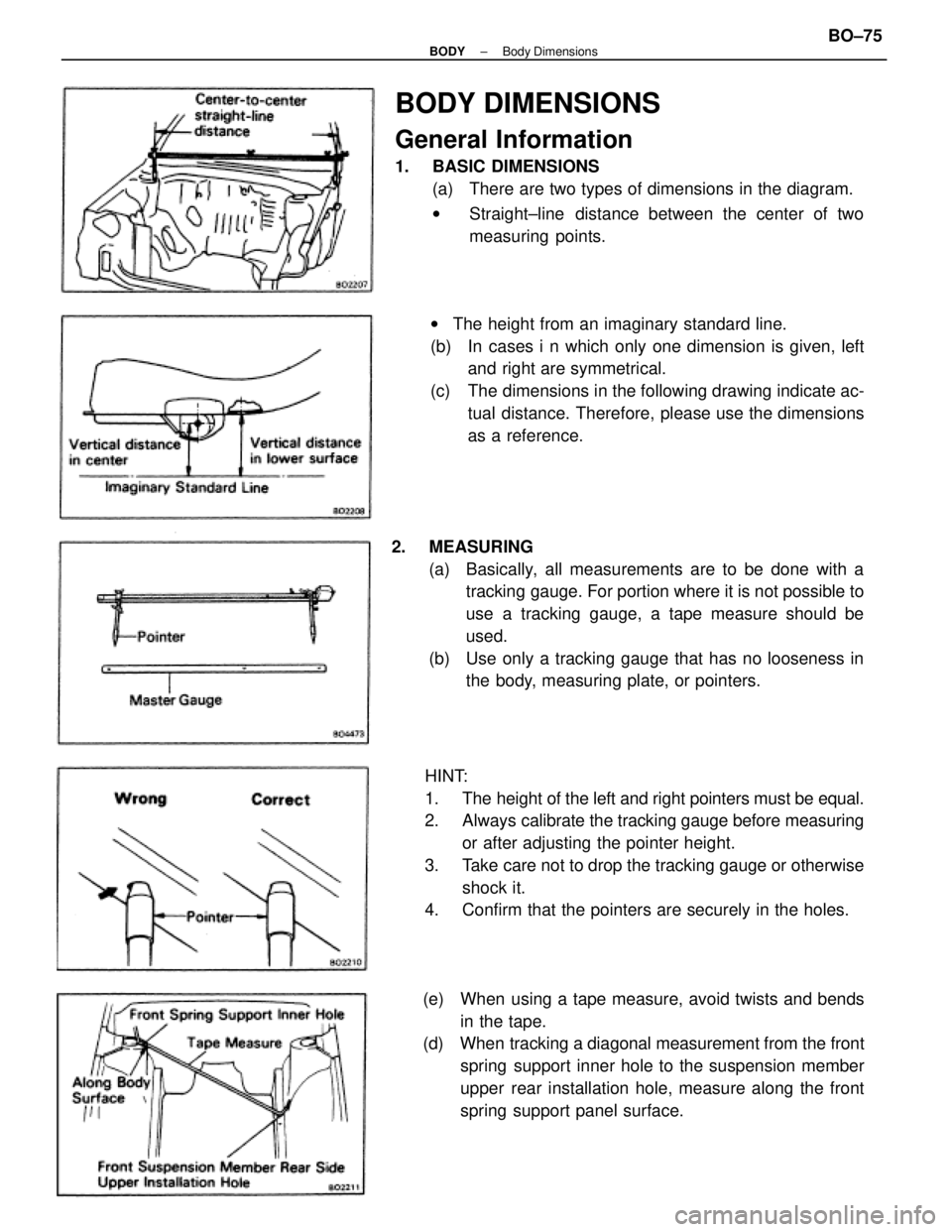

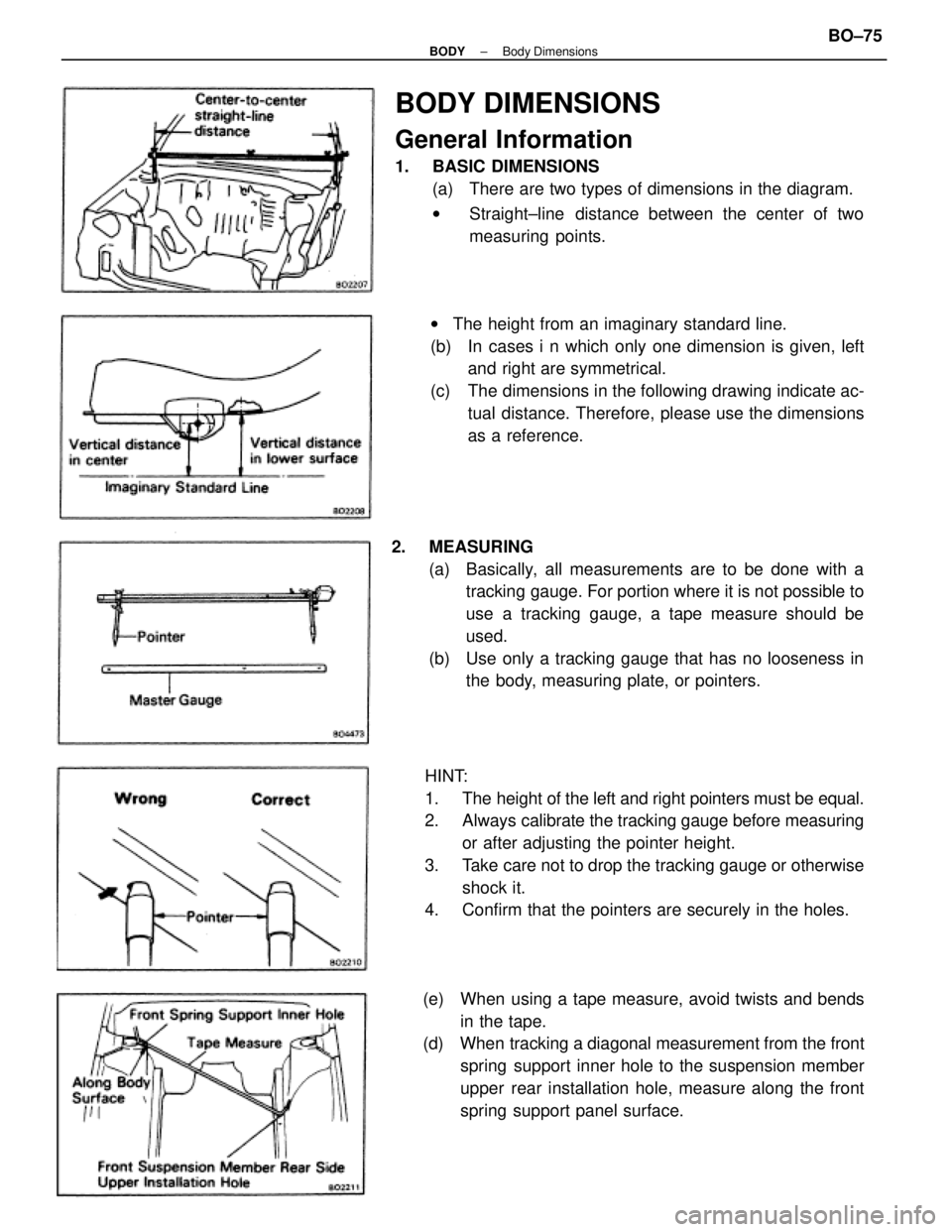

1. BASIC DIMENSIONS

(a) There are two types of dimensions in the diagram.

wStraight±line distance between the center of two

measuring points.

HINT:

1. The height of the left and right pointers must be equal.

2. Always calibrate the tracking gauge before measuring

or after adjusting the pointer height.

3. Take care not to drop the tracking gauge or otherwise

shock it.

4. Confirm that the pointers are securely in the holes. 2. MEASURING

(a) Basically, all measurements are to be done with a

tracking gauge. For portion where it is not possible to

use a tracking gauge, a tape measure should be

used.

(b) Use only a tracking gauge that has no looseness in

the body, measuring plate, or pointers. wThe height from an imaginary standard line.

(b) In cases i n which only one dimension is given, left

and right are symmetrical.

(c) The dimensions in the following drawing indicate ac-

tual distance. Therefore, please use the dimensions

as a reference.

(e) When using a tape measure, avoid twists and bends

in the tape.

(d) When tracking a diagonal measurement from the front

spring support inner hole to the suspension member

upper rear installation hole, measure along the front

spring support panel surface.

± BODYBody DimensionsBO±75

Page 742 of 2389

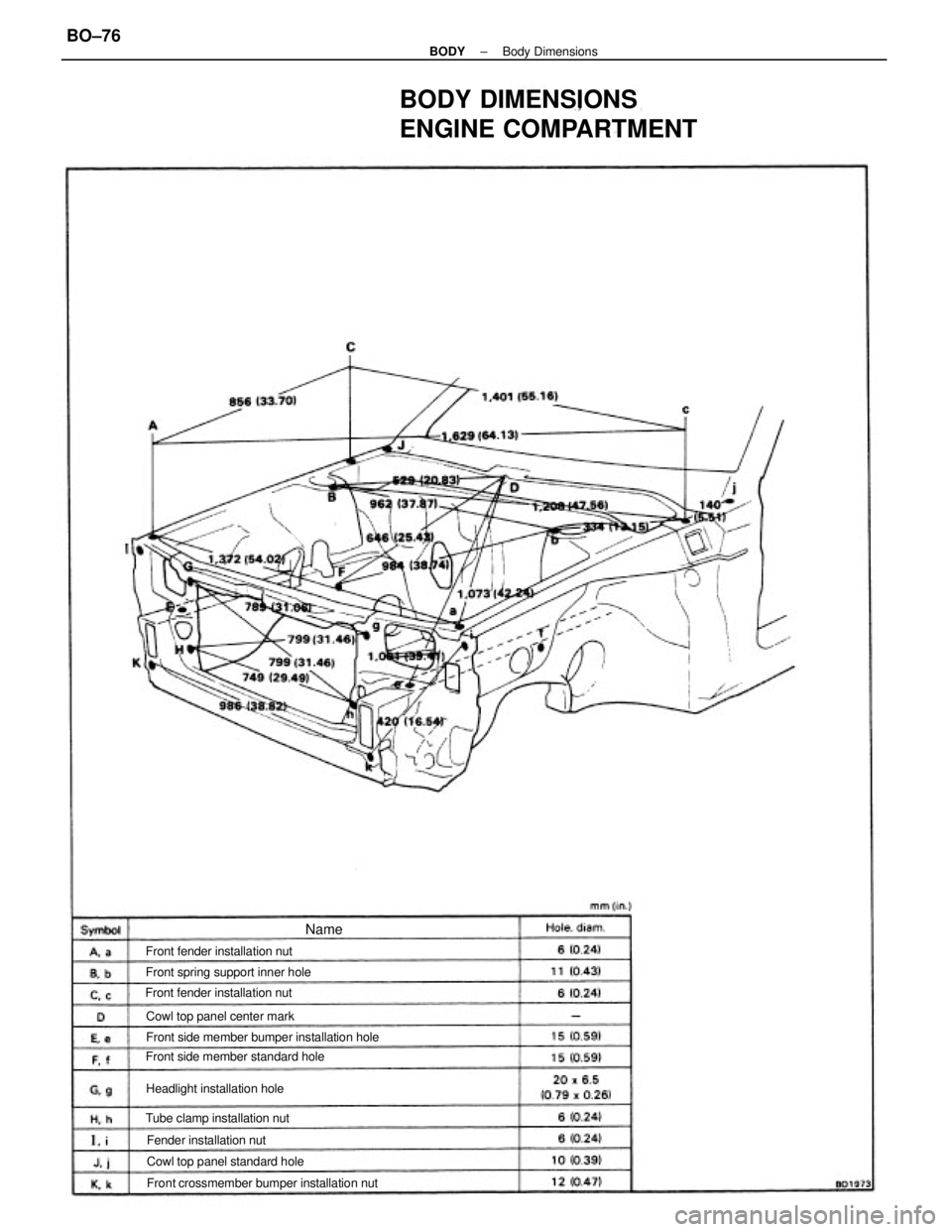

BODY DIMENSIONS

ENGINE COMPARTMENT

Front crossmember bumper installation nut Front side member bumper installation hole

Front side member standard hole Front spring support inner hole

Cowl top panel standard hole Cowl top panel center mark

Tube clamp installation nut Front fender installation nut

Headlight installation hole Front fender installation nut

Fender installation nut

Name

± BODYBody DimensionsBO±76

Page 743 of 2389

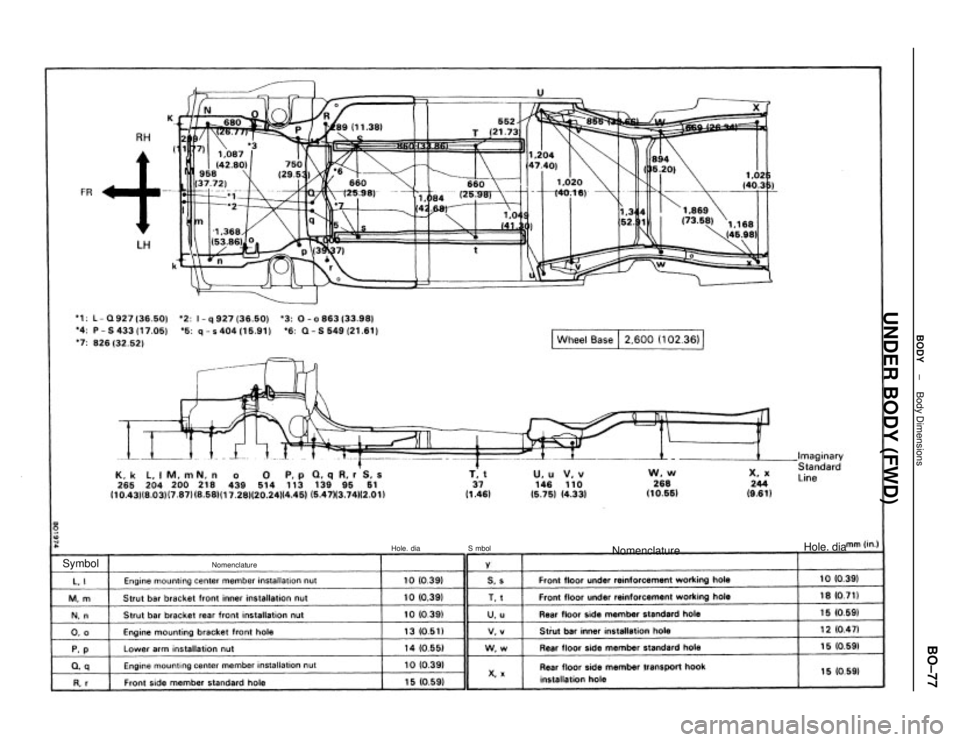

UNDER BODY (FWD)

Nomenclature

Nomenclature

Hole. dia

Hole. dia

Symbol

S mbol

± BODYBody DimensionsBO±77

Page 744 of 2389

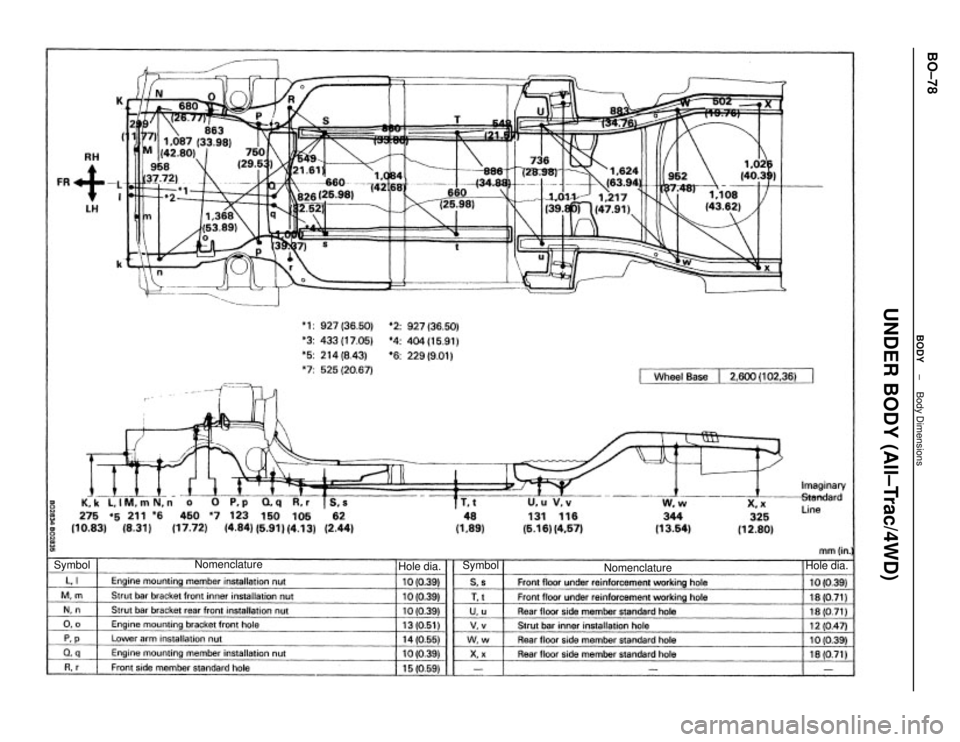

UNDER BODY (All±Trac/4WD)

Nomenclature Nomenclature

Hole dia.

Hole dia.Symbol Symbol

± BODYBody DimensionsBO±78

Page 745 of 2389

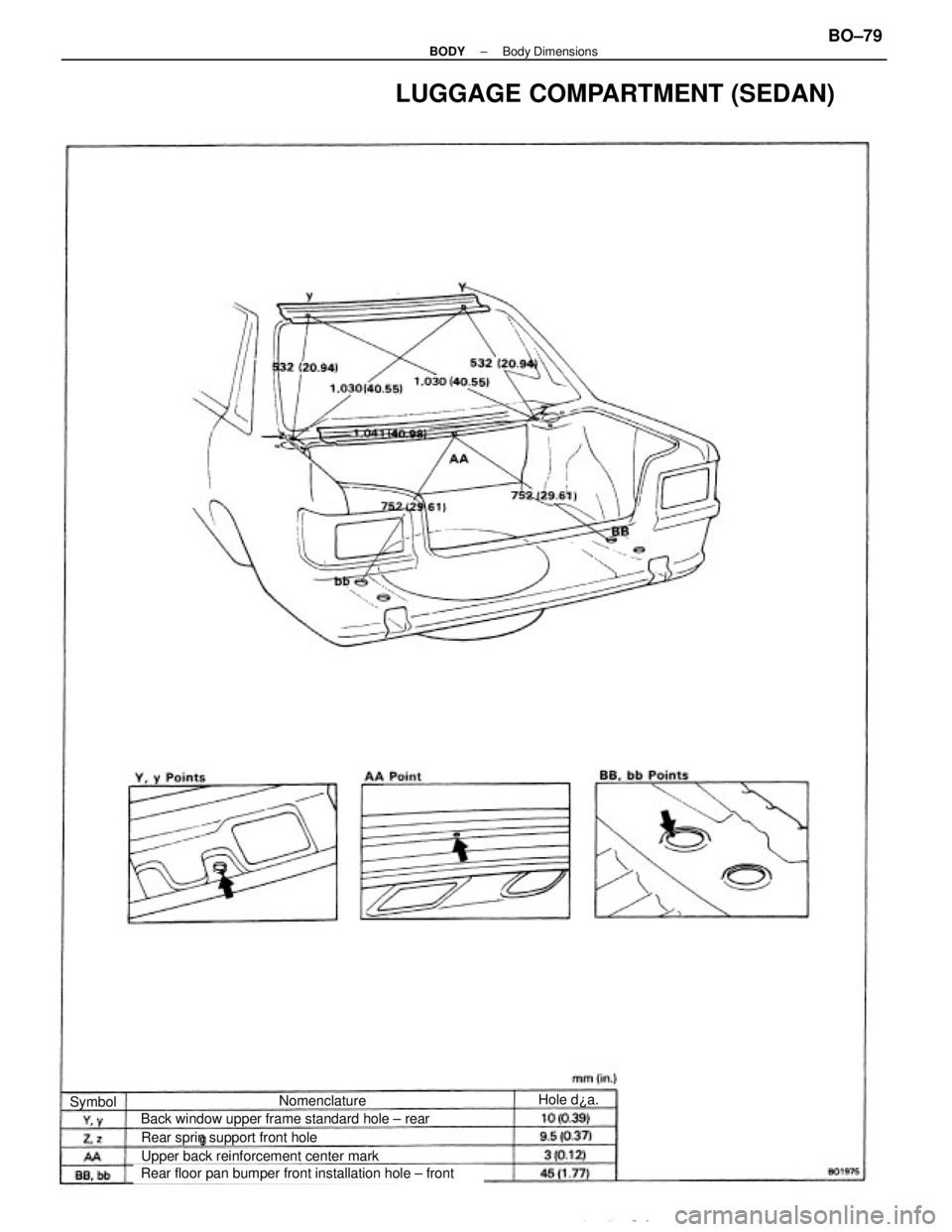

LUGGAGE COMPARTMENT (SEDAN)

Rear floor pan bumper front installation hole ± front Back window upper frame standard hole ± rear

Upper back reinforcement center mark Rear sprin support front holeNomenclatureHole d¿a.

Symbol

± BODYBody DimensionsBO±79

Page 746 of 2389

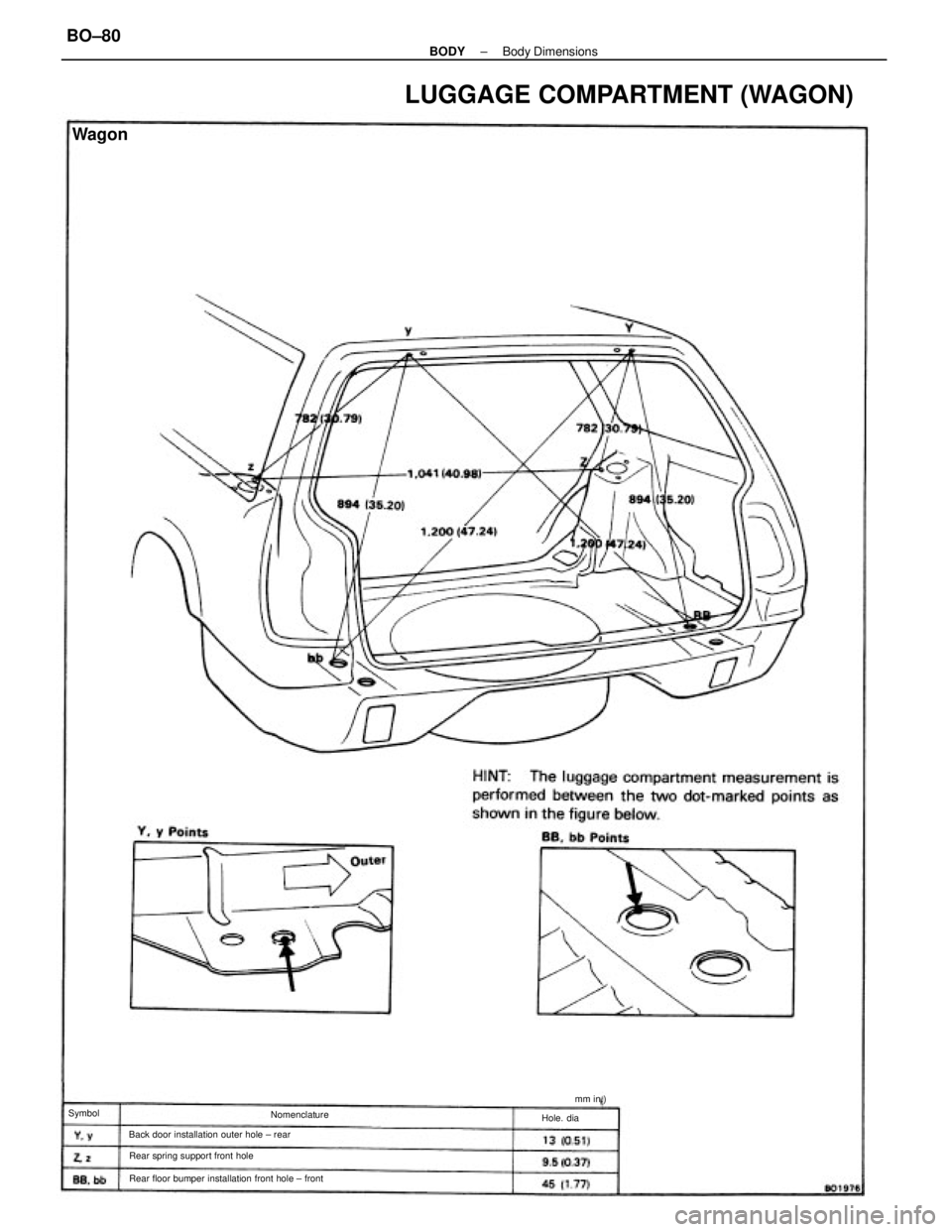

LUGGAGE COMPARTMENT (WAGON)

Rear floor bumper installation front hole ± front Back door installation outer hole ± rear

Rear spring support front hole

Wagon

Nomenclature

Hole. dia Symbolmm in.)

± BODYBody DimensionsBO±80

Page 747 of 2389

BODY ELECTRICAL SYSTEM

± BODY ELECTRICAL SYSTEMBE±1

Page 748 of 2389

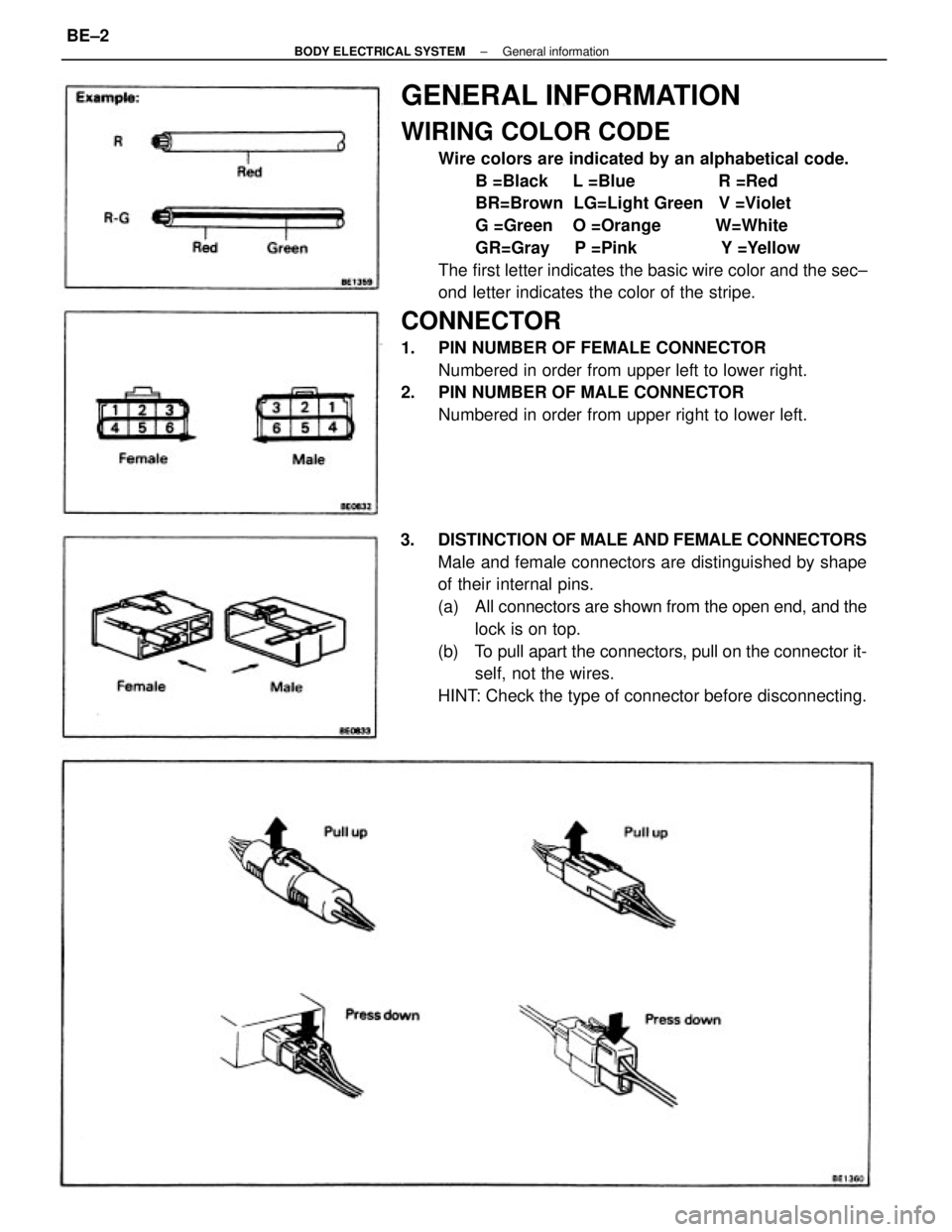

GENERAL INFORMATION

WIRING COLOR CODE

Wire colors are indicated by an alphabetical code.

B =Black L =Blue R =Red

BR=Brown LG=Light Green V =Violet

G =Green O =Orange W=White

GR=Gray P =Pink Y =Yellow

The first letter indicates the basic wire color and the sec±

ond letter indicates the color of the stripe.

CONNECTOR

1. PIN NUMBER OF FEMALE CONNECTOR

Numbered in order from upper left to lower right.

2. PIN NUMBER OF MALE CONNECTOR

Numbered in order from upper right to lower left.

3. DISTINCTION OF MALE AND FEMALE CONNECTORS

Male and female connectors are distinguished by shape

of their internal pins.

(a) All connectors are shown from the open end, and the

lock is on top.

(b) To pull apart the connectors, pull on the connector it-

self, not the wires.

HINT: Check the type of connector before disconnecting.

± BODY ELECTRICAL SYSTEMGeneral informationBE±2

Page 749 of 2389

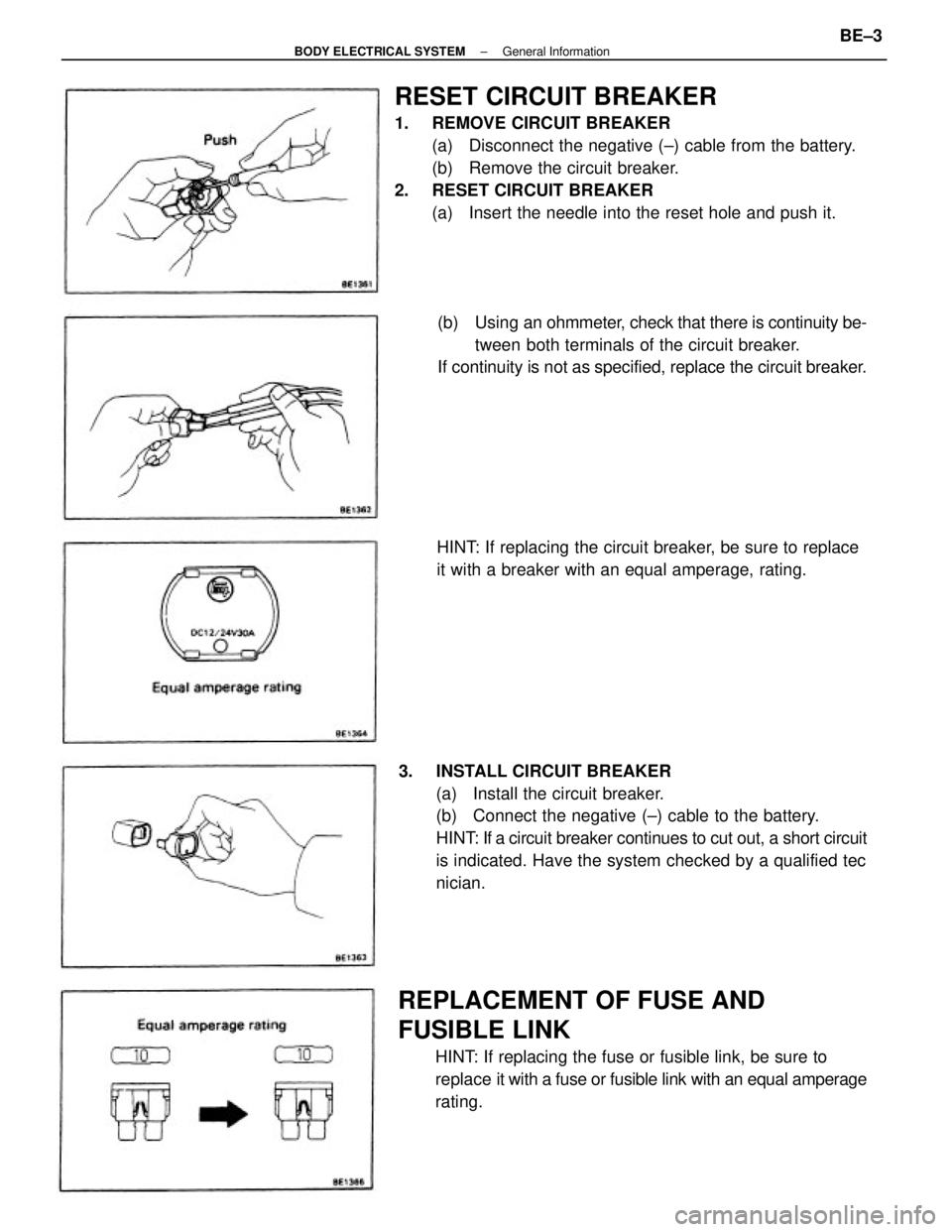

RESET CIRCUIT BREAKER

1. REMOVE CIRCUIT BREAKER

(a) Disconnect the negative (±) cable from the battery.

(b) Remove the circuit breaker.

2. RESET CIRCUIT BREAKER

(a) Insert the needle into the reset hole and push it.

3. INSTALL CIRCUIT BREAKER

(a) Install the circuit breaker.

(b) Connect the negative (±) cable to the battery.

HINT: If a circuit breaker continues to cut out, a short circuit

is indicated. Have the system checked by a qualified tec

nician.

REPLACEMENT OF FUSE AND

FUSIBLE LINK

HINT: If replacing the fuse or fusible link, be sure to

replace it with a fuse or fusible link with an equal amperage

rating.(b) Using an ohmmeter, check that there is continuity be-

tween both terminals of the circuit breaker.

If continuity is not as specified, replace the circuit breaker.

HINT: If replacing the circuit breaker, be sure to replace

it with a breaker with an equal amperage, rating.

± BODY ELECTRICAL SYSTEMGeneral InformationBE±3

Page 750 of 2389

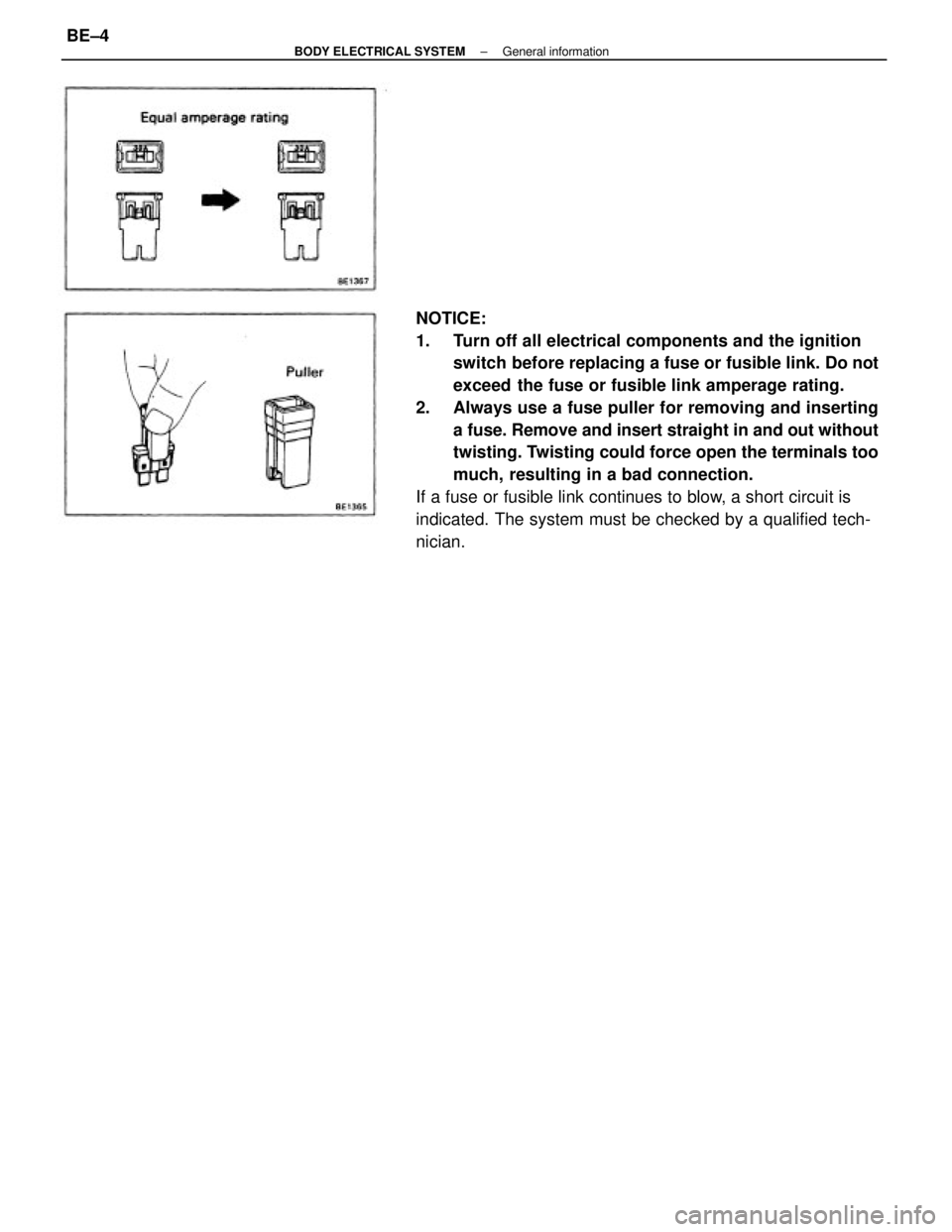

NOTICE:

1. Turn off all electrical components and the ignition

switch before replacing a fuse or fusible link. Do not

exceed the fuse or fusible link amperage rating.

2. Always use a fuse puller for removing and inserting

a fuse. Remove and insert straight in and out without

twisting. Twisting could force open the terminals too

much, resulting in a bad connection.

If a fuse or fusible link continues to blow, a short circuit is

indicated. The system must be checked by a qualified tech-

nician.

± BODY ELECTRICAL SYSTEMGeneral informationBE±4

Trending: fold seats, odometer, battery replacement, towing, length, emergency towing, radio antenna