TOYOTA CAMRY V20 1986 Service Information

Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 771 of 2389

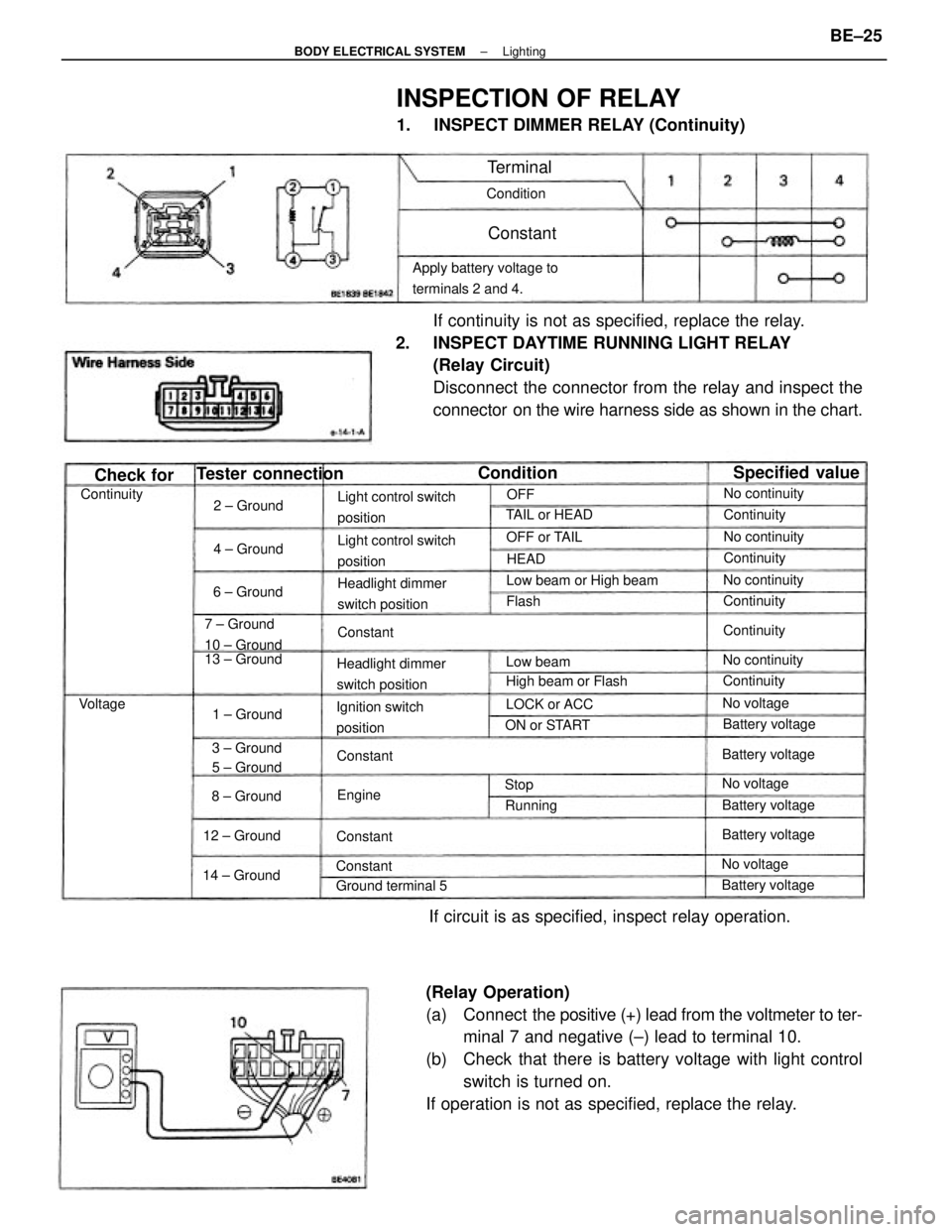

(Relay Operation)

(a) Connect the positive (+) lead from the voltmeter to ter-

minal 7 and negative (±) lead to terminal 10.

(b) Check that there is battery voltage with light control

switch is turned on.

If operation is not as specified, replace the relay.If continuity is not as specified, replace the relay.

2. INSPECT DAYTIME RUNNING LIGHT RELAY

(Relay Circuit)

Disconnect the connector from the relay and inspect the

connector on the wire harness side as shown in the chart.

INSPECTION OF RELAY

1. INSPECT DIMMER RELAY (Continuity)

If circuit is as specified, inspect relay operation.

Apply battery voltage to

terminals 2 and 4.

Light control switch

position

Light control switch

position

Headlight dimmer

switch positionHeadlight dimmer

switch positionLow beam or High beam

Ignition switch

position 7 ± Ground

10 ± Ground

High beam or Flash 13 ± Ground

3 ± Ground

5 ± Ground

Tester connection

Ground terminal 5

Specified value

Battery voltageBattery voltageBattery voltage

Battery voltage Battery voltageNo continuity

No continuity TAIL or HEADNo continuity

No continuity

14 ± Ground12 ± GroundON or STARTLOCK or ACC

1 ± GroundOFF or TAIL

8 ± Ground2 ± Ground

6 ± Ground4 ± Ground

No voltage

No voltage

No voltageContinuity

Continuity Continuity

Continuity

ContinuityContinuity

Condition

Check for

Low beam Condition

Running

Terminal

Constant

Constant

Constant

Constant

Constant Voltage

EngineHEAD

Flash

StopOFF

± BODY ELECTRICAL SYSTEMLightingBE±25

Page 772 of 2389

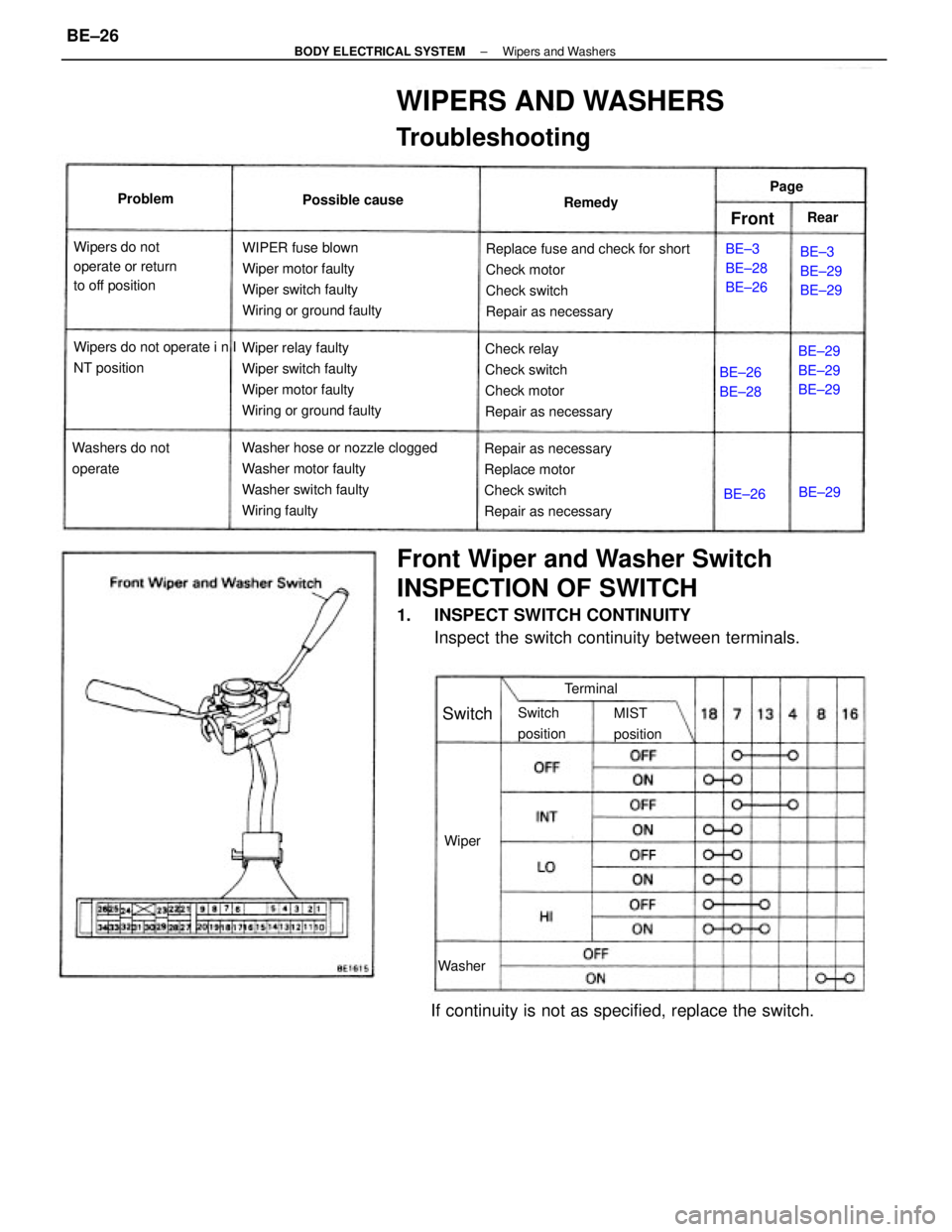

Front Wiper and Washer Switch

INSPECTION OF SWITCH

1. INSPECT SWITCH CONTINUITY

Inspect the switch continuity between terminals.

WIPERS AND WASHERS

Troubleshooting

Replace fuse and check for short

Check motor

Check switch

Repair as necessary

Washer hose or nozzle clogged

Washer motor faulty

Washer switch faulty

Wiring faultyWIPER fuse blown

Wiper motor faulty

Wiper switch faulty

Wiring or ground faulty

Wiper relay faulty

Wiper switch faulty

Wiper motor faulty

Wiring or ground faulty

Repair as necessary

Replace motor

Check switch

Repair as necessaryCheck relay

Check switch

Check motor

Repair as necessary

If continuity is not as specified, replace the switch.

Wipers do not

operate or return

to off position

Wipers do not operate i n I

NT position

Washers do not

operateBE±29

BE±29

BE±29BE±3

BE±29

BE±29 BE±3

BE±28

BE±26 Possible cause

BE±26

BE±28

Switch

positionMIST

position Terminal Remedy Problem

Washer

Switch

WiperBE±26BE±29 Page

FrontRear

± BODY ELECTRICAL SYSTEMWipers and WashersBE±26

Page 773 of 2389

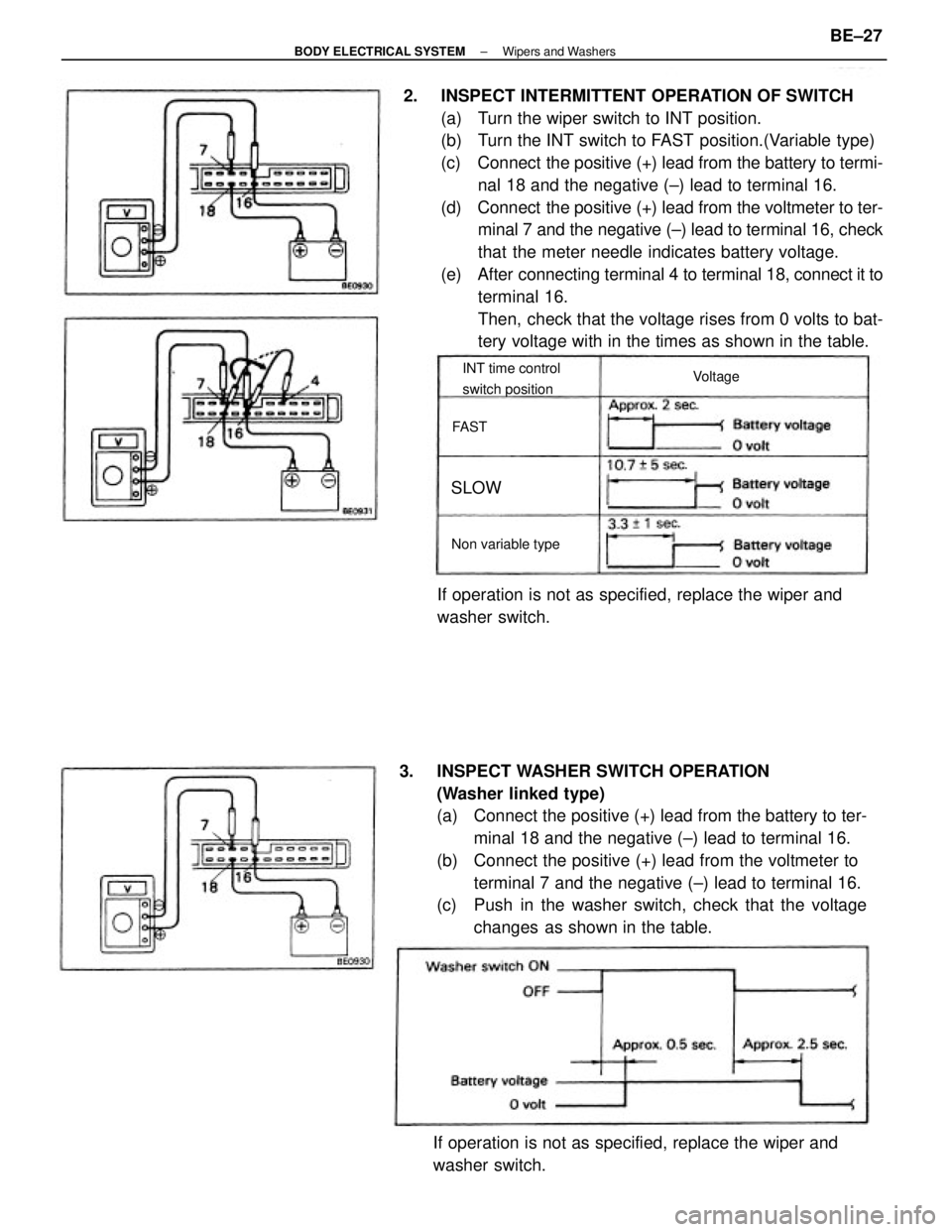

2. INSPECT INTERMITTENT OPERATION OF SWITCH

(a) Turn the wiper switch to INT position.

(b) Turn the INT switch to FAST position.(Variable type)

(c) Connect the positive (+) lead from the battery to termi-

nal 18 and the negative (±) lead to terminal 16.

(d) Connect the positive (+) lead from the voltmeter to ter-

minal 7 and the negative (±) lead to terminal 16, check

that the meter needle indicates battery voltage.

(e) After connecting terminal 4 to terminal 18, connect it to

terminal 16.

Then, check that the voltage rises from 0 volts to bat-

tery voltage with in the times as shown in the table.

3. INSPECT WASHER SWITCH OPERATION

(Washer linked type)

(a) Connect the positive (+) lead from the battery to ter-

minal 18 and the negative (±) lead to terminal 16.

(b) Connect the positive (+) lead from the voltmeter to

terminal 7 and the negative (±) lead to terminal 16.

(c) Push in the washer switch, check that the voltage

changes as shown in the table.

If operation is not as specified, replace the wiper and

washer switch.If operation is not as specified, replace the wiper and

washer switch.

INT time control

switch position

Non variable typeVoltage

SLOW

FAST

± BODY ELECTRICAL SYSTEMWipers and WashersBE±27

Page 774 of 2389

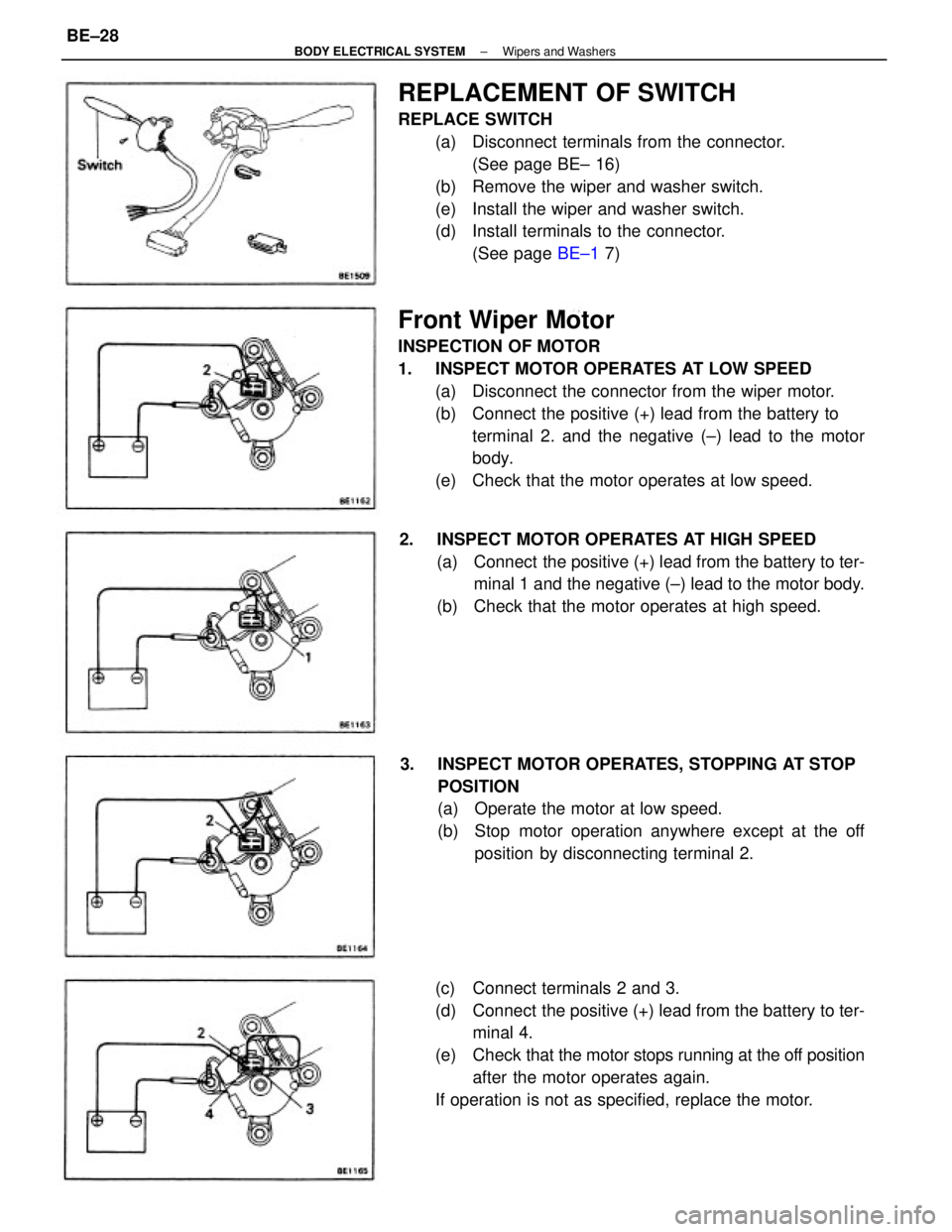

Front Wiper Motor

INSPECTION OF MOTOR

1. INSPECT MOTOR OPERATES AT LOW SPEED

(a) Disconnect the connector from the wiper motor.

(b) Connect the positive (+) lead from the battery to

terminal 2. and the negative (±) lead to the motor

body.

(e) Check that the motor operates at low speed.

REPLACEMENT OF SWITCH

REPLACE SWITCH

(a) Disconnect terminals from the connector.

(See page BE± 16)

(b) Remove the wiper and washer switch.

(e) Install the wiper and washer switch.

(d) Install terminals to the connector.

(See page BE±1 7)

(c) Connect terminals 2 and 3.

(d) Connect the positive (+) lead from the battery to ter-

minal 4.

(e) Check that the motor stops running at the off position

after the motor operates again.

If operation is not as specified, replace the motor. 3. INSPECT MOTOR OPERATES, STOPPING AT STOP

POSITION

(a) Operate the motor at low speed.

(b) Stop motor operation anywhere except at the off

position by disconnecting terminal 2. 2. INSPECT MOTOR OPERATES AT HIGH SPEED

(a) Connect the positive (+) lead from the battery to ter-

minal 1 and the negative (±) lead to the motor body.

(b) Check that the motor operates at high speed.

± BODY ELECTRICAL SYSTEMWipers and WashersBE±28

Page 775 of 2389

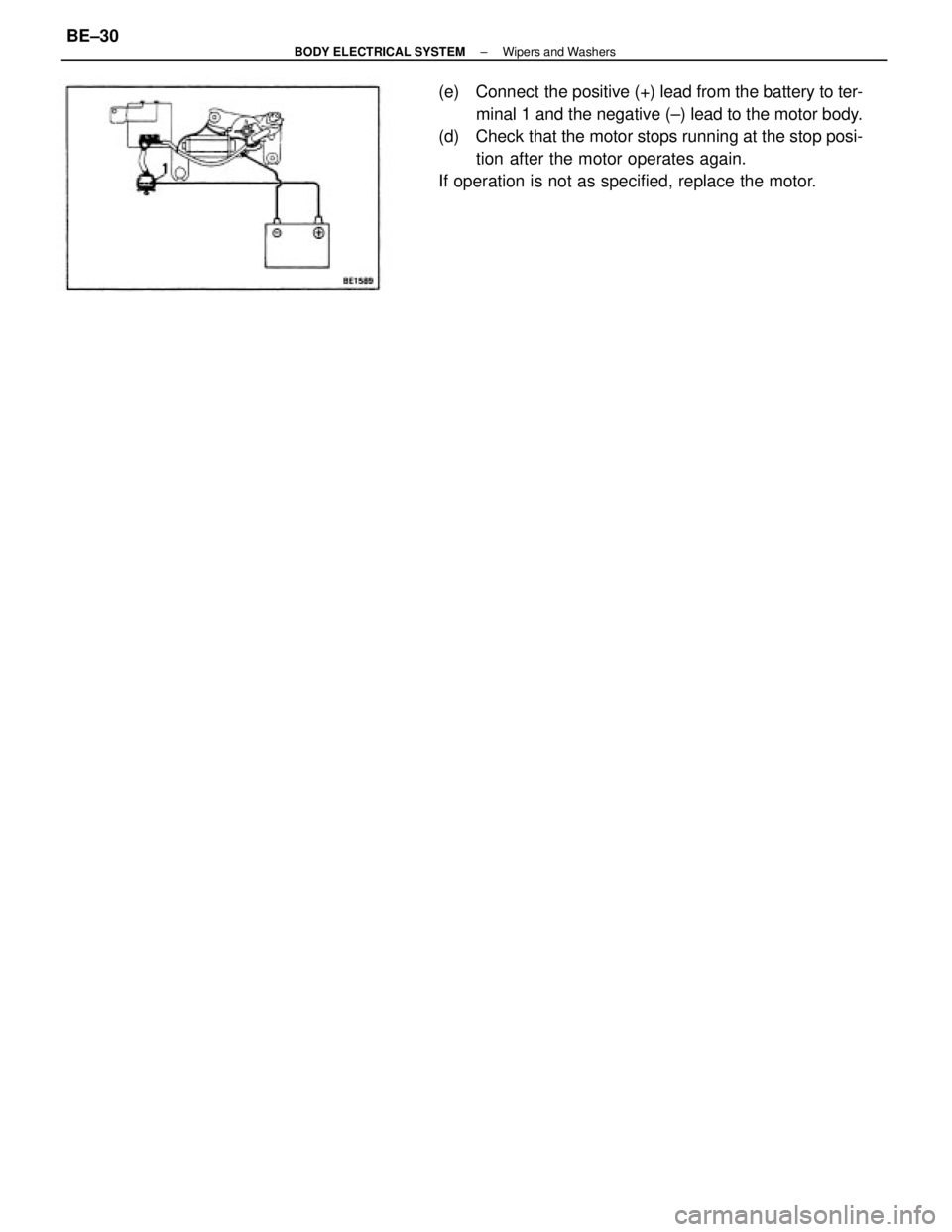

Rear Wiper Motor and Relay

INSPECTION OF MOTOR AND RELAY

1. INSPECT RELAY AND MOTOR OPERATES

(a) Connect the positive (+) lead from the battery to terminal

1 and negative (±) leads to both terminal 3 and

motor body.

(b) Check that the motor operates.

2. INSPECT INTERMITTENT OPERATION OF RELAY

(a) Connect the positive 1+y lead from the battery to ter-

minal 1 and negative t±) leads to both terminal 2 and

motor body.

(b) Check that the motor operates intermittently for 9

15 seconds.

If operation is not as specified, replace the relay.

3. INSPECT MOTOR OPERATES, STOPPING AT STOP

POSITION

(a) Start motor operation by connecting the positive (+j

lead from the battery to terminal 1 and the negative (±

lead to both terminal 3 and motor body.

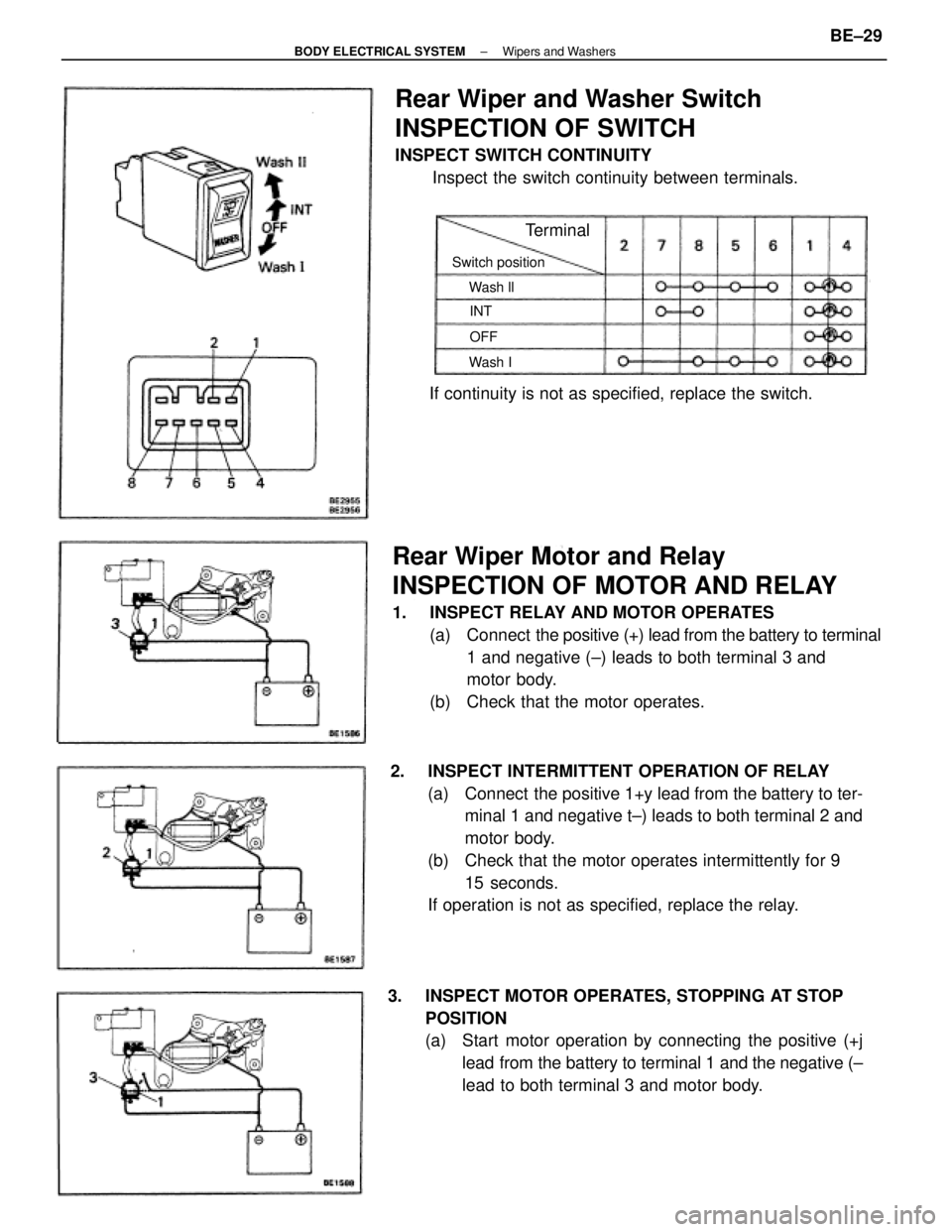

Rear Wiper and Washer Switch

INSPECTION OF SWITCH

INSPECT SWITCH CONTINUITY

Inspect the switch continuity between terminals.

If continuity is not as specified, replace the switch.

Switch position

Terminal

Wash ll

Wash IOFF INT

± BODY ELECTRICAL SYSTEMWipers and WashersBE±29

Page 776 of 2389

(e) Connect the positive (+) lead from the battery to ter-

minal 1 and the negative (±) lead to the motor body.

(d) Check that the motor stops running at the stop posi-

tion after the motor operates again.

If operation is not as specified, replace the motor.

± BODY ELECTRICAL SYSTEMWipers and WashersBE±30

Page 777 of 2389

Replace fuse and check for short

Replace bulb

Check switch

Check switch

Check switch

Check relay

Repair a s necessary ºDOMEº fuse blown

Bulb burned out

Door courtesy switch faulty

Unlock warning switch faulty

Buckle switch faulty

Seat belt warning relay faulty

Wiring or ground faultyºGAUGEº fuse blown

Bulb burned out

Brake fluid level warning switch faulty

Parking brake switch faulty

Wiring or ground faultyReplace fuse and check for short

Replace bulb

Check switch

Check switch

Repair as necessary ºGAUGEº fuse blown

Water temperature gauge faulty

Water temperature sender gauge faulty

Wiring or ground faulty

ºGAUGEº fuse blown

Buibburned out

oil pressure warning switch faulty

Wiring or ground faultyºGAUGEº fuse blown

Bulb burned out

Fuel level warning switch faulty

Wiring or ground faulty

Replace fuse and check for short

Replace bulb

Check switch

±Repair as necessaryReplace fuse and check for short

Replace bulb

Check switch

Repair as necessary

Replace fuse and check for short

Replace bulb

Check switch

Repair as necessaryReplace fuse and check for short

Check gauge

Check sender gauge

Repair as necessaryReplace fuse .and check for short

Check gauge

Check sender gauge

Repair as necessary

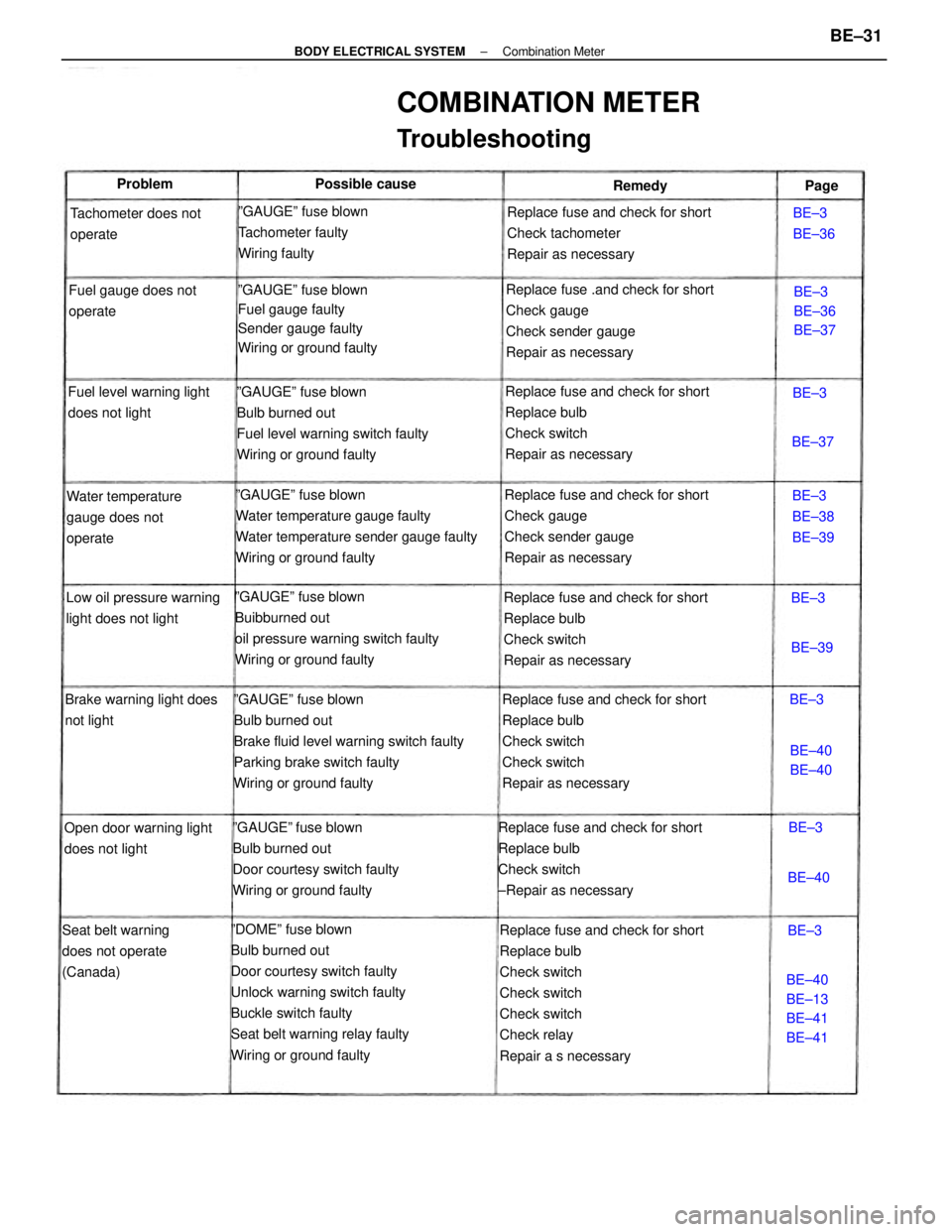

COMBINATION METER

Troubleshooting

ºGAUGEº fuse blown

Bulb burned out

Door courtesy switch faulty

Wiring or ground faultyReplace fuse and check for short

Check tachometer

Repair as necessary

ºGAUGEº fuse blown

Fuel gauge faulty

Sender gauge faulty

Wiring or ground faultyºGAUGEº fuse blown

Tachometer faulty

Wiring faulty

Low oil pressure warning

light does not lightWater temperature

gauge does not

operate

Seat belt warning

does not operate

(Canada)Tachometer does not

operate

Brake warning light does

not lightFuel gauge does not

operate

Open door warning light

does not lightFuel level warning light

does not light

BE±40

BE±13

BE±41

BE±41BE±3

BE±38

BE±39BE±3

BE±36

BE±37 Possible cause

BE±3

BE±36

BE±40

BE±40 Problem

Remedy

BE±40BE±39BE±37Page

BE±3BE±3

BE±3

BE±3

BE±3

± BODY ELECTRICAL SYSTEMCombination MeterBE±31

Page 778 of 2389

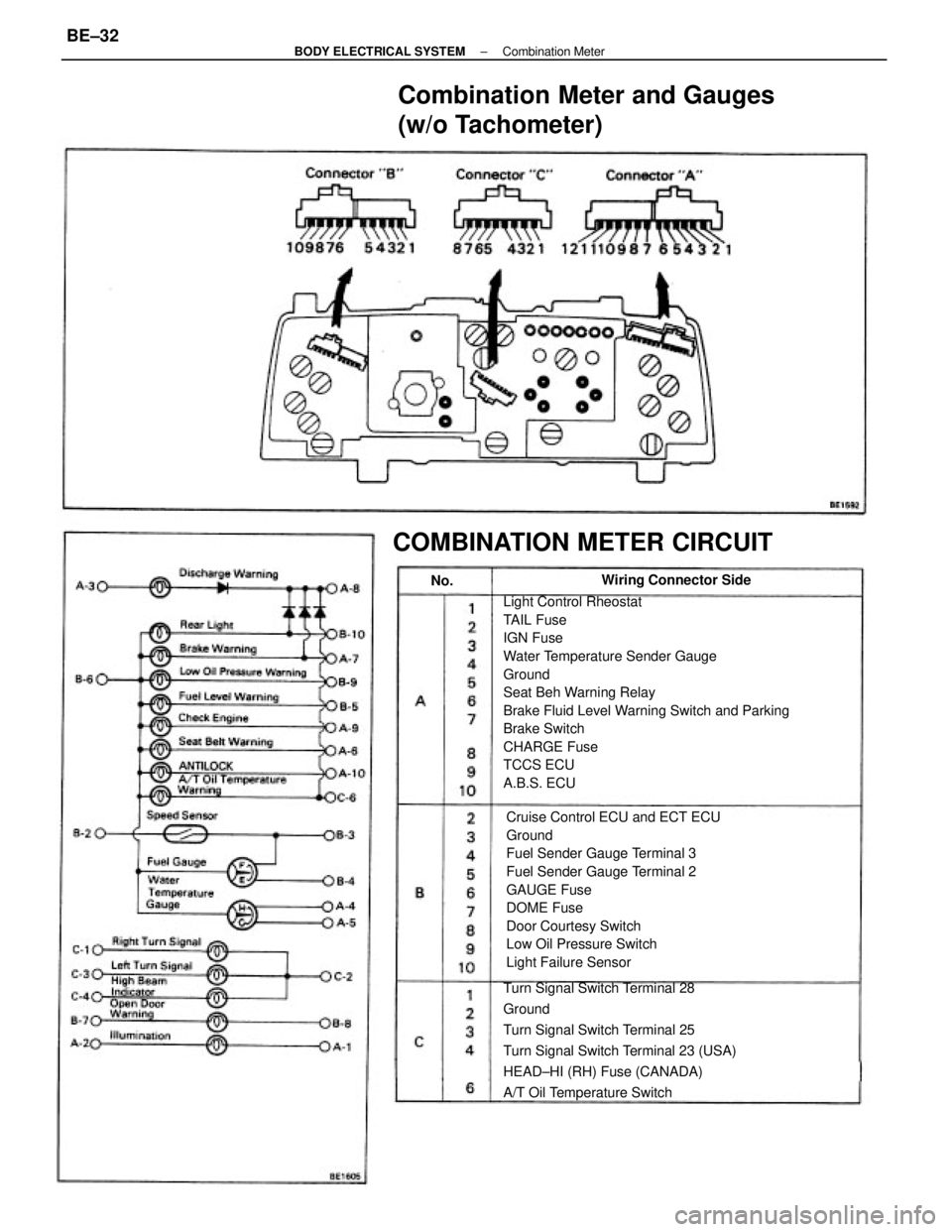

Light Control Rheostat

TAIL Fuse

IGN Fuse

Water Temperature Sender Gauge

Ground

Seat Beh Warning Relay

Brake Fluid Level Warning Switch and Parking

Brake Switch

CHARGE Fuse

TCCS ECU

A.B.S. ECU

Cruise Control ECU and ECT ECU

Ground

Fuel Sender Gauge Terminal 3

Fuel Sender Gauge Terminal 2

GAUGE Fuse

DOME Fuse

Door Courtesy Switch

Low Oil Pressure Switch

Light Failure Sensor

Combination Meter and Gauges

(w/o Tachometer)

Turn Signal Switch Terminal 28

Ground

Turn Signal Switch Terminal 25

Turn Signal Switch Terminal 23 (USA)

HEAD±HI (RH) Fuse (CANADA)

A/T Oil Temperature Switch

COMBINATION METER CIRCUIT

Wiring Connector Side

No.

± BODY ELECTRICAL SYSTEMCombination MeterBE±32

Page 779 of 2389

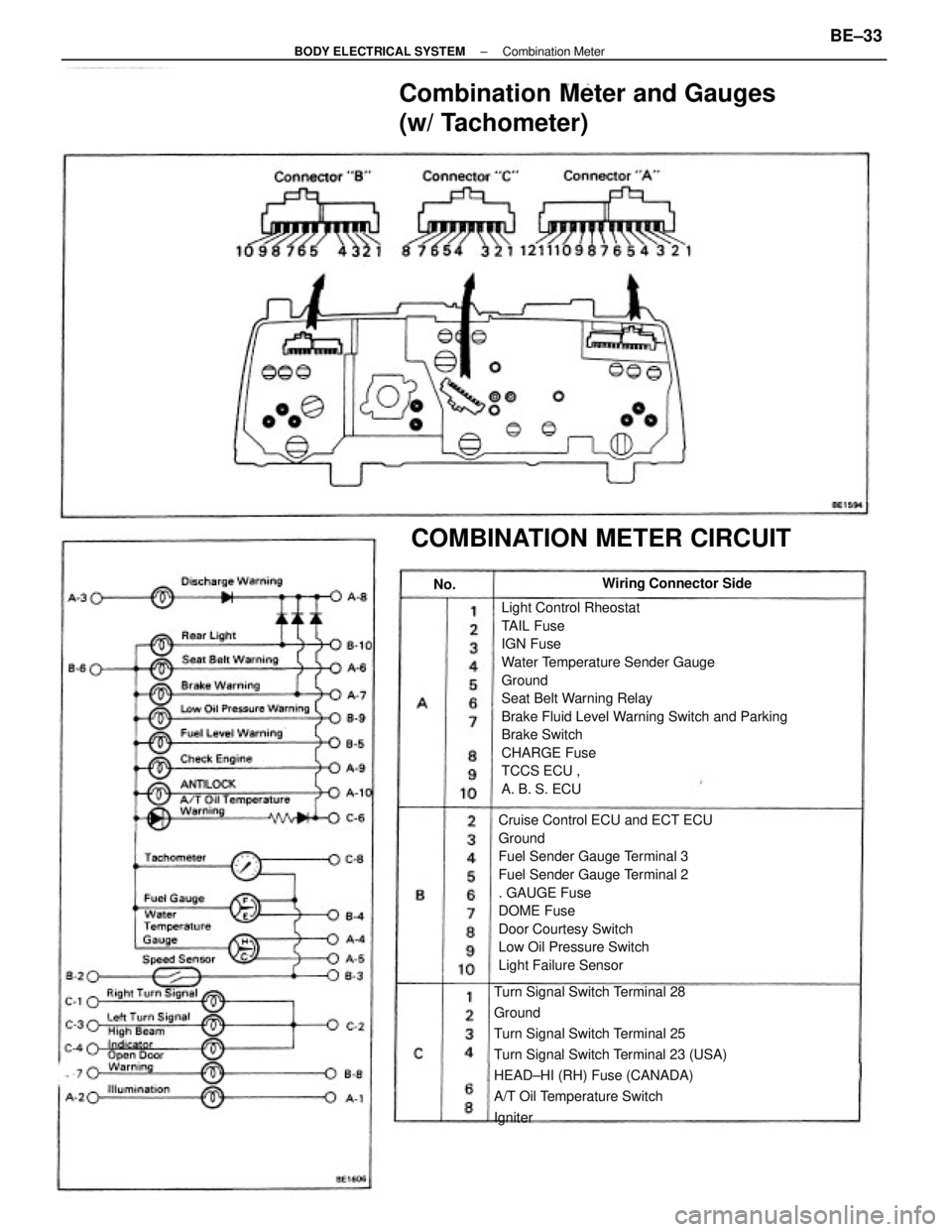

Light Control Rheostat

TAIL Fuse

IGN Fuse

Water Temperature Sender Gauge

Ground

Seat Belt Warning Relay

Brake Fluid Level Warning Switch and Parking

Brake Switch

CHARGE Fuse

TCCS ECU ,

A. B. S. ECU

Cruise Control ECU and ECT ECU

Ground

Fuel Sender Gauge Terminal 3

Fuel Sender Gauge Terminal 2

. GAUGE Fuse

DOME Fuse

Door Courtesy Switch

Low Oil Pressure Switch

Light Failure Sensor

Turn Signal Switch Terminal 28

Ground

Turn Signal Switch Terminal 25

Turn Signal Switch Terminal 23 (USA)

HEAD±HI (RH) Fuse (CANADA)

A/T Oil Temperature Switch

Igniter

Combination Meter and Gauges

(w/ Tachometer)

COMBINATION METER CIRCUIT

Wiring Connector Side

No.

± BODY ELECTRICAL SYSTEMCombination MeterBE±33

Page 780 of 2389

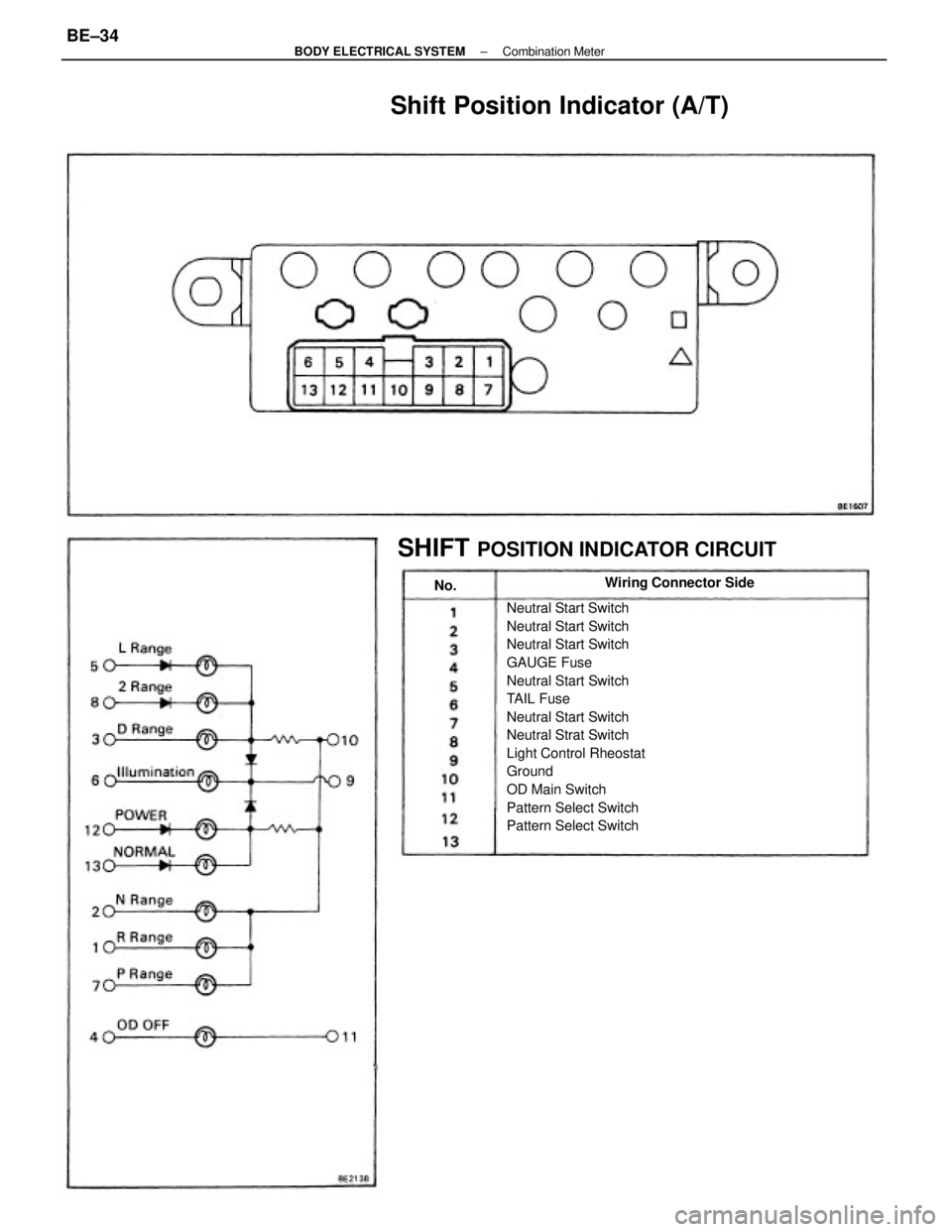

Neutral Start Switch

Neutral Start Switch

Neutral Start Switch

GAUGE Fuse

Neutral Start Switch

TAIL Fuse

Neutral Start Switch

Neutral Strat Switch

Light Control Rheostat

Ground

OD Main Switch

Pattern Select Switch

Pattern Select Switch

Shift Position Indicator (A/T)

SHIFT

POSITION INDICATOR CIRCUIT

Wiring Connector Side

No.

± BODY ELECTRICAL SYSTEMCombination MeterBE±34