TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006,

Model line: RAV4,

Model: TOYOTA RAV4 2006

Pages: 2000, PDF Size: 45.84 MB

TOYOTA RAV4 2006 Service Repair Manual

RAV4 2006

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57463/w960_57463-0.png

TOYOTA RAV4 2006 Service Repair Manual

Trending: automatic transmission, rese, headlight, park assist, Control arm, fuel consumption, check oil

Page 1121 of 2000

U151E AUTOMATIC TRANSAXLE – FORWARD CLUTCHAX–255

AX

(d) Remove the forward clutch return spring from the

input shaft.

4. REMOVE FORWARD CLUTCH RETURN SPRING

SUB-ASSEMBLY

(a) Place the forward clutch drum onto the oil pump.

(b) Holding the forward clutch piston by hand, apply

compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi) to the

oil pump to remove the forward clutch piston.

HINT:

When the piston cannot be removed because it is

slanted, blow air again with the protruding side

pushed, or remove the piston using needle nose

pliers with vinyl tape on the tip.

5. REMOVE INPUT SHAFT OIL SEAL RING

(a) Remove the input shaft oil seal ring from the input

shaft.

INSPECTION

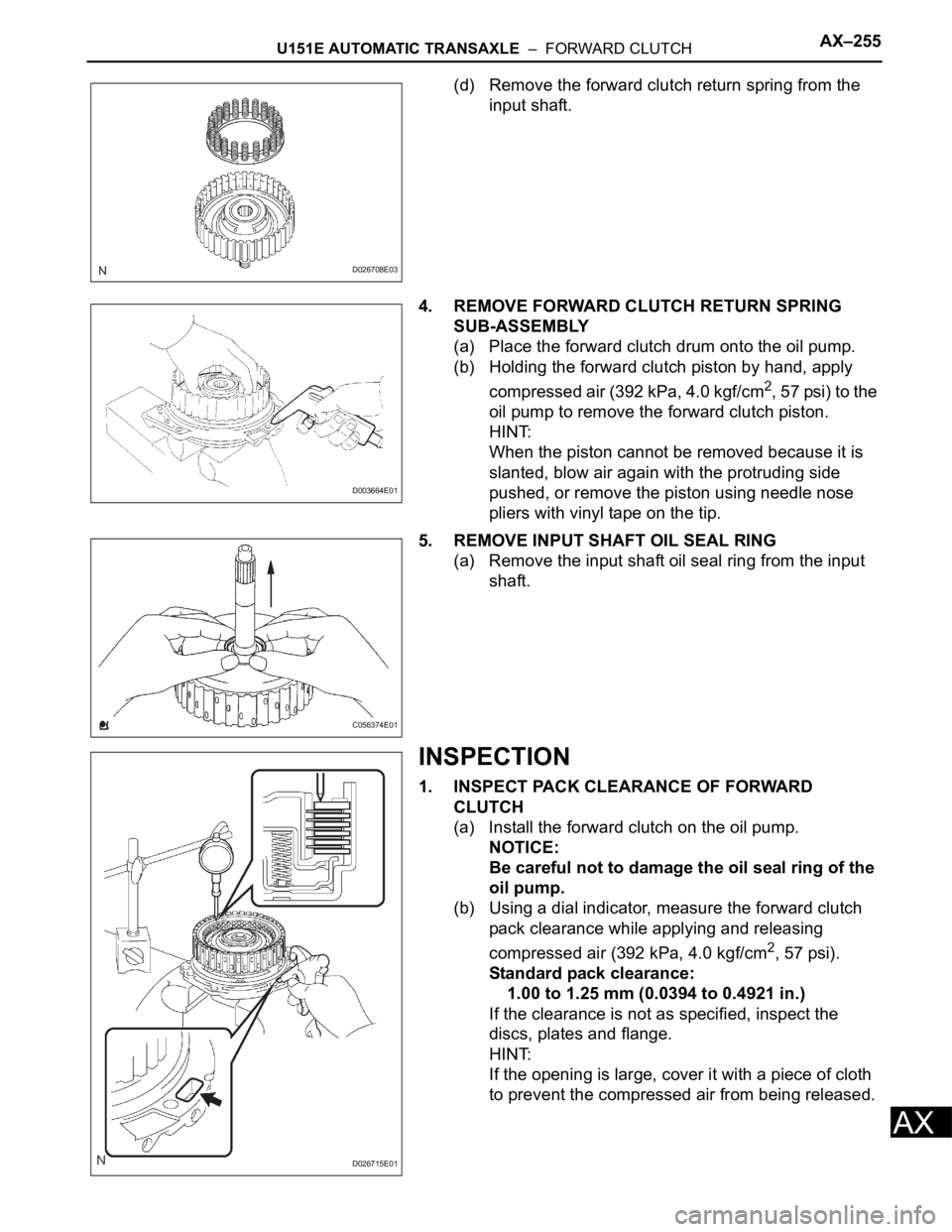

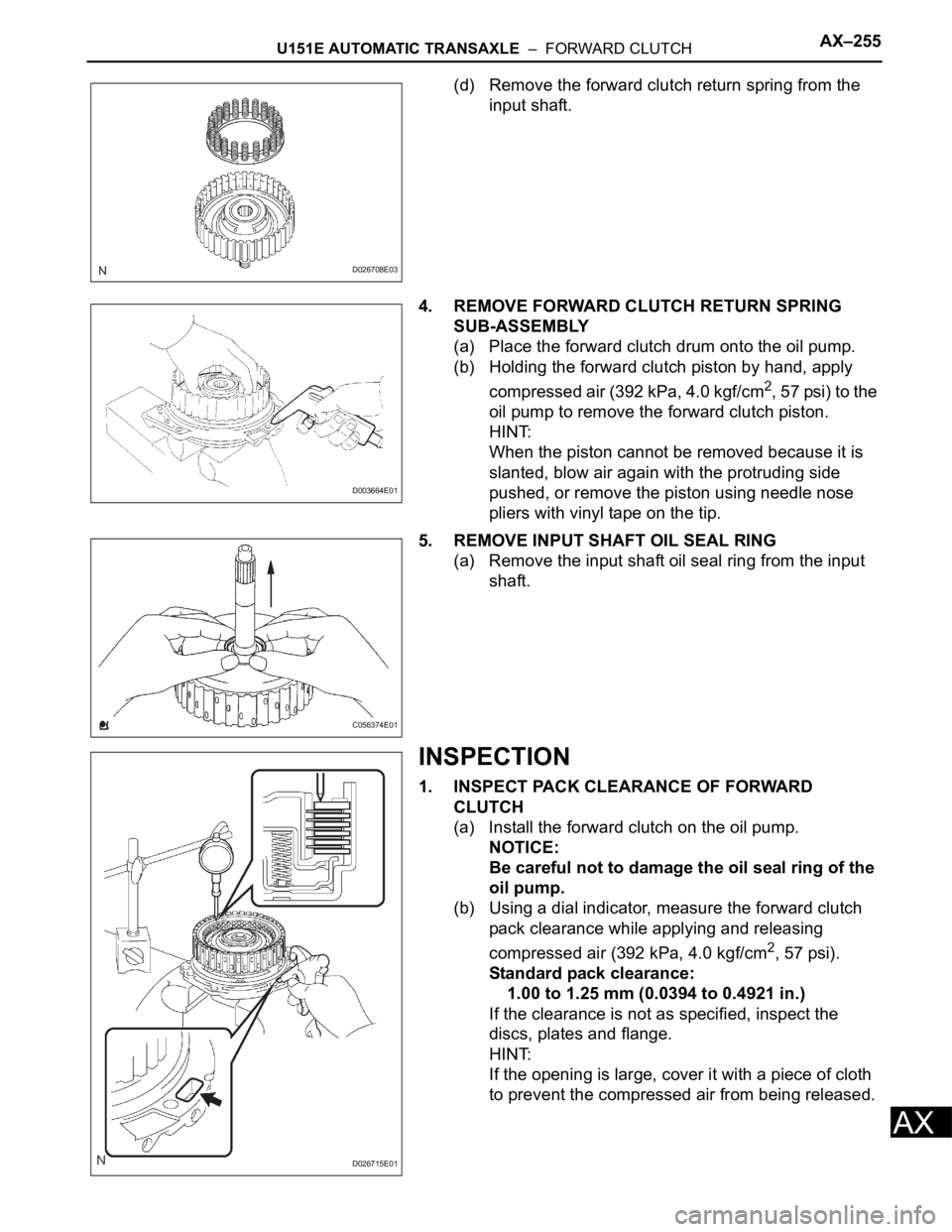

1. INSPECT PACK CLEARANCE OF FORWARD

CLUTCH

(a) Install the forward clutch on the oil pump.

NOTICE:

Be careful not to damage the oil seal ring of the

oil pump.

(b) Using a dial indicator, measure the forward clutch

pack clearance while applying and releasing

compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi).

Standard pack clearance:

1.00 to 1.25 mm (0.0394 to 0.4921 in.)

If the clearance is not as specified, inspect the

discs, plates and flange.

HINT:

If the opening is large, cover it with a piece of cloth

to prevent the compressed air from being released.

D026708E03

D003664E01

C056374E01

D026715E01

Page 1122 of 2000

AX–256U151E AUTOMATIC TRANSAXLE – FORWARD CLUTCH

AX

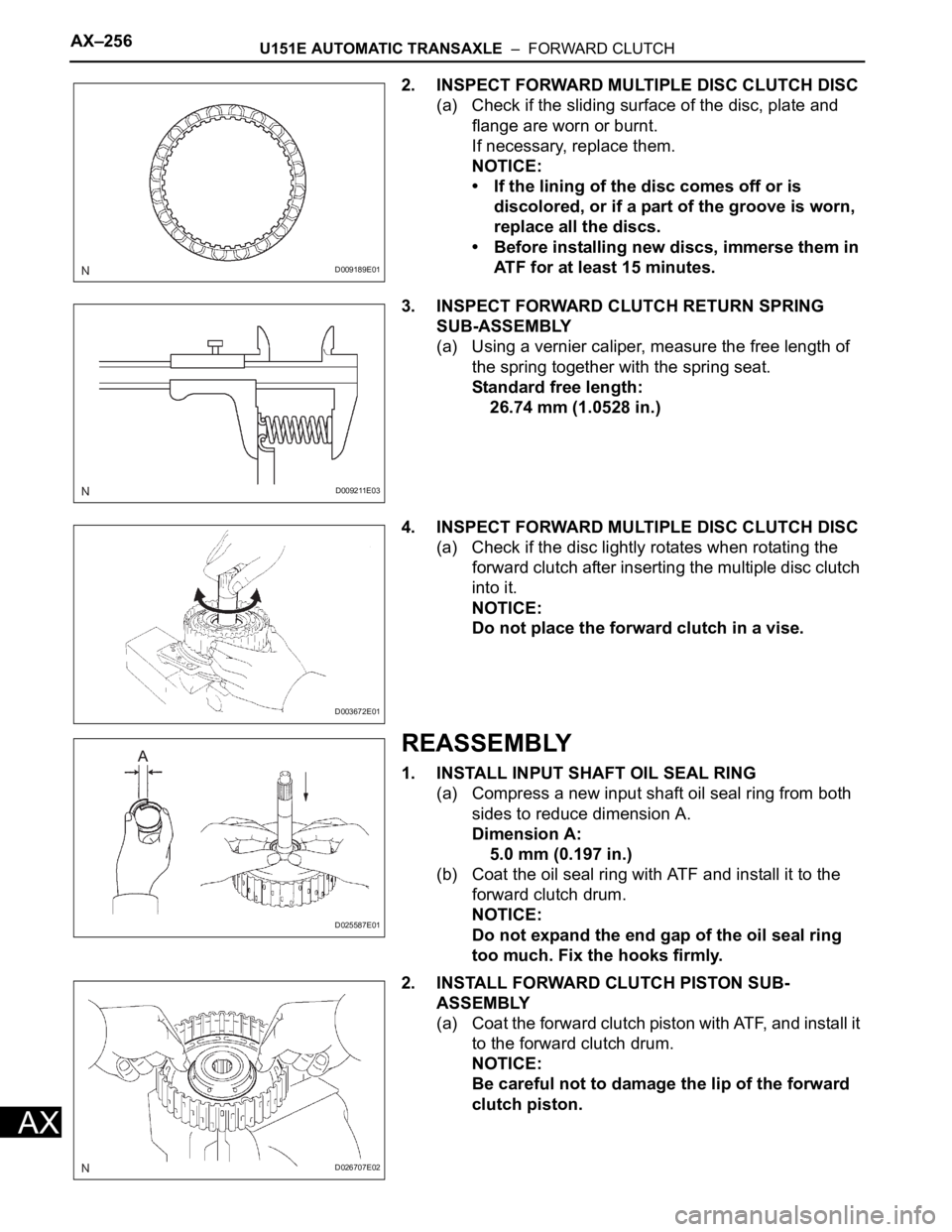

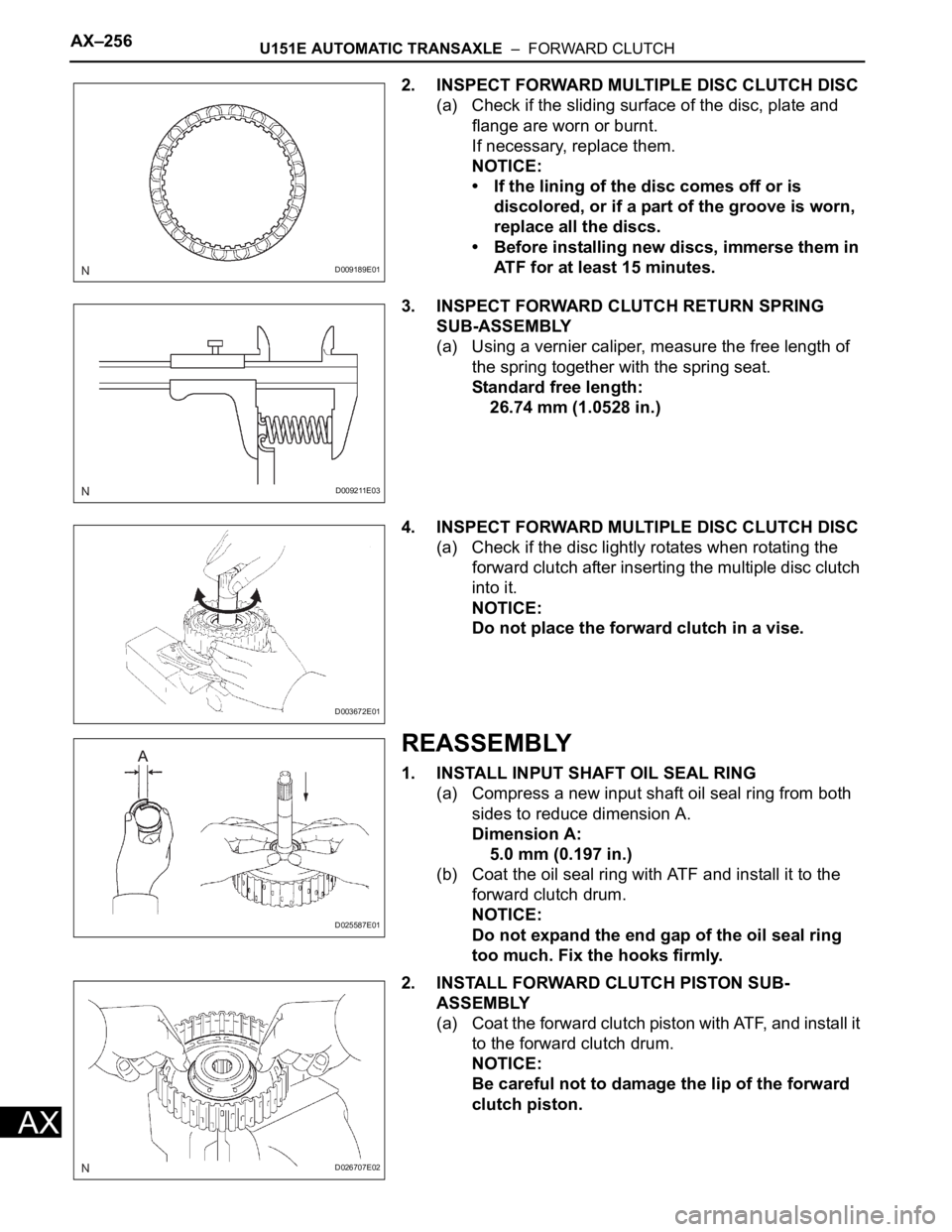

2. INSPECT FORWARD MULTIPLE DISC CLUTCH DISC

(a) Check if the sliding surface of the disc, plate and

flange are worn or burnt.

If necessary, replace them.

NOTICE:

• If the lining of the disc comes off or is

discolored, or if a part of the groove is worn,

replace all the discs.

• Before installing new discs, immerse them in

ATF for at least 15 minutes.

3. INSPECT FORWARD CLUTCH RETURN SPRING

SUB-ASSEMBLY

(a) Using a vernier caliper, measure the free length of

the spring together with the spring seat.

Standard free length:

26.74 mm (1.0528 in.)

4. INSPECT FORWARD MULTIPLE DISC CLUTCH DISC

(a) Check if the disc lightly rotates when rotating the

forward clutch after inserting the multiple disc clutch

into it.

NOTICE:

Do not place the forward clutch in a vise.

REASSEMBLY

1. INSTALL INPUT SHAFT OIL SEAL RING

(a) Compress a new input shaft oil seal ring from both

sides to reduce dimension A.

Dimension A:

5.0 mm (0.197 in.)

(b) Coat the oil seal ring with ATF and install it to the

forward clutch drum.

NOTICE:

Do not expand the end gap of the oil seal ring

too much. Fix the hooks firmly.

2. INSTALL FORWARD CLUTCH PISTON SUB-

ASSEMBLY

(a) Coat the forward clutch piston with ATF, and install it

to the forward clutch drum.

NOTICE:

Be careful not to damage the lip of the forward

clutch piston.

D009189E01

D009211E03

D003672E01

D025587E01

D026707E02

Page 1123 of 2000

U151E AUTOMATIC TRANSAXLE – FORWARD CLUTCHAX–257

AX

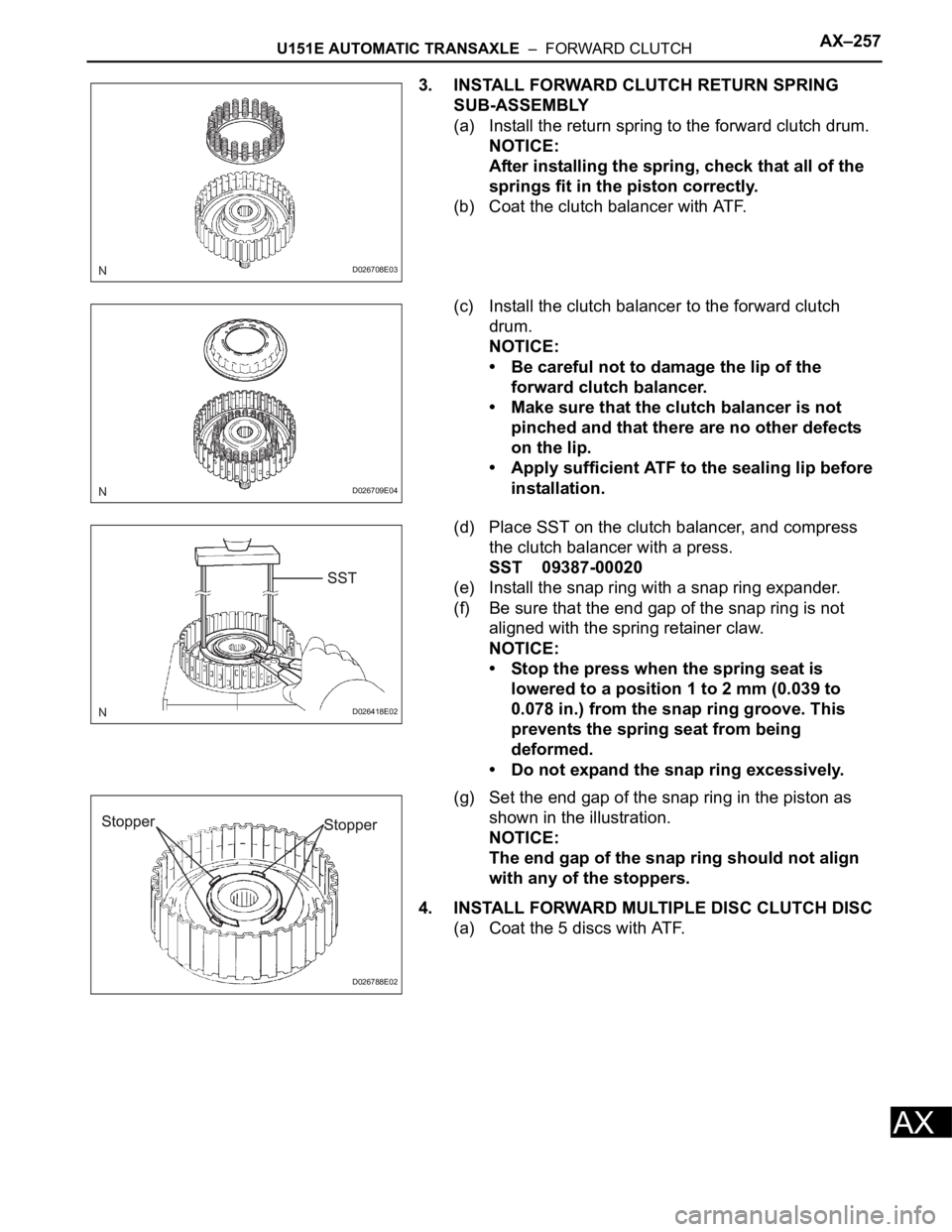

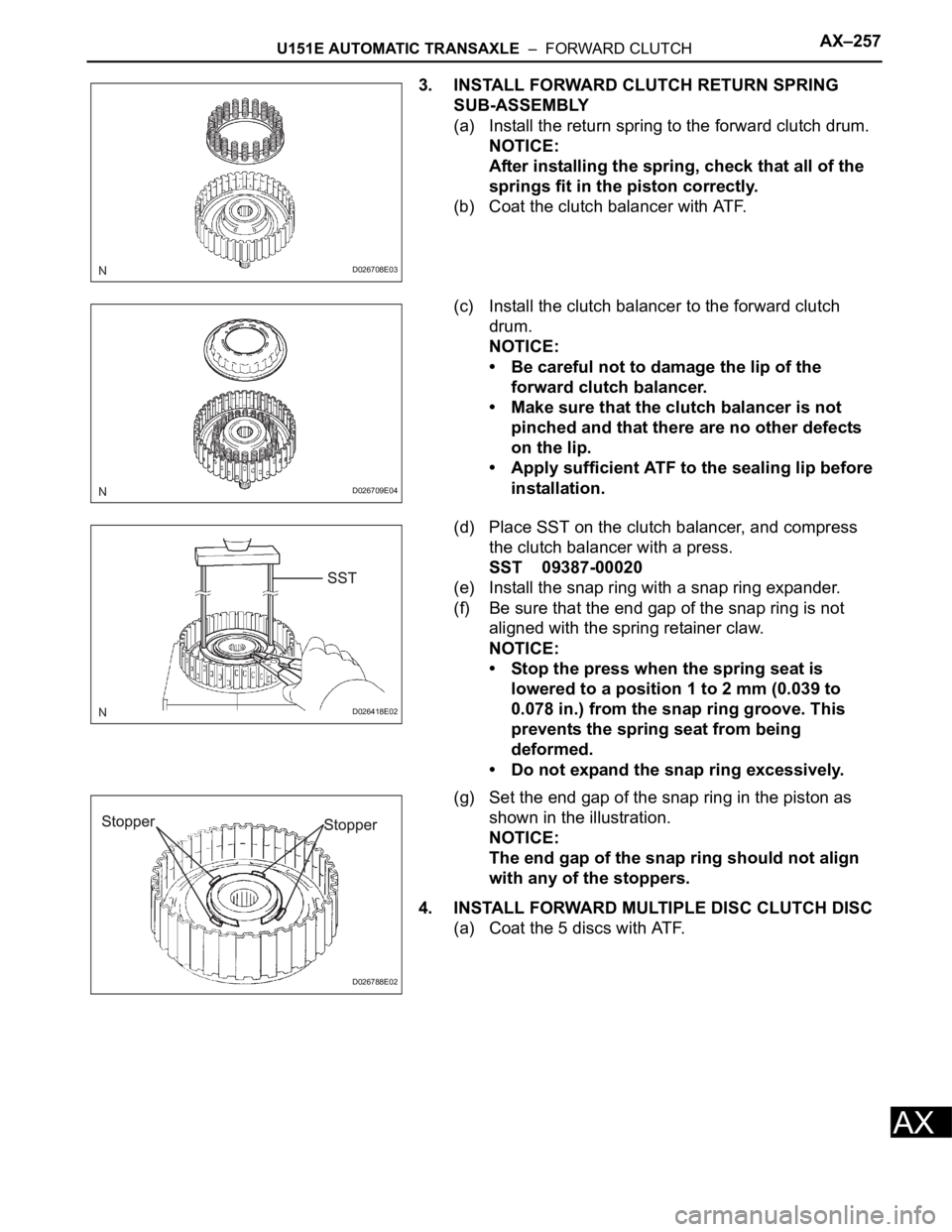

3. INSTALL FORWARD CLUTCH RETURN SPRING

SUB-ASSEMBLY

(a) Install the return spring to the forward clutch drum.

NOTICE:

After installing the spring, check that all of the

springs fit in the piston correctly.

(b) Coat the clutch balancer with ATF.

(c) Install the clutch balancer to the forward clutch

drum.

NOTICE:

• Be careful not to damage the lip of the

forward clutch balancer.

• Make sure that the clutch balancer is not

pinched and that there are no other defects

on the lip.

• Apply sufficient ATF to the sealing lip before

installation.

(d) Place SST on the clutch balancer, and compress

the clutch balancer with a press.

SST 09387-00020

(e) Install the snap ring with a snap ring expander.

(f) Be sure that the end gap of the snap ring is not

aligned with the spring retainer claw.

NOTICE:

• Stop the press when the spring seat is

lowered to a position 1 to 2 mm (0.039 to

0.078 in.) from the snap ring groove. This

prevents the spring seat from being

deformed.

• Do not expand the snap ring excessively.

(g) Set the end gap of the snap ring in the piston as

shown in the illustration.

NOTICE:

The end gap of the snap ring should not align

with any of the stoppers.

4. INSTALL FORWARD MULTIPLE DISC CLUTCH DISC

(a) Coat the 5 discs with ATF.

D026708E03

D026709E04

D026418E02

D026788E02

Page 1124 of 2000

AX–258U151E AUTOMATIC TRANSAXLE – FORWARD CLUTCH

AX

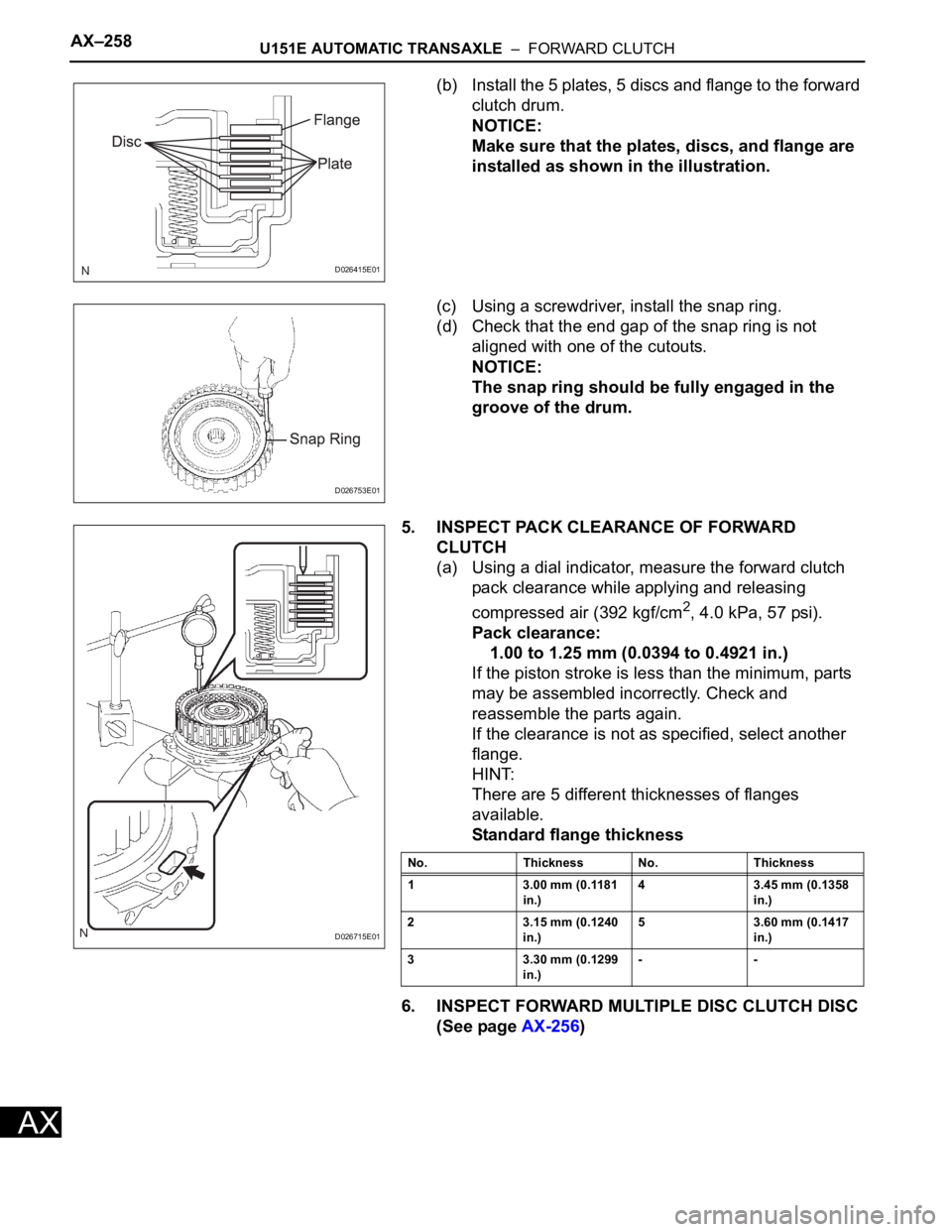

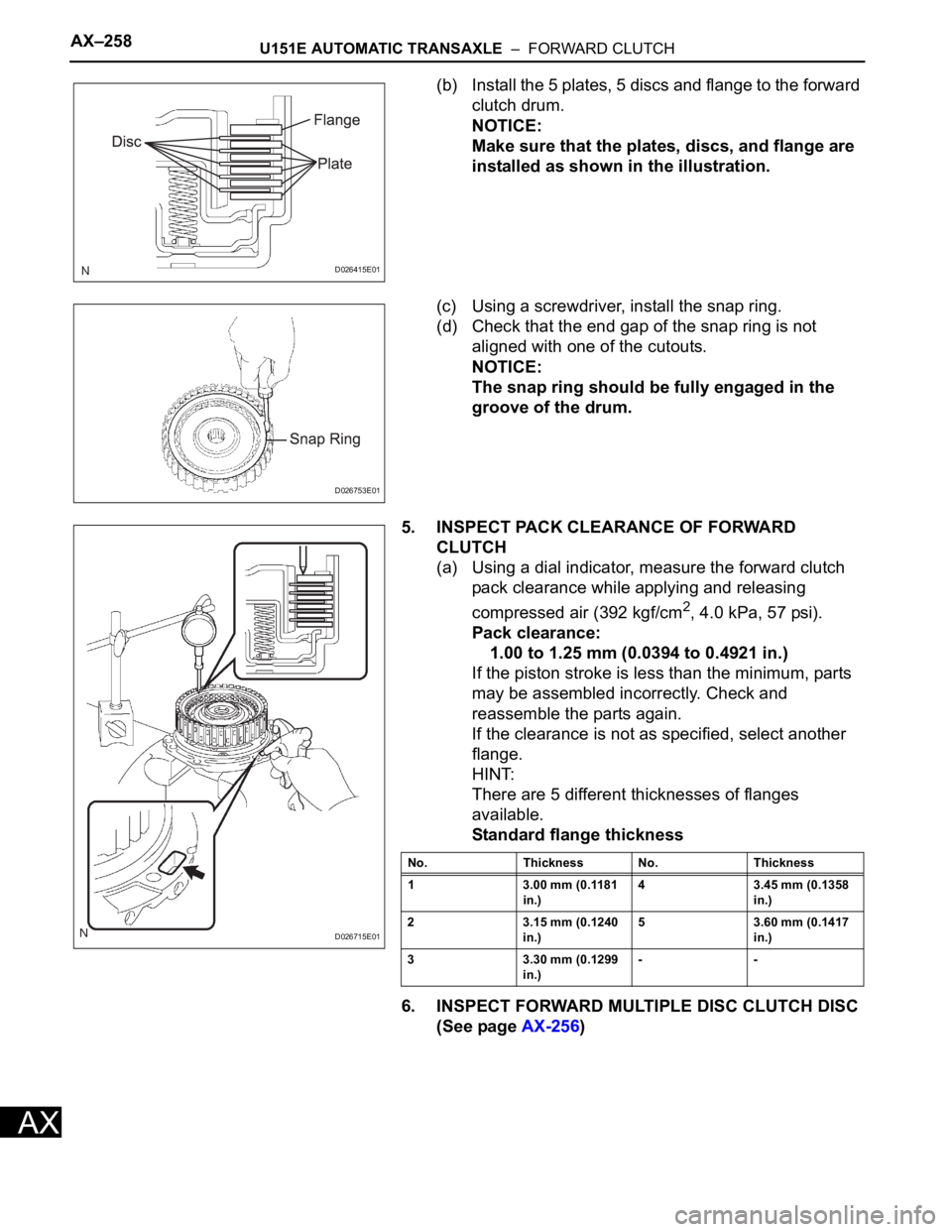

(b) Install the 5 plates, 5 discs and flange to the forward

clutch drum.

NOTICE:

Make sure that the plates, discs, and flange are

installed as shown in the illustration.

(c) Using a screwdriver, install the snap ring.

(d) Check that the end gap of the snap ring is not

aligned with one of the cutouts.

NOTICE:

The snap ring should be fully engaged in the

groove of the drum.

5. INSPECT PACK CLEARANCE OF FORWARD

CLUTCH

(a) Using a dial indicator, measure the forward clutch

pack clearance while applying and releasing

compressed air (392 kgf/cm

2, 4.0 kPa, 57 psi).

Pack clearance:

1.00 to 1.25 mm (0.0394 to 0.4921 in.)

If the piston stroke is less than the minimum, parts

may be assembled incorrectly. Check and

reassemble the parts again.

If the clearance is not as specified, select another

flange.

HINT:

There are 5 different thicknesses of flanges

available.

Standard flange thickness

6. INSPECT FORWARD MULTIPLE DISC CLUTCH DISC

(See page AX-256)

D026415E01

D026753E01

D026715E01

No. Thickness No. Thickness

1 3.00 mm (0.1181

in.)4 3.45 mm (0.1358

in.)

2 3.15 mm (0.1240

in.)5 3.60 mm (0.1417

in.)

3 3.30 mm (0.1299

in.)--

Page 1125 of 2000

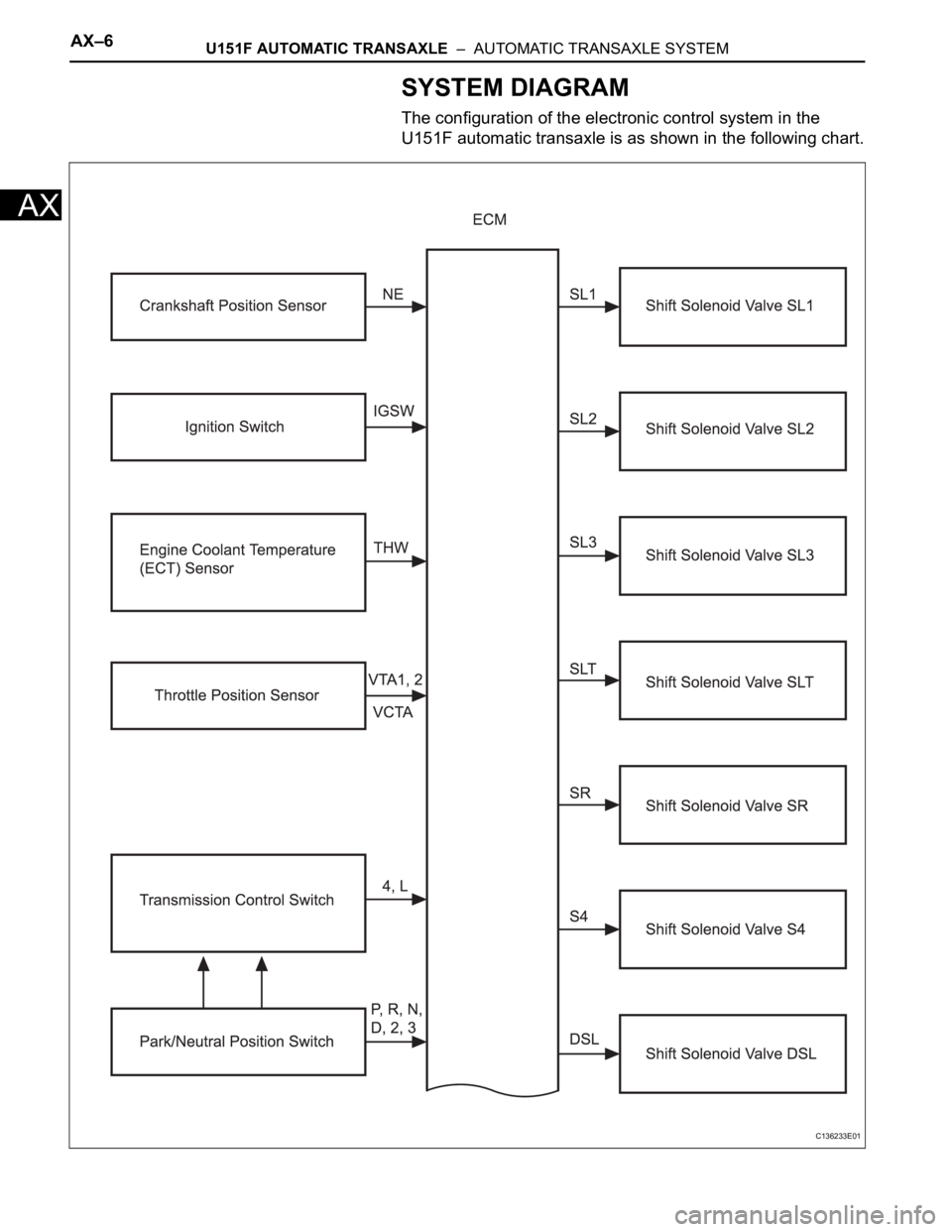

AX–6U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

SYSTEM DIAGRAM

The configuration of the electronic control system in the

U151F automatic transaxle is as shown in the following chart.

C136233E01

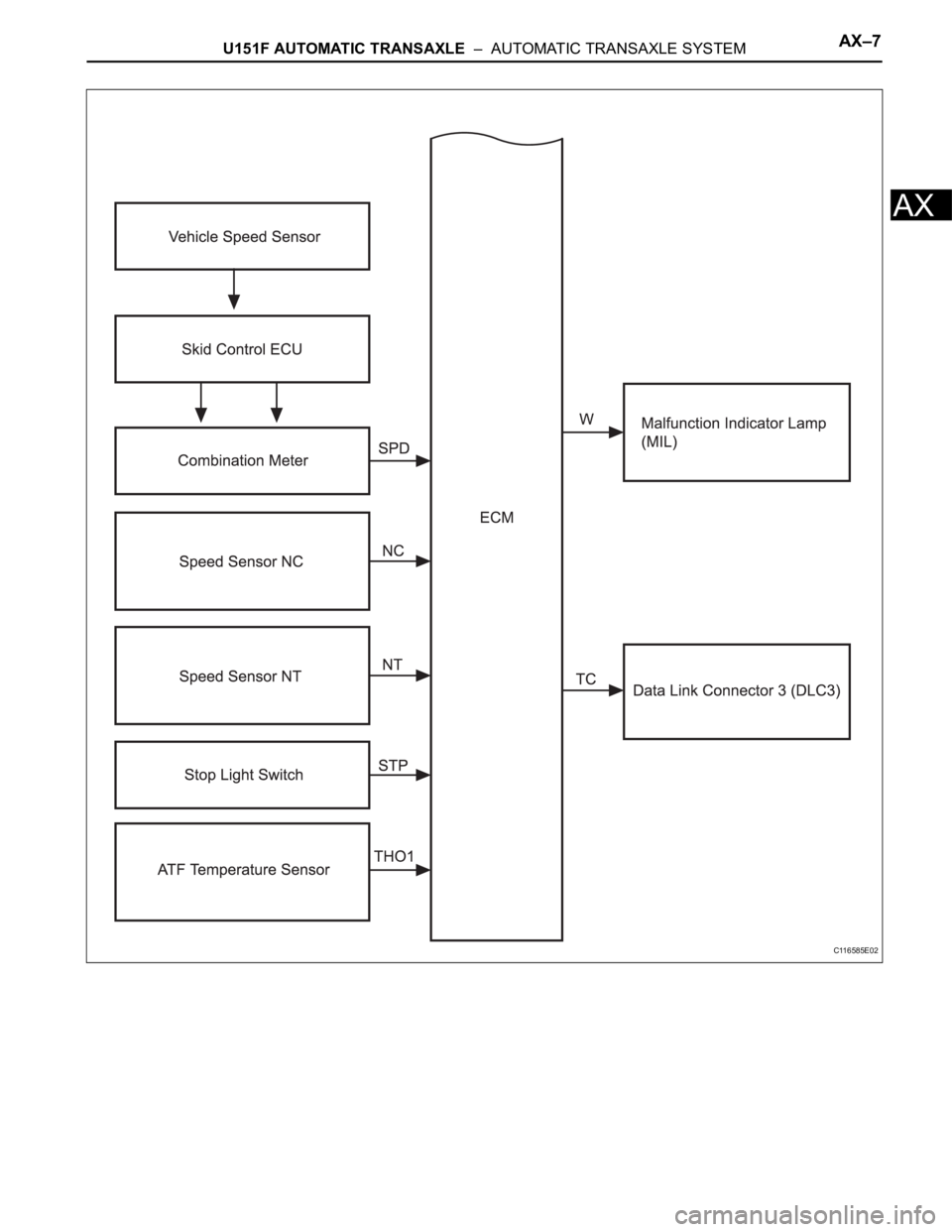

Page 1126 of 2000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–7

AX

C116585E02

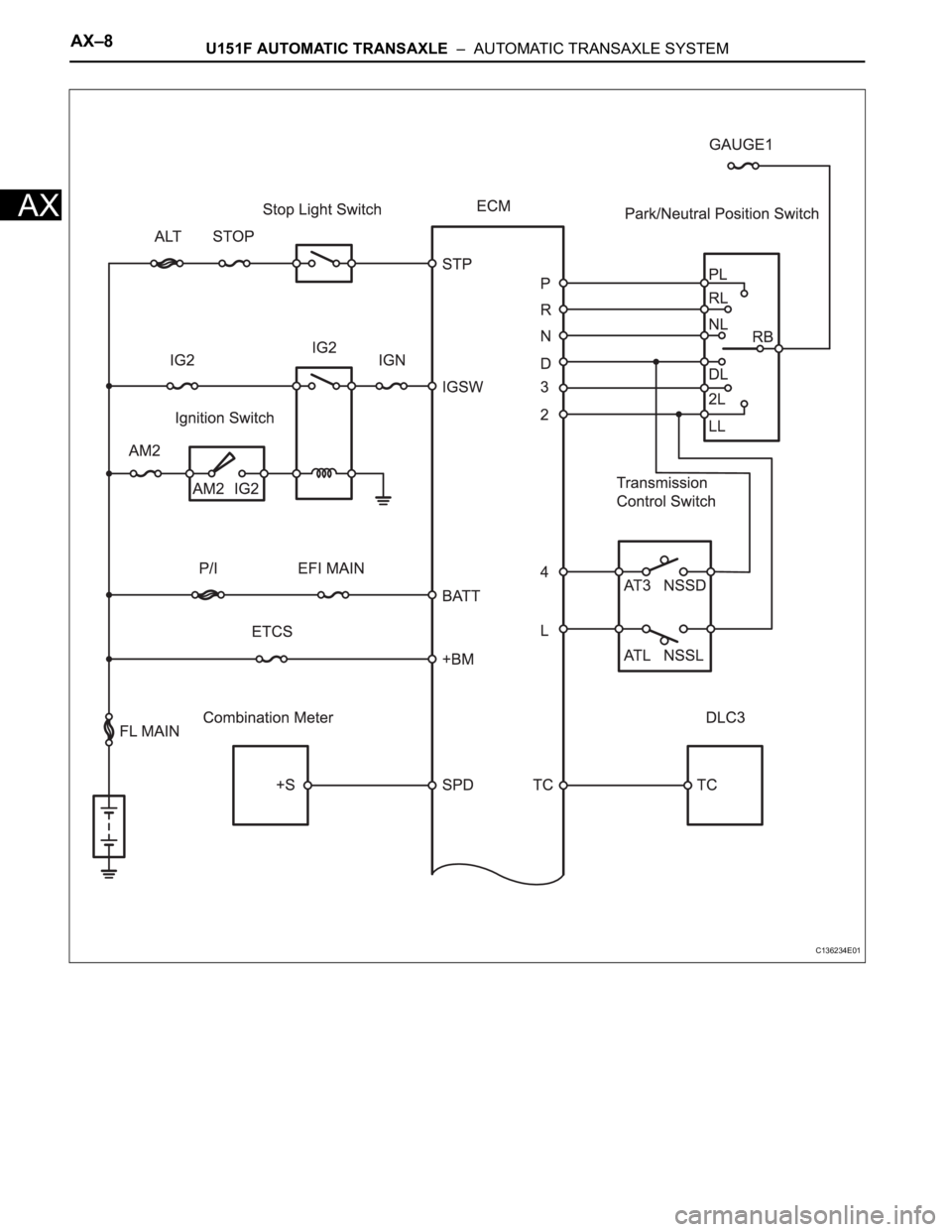

Page 1127 of 2000

AX–8U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

C136234E01

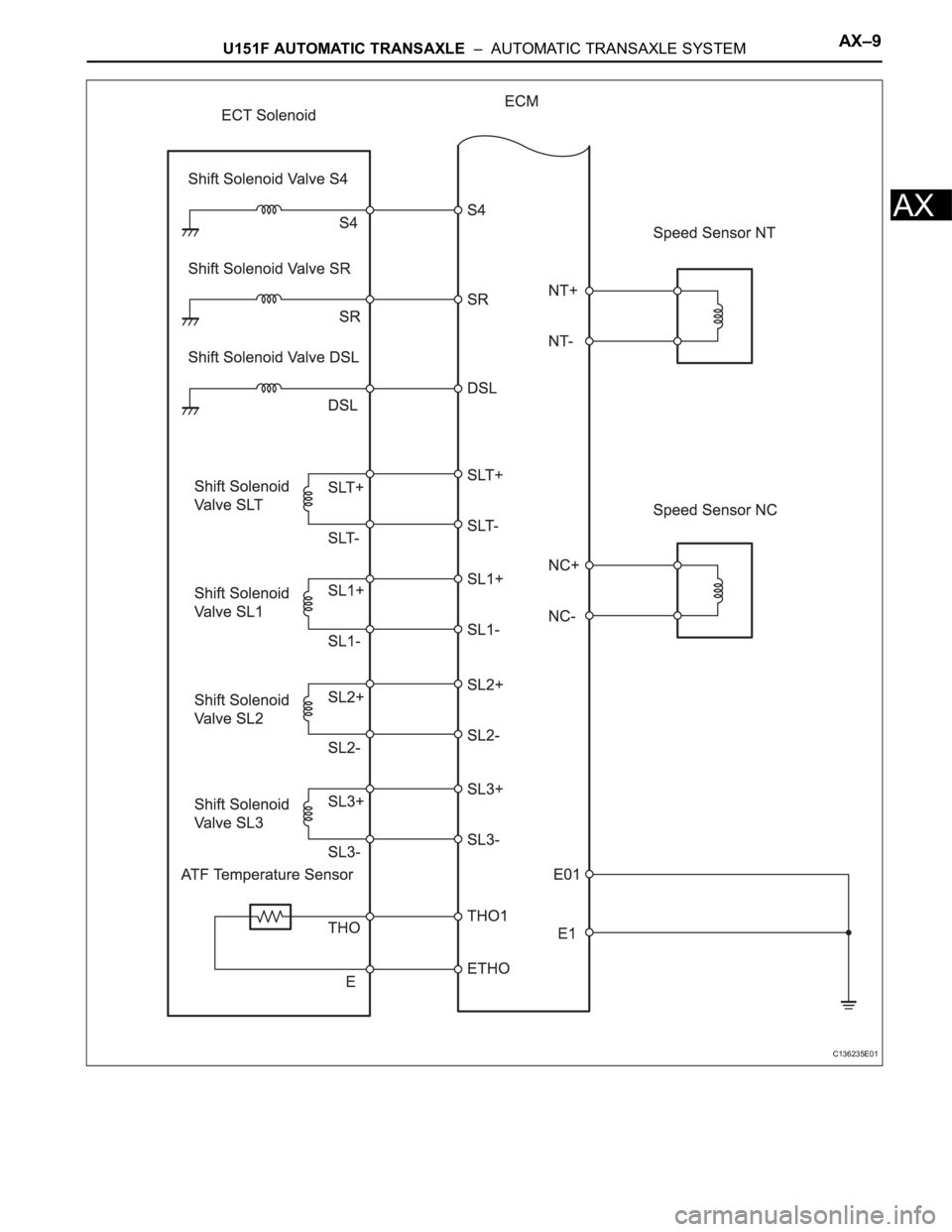

Page 1128 of 2000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–9

AX

C136235E01

Page 1129 of 2000

AX–10U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

(a) The Electronic Controlled Automatic Transaxle

(ECT) is an automatic transaxle that electronically

controls shift timing using the Engine Control

Module (ECM). The ECM detects electrical signals

that indicate engine and driving conditions, and

controls the shift point based on driver habits and

road conditions. As a result, fuel efficiency and

power transaxle performance are improved.

Shift shock is reduced by controlling the engine and

transaxle simultaneously.

In addition, the ECT has the following features:

• Diagnostic function.

• Fail-safe function when a malfunction occurs.

Page 1130 of 2000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–11

AX

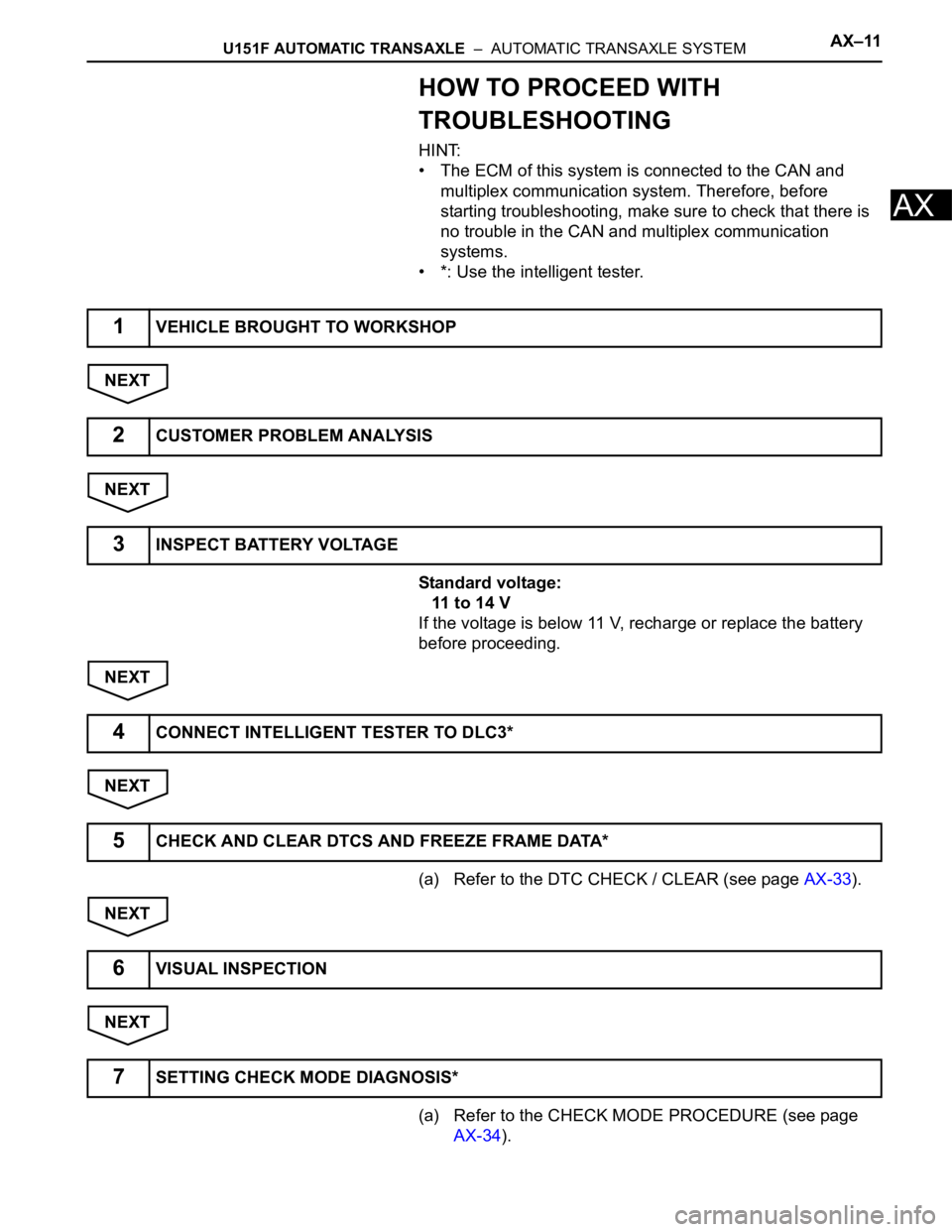

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• The ECM of this system is connected to the CAN and

multiplex communication system. Therefore, before

starting troubleshooting, make sure to check that there is

no trouble in the CAN and multiplex communication

systems.

• *: Use the intelligent tester.

NEXT

NEXT

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

NEXT

NEXT

(a) Refer to the DTC CHECK / CLEAR (see page AX-33).

NEXT

NEXT

(a) Refer to the CHECK MODE PROCEDURE (see page

AX-34).

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS

3INSPECT BATTERY VOLTAGE

4CONNECT INTELLIGENT TESTER TO DLC3*

5CHECK AND CLEAR DTCS AND FREEZE FRAME DATA*

6VISUAL INSPECTION

7SETTING CHECK MODE DIAGNOSIS*

Trending: load capacity, tow bar, manual transmission, reten, Install intake manifold, low oil pressure, bolt pattern