TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 421 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–115

ES

OK

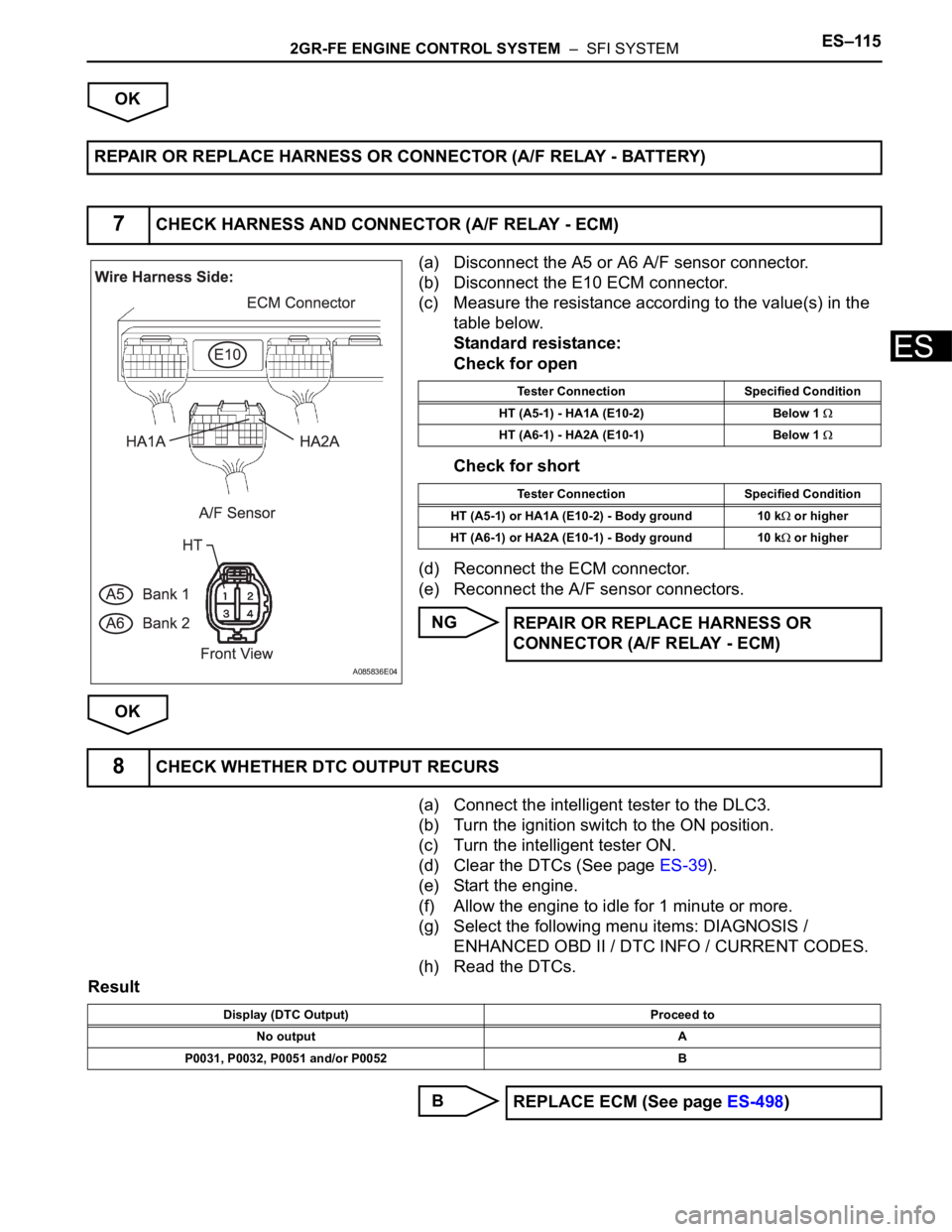

(a) Disconnect the A5 or A6 A/F sensor connector.

(b) Disconnect the E10 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Check for short

(d) Reconnect the ECM connector.

(e) Reconnect the A/F sensor connectors.

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the intelligent tester ON.

(d) Clear the DTCs (See page ES-39).

(e) Start the engine.

(f) Allow the engine to idle for 1 minute or more.

(g) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(h) Read the DTCs.

Result

B REPAIR OR REPLACE HARNESS OR CONNECTOR (A/F RELAY - BATTERY)

7CHECK HARNESS AND CONNECTOR (A/F RELAY - ECM)

A085836E04

Tester Connection Specified Condition

HT (A5-1) - HA1A (E10-2) Below 1

HT (A6-1) - HA2A (E10-1) Below 1

Tester Connection Specified Condition

HT (A5-1) or HA1A (E10-2) - Body ground 10 k

or higher

HT (A6-1) or HA2A (E10-1) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (A/F RELAY - ECM)

8CHECK WHETHER DTC OUTPUT RECURS

Display (DTC Output) Proceed to

No output A

P0031, P0032, P0051 and/or P0052 B

REPLACE ECM (See page ES-498)

Page 422 of 3000

ES–1162GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

A

CHECK FOR INTERMITTENT PROBLEMS

Page 423 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–117

ES

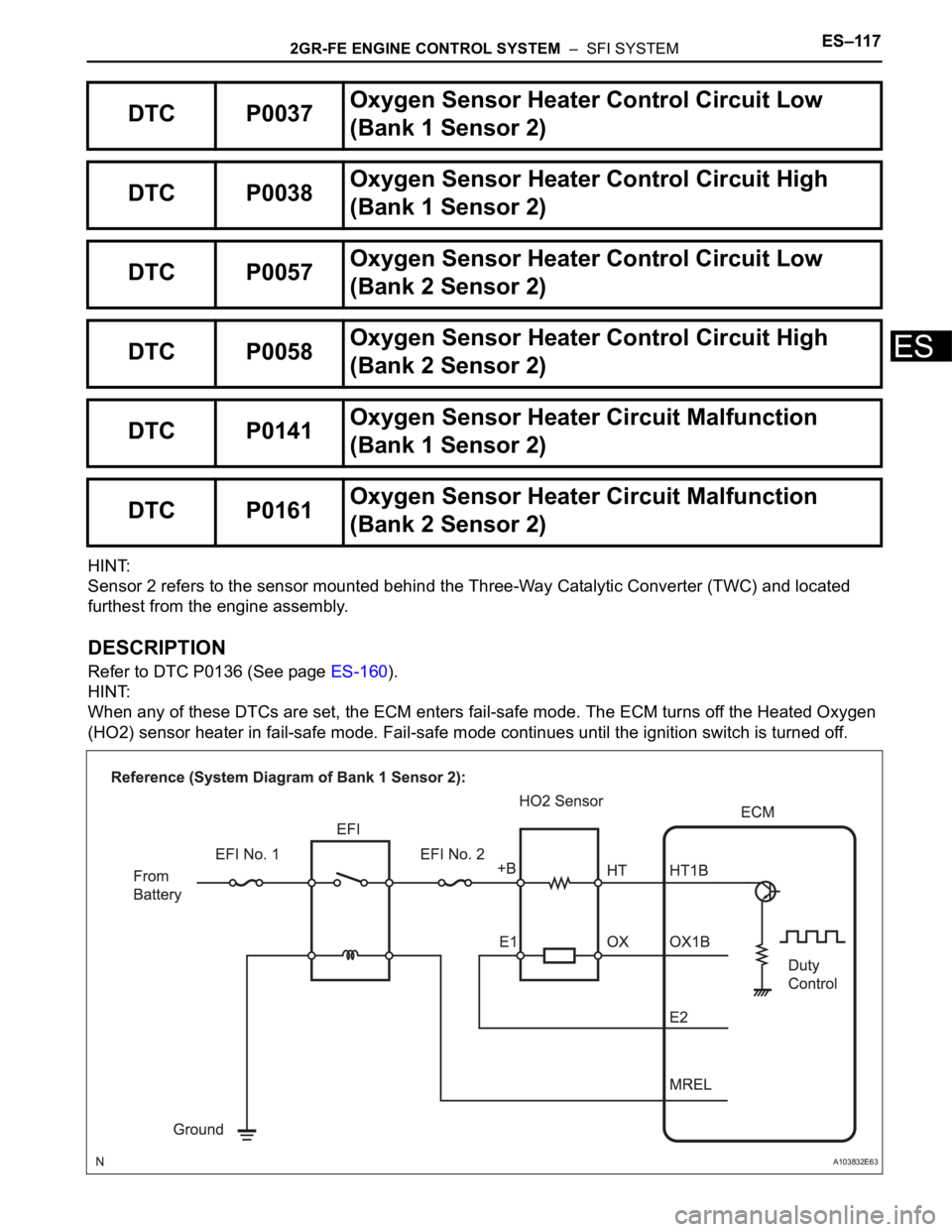

HINT:

Sensor 2 refers to the sensor mounted behind the Three-Way Catalytic Converter (TWC) and located

furthest from the engine assembly.

DESCRIPTION

Refer to DTC P0136 (See page ES-160).

HINT:

When any of these DTCs are set, the ECM enters fail-safe mode. The ECM turns off the Heated Oxygen

(HO2) sensor heater in fail-safe mode. Fail-safe mode continues until the ignition switch is turned off.

DTC P0037Oxygen Sensor Heater Control Circuit Low

(Bank 1 Sensor 2)

DTC P0038Oxygen Sensor Heater Control Circuit High

(Bank 1 Sensor 2)

DTC P0057Oxygen Sensor Heater Control Circuit Low

(Bank 2 Sensor 2)

DTC P0058Oxygen Sensor Heater Control Circuit High

(Bank 2 Sensor 2)

DTC P0141Oxygen Sensor Heater Circuit Malfunction

(Bank 1 Sensor 2)

DTC P0161Oxygen Sensor Heater Circuit Malfunction

(Bank 2 Sensor 2)

A103832E63

Page 424 of 3000

ES–1182GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

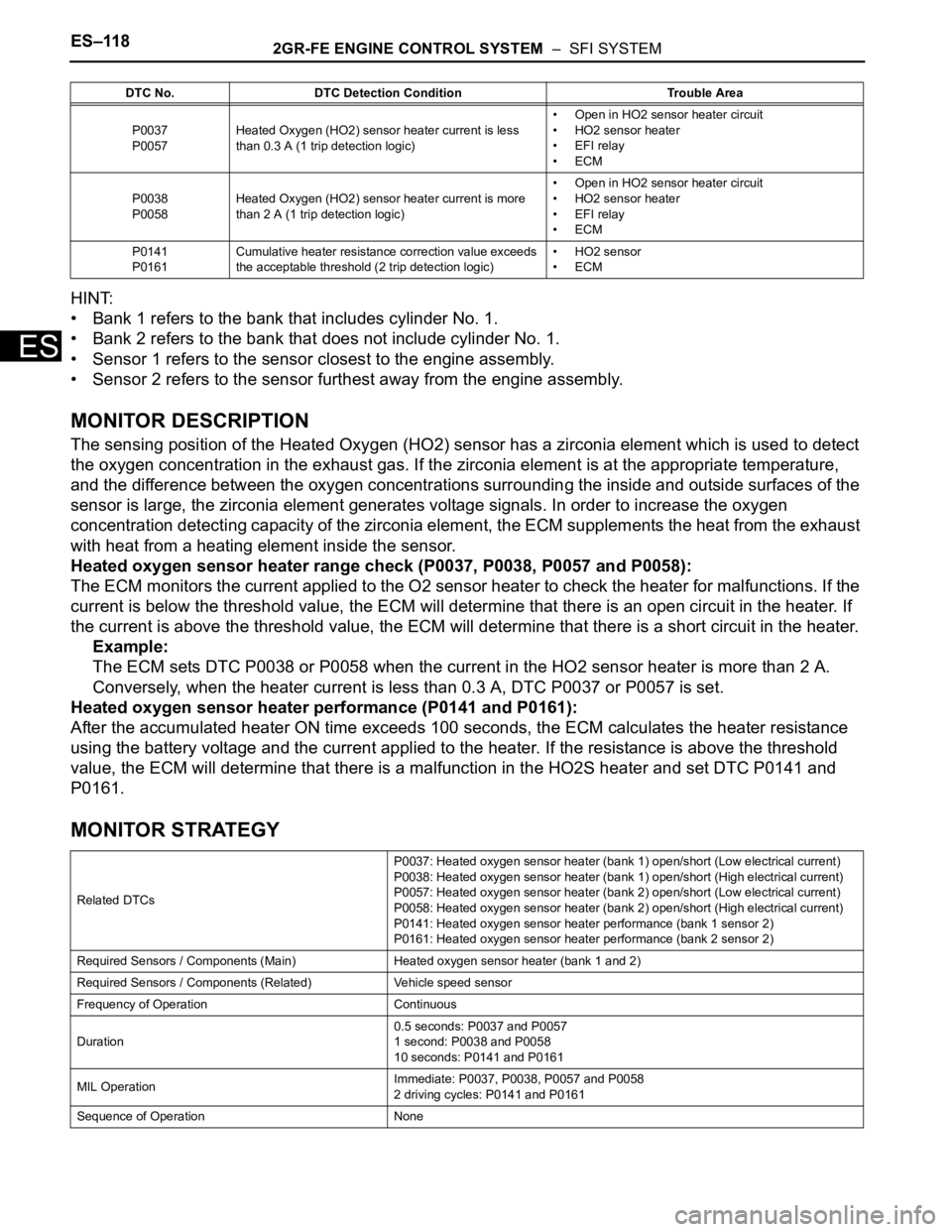

HINT:

• Bank 1 refers to the bank that includes cylinder No. 1.

• Bank 2 refers to the bank that does not include cylinder No. 1.

• Sensor 1 refers to the sensor closest to the engine assembly.

• Sensor 2 refers to the sensor furthest away from the engine assembly.

MONITOR DESCRIPTION

The sensing position of the Heated Oxygen (HO2) sensor has a zirconia element which is used to detect

the oxygen concentration in the exhaust gas. If the zirconia element is at the appropriate temperature,

and the difference between the oxygen concentrations surrounding the inside and outside surfaces of the

sensor is large, the zirconia element generates voltage signals. In order to increase the oxygen

concentration detecting capacity of the zirconia element, the ECM supplements the heat from the exhaust

with heat from a heating element inside the sensor.

Heated oxygen sensor heater range check (P0037, P0038, P0057 and P0058):

The ECM monitors the current applied to the O2 sensor heater to check the heater for malfunctions. If the

current is below the threshold value, the ECM will determine that there is an open circuit in the heater. If

the current is above the threshold value, the ECM will determine that there is a short circuit in the heater.

Example:

The ECM sets DTC P0038 or P0058 when the current in the HO2 sensor heater is more than 2 A.

Conversely, when the heater current is less than 0.3 A, DTC P0037 or P0057 is set.

Heated oxygen sensor heater performance (P0141 and P0161):

After the accumulated heater ON time exceeds 100 seconds, the ECM calculates the heater resistance

using the battery voltage and the current applied to the heater. If the resistance is above the threshold

value, the ECM will determine that there is a malfunction in the HO2S heater and set DTC P0141 and

P0161.

MONITOR STRATEGY

DTC No. DTC Detection Condition Trouble Area

P0037

P0057Heated Oxygen (HO2) sensor heater current is less

than 0.3 A (1 trip detection logic)• Open in HO2 sensor heater circuit

• HO2 sensor heater

• EFI relay

•ECM

P0038

P0058Heated Oxygen (HO2) sensor heater current is more

than 2 A (1 trip detection logic)• Open in HO2 sensor heater circuit

• HO2 sensor heater

• EFI relay

•ECM

P0141

P0161Cumulative heater resistance correction value exceeds

the acceptable threshold (2 trip detection logic)• HO2 sensor

•ECM

Related DTCsP0037: Heated oxygen sensor heater (bank 1) open/short (Low electrical current)

P0038: Heated oxygen sensor heater (bank 1) open/short (High electrical current)

P0057: Heated oxygen sensor heater (bank 2) open/short (Low electrical current)

P0058: Heated oxygen sensor heater (bank 2) open/short (High electrical current)

P0141: Heated oxygen sensor heater performance (bank 1 sensor 2)

P0161: Heated oxygen sensor heater performance (bank 2 sensor 2)

Required Sensors / Components (Main) Heated oxygen sensor heater (bank 1 and 2)

Required Sensors / Components (Related) Vehicle speed sensor

Frequency of Operation Continuous

Duration0.5 seconds: P0037 and P0057

1 second: P0038 and P0058

10 seconds: P0141 and P0161

MIL OperationImmediate: P0037, P0038, P0057 and P0058

2 driving cycles: P0141 and P0161

Sequence of Operation None

Page 425 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–119

ES

TYPICAL ENABLING CONDITIONS

All:

P0037 and P0057:

P0038 and P0058 Case 1:

P0038 and P0058 Case 2:

P0141 and P0161:

TYPICAL MALFUNCTION THRESHOLDS

P0037 and P0057:

P0038 and P0058:

P0141 and P0161 (Heater performance monitor check):

COMPONENT OPERATING RANGE

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

WIRING DIAGRAM

Refer to DTC P0136 (See page ES-167).

INSPECTION PROCEDURE

HINT:

• If other DTCs relating to different systems that have terminal E2 as the ground terminal are output

simultaneously, terminal E2 may have an open circuit.

Monitor runs whenever following DTCs are not present None

Battery voltage 10.5 to 20 V

Battery voltage 10.5 V or more

Engine Running

Sta r t e r OF F

Battery voltage 10.5 to 20 V

One of the following conditions is met: Condition A or B

A. All of the following conditions are met: Conditions 1, 2, 3, 4 and 5

1. Battery voltage 10.5 V or more

2. Fuel cut OFF

3. Time after fuel cut ON to OFF 30 seconds or more

4. Accumulated heater ON time 100 seconds or more

5. Learned heater OFF current operation Completed

B. Duration that rear heated oxygen sensor impedance is less than 15

k

2 seconds or more

Heater Current - Learned heater OFF current Less than 0.3 A

Learned heater OFF current More than 2 A

Heater Current - Learned heater OFF current 2 A or more

Accumulated heater resistance Varies with sensor element temperature (Example: More than 23

)

Heated Oxygen (HO2) sensor heater current0.4 to 1 A (when engine idles, HO2 sensor warmed up and battery voltage 11 to 14

V)

Page 426 of 3000

ES–1202GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

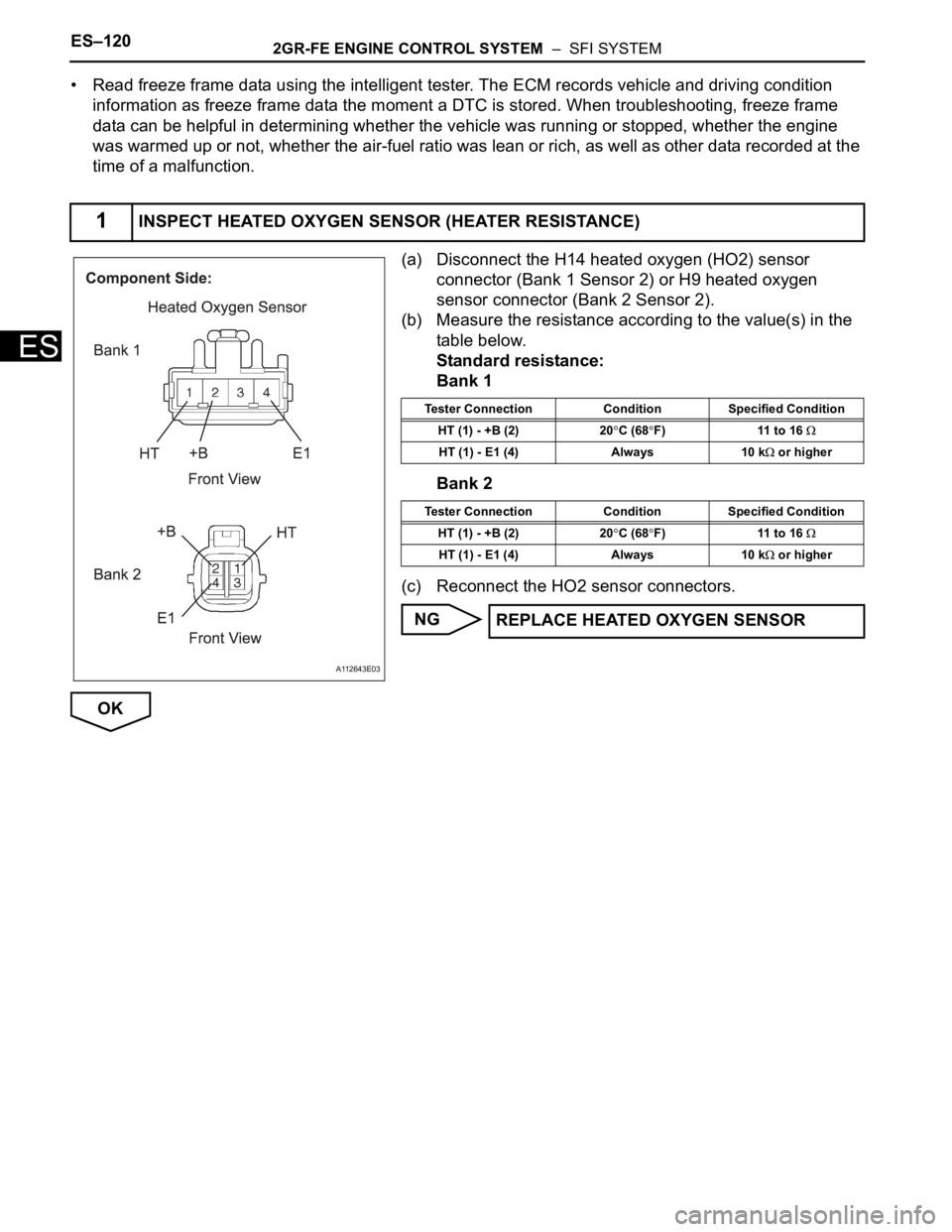

(a) Disconnect the H14 heated oxygen (HO2) sensor

connector (Bank 1 Sensor 2) or H9 heated oxygen

sensor connector (Bank 2 Sensor 2).

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Bank 1

Bank 2

(c) Reconnect the HO2 sensor connectors.

NG

OK

1INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE)

A112643E03

Tester Connection Condition Specified Condition

HT (1) - +B (2) 20

C (68F) 11 to 16

HT (1) - E1 (4) Always 10 k or higher

Tester Connection Condition Specified Condition

HT (1) - +B (2) 20

C (68F) 11 to 16

HT (1) - E1 (4) Always 10 k or higher

REPLACE HEATED OXYGEN SENSOR

Page 427 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–121

ES

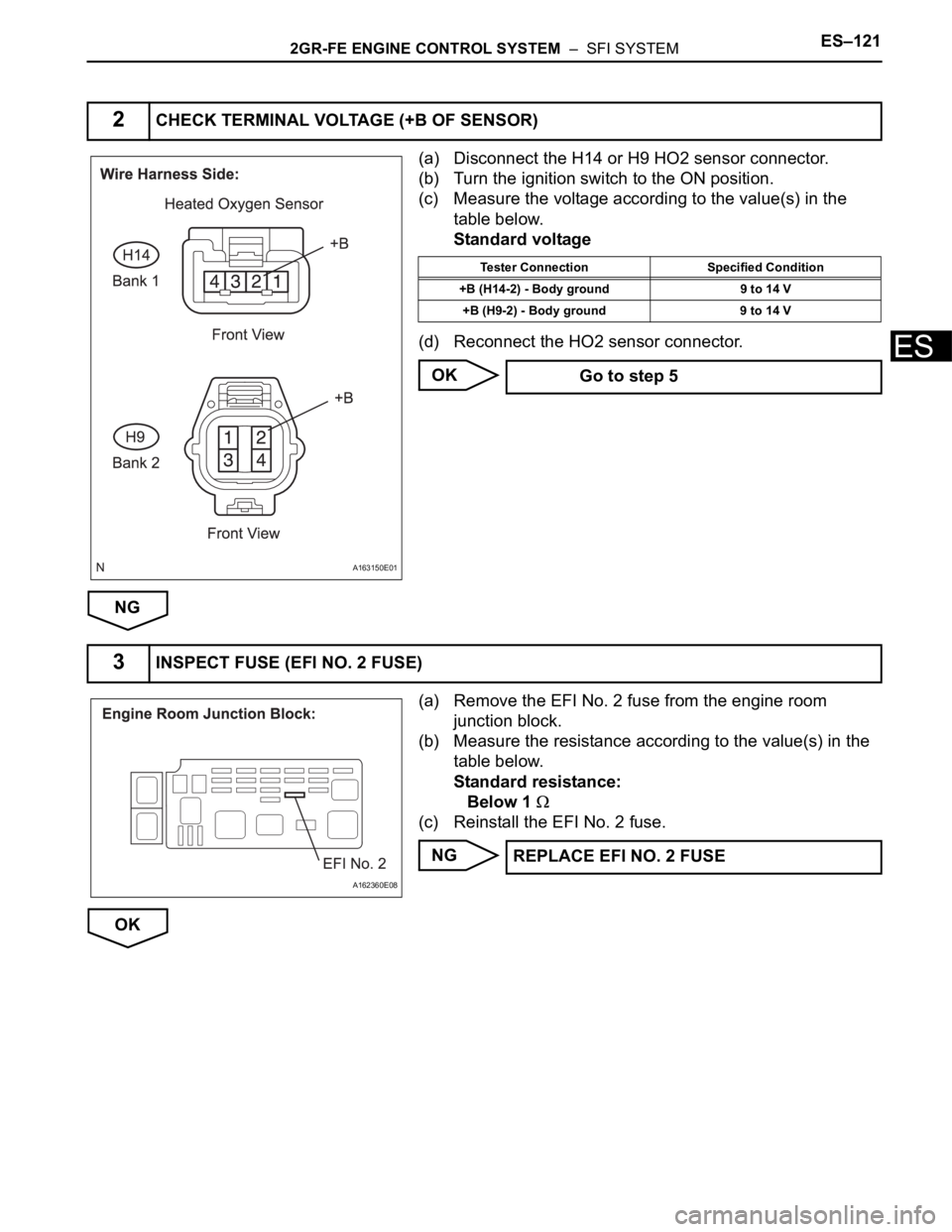

(a) Disconnect the H14 or H9 HO2 sensor connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the

table below.

Standard voltage

(d) Reconnect the HO2 sensor connector.

OK

NG

(a) Remove the EFI No. 2 fuse from the engine room

junction block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Below 1

(c) Reinstall the EFI No. 2 fuse.

NG

OK

2CHECK TERMINAL VOLTAGE (+B OF SENSOR)

A163150E01

Tester Connection Specified Condition

+B (H14-2) - Body ground 9 to 14 V

+B (H9-2) - Body ground 9 to 14 V

Go to step 5

3INSPECT FUSE (EFI NO. 2 FUSE)

A162360E08

REPLACE EFI NO. 2 FUSE

Page 428 of 3000

ES–1222GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

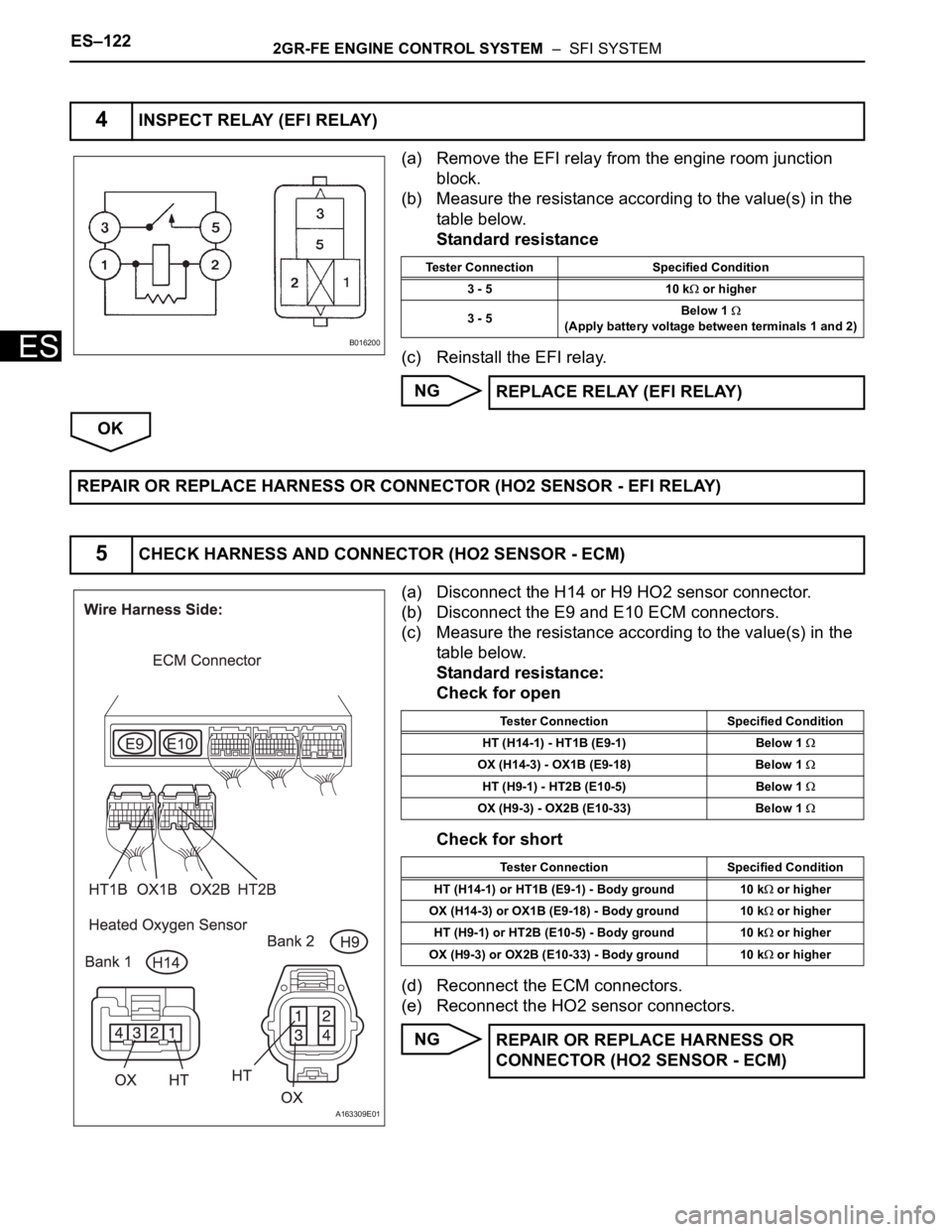

(a) Remove the EFI relay from the engine room junction

block.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reinstall the EFI relay.

NG

OK

(a) Disconnect the H14 or H9 HO2 sensor connector.

(b) Disconnect the E9 and E10 ECM connectors.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

Check for short

(d) Reconnect the ECM connectors.

(e) Reconnect the HO2 sensor connectors.

NG

4INSPECT RELAY (EFI RELAY)

B016200

Tester Connection Specified Condition

3 - 5 10 k

or higher

3 - 5Below 1

(Apply battery voltage between terminals 1 and 2)

REPLACE RELAY (EFI RELAY)

REPAIR OR REPLACE HARNESS OR CONNECTOR (HO2 SENSOR - EFI RELAY)

5CHECK HARNESS AND CONNECTOR (HO2 SENSOR - ECM)

A163309E01

Tester Connection Specified Condition

HT (H14-1) - HT1B (E9-1) Below 1

OX (H14-3) - OX1B (E9-18) Below 1

HT (H9-1) - HT2B (E10-5) Below 1

OX (H9-3) - OX2B (E10-33) Below 1

Tester Connection Specified Condition

HT (H14-1) or HT1B (E9-1) - Body ground 10 k

or higher

OX (H14-3) or OX1B (E9-18) - Body ground 10 k

or higher

HT (H9-1) or HT2B (E10-5) - Body ground 10 k

or higher

OX (H9-3) or OX2B (E10-33) - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (HO2 SENSOR - ECM)

Page 429 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–123

ES

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the intelligent tester ON.

(d) Clear the DTCs (See page ES-39).

(e) Start the engine.

(f) Allow the engine to idle for 1 minute or more.

(g) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(h) Read the DTCs.

Result

B

A

6CHECK WHETHER DTC OUTPUT RECURS

Display (DTC Output) Proceed to

No output A

P0037, P0038, P0057, P0058, P0141 and/or P0161 B

REPLACE ECM

CHECK FOR INTERMITTENT PROBLEMS

Page 430 of 3000

ES–1242GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

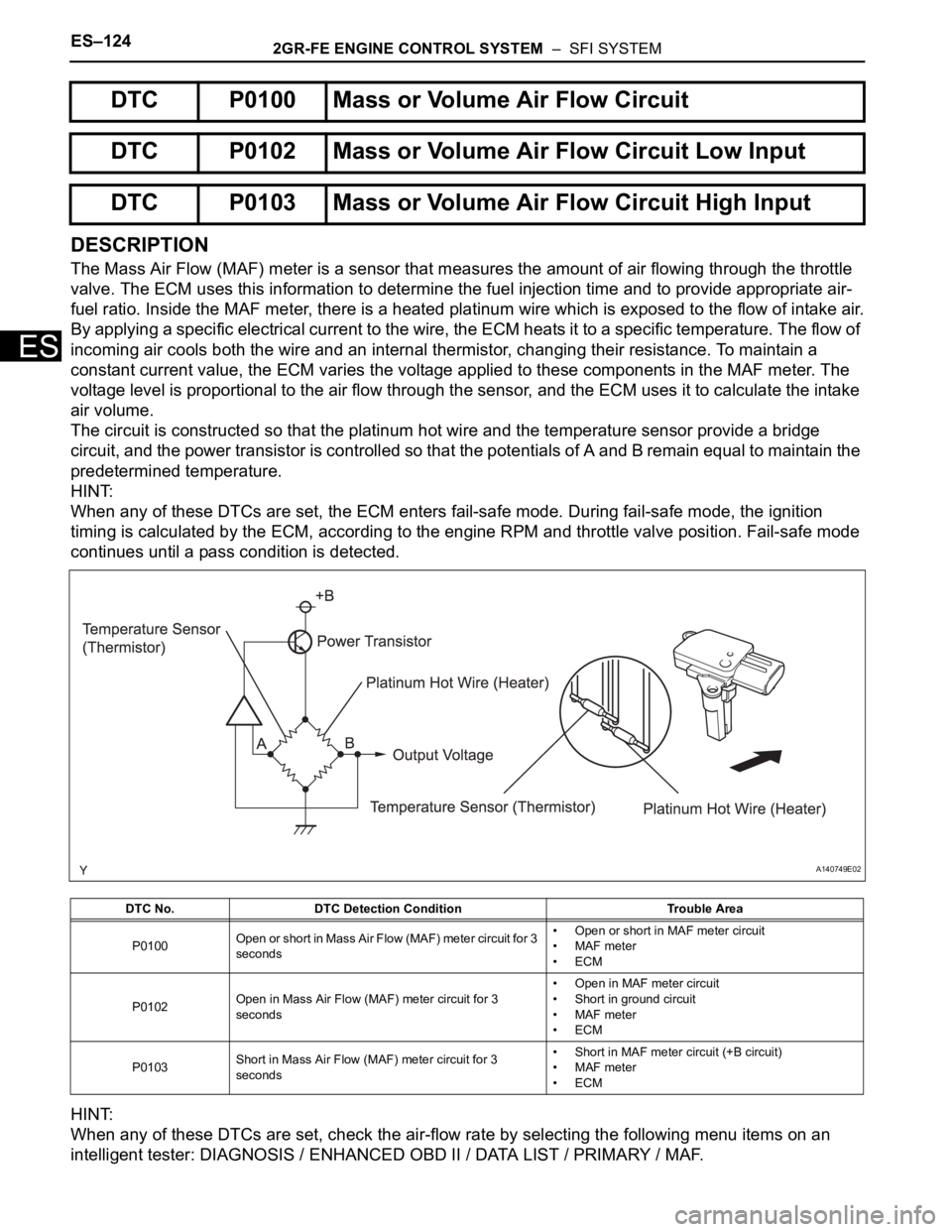

DESCRIPTION

The Mass Air Flow (MAF) meter is a sensor that measures the amount of air flowing through the throttle

valve. The ECM uses this information to determine the fuel injection time and to provide appropriate air-

fuel ratio. Inside the MAF meter, there is a heated platinum wire which is exposed to the flow of intake air.

By applying a specific electrical current to the wire, the ECM heats it to a specific temperature. The flow of

incoming air cools both the wire and an internal thermistor, changing their resistance. To maintain a

constant current value, the ECM varies the voltage applied to these components in the MAF meter. The

voltage level is proportional to the air flow through the sensor, and the ECM uses it to calculate the intake

air volume.

The circuit is constructed so that the platinum hot wire and the temperature sensor provide a bridge

circuit, and the power transistor is controlled so that the potentials of A and B remain equal to maintain the

predetermined temperature.

HINT:

When any of these DTCs are set, the ECM enters fail-safe mode. During fail-safe mode, the ignition

timing is calculated by the ECM, according to the engine RPM and throttle valve position. Fail-safe mode

continues until a pass condition is detected.

HINT:

When any of these DTCs are set, check the air-flow rate by selecting the following menu items on an

intelligent tester: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / MAF.

DTC P0100 Mass or Volume Air Flow Circuit

DTC P0102 Mass or Volume Air Flow Circuit Low Input

DTC P0103 Mass or Volume Air Flow Circuit High Input

DTC No. DTC Detection Condition Trouble Area

P0100Open or short in Mass Air Flow (MAF) meter circuit for 3

seconds• Open or short in MAF meter circuit

• MAF meter

•ECM

P0102Open in Mass Air Flow (MAF) meter circuit for 3

seconds• Open in MAF meter circuit

• Short in ground circuit

• MAF meter

•ECM

P0103Short in Mass Air Flow (MAF) meter circuit for 3

seconds• Short in MAF meter circuit (+B circuit)

• MAF meter

•ECM

A140749E02