YAMAHA VX110 2005 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 51 of 347

3-2

E

INSP

ADJ

CONTROL SYSTEM

PERIODIC SERVICE

CONTROL SYSTEM

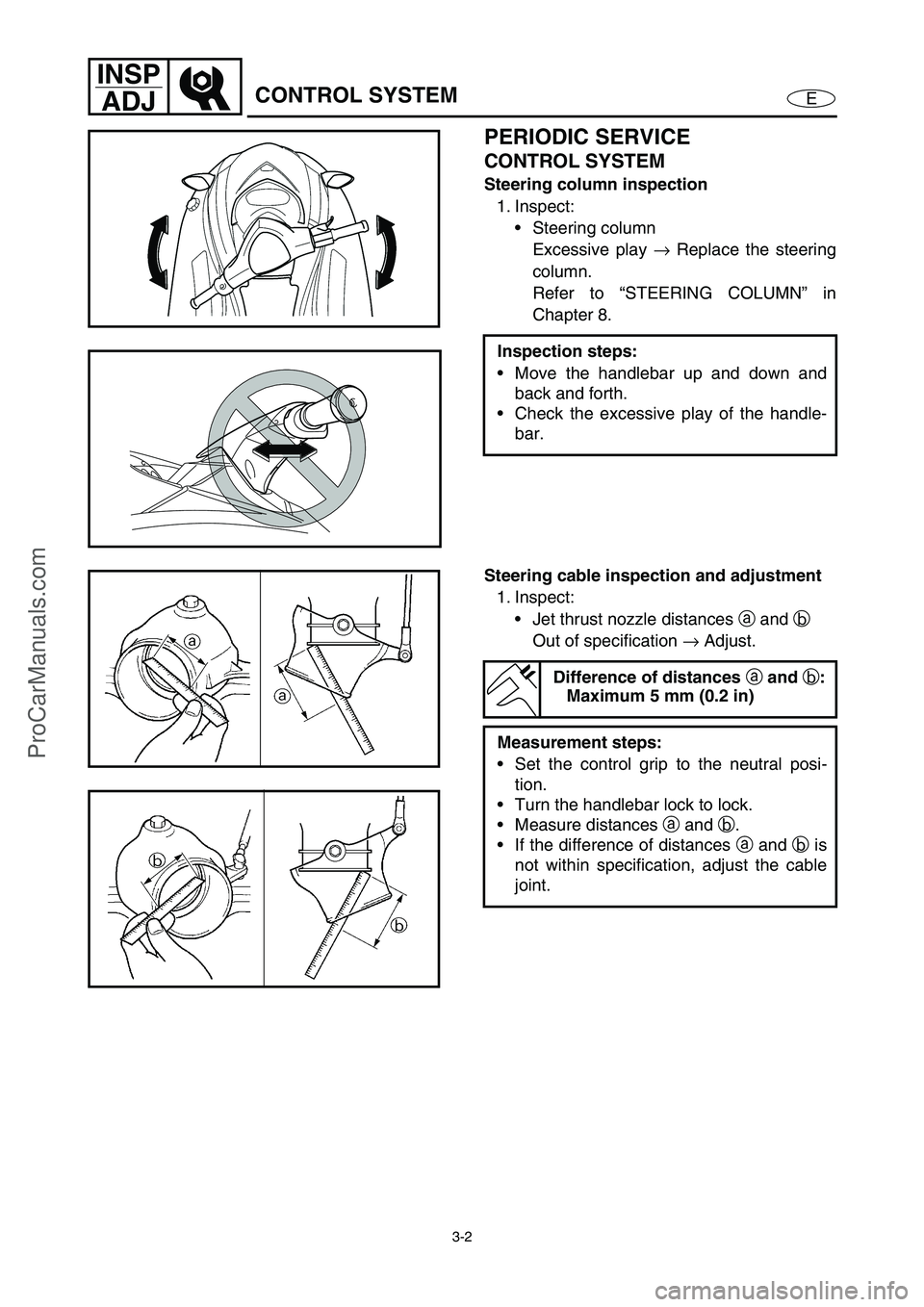

Steering column inspection

1. Inspect:

Steering column

Excessive play →

Replace the steering

column.

Refer to “STEERING COLUMN” in

Chapter 8.

Inspection steps:

Move the handlebar up and down and

back and forth.

Check the excessive play of the handle-

bar.

Steering cable inspection and adjustment

1. Inspect:

Jet thrust nozzle distances a

and b

Out of specification →

Adjust.

Difference of distances

a and

b:

Maximum 5 mm (0.2 in)

Measurement steps:

Set the control grip to the neutral posi-

tion.

Turn the handlebar lock to lock.

Measure distances a

and b

.

If the difference of distances a

and b

is

not within specification, adjust the cable

joint.

ProCarManuals.com

Page 52 of 347

3-3

E

INSP

ADJ

CONTROL SYSTEM

2. Adjust:

Steering cable joint

(steering column end)

NOTE:

Adjust the cable joint at the jet pump end.

Refer to “REMOTE CONTROL CABLES AND

SPEED SENSOR LEAD” in Chapter 8. Adjustment steps:

Set the control grip to the neutral posi-

tion.

Loosen the locknut 1

.

Disconnect the cable joint 2

from the ball

joint 3

.

Turn the cable joint 2

in or out to adjust

the steering cable length c

.

Steering cable length

c:

218.8 mm (8.61 in)

NOTE:

Check that the sum of lengths c

and d

is

581.8 ±

1 mm (22.91 ±

0.04 in).

If the sum of lengths c

and d

is out of

specification, adjust length d

, and then

check the jet thrust nozzle distances

again.

WARNING

The cable joint must be screwed in more

than 8 mm (0.31 in).

Connect the cable joint and tighten the

locknut.

T R..

Locknut:

6.8 N m (0.68 kgf m, 4.9 ft lb)

c

d

ProCarManuals.com

Page 53 of 347

3-4

E

INSP

ADJ

CONTROL SYSTEM

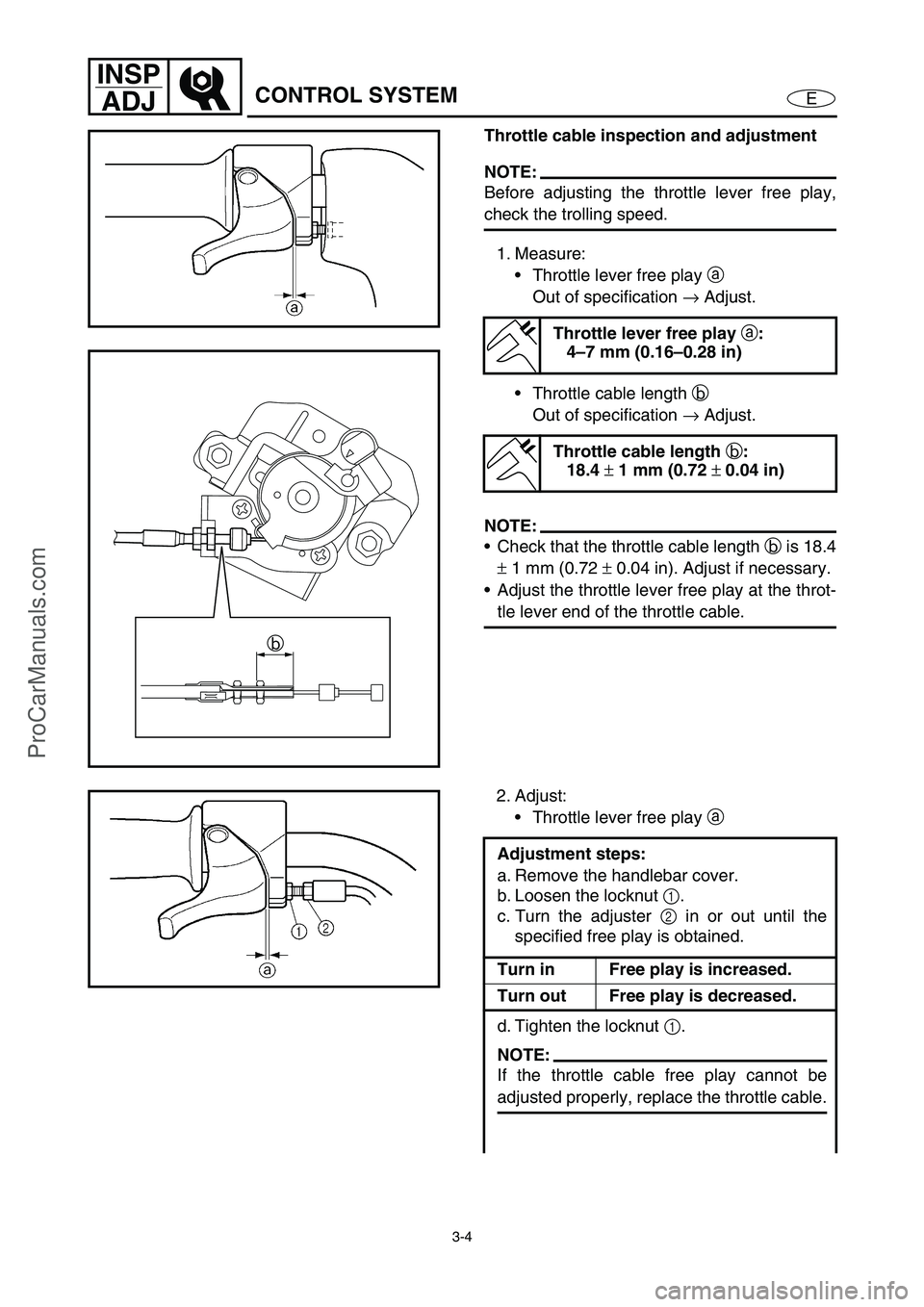

Throttle cable inspection and adjustment

NOTE:

Before adjusting the throttle lever free play,

check the trolling speed.

1. Measure:

Throttle lever free play a

Out of specification →

Adjust.

Throttle cable length b

Out of specification →

Adjust.

NOTE:

Check that the throttle cable length b

is 18.4

±

1 mm (0.72 ±

0.04 in). Adjust if necessary.

Adjust the throttle lever free play at the throt-

tle lever end of the throttle cable.

Throttle lever free play

a:

4–7 mm (0.16–0.28 in)

Throttle cable length

b:

18.4

± 1 mm (0.72

± 0.04 in)

b

2. Adjust:

Throttle lever free play a

Adjustment steps:

a. Remove the handlebar cover.

b. Loosen the locknut 1

.

c. Turn the adjuster 2

in or out until the

specified free play is obtained.

Turn in Free play is increased.

Turn out Free play is decreased.

d. Tighten the locknut 1

.

NOTE:

If the throttle cable free play cannot be

adjusted properly, replace the throttle cable.

ProCarManuals.com

Page 54 of 347

3-5

E

INSP

ADJ

CONTROL SYSTEM

WARNING

After adjusting the free play, turn the han-

dlebar to the right and left and make sure

that the trolling speed does not increase.e. Install the handlebar cover.

T R..

Lower handlebar cover screw:

3.7 N m (0.37 kgf m, 2.7 ft lb)

LOCTITE 242

Upper handlebar cover screw:

1.1 N m (0.11 kgf m, 0.8 ft lb)

Shift cable inspection and adjustment

(Deluxe model only)

1. Check:

Reverse gate stopper lever position

Incorrect →

Adjust.

2. Adjust:

Shift cable joint Checking steps:

Set the shift lever to the reverse position.

Check that the reverse gate 1

contacts

the stopper 2

.

Adjustment steps:

Loosen the locknut 1

.

Disconnect the cable joint 2

from the ball

joint 3

.

Situate the reverse gate to the stopper.

Turn the cable joint in or out to align it

with the ball joint.

Turn in Length is decreased.

Turn out Length is increased.

1

23

ProCarManuals.com

Page 55 of 347

3-6

E

INSP

ADJ

CONTROL SYSTEM

Turn out the cable joint nine times a

to

extend the cable 7 mm (0.28 in) from the

aligned position.

WARNING

The cable joint must be screwed in more

than 8 mm (0.31 in).

Connect the cable joint and tighten the

locknut.

T R..

Locknut:

3.8 N m (0.38 kgf m, 2.7 ft lb)

Trolling speed inspection

1. Inspect:

Trolling speed

Trolling speed:

1,550–1,750 r/min

Checking steps (watercraft in water):

Start the engine and allow it to warm up

for 15 minutes.

Check the engine trolling speed using the

tachometer of the multifunction meter or

using the Yamaha Diagnostic System.

ProCarManuals.com

Page 56 of 347

3-7

E

INSP

ADJ

FUEL SYSTEM

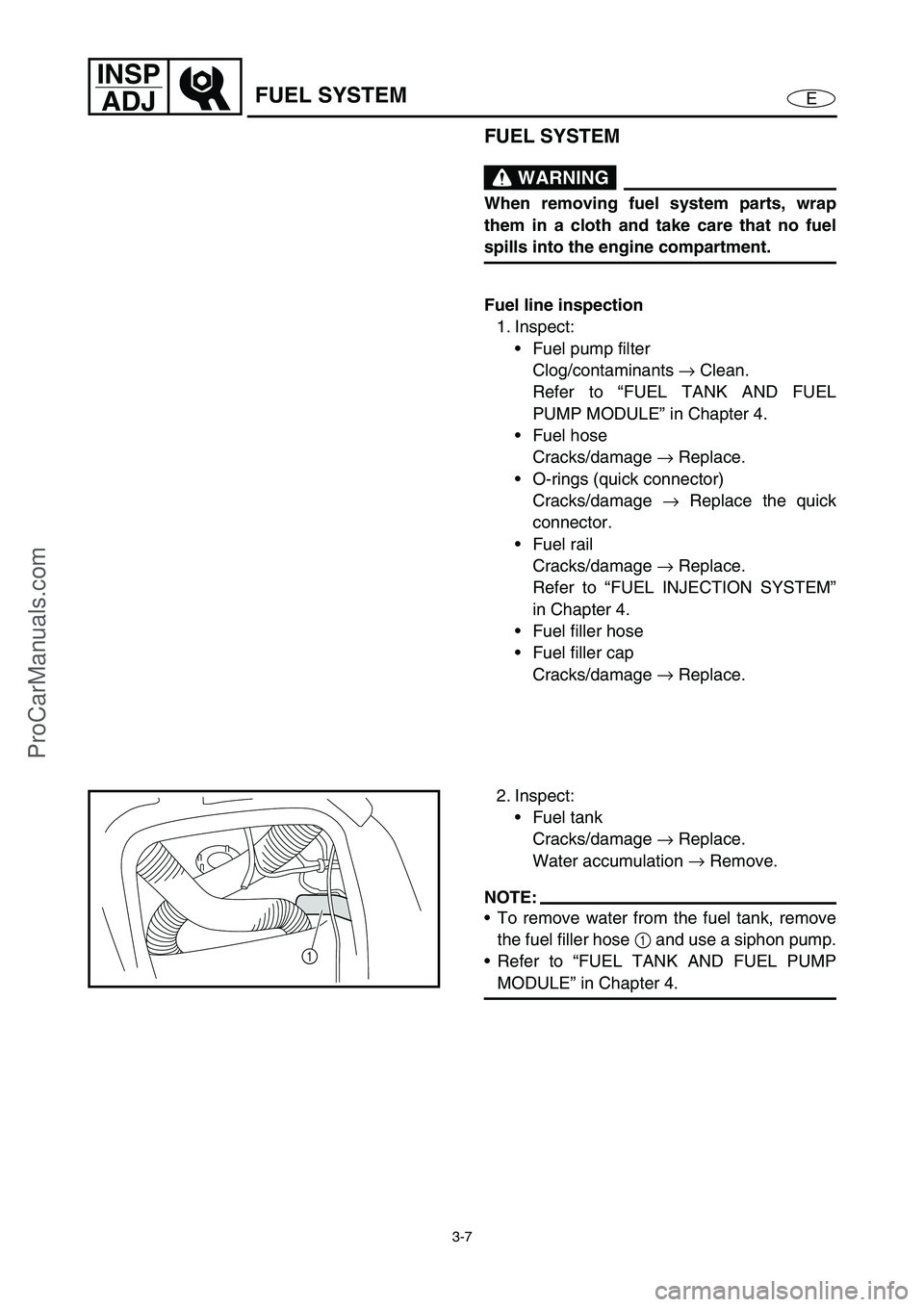

FUEL SYSTEM

WARNING

When removing fuel system parts, wrap

them in a cloth and take care that no fuel

spills into the engine compartment.

Fuel line inspection

1. Inspect:

Fuel pump filter

Clog/contaminants →

Clean.

Refer to “FUEL TANK AND FUEL

PUMP MODULE” in Chapter 4.

Fuel hose

Cracks/damage →

Replace.

O-rings (quick connector)

Cracks/damage →

Replace the quick

connector.

Fuel rail

Cracks/damage →

Replace.

Refer to “FUEL INJECTION SYSTEM”

in Chapter 4.

Fuel filler hose

Fuel filler cap

Cracks/damage →

Replace.

2. Inspect:

Fuel tank

Cracks/damage →

Replace.

Water accumulation →

Remove.

NOTE:

To remove water from the fuel tank, remove

the fuel filler hose 1

and use a siphon pump.

Refer to “FUEL TANK AND FUEL PUMP

MODULE” in Chapter 4.

1

ProCarManuals.com

Page 57 of 347

3-8

E

INSP

ADJ

FUEL SYSTEM/POWER UNIT

Water separator inspection

1. Inspect:

Water separator 1

Water accumulation →

Drain.

NOTE:

To drain the water, remove the drain plug.

POWER UNIT

Valve clearance adjustment

The following procedure applies to all of the

valves.

NOTE:

Valve clearance adjustment should be made

on a cold engine, at room temperature.

When the valve clearance is to be measured

or adjusted, the piston must be at top dead

center (TDC) of the compression stroke.

1. Remove:

Ignition coils

Spark plugs

Cylinder head cover

Cylinder head cover gasket

Refer to “CAMSHAFTS” in Chapter 5.

2. Install:

Dial gauge needle

Dial gauge stand 1

(into spark plug hole #1)

Dial gauge 2

Dial gauge stand:

90890-06583

Dial gauge needle:

90890-06584

Dial gauge stand set:

YB-06585/90890-06585

Dial indicator gauge:

YU-03097

Dial gauge set:

90890-012522

1

ProCarManuals.com

Page 58 of 347

3-9

E

INSP

ADJ

POWER UNIT

3. Measure:

Valve clearance

Out of specification →

Adjust.

Valve clearance (cold):

Intake valve:

0.11–0.20 mm

(0.0043–0.0079 in)

Exhaust valve:

0.25–0.34 mm

(0.0098–0.0134 in)

Measurement steps:

Turn the drive coupling counterclockwise,

and then check if cylinder #1 is at TDC of

the compression stroke with a dial gauge.

NOTE:

TDC of the compression stroke can be

found when the camshaft lobes are turned

away from each other.

Measure the valve clearance with a thick-

ness gauge 1

.

NOTE:

If the valve clearance is incorrect, record

the measured reading.

Measure the valve clearance in the follow-

ing sequence.

Valve clearance measuring sequence:

Cylinder #1

→ #2

→ #4

→ #3

ÈBow end

To measure the valve clearances of the

other cylinders, starting with cylinder #1

at TDC, turn the drive coupling counter-

clockwise as specified in the following

table.

ÉDegrees that the crankshaft is turned clock-

wise

ÊCylinder

ËCombustion cycle

Cylinder #2 180°

Cylinder #4 360°

Cylinder #3 540°

INEX

1

7205403601800

#4 #3

#2

#1

É

Ê

Ë

Ë

Ë

Ë

ProCarManuals.com

Page 59 of 347

3-10

E

INSP

ADJ

POWER UNIT

4. Remove:

Timing chain tensioner cap bolt 1

Gasket

1

5. Turn the timing chain tensioner rod fully

clockwise with a thin screwdriver 1

.

NOTE:

Make sure that the tensioner rod has been fully

turned clockwise.

1

6. Remove:

Intake camshaft caps

Exhaust camshaft caps

Timing chain

(from the camshaft sprockets)

Intake camshaft

Exhaust camshaft

NOTE:

Refer to “CAMSHAFTS” in Chapter 5.

When removing the timing chain and cam-

shafts, fasten the timing chain with a wire to

prevent it from falling into the crankcase.

ProCarManuals.com

Page 60 of 347

3-11

E

INSP

ADJ

POWER UNIT

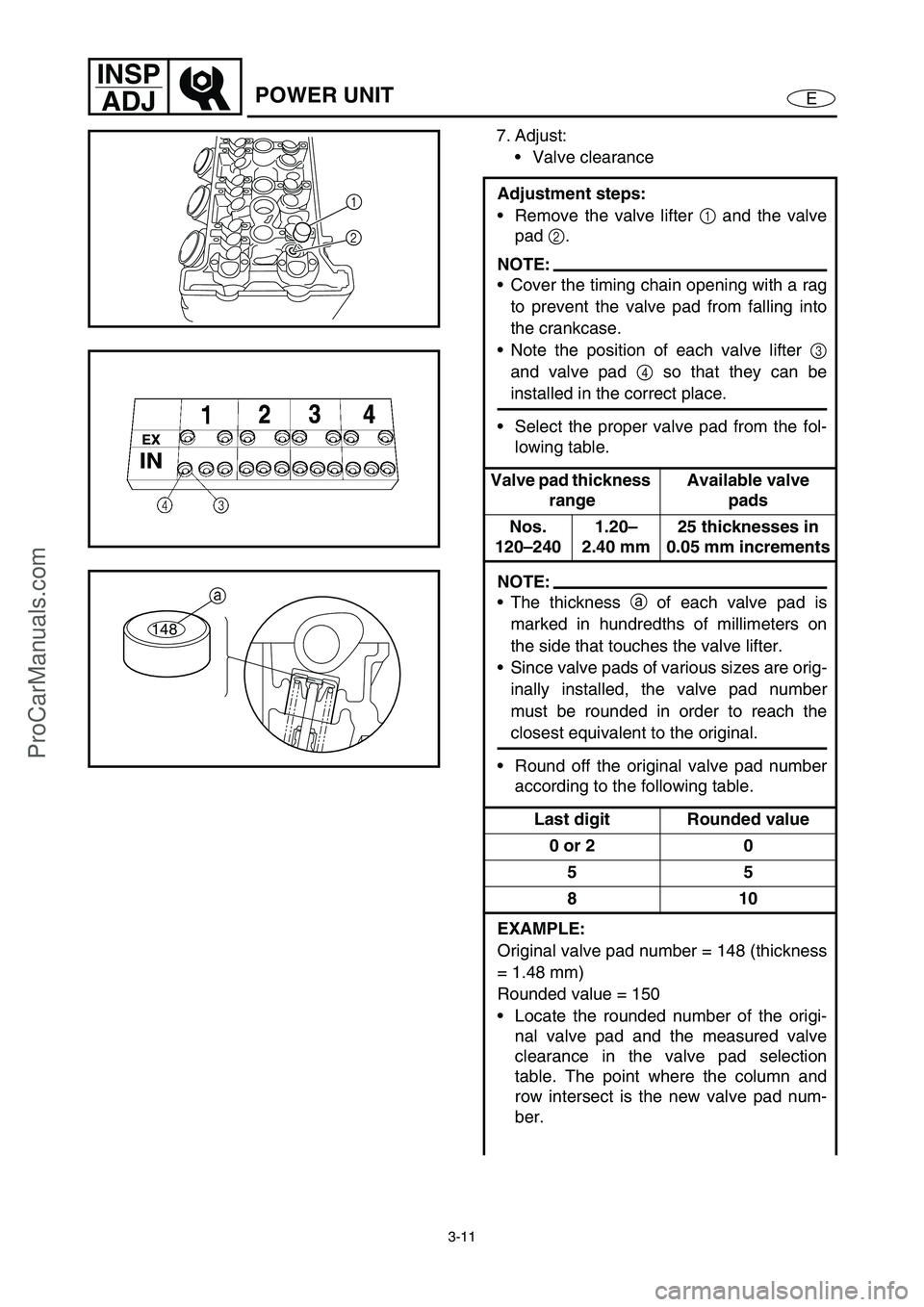

7. Adjust:

Valve clearance

Adjustment steps:

Remove the valve lifter 1

and the valve

pad 2

.

NOTE:

Cover the timing chain opening with a rag

to prevent the valve pad from falling into

the crankcase.

Note the position of each valve lifter 3

and valve pad 4

so that they can be

installed in the correct place.

Select the proper valve pad from the fol-

lowing table.

Valve pad thickness

rangeAvailable valve

pads

Nos.

120–2401.20–

2.40 mm25 thicknesses in

0.05 mm increments

NOTE:

The thickness a

of each valve pad is

marked in hundredths of millimeters on

the side that touches the valve lifter.

Since valve pads of various sizes are orig-

inally installed, the valve pad number

must be rounded in order to reach the

closest equivalent to the original.

Round off the original valve pad number

according to the following table.

Last digit Rounded value

0 or 2 0

55

810

EXAMPLE:

Original valve pad number = 148 (thickness

= 1.48 mm)

Rounded value = 150

Locate the rounded number of the origi-

nal valve pad and the measured valve

clearance in the valve pad selection

table. The point where the column and

row intersect is the new valve pad num-

ber.

1

2

148

a

ProCarManuals.com