YAMAHA VX110 2005 Service Manual

Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 101 of 347

5-2

EPOWRENGINE UNIT

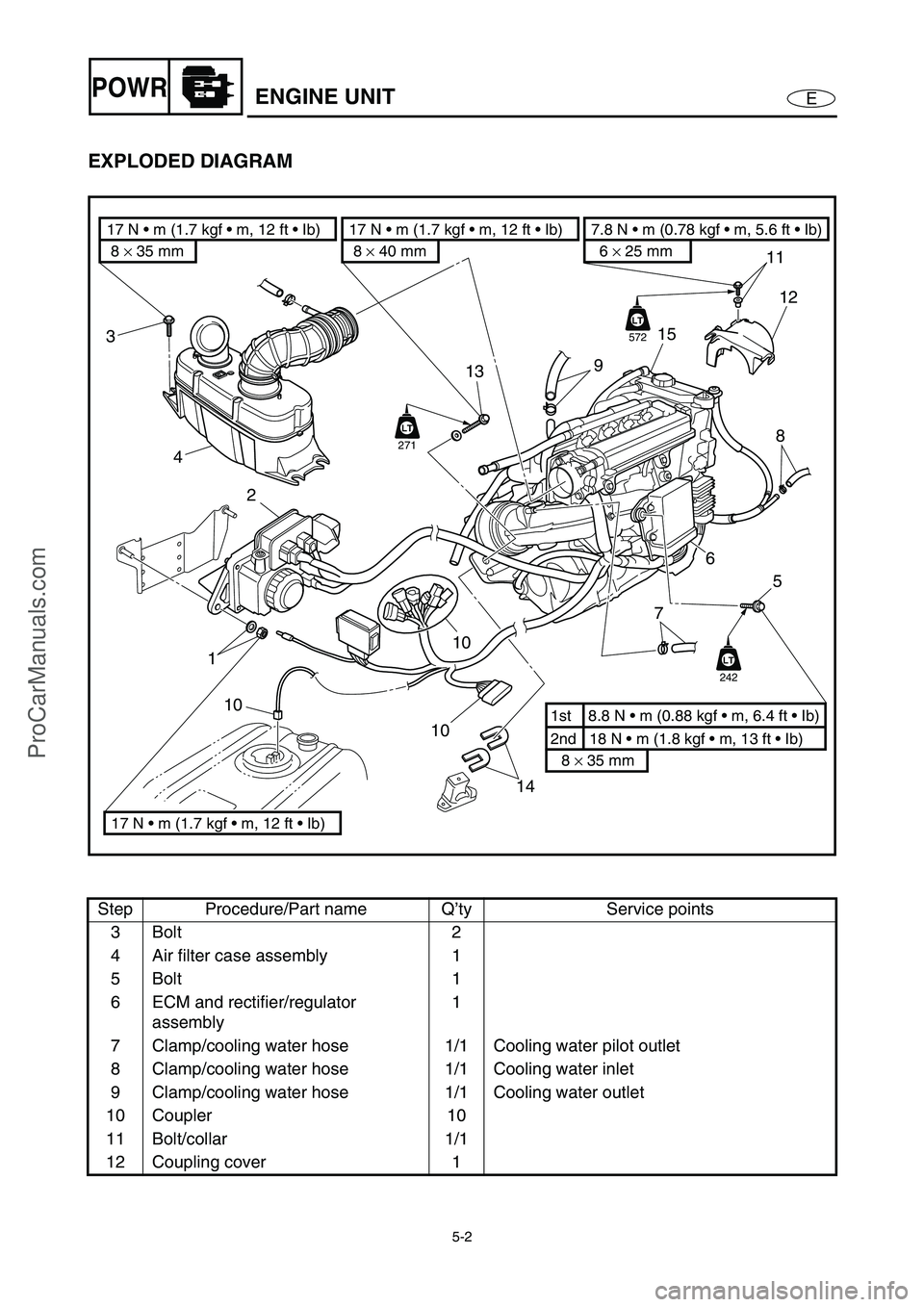

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

3Bolt 2

4 Air filter case assembly 1

5Bolt 1

6 ECM and rectifier/regulator

assembly1

7 Clamp/cooling water hose 1/1 Cooling water pilot outlet

8 Clamp/cooling water hose 1/1 Cooling water inlet

9 Clamp/cooling water hose 1/1 Cooling water outlet

10 Coupler 10

11 Bolt/collar 1/1

12 Coupling cover 1

14 10

10

2

113

3

4

11

15

12

8

7

9

6

5

2nd 18 N m (1.8 kgf m, 13 ft Ib) 1st 8.8 N m (0.88 kgf m, 6.4 ft Ib)

8 × 35 mm

6 × 25 mm

7.8 N m (0.78 kgf m, 5.6 ft Ib)

8 × 35 mm 17 N m (1.7 kgf m, 12 ft Ib)

17 N m (1.7 kgf m, 12 ft Ib)8 × 40 mm

17 N m (1.7 kgf m, 12 ft Ib)

10LT

242

LT

LT

572

LT

LT

271

ProCarManuals.com

Page 102 of 347

5-3

EPOWRENGINE UNIT

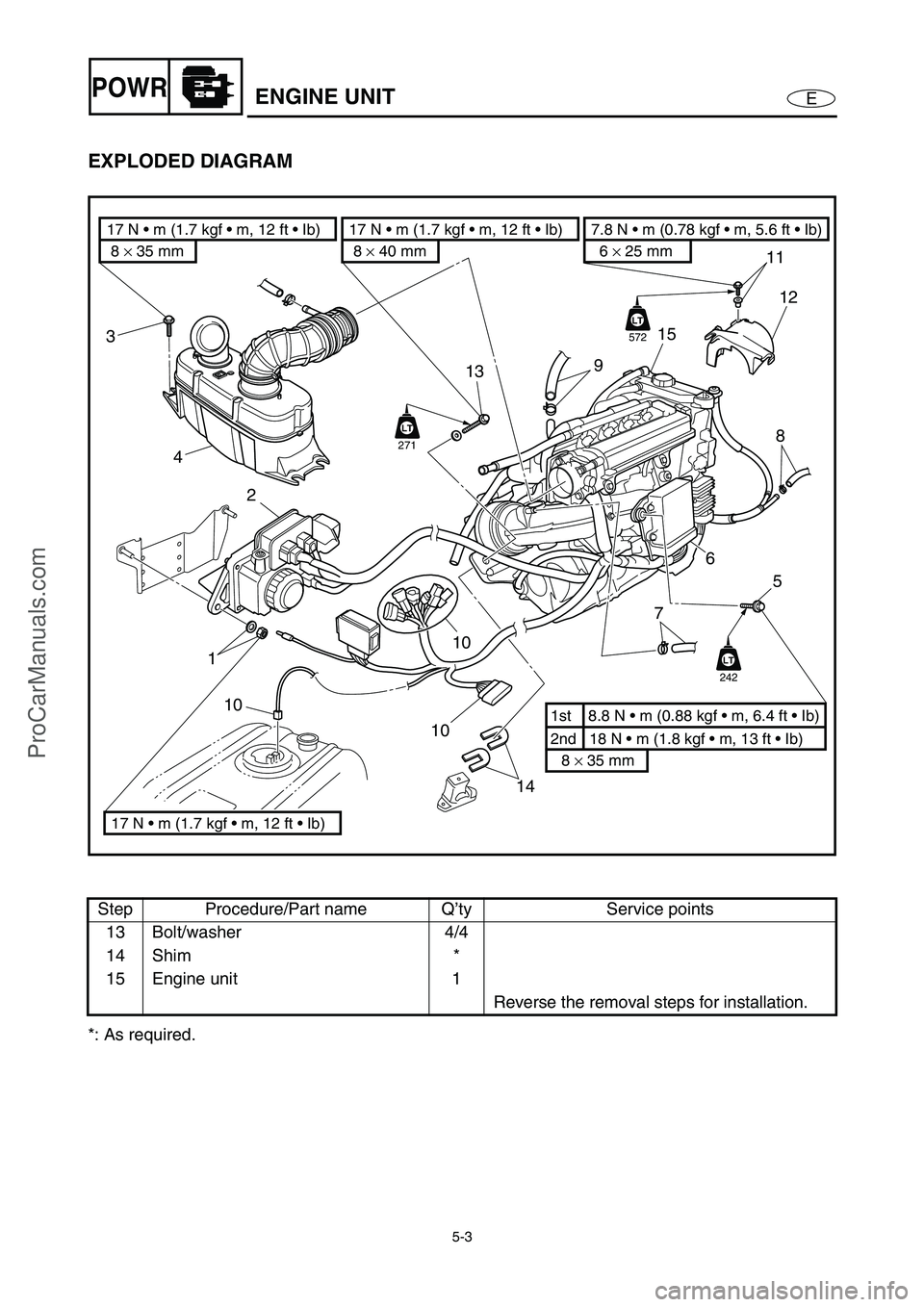

EXPLODED DIAGRAM

*: As required.Step Procedure/Part name Q’ty Service points

13 Bolt/washer 4/4

14 Shim *

15 Engine unit 1

Reverse the removal steps for installation.

14 10

10

2

113

3

4

11

15

12

8

7

9

6

5

2nd 18 N m (1.8 kgf m, 13 ft Ib) 1st 8.8 N m (0.88 kgf m, 6.4 ft Ib)

8 × 35 mm

6 × 25 mm

7.8 N m (0.78 kgf m, 5.6 ft Ib)

8 × 35 mm 17 N m (1.7 kgf m, 12 ft Ib)

17 N m (1.7 kgf m, 12 ft Ib)8 × 40 mm

17 N m (1.7 kgf m, 12 ft Ib)

10LT

242

LT

LT

572

LT

LT

271

ProCarManuals.com

Page 103 of 347

5-4

EPOWRENGINE UNIT

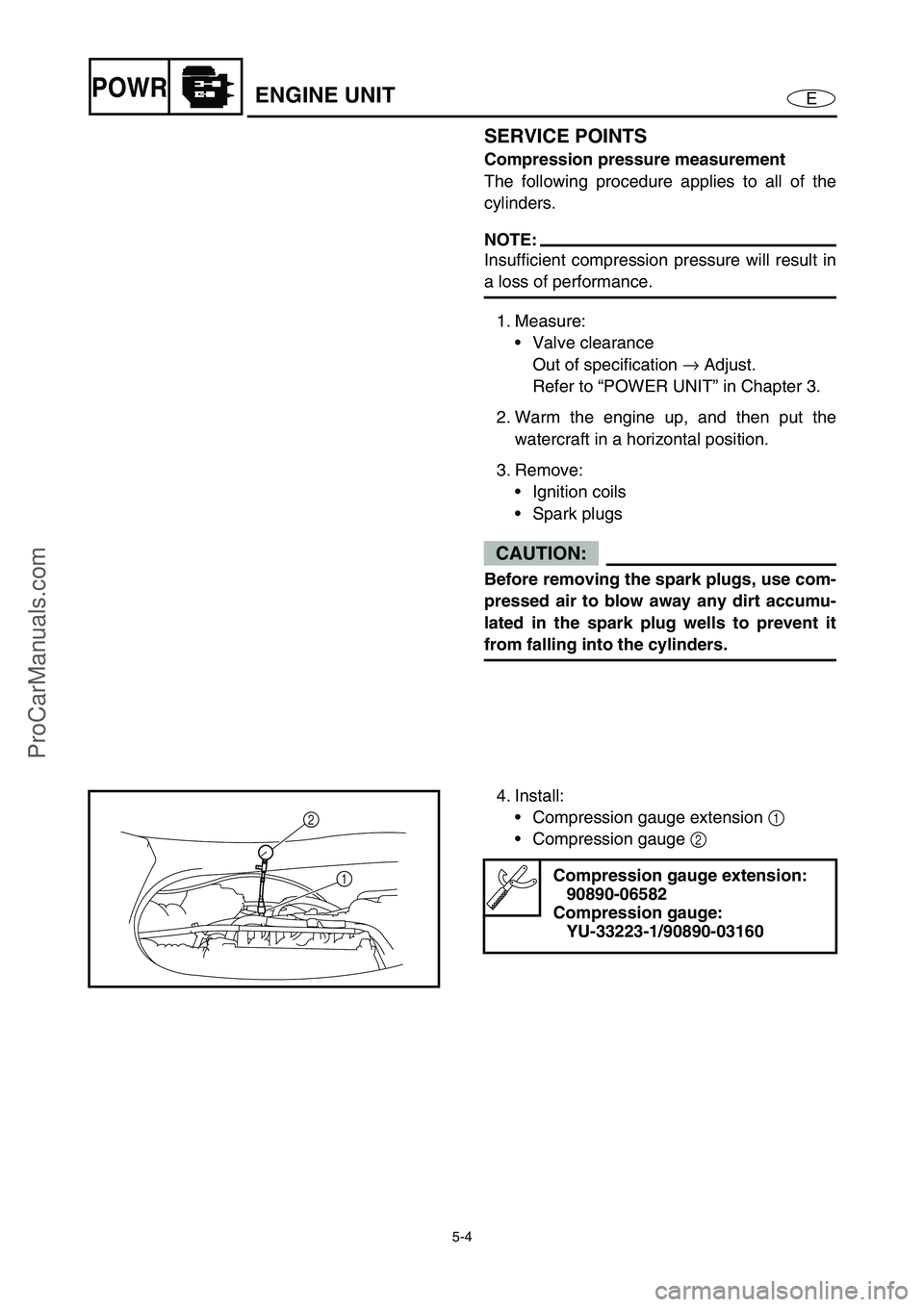

SERVICE POINTS

Compression pressure measurement

The following procedure applies to all of the

cylinders.

NOTE:

Insufficient compression pressure will result in

a loss of performance.

1. Measure:

Valve clearance

Out of specification →

Adjust.

Refer to “POWER UNIT” in Chapter 3.

2. Warm the engine up, and then put the

watercraft in a horizontal position.

3. Remove:

Ignition coils

Spark plugs

CAUTION:

Before removing the spark plugs, use com-

pressed air to blow away any dirt accumu-

lated in the spark plug wells to prevent it

from falling into the cylinders.

4. Install:

Compression gauge extension 1

Compression gauge 2

Compression gauge extension:

90890-06582

Compression gauge:

YU-33223-1/90890-03160

2

1

ProCarManuals.com

Page 104 of 347

5-5

EPOWRENGINE UNIT

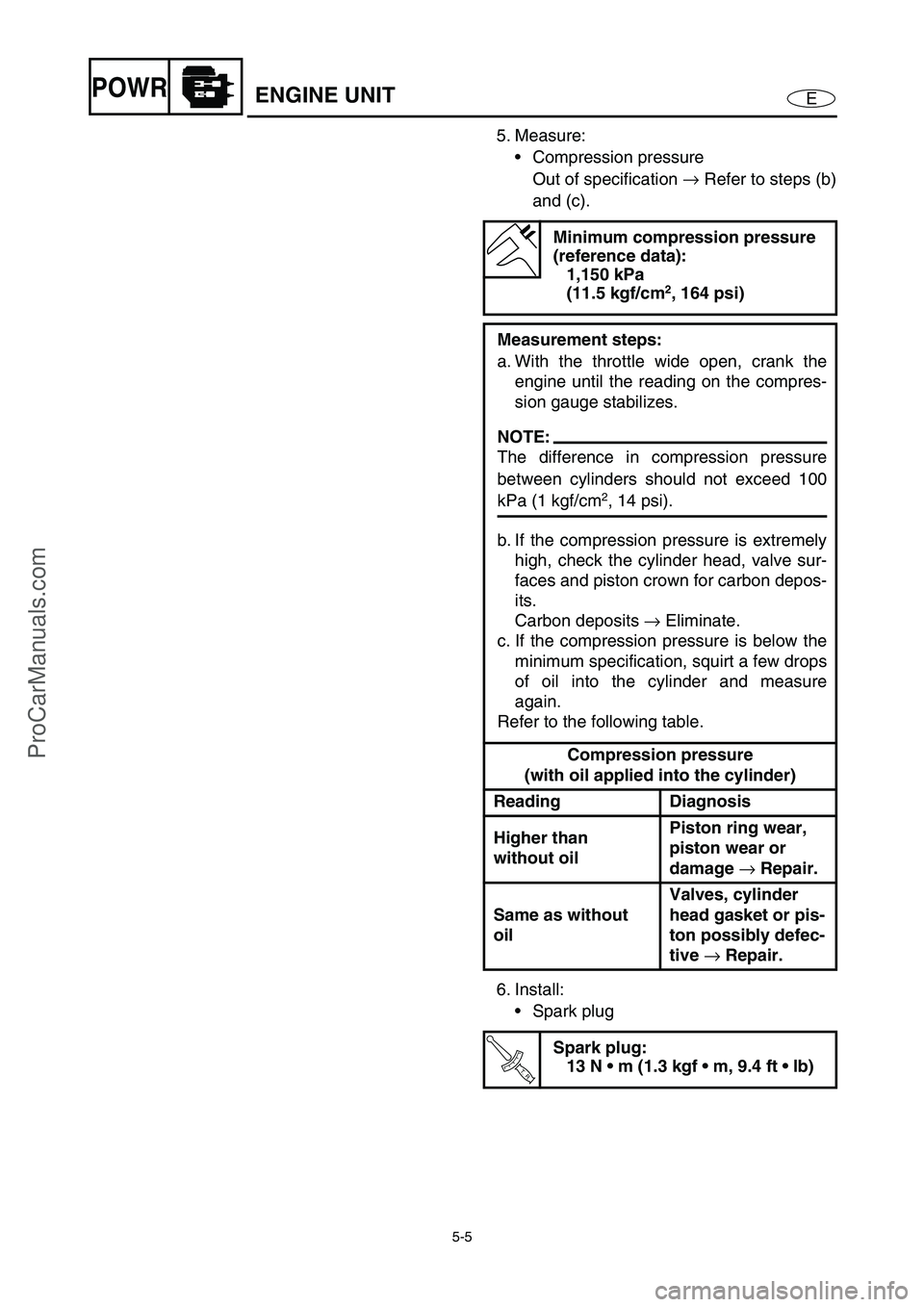

5. Measure:

Compression pressure

Out of specification →

Refer to steps (b)

and (c).

6. Install:

Spark plug

Minimum compression pressure

(reference data):

1,150 kPa

(11.5 kgf/cm

2, 164 psi)

Measurement steps:

a. With the throttle wide open, crank the

engine until the reading on the compres-

sion gauge stabilizes.

NOTE:

The difference in compression pressure

between cylinders should not exceed 100

kPa (1 kgf/cm2, 14 psi).

b. If the compression pressure is extremely

high, check the cylinder head, valve sur-

faces and piston crown for carbon depos-

its.

Carbon deposits →

Eliminate.

c. If the compression pressure is below the

minimum specification, squirt a few drops

of oil into the cylinder and measure

again.

Refer to the following table.

Compression pressure

(with oil applied into the cylinder)

Reading Diagnosis

Higher than

without oilPiston ring wear,

piston wear or

damage

→ Repair.

Same as without

oilValves, cylinder

head gasket or pis-

ton possibly defec-

tive

→ Repair.

T R..

Spark plug:

13 N m (1.3 kgf m, 9.4 ft lb)

ProCarManuals.com

Page 105 of 347

5-6

EPOWRENGINE UNIT

7. Install:

Ignition coils

T R..

Ignition coils bolt:

7.6 N m (0.76 kgf m, 5.5 ft lb)

LOCTITE 572

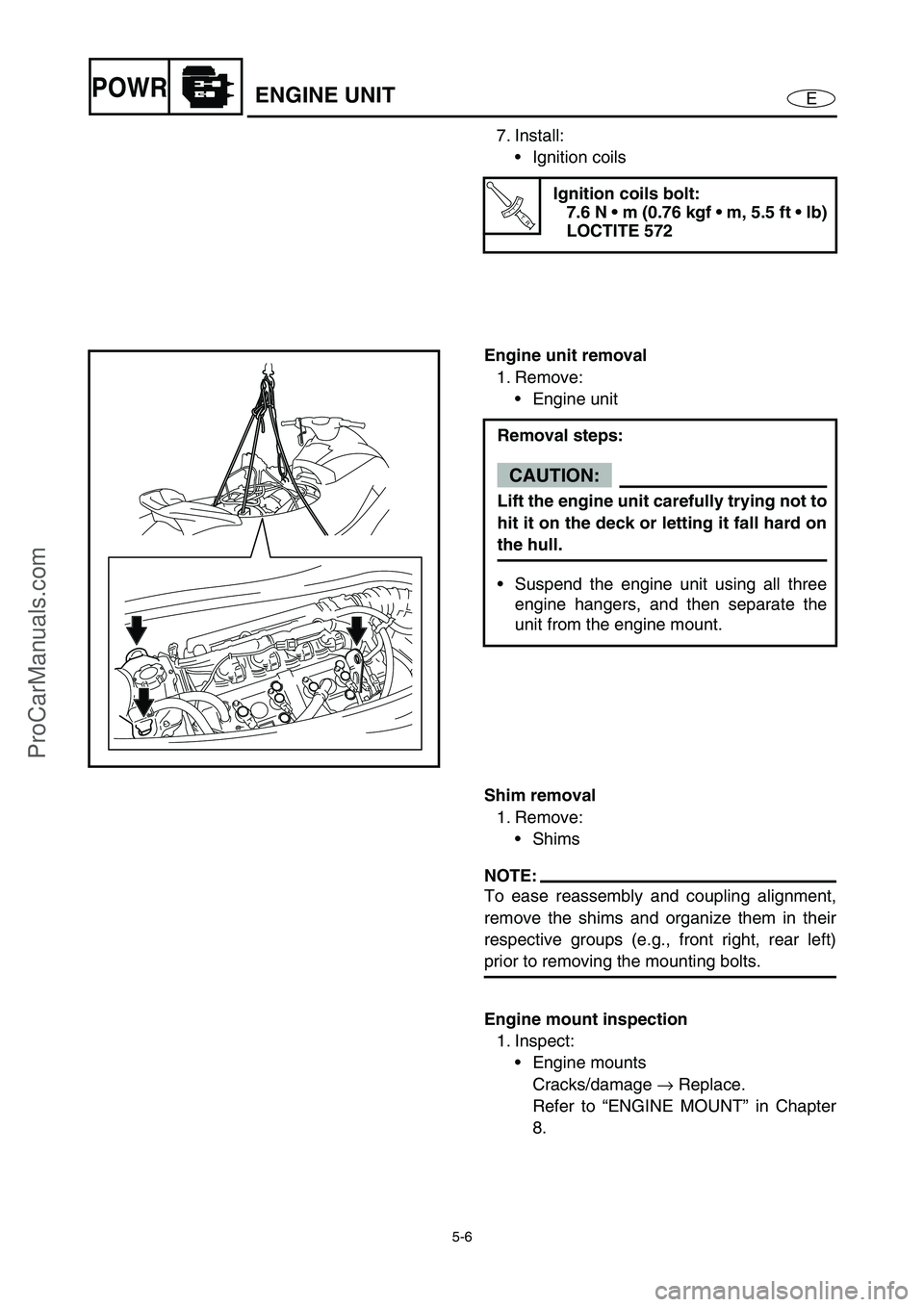

Engine unit removal

1. Remove:

Engine unit

Removal steps:

CAUTION:

Lift the engine unit carefully trying not to

hit it on the deck or letting it fall hard on

the hull.

Suspend the engine unit using all three

engine hangers, and then separate the

unit from the engine mount.

Shim removal

1. Remove:

Shims

NOTE:

To ease reassembly and coupling alignment,

remove the shims and organize them in their

respective groups (e.g., front right, rear left)

prior to removing the mounting bolts.

Engine mount inspection

1. Inspect:

Engine mounts

Cracks/damage →

Replace.

Refer to “ENGINE MOUNT” in Chapter

8.

ProCarManuals.com

Page 106 of 347

5-7

EPOWRENGINE UNIT

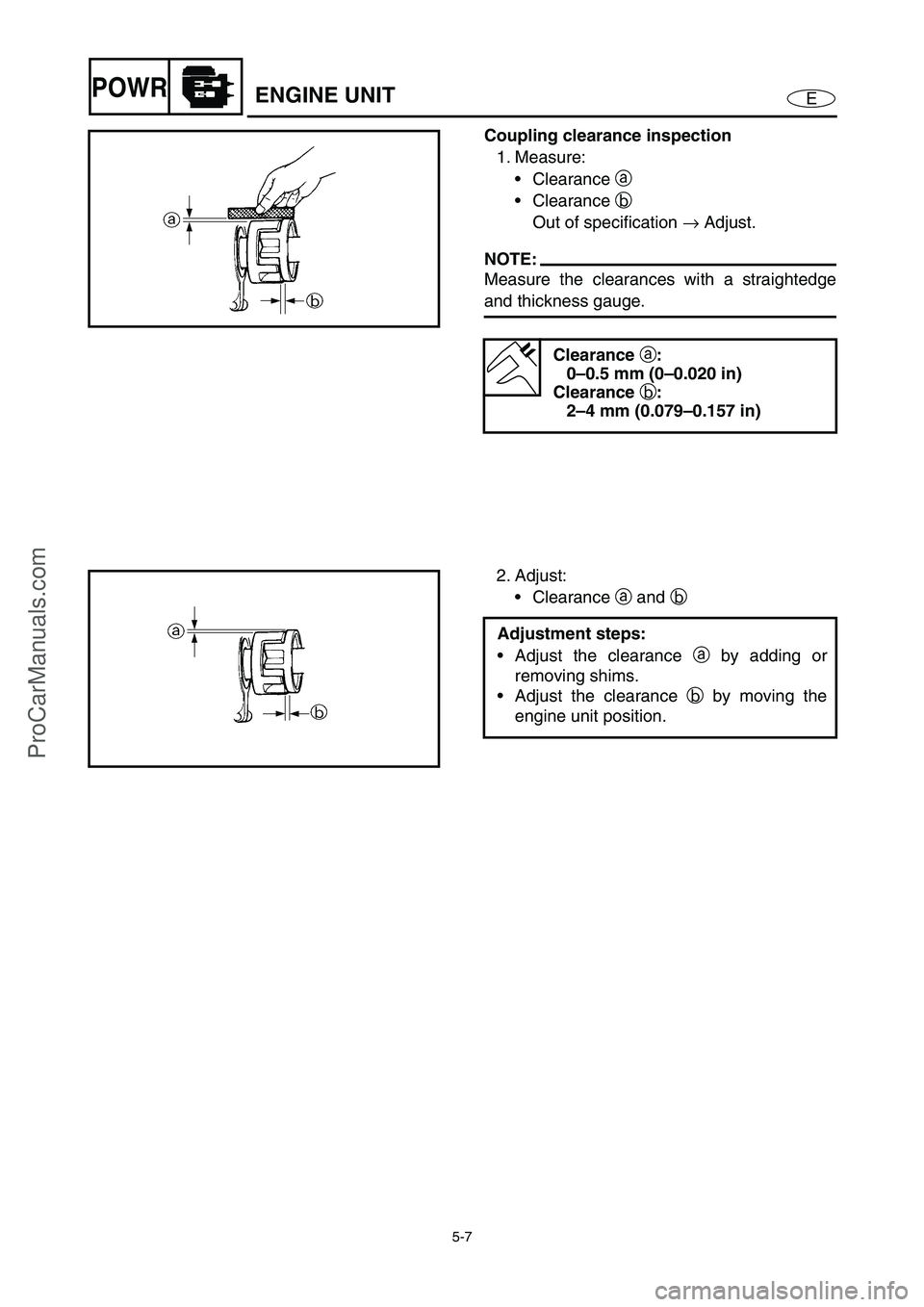

Coupling clearance inspection

1. Measure:

Clearance a

Clearance b

Out of specification →

Adjust.

NOTE:

Measure the clearances with a straightedge

and thickness gauge.

Clearance

a:

0–0.5 mm (0–0.020 in)

Clearance

b:

2–4 mm (0.079–0.157 in)

2. Adjust:

Clearance a

and b

Adjustment steps:

Adjust the clearance a

by adding or

removing shims.

Adjust the clearance b

by moving the

engine unit position.

ProCarManuals.com

Page 107 of 347

5-8

EPOWREXHAUST PIPES 1 AND 2

EXHAUST PIPES 1 AND 2

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

EXHAUST PIPES 1 AND 2

REMOVALFollow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

È

For cooling water pilot outlet on port side

É

From water jacket

1 Clamp/cooling water hose 1/1

2 Clamp/cooling water hose 1/1

3Bolt 2

4 Thermoswitch (exhaust) 1

5 Exhaust joint clamp 2 Slide the outer exhaust joint for exhaust

manifold side

6 Exhaust joint clamp 2

6

64 3

É

5

2

È 6 × 16 mm

7.6 N m (0.76 kgf m, 5.5 ft Ib)

2nd 3.4 N m (0.34 kgf m, 2.5 ft Ib) 1st 3.4 N m (0.34 kgf m, 2.5 ft Ib)LT

242

LT

242

LT

572

LT

LT

572

LT

LT

242

1

LT

242

LT

242

ProCarManuals.com

Page 108 of 347

5-9

EPOWREXHAUST PIPES 1 AND 2

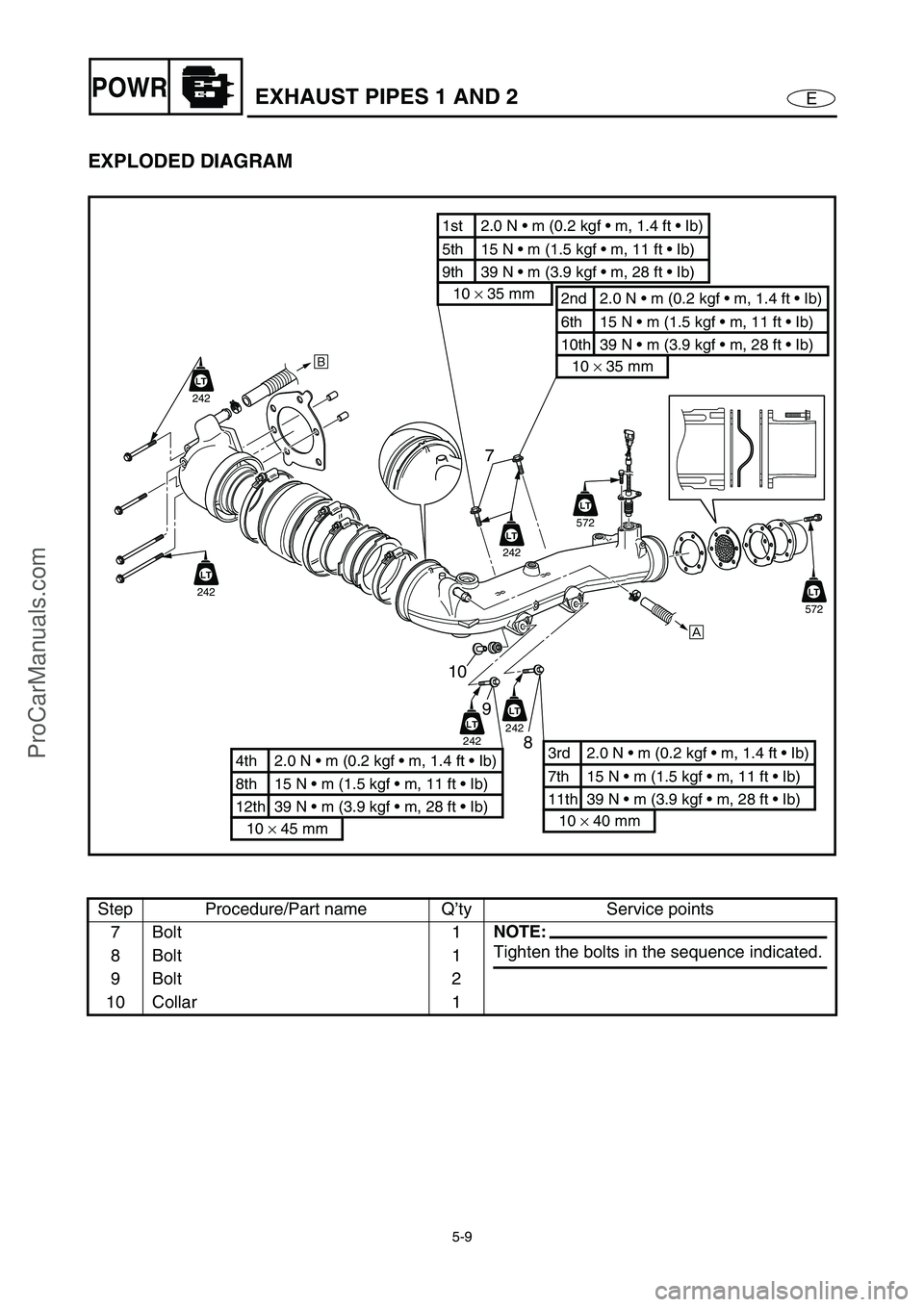

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

7Bolt 1

NOTE:

Tighten the bolts in the sequence indicated.

8Bolt 1

9Bolt 2

10 Collar 1

7

10

9

8

É

È

6th 15 N m (1.5 kgf m, 11 ft Ib) 2nd 2.0 N m (0.2 kgf m, 1.4 ft Ib)

10th 39 N m (3.9 kgf m, 28 ft Ib)

10 × 35 mm

5th 15 N m (1.5 kgf m, 11 ft Ib) 1st 2.0 N m (0.2 kgf m, 1.4 ft Ib)

9th 39 N m (3.9 kgf m, 28 ft Ib)

10 × 35 mm

8th 15 N m (1.5 kgf m, 11 ft Ib) 4th 2.0 N m (0.2 kgf m, 1.4 ft Ib)

12th 39 N m (3.9 kgf m, 28 ft Ib)

10 × 45 mm

7th 15 N m (1.5 kgf m, 11 ft Ib) 3rd 2.0 N m (0.2 kgf m, 1.4 ft Ib)

11th 39 N m (3.9 kgf m, 28 ft Ib)

10 × 40 mm

LT

242

LT

242

LT

572

LT

LT

572

LT

LT

242

LT

242

LT

242

ProCarManuals.com

Page 109 of 347

5-10

EPOWR

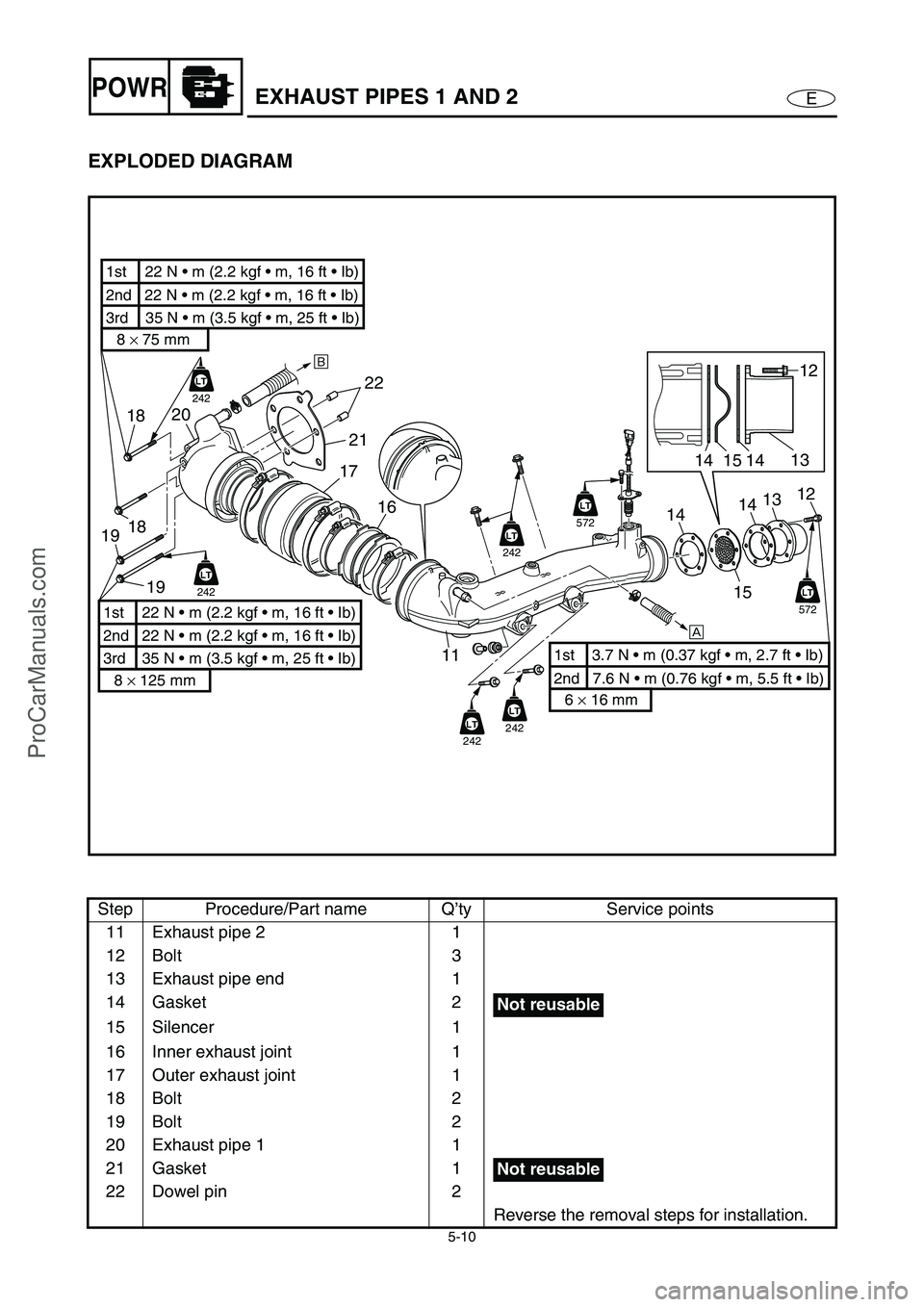

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

11 Exhaust pipe 2 1

12 Bolt 3

13 Exhaust pipe end 1

14 Gasket 2

15 Silencer 1

16 Inner exhaust joint 1

17 Outer exhaust joint 1

18 Bolt 2

19 Bolt 2

20 Exhaust pipe 1 1

21 Gasket 1

22 Dowel pin 2

Reverse the removal steps for installation.

1417 20

16

1112

13

14

É

18

19

È

22

21

2nd 22 N • m (2.2 kgf m, 16 ft Ib) 1st

22 N m (2.2 kgf m, 16 ft Ib)

3rd 35 N m (3.5 kgf m, 25 ft Ib)

8 × 75 mm

2nd 22 N m (2.2 kgf m, 16 ft Ib) 1st 22 N m (2.2 kgf m, 16 ft Ib)

3rd 35 N m (3.5 kgf m, 25 ft Ib)

8 × 125 mm

2nd 7.6 N m (0.76 kgf m, 5.5 ft Ib)

1st 3.7 N m (0.37 kgf m, 2.7 ft Ib)

6 × 16 mm

LT

242

19

18

LT

242

LT

572

LT

LT

572

LT

LT

242

LT

242

LT

242

12

13

15

14

14

15

Not reusable

Not reusable

EXHAUST PIPES 1 AND 2

ProCarManuals.com

Page 110 of 347

5-11

EPOWREXHAUST MANIFOLD

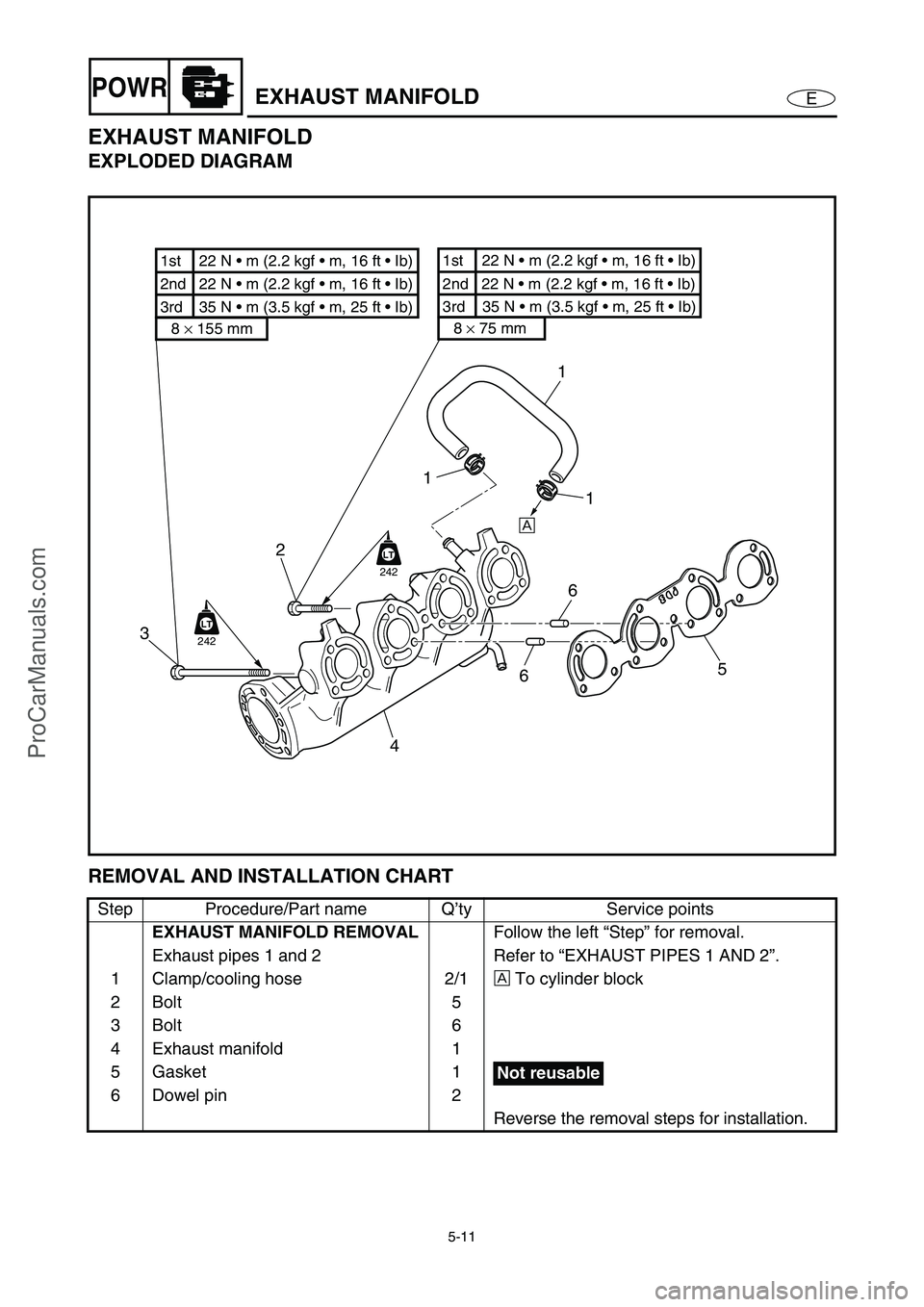

EXHAUST MANIFOLD

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

EXHAUST MANIFOLD REMOVAL

Follow the left “Step” for removal.

Exhaust pipes 1 and 2 Refer to “EXHAUST PIPES 1 AND 2”.

1 Clamp/cooling hose 2/1È

To cylinder block

2Bolt 5

3Bolt 6

4 Exhaust manifold 1

5Gasket 1

6 Dowel pin 2

Reverse the removal steps for installation.

6

5 3È

6

2

4

1

1

1

2nd 22 N m (2.2 kgf m, 16 ft Ib) 1st

22 N m (2.2 kgf m, 16 ft Ib)

3rd 35 N m (3.5 kgf m, 25 ft Ib)

8 × 75 mm

2nd 22 N m (2.2 kgf m, 16 ft Ib) 1st 22 N m (2.2 kgf m, 16 ft Ib)

3rd 35 N m (3.5 kgf m, 25 ft Ib)

8 × 155 mm

LT

242

LT

242

Not reusable

ProCarManuals.com