TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 181 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–5

BC

• After the ABS warning light goes off and if

vehicle speed exceeds 50 mph (80 km/h), the

signal check code will be stored again.

Decelerate or stop the vehicle before the

speed reaches 50 mph (80 km/h).

• If the signal check has not been completed,

the ABS warning light blinks while driving

and the ABS system does not operate.

HINT:

When the signal check has been completed, the

ABS warning light goes off while driving and blinks

in the Test Mode pattern while stationary.

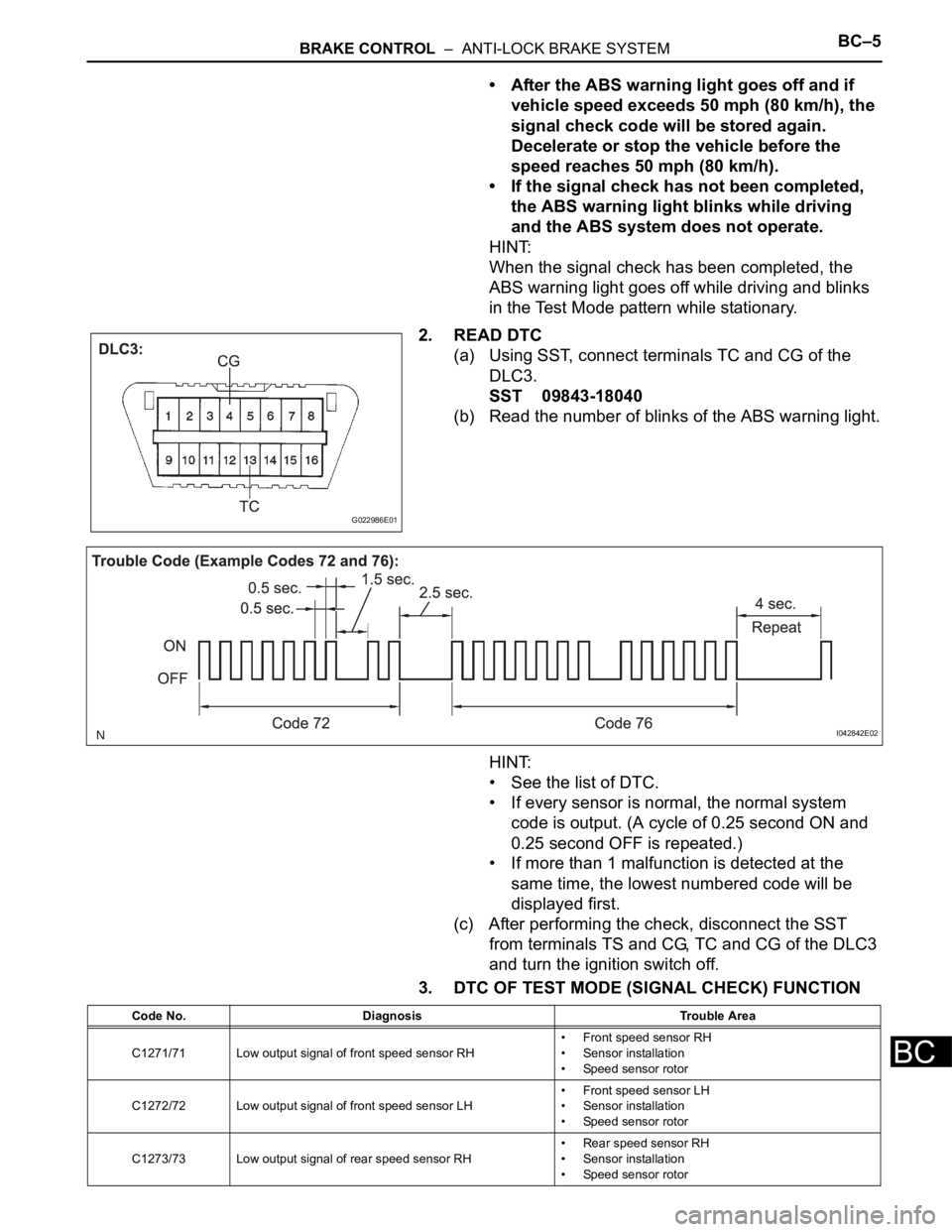

2. READ DTC

(a) Using SST, connect terminals TC and CG of the

DLC3.

SST 09843-18040

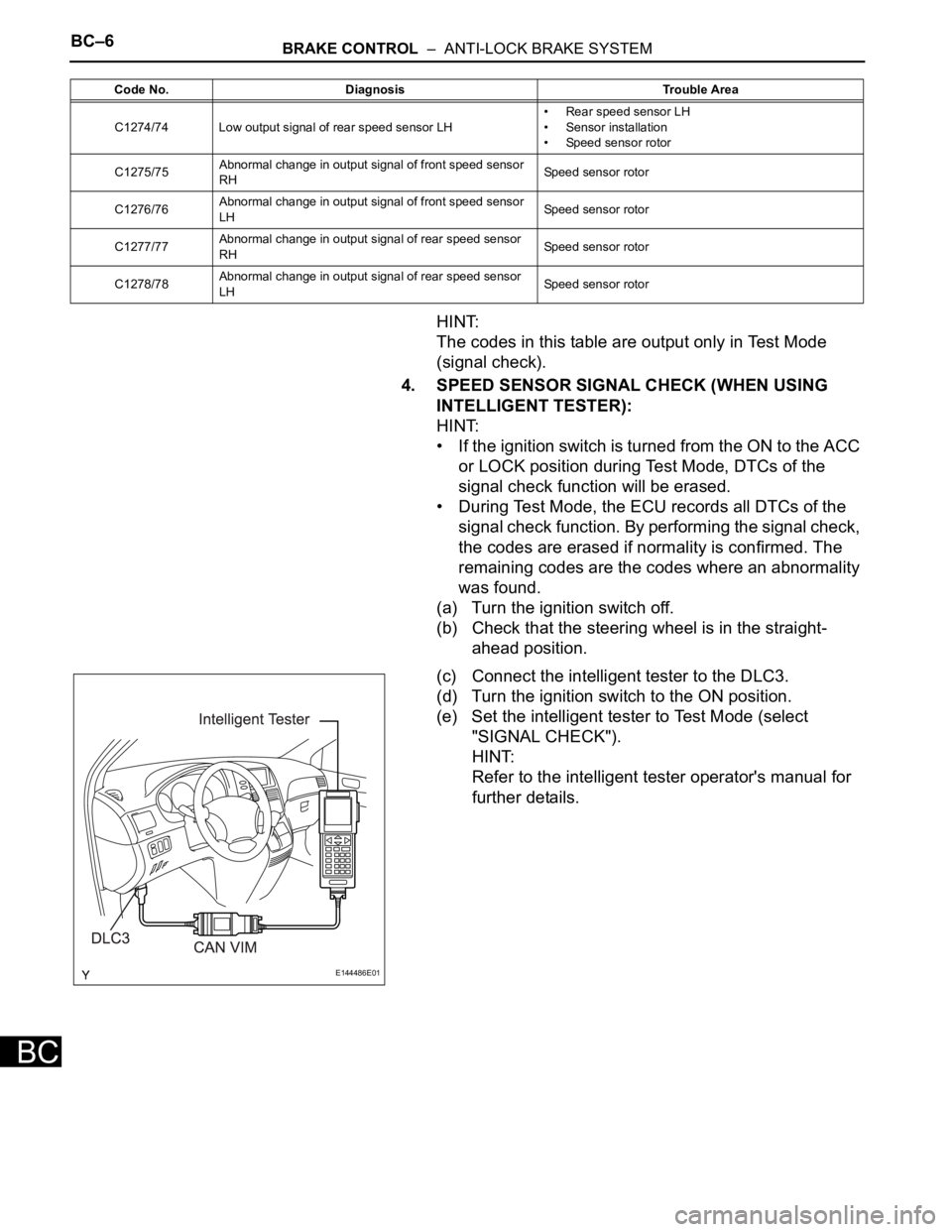

(b) Read the number of blinks of the ABS warning light.

HINT:

• See the list of DTC.

• If every sensor is normal, the normal system

code is output. (A cycle of 0.25 second ON and

0.25 second OFF is repeated.)

• If more than 1 malfunction is detected at the

same time, the lowest numbered code will be

displayed first.

(c) After performing the check, disconnect the SST

from terminals TS and CG, TC and CG of the DLC3

and turn the ignition switch off.

3. DTC OF TEST MODE (SIGNAL CHECK) FUNCTION

G022986E01

I042842E02

Code No. Diagnosis Trouble Area

C1271/71 Low output signal of front speed sensor RH• Front speed sensor RH

• Sensor installation

• Speed sensor rotor

C1272/72 Low output signal of front speed sensor LH• Front speed sensor LH

• Sensor installation

• Speed sensor rotor

C1273/73 Low output signal of rear speed sensor RH• Rear speed sensor RH

• Sensor installation

• Speed sensor rotor

Page 182 of 3000

BC–6BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

HINT:

The codes in this table are output only in Test Mode

(signal check).

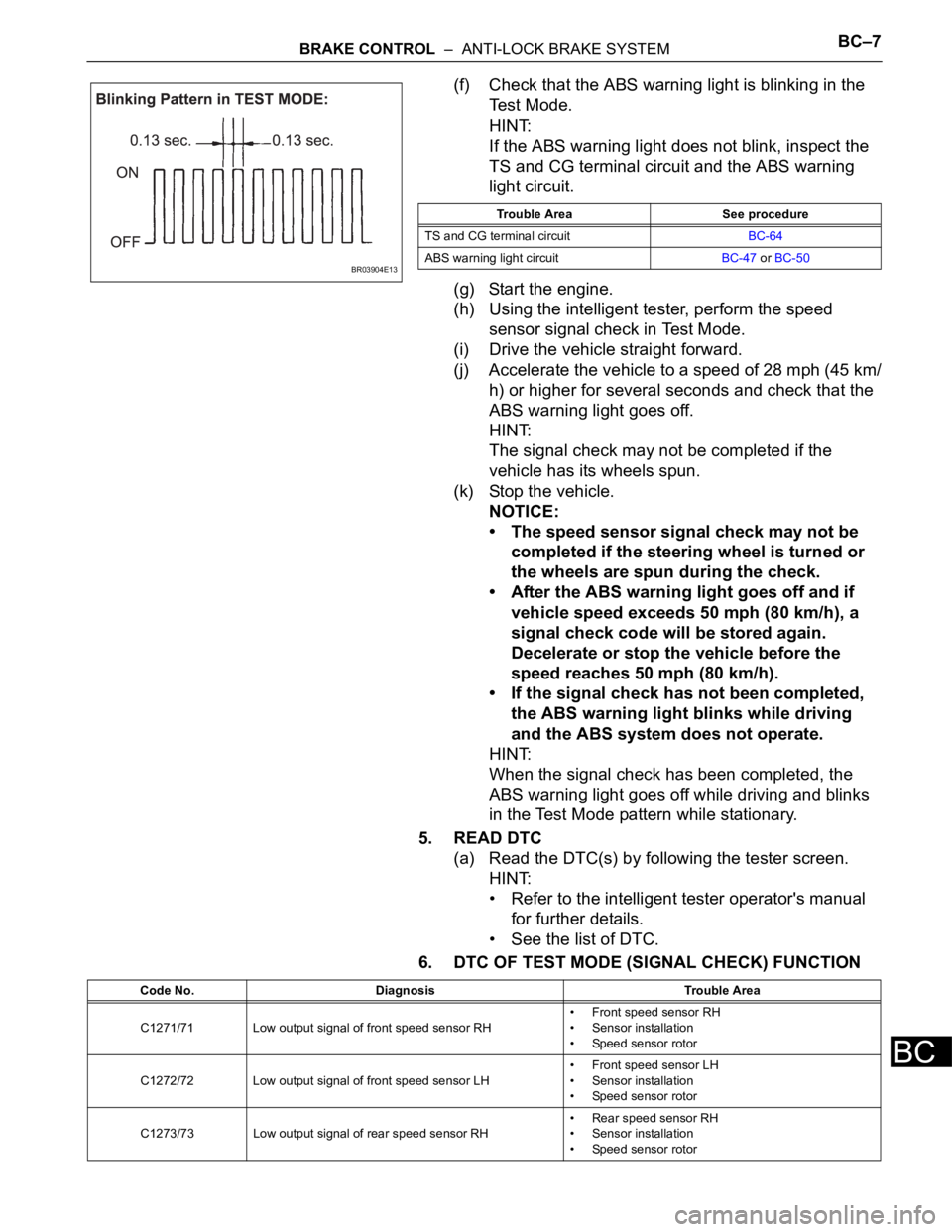

4. SPEED SENSOR SIGNAL CHECK (WHEN USING

INTELLIGENT TESTER):

HINT:

• If the ignition switch is turned from the ON to the ACC

or LOCK position during Test Mode, DTCs of the

signal check function will be erased.

• During Test Mode, the ECU records all DTCs of the

signal check function. By performing the signal check,

the codes are erased if normality is confirmed. The

remaining codes are the codes where an abnormality

was found.

(a) Turn the ignition switch off.

(b) Check that the steering wheel is in the straight-

ahead position.

(c) Connect the intelligent tester to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Set the intelligent tester to Test Mode (select

"SIGNAL CHECK").

HINT:

Refer to the intelligent tester operator's manual for

further details.

C1274/74 Low output signal of rear speed sensor LH• Rear speed sensor LH

• Sensor installation

• Speed sensor rotor

C1275/75Abnormal change in output signal of front speed sensor

RHSpeed sensor rotor

C1276/76Abnormal change in output signal of front speed sensor

LHSpeed sensor rotor

C1277/77Abnormal change in output signal of rear speed sensor

RHSpeed sensor rotor

C1278/78Abnormal change in output signal of rear speed sensor

LHSpeed sensor rotor Code No. Diagnosis Trouble Area

E144486E01

Page 183 of 3000

BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEMBC–7

BC

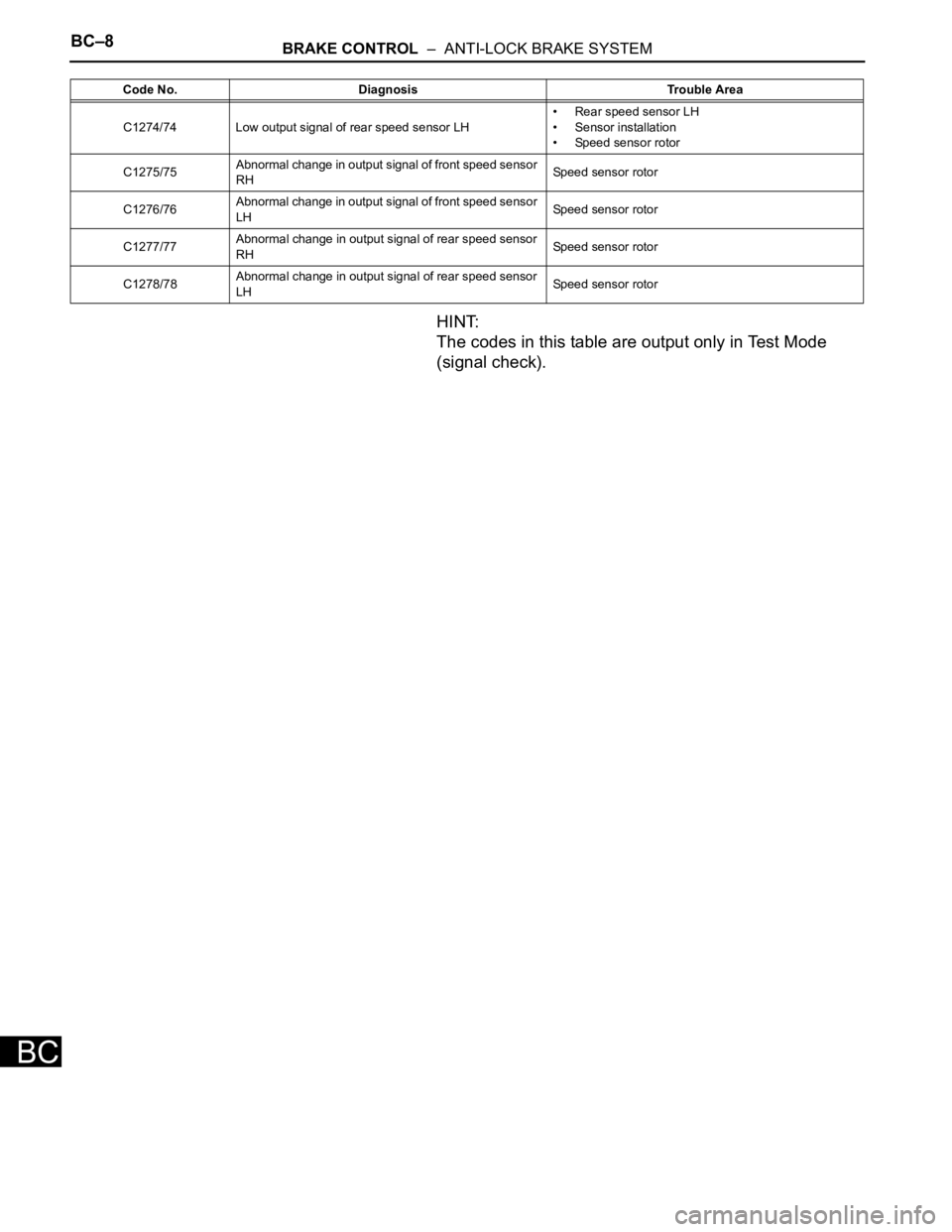

(f) Check that the ABS warning light is blinking in the

Test Mode.

HINT:

If the ABS warning light does not blink, inspect the

TS and CG terminal circuit and the ABS warning

light circuit.

(g) Start the engine.

(h) Using the intelligent tester, perform the speed

sensor signal check in Test Mode.

(i) Drive the vehicle straight forward.

(j) Accelerate the vehicle to a speed of 28 mph (45 km/

h) or higher for several seconds and check that the

ABS warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun.

(k) Stop the vehicle.

NOTICE:

• The speed sensor signal check may not be

completed if the steering wheel is turned or

the wheels are spun during the check.

• After the ABS warning light goes off and if

vehicle speed exceeds 50 mph (80 km/h), a

signal check code will be stored again.

Decelerate or stop the vehicle before the

speed reaches 50 mph (80 km/h).

• If the signal check has not been completed,

the ABS warning light blinks while driving

and the ABS system does not operate.

HINT:

When the signal check has been completed, the

ABS warning light goes off while driving and blinks

in the Test Mode pattern while stationary.

5. READ DTC

(a) Read the DTC(s) by following the tester screen.

HINT:

• Refer to the intelligent tester operator's manual

for further details.

• See the list of DTC.

6. DTC OF TEST MODE (SIGNAL CHECK) FUNCTION

BR03904E13

Trouble Area See procedure

TS and CG terminal circuitBC-64

ABS warning light circuitBC-47 or BC-50

Code No. Diagnosis Trouble Area

C1271/71 Low output signal of front speed sensor RH• Front speed sensor RH

• Sensor installation

• Speed sensor rotor

C1272/72 Low output signal of front speed sensor LH• Front speed sensor LH

• Sensor installation

• Speed sensor rotor

C1273/73 Low output signal of rear speed sensor RH• Rear speed sensor RH

• Sensor installation

• Speed sensor rotor

Page 184 of 3000

BC–8BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

HINT:

The codes in this table are output only in Test Mode

(signal check).

C1274/74 Low output signal of rear speed sensor LH• Rear speed sensor LH

• Sensor installation

• Speed sensor rotor

C1275/75Abnormal change in output signal of front speed sensor

RHSpeed sensor rotor

C1276/76Abnormal change in output signal of front speed sensor

LHSpeed sensor rotor

C1277/77Abnormal change in output signal of rear speed sensor

RHSpeed sensor rotor

C1278/78Abnormal change in output signal of rear speed sensor

LHSpeed sensor rotor Code No. Diagnosis Trouble Area

Page 185 of 3000

BRAKE – BRAKE PEDALBR–11

BR

REMOVAL

1. SEPARATE BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

3. REMOVE COWL SIDE TRIM BOARD LH

4. REMOVE INSTRUMENT PANEL FINISH PANEL SUB-

ASSEMBLY LOWER LH

(a) Remove the 2 bolts and instrument panel finish

panel sub-assembly lower LH.

5. REMOVE INSTRUMENT PANEL SAFETY PAD

INSERT SUB-ASSEMBLY NO. 1

(a) Remove the 4 bolts and instrument panel safety pad

insert sub-assembly No. 1.

6. LOOSEN BRAKE PEDAL SHAFT

(a) Loosen the 2 brake pedal shafts.

7. REMOVE BRAKE PEDAL SUPPORT ASSEMBLY

(a) Remove the 4 nuts and brake pedal support sub-

assembly.

(b) Using needle-nose pliers, remove the tension

spring.

(c) Remove the clip and clevis pin from the brake pedal

lever.

(d) Remove the 2 bolts from the brake pedal bracket

No. 3.

(e) Remove the stop light switch harness clamp from

the brake pedal support sub-assembly.

(f) Disconnect the stop light switch connector.

F045360E01

G024262

G024263

Page 186 of 3000

BR–12BRAKE – BRAKE PEDAL

BR

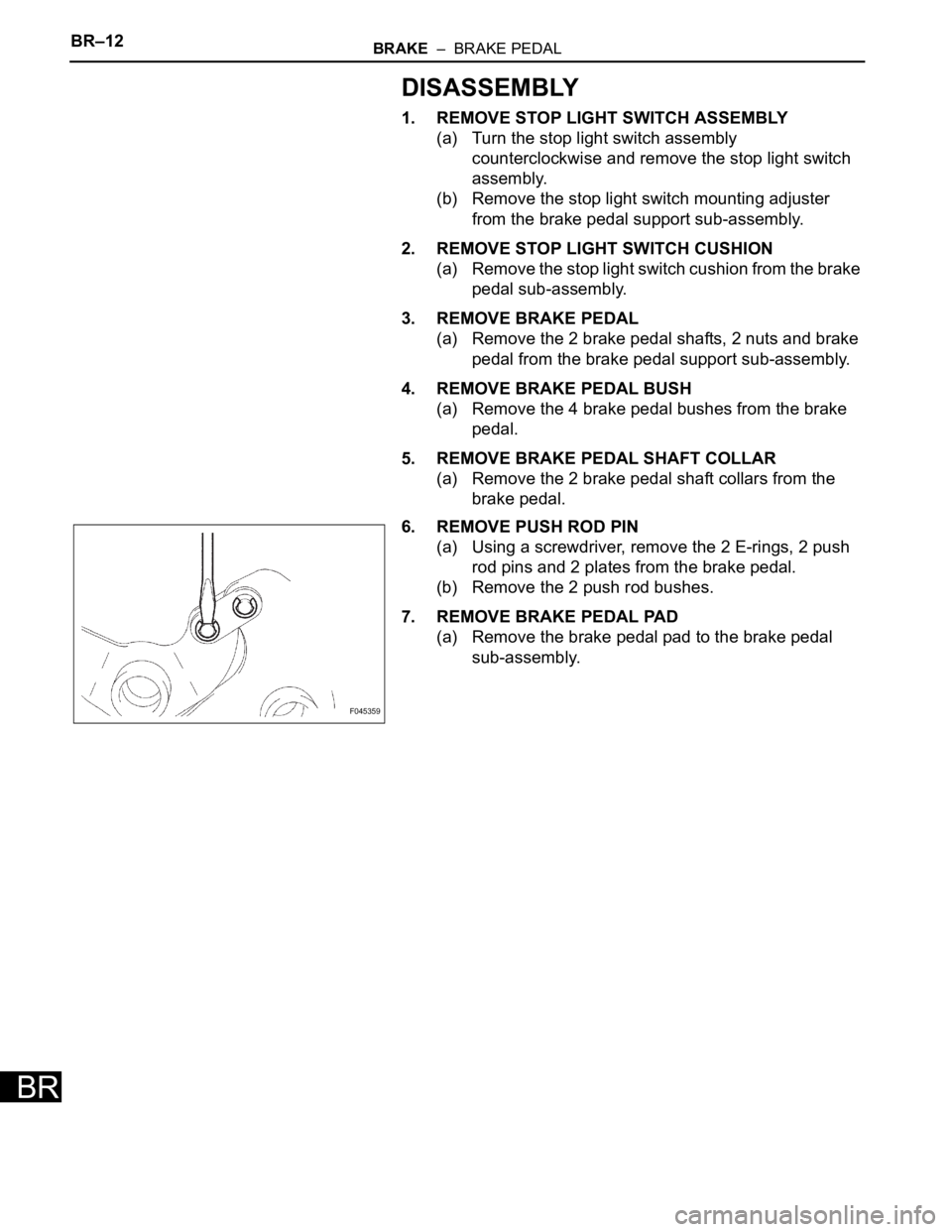

DISASSEMBLY

1. REMOVE STOP LIGHT SWITCH ASSEMBLY

(a) Turn the stop light switch assembly

counterclockwise and remove the stop light switch

assembly.

(b) Remove the stop light switch mounting adjuster

from the brake pedal support sub-assembly.

2. REMOVE STOP LIGHT SWITCH CUSHION

(a) Remove the stop light switch cushion from the brake

pedal sub-assembly.

3. REMOVE BRAKE PEDAL

(a) Remove the 2 brake pedal shafts, 2 nuts and brake

pedal from the brake pedal support sub-assembly.

4. REMOVE BRAKE PEDAL BUSH

(a) Remove the 4 brake pedal bushes from the brake

pedal.

5. REMOVE BRAKE PEDAL SHAFT COLLAR

(a) Remove the 2 brake pedal shaft collars from the

brake pedal.

6. REMOVE PUSH ROD PIN

(a) Using a screwdriver, remove the 2 E-rings, 2 push

rod pins and 2 plates from the brake pedal.

(b) Remove the 2 push rod bushes.

7. REMOVE BRAKE PEDAL PAD

(a) Remove the brake pedal pad to the brake pedal

sub-assembly.

F045359

Page 187 of 3000

PARKING BRAKE – PARKING BRAKE PEDALPB–5

PB

REMOVAL

1. DISCONNECT BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

3. REMOVE COWL SIDE TRIM BOARD LH

4. REMOVE INSTRUMENT PANEL FINISH PANEL SUB-

ASSEMBLY LOWER LH (See page IP-6)

5. REMOVE REAR DOOR SCUFF PLATE RH

6. REMOVE REAR DOOR SCUFF PLATE LH

7. REMOVE FRONT SEAT ASSEMBLY LH

HINT:

• Manual Seat Type (See page SE-48)

• Power Seat Type (See page SE-58)

• Fold Flat Type (See page SE-40)

8. REMOVE REAR SEAT NO.1 ASSEMBLY

HINT:

• Captain Seat Type (See page SE-68)

• Center Seat Type (See page SE-77)

9. REMOVE REAR FLOOR SEAT LOCK COVER

10. REMOVE REAR FLOOR SEAT LOCK COVER

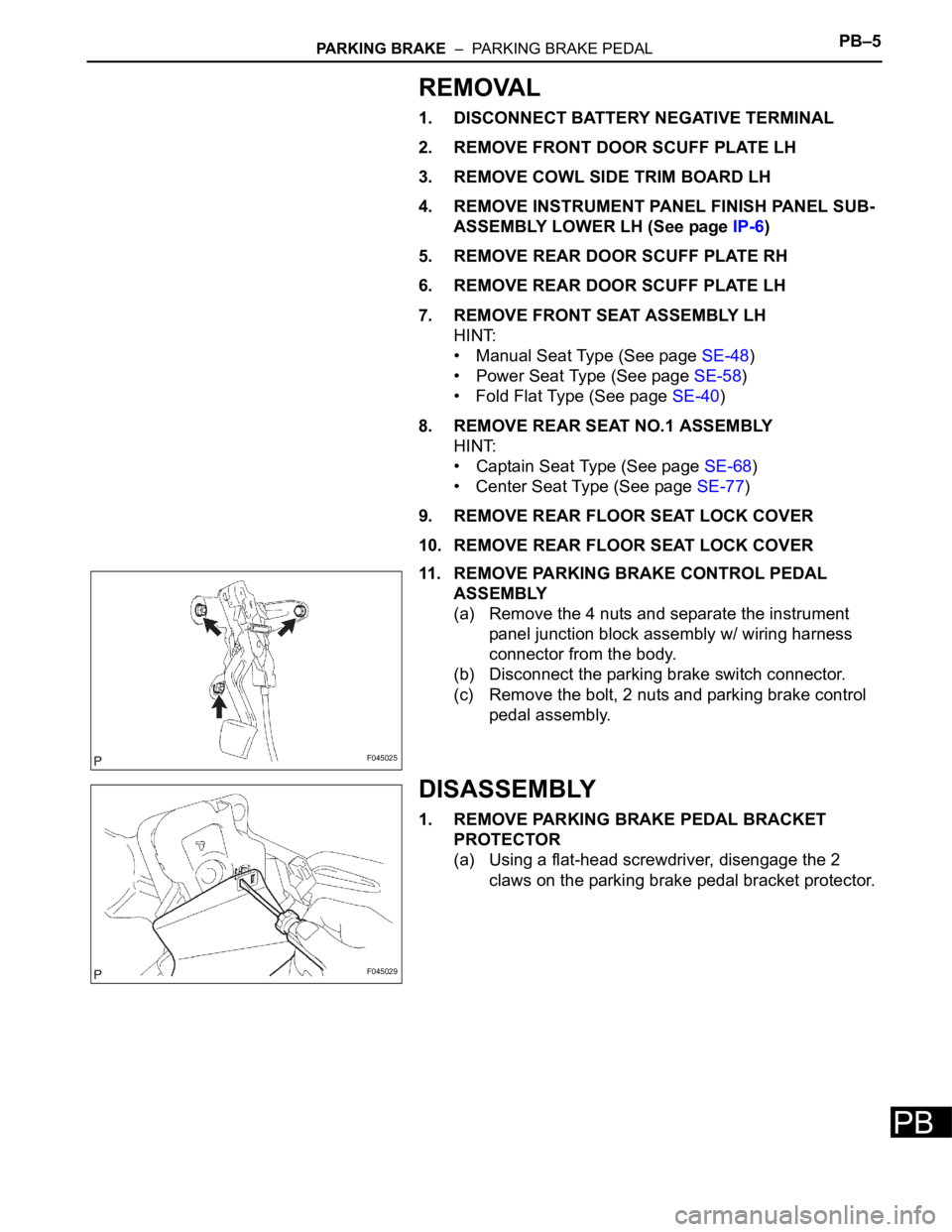

11. REMOVE PARKING BRAKE CONTROL PEDAL

ASSEMBLY

(a) Remove the 4 nuts and separate the instrument

panel junction block assembly w/ wiring harness

connector from the body.

(b) Disconnect the parking brake switch connector.

(c) Remove the bolt, 2 nuts and parking brake control

pedal assembly.

DISASSEMBLY

1. REMOVE PARKING BRAKE PEDAL BRACKET

PROTECTOR

(a) Using a flat-head screwdriver, disengage the 2

claws on the parking brake pedal bracket protector.

F045025

F045029

Page 188 of 3000

PB–6PARKING BRAKE – PARKING BRAKE PEDAL

PB

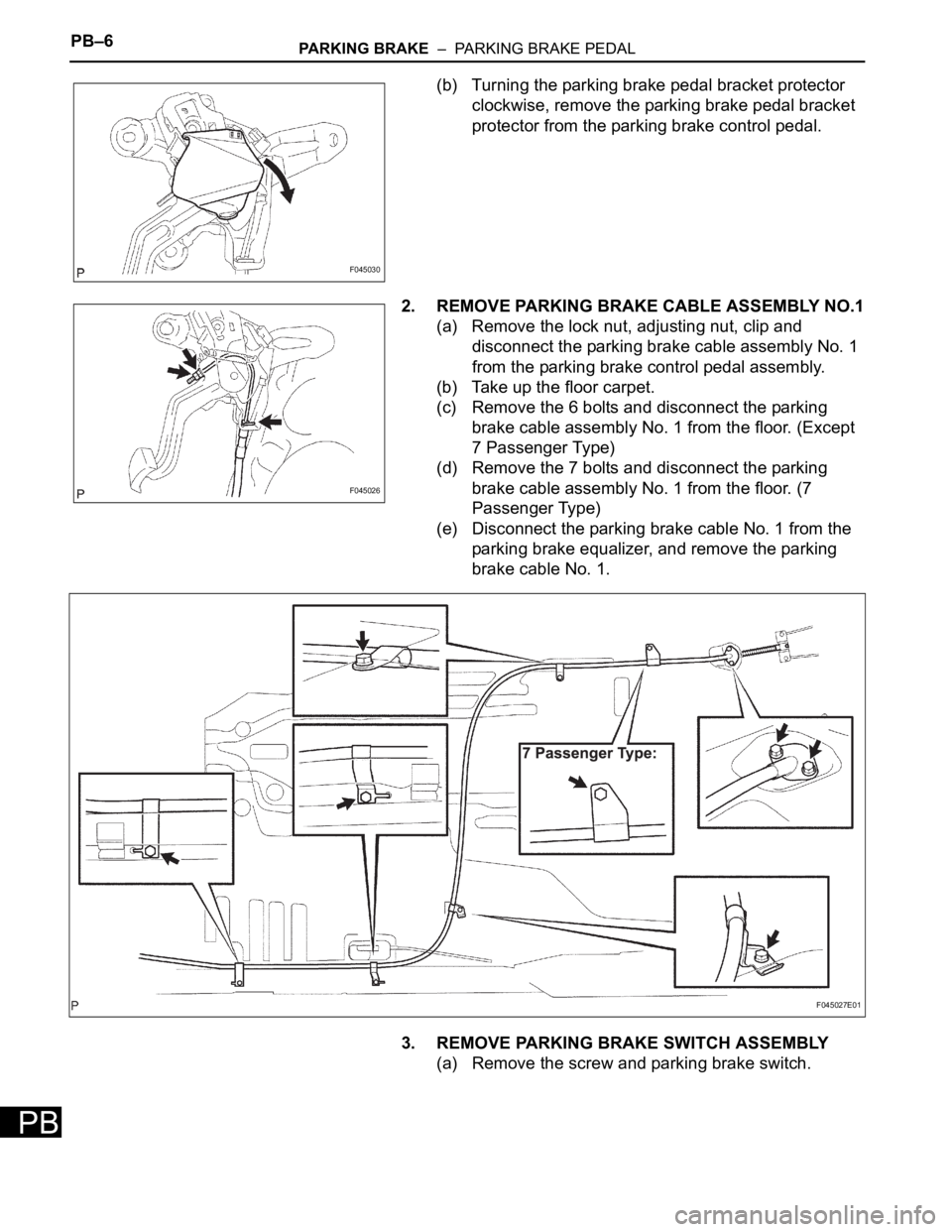

(b) Turning the parking brake pedal bracket protector

clockwise, remove the parking brake pedal bracket

protector from the parking brake control pedal.

2. REMOVE PARKING BRAKE CABLE ASSEMBLY NO.1

(a) Remove the lock nut, adjusting nut, clip and

disconnect the parking brake cable assembly No. 1

from the parking brake control pedal assembly.

(b) Take up the floor carpet.

(c) Remove the 6 bolts and disconnect the parking

brake cable assembly No. 1 from the floor. (Except

7 Passenger Type)

(d) Remove the 7 bolts and disconnect the parking

brake cable assembly No. 1 from the floor. (7

Passenger Type)

(e) Disconnect the parking brake cable No. 1 from the

parking brake equalizer, and remove the parking

brake cable No. 1.

3. REMOVE PARKING BRAKE SWITCH ASSEMBLY

(a) Remove the screw and parking brake switch.

F045030

F045026

F045027E01

Page 189 of 3000

STEERING COLUMN – STEERING SYSTEMSR–3

SR

REPAIR

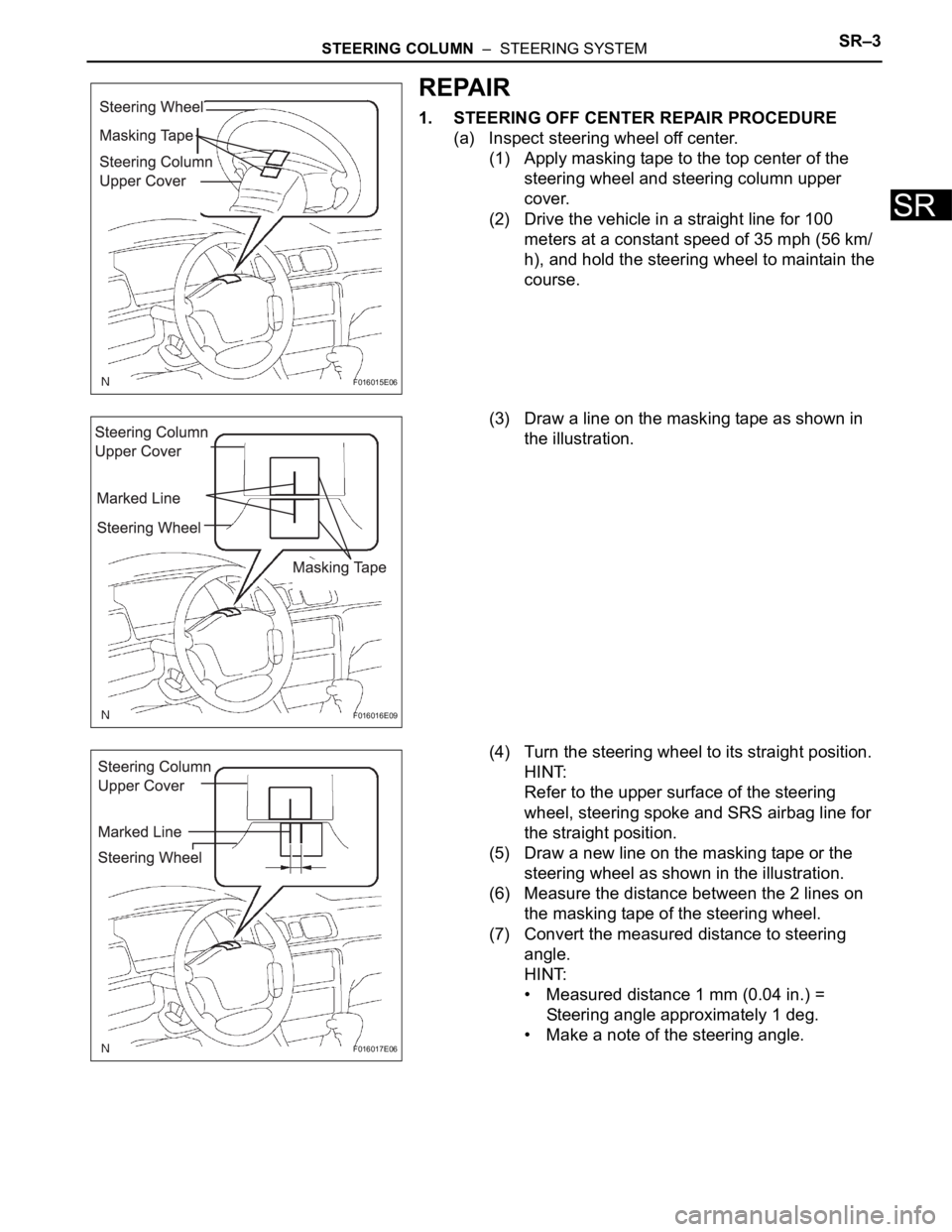

1. STEERING OFF CENTER REPAIR PROCEDURE

(a) Inspect steering wheel off center.

(1) Apply masking tape to the top center of the

steering wheel and steering column upper

cover.

(2) Drive the vehicle in a straight line for 100

meters at a constant speed of 35 mph (56 km/

h), and hold the steering wheel to maintain the

course.

(3) Draw a line on the masking tape as shown in

the illustration.

(4) Turn the steering wheel to its straight position.

HINT:

Refer to the upper surface of the steering

wheel, steering spoke and SRS airbag line for

the straight position.

(5) Draw a new line on the masking tape or the

steering wheel as shown in the illustration.

(6) Measure the distance between the 2 lines on

the masking tape of the steering wheel.

(7) Convert the measured distance to steering

angle.

HINT:

• Measured distance 1 mm (0.04 in.) =

Steering angle approximately 1 deg.

• Make a note of the steering angle.

F016015E06

F016016E09

F016017E06

Page 190 of 3000

SR–4STEERING COLUMN – STEERING SYSTEM

SR

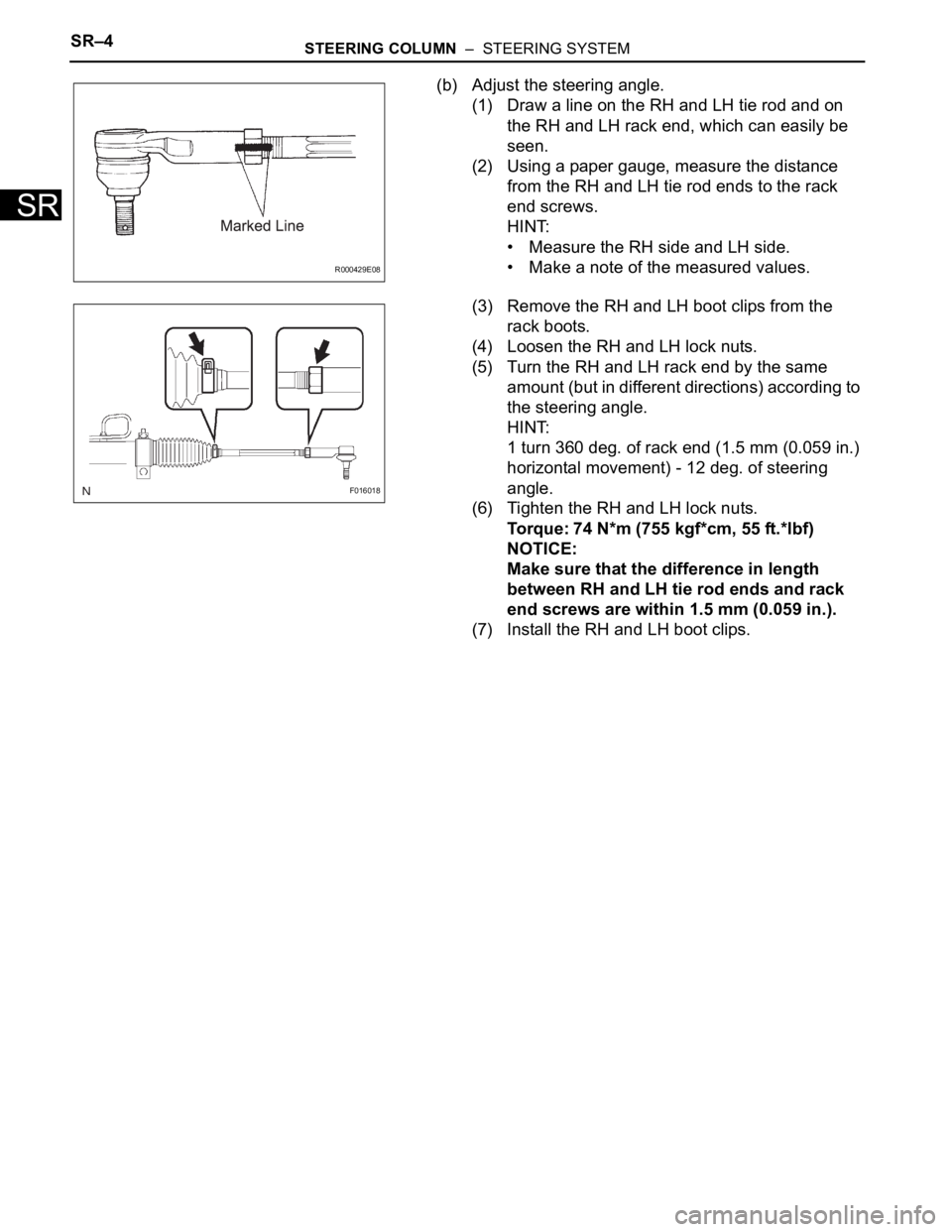

(b) Adjust the steering angle.

(1) Draw a line on the RH and LH tie rod and on

the RH and LH rack end, which can easily be

seen.

(2) Using a paper gauge, measure the distance

from the RH and LH tie rod ends to the rack

end screws.

HINT:

• Measure the RH side and LH side.

• Make a note of the measured values.

(3) Remove the RH and LH boot clips from the

rack boots.

(4) Loosen the RH and LH lock nuts.

(5) Turn the RH and LH rack end by the same

amount (but in different directions) according to

the steering angle.

HINT:

1 turn 360 deg. of rack end (1.5 mm (0.059 in.)

horizontal movement) - 12 deg. of steering

angle.

(6) Tighten the RH and LH lock nuts.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

NOTICE:

Make sure that the difference in length

between RH and LH tie rod ends and rack

end screws are within 1.5 mm (0.059 in.).

(7) Install the RH and LH boot clips.

R000429E08

F016018