YAMAHA VX110 2005 Owners Manual

Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 91 of 347

4-14

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

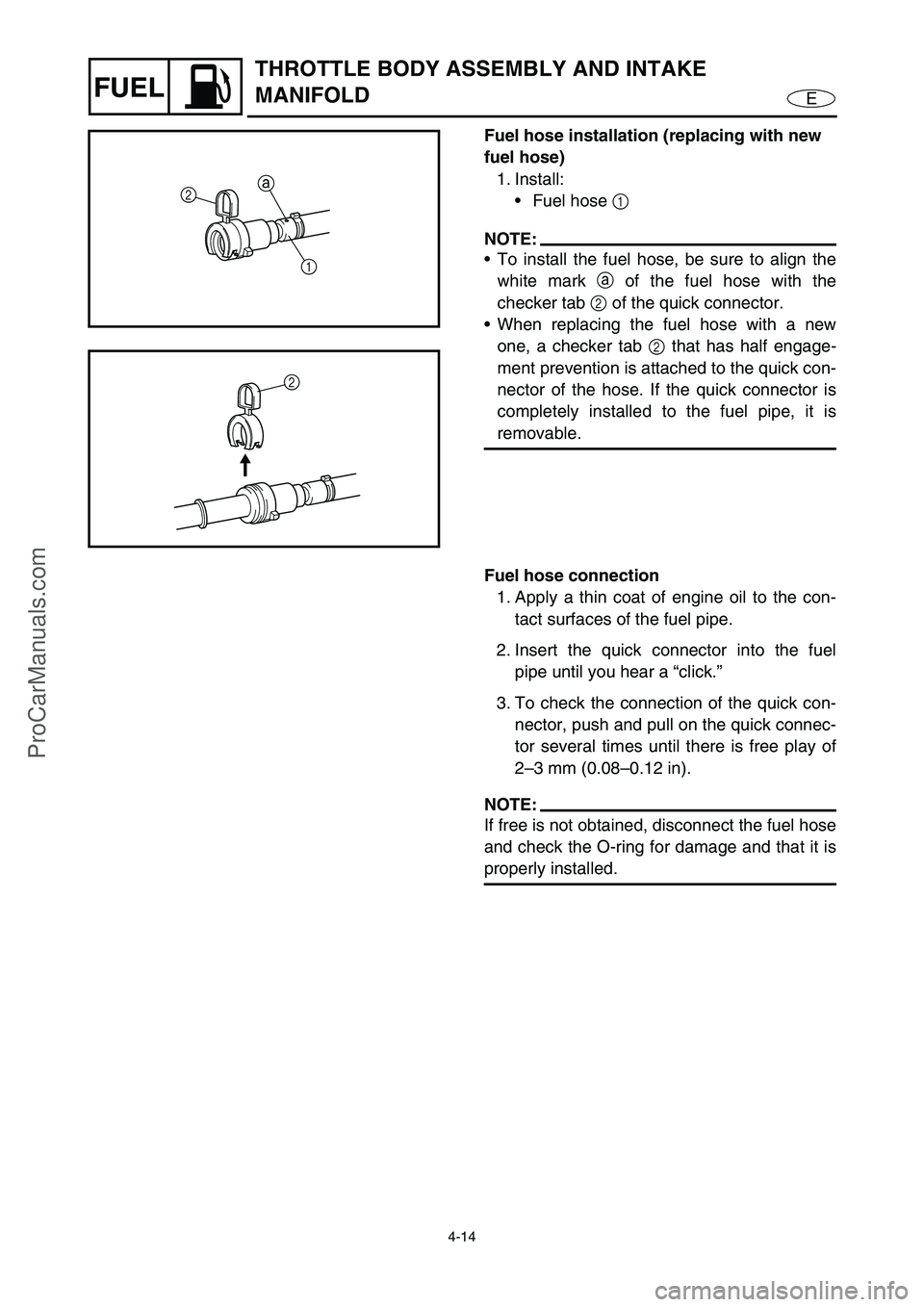

Fuel hose installation (replacing with new

fuel hose)

1. Install:

Fuel hose 1

NOTE:

To install the fuel hose, be sure to align the

white mark a

of the fuel hose with the

checker tab 2

of the quick connector.

When replacing the fuel hose with a new

one, a checker tab 2

that has half engage-

ment prevention is attached to the quick con-

nector of the hose. If the quick connector is

completely installed to the fuel pipe, it is

removable.

2

1a

2

Fuel hose connection

1. Apply a thin coat of engine oil to the con-

tact surfaces of the fuel pipe.

2. Insert the quick connector into the fuel

pipe until you hear a “click.”

3. To check the connection of the quick con-

nector, push and pull on the quick connec-

tor several times until there is free play of

2–3 mm (0.08–0.12 in).

NOTE:

If free is not obtained, disconnect the fuel hose

and check the O-ring for damage and that it is

properly installed.

ProCarManuals.com

Page 92 of 347

4-15

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

Fuel injectors inspection

NOTE:

Do not remove the throttle body assembly.

1. Check:

Fuel injectors

Dirt/residue →

Clean.

Damage →

Replace.

2. Measure:

Fuel injectors resistance

Out of specification →

Replace.

3. Check the operation of the fuel injector

using the “Stationary Test” of the Yamaha

Diagnostic System.

Digital multimeter:

YU-34899-A

Digital circuit tester:

90890-03174

Fuel injector resistance:

(reference data)

11.5–12.5

Ω at 20 °C (68 °F)

Throttle body assembly inspection

CAUTION:

The throttle body assembly should not be

disassembled.

1. Check:

Throttle body assembly

Cracks/damage →

Replace the throttle

body assembly.

Accelerator position sensor inspection

1. Inspect:

Accelerator position sensor

Damage/cracks →

Replace the acceler-

ator position sensor.

ProCarManuals.com

Page 93 of 347

4-16

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

Intake assembly installation

1. Install:

Intake screw clamp

Intake manifold joint

Intake assembly

NOTE:

Install the intake screw clamp in the direction

shown in the illustration, making sure to align

the indentation in the clamp with the projec-

tion a

on the intake manifold joint.

Tighten the clamp screw until both ends of

the intake screw clamp contact the spacer 1

around the screw.

a

11

2. Install:

Fuel hose 2 (fuel rail side)

Fuel hose clamps

WARNING

Do not reuse the fuel hose clamps, always

replace them with new ones.

NOTE:

Install the fuel hose with the white mark a

facing up.

Install the fuel hose clamps at the locations

shown in the illustration, and then crimp

them to securely fasten them.

2a

8 mm (0.31 in) 6 mm (0.24 in)

ProCarManuals.com

Page 94 of 347

4-17

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

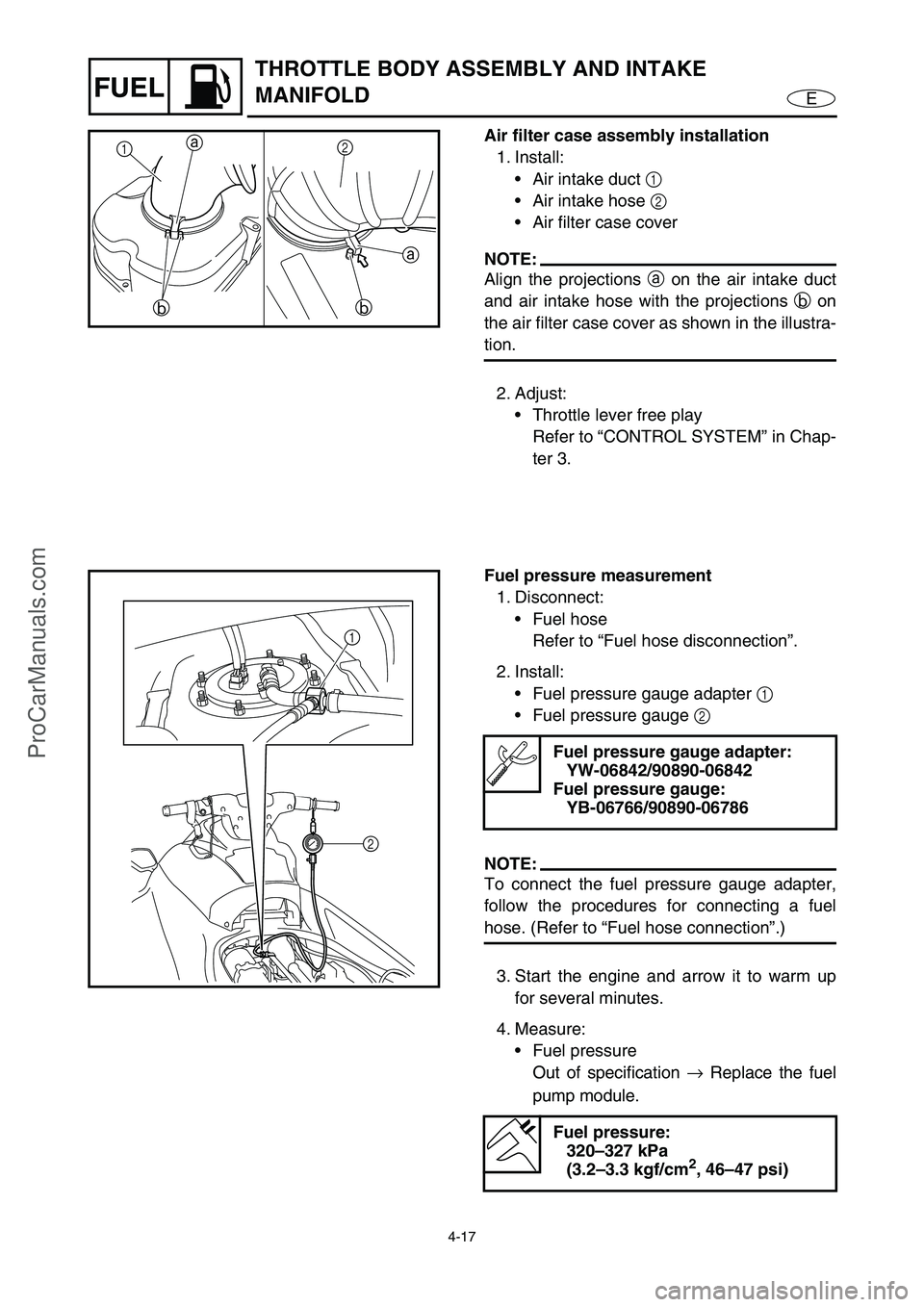

Air filter case assembly installation

1. Install:

Air intake duct 1

Air intake hose 2

Air filter case cover

NOTE:

Align the projections a

on the air intake duct

and air intake hose with the projections b

on

the air filter case cover as shown in the illustra-

tion.

2. Adjust:

Throttle lever free play

Refer to “CONTROL SYSTEM” in Chap-

ter 3.

a

b a

b

2

1

Fuel pressure measurement

1. Disconnect:

Fuel hose

Refer to “Fuel hose disconnection”.

2. Install:

Fuel pressure gauge adapter 1

Fuel pressure gauge 2

NOTE:

To connect the fuel pressure gauge adapter,

follow the procedures for connecting a fuel

hose. (Refer to “Fuel hose connection”.)

3. Start the engine and arrow it to warm up

for several minutes.

4. Measure:

Fuel pressure

Out of specification →

Replace the fuel

pump module.

Fuel pressure gauge adapter:

YW-06842/90890-06842

Fuel pressure gauge:

YB-06766/90890-06786

Fuel pressure:

320–327 kPa

(3.2–3.3 kgf/cm

2, 46–47 psi)

2

1

ProCarManuals.com

Page 95 of 347

4-18

EFUEL

5. Remove:

Fuel pressure gauge

Fuel pressure gauge adapter

NOTE:

To disconnect the fuel pressure gauge

adapter, follow the procedures for disconnect-

ing a fuel hose. (Refer to “Fuel hose discon-

nection”.)

6. Connect:

Fuel hose

Refer to “Fuel hose connection”.

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

ProCarManuals.com

Page 96 of 347

ProCarManuals.com

Page 97 of 347

EPOWR

1

2

3

4

5

6

7

8

9

CHAPTER 5

POWER UNIT

ENGINE UNIT .................................................................................................. 5-1

EXPLODED DIAGRAM ............................................................................. 5-1

REMOVAL AND INSTALLATION CHART ................................................ 5-1

SERVICE POINTS .................................................................................... 5-4

Compression pressure measurement ................................................. 5-4

Engine unit removal ............................................................................ 5-6

Shim removal ...................................................................................... 5-6

Engine mount inspection ..................................................................... 5-6

Coupling clearance inspection ............................................................ 5-7

EXHAUST PIPES 1 AND 2.............................................................................. 5-8

EXPLODED DIAGRAM ............................................................................. 5-8

REMOVAL AND INSTALLATION CHART ................................................ 5-8

EXHAUST MANIFOLD .................................................................................. 5-11

EXPLODED DIAGRAM ........................................................................... 5-11

REMOVAL AND INSTALLATION CHART .............................................. 5-11

OIL TANK ...................................................................................................... 5-12

EXPLODED DIAGRAM ........................................................................... 5-12

REMOVAL AND INSTALLATION CHART .............................................. 5-12

SERVICE POINTS .................................................................................. 5-17

Oil tank removal ................................................................................ 5-17

Oil strainer inspection........................................................................ 5-18

Oil tank installation ............................................................................ 5-18

OIL PUMP ...................................................................................................... 5-21

EXPLODED DIAGRAM ........................................................................... 5-21

REMOVAL AND INSTALLATION CHART .............................................. 5-21

SERVICE POINTS .................................................................................. 5-23

Oil strainer inspection........................................................................ 5-23

Oil pump installation .......................................................................... 5-23

REDUCTION DRIVE GEAR .......................................................................... 5-24

EXPLODED DIAGRAM ........................................................................... 5-24

REMOVAL AND INSTALLATION CHART .............................................. 5-24

SERVICE POINTS .................................................................................. 5-28

Drive coupling removal...................................................................... 5-28

Drive shaft removal ........................................................................... 5-28

Bearing removal ................................................................................ 5-28

Oil pump drive shaft inspection ......................................................... 5-29

Drive shaft inspection ........................................................................ 5-29

Bearing installing ............................................................................... 5-30

Drive shaft installation ....................................................................... 5-32

Drive coupling installation ................................................................. 5-32

ProCarManuals.com

Page 98 of 347

EPOWR

GENERATOR AND STARTER MOTOR ....................................................... 5-33

EXPLODED DIAGRAM ........................................................................... 5-33

REMOVAL AND INSTALLATION CHART ............................................. 5-33

SERVICE POINTS .................................................................................. 5-38

Flywheel magneto removal ............................................................... 5-38

Starter clutch inspection .................................................................... 5-38

Flywheel magneto installation ........................................................... 5-40

CAMSHAFTS................................................................................................. 5-41

EXPLODED DIAGRAM ........................................................................... 5-41

REMOVAL AND INSTALLATION CHART .............................................. 5-41

SERVICE POINTS .................................................................................. 5-46

Camshaft removal ............................................................................. 5-46

Camshaft inspection.......................................................................... 5-47

Camshaft sprockets inspection ......................................................... 5-49

Timing chain tensioner inspection ..................................................... 5-49

Camshaft installation ......................................................................... 5-50

CYLINDER HEAD.......................................................................................... 5-54

EXPLODED DIAGRAM ........................................................................... 5-54

REMOVAL AND INSTALLATION CHART ............................................. 5-54

SERVICE POINTS .................................................................................. 5-56

Cylinder head removal ...................................................................... 5-56

Cylinder head inspection ................................................................... 5-56

Cylinder head installation .................................................................. 5-57

VALVES AND VALVE SPRINGS .................................................................. 5-59

EXPLODED DIAGRAM ........................................................................... 5-59

REMOVAL AND INSTALLATION CHART ............................................. 5-59

SERVICE POINTS .................................................................................. 5-61

Valve removal ................................................................................... 5-61

Valve spring inspection ..................................................................... 5-62

Valve inspection ................................................................................ 5-62

Valve guide inspection ...................................................................... 5-64

Valve guide replacement................................................................... 5-64

Valve seat inspection ........................................................................ 5-66

Valve seat reface .............................................................................. 5-67

Valve installation ............................................................................... 5-69

CRANKCASE ................................................................................................ 5-71

EXPLODED DIAGRAM ........................................................................... 5-71

REMOVAL AND INSTALLATION CHART .............................................. 5-71

SERVICE POINTS .................................................................................. 5-75

Crankcase disassembly .................................................................... 5-75

Crankcase inspection ........................................................................ 5-76

Timing chain inspection..................................................................... 5-76

Crankcase assembly ......................................................................... 5-77

ProCarManuals.com

Page 99 of 347

EPOWR

CONNECTING RODS AND PISTONS .......................................................... 5-80

EXPLODED DIAGRAM ........................................................................... 5-80

REMOVAL AND INSTALLATION CHART .............................................. 5-80

SERVICE POINTS .................................................................................. 5-82

Connecting rod and piston removal .................................................. 5-82

Cylinder and piston inspection .......................................................... 5-83

Piston ring inspection ........................................................................ 5-84

Piston pin inspection ......................................................................... 5-86

Connecting rod inspection................................................................. 5-87

Connecting rod and piston installation .............................................. 5-89

CRANKSHAFT .............................................................................................. 5-93

EXPLODED DIAGRAM ........................................................................... 5-93

REMOVAL AND INSTALLATION CHART .............................................. 5-93

SERVICE POINTS .................................................................................. 5-94

Crankshaft removal ........................................................................... 5-94

Crankshaft inspection........................................................................ 5-94

Crankshaft installation ....................................................................... 5-97

COOLING WATER HOSE ............................................................................. 5-98

EXPLODED DIAGRAM ........................................................................... 5-98

REMOVAL AND INSTALLATION CHART .............................................. 5-98

ProCarManuals.com

Page 100 of 347

5-1

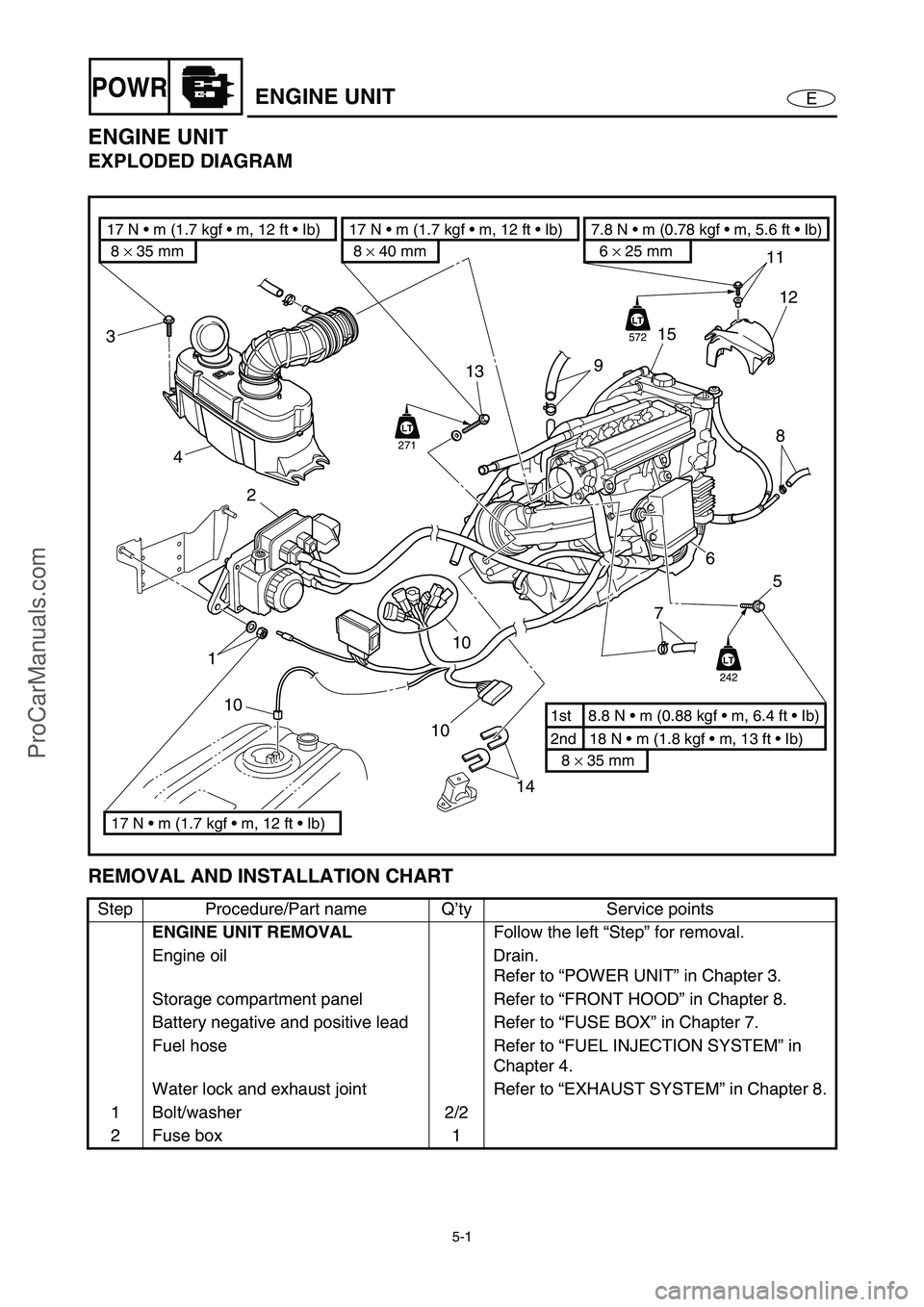

EPOWRENGINE UNIT

ENGINE UNIT

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

ENGINE UNIT REMOVAL

Follow the left “Step” for removal.

Engine oil Drain.

Refer to “POWER UNIT” in Chapter 3.

Storage compartment panel Refer to “FRONT HOOD” in Chapter 8.

Battery negative and positive lead Refer to “FUSE BOX” in Chapter 7.

Fuel hose Refer to “FUEL INJECTION SYSTEM” in

Chapter 4.

Water lock and exhaust joint Refer to “EXHAUST SYSTEM” in Chapter 8.

1 Bolt/washer 2/2

2 Fuse box 1

14 10

10

2

113

3

4

11

15

12

8

7

9

6

5

2nd 18 N m (1.8 kgf m, 13 ft Ib) 1st 8.8 N m (0.88 kgf m, 6.4 ft Ib)

8 × 35 mm

6 × 25 mm

7.8 N m (0.78 kgf m, 5.6 ft Ib)

8 × 35 mm 17 N m (1.7 kgf m, 12 ft Ib)

17 N m (1.7 kgf m, 12 ft Ib)8 × 40 mm

17 N m (1.7 kgf m, 12 ft Ib)

10LT

242

LT

LT

572

LT

LT

271

ProCarManuals.com