YAMAHA VX110 2005 Service Manual

VX110 2005

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/57494/w960_57494-0.png

YAMAHA VX110 2005 Service Manual

Trending: fuel pump, key, check engine light, remote control, jump start, fuses, wiring diagram

Page 131 of 347

5-32

EPOWRREDUCTION DRIVE GEAR

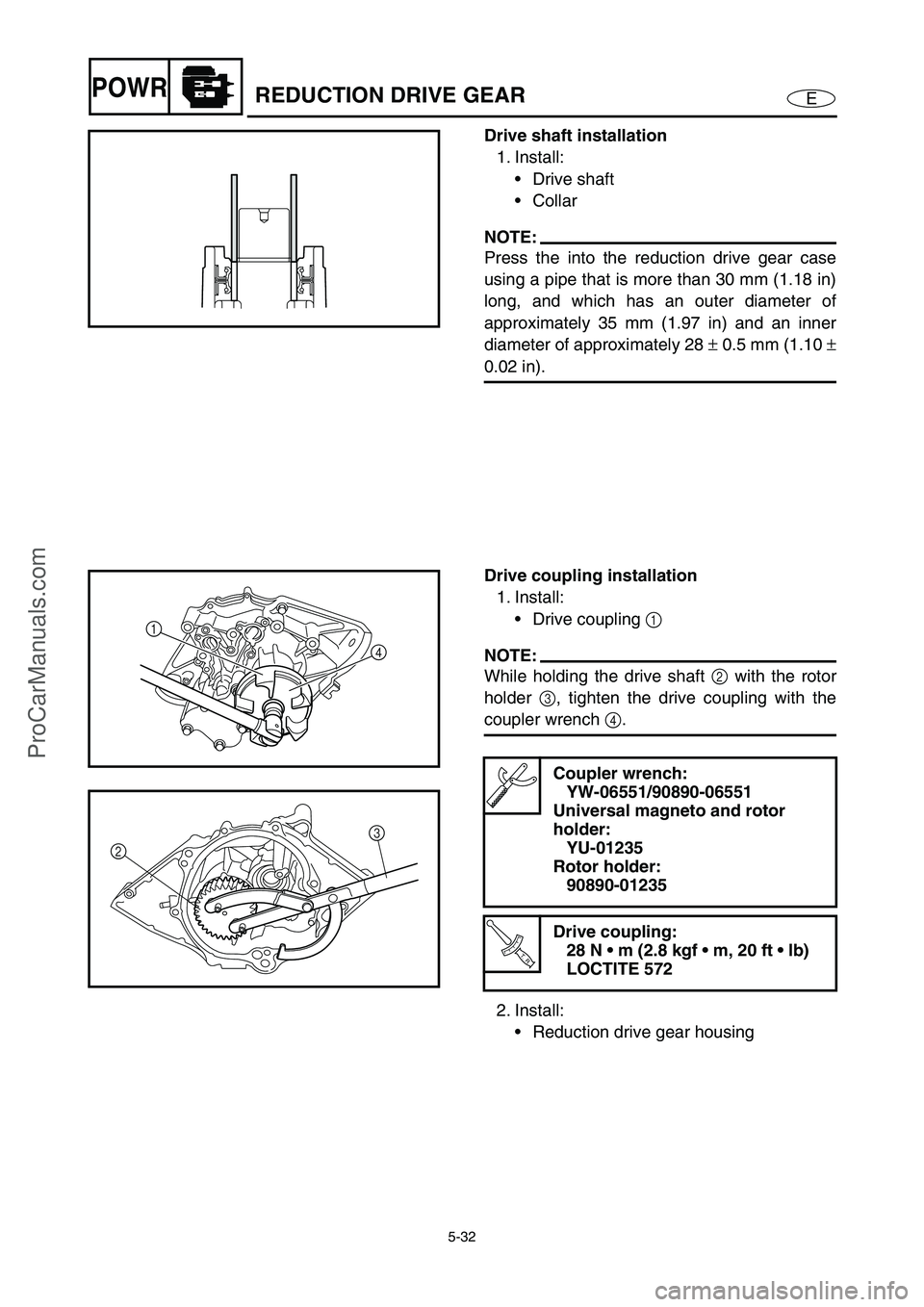

Drive shaft installation

1. Install:

Drive shaft

Collar

NOTE:

Press the into the reduction drive gear case

using a pipe that is more than 30 mm (1.18 in)

long, and which has an outer diameter of

approximately 35 mm (1.97 in) and an inner

diameter of approximately 28 ±

0.5 mm (1.10 ±

0.02 in).

Drive coupling installation

1. Install:

Drive coupling 1

NOTE:

While holding the drive shaft 2

with the rotor

holder 3

, tighten the drive coupling with the

coupler wrench 4

.

2. Install:

Reduction drive gear housing

Coupler wrench:

YW-06551/90890-06551

Universal magneto and rotor

holder:

YU-01235

Rotor holder:

90890-01235

T R..

Drive coupling:

28 N m (2.8 kgf m, 20 ft lb)

LOCTITE 572

1

4

23

ProCarManuals.com

Page 132 of 347

5-33

EPOWRGENERATOR AND STARTER MOTOR

GENERATOR AND STARTER MOTOR

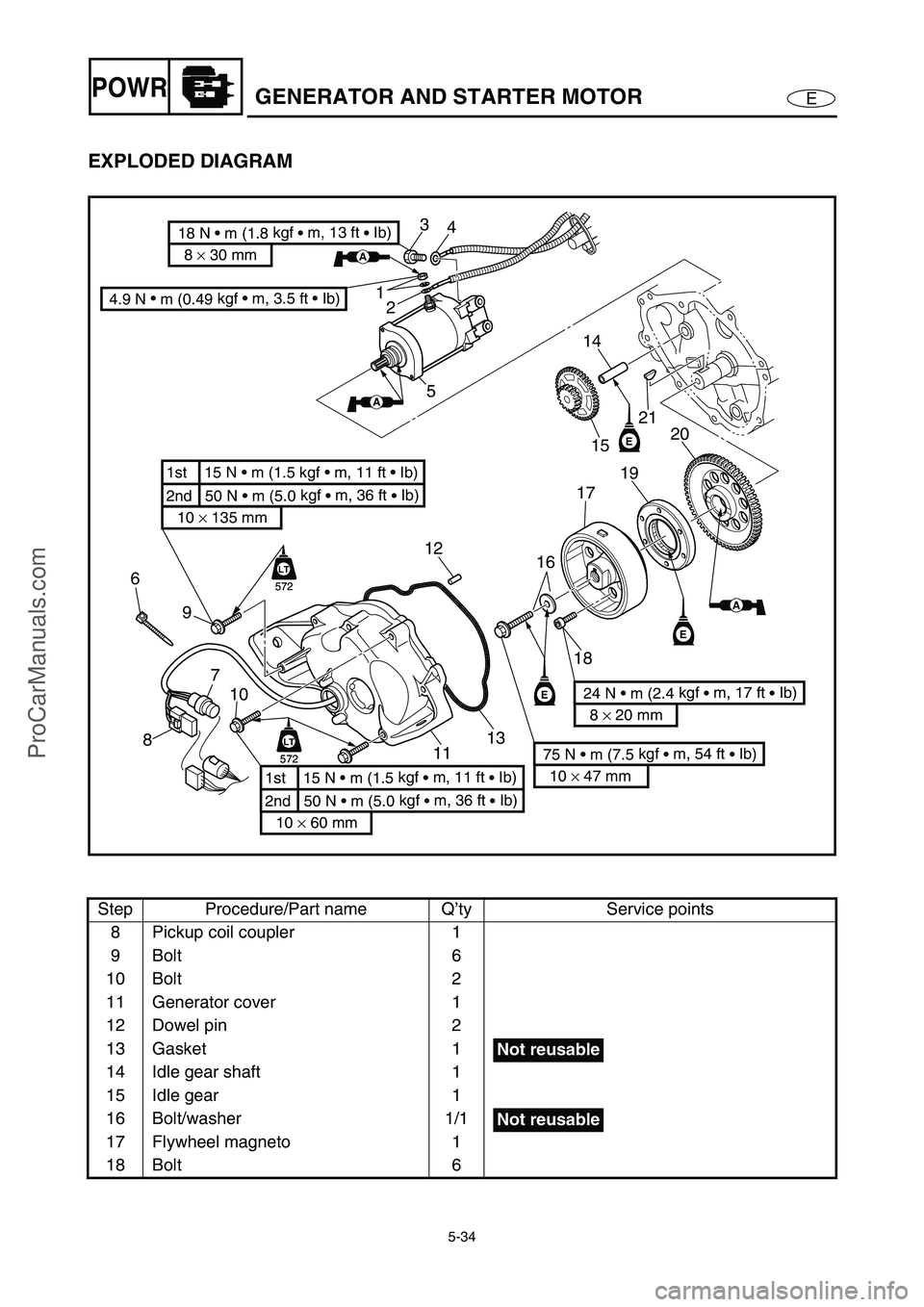

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

GENERATOR COVER AND

FLYWHEEL MAGNETO

REMOVALFollow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

1 Nut/washer 1/1

2 Starter motor lead 1

3Bolt 2

4 Battery negative lead 1

5 Starter motor 1

6 Band 1

7 Lighting coil coupler 1

4 3

2 1

5

7

89

1113 12

18 16171920 21

15 14

AA

E

E

E

LT

572

LT

572

AA

AA

8 × 30 mm

18 N m (1.8 kgf

m, 13 ft

Ib)

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

10 × 47 mm

75 N m (7.5 kgf

m, 54 ft

Ib) 8 × 20 mm

24 N m (2.4 kgf

m, 17 ft

Ib)

10 × 60 mm

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf

m, 11 ft

Ib)

6

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

10 × 135 mm

10

LT

572

LT

572

ProCarManuals.com

Page 133 of 347

5-34

EPOWRGENERATOR AND STARTER MOTOR

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

8 Pickup coil coupler 1

9Bolt 6

10 Bolt 2

11 Generator cover 1

12 Dowel pin 2

13 Gasket 1

14 Idle gear shaft 1

15 Idle gear 1

16 Bolt/washer 1/1

17 Flywheel magneto 1

18 Bolt 6

4 3

2 1

5

7

89

1113 12

18 16171920 21

15 14

AA

E

E

E

LT

572

LT

572

AA

AA

8 × 30 mm

18 N m (1.8 kgf

m, 13 ft

Ib)

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

10 × 47 mm

75 N m (7.5 kgf

m, 54 ft

Ib) 8 × 20 mm

24 N m (2.4 kgf

m, 17 ft

Ib)

10 × 60 mm

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf

m, 11 ft

Ib)

6

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

10 × 135 mm

10

LT

572

LT

572

Not reusable

Not reusable

ProCarManuals.com

Page 134 of 347

5-35

EPOWRGENERATOR AND STARTER MOTOR

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

19 Starter clutch 1

20 Starter gear 1

21 Woodruff key 1

Reverse the removal steps for installation.

4 3

2 1

5

7

89

1113 12

18 16171920 21

15 14

AA

E

E

E

LT

572

LT

572

AA

AA

8 × 30 mm

18 N m (1.8 kgf

m, 13 ft

Ib)

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

10 × 47 mm

75 N m (7.5 kgf

m, 54 ft

Ib) 8 × 20 mm

24 N m (2.4 kgf

m, 17 ft

Ib)

10 × 60 mm

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf

m, 11 ft

Ib)

6

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

10 × 135 mm

10

LT

572

LT

572

ProCarManuals.com

Page 135 of 347

5-36

EPOWRGENERATOR AND STARTER MOTOR

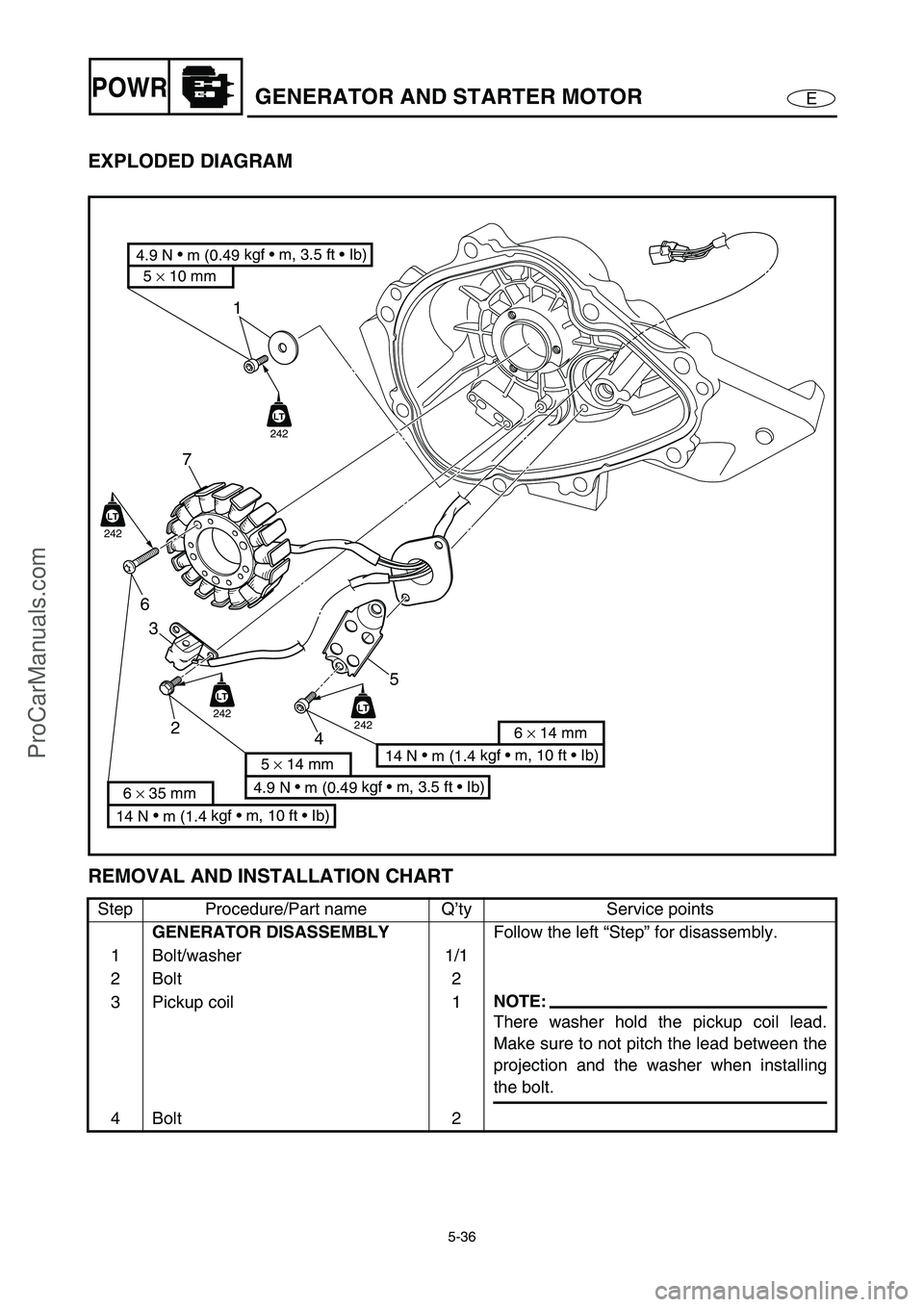

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

GENERATOR DISASSEMBLY

Follow the left “Step” for disassembly.

1 Bolt/washer 1/1

2Bolt 2

3 Pickup coil 1

NOTE:

There washer hold the pickup coil lead.

Make sure to not pitch the lead between the

projection and the washer when installing

the bolt.

4Bolt 2

1

7

6

3

2

45

LT

242

LT

242

LT

242LT

242

14 N

m (1.4 kgf m, 10 ft Ib)

6 × 14 mm

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

5 × 14 mm

14 N

m (1.4 kgf m, 10 ft Ib)

6 × 35 mm

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

5 × 10 mm

ProCarManuals.com

Page 136 of 347

5-37

EPOWRGENERATOR AND STARTER MOTOR

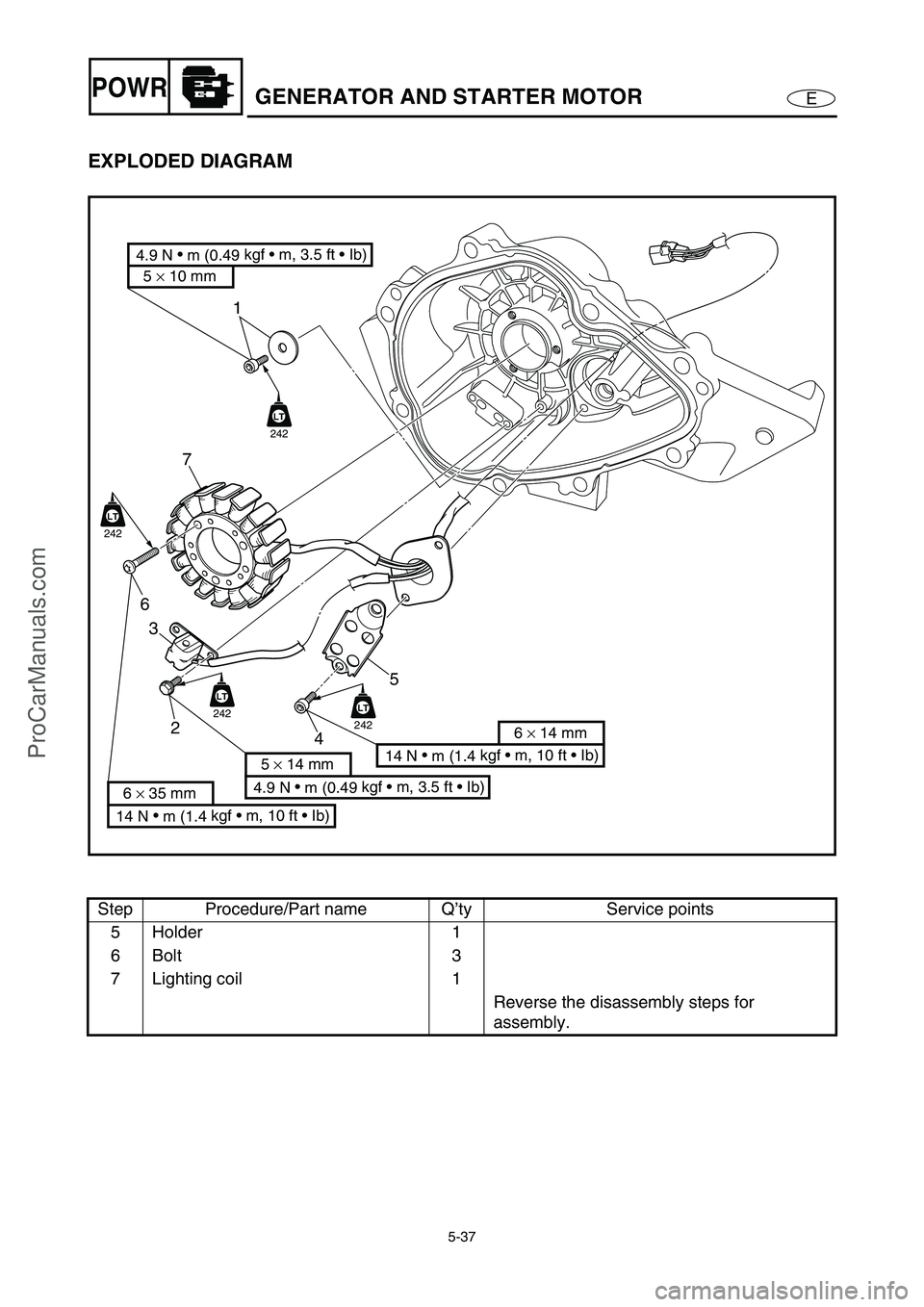

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

5 Holder 1

6Bolt 3

7 Lighting coil 1

Reverse the disassembly steps for

assembly.

1

7

6

3

2

45

LT

242

LT

242

LT

242LT

242

14 N

m (1.4 kgf m, 10 ft Ib)

6 × 14 mm

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

5 × 14 mm

14 N

m (1.4 kgf m, 10 ft Ib)

6 × 35 mm

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

5 × 10 mm

ProCarManuals.com

Page 137 of 347

5-38

EPOWRGENERATOR AND STARTER MOTOR

SERVICE POINTS

Flywheel magneto removal

1. Remove:

Flywheel magneto bolt 1

Washer

NOTE:

While holding the flywheel magneto 2

with the

sheave holder 3

, loosen the flywheel magneto

bolt.

Sheave holder:

YS-01880-A/90890-01701

2. Remove:

Flywheel magneto 1

Woodruff key

NOTE:

While holding the flywheel magneto with

sheave holder 2

, remove the flywheel mag-

neto with the rotor puller 3

.

Rotor puller:

YM-01082/90890-01080

Starter clutch inspection

1. Check:

Starter clutch rollers 1

Damage/wear →

Replace.

ProCarManuals.com

Page 138 of 347

5-39

EPOWRGENERATOR AND STARTER MOTOR

2. Check:

Starter clutch 1

Starter gear 2

Burrs/chips/roughness/wear →

Replace

the defective part(s).

3. Check:

Starter clutch gear’s contacting surfaces

a

Damage/pitting/wear →

Replace the

starter clutch gear.

12

a

4. Check:

Starter clutch operation

Checking steps:

Install the starter gear 1

onto the starter

clutch 2

and hold the starter clutch.

When turning the starter gear clockwise

È, it should turn freely, otherwise the

starter clutch is faulty and must be

replaced.

When turning the starter gear counter-

clockwise É, the starter clutch and the

starter gear should engage, otherwise

the starter clutch is faulty and must be

replaced.

ProCarManuals.com

Page 139 of 347

5-40

EPOWRGENERATOR AND STARTER MOTOR

Flywheel magneto installation

1. Install:

Woodruff key

Flywheel magneto

Washer

Flywheel magneto bolt

NOTE:

Clean the tapered portion of the crankshaft

and the flywheel magneto hub.

When installing the flywheel magneto, make

sure the woodruff key is properly seated in

the keyway of the crankshaft.

Lubricate the flywheel magneto bolt and

washer with engine oil.

2. Tighten:

Flywheel magneto bolt 1

NOTE:

While holding the flywheel magneto 2

with the

sheave holder 3

, tighten the flywheel mag-

neto bolt.

CAUTION:

Do not reuse the flywheel magneto bolt and

washer, always replace them with new

ones.

T R..

Flywheel magneto bolt:

75 N m (7.5 kgf m, 54 ft lb)

Sheave holder:

YS-01880-A/90890-01701

ProCarManuals.com

Page 140 of 347

5-41

EPOWRCAMSHAFTS

CAMSHAFTS

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CYLINDER HEAD COVER

REMOVALFollow the left “Step” for removal.

1Bolt 4

2 Ignition coil 4

3 Spark plug 4

4 Clamp/breather hose 1/1È

To oil tank

Paint mark a

5Bolt 1

6 Cam position sensor 1

7 Clamp/cooling water hose 1/1É

To transom plate

8 Rubber seal 1

E

4

65

7 8

10

11

12

13 9

LT

572

LT

14

16

15

3

13 N

m (1.3 kgf m, 9.4 ft Ib)

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 16 mm 6 × 16 mm

2nd 7.6 N m (0.76 kgf

m, 5.5 ft

Ib) 1st 3.7 N m (0.37 kgf

m, 2.7 ft

Ib)

12 N

m (1.2 kgf m, 8.7 ft Ib)

6 × 22 mm

aÈ

É

1

2

7.6 N

m (0.76 kgf m, 5.5 ft Ib)

6 × 16 mm

LT

572

LTAA

1280B

1280B

ProCarManuals.com

Trending: service interval, torque, fuse diagram, cooling, width, ad blue, remote start