TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 701 of 2389

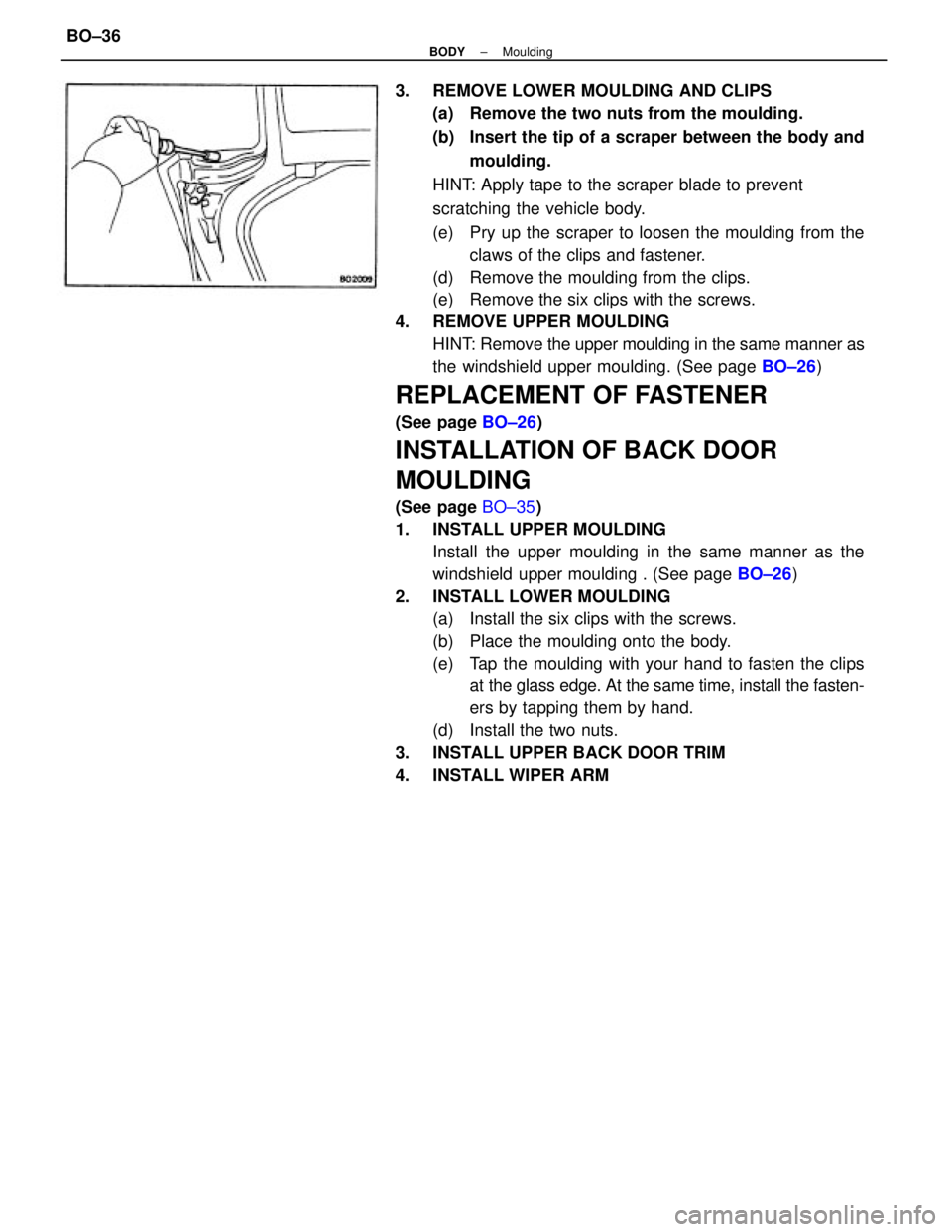

2. REMOVE UPPER BACK DOOR TRIM

Using a screwdriver, remove the upper back door trim with

the clips.

HINT: Tape the screwdrier tip before use.

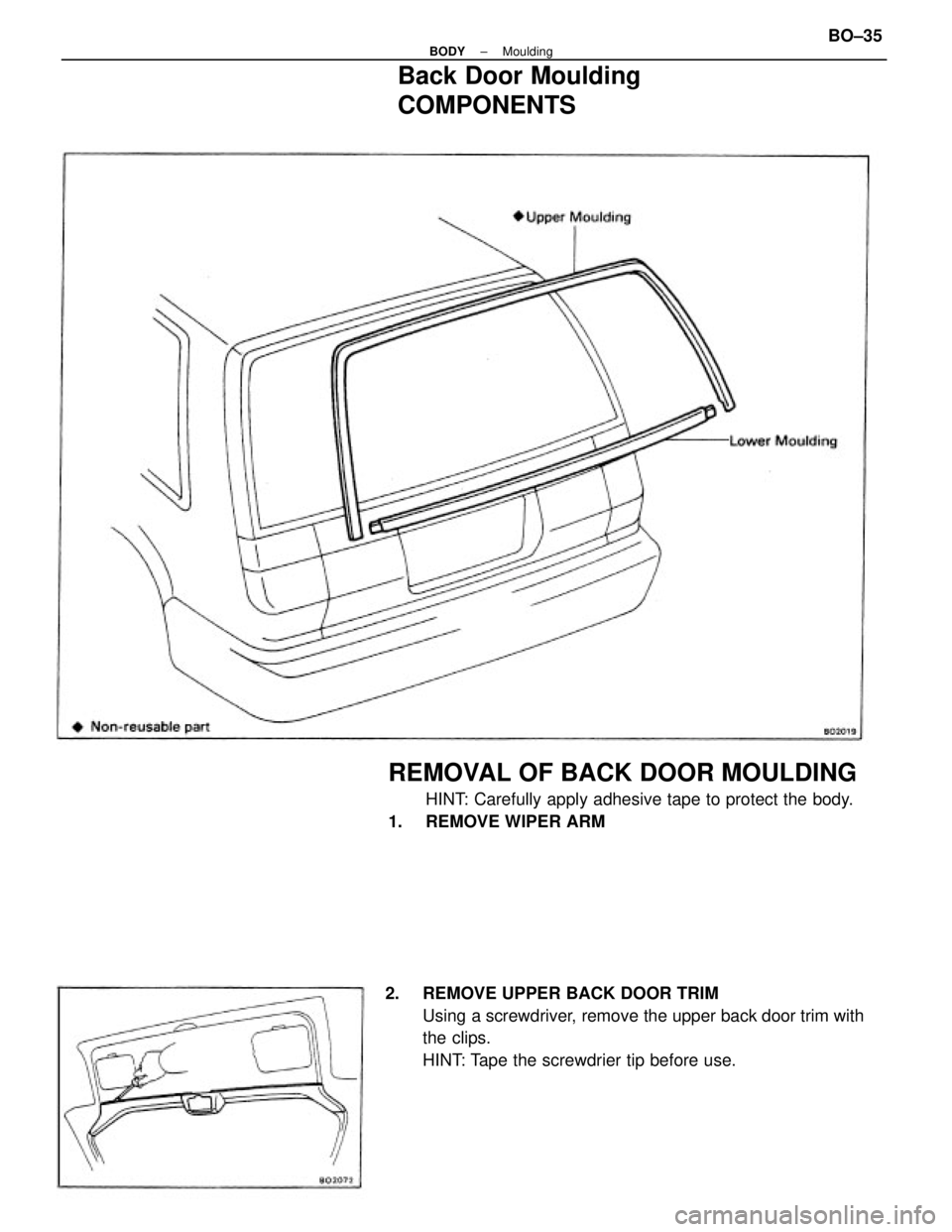

REMOVAL OF BACK DOOR MOULDING

HINT: Carefully apply adhesive tape to protect the body.

1. REMOVE WIPER ARM

Back Door Moulding

COMPONENTS

± BODYMouldingBO±35

Page 702 of 2389

3. REMOVE LOWER MOULDING AND CLIPS

(a) Remove the two nuts from the moulding.

(b) Insert the tip of a scraper between the body and

moulding.

HINT: Apply tape to the scraper blade to prevent

scratching the vehicle body.

(e) Pry up the scraper to loosen the moulding from the

claws of the clips and fastener.

(d) Remove the moulding from the clips.

(e) Remove the six clips with the screws.

4. REMOVE UPPER MOULDING

HINT: Remove the upper moulding in the same manner as

the windshield upper moulding. (See page BO±26)

REPLACEMENT OF FASTENER

(See page BO±26)

INSTALLATION OF BACK DOOR

MOULDING

(See page BO±35)

1. INSTALL UPPER MOULDING

Install the upper moulding in the same manner as the

windshield upper moulding . (See page BO±26)

2. INSTALL LOWER MOULDING

(a) Install the six clips with the screws.

(b) Place the moulding onto the body.

(e) Tap the moulding with your hand to fasten the clips

at the glass edge. At the same time, install the fasten-

ers by tapping them by hand.

(d) Install the two nuts.

3. INSTALL UPPER BACK DOOR TRIM

4. INSTALL WIPER ARM

± BODYMouldingBO±36

Page 703 of 2389

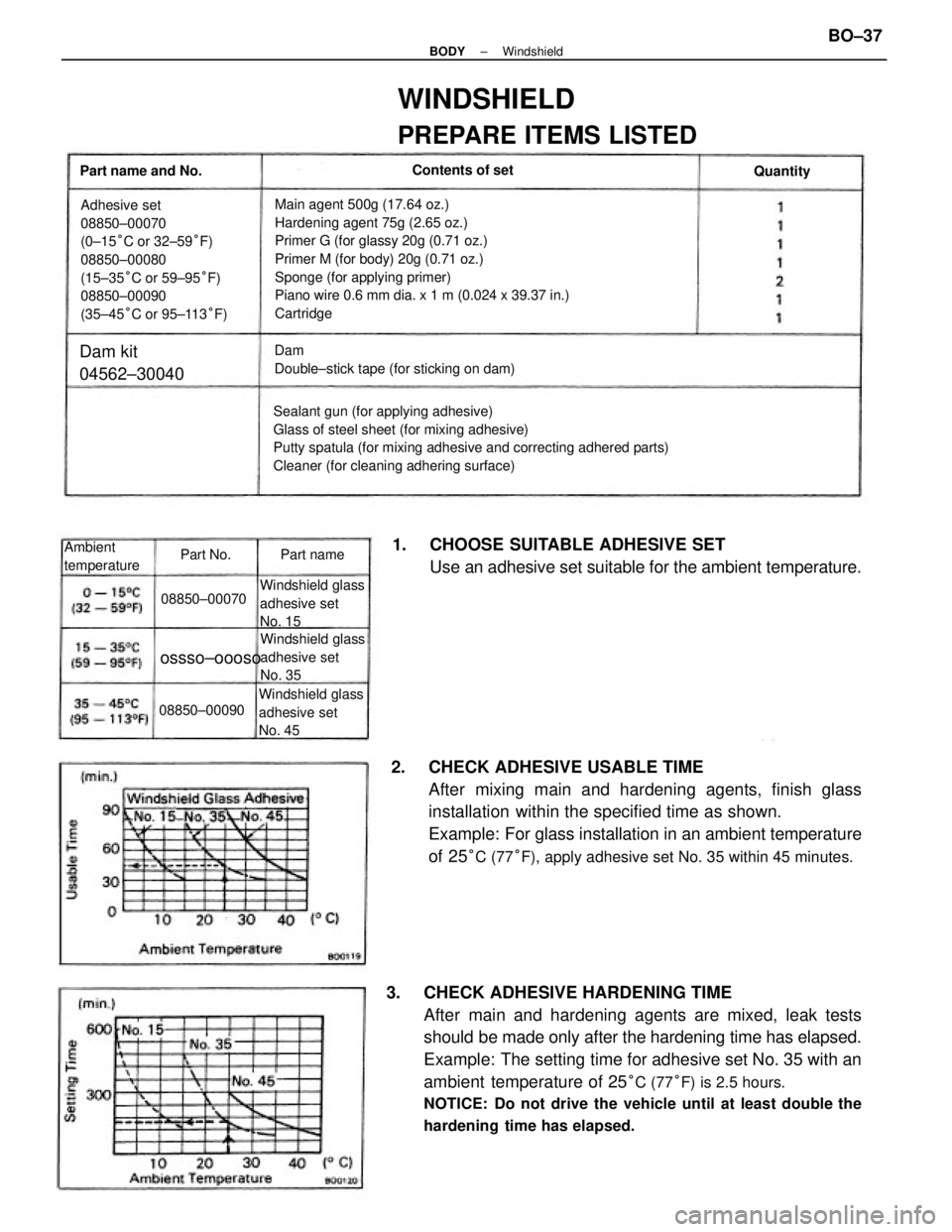

3. CHECK ADHESIVE HARDENING TIME

After main and hardening agents are mixed, leak tests

should be made only after the hardening time has elapsed.

Example: The setting time for adhesive set No. 35 with an

ambient temperature of 25

°C (77°F) is 2.5 hours.

NOTICE: Do not drive the vehicle until at least double the

hardening time has elapsed.

2. CHECK ADHESIVE USABLE TIME

After mixing main and hardening agents, finish glass

installation within the specified time as shown.

Example: For glass installation in an ambient temperature

of 25

°C (77°F), apply adhesive set No. 35 within 45 minutes.

Main agent 500g (17.64 oz.)

Hardening agent 75g (2.65 oz.)

Primer G (for glassy 20g (0.71 oz.)

Primer M (for body) 20g (0.71 oz.)

Sponge (for applying primer)

Piano wire 0.6 mm dia. x 1 m (0.024 x 39.37 in.)

Cartridge

Sealant gun (for applying adhesive)

Glass of steel sheet (for mixing adhesive)

Putty spatula (for mixing adhesive and correcting adhered parts)

Cleaner (for cleaning adhering surface)

1. CHOOSE SUITABLE ADHESIVE SET

Use an adhesive set suitable for the ambient temperature.

Adhesive set

08850±00070

(0±15°C or 32±59°F)

08850±00080

(15±35°C or 59±95°F)

08850±00090

(35±45°C or 95±113°F)

WINDSHIELD

PREPARE ITEMS LISTED

Dam

Double±stick tape (for sticking on dam)

Windshield glass

adhesive set

No. 15

Windshield glass

adhesive set

No. 45Windshield glass

adhesive set

No. 35Dam kit

04562±30040

Ambient

temperaturePart name and No.Contents of set

08850±00070

ossso±oooso

08850±00090Quantity

Part name Part No.

± BODYWindshieldBO±37

Page 704 of 2389

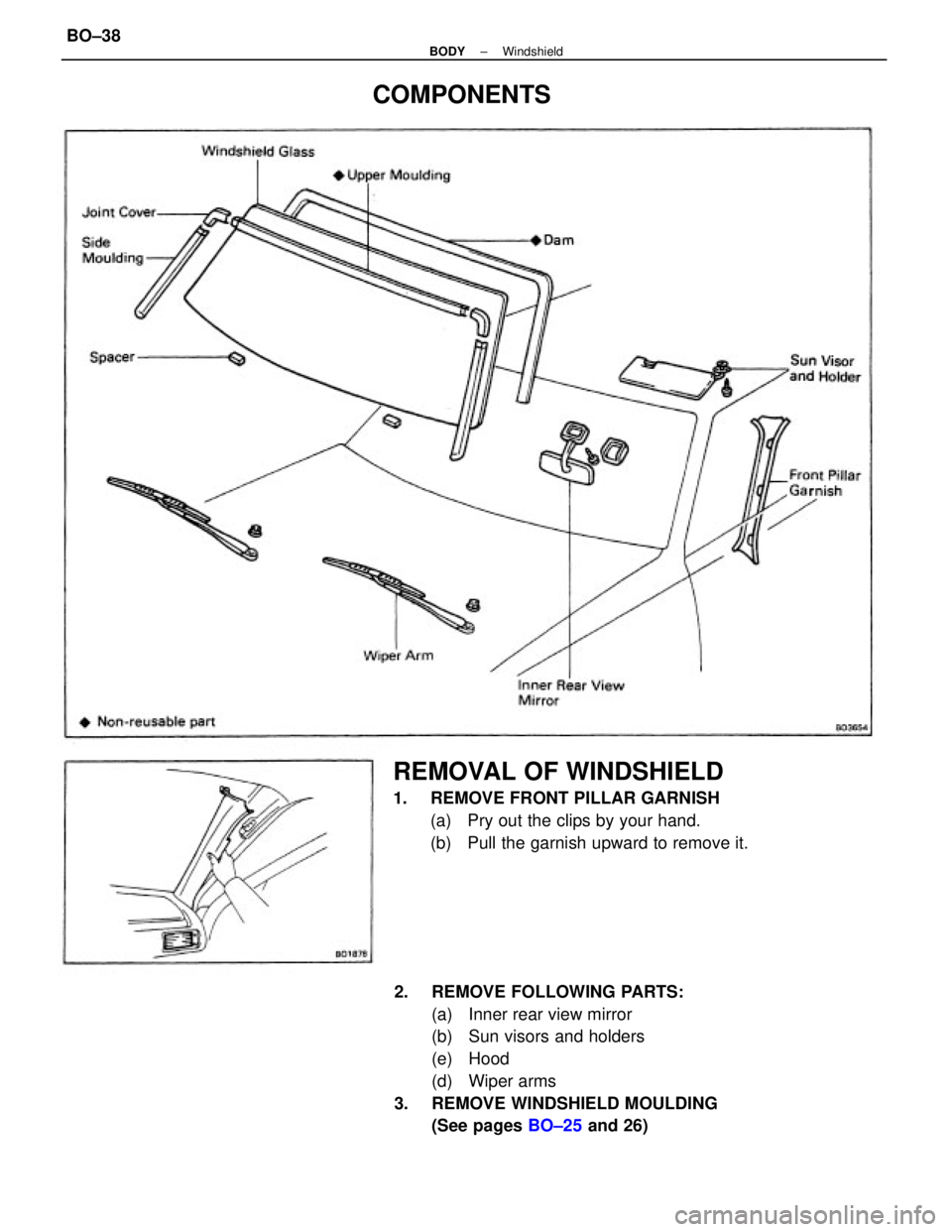

2. REMOVE FOLLOWING PARTS:

(a) Inner rear view mirror

(b) Sun visors and holders

(e) Hood

(d) Wiper arms

3. REMOVE WINDSHIELD MOULDING

(See pages BO±25 and 26)

REMOVAL OF WINDSHIELD

1. REMOVE FRONT PILLAR GARNISH

(a) Pry out the clips by your hand.

(b) Pull the garnish upward to remove it.

COMPONENTS

± BODYWindshieldBO±38

Page 705 of 2389

4. REMOVE CUPS

(See page BO±25)

Be careful not to damage the clips when removing them

from around the glass.

HINT: It is not necessary to remove the fasteners but dam-

aged fasteners should be replaced.

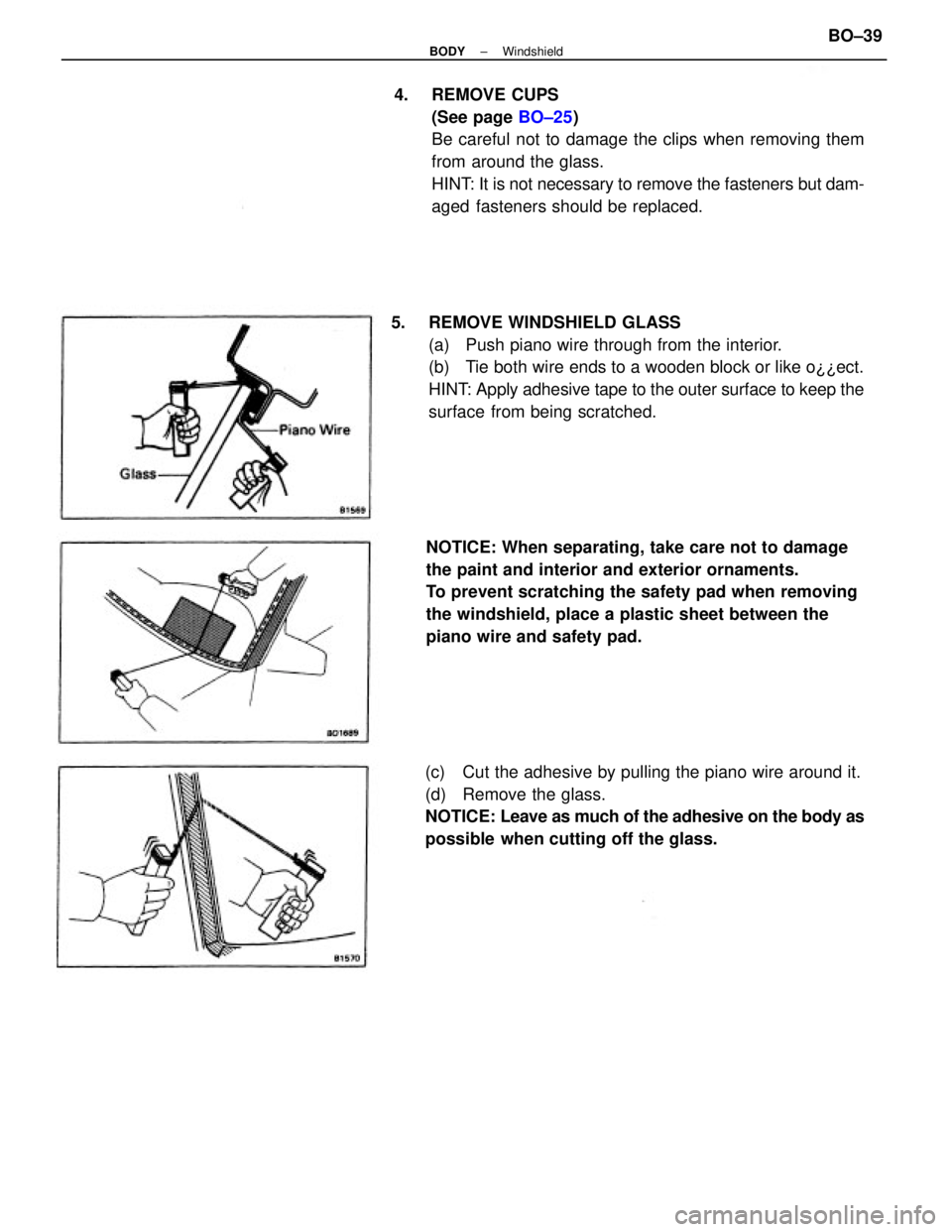

5. REMOVE WINDSHIELD GLASS

(a) Push piano wire through from the interior.

(b) Tie both wire ends to a wooden block or like o¿¿ect.

HINT: Apply adhesive tape to the outer surface to keep the

surface from being scratched.

NOTICE: When separating, take care not to damage

the paint and interior and exterior ornaments.

To prevent scratching the safety pad when removing

the windshield, place a plastic sheet between the

piano wire and safety pad.

(c) Cut the adhesive by pulling the piano wire around it.

(d) Remove the glass.

NOTICE: Leave as much of the adhesive on the body as

possible when cutting off the glass.

± BODYWindshieldBO±39

Page 706 of 2389

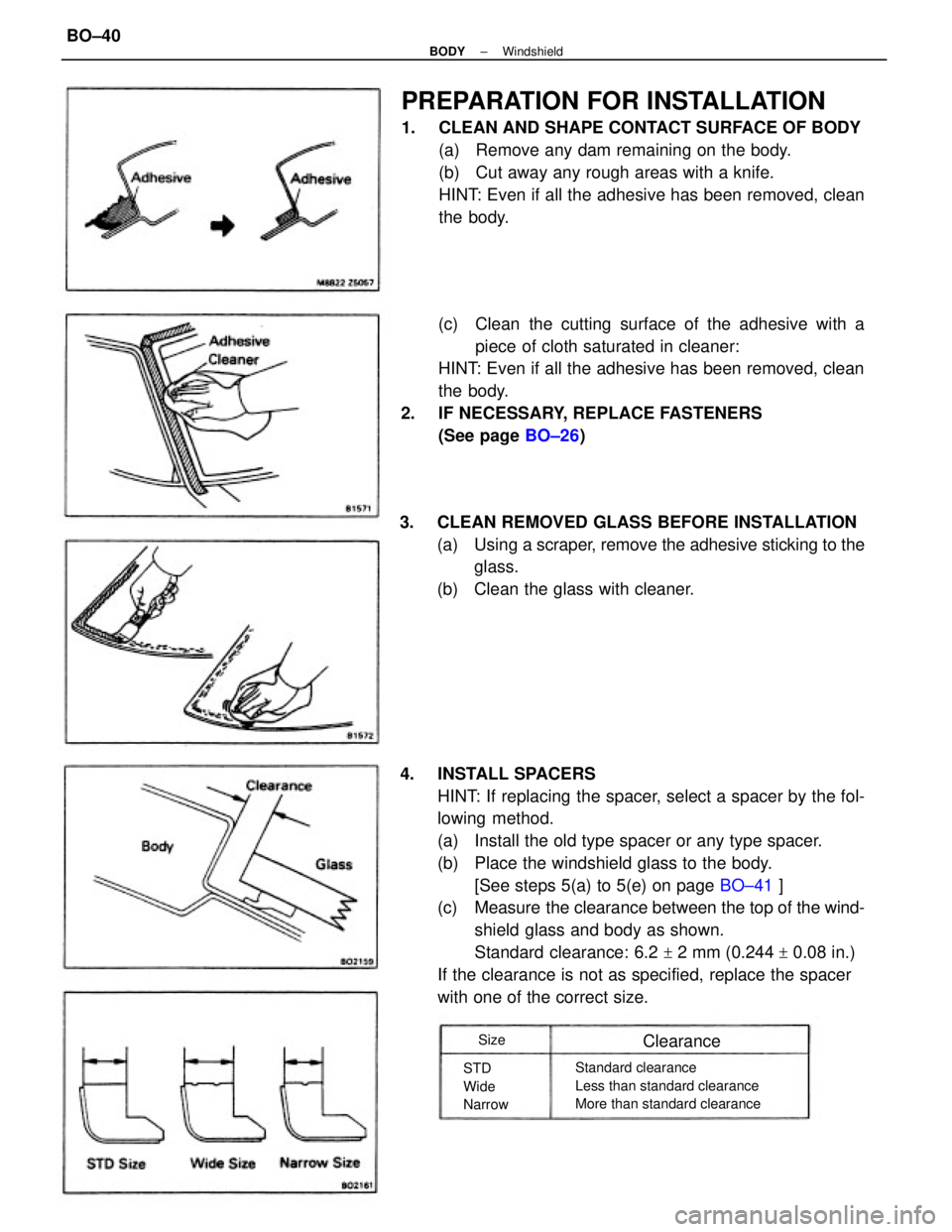

4. INSTALL SPACERS

HINT: If replacing the spacer, select a spacer by the fol-

lowing method.

(a) Install the old type spacer or any type spacer.

(b) Place the windshield glass to the body.

[See steps 5(a) to 5(e) on page BO±41 ]

(c) Measure the clearance between the top of the wind-

shield glass and body as shown.

Standard clearance: 6.2

+ 2 mm (0.244 + 0.08 in.)

If the clearance is not as specified, replace the spacer

with one of the correct size.

PREPARATION FOR INSTALLATION

1. CLEAN AND SHAPE CONTACT SURFACE OF BODY

(a) Remove any dam remaining on the body.

(b) Cut away any rough areas with a knife.

HINT: Even if all the adhesive has been removed, clean

the body.

(c) Clean the cutting surface of the adhesive with a

piece of cloth saturated in cleaner:

HINT: Even if all the adhesive has been removed, clean

the body.

2. IF NECESSARY, REPLACE FASTENERS

(See page BO±26)

3. CLEAN REMOVED GLASS BEFORE INSTALLATION

(a) Using a scraper, remove the adhesive sticking to the

glass.

(b) Clean the glass with cleaner.

Standard clearance

Less than standard clearance

More than standard clearance STD

Wide

Narrow

ClearanceSize

± BODYWindshieldBO±40

Page 707 of 2389

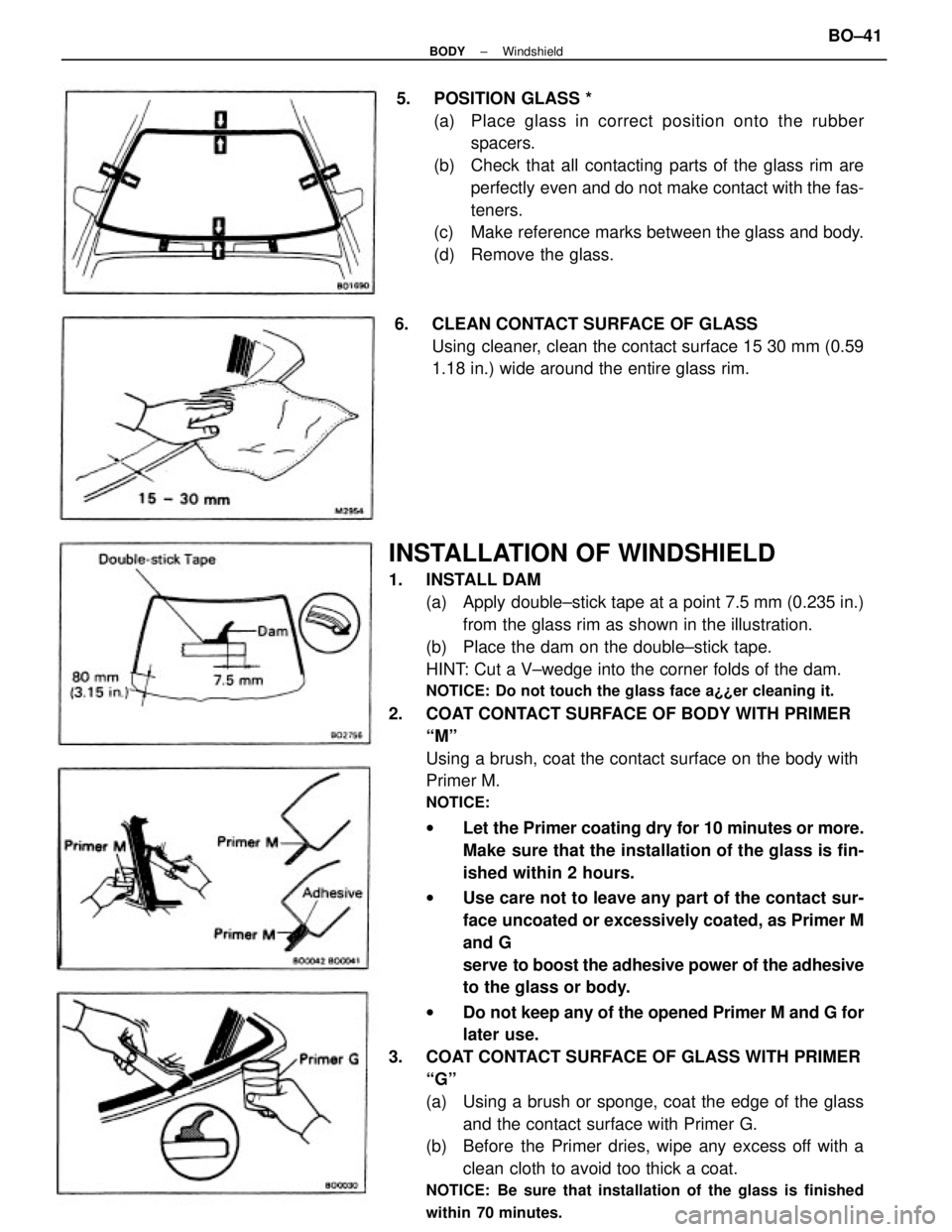

INSTALLATION OF WINDSHIELD

1. INSTALL DAM

(a) Apply double±stick tape at a point 7.5 mm (0.235 in.)

from the glass rim as shown in the illustration.

(b) Place the dam on the double±stick tape.

HINT: Cut a V±wedge into the corner folds of the dam.

NOTICE: Do not touch the glass face a¿¿er cleaning it.

2. COAT CONTACT SURFACE OF BODY WITH PRIMER

ªMº

Using a brush, coat the contact surface on the body with

Primer M.

NOTICE:

wLet the Primer coating dry for 10 minutes or more.

Make sure that the installation of the glass is fin-

ished within 2 hours.

wUse care not to leave any part of the contact sur-

face uncoated or excessively coated, as Primer M

and G

serve to boost the adhesive power of the adhesive

to the glass or body.

wDo not keep any of the opened Primer M and G for

later use.

3. COAT CONTACT SURFACE OF GLASS WITH PRIMER

ªGº

(a) Using a brush or sponge, coat the edge of the glass

and the contact surface with Primer G.

(b) Before the Primer dries, wipe any excess off with a

clean cloth to avoid too thick a coat.

NOTICE: Be sure that installation of the glass is finished

within 70 minutes.

5. POSITION GLASS *

(a) Place glass in correct position onto the rubber

spacers.

(b) Check that all contacting parts of the glass rim are

perfectly even and do not make contact with the fas-

teners.

(c) Make reference marks between the glass and body.

(d) Remove the glass.

6. CLEAN CONTACT SURFACE OF GLASS

Using cleaner, clean the contact surface 15 30 mm (0.59

1.18 in.) wide around the entire glass rim.

± BODYWindshieldBO±41

Page 708 of 2389

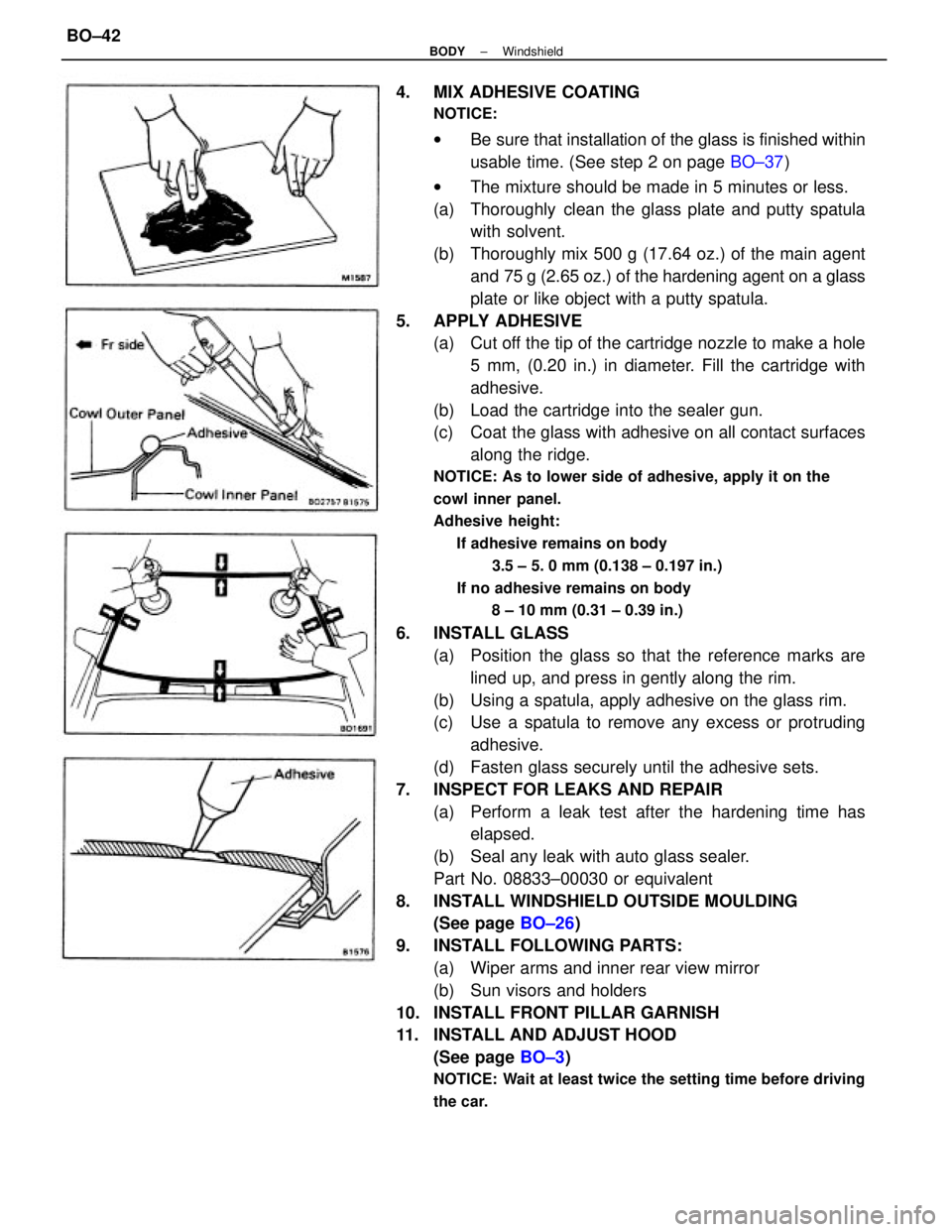

4. MIX ADHESIVE COATING

NOTICE:

wBe sure that installation of the glass is finished within

usable time. (See step 2 on page BO±37)

wThe mixture should be made in 5 minutes or less.

(a) Thoroughly clean the glass plate and putty spatula

with solvent.

(b) Thoroughly mix 500 g (17.64 oz.) of the main agent

and 75 g (2.65 oz.) of the hardening agent on a glass

plate or like object with a putty spatula.

5. APPLY ADHESIVE

(a) Cut off the tip of the cartridge nozzle to make a hole

5 mm, (0.20 in.) in diameter. Fill the cartridge with

adhesive.

(b) Load the cartridge into the sealer gun.

(c) Coat the glass with adhesive on all contact surfaces

along the ridge.

NOTICE: As to lower side of adhesive, apply it on the

cowl inner panel.

Adhesive height:

If adhesive remains on body

3.5 ± 5. 0 mm (0.138 ± 0.197 in.)

If no adhesive remains on body

8 ± 10 mm (0.31 ± 0.39 in.)

6. INSTALL GLASS

(a) Position the glass so that the reference marks are

lined up, and press in gently along the rim.

(b) Using a spatula, apply adhesive on the glass rim.

(c) Use a spatula to remove any excess or protruding

adhesive.

(d) Fasten glass securely until the adhesive sets.

7. INSPECT FOR LEAKS AND REPAIR

(a) Perform a leak test after the hardening time has

elapsed.

(b) Seal any leak with auto glass sealer.

Part No. 08833±00030 or equivalent

8. INSTALL WINDSHIELD OUTSIDE MOULDING

(See page BO±26)

9. INSTALL FOLLOWING PARTS:

(a) Wiper arms and inner rear view mirror

(b) Sun visors and holders

10. INSTALL FRONT PILLAR GARNISH

11. INSTALL AND ADJUST HOOD

(See page BO±3)

NOTICE: Wait at least twice the setting time before driving

the car.

± BODYWindshieldBO±42

Page 709 of 2389

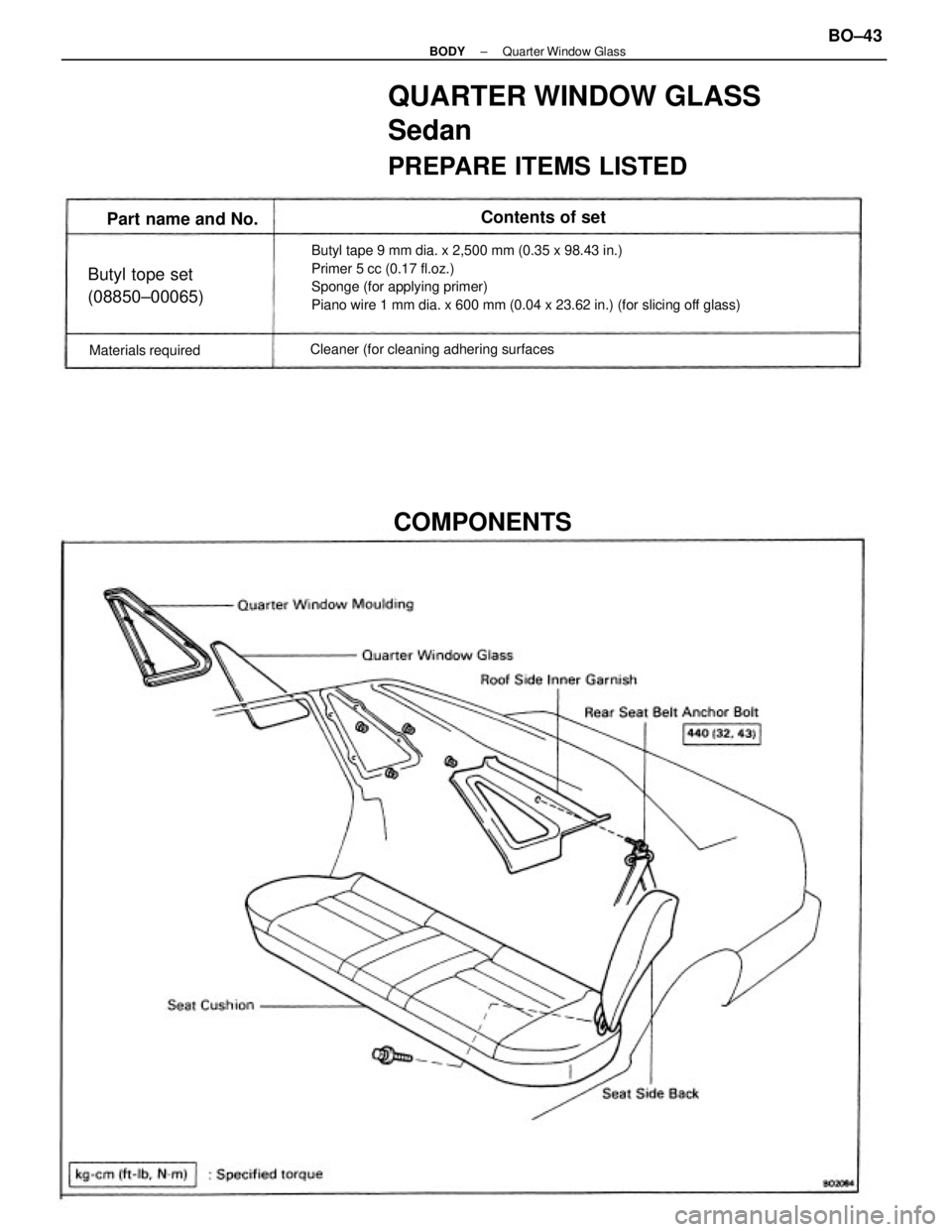

Butyl tape 9 mm dia. x 2,500 mm (0.35 x 98.43 in.)

Primer 5 cc (0.17 fl.oz.)

Sponge (for applying primer)

Piano wire 1 mm dia. x 600 mm (0.04 x 23.62 in.) (for slicing off glass)

QUARTER WINDOW GLASS

Sedan

PREPARE ITEMS LISTED

Cleaner (for cleaning adhering surfaces

Butyl tope set

(08850±00065)

COMPONENTS

Materials required

Part name and No.Contents of set

± BODYQuarter Window GlassBO±43

Page 710 of 2389

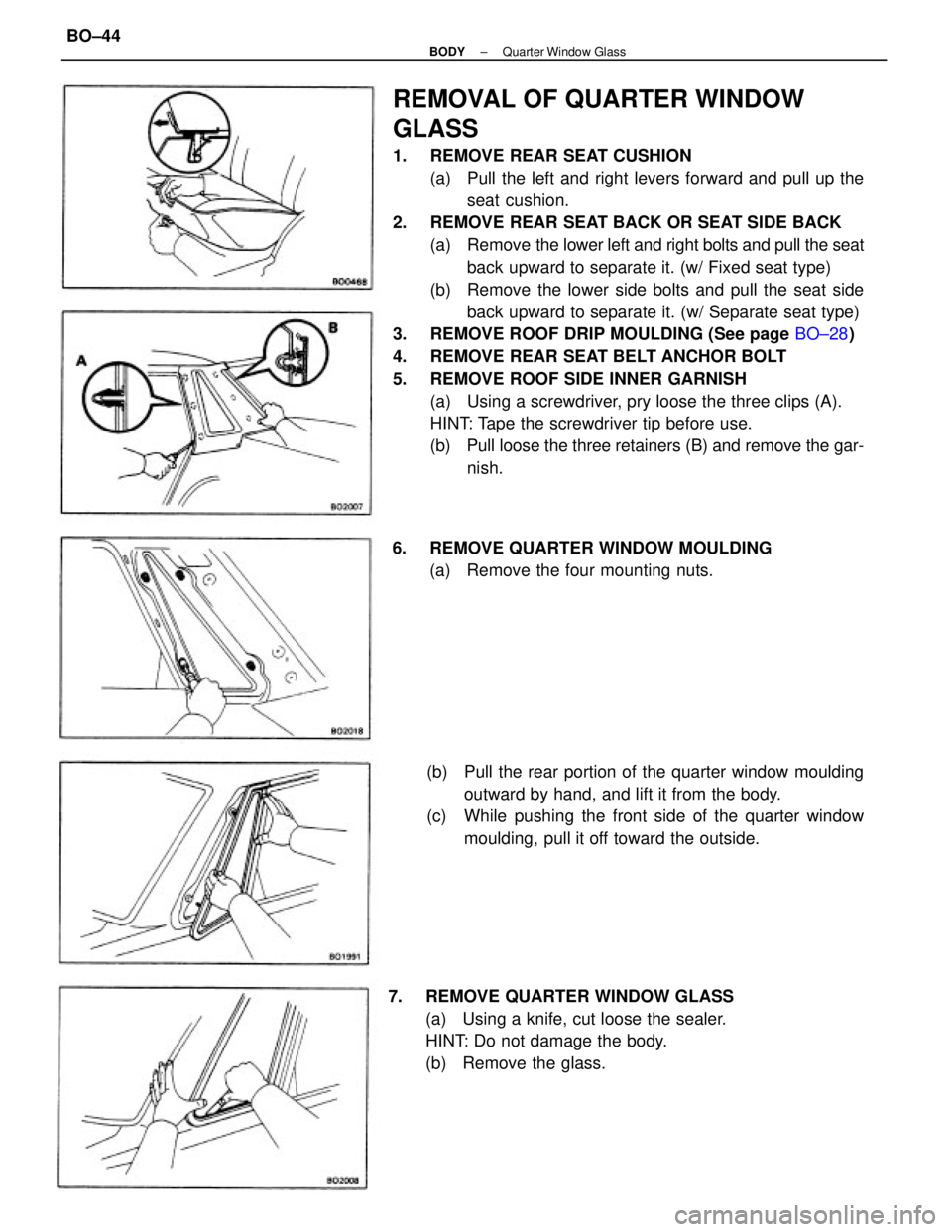

REMOVAL OF QUARTER WINDOW

GLASS

1. REMOVE REAR SEAT CUSHION

(a) Pull the left and right levers forward and pull up the

seat cushion.

2. REMOVE REAR SEAT BACK OR SEAT SIDE BACK

(a) Remove the lower left and right bolts and pull the seat

back upward to separate it. (w/ Fixed seat type)

(b) Remove the lower side bolts and pull the seat side

back upward to separate it. (w/ Separate seat type)

3. REMOVE ROOF DRIP MOULDING (See page BO±28)

4. REMOVE REAR SEAT BELT ANCHOR BOLT

5. REMOVE ROOF SIDE INNER GARNISH

(a) Using a screwdriver, pry loose the three clips (A).

HINT: Tape the screwdriver tip before use.

(b) Pull loose the three retainers (B) and remove the gar-

nish.

(b) Pull the rear portion of the quarter window moulding

outward by hand, and lift it from the body.

(c) While pushing the front side of the quarter window

moulding, pull it off toward the outside.

7. REMOVE QUARTER WINDOW GLASS

(a) Using a knife, cut loose the sealer.

HINT: Do not damage the body.

(b) Remove the glass. 6. REMOVE QUARTER WINDOW MOULDING

(a) Remove the four mounting nuts.

± BODYQuarter Window GlassBO±44