YAMAHA VX110 2005 Service Manual

Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 141 of 347

5-42

EPOWRCAMSHAFTS

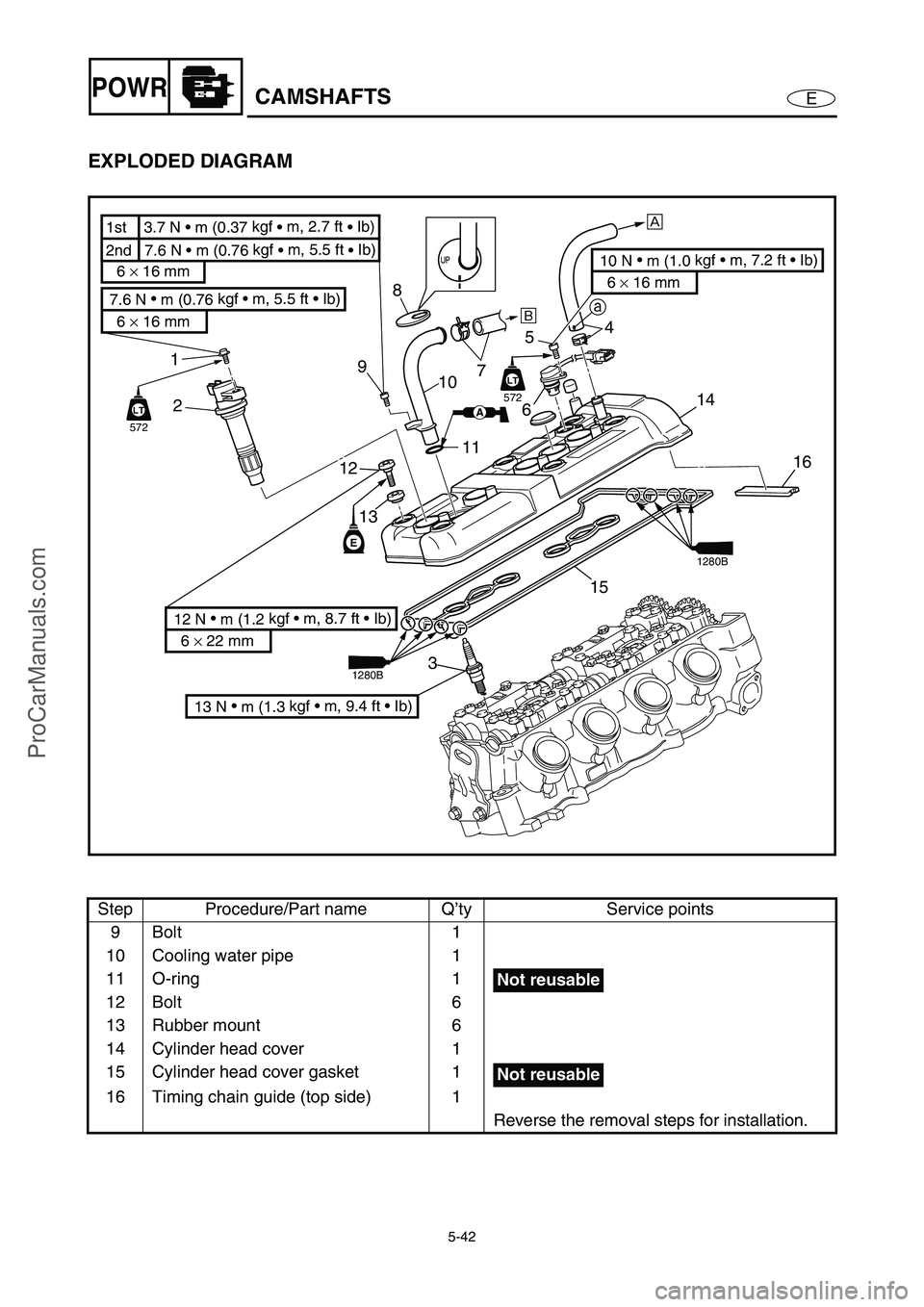

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

9Bolt 1

10 Cooling water pipe 1

11 O-ring 1

12 Bolt 6

13 Rubber mount 6

14 Cylinder head cover 1

15 Cylinder head cover gasket 1

16 Timing chain guide (top side) 1

Reverse the removal steps for installation.

E

4

65

7 8

10

11

12

13 9

LT

572

LT

14

16

15

3

13 N

m (1.3 kgf m, 9.4 ft Ib)

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 16 mm 6 × 16 mm

2nd 7.6 N m (0.76 kgf

m, 5.5 ft

Ib) 1st 3.7 N m (0.37 kgf

m, 2.7 ft

Ib)

12 N

m (1.2 kgf m, 8.7 ft Ib)

6 × 22 mm

aÈ

É

1

2

7.6 N

m (0.76 kgf m, 5.5 ft Ib)

6 × 16 mm

LT

572

LTAA

1280B

1280B

Not reusable

Not reusable

ProCarManuals.com

Page 142 of 347

5-43

EPOWRCAMSHAFTS

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CAMSHAFT REMOVAL

Follow the left “Step” for removal.

Cylinder head cover

Reduction drive gear case Refer to “REDUCTION DRIVE GEAR”.

NOTE:

When removing camshafts it is not neces-

sary to remove the reduction drive gear

case.

1 Thermoswitch (engine) coupler 1

2 Engine temperature sensor coupler 1

3 Cap bolt 1

4Gasket 1

5Bolt 2

M

E

EE

E

E

E

M

12

13

12

13

12

13

141819

10

20

10

10

15

11

16

9

17

822

21

3 4

5 6 7

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 25 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 8 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

2324

25

26

27

12

6 × 16 mm

AA

Not reusable

ProCarManuals.com

Page 143 of 347

5-44

EPOWRCAMSHAFTS

EXPLODED DIAGRAM

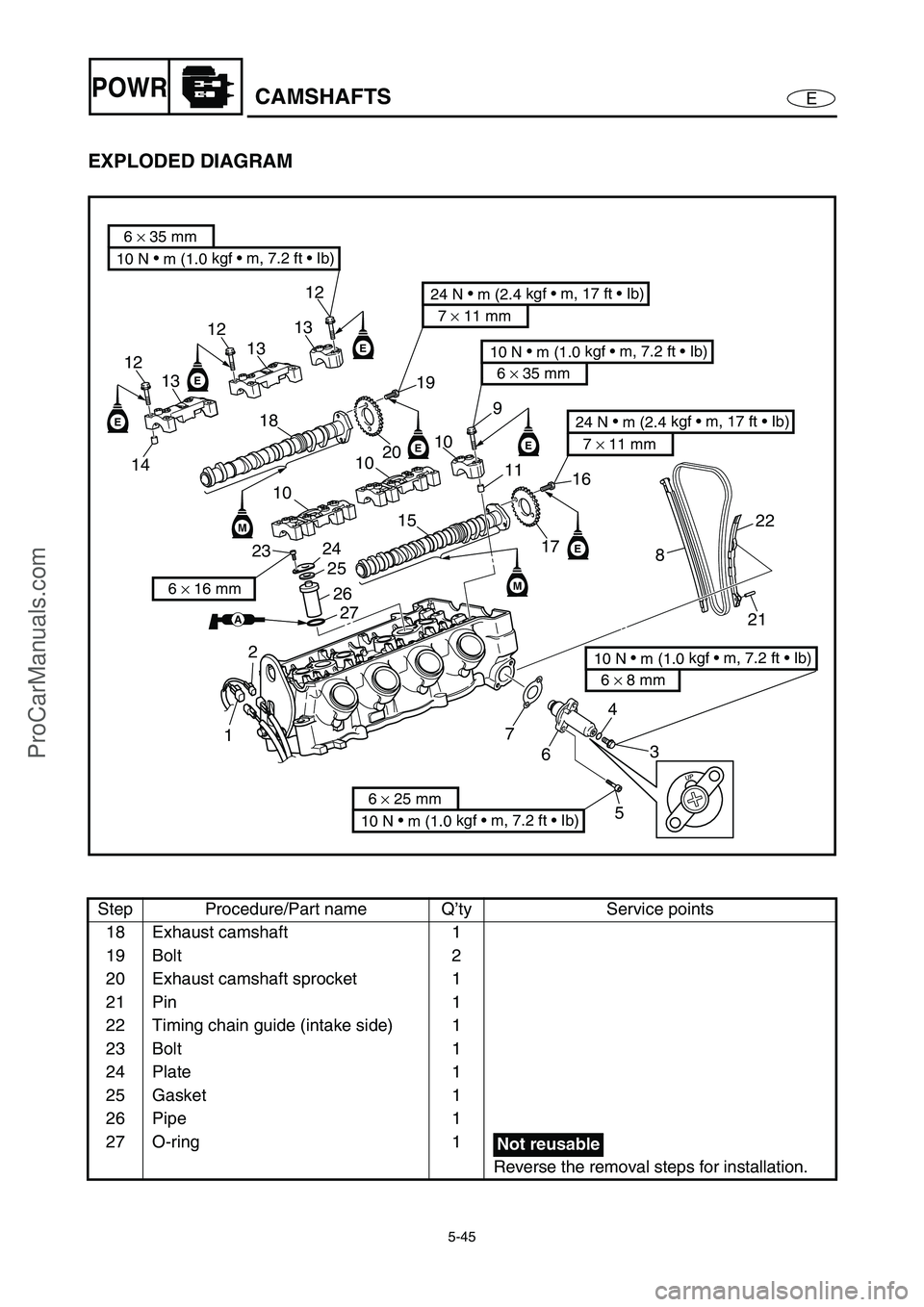

Step Procedure/Part name Q’ty Service points

6 Timing chain tensioner 1

7 Timing chain tensioner gasket 1

8 Timing chain guide (exhaust side) 1

9Bolt 18

10 Intake camshaft cap 3

11 Dowel pin 6

12 Bolt 10

13 Exhaust camshaft cap 3

14 Dowel pin 6

15 Intake camshaft 1

16 Bolt 2

17 Intake camshaft sprocket 1

M

E

EE

E

E

E

M

12

13

12

13

12

13

141819

10

20

10

10

15

11

16

9

17

822

21

3 4

5 6 7

10 N •

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 25 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 8 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

2324

25

26

27

12

6 × 16 mm

AA

Not reusable

ProCarManuals.com

Page 144 of 347

5-45

EPOWRCAMSHAFTS

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

18 Exhaust camshaft 1

19 Bolt 2

20 Exhaust camshaft sprocket 1

21 Pin 1

22 Timing chain guide (intake side) 1

23 Bolt 1

24 Plate 1

25 Gasket 1

26 Pipe 1

27 O-ring 1

Reverse the removal steps for installation.

M

E

EE

E

E

E

M

12

13

12

13

12

13

141819

10

20

10

10

15

11

16

9

17

822

21

3 4

5 6 7

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 35 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 25 mm

10 N

m (1.0 kgf m, 7.2 ft Ib)

6 × 8 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

24 N

m (2.4 kgf m, 17 ft Ib)

7 × 11 mm

2324

25

26

27

12

6 × 16 mm

AA

Not reusable

ProCarManuals.com

Page 145 of 347

5-46

EPOWRCAMSHAFTS

SERVICE POINTS

Camshaft removal

1. Install:

Dial gauge needle

Dial gauge stand 1

(into spark plug hole #1)

Dial gauge 2

2. Turn the drive coupling counterclockwise,

and then check if cylinder #1 is at TDC of

the compression stroke with a dial gauge.

NOTE:

TDC on the compression stroke can be found

when the camshaft lobes are turned away from

each other.

Dial gauge stand:

90890-06583

Dial gauge needle:

90890-06584

Dial gauge stand set:

YB-06585/90890-06585

Dial indicator gauge:

YU-03097

Dial gauge set:

90890-01252

2

1

INEX

3. Make the alignment marks a on the timing

chain and camshaft sprockets.

a

4. Remove:

Timing chain tensioner 1

Gasket

1

ProCarManuals.com

Page 146 of 347

5-47

EPOWRCAMSHAFTS

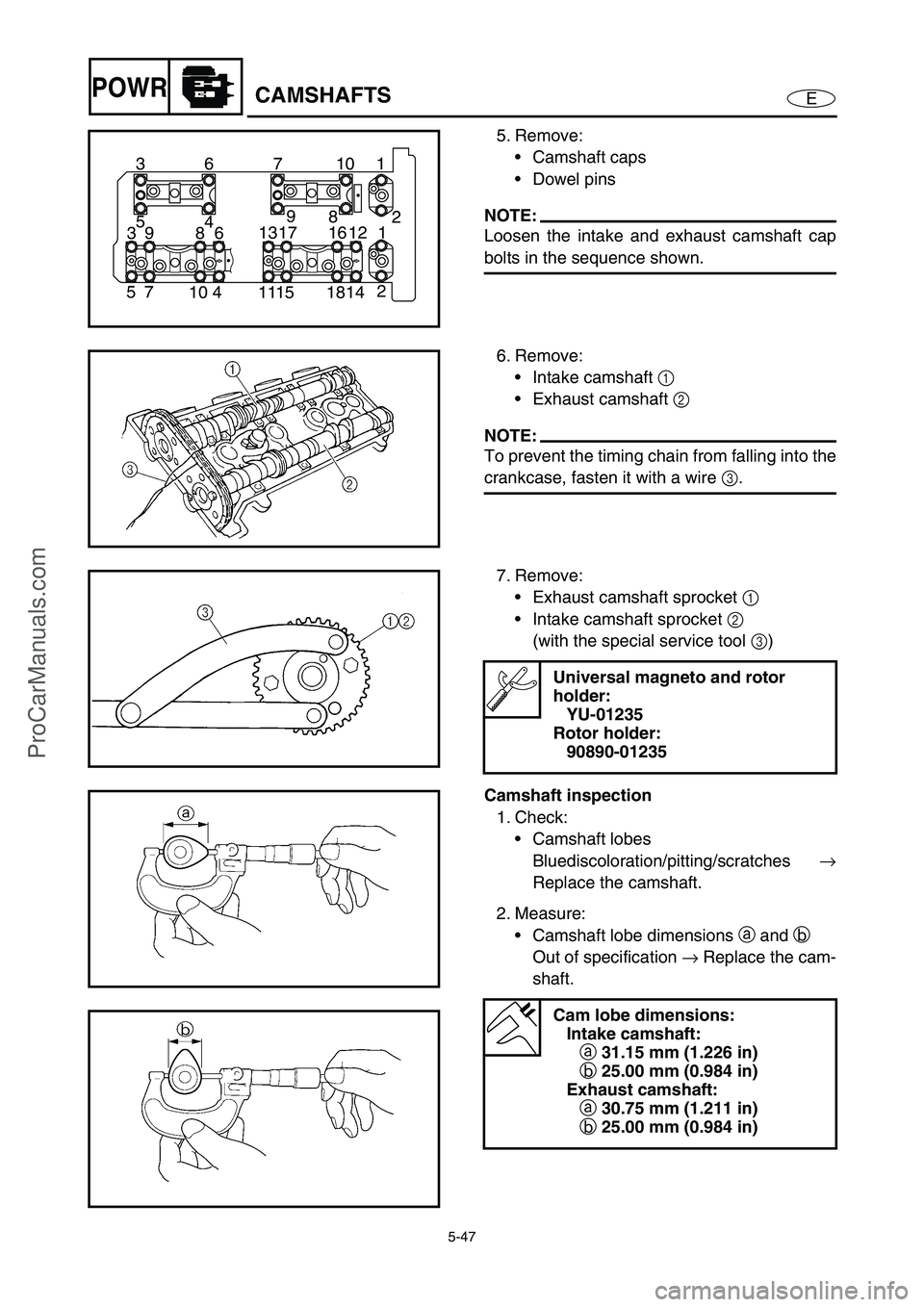

5. Remove:

Camshaft caps

Dowel pins

NOTE:

Loosen the intake and exhaust camshaft cap

bolts in the sequence shown.

1 10 7 6 3

2

14 18 15 11 4 10 7 52 8 9

4 5

1 12 16 17 13

6 8 9 3

6. Remove:

Intake camshaft 1

Exhaust camshaft 2

NOTE:

To prevent the timing chain from falling into the

crankcase, fasten it with a wire 3

.

7. Remove:

Exhaust camshaft sprocket 1

Intake camshaft sprocket 2

(with the special service tool 3

)

Universal magneto and rotor

holder:

YU-01235

Rotor holder:

90890-01235

Camshaft inspection

1. Check:

Camshaft lobes

Bluediscoloration/pitting/scratches →

Replace the camshaft.

2. Measure:

Camshaft lobe dimensions a

and b

Out of specification →

Replace the cam-

shaft.

Cam lobe dimensions:

Intake camshaft:

a 31.15 mm (1.226 in)

b 25.00 mm (0.984 in)

Exhaust camshaft:

a 30.75 mm (1.211 in)

b 25.00 mm (0.984 in)

ProCarManuals.com

Page 147 of 347

5-48

EPOWRCAMSHAFTS

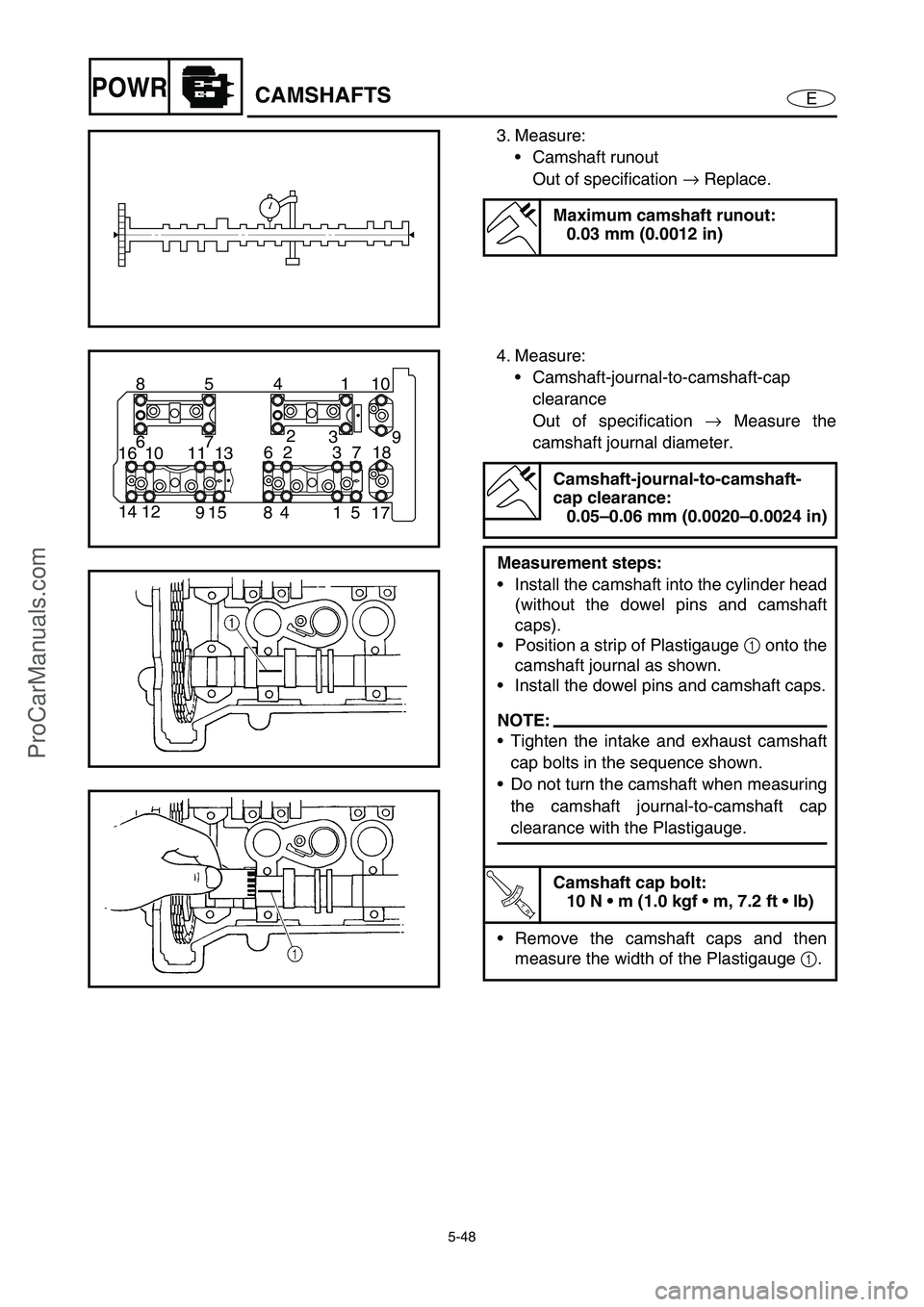

3. Measure:

Camshaft runout

Out of specification →

Replace.

Maximum camshaft runout:

0.03 mm (0.0012 in)

4. Measure:

Camshaft-journal-to-camshaft-cap

clearance

Out of specification →

Measure the

camshaft journal diameter.

Camshaft-journal-to-camshaft-

cap clearance:

0.05–0.06 mm (0.0020–0.0024 in)

Measurement steps:

Install the camshaft into the cylinder head

(without the dowel pins and camshaft

caps).

Position a strip of Plastigauge 1

onto the

camshaft journal as shown.

Install the dowel pins and camshaft caps.

NOTE:

Tighten the intake and exhaust camshaft

cap bolts in the sequence shown.

Do not turn the camshaft when measuring

the camshaft journal-to-camshaft cap

clearance with the Plastigauge.

T R..

Camshaft cap bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

Remove the camshaft caps and then

measure the width of the Plastigauge 1

.

10 1 4 5 8

17 5 1 4 8 15 9 12 149 3 2

7 6

18 7 3 2 6

13 11 10 16

ProCarManuals.com

Page 148 of 347

5-49

EPOWRCAMSHAFTS

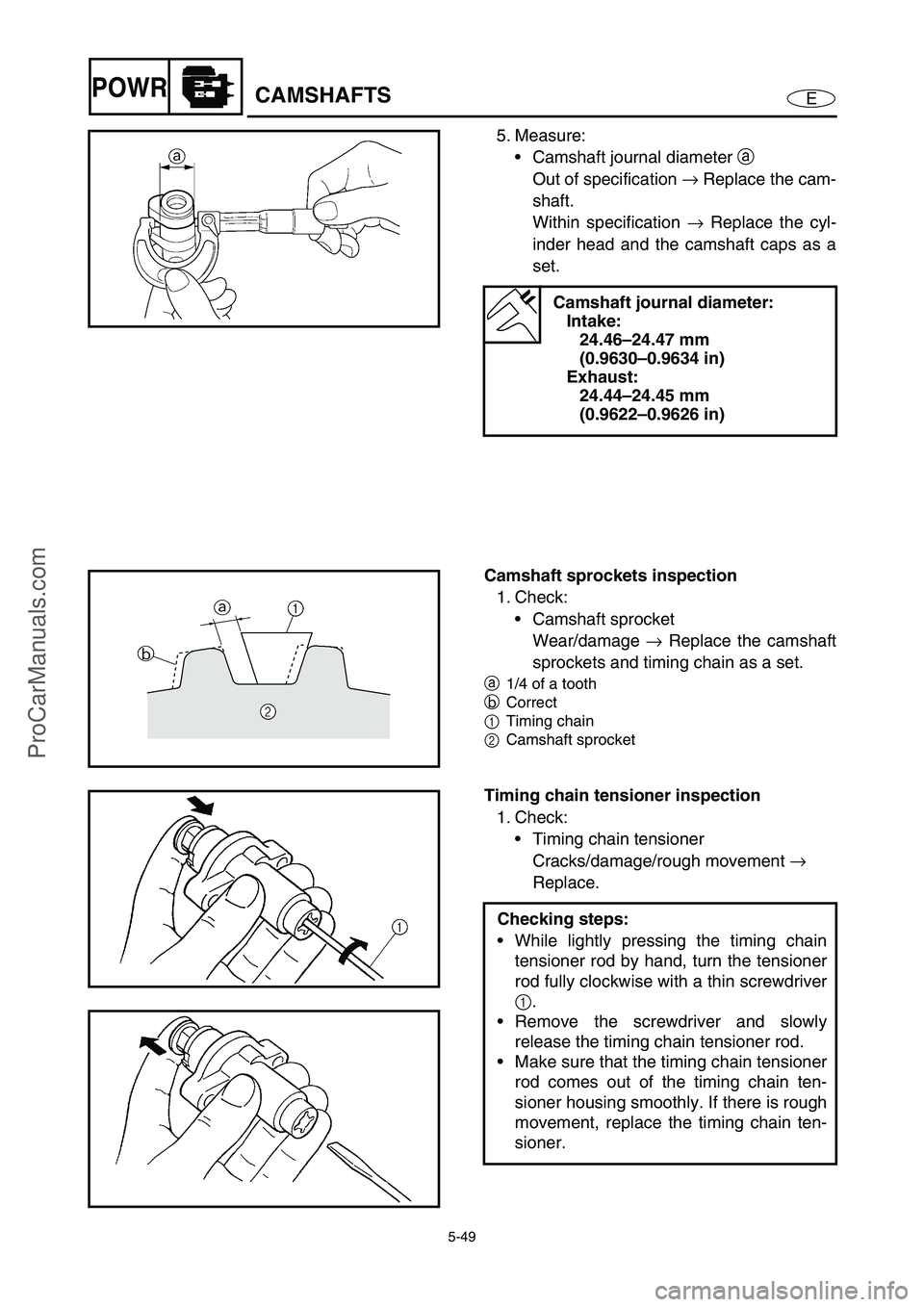

5. Measure:

Camshaft journal diameter a

Out of specification →

Replace the cam-

shaft.

Within specification →

Replace the cyl-

inder head and the camshaft caps as a

set.

Camshaft journal diameter:

Intake:

24.46–24.47 mm

(0.9630–0.9634 in)

Exhaust:

24.44–24.45 mm

(0.9622–0.9626 in)

Camshaft sprockets inspection

1. Check:

Camshaft sprocket

Wear/damage →

Replace the camshaft

sprockets and timing chain as a set.

a

1/4 of a tooth

b

Correct

1Timing chain

2Camshaft sprocket

Timing chain tensioner inspection

1. Check:

Timing chain tensioner

Cracks/damage/rough movement →

Replace.

Checking steps:

While lightly pressing the timing chain

tensioner rod by hand, turn the tensioner

rod fully clockwise with a thin screwdriver

1

.

Remove the screwdriver and slowly

release the timing chain tensioner rod.

Make sure that the timing chain tensioner

rod comes out of the timing chain ten-

sioner housing smoothly. If there is rough

movement, replace the timing chain ten-

sioner.

ProCarManuals.com

Page 149 of 347

5-50

EPOWRCAMSHAFTS

Camshaft installation

1. Install:

Exhaust camshaft sprocket 1

Intake camshaft sprocket 2

(with the special service tool 3

)

NOTE:

Install the camshaft sprocket with the punch

mark a

facing outside.

Universal magneto and rotor

holder:

YU-01235

Rotor holder:

90890-01235

T R..

Camshaft sprocket bolt:

24 N m (2.4 kgf m, 17 ft lb)

2. Install:

Exhaust camshaft

Intake camshaft

Exhaust camshaft caps

Intake camshaft caps

Installation steps:

Turn the drive coupling counterclockwise,

and then check if cylinder #1 is at TDC of

the compression stroke with a dial gauge.

Install the timing chain onto both cam-

shaft sprockets, and then install the cam-

shaft.

CAUTION:

Do not turn the crankshaft when install-

ing the camshaft to avoid damage or

improper valve timing.

NOTE:

Make sure that the punch marks a

on the

camshafts face up.

Be sure to align the alignment marks b

made during removal to install the timing

chain and camshaft sprockets.

b

ProCarManuals.com

Page 150 of 347

5-51

EPOWRCAMSHAFTS

Install the exhaust and intake camshaft

caps.

NOTE:

Gradually tighten the intake and exhaust

camshaft cap bolts in 2–3 steps in the

sequence shown.

T R..

Camshaft cap bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

NOTE:

Make sure that the punch marks c

on the

camshafts are aligned with the arrow marks

d

on the camshaft caps.

Out of alignment →

Reinstall.

Remove the wire from the timing chain.

10 1 4 5 8

17 5 1 4 8 15 9 12 149 3 2

7 6

18 7 3 2 6

13 11 10 16

3. Install:

Timing chain tensioner

Installation steps:

While lightly pressing the timing chain

tensioner rod by hand, turn the tensioner

rod fully clockwise with a thin screwdriver

1

.

NOTE:

Make sure that the tensioner rod has been

fully set clockwise.

With the timing chain tensioner rod

turned all the way into the timing chain

tensioner housing (with the thin screw-

driver still installed), install the gasket and

the timing chain tensioner 2

onto the cyl-

inder block.

WARNING

Always use a new gasket.

Tighten the timing chain tensioner bolts

3

to the specified torque.

NOTE:

The “UP” mark on the timing chain ten-

sioner should face up.

33

2

ProCarManuals.com