YAMAHA VX110 2005 Manual PDF

Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 71 of 347

3-22

E

INSP

ADJ

ELECTRICAL

ELECTRICAL

Battery inspection

WARNING

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Electro-

lyte contains sulfuric acid. Avoid contact

with skin, eyes or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

egg or vegetable oil. Call physician immedi-

ately.

Eyes: Flush with water for 15 minutes and

get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flame, cigarettes, etc., well away. If

using or charging the battery in an

enclosed space, make sure that it is well

ventilated. Always shield your eyes when

working near batteries.

KEEP OUT OF THE REACH OF CHILDREN.

CAUTION:

Be careful not to place the battery on its

side.

Make sure to remove the battery from the

battery compartment when adding battery

electrolyte or charging the battery.

When checking the battery, make sure the

breather hose is connected to the battery

and not obstructed.

ProCarManuals.com

Page 72 of 347

3-23

E

INSP

ADJ

ELECTRICAL

1. Remove:

Bands

Battery negative lead 1

Battery positive lead 2

Battery

Battery breather hose 3

WARNING

When removing the battery, disconnect

the negative lead first.

Remove the battery to prevent acid loss

during turning the watercraft on its side

for the impeller, etc.

2. Inspect:

Electrolyte level

Low →

Add distilled water.

The electrolyte level should be between

the maximum a

and minimum b

level

marks.

CAUTION:

Use only distilled water. Other types of

water contain minerals which are harmful

to batteries.Filling steps:

Remove each filler cap.

Add distilled water to the maximum level

mark.

When the electrolyte level reaches the

maximum level mark, allow the cell to

stand for 20 minutes. If the electrolyte

level drops, add more distilled water so

the level reaches the maximum level

mark.

ProCarManuals.com

Page 73 of 347

3-24

E

INSP

ADJ

ELECTRICAL

3. Inspect:

Specific gravity

Out of specification →

Charge.

4. Install:

Filler caps

CAUTION:

Before installation, rinse off any fluid from

the battery box and battery and make sure

that the battery is dry before installing it.

Specific gravity at 20 °C (68 °F):

1.28

Charging current:

1.9 A

× 10 h

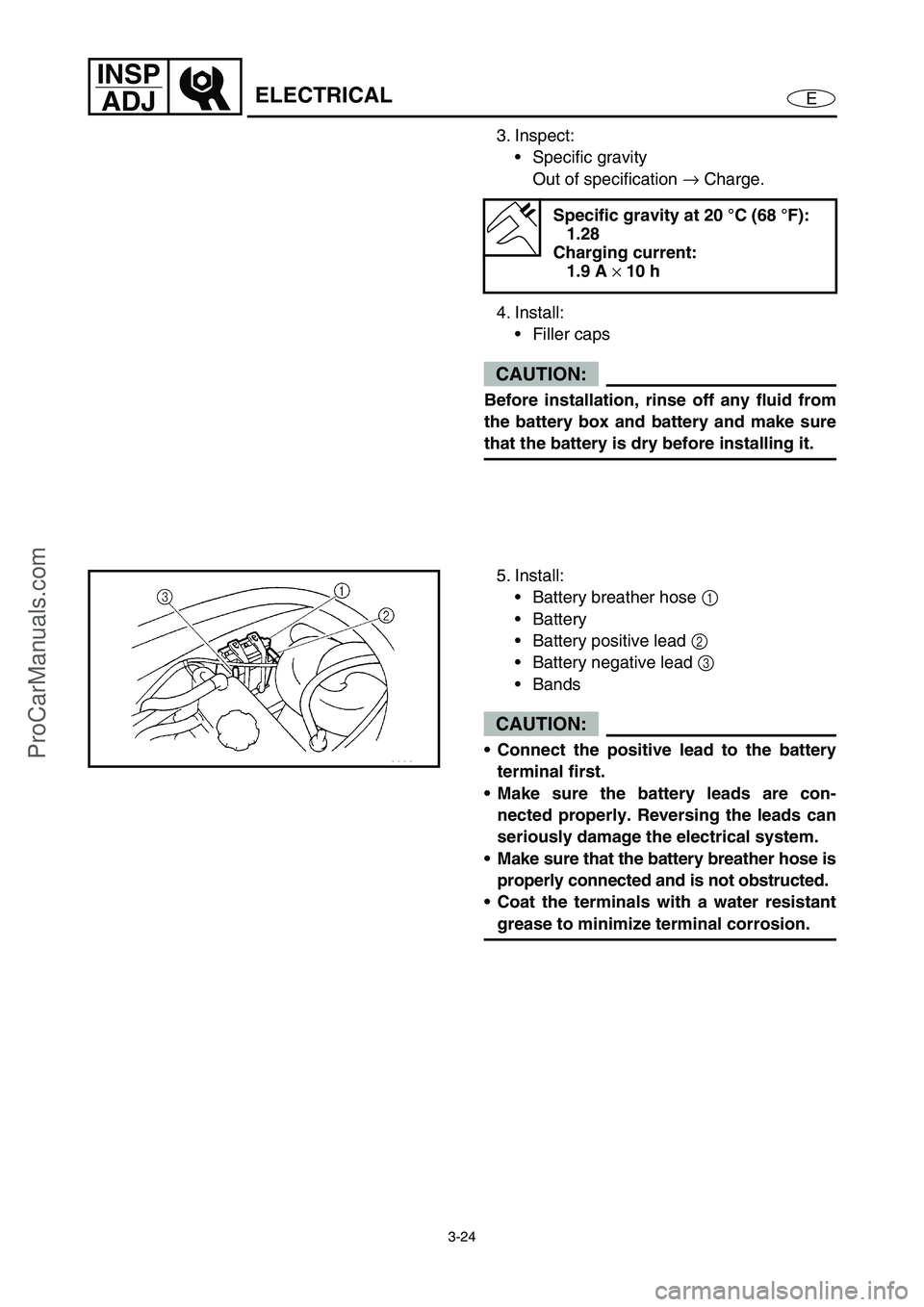

5. Install:

Battery breather hose 1

Battery

Battery positive lead 2

Battery negative lead 3

Bands

CAUTION:

Connect the positive lead to the battery

terminal first.

Make sure the battery leads are con-

nected properly. Reversing the leads can

seriously damage the electrical system.

Make sure that the battery breather hose is

properly connected and is not obstructed.

Coat the terminals with a water resistant

grease to minimize terminal corrosion.

ProCarManuals.com

Page 74 of 347

3-25

E

INSP

ADJ

JET PUMP UNIT

JET PUMP UNIT

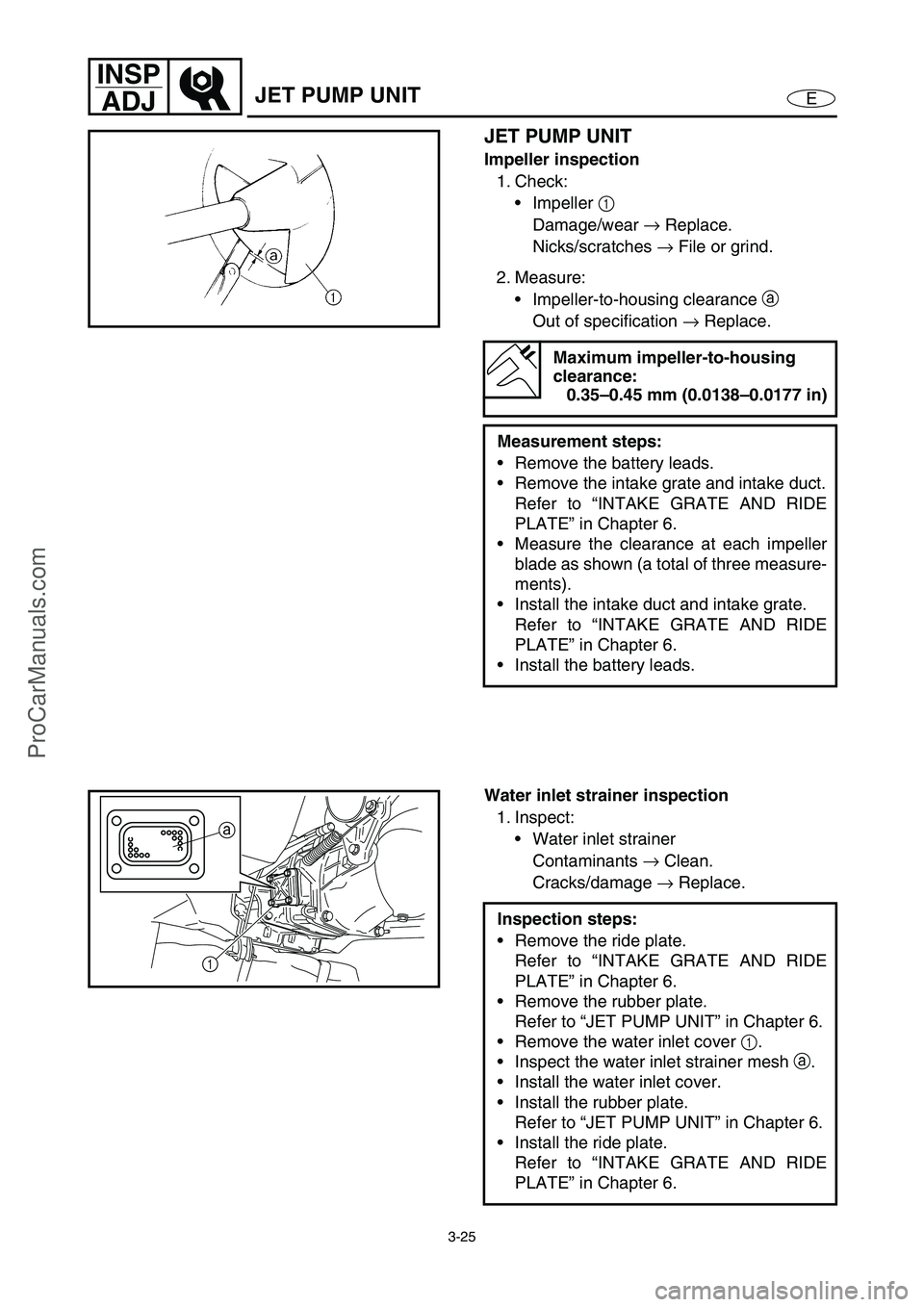

Impeller inspection

1. Check:

Impeller 1

Damage/wear →

Replace.

Nicks/scratches →

File or grind.

2. Measure:

Impeller-to-housing clearancea

Out of specification →

Replace.

Maximum impeller-to-housing

clearance:

0.35–0.45 mm (0.0138–0.0177 in)

Measurement steps:

Remove the battery leads.

Remove the intake grate and intake duct.

Refer to “INTAKE GRATE AND RIDE

PLATE” in Chapter 6.

Measure the clearance at each impeller

blade as shown (a total of three measure-

ments).

Install the intake duct and intake grate.

Refer to “INTAKE GRATE AND RIDE

PLATE” in Chapter 6.

Install the battery leads.

Water inlet strainer inspection

1. Inspect:

Water inlet strainer

Contaminants →

Clean.

Cracks/damage →

Replace.

Inspection steps:

Remove the ride plate.

Refer to “INTAKE GRATE AND RIDE

PLATE” in Chapter 6.

Remove the rubber plate.

Refer to “JET PUMP UNIT” in Chapter 6.

Remove the water inlet cover 1

.

Inspect the water inlet strainer mesh a

.

Install the water inlet cover.

Install the rubber plate.

Refer to “JET PUMP UNIT” in Chapter 6.

Install the ride plate.

Refer to “INTAKE GRATE AND RIDE

PLATE” in Chapter 6.

a

1

ProCarManuals.com

Page 75 of 347

3-26

E

INSP

ADJ

BILGE PUMP/GENERAL

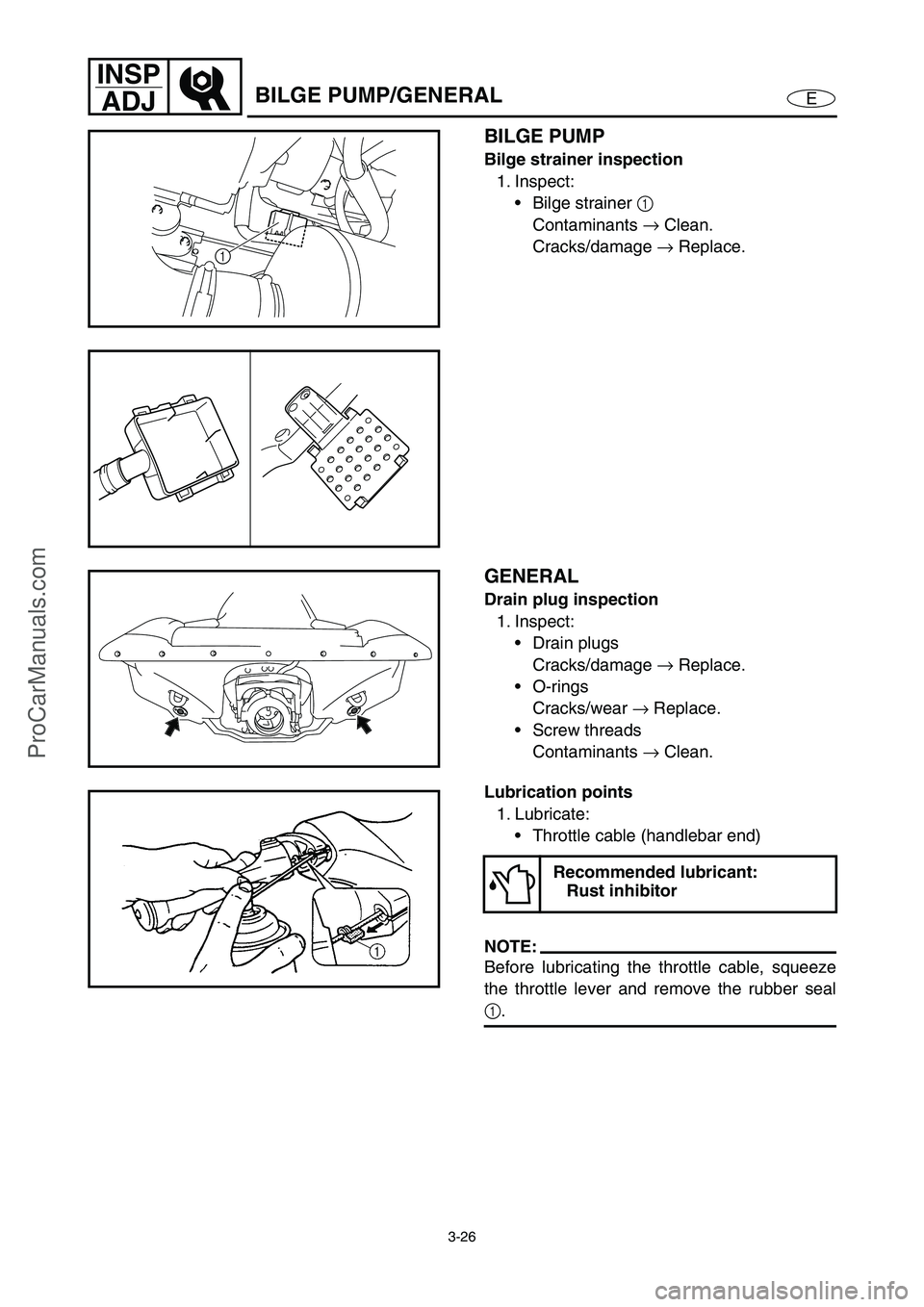

BILGE PUMP

Bilge strainer inspection

1. Inspect:

Bilge strainer 1

Contaminants →

Clean.

Cracks/damage →

Replace.

1

GENERAL

Drain plug inspection

1. Inspect:

Drain plugs

Cracks/damage →

Replace.

O-rings

Cracks/wear →

Replace.

Screw threads

Contaminants →

Clean.

Lubrication points

1. Lubricate:

Throttle cable (handlebar end)

NOTE:

Before lubricating the throttle cable, squeeze

the throttle lever and remove the rubber seal

1

.

Recommended lubricant:

Rust inhibitor

ProCarManuals.com

Page 76 of 347

3-27

E

INSP

ADJ

GENERAL

2. Lubricate:

Nozzle pivot shaft

Steering cable (nozzle end)

Recommended grease:

Yamaha marine grease,

Yamaha grease A

(Water resistant grease)

3. Lubricate:

Steering cable

Steering cable joint

NOTE:

Disconnect the joints and apply a small

amount of grease.

Recommended grease:

Yamaha marine grease,

Yamaha grease A

(Water resistant grease)

4. Lubricate: (Deluxe model only)

Shift cable (shift lever end)

Shift cable (reverse gate end)

Shift cable joint

NOTE:

Disconnect the joints and apply a small

amount of grease.

Recommended grease:

Yamaha marine grease,

Yamaha grease A

(Water resistant grease)

ProCarManuals.com

Page 77 of 347

EFUEL

1

2

3

4

5

6

7

8

9

CHAPTER 4

FUEL SYSTEM

FUEL TANK AND FUEL PUMP MODULE...................................................... 4-1

EXPLODED DIAGRAM ............................................................................. 4-1

REMOVAL AND INSTALLATION CHART ................................................ 4-1

SERVICE POINTS .................................................................................... 4-4

Fuel hose disconnection ..................................................................... 4-4

Fuel pump module removal................................................................. 4-4

Check valve inspection ....................................................................... 4-4

Fuel sender inspection ........................................................................ 4-5

Fuel tank inspection ............................................................................ 4-5

Fuel hose inspection ........................................................................... 4-5

Fuel pump filter inspection .................................................................. 4-5

Fuel pump module installation ............................................................ 4-6

Fuel hose connect ............................................................................... 4-6

FUEL INJECTION SYSTEM ............................................................................ 4-7

EXPLODED DIAGRAM ............................................................................. 4-7

REMOVAL AND INSTALLATION CHART ................................................ 4-7

THROTTLE BODY ASSEMBLY AND INTAKE MANIFOLD ........................ 4-10

EXPLODED DIAGRAM ........................................................................... 4-10

REMOVAL AND INSTALLATION CHART .............................................. 4-10

SERVICE POINTS .................................................................................. 4-12

Fuel hose clamps removal ................................................................ 4-12

Hose clamps installation ................................................................... 4-12

Fuel hose disconnection ................................................................... 4-12

Fuel line inspection ........................................................................... 4-13

Fuel hose installation (replacing with new fuel hose) ........................ 4-14

Fuel hose connection ........................................................................ 4-14

Fuel injectors inspection.................................................................... 4-15

Throttle body assembly inspection .................................................... 4-15

Accelerator position sensor inspection.............................................. 4-15

Intake assembly installation .............................................................. 4-16

Air filter case assembly installation ................................................... 4-17

Fuel pressure measurement ............................................................. 4-17

ProCarManuals.com

Page 78 of 347

4-1

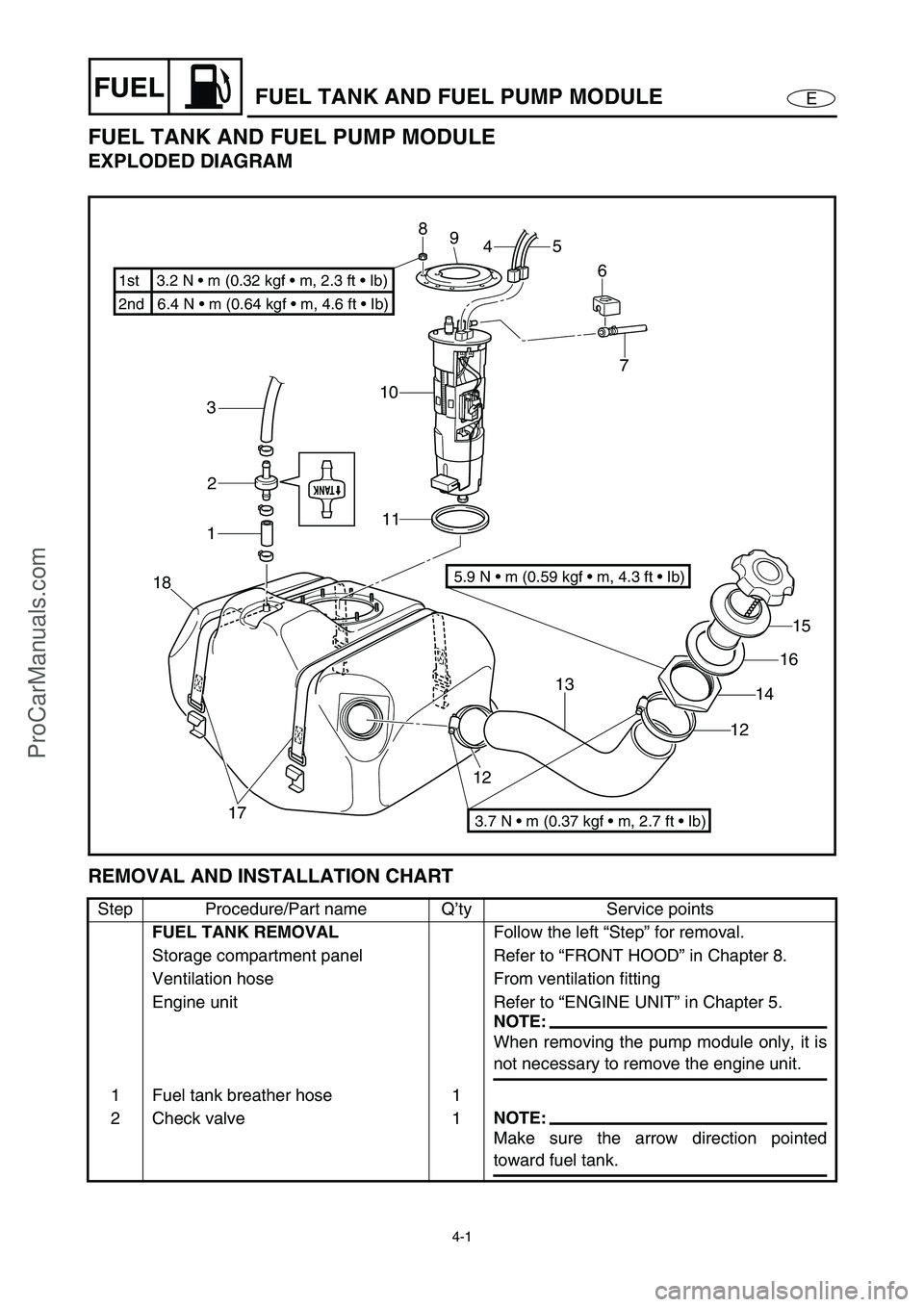

EFUELFUEL TANK AND FUEL PUMP MODULE

FUEL TANK AND FUEL PUMP MODULE

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

FUEL TANK REMOVAL

Follow the left “Step” for removal.

Storage compartment panel Refer to “FRONT HOOD” in Chapter 8.

Ventilation hose From ventilation fitting

Engine unit Refer to “ENGINE UNIT” in Chapter 5.

NOTE:

When removing the pump module only, it is

not necessary to remove the engine unit.

1 Fuel tank breather hose 1

2 Check valve 1

NOTE:

Make sure the arrow direction pointed

toward fuel tank.

7

10

11 3

2

1

18

17121315

16

14

12 6 5

4 8

9

2nd 6.4 N • m (0.64 kgf m, 4.6 ft Ib) 1st 3.2 N m (0.32 kgf m, 2.3 ft Ib)

3.7 N m (0.37 kgf m, 2.7 ft Ib)

5.9 N m (0.59 kgf m, 4.3 ft Ib)

ProCarManuals.com

Page 79 of 347

4-2

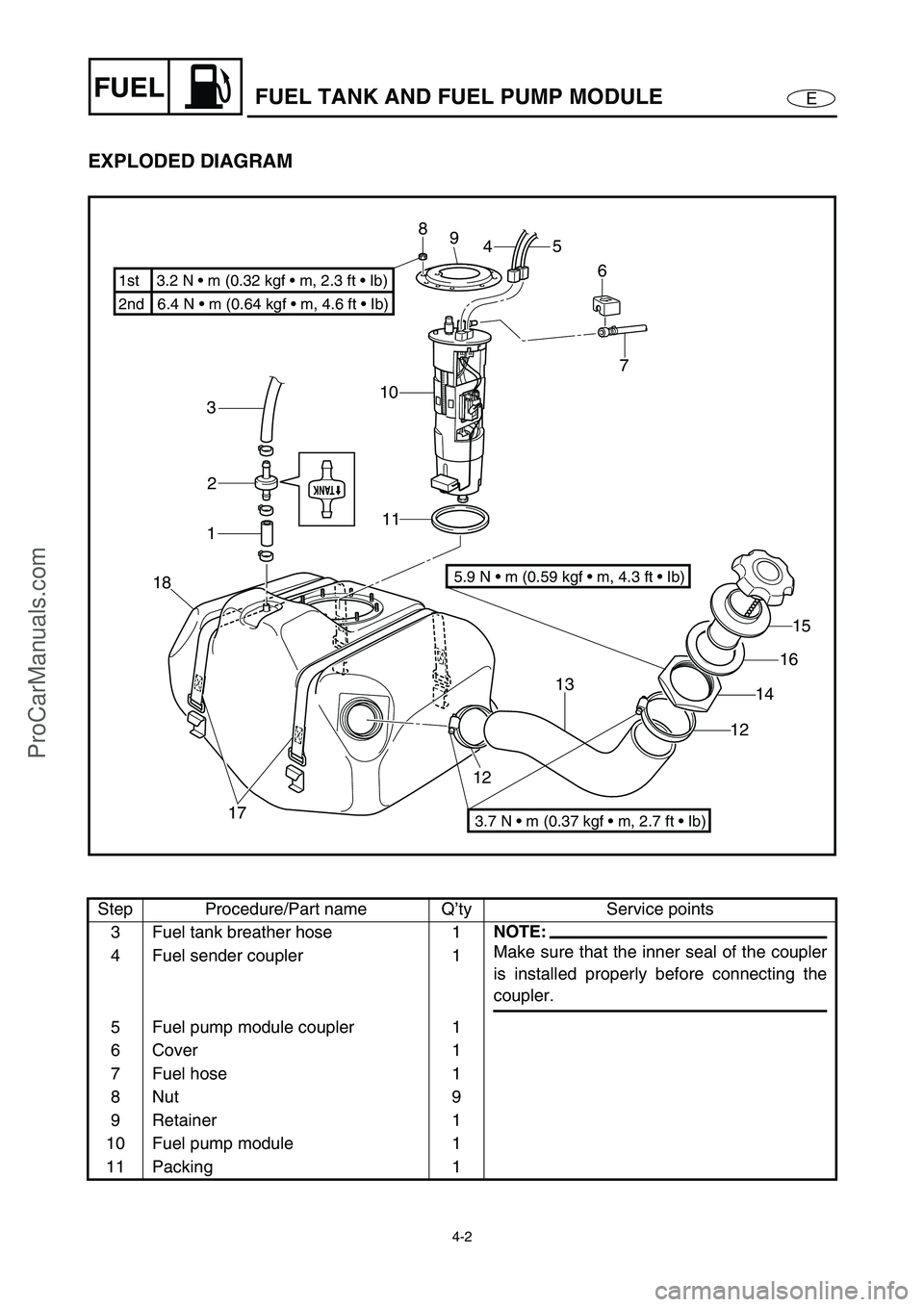

EFUELFUEL TANK AND FUEL PUMP MODULE

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

3 Fuel tank breather hose 1

NOTE:

Make sure that the inner seal of the coupler

is installed properly before connecting the

coupler. 4 Fuel sender coupler 1

5 Fuel pump module coupler 1

6 Cover 1

7 Fuel hose 1

8Nut 9

9 Retainer 1

10 Fuel pump module 1

11 Packing 1

7

10

11 3

2

1

18

17121315

16

14

12 6 5

4 8

9

2nd 6.4 N m (0.64 kgf m, 4.6 ft Ib) 1st 3.2 N m (0.32 kgf m, 2.3 ft Ib)

3.7 N m (0.37 kgf m, 2.7 ft Ib)

5.9 N m (0.59 kgf m, 4.3 ft Ib)

ProCarManuals.com

Page 80 of 347

4-3

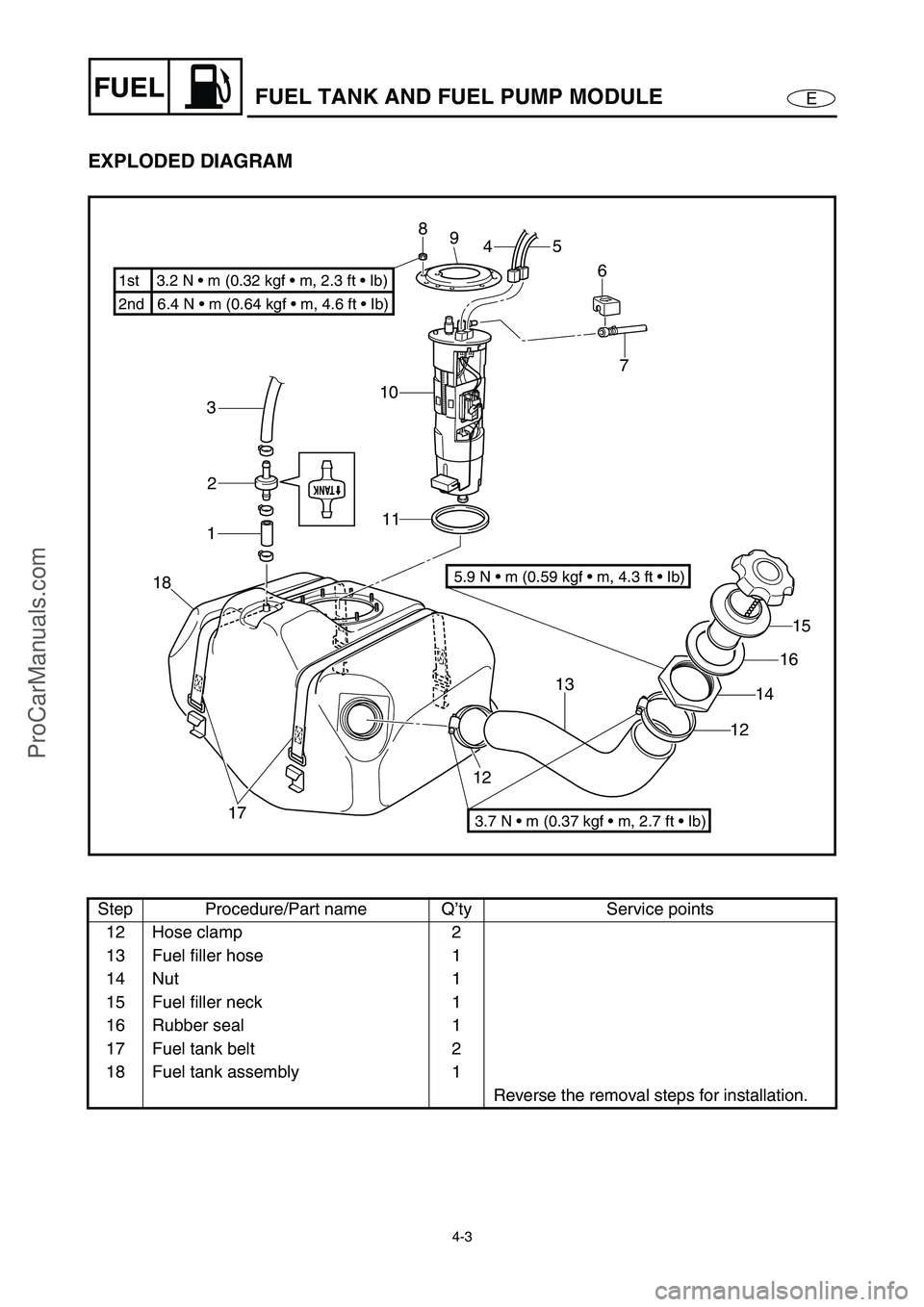

EFUELFUEL TANK AND FUEL PUMP MODULE

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

12 Hose clamp 2

13 Fuel filler hose 1

14 Nut 1

15 Fuel filler neck 1

16 Rubber seal 1

17 Fuel tank belt 2

18 Fuel tank assembly 1

Reverse the removal steps for installation.

7

10

11 3

2

1

18

17121315

16

14

12 6 5

4 8

9

2nd 6.4 N m (0.64 kgf m, 4.6 ft Ib) 1st 3.2 N m (0.32 kgf m, 2.3 ft Ib)

3.7 N m (0.37 kgf m, 2.7 ft Ib)

5.9 N m (0.59 kgf m, 4.3 ft Ib)

ProCarManuals.com