YAMAHA VX110 2005 Repair Manual

Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 61 of 347

3-12

E

INSP

ADJ

POWER UNIT

NOTE:

The new valve pad number is only an

approximation. The valve clearance must

be measured again and the above steps

should be repeated if the measurement is

still incorrect.

Install the new valve pad 5

and the valve

lifter 6

.

NOTE:

Lubricate the valve pad with molybdenum

disulfide grease.

Lubricate the valve lifter with molybdenum

disulfide oil.

The valve lifter must turn smoothly when

rotated by hand.

Install the valve lifter and the valve pad in

the correct place.

Install the exhaust and intake camshafts,

timing chain, and camshaft caps.

T R..

Camshaft cap bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

NOTE:

Refer to “Camshaft installation — CAM-

SHAFTS” in Chapter 5.

Lubricate the camshafts, camshaft lobes,

and camshaft journals.

Install the exhaust camshaft first.

Align the camshaft marks with the cam-

shaft cap marks.

Turn the crankshaft clockwise several full

turns to seat the parts.

Measure the valve clearance again.

If the valve clearance is still out of specifi-

cation, repeat all of the valve clearance

adjustment steps until the specified clear-

ance is obtained.

6

5

ProCarManuals.com

Page 62 of 347

3-13

E

INSP

ADJ

POWER UNIT

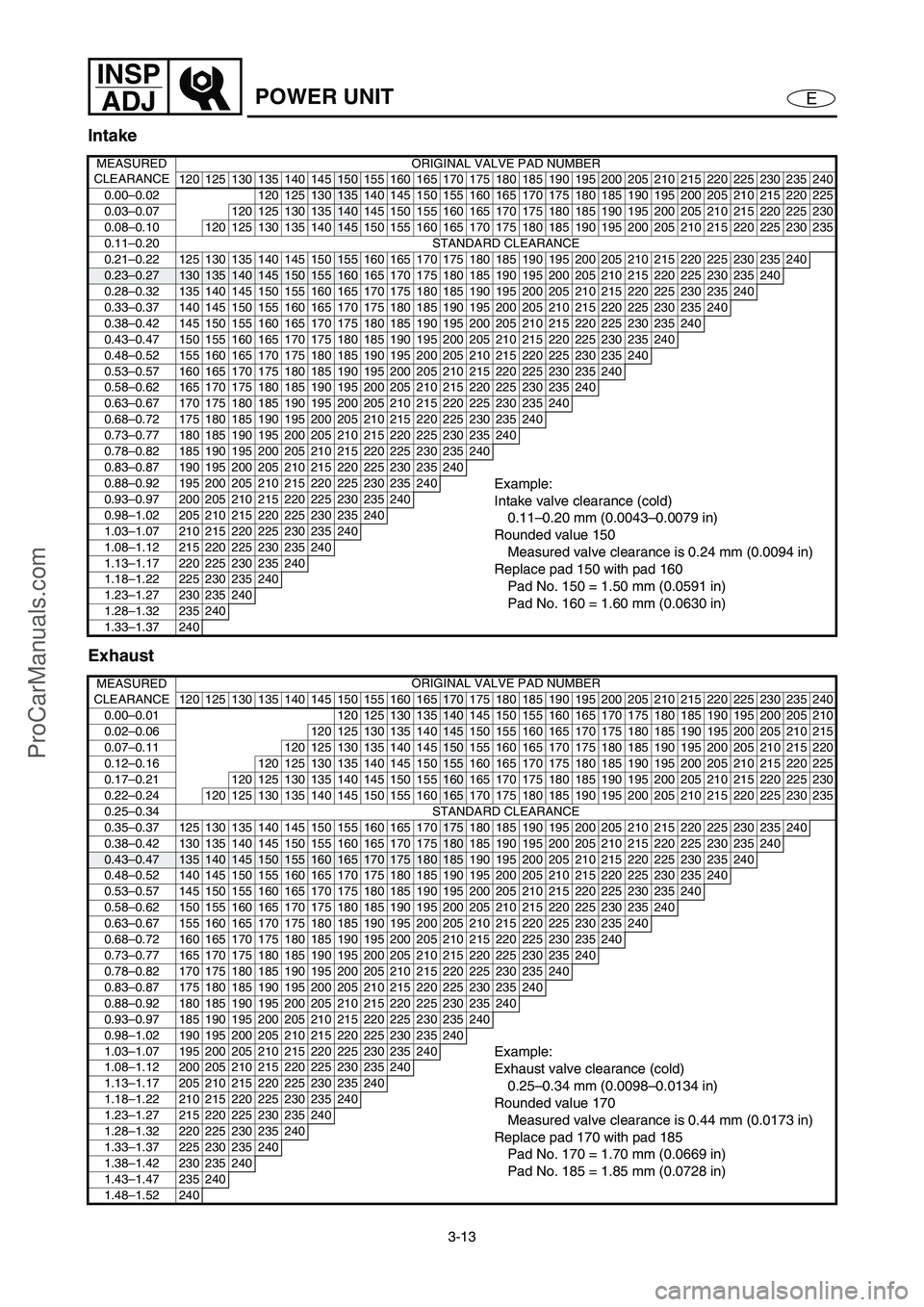

Intake

Exhaust

MEASURED

CLEARANCEORIGINAL VALVE PAD NUMBER

120 125 130 135 140 145

150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.00–0.02 120 125 130

135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225

0.03–0.07 120 125 130 135

140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230

0.08–0.10 120 125 130 135 140

145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235

0.11–0.20 STANDARD CLEARANCE

0.21–0.22 125 130 135 140 145 150

155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.23–0.27130135140145150155160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.28–0.32 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.33–0.37 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.38–0.42 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.43–0.47 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.48–0.52 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.53–0.57 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.58–0.62 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.63–0.67 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.68–0.72 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.73–0.77 180 185 190 195 200 205 210 215 220 225 230 235 240

0.78–0.82 185 190 195 200 205 210 215 220 225 230 235 240

0.83–0.87 190 195 200 205 210 215 220 225 230 235 240

0.88–0.92 195 200 205 210 215 220 225 230 235 240

Example:

Intake valve clearance (cold)

0.11–0.20 mm (0.0043–0.0079 in)

Rounded value 150

Measured valve clearance is 0.24 mm (0.0094 in)

Replace pad 150 with pad 160

Pad No. 150 = 1.50 mm (0.0591 in)

Pad No. 160 = 1.60 mm (0.0630 in)0.93–0.97 200 205 210 215 220 225 230 235 240

0.98–1.02 205 210 215 220 225 230 235 240

1.03–1.07 210 215 220 225 230 235 240

1.08–1.12 215 220 225 230 235 240

1.13–1.17 220 225 230 235 240

1.18–1.22 225 230 235 240

1.23–1.27 230 235 240

1.28–1.32 235 240

1.33–1.37 240

MEASURED

CLEARANCEORIGINAL VALVE PAD NUMBER

120 125 130 135 140 145 150 155 160 165

170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.00–0.01 120 125 130 135

140 145 150 155 160 165 170 175 180 185 190 195 200 205 210

0.02–0.06 120 125 130 135 140

145 150 155 160 165 170 175 180 185 190 195 200 205 210 215

0.07–0.11 120 125 130 135 140 145

150 155 160 165 170 175 180 185 190 195 200 205 210 215 220

0.12–0.16 120 125 130 135 140 145 150

155 160 165 170 175 180 185 190 195 200 205 210 215 220 225

0.17–0.21 120 125 130 135 140 145 150 155

160 165 170 175 180 185 190 195 200 205 210 215 220 225 230

0.22–0.24 120 125 130 135 140 145 150 155 160

165 170 175 180 185 190 195 200 205 210 215 220 225 230 235

0.25–0.34 STANDARD CLEARANCE

0.35–0.37 125 130 135 140 145 150 155 160 165 170

175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.38–0.42 130 135 140 145 150 155 160 165 170 175

180 185 190 195 200 205 210 215 220 225 230 235 240

0.43–0.47135140145150155160165170175180185 190 195 200 205 210 215 220 225 230 235 240

0.48–0.52 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.53–0.57 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.58–0.62 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.63–0.67 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.68–0.72 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.73–0.77 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.78–0.82 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.83–0.87 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.88–0.92 180 185 190 195 200 205 210 215 220 225 230 235 240

0.93–0.97 185 190 195 200 205 210 215 220 225 230 235 240

0.98–1.02 190 195 200 205 210 215 220 225 230 235 240

1.03–1.07 195 200 205 210 215 220 225 230 235 240

Example:

Exhaust valve clearance (cold)

0.25–0.34 mm (0.0098–0.0134 in)

Rounded value 170

Measured valve clearance is 0.44 mm (0.0173 in)

Replace pad 170 with pad 185

Pad No. 170 = 1.70 mm (0.0669 in)

Pad No. 185 = 1.85 mm (0.0728 in)1.08–1.12 200 205 210 215 220 225 230 235 240

1.13–1.17 205 210 215 220 225 230 235 240

1.18–1.22 210 215 220 225 230 235 240

1.23–1.27 215 220 225 230 235 240

1.28–1.32 220 225 230 235 240

1.33–1.37 225 230 235 240

1.38–1.42 230 235 240

1.43–1.47 235 240

1.48–1.52 240

ProCarManuals.com

Page 63 of 347

3-14

E

INSP

ADJ

POWER UNIT

8. Remove:

Dial gauge

Dial gauge stand

Dial gauge needle

9. Install:

All removed parts

NOTE:

For installation, reverse the removal proce-

dure.

Engine oil level check

1. Check:

Engine oil level

Checking steps:

CAUTION:

When checking the engine oil level on

water, be careful of other watercraft,

boats, swimmers, or obstacles. The

water current or wind can cause the

watercraft to move and lead to a colli-

sion.

When checking the engine oil level on

land, supply water to the cooling water

passages.

Make sure that engine has enough oil

but do not overfill. If there is too little

oil, the engine can be damaged. If there

is too much oil, the air filter can

become saturated with oil, perma-

nently damaging the filter and reduc-

ing engine performance. Follow the

checking procedure carefully.

Make sure that debris or water does

not enter the oil tank filler hole. Debris

or water in the engine oil can cause

serious engine damage.

ProCarManuals.com

Page 64 of 347

3-15

E

INSP

ADJ

POWER UNIT

Place the watercraft in a horizontal posi-

tion or launch the watercraft.

Remove the seat.

Remove the oil tank filler cap 1

and

check for oil on the dipstick 2

.

If there is no oil on the dipstick, pour

enough oil so that the tip of the dipstick

comes into contact with the oil, and then

install the filler cap.

Start the engine.

CAUTION:

When starting the engine make sure the

dipstick is securely fitted into the oil

tank.

NOTE:

The engine cannot be started if the

Yamaha Security System is in the lock

mode. (Deluxe model only)

For information on the Yamaha Security

System, see the owner’s manual. (Deluxe

model only)

Run the engine at trolling speed for 6

minutes or more, and then turn the

engine off.

CAUTION:

When checking the oil level on land, be

sure to connect a garden hose to the

watercraft for proper water supply.

NOTE:

If the ambient temperature is 20°C (68°F)

or less, warm up the engine for an addi-

tional 5 minutes.

Remove the oil tank filler cap 1

, wipe the

dipstick 2

clean, and then screw the filler

cap into the filler hole completely.

ProCarManuals.com

Page 65 of 347

3-16

E

INSP

ADJ

POWER UNIT

Remove the oil tank filler cap again and

check that the oil level is between the

minimum level mark a

and maximum

level mark b

on the dipstick.

If the engine oil is below the minimum

level mark b

, add sufficient oil of the rec-

ommended type to raise it to the correct

level.

If the engine oil is above the maximum

level mark a

, extract sufficient oil using

an oil changer to lower it to the correct

level.

NOTE:

If the oil temperature is low, the reading on

the dipstick will be low, and if the tempera-

ture is high, the reading on the dipstick will

be high.

Engine oil change — using oil changer

WARNING

Avoid changing the engine oil immediately

after turning the engine off. The oil is hot

and should be handled with care to avoid

burns.

CAUTION:

Do not run the engine with too much or

not enough oil in the oil tank. Oil could

spray out or the engine could be dam-

aged.

Do not run the engine for more than 15

seconds without supplying water, when

checking the oil level on land.

The engine could overheat.

Be sure to change the engine oil after the

first 10 hours of operation, and every 100

hours thereafter or at the start of a new

season, otherwise the engine will wear

quickly.

1. Warm the engine up, and then put the

watercraft in a horizontal position.

ProCarManuals.com

Page 66 of 347

3-17

E

INSP

ADJ

POWER UNIT

2. Remove:

Oil tank filler cap 1

3. Insert the tube of an oil changer into the oil

filler hole.

4. Operate the oil changer to extract the oil.

5. If the oil filter is also to be replaced, per-

form the following procedure.

6. Pour the specified amount of the recom-

mended engine oil into the oil filler hole. Replacing steps:

Place a rag under the oil filter.

Remove the oil filter 1

with an oil filter

wrench.

Oil filter wrench:

YB-01426/90890-01426

Lubricate the O-ring 2

of the new oil filter

with a thin coat of engine oil.

CAUTION:

Make sure the O-ring

2 is positioned

correctly in the groove of the oil filter.

Tighten the new oil filter to specification

with an oil filter wrench.

T R..

Oil filter:

17 N m (1.7 kgf m, 12 ft lb)

1

ProCarManuals.com

Page 67 of 347

3-18

E

INSP

ADJ

POWER UNIT

7. Fill:

Oil tank

(with the specified amount of the recom-

mended engine oil)

CAUTION:

When starting the engine make sure the

dipstick is securely fitted into the oil tank.

8. Install:

Oil tank filler cap

Recommended oil:

SAE 10W-30, 20W-40, 20W-50

API SE, SF, SG, SH, SJ, SL

Oil quantity:

Total amount:

4.3 L (4.5 US qt, 3.8 Imp qt)

Without oil filter replacement:

2.0 L (2.1 US qt, 1.8 Imp qt)

With oil filter replacement:

2.2 L (2.3 US qt, 1.9 Imp qt)

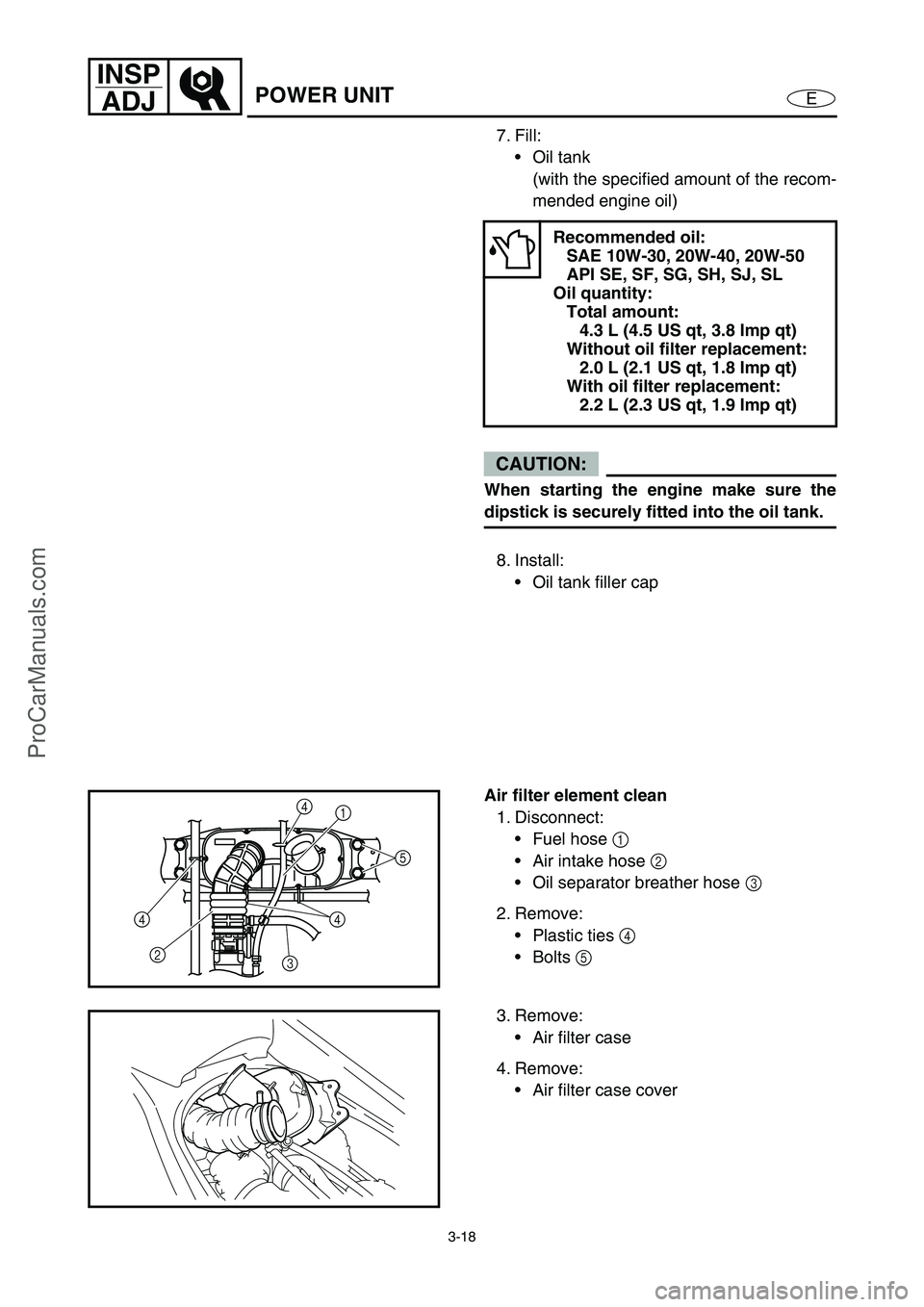

Air filter element clean

1. Disconnect:

Fuel hose 1

Air intake hose 2

Oil separator breather hose 3

2. Remove:

Plastic ties 4

Bolts 5

1

2 4

45 4

3

3. Remove:

Air filter case

4. Remove:

Air filter case cover

ProCarManuals.com

Page 68 of 347

3-19

E

INSP

ADJ

POWER UNIT

5. Remove the air filter element and check it

for dirt and oil. Replace the air filter ele-

ment if there is any oil buildup.

CAUTION:

Do not start the engine with the air filter

case removed, otherwise the engine

could be damaged.

If cleaning the air filter element, use cold

or lukewarm water and let it air dry com-

pletely. Do not use detergent or a solvent

to clean the air filter element, or dry it with

heat or compressed air, otherwise it

could be damaged.

6. Install:

Air filter element

NOTE:

Install the air filter element with its projections

a

facing away from the projections b

on the

air filter case.

7. Install:

Air filter case cover

8. Install:

Air filter case

T R..

Air filter case cover screw (short):

1.5 N m (0.15 kgf m, 1.1 ft lb)

LOCTITE 572

Air filter case cover screw (long):

1.2 N m (0.12 kgf m, 0.9 ft lb)

LOCTITE 572

T R..

Air filter case:

17 N m (1.7 kgf m, 12 ft lb)

a

b

ProCarManuals.com

Page 69 of 347

3-20

E

INSP

ADJ

POWER UNIT

Spark plug inspection

1. Remove:

Ignition coils

CAUTION:

Be careful not to get any foreign sub-

stances or water in spark plug hole.

2. Inspect:

Electrodes 1

Damage/wear →

Replace.

Insulator color 2

Distinctly different color →

Check the

engine condition.

Color guide:

Medium to light tan color:

Normal

Whitish color:

Lean fuel mixture

Air leak

Incorrect settings

Blackish color:

Overly rich mixture

Electrical malfunction

Defective spark plug

3. Clean:

Spark plug

(with a spark plug cleaner or wire brush)

4. Measure:

Spark plug gap a

Out of specification →

Regap.

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)

ProCarManuals.com

Page 70 of 347

3-21

E

INSP

ADJ

POWER UNIT

5. Tighten:

Spark plug

NOTE:

Before installing the spark plug, clean the

gasket surface and spark plug surface. Also,

it is suggested to apply a thin film of anti-

seize compound to the spark plug threads to

prevent thread seizure.

If a torque wrench is not available, a good

estimate of the correct tightening torque for a

new spark plug is to finger tighten a

the

spark plug and then tighten it another 1/4 to

1/2 of a turnb

.

T R..

Spark plug:

13 N m (1.3 kgf m, 9.4 ft lb)

6. Install:

Ignition coils

T R..

Ignition coil bolt:

7.6 N m (0.76 kgf m, 5.5 ft lb)

LOCTITE 572

ProCarManuals.com