TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1981 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–93

ES

DESCRIPTION

The Mass Air Flow (MAF) meter is a sensor that measures the amount of air flowing through the throttle

valve.

The ECM uses this information to determine the fuel injection time and to provide the appropriate air-fuel

ratio.

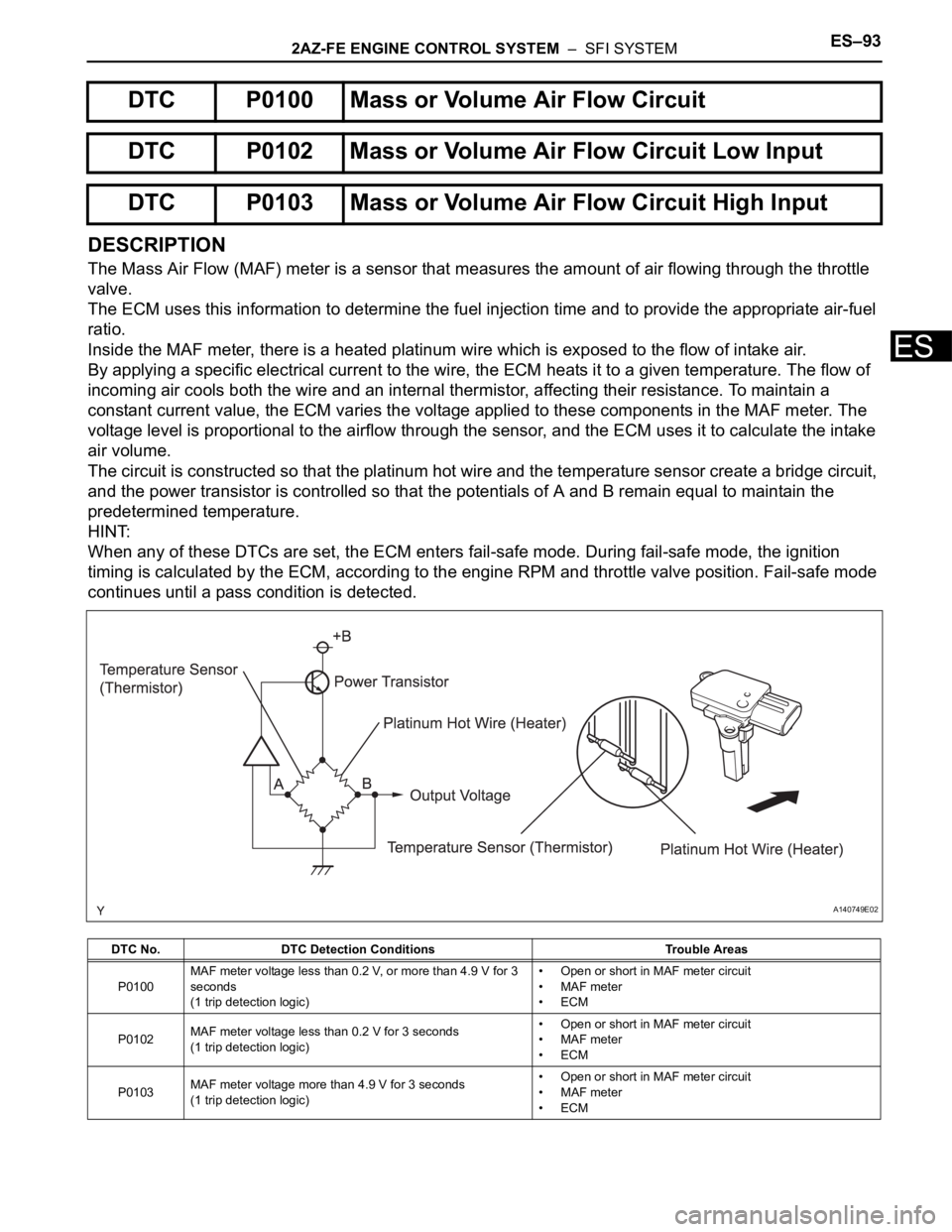

Inside the MAF meter, there is a heated platinum wire which is exposed to the flow of intake air.

By applying a specific electrical current to the wire, the ECM heats it to a given temperature. The flow of

incoming air cools both the wire and an internal thermistor, affecting their resistance. To maintain a

constant current value, the ECM varies the voltage applied to these components in the MAF meter. The

voltage level is proportional to the airflow through the sensor, and the ECM uses it to calculate the intake

air volume.

The circuit is constructed so that the platinum hot wire and the temperature sensor create a bridge circuit,

and the power transistor is controlled so that the potentials of A and B remain equal to maintain the

predetermined temperature.

HINT:

When any of these DTCs are set, the ECM enters fail-safe mode. During fail-safe mode, the ignition

timing is calculated by the ECM, according to the engine RPM and throttle valve position. Fail-safe mode

continues until a pass condition is detected.

DTC P0100 Mass or Volume Air Flow Circuit

DTC P0102 Mass or Volume Air Flow Circuit Low Input

DTC P0103 Mass or Volume Air Flow Circuit High Input

DTC No. DTC Detection Conditions Trouble Areas

P0100MAF meter voltage less than 0.2 V, or more than 4.9 V for 3

seconds

(1 trip detection logic)• Open or short in MAF meter circuit

• MAF meter

•ECM

P0102MAF meter voltage less than 0.2 V for 3 seconds

(1 trip detection logic)• Open or short in MAF meter circuit

• MAF meter

•ECM

P0103MAF meter voltage more than 4.9 V for 3 seconds

(1 trip detection logic)• Open or short in MAF meter circuit

• MAF meter

•ECM

A140749E02

Page 1982 of 2000

ES–942AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

HINT:

When any of these DTCs are set, check the air-flow rate by selecting the following menu items on the

intelligent tester: DIAGNOSIS / ENHANCED OBD II/ DATA LIST / PRIMARY / MAF.

MONITOR DESCRIPTION

If there is a defect in the MAF meter or an open or short circuit, the voltage level deviates from the normal

operating range. The ECM interprets this deviation as a malfunction in the MAF meter and sets a DTC.

Example:

When the sensor output voltage remains less than 0.2 V, or more than 4.9 V, for more than 3 seconds, the

ECM sets a DTC.

If the malfunction is not repaired successfully, a DTC is set 3 seconds after the engine is next started.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

P0100:

P0102:

P0103:

COMPONENT OPERATING RANGE

Mass Air Flow Rate (g/sec.) Malfunctions

Approximately 0.0• Open in Mass Air Flow (MAF) meter power source circuit

• Open or short in VG circuit

271.0 or more • Open in E2G circuit

Related DTCsP0100: MAF meter range check (Fluctuating)

P0102: MAF meter range check (Low voltage)

P0103: MAF meter range check (High voltage)

Required Sensors/Components (Main) MAF meter

Required Sensors/Components (Related) Crankshaft position sensor

Frequency of Operation Continuous

Duration 3 seconds

MIL OperationImmediate: Engine RPM less than 4,000 rpm

2 driving cycles: Engine RPM 4,000 rpm or more

Sequence of Operation None

Monitor runs whenever following DTCs not present None

MAF meter voltage Less than 0.2 V, or more than 4.9 V

MAF meter voltage Less than 0.2 V

MAF meter voltage More than 4.9 V

MAF meter voltage Between 0.4 V and 2.2 V

Page 1983 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–95

ES

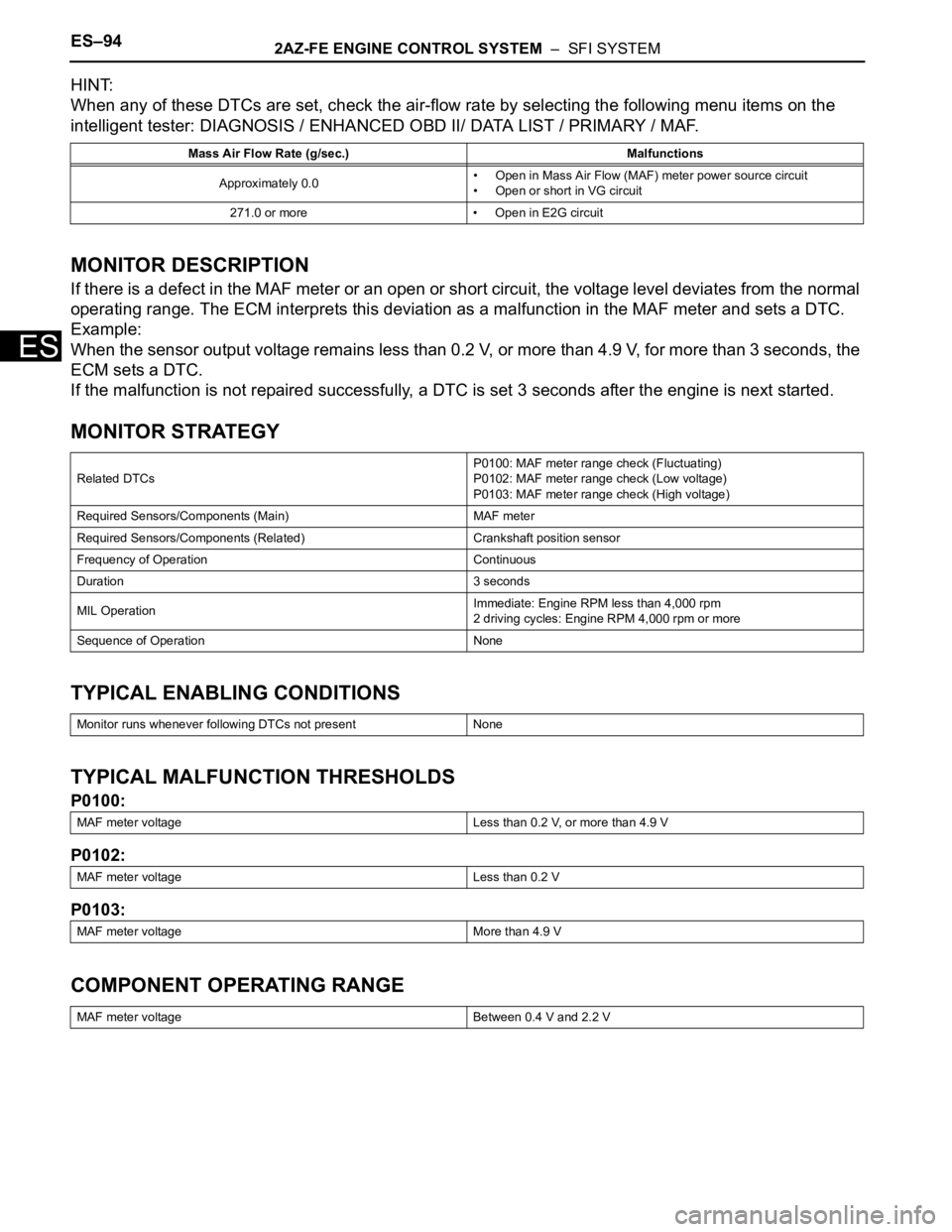

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when

malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was

moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other

data from the time the malfunction occurred.

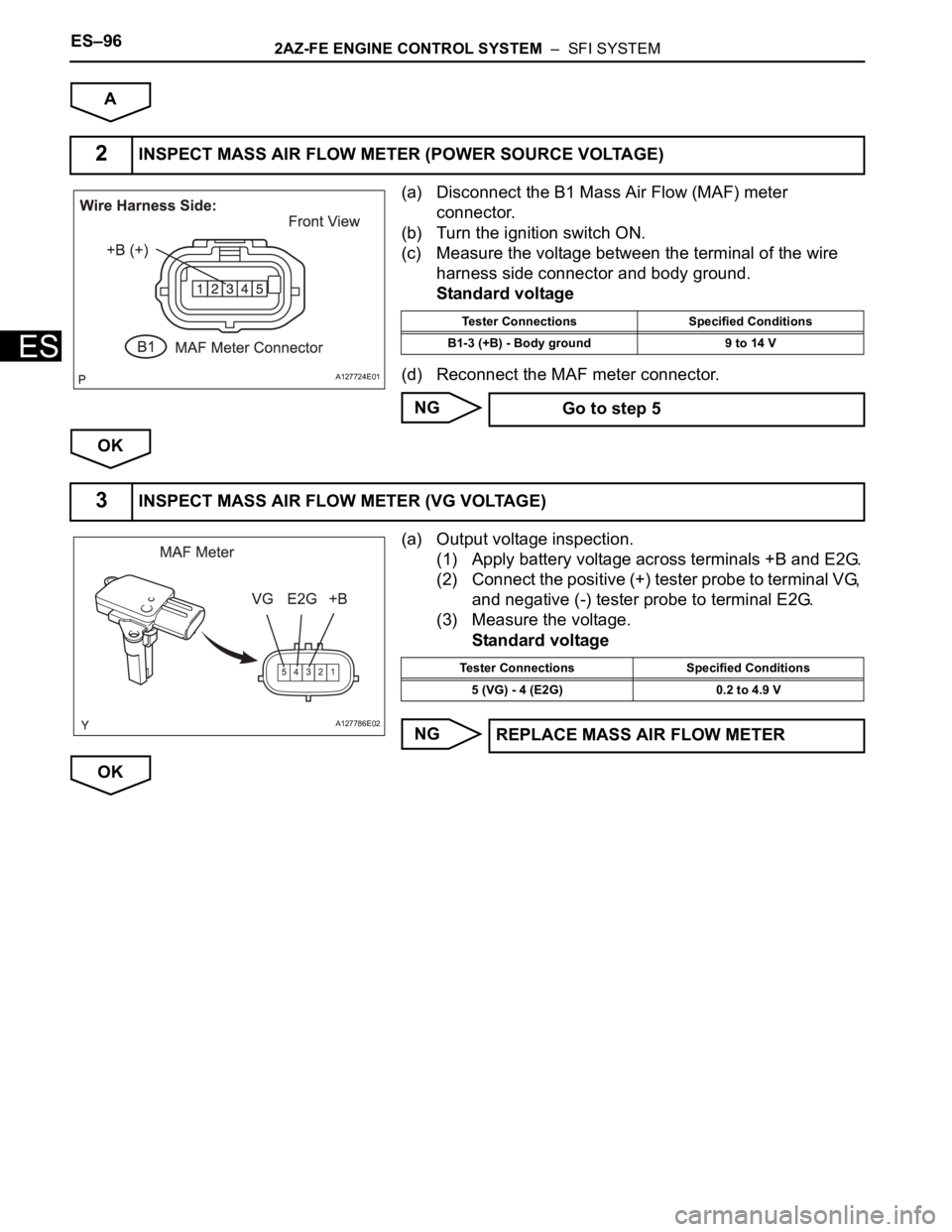

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY / MAF.

(e) Read the values displayed on the tester.

Result

HINT:

*1: The value must change when the throttle valve is

open or closed with the engine running.

B

C

1READ VALUE USING INTELLIGENT TESTER (MASS AIR FLOW RATE)

A127248E02

Mass Air Flow Rate (g/sec.) Proceed To

0.0 A

271.0 or more B

Between 1.0 and 270.0 (*1) C

Go to step 6

CHECK FOR INTERMITTENT PROBLEMS

Page 1984 of 2000

ES–962AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

A

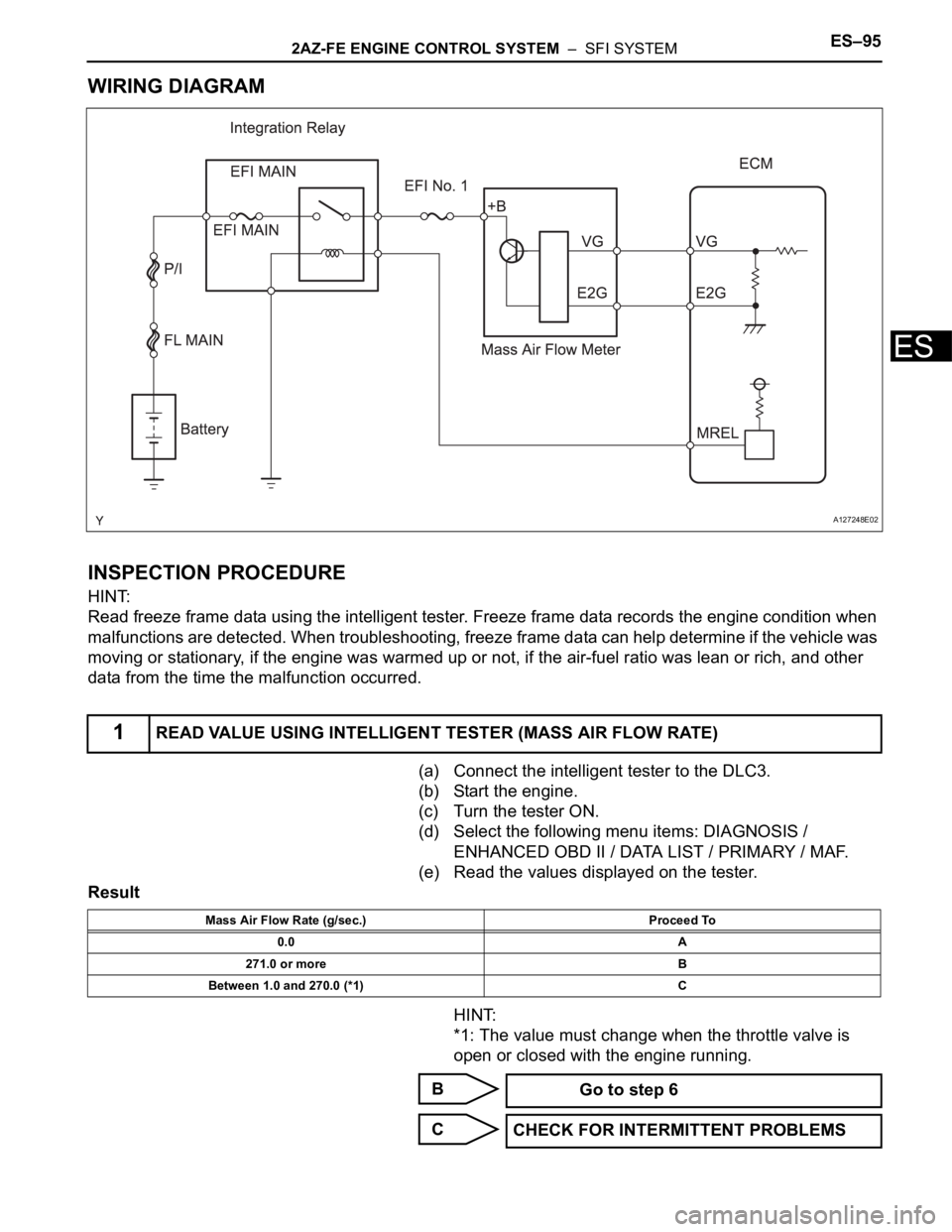

(a) Disconnect the B1 Mass Air Flow (MAF) meter

connector.

(b) Turn the ignition switch ON.

(c) Measure the voltage between the terminal of the wire

harness side connector and body ground.

Standard voltage

(d) Reconnect the MAF meter connector.

NG

OK

(a) Output voltage inspection.

(1) Apply battery voltage across terminals +B and E2G.

(2) Connect the positive (+) tester probe to terminal VG,

and negative (-) tester probe to terminal E2G.

(3) Measure the voltage.

Standard voltage

NG

OK

2INSPECT MASS AIR FLOW METER (POWER SOURCE VOLTAGE)

A127724E01

Tester Connections Specified Conditions

B1-3 (+B) - Body ground 9 to 14 V

Go to step 5

3INSPECT MASS AIR FLOW METER (VG VOLTAGE)

A127786E02

Tester Connections Specified Conditions

5 (VG) - 4 (E2G) 0.2 to 4.9 V

REPLACE MASS AIR FLOW METER

Page 1985 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–97

ES

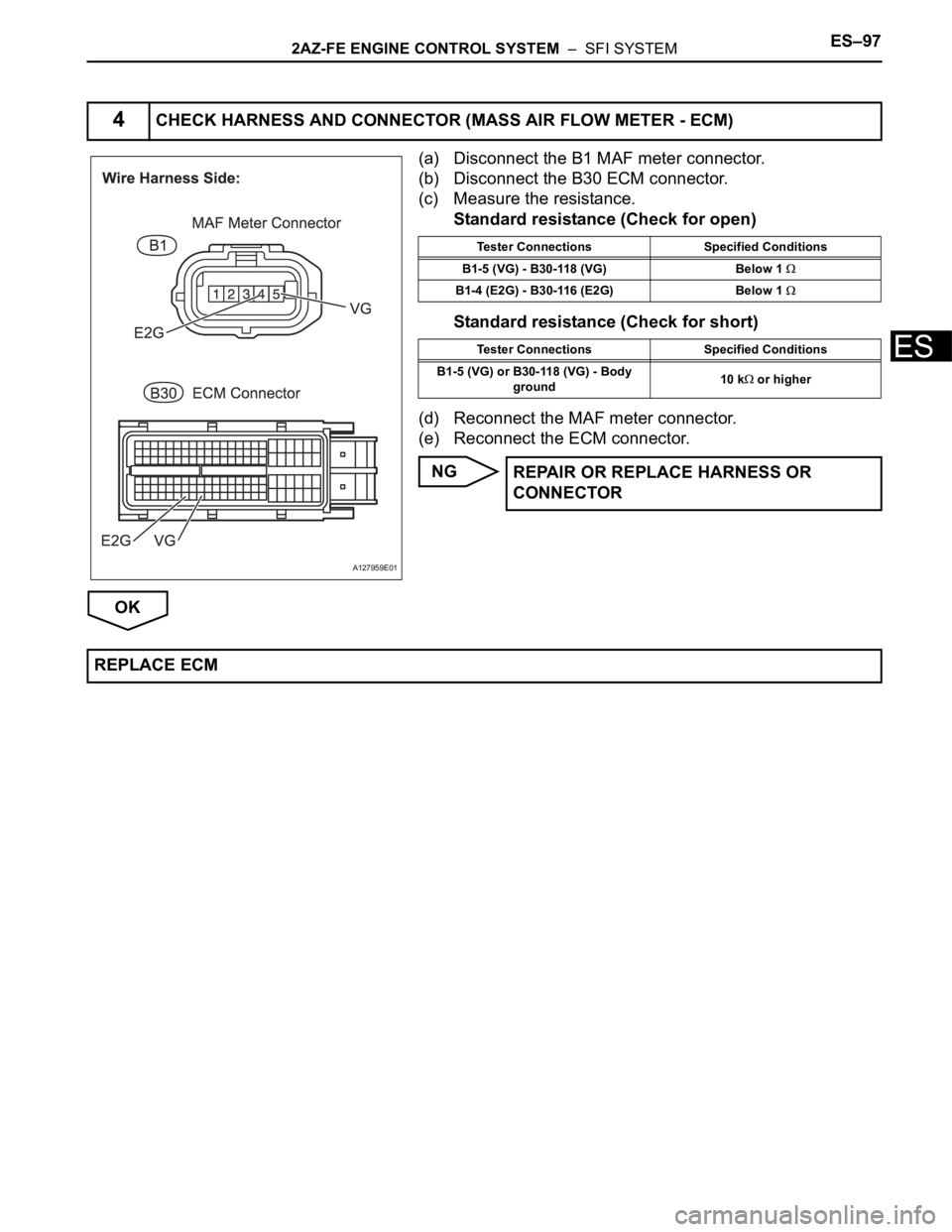

(a) Disconnect the B1 MAF meter connector.

(b) Disconnect the B30 ECM connector.

(c) Measure the resistance.

Standard resistance (Check for open)

Standard resistance (Check for short)

(d) Reconnect the MAF meter connector.

(e) Reconnect the ECM connector.

NG

OK

4CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM)

A127959E01

Tester Connections Specified Conditions

B1-5 (VG) - B30-118 (VG) Below 1

B1-4 (E2G) - B30-116 (E2G) Below 1

Tester Connections Specified Conditions

B1-5 (VG) or B30-118 (VG) - Body

ground10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

REPLACE ECM

Page 1986 of 2000

ES–982AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

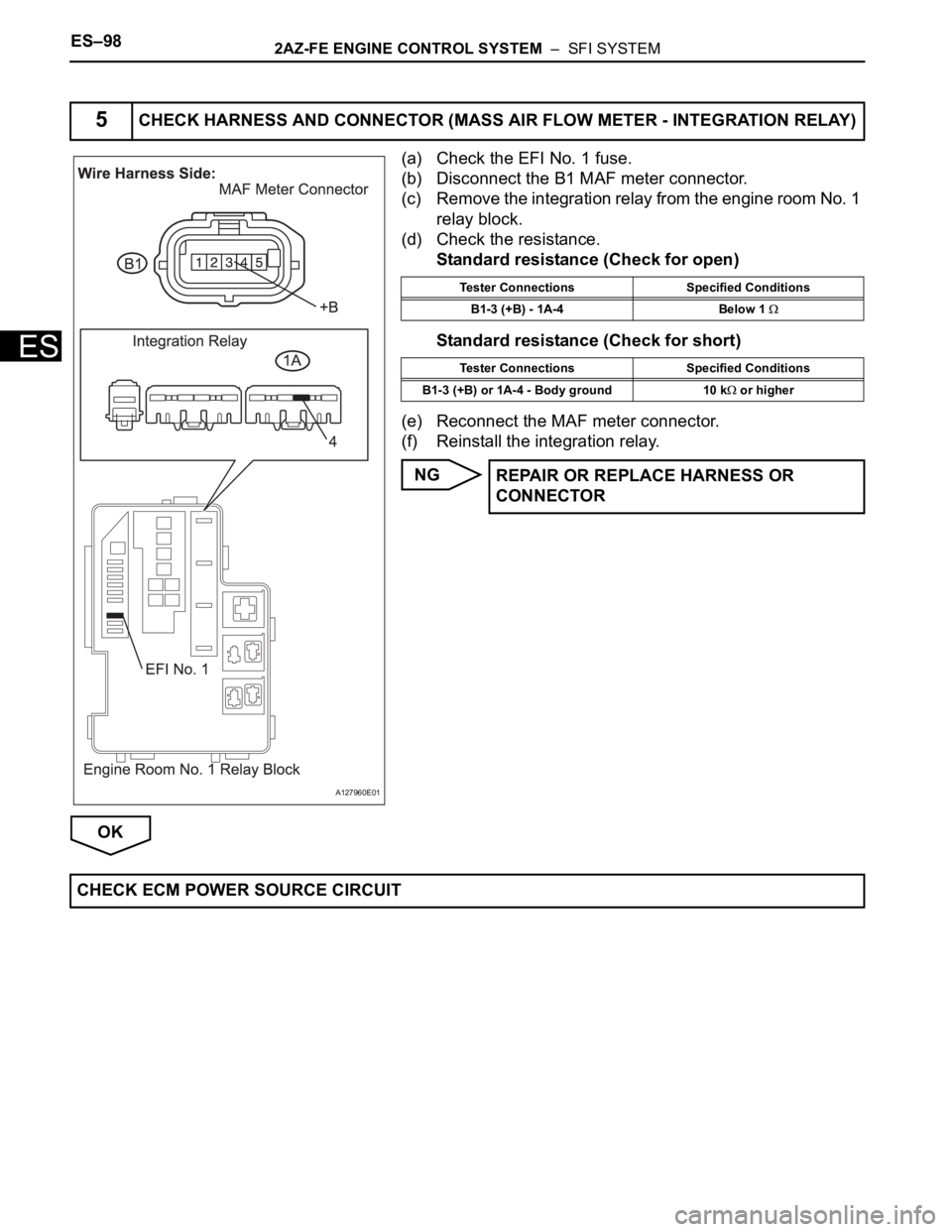

(a) Check the EFI No. 1 fuse.

(b) Disconnect the B1 MAF meter connector.

(c) Remove the integration relay from the engine room No. 1

relay block.

(d) Check the resistance.

Standard resistance (Check for open)

Standard resistance (Check for short)

(e) Reconnect the MAF meter connector.

(f) Reinstall the integration relay.

NG

OK

5CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - INTEGRATION RELAY)

A127960E01

Tester Connections Specified Conditions

B1-3 (+B) - 1A-4 Below 1

Tester Connections Specified Conditions

B1-3 (+B) or 1A-4 - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

CHECK ECM POWER SOURCE CIRCUIT

Page 1987 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–99

ES

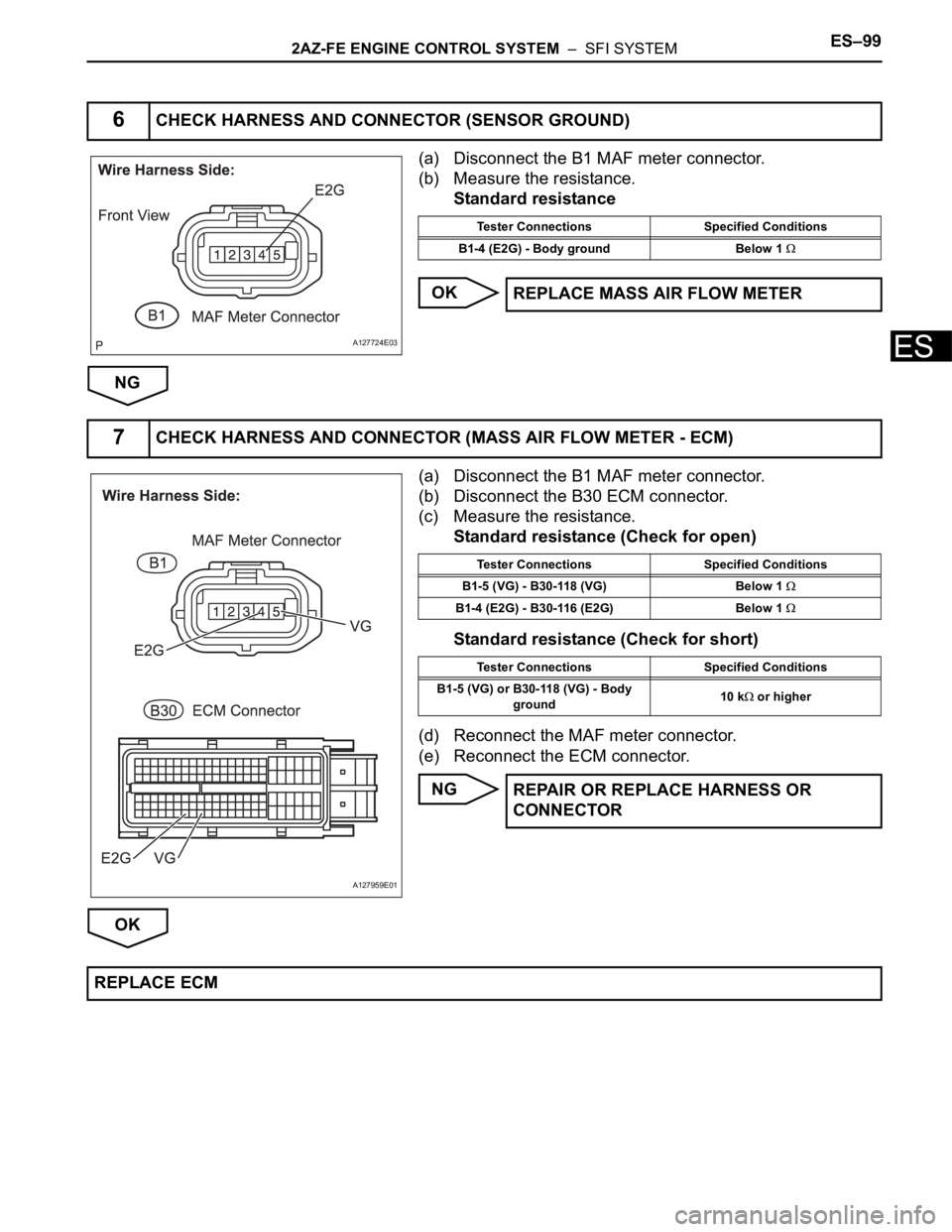

(a) Disconnect the B1 MAF meter connector.

(b) Measure the resistance.

Standard resistance

OK

NG

(a) Disconnect the B1 MAF meter connector.

(b) Disconnect the B30 ECM connector.

(c) Measure the resistance.

Standard resistance (Check for open)

Standard resistance (Check for short)

(d) Reconnect the MAF meter connector.

(e) Reconnect the ECM connector.

NG

OK

6CHECK HARNESS AND CONNECTOR (SENSOR GROUND)

A127724E03

Tester Connections Specified Conditions

B1-4 (E2G) - Body ground Below 1

REPLACE MASS AIR FLOW METER

7CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM)

A127959E01

Tester Connections Specified Conditions

B1-5 (VG) - B30-118 (VG) Below 1

B1-4 (E2G) - B30-116 (E2G) Below 1

Tester Connections Specified Conditions

B1-5 (VG) or B30-118 (VG) - Body

ground10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR

REPLACE ECM

Page 1988 of 2000

ES–1002AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

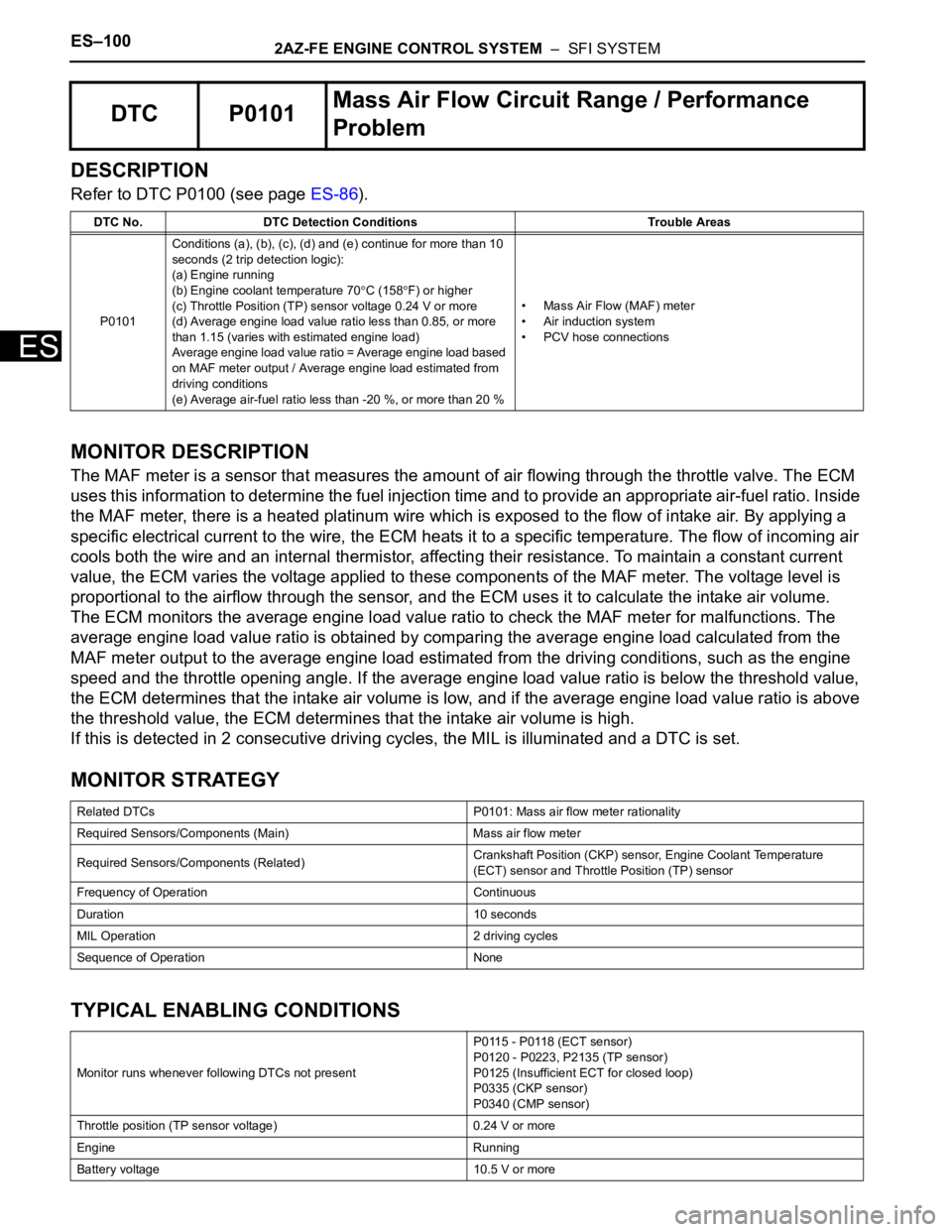

DESCRIPTION

Refer to DTC P0100 (see page ES-86).

MONITOR DESCRIPTION

The MAF meter is a sensor that measures the amount of air flowing through the throttle valve. The ECM

uses this information to determine the fuel injection time and to provide an appropriate air-fuel ratio. Inside

the MAF meter, there is a heated platinum wire which is exposed to the flow of intake air. By applying a

specific electrical current to the wire, the ECM heats it to a specific temperature. The flow of incoming air

cools both the wire and an internal thermistor, affecting their resistance. To maintain a constant current

value, the ECM varies the voltage applied to these components of the MAF meter. The voltage level is

proportional to the airflow through the sensor, and the ECM uses it to calculate the intake air volume.

The ECM monitors the average engine load value ratio to check the MAF meter for malfunctions. The

average engine load value ratio is obtained by comparing the average engine load calculated from the

MAF meter output to the average engine load estimated from the driving conditions, such as the engine

speed and the throttle opening angle. If the average engine load value ratio is below the threshold value,

the ECM determines that the intake air volume is low, and if the average engine load value ratio is above

the threshold value, the ECM determines that the intake air volume is high.

If this is detected in 2 consecutive driving cycles, the MIL is illuminated and a DTC is set.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

DTC P0101Mass Air Flow Circuit Range / Performance

Problem

DTC No. DTC Detection Conditions Trouble Areas

P0101Conditions (a), (b), (c), (d) and (e) continue for more than 10

seconds (2 trip detection logic):

(a) Engine running

(b) Engine coolant temperature 70

C (158F) or higher

(c) Throttle Position (TP) sensor voltage 0.24 V or more

(d) Average engine load value ratio less than 0.85, or more

than 1.15 (varies with estimated engine load)

Average engine load value ratio = Average engine load based

on MAF meter output / Average engine load estimated from

driving conditions

(e) Average air-fuel ratio less than -20 %, or more than 20 %• Mass Air Flow (MAF) meter

• Air induction system

• PCV hose connections

Related DTCs P0101: Mass air flow meter rationality

Required Sensors/Components (Main) Mass air flow meter

Required Sensors/Components (Related)Crankshaft Position (CKP) sensor, Engine Coolant Temperature

(ECT) sensor and Throttle Position (TP) sensor

Frequency of Operation Continuous

Duration 10 seconds

MIL Operation 2 driving cycles

Sequence of Operation None

Monitor runs whenever following DTCs not presentP0115 - P0118 (ECT sensor)

P0120 - P0223, P2135 (TP sensor)

P0125 (Insufficient ECT for closed loop)

P0335 (CKP sensor)

P0340 (CMP sensor)

Throttle position (TP sensor voltage) 0.24 V or more

Engine Running

Battery voltage 10.5 V or more

Page 1989 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–101

ES

TYPICAL MALFUNCTION THRESHOLDS

WIRING DIAGRAM

Refer to DTC P0100 (see page ES-88).

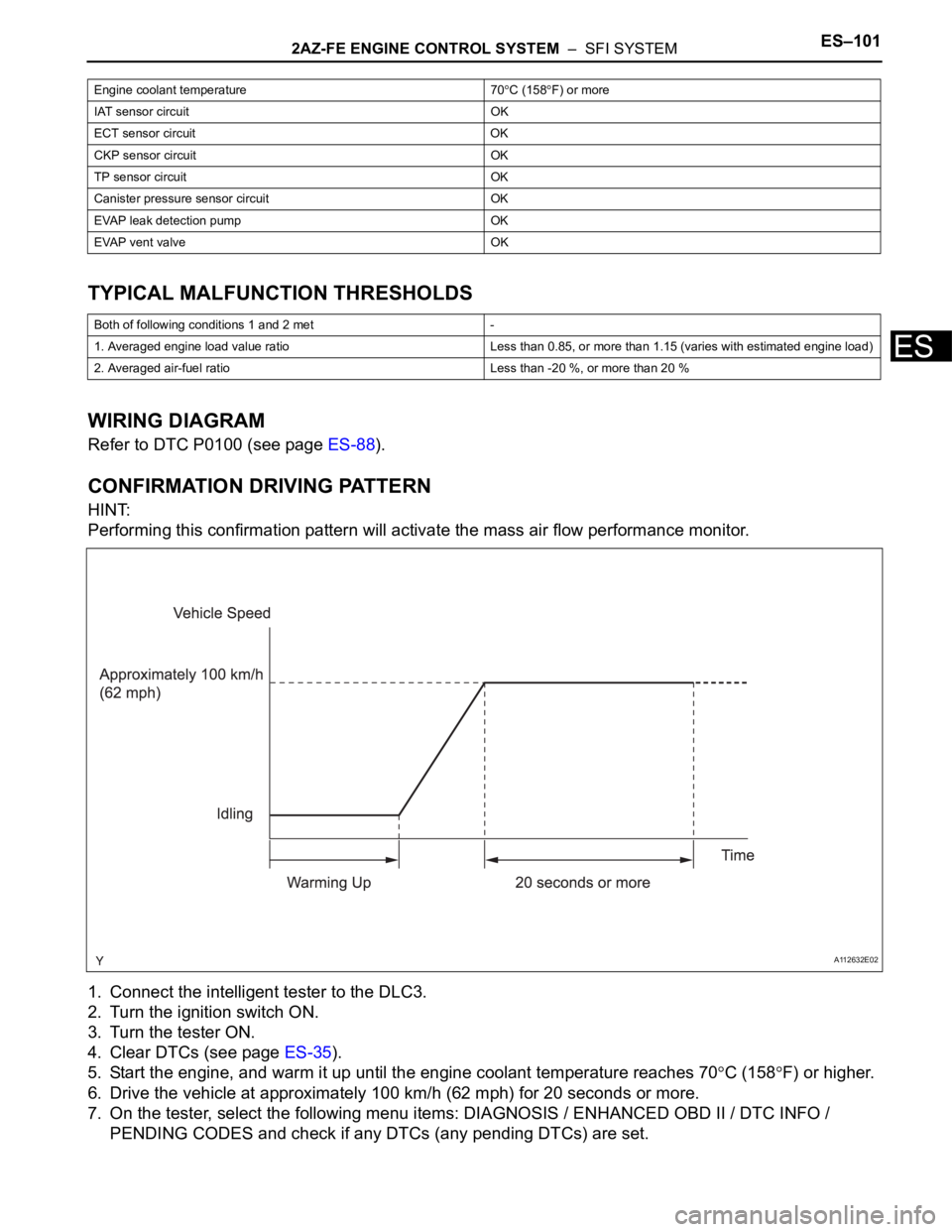

CONFIRMATION DRIVING PATTERN

HINT:

Performing this confirmation pattern will activate the mass air flow performance monitor.

1. Connect the intelligent tester to the DLC3.

2. Turn the ignition switch ON.

3. Turn the tester ON.

4. Clear DTCs (see page ES-35).

5. Start the engine, and warm it up until the engine coolant temperature reaches 70

C (158F) or higher.

6. Drive the vehicle at approximately 100 km/h (62 mph) for 20 seconds or more.

7. On the tester, select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC INFO /

PENDING CODES and check if any DTCs (any pending DTCs) are set.

Engine coolant temperature 70C (158F) or more

IAT sensor circuit OK

ECT sensor circuit OK

CKP sensor circuit OK

TP sensor circuit OK

Canister pressure sensor circuit OK

EVAP leak detection pump OK

EVAP vent valve OK

Both of following conditions 1 and 2 met -

1. Averaged engine load value ratio Less than 0.85, or more than 1.15 (varies with estimated engine load)

2. Averaged air-fuel ratio Less than -20 %, or more than 20 %

A112632E02

Page 1990 of 2000

ES–1022AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

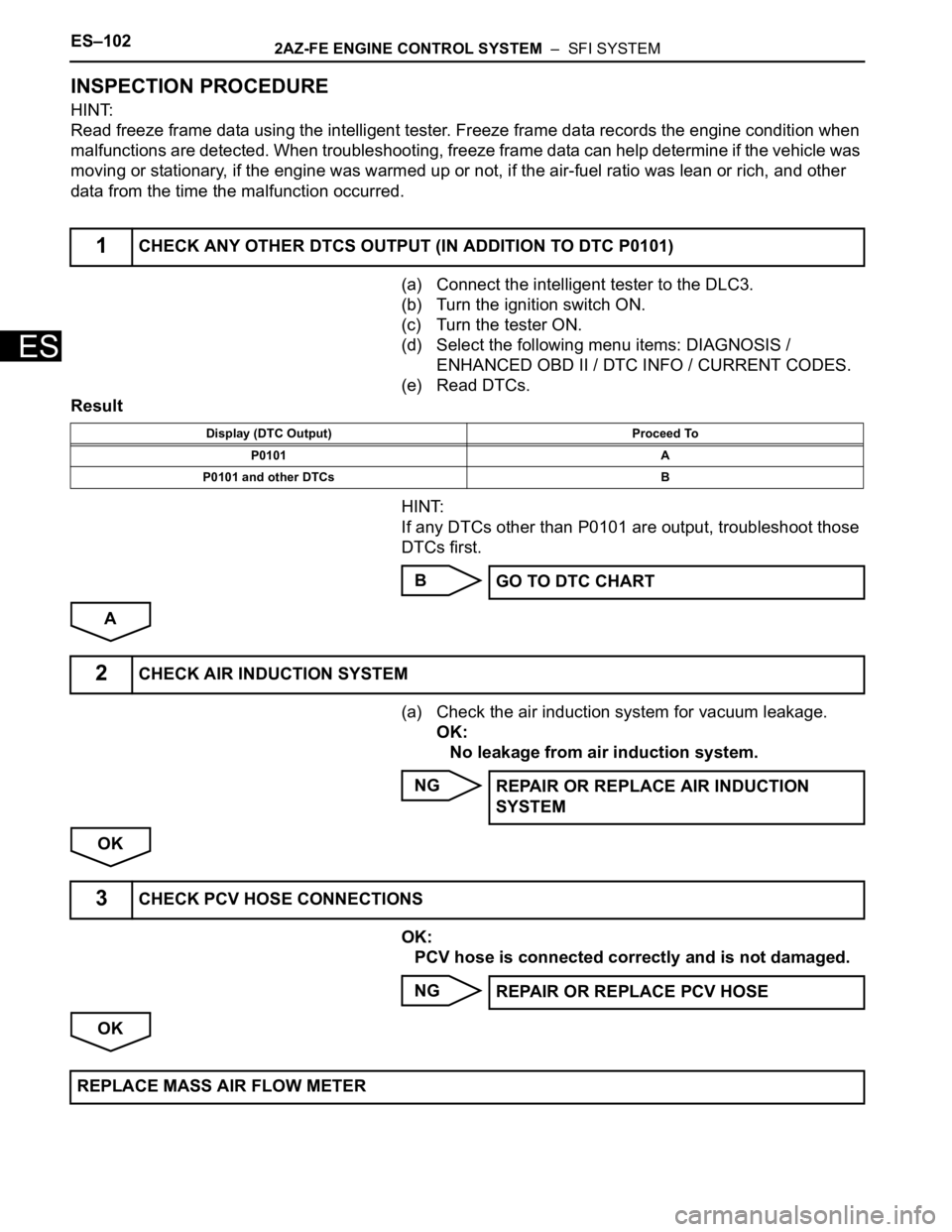

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when

malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was

moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other

data from the time the malfunction occurred.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch ON.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read DTCs.

Result

HINT:

If any DTCs other than P0101 are output, troubleshoot those

DTCs first.

B

A

(a) Check the air induction system for vacuum leakage.

OK:

No leakage from air induction system.

NG

OK

OK:

PCV hose is connected correctly and is not damaged.

NG

OK

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0101)

Display (DTC Output) Proceed To

P0101 A

P0101 and other DTCs B

GO TO DTC CHART

2CHECK AIR INDUCTION SYSTEM

REPAIR OR REPLACE AIR INDUCTION

SYSTEM

3CHECK PCV HOSE CONNECTIONS

REPAIR OR REPLACE PCV HOSE

REPLACE MASS AIR FLOW METER