TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 191 of 3000

POWER STEERING – VANE PUMPPS–9

PS

REMOVAL

1. DRAIN POWER STEERING FLUID

2. REMOVE FRONT WHEEL RH

3. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

4. REMOVE FAN AND GENERATOR V BELT (See page

EM-6)

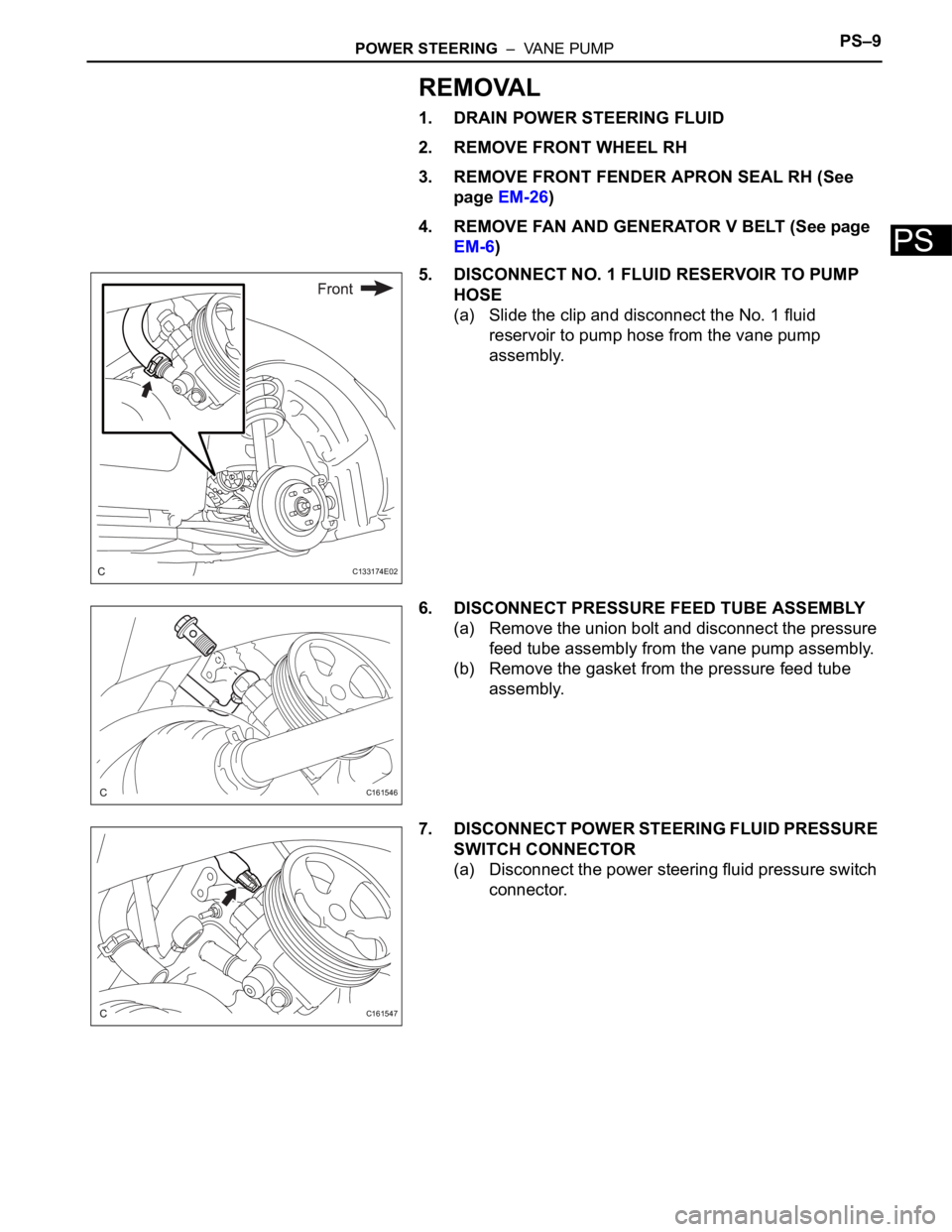

5. DISCONNECT NO. 1 FLUID RESERVOIR TO PUMP

HOSE

(a) Slide the clip and disconnect the No. 1 fluid

reservoir to pump hose from the vane pump

assembly.

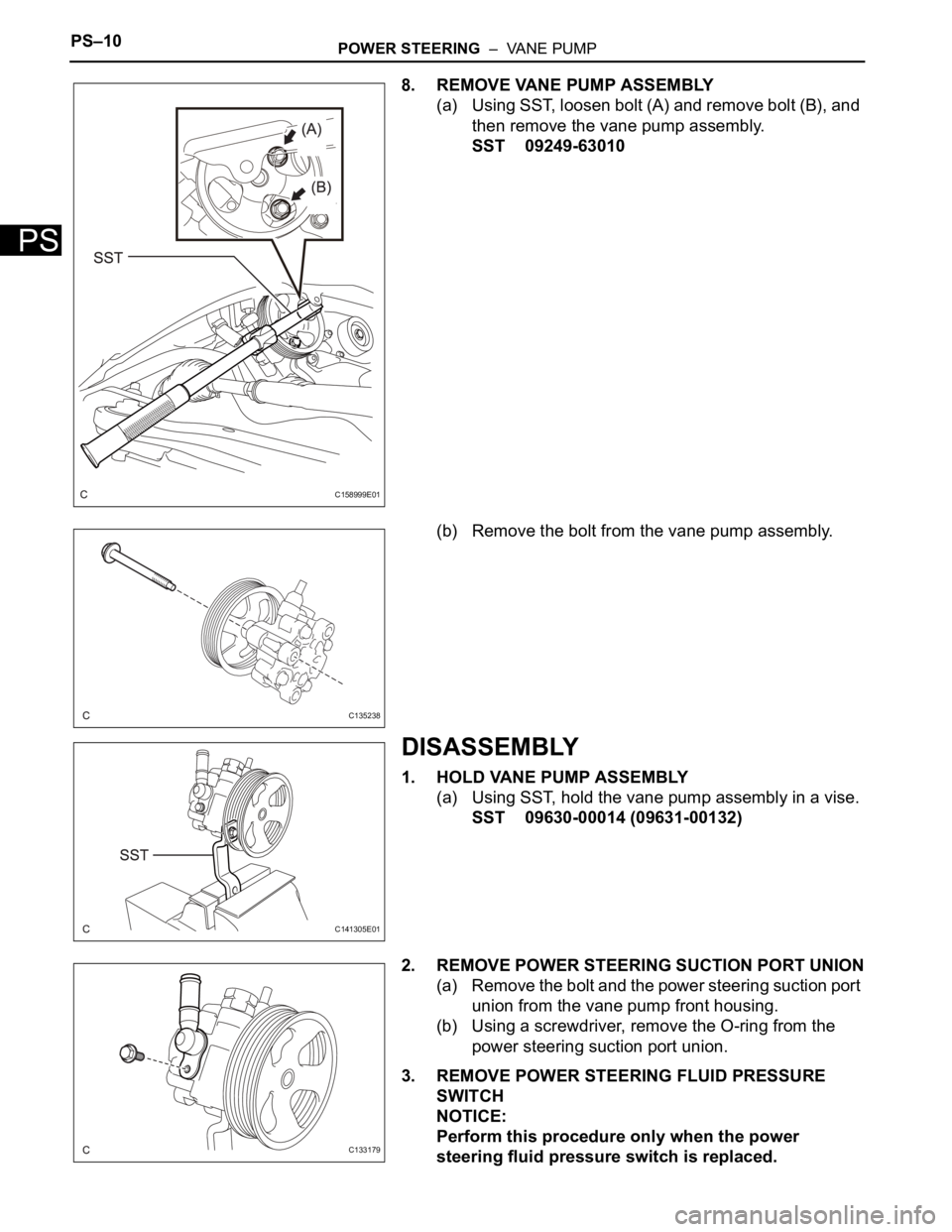

6. DISCONNECT PRESSURE FEED TUBE ASSEMBLY

(a) Remove the union bolt and disconnect the pressure

feed tube assembly from the vane pump assembly.

(b) Remove the gasket from the pressure feed tube

assembly.

7. DISCONNECT POWER STEERING FLUID PRESSURE

SWITCH CONNECTOR

(a) Disconnect the power steering fluid pressure switch

connector.

C133174E02

C161546

C161547

Page 192 of 3000

PS–10POWER STEERING – VANE PUMP

PS

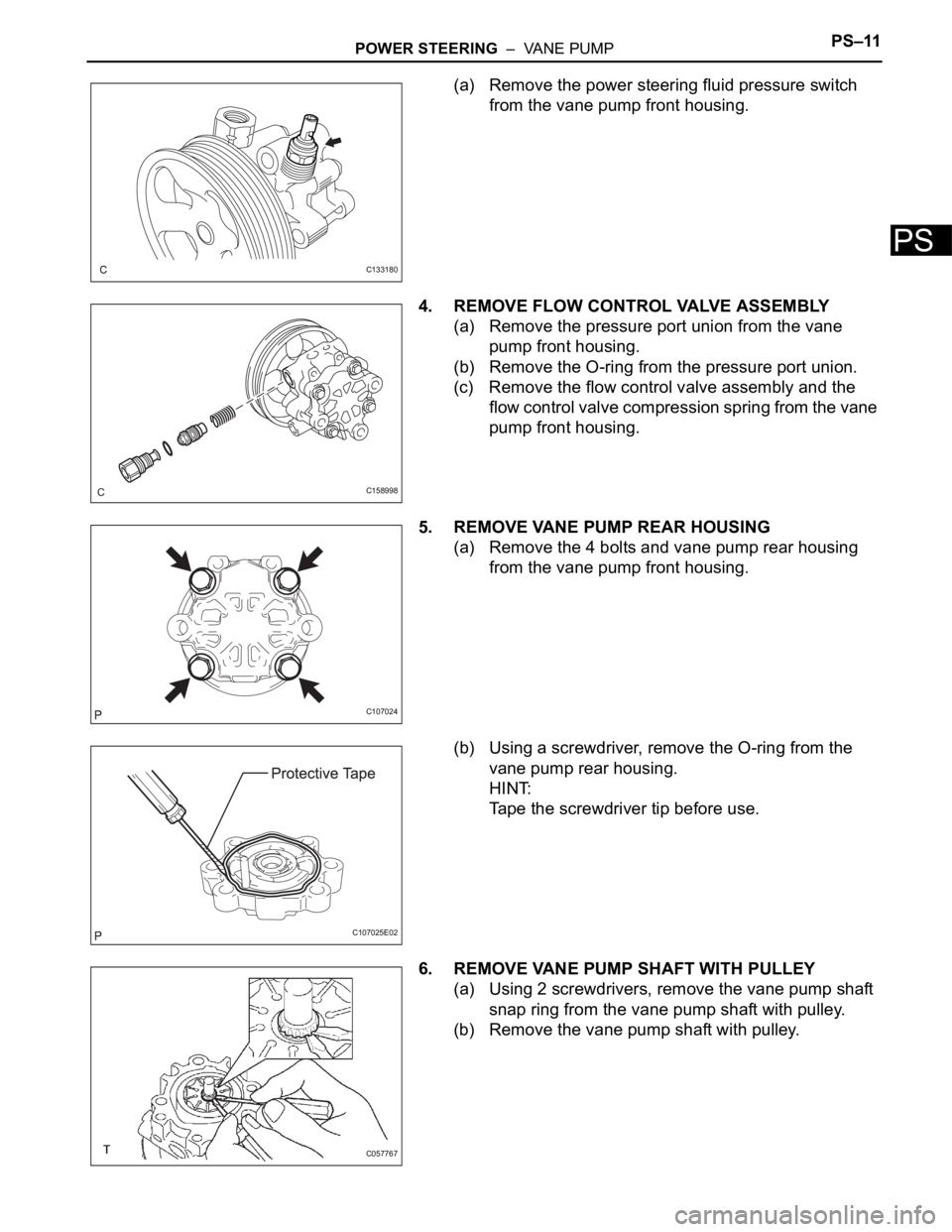

8. REMOVE VANE PUMP ASSEMBLY

(a) Using SST, loosen bolt (A) and remove bolt (B), and

then remove the vane pump assembly.

SST 09249-63010

(b) Remove the bolt from the vane pump assembly.

DISASSEMBLY

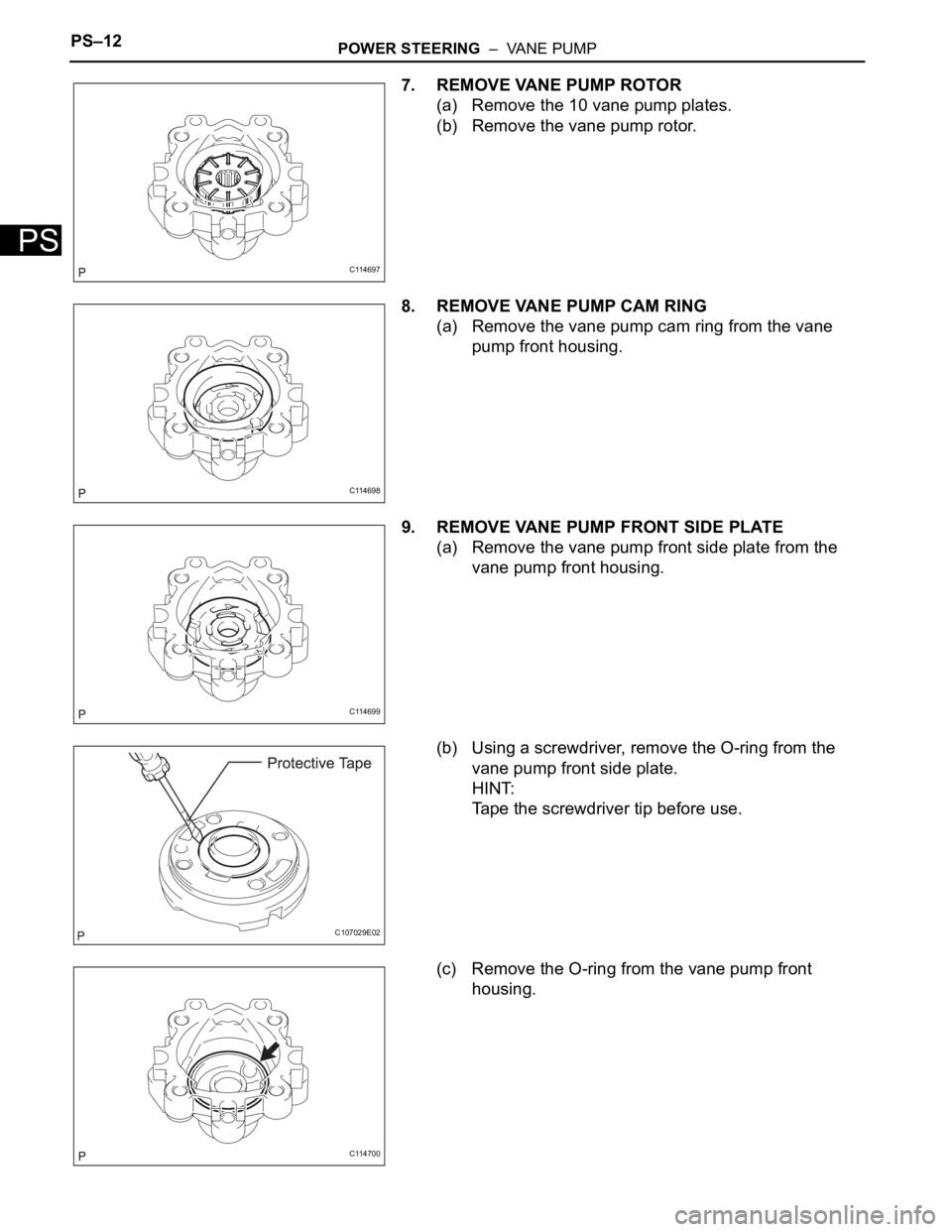

1. HOLD VANE PUMP ASSEMBLY

(a) Using SST, hold the vane pump assembly in a vise.

SST 09630-00014 (09631-00132)

2. REMOVE POWER STEERING SUCTION PORT UNION

(a) Remove the bolt and the power steering suction port

union from the vane pump front housing.

(b) Using a screwdriver, remove the O-ring from the

power steering suction port union.

3. REMOVE POWER STEERING FLUID PRESSURE

SWITCH

NOTICE:

Perform this procedure only when the power

steering fluid pressure switch is replaced.

C158999E01

C135238

C141305E01

C133179

Page 193 of 3000

POWER STEERING – VANE PUMPPS–11

PS

(a) Remove the power steering fluid pressure switch

from the vane pump front housing.

4. REMOVE FLOW CONTROL VALVE ASSEMBLY

(a) Remove the pressure port union from the vane

pump front housing.

(b) Remove the O-ring from the pressure port union.

(c) Remove the flow control valve assembly and the

flow control valve compression spring from the vane

pump front housing.

5. REMOVE VANE PUMP REAR HOUSING

(a) Remove the 4 bolts and vane pump rear housing

from the vane pump front housing.

(b) Using a screwdriver, remove the O-ring from the

vane pump rear housing.

HINT:

Tape the screwdriver tip before use.

6. REMOVE VANE PUMP SHAFT WITH PULLEY

(a) Using 2 screwdrivers, remove the vane pump shaft

snap ring from the vane pump shaft with pulley.

(b) Remove the vane pump shaft with pulley.

C133180

C158998

C107024

C107025E02

C057767

Page 194 of 3000

PS–12POWER STEERING – VANE PUMP

PS

7. REMOVE VANE PUMP ROTOR

(a) Remove the 10 vane pump plates.

(b) Remove the vane pump rotor.

8. REMOVE VANE PUMP CAM RING

(a) Remove the vane pump cam ring from the vane

pump front housing.

9. REMOVE VANE PUMP FRONT SIDE PLATE

(a) Remove the vane pump front side plate from the

vane pump front housing.

(b) Using a screwdriver, remove the O-ring from the

vane pump front side plate.

HINT:

Tape the screwdriver tip before use.

(c) Remove the O-ring from the vane pump front

housing.

C114697

C114698

C114699

C107029E02

C114700

Page 195 of 3000

POWER STEERING – VANE PUMPPS–13

PS

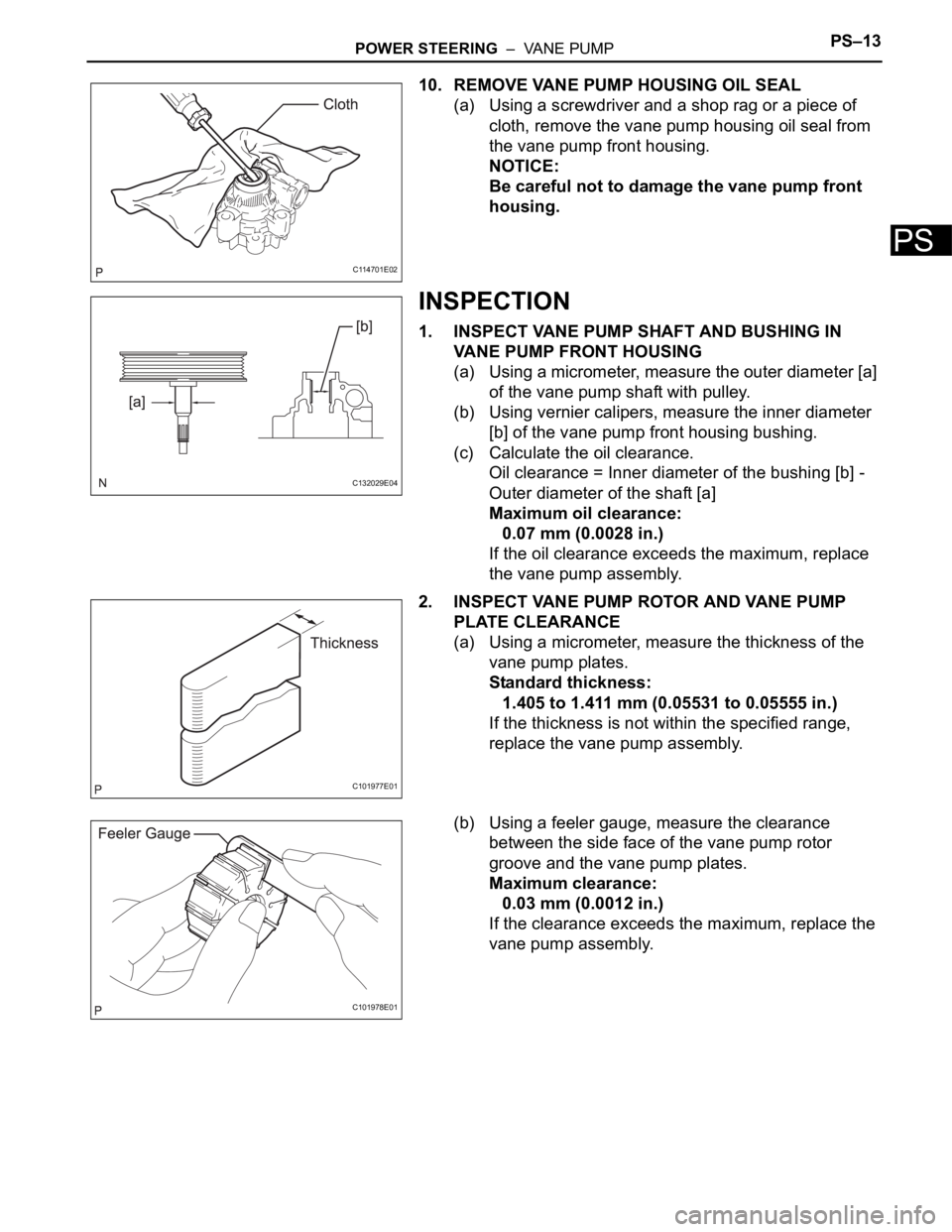

10. REMOVE VANE PUMP HOUSING OIL SEAL

(a) Using a screwdriver and a shop rag or a piece of

cloth, remove the vane pump housing oil seal from

the vane pump front housing.

NOTICE:

Be careful not to damage the vane pump front

housing.

INSPECTION

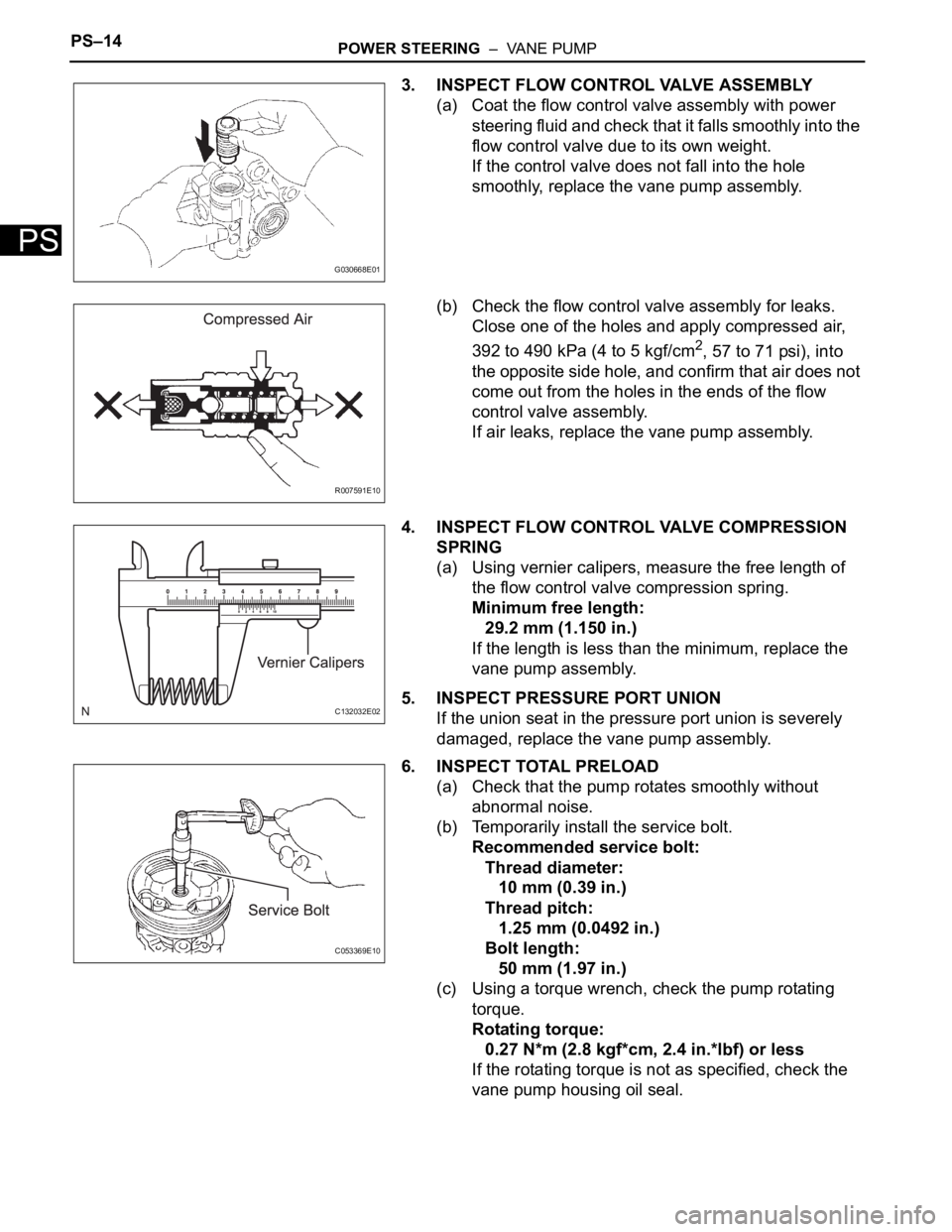

1. INSPECT VANE PUMP SHAFT AND BUSHING IN

VANE PUMP FRONT HOUSING

(a) Using a micrometer, measure the outer diameter [a]

of the vane pump shaft with pulley.

(b) Using vernier calipers, measure the inner diameter

[b] of the vane pump front housing bushing.

(c) Calculate the oil clearance.

Oil clearance = Inner diameter of the bushing [b] -

Outer diameter of the shaft [a]

Maximum oil clearance:

0.07 mm (0.0028 in.)

If the oil clearance exceeds the maximum, replace

the vane pump assembly.

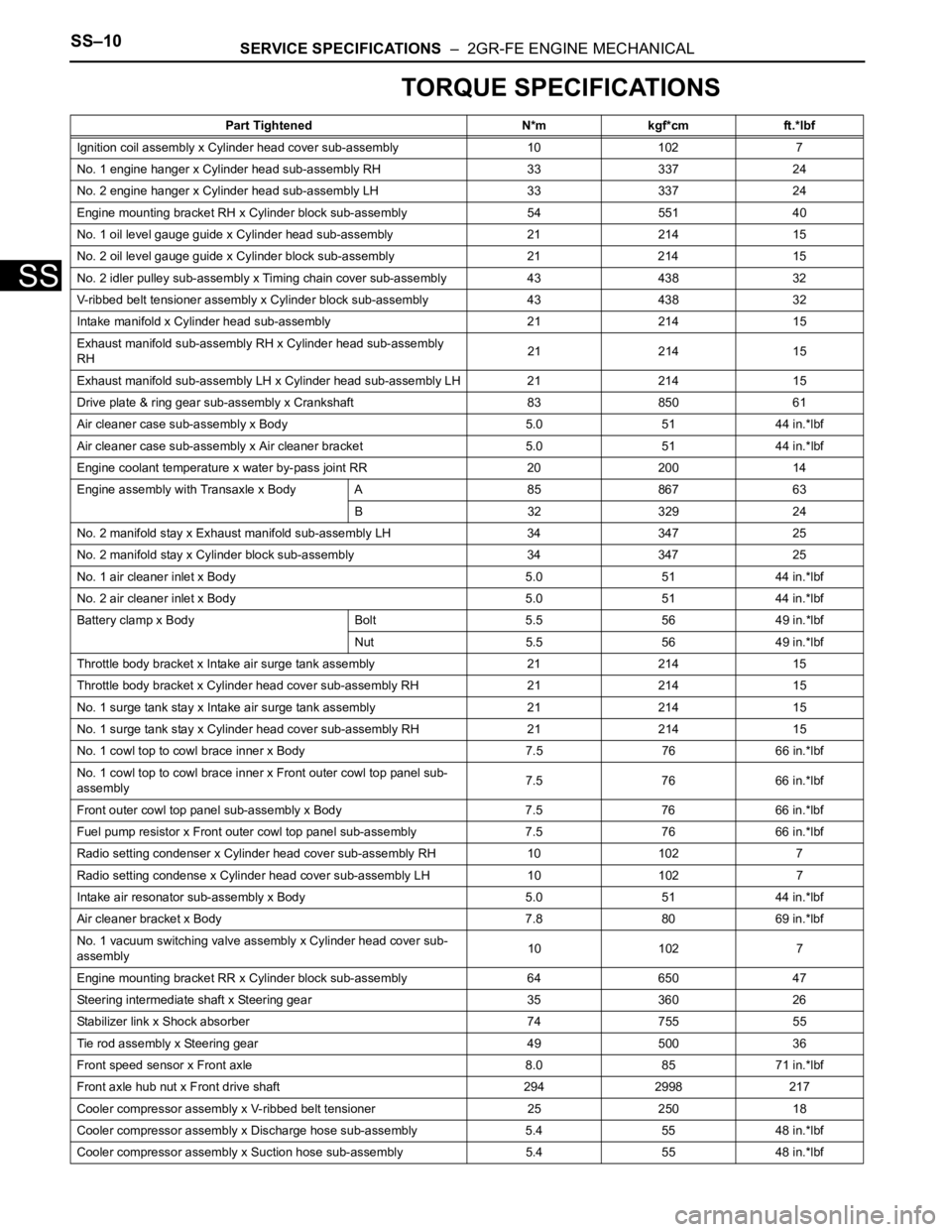

2. INSPECT VANE PUMP ROTOR AND VANE PUMP

PLATE CLEARANCE

(a) Using a micrometer, measure the thickness of the

vane pump plates.

Standard thickness:

1.405 to 1.411 mm (0.05531 to 0.05555 in.)

If the thickness is not within the specified range,

replace the vane pump assembly.

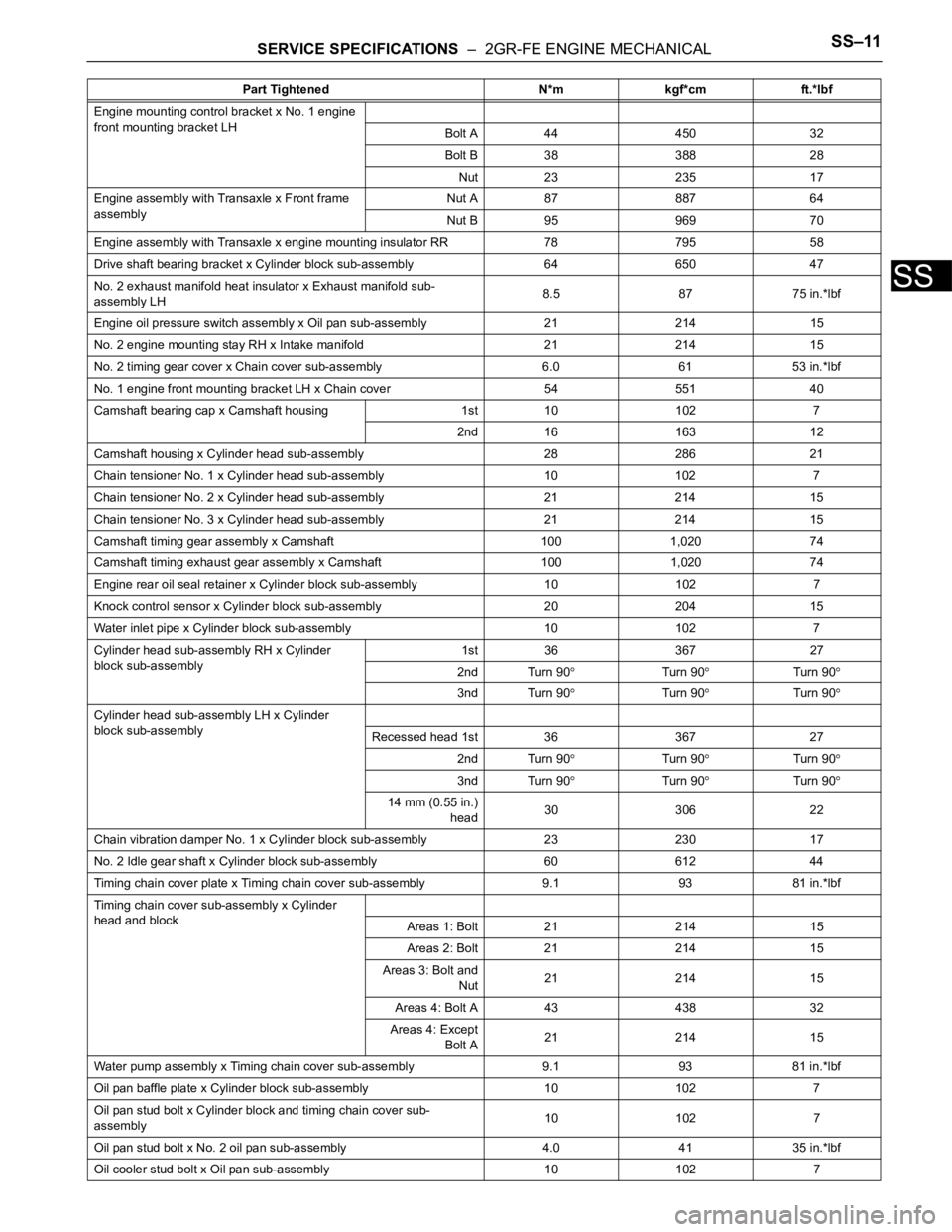

(b) Using a feeler gauge, measure the clearance

between the side face of the vane pump rotor

groove and the vane pump plates.

Maximum clearance:

0.03 mm (0.0012 in.)

If the clearance exceeds the maximum, replace the

vane pump assembly.

C114701E02

C132029E04

C101977E01

C101978E01

Page 196 of 3000

PS–14POWER STEERING – VANE PUMP

PS

3. INSPECT FLOW CONTROL VALVE ASSEMBLY

(a) Coat the flow control valve assembly with power

steering fluid and check that it falls smoothly into the

flow control valve due to its own weight.

If the control valve does not fall into the hole

smoothly, replace the vane pump assembly.

(b) Check the flow control valve assembly for leaks.

Close one of the holes and apply compressed air,

392 to 490 kPa (4 to 5 kgf/cm

2, 57 to 71 psi), into

the opposite side hole, and confirm that air does not

come out from the holes in the ends of the flow

control valve assembly.

If air leaks, replace the vane pump assembly.

4. INSPECT FLOW CONTROL VALVE COMPRESSION

SPRING

(a) Using vernier calipers, measure the free length of

the flow control valve compression spring.

Minimum free length:

29.2 mm (1.150 in.)

If the length is less than the minimum, replace the

vane pump assembly.

5. INSPECT PRESSURE PORT UNION

If the union seat in the pressure port union is severely

damaged, replace the vane pump assembly.

6. INSPECT TOTAL PRELOAD

(a) Check that the pump rotates smoothly without

abnormal noise.

(b) Temporarily install the service bolt.

Recommended service bolt:

Thread diameter:

10 mm (0.39 in.)

Thread pitch:

1.25 mm (0.0492 in.)

Bolt length:

50 mm (1.97 in.)

(c) Using a torque wrench, check the pump rotating

torque.

Rotating torque:

0.27 N*m (2.8 kgf*cm, 2.4 in.*lbf) or less

If the rotating torque is not as specified, check the

vane pump housing oil seal.

G030668E01

R007591E10

C132032E02

C053369E10

Page 197 of 3000

SS–10SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICAL

SS

TORQUE SPECIFICATIONS

Part Tightened N*m kgf*cm ft.*lbf

Ignition coil assembly x Cylinder head cover sub-assembly 10 102 7

No. 1 engine hanger x Cylinder head sub-assembly RH 33 337 24

No. 2 engine hanger x Cylinder head sub-assembly LH 33 337 24

Engine mounting bracket RH x Cylinder block sub-assembly 54 551 40

No. 1 oil level gauge guide x Cylinder head sub-assembly 21 214 15

No. 2 oil level gauge guide x Cylinder block sub-assembly 21 214 15

No. 2 idler pulley sub-assembly x Timing chain cover sub-assembly 43 438 32

V-ribbed belt tensioner assembly x Cylinder block sub-assembly 43 438 32

Intake manifold x Cylinder head sub-assembly 21 214 15

Exhaust manifold sub-assembly RH x Cylinder head sub-assembly

RH21 214 15

Exhaust manifold sub-assembly LH x Cylinder head sub-assembly LH 21 214 15

Drive plate & ring gear sub-assembly x Crankshaft 83 850 61

Air cleaner case sub-assembly x Body 5.0 51 44 in.*lbf

Air cleaner case sub-assembly x Air cleaner bracket 5.0 51 44 in.*lbf

Engine coolant temperature x water by-pass joint RR 20 200 14

Engine assembly with Transaxle x Body A 85 867 63

B 32 329 24

No. 2 manifold stay x Exhaust manifold sub-assembly LH 34 347 25

No. 2 manifold stay x Cylinder block sub-assembly 34 347 25

No. 1 air cleaner inlet x Body 5.0 51 44 in.*lbf

No. 2 air cleaner inlet x Body 5.0 51 44 in.*lbf

Battery clamp x Body Bolt 5.5 56 49 in.*lbf

Nut 5.5 56 49 in.*lbf

Throttle body bracket x Intake air surge tank assembly 21 214 15

Throttle body bracket x Cylinder head cover sub-assembly RH 21 21415

No. 1 surge tank stay x Intake air surge tank assembly 21 214 15

No. 1 surge tank stay x Cylinder head cover sub-assembly RH 21 21415

No. 1 cowl top to cowl brace inner x Body 7.5 76 66 in.*lbf

No. 1 cowl top to cowl brace inner x Front outer cowl top panel sub-

assembly7.5 76 66 in.*lbf

Front outer cowl top panel sub-assembly x Body 7.5 76 66 in.*lbf

Fuel pump resistor x Front outer cowl top panel sub-assembly 7.576 66 in.*lbf

Radio setting condenser x Cylinder head cover sub-assembly RH 10102 7

Radio setting condense x Cylinder head cover sub-assembly LH 10 102 7

Intake air resonator sub-assembly x Body 5.0 51 44 in.*lbf

Air cleaner bracket x Body 7.8 80 69 in.*lbf

No. 1 vacuum switching valve assembly x Cylinder head cover sub-

assembly10 102 7

Engine mounting bracket RR x Cylinder block sub-assembly 64 650 47

Steering intermediate shaft x Steering gear 35 360 26

Stabilizer link x Shock absorber 74 755 55

Tie rod assembly x Steering gear 49 500 36

Front speed sensor x Front axle 8.0 85 71 in.*lbf

Front axle hub nut x Front drive shaft 294 2998 217

Cooler compressor assembly x V-ribbed belt tensioner 25 250 18

Cooler compressor assembly x Discharge hose sub-assembly 5.4 55 48 in.*lbf

Cooler compressor assembly x Suction hose sub-assembly 5.4 55 48 in.*lbf

Page 198 of 3000

SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICALSS–11

SS

Engine mounting control bracket x No. 1 engine

front mounting bracket LH

Bolt A 44 450 32

Bolt B 38 388 28

Nut 23 235 17

Engine assembly with Transaxle x Front frame

assemblyNut A 87 887 64

Nut B 95 969 70

Engine assembly with Transaxle x engine mounting insulator RR 78795 58

Drive shaft bearing bracket x Cylinder block sub-assembly 64 650 47

No. 2 exhaust manifold heat insulator x Exhaust manifold sub-

assembly LH8.5 87 75 in.*lbf

Engine oil pressure switch assembly x Oil pan sub-assembly 21 21415

No. 2 engine mounting stay RH x Intake manifold 21 214 15

No. 2 timing gear cover x Chain cover sub-assembly 6.0 61 53 in.*lbf

No. 1 engine front mounting bracket LH x Chain cover 54 551 40

Camshaft bearing cap x Camshaft housing 1st 10 102 7

2nd 16 163 12

Camshaft housing x Cylinder head sub-assembly 28 286 21

Chain tensioner No. 1 x Cylinder head sub-assembly 10 102 7

Chain tensioner No. 2 x Cylinder head sub-assembly 21 214 15

Chain tensioner No. 3 x Cylinder head sub-assembly 21 214 15

Camshaft timing gear assembly x Camshaft 100 1,020 74

Camshaft timing exhaust gear assembly x Camshaft 100 1,020 74

Engine rear oil seal retainer x Cylinder block sub-assembly 10 1027

Knock control sensor x Cylinder block sub-assembly 20 204 15

Water inlet pipe x Cylinder block sub-assembly 10 102 7

Cylinder head sub-assembly RH x Cylinder

block sub-assembly1st 36 367 27

2nd Turn 90

Turn 90Turn 90

3nd Turn 90Turn 90Turn 90

Cylinder head sub-assembly LH x Cylinder

block sub-assembly

Recessed head 1st 36 367 27

2nd Turn 90

Turn 90Turn 90

3nd Turn 90Turn 90Turn 90

14 mm (0.55 in.)

head30 306 22

Chain vibration damper No. 1 x Cylinder block sub-assembly 23 23017

No. 2 Idle gear shaft x Cylinder block sub-assembly 60 612 44

Timing chain cover plate x Timing chain cover sub-assembly 9.1 9381 in.*lbf

Timing chain cover sub-assembly x Cylinder

head and block

Areas 1: Bolt 21 214 15

Areas 2: Bolt 21 214 15

Areas 3: Bolt and

Nut21 214 15

Areas 4: Bolt A 43 438 32

Areas 4: Except

Bolt A21 214 15

Water pump assembly x Timing chain cover sub-assembly 9.1 93 81 in.*lbf

Oil pan baffle plate x Cylinder block sub-assembly 10 102 7

Oil pan stud bolt x Cylinder block and timing chain cover sub-

assembly10 102 7

Oil pan stud bolt x No. 2 oil pan sub-assembly 4.0 41 35 in.*lbf

Oil cooler stud bolt x Oil pan sub-assembly 10 102 7Part Tightened N*m kgf*cm ft.*lbf

Page 199 of 3000

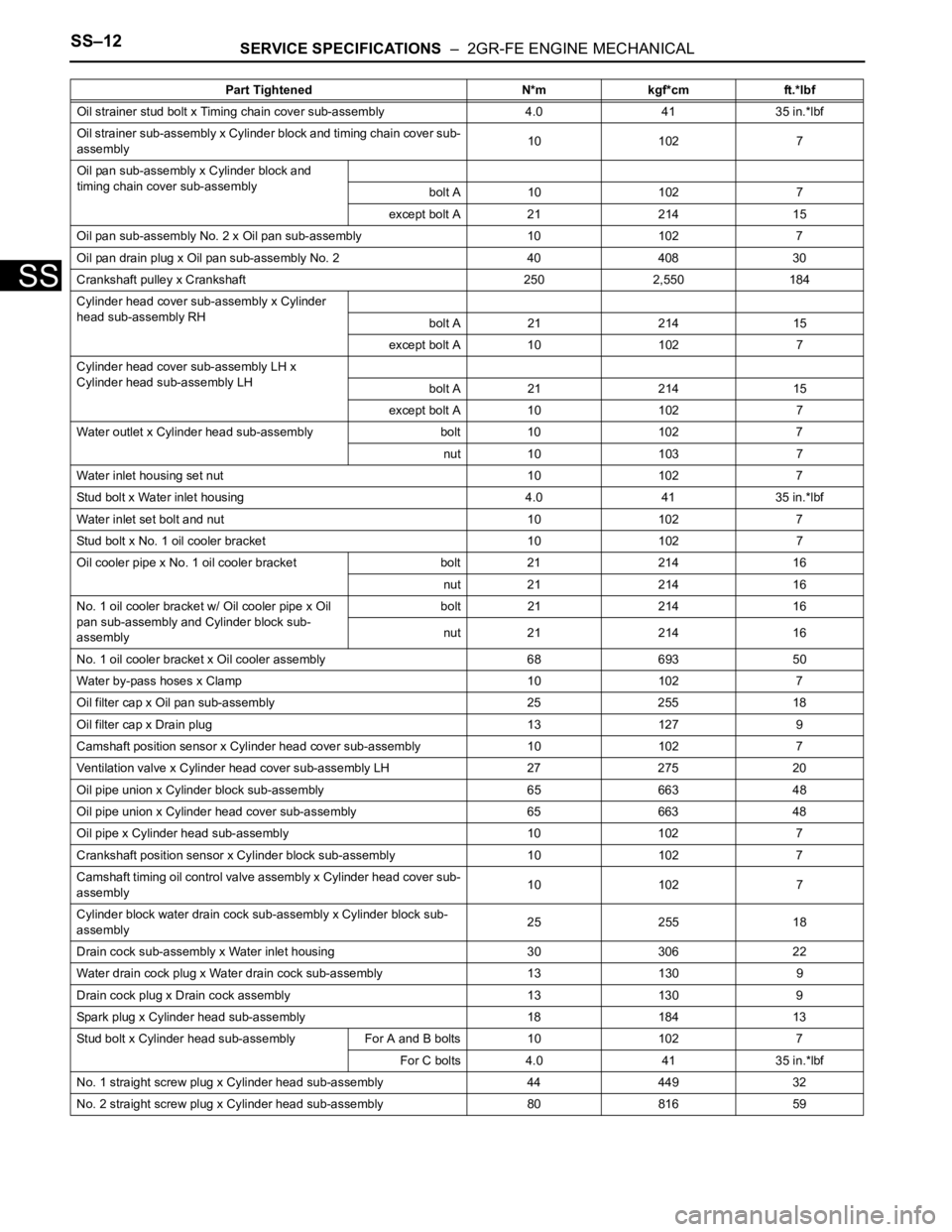

SS–12SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICAL

SS

Oil strainer stud bolt x Timing chain cover sub-assembly 4.0 41 35 in.*lbf

Oil strainer sub-assembly x Cylinder block and timing chain cover sub-

assembly10 102 7

Oil pan sub-assembly x Cylinder block and

timing chain cover sub-assembly

bolt A 10 102 7

except bolt A 21 214 15

Oil pan sub-assembly No. 2 x Oil pan sub-assembly 10 102 7

Oil pan drain plug x Oil pan sub-assembly No. 2 40 408 30

Crankshaft pulley x Crankshaft 250 2,550 184

Cylinder head cover sub-assembly x Cylinder

head sub-assembly RH

bolt A 21 214 15

except bolt A 10 102 7

Cylinder head cover sub-assembly LH x

Cylinder head sub-assembly LH

bolt A 21 214 15

except bolt A 10 102 7

Water outlet x Cylinder head sub-assembly bolt 10 102 7

nut 10 103 7

Water inlet housing set nut 10 102 7

Stud bolt x Water inlet housing 4.0 41 35 in.*lbf

Water inlet set bolt and nut 10 102 7

Stud bolt x No. 1 oil cooler bracket 10 102 7

Oil cooler pipe x No. 1 oil cooler bracket bolt 21 214 16

nut 21 214 16

No. 1 oil cooler bracket w/ Oil cooler pipe x Oil

pan sub-assembly and Cylinder block sub-

assemblybolt 21 214 16

nut 21 214 16

No. 1 oil cooler bracket x Oil cooler assembly 68 693 50

Water by-pass hoses x Clamp 10 102 7

Oil filter cap x Oil pan sub-assembly 25 255 18

Oil filter cap x Drain plug 13 127 9

Camshaft position sensor x Cylinder head cover sub-assembly 10 1027

Ventilation valve x Cylinder head cover sub-assembly LH 27 275 20

Oil pipe union x Cylinder block sub-assembly 65 663 48

Oil pipe union x Cylinder head cover sub-assembly 65 663 48

Oil pipe x Cylinder head sub-assembly 10 102 7

Crankshaft position sensor x Cylinder block sub-assembly 10 102 7

Camshaft timing oil control valve assembly x Cylinder head cover sub-

assembly10 102 7

Cylinder block water drain cock sub-assembly x Cylinder block sub-

assembly25 255 18

Drain cock sub-assembly x Water inlet housing 30 306 22

Water drain cock plug x Water drain cock sub-assembly 13 130 9

Drain cock plug x Drain cock assembly 13 130 9

Spark plug x Cylinder head sub-assembly 18 184 13

Stud bolt x Cylinder head sub-assembly For A and B bolts 10 102 7

For C bolts 4.0 41 35 in.*lbf

No. 1 straight screw plug x Cylinder head sub-assembly 44 449 32

No. 2 straight screw plug x Cylinder head sub-assembly 80 816 59Part Tightened N*m kgf*cm ft.*lbf

Page 200 of 3000

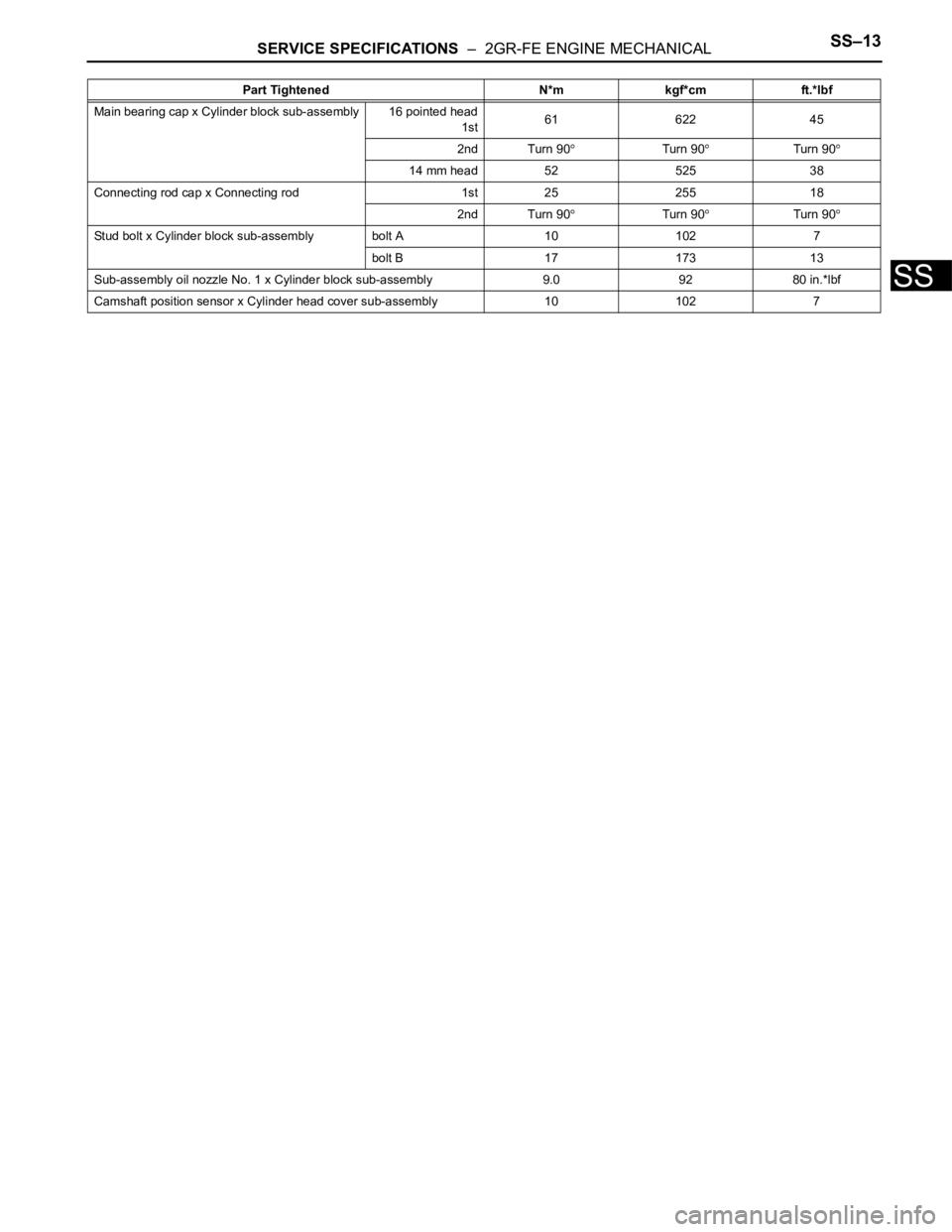

SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICALSS–13

SS

Main bearing cap x Cylinder block sub-assembly 16 pointed head

1st61 622 45

2nd Turn 90

Turn 90Turn 90

14 mm head 52 525 38

Connecting rod cap x Connecting rod 1st 25 255 18

2nd Turn 90

Turn 90Turn 90

Stud bolt x Cylinder block sub-assembly bolt A 10 102 7

bolt B 17 173 13

Sub-assembly oil nozzle No. 1 x Cylinder block sub-assembly 9.0 92 80 in.*lbf

Camshaft position sensor x Cylinder head cover sub-assembly 10 1027 Part Tightened N*m kgf*cm ft.*lbf