YAMAHA VX110 2005 Service Manual

VX110 2005

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/57494/w960_57494-0.png

YAMAHA VX110 2005 Service Manual

Trending: check engine, USB port, spark plugs replace, open gas tank, remove seats, fuse chart, wheel torque

Page 171 of 347

5-72

EPOWRCRANKCASE

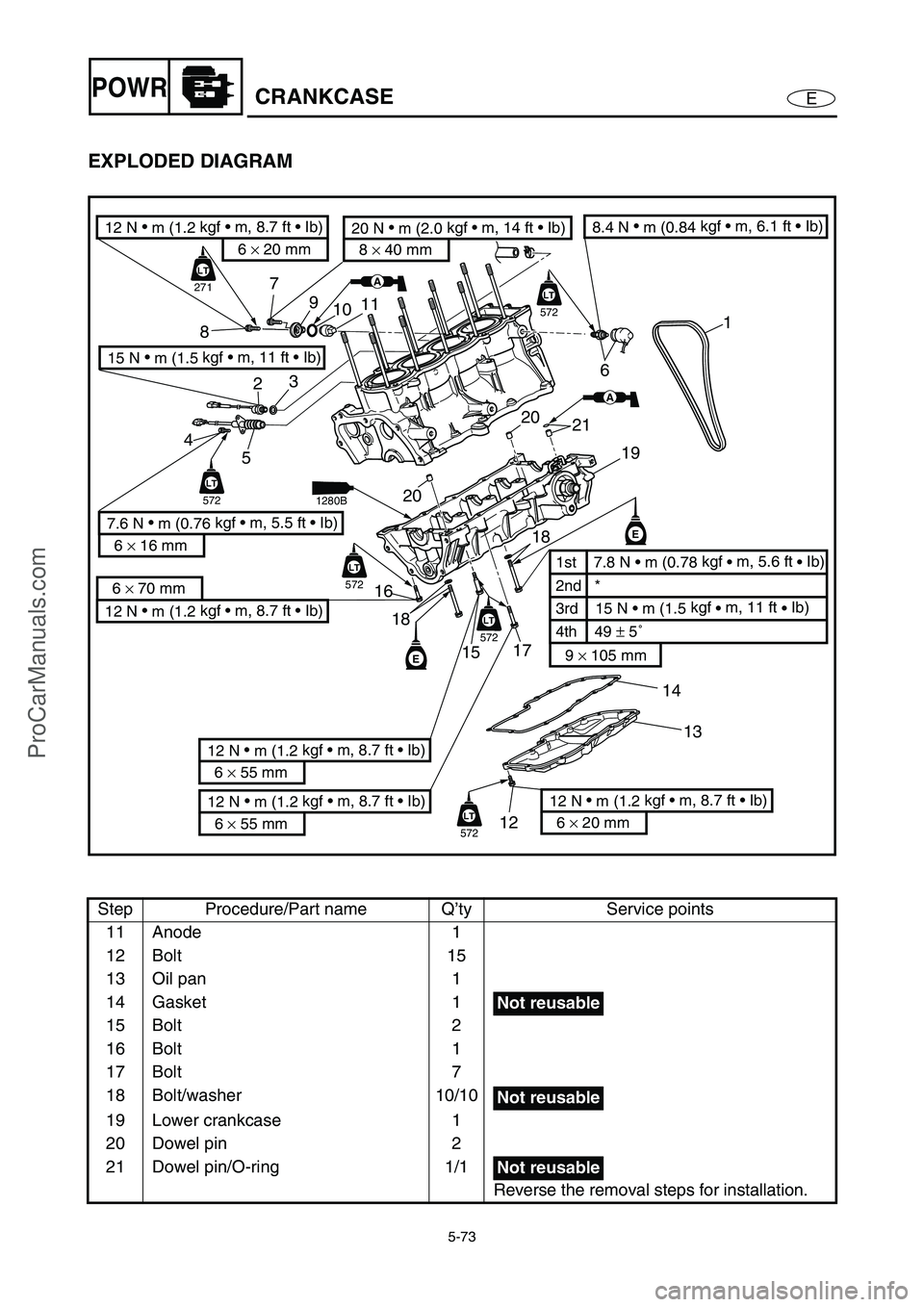

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

Reduction drive gear case Refer to “REDUCTION DRIVE GEAR”.

Cylinder head Refer to “CAMSHAFTS”.

1 Timing chain 1

2 Engine temperature sensor 1

3 Washer 1

4Bolt 2

5 Thermoswitch (engine) 1

6 Oil pressure switch 1

7Bolt 1

8Bolt 1

9 Anode cover 1

10 Grommet 1

6

21 20

20 11

10 9

87

23

4

5

16

151718

13 14

1219

1

LT

271

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

E

E

AA

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 70 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

20 N •

m (2.0 kgf • m, 14 ft • Ib)

8 × 40 mm

2nd *

3rd 15 N • m (1.5 kgf

• m, 11 ft

• Ib) 1st 7.8 N • m (0.78 kgf

• m, 5.6 ft

• Ib)

9 × 105 mm

4th 49 ± 5˚

8.4 N •

m (0.84 kgf • m, 6.1 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

7.6 N •

m (0.76 kgf • m, 5.5 ft • Ib)

6 × 16 mm

15 N •

m (1.5 kgf • m, 11 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

18

AA

1280B

ProCarManuals.com

Page 172 of 347

5-73

EPOWRCRANKCASE

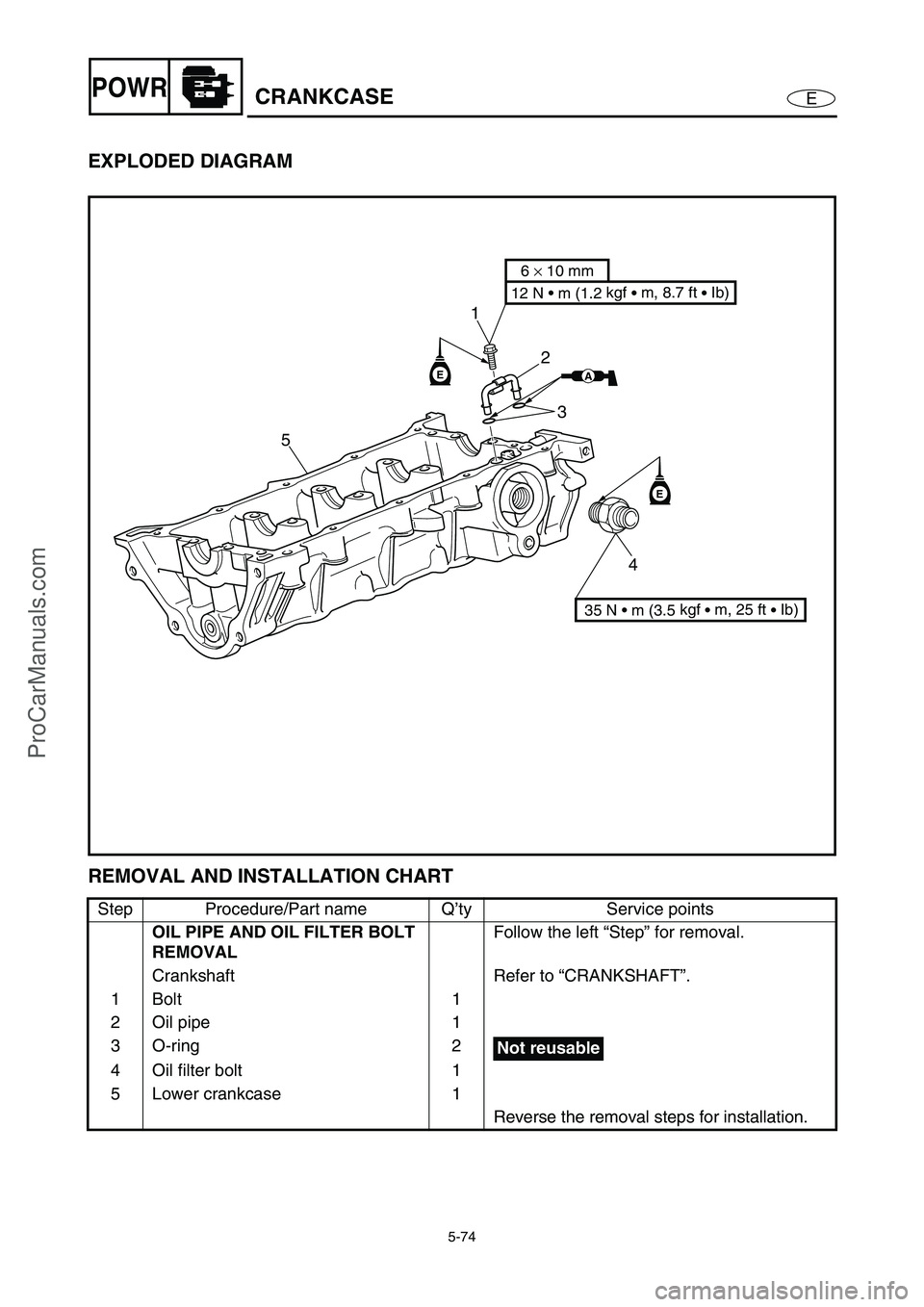

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

11 Anode 1

12 Bolt 15

13 Oil pan 1

14 Gasket 1

15 Bolt 2

16 Bolt 1

17 Bolt 7

18 Bolt/washer 10/10

19 Lower crankcase 1

20 Dowel pin 2

21 Dowel pin/O-ring 1/1

Reverse the removal steps for installation.

6

21 20

20 11

10 9

87

23

4

5

16

151718

13 14

1219

1

LT

271

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

E

E

AA

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 70 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

20 N •

m (2.0 kgf • m, 14 ft • Ib)

8 × 40 mm

2nd *

3rd 15 N • m (1.5 kgf

• m, 11 ft

• Ib) 1st 7.8 N • m (0.78 kgf

• m, 5.6 ft

• Ib)

9 × 105 mm

4th 49 ± 5˚

8.4 N •

m (0.84 kgf • m, 6.1 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

7.6 N •

m (0.76 kgf • m, 5.5 ft • Ib)

6 × 16 mm

15 N •

m (1.5 kgf • m, 11 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

18

AA

1280B

Not reusable

Not reusable

Not reusable

ProCarManuals.com

Page 173 of 347

5-74

EPOWRCRANKCASE

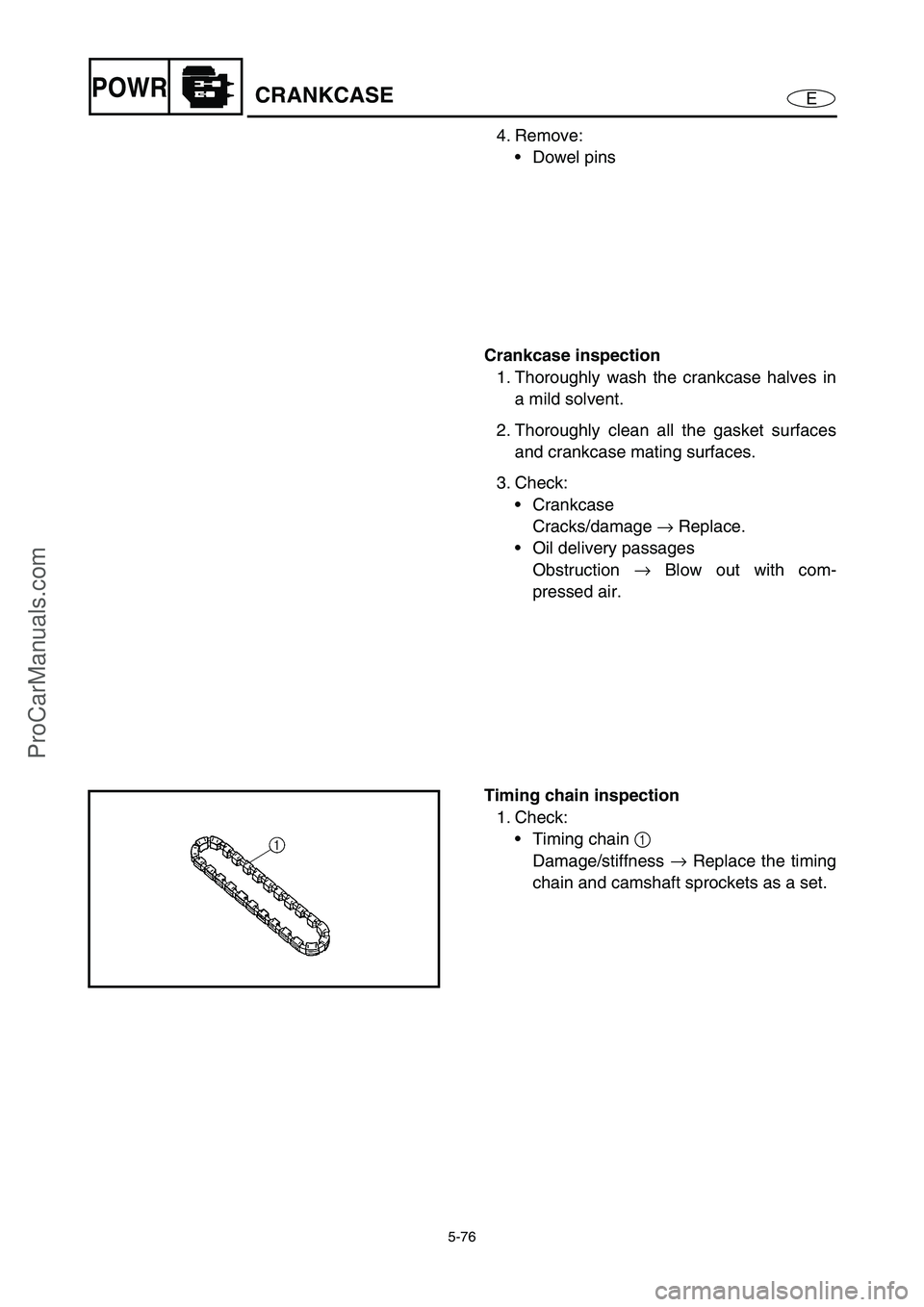

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

OIL PIPE AND OIL FILTER BOLT

REMOVALFollow the left “Step” for removal.

Crankshaft Refer to “CRANKSHAFT”.

1Bolt 1

2 Oil pipe 1

3 O-ring 2

4 Oil filter bolt 1

5 Lower crankcase 1

Reverse the removal steps for installation.

E

E

51

2

3

4

AA

6 × 10 mm

12 N • m (1.2 kgf

• m, 8.7 ft

• Ib)

35 N • m (3.5 kgf

• m, 25 ft

• Ib)

Not reusable

ProCarManuals.com

Page 174 of 347

5-75

EPOWRCRANKCASE

SERVICE POINTS

Crankcase disassembly

1. Remove:

Oil pan bolts

NOTE:

Loosen each bolt 1/4 of a turn at a time, in

stages and in a crisscross pattern. After all of

the bolts are fully loosened, remove them.

Loosen the bolts in decreasing numerical

order (refer to the numbers in the illustra-

tion).

The numbers embossed on the oil pan indi-

cate the oil pan tightening sequence.

106

24812

15

11

7

3 1 5 9

13 14

2. Remove:

Crankcase bolts

NOTE:

Loosen each bolt 1/4 of a turn at a time, in

stages and in a crisscross pattern. After all of

the bolts are fully loosened, remove them.

Loosen the bolts in decreasing numerical

order (refer to the numbers in the illustra-

tion).

The numbers embossed on the crankcase

indicate the crankcase tightening sequence.

3. Remove:

Lower crankcase

CAUTION:

Tap on one side of the crankcase with a

soft-face hammer. Tap only on reinforced

portions of the crankcase, not on the

crankcase mating surfaces. Work slowly

and carefully and make sure the crankcase

halves separate evenly.

M9

× 105 mm bolts:

1–

0

M6

× 55 mm bolts:

A–

H,

J

M6

× 70 mm bolts:

I

15397

ICAEG

86240

HFBDJ

ProCarManuals.com

Page 175 of 347

5-76

EPOWRCRANKCASE

4. Remove:

Dowel pins

Crankcase inspection

1. Thoroughly wash the crankcase halves in

a mild solvent.

2. Thoroughly clean all the gasket surfaces

and crankcase mating surfaces.

3. Check:

Crankcase

Cracks/damage →

Replace.

Oil delivery passages

Obstruction →

Blow out with com-

pressed air.

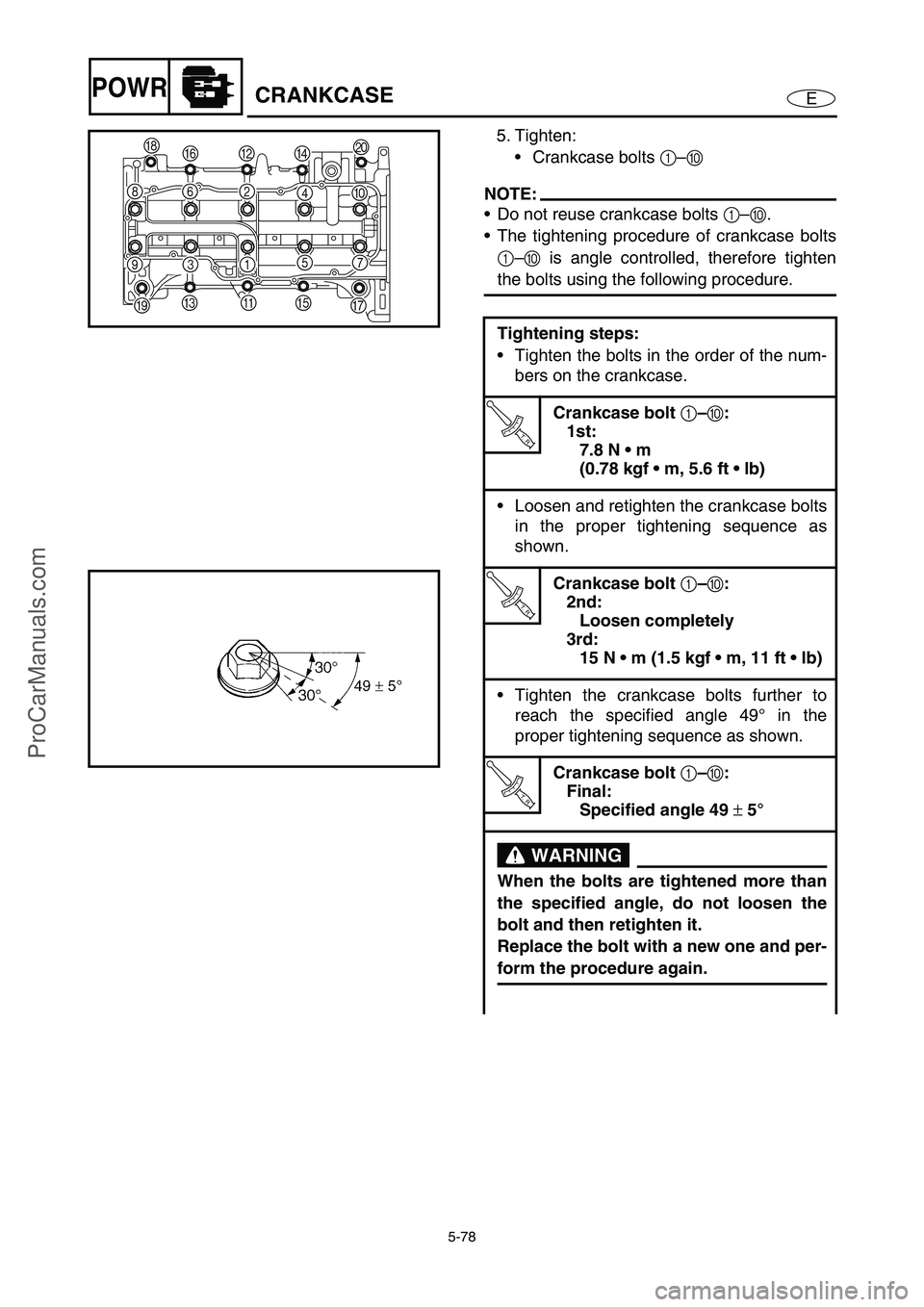

Timing chain inspection

1. Check:

Timing chain 1

Damage/stiffness →

Replace the timing

chain and camshaft sprockets as a set.

ProCarManuals.com

Page 176 of 347

5-77

EPOWRCRANKCASE

Crankcase assembly

1. Lubricate:

Crankshaft journal bearings

(with the recommended lubricant)

2. Apply:

ThreeBond 1280B

(onto the crankcase mating surfaces)

NOTE:

Do not allow any sealant to come into contact

with the oil gallery or crankshaft journal bear-

ings.

Recommended lubricant:

Engine oil

3. Install:

Dowel pins 1

O-ring 2

11

2

1

1280B

4. Install:

Crankcase bolts

NOTE:

Lubricate the bolt 1

–0 threads and wash-

ers with engine oil.

Finger tighten the crankcase bolts.

M9

× 105 mm bolts:

1–

0

M6

× 55 mm bolts:

A–

H,

J

M6

× 70 mm bolts:

I

15397

ICAEG

86240

HFBDJ

ProCarManuals.com

Page 177 of 347

5-78

EPOWRCRANKCASE

5. Tighten:

Crankcase bolts 1

–0

NOTE:

Do not reuse crankcase bolts 1

–0

.

The tightening procedure of crankcase bolts

1

–0

is angle controlled, therefore tighten

the bolts using the following procedure.

Tightening steps:

Tighten the bolts in the order of the num-

bers on the crankcase.

T R..

Crankcase bolt

1–

0:

1st:

7.8 N m

(0.78 kgf m, 5.6 ft lb)

Loosen and retighten the crankcase bolts

in the proper tightening sequence as

shown.

T R..

Crankcase bolt

1–

0:

2nd:

Loosen completely

3rd:

15 N m (1.5 kgf m, 11 ft lb)

Tighten the crankcase bolts further to

reach the specified angle 49° in the

proper tightening sequence as shown.

T R..

Crankcase bolt

1–

0:

Final:

Specified angle 49

± 5°

WARNING

When the bolts are tightened more than

the specified angle, do not loosen the

bolt and then retighten it.

Replace the bolt with a new one and per-

form the procedure again.

15397

ICAEG

86240

HFBDJ

ProCarManuals.com

Page 178 of 347

5-79

EPOWRCRANKCASE

CAUTION:

Do not use a torque wrench to tighten

the bolt to the specified angle.

Tighten the bolt until it is at the speci-

fied angle.

NOTE:

When using a hexagonal bolt, note that the

angle from one corner to another is 60°.

6. Tighten:

Crankcase bolts A

–J

NOTE:

Tighten the bolts in the order of the numbers

on the crankcase.

7. Tighten:

Oil pan bolts

NOTE:

Tighten the bolts in the order of the numbers

on the oil pan.

T R..

Crankcase bolt

A–

J:

12 N m (1.2 kgf m, 8.7 ft lb)

LOCTITE 572

T R..

Oil pan bolt:

12 N m (1.2 kgf m, 8.7 ft lb)

LOCTITE 572

15397

ICAEG

86240

HFBDJ

106

24812

15

11

7

3 1 5 9

13 14

ProCarManuals.com

Page 179 of 347

5-80

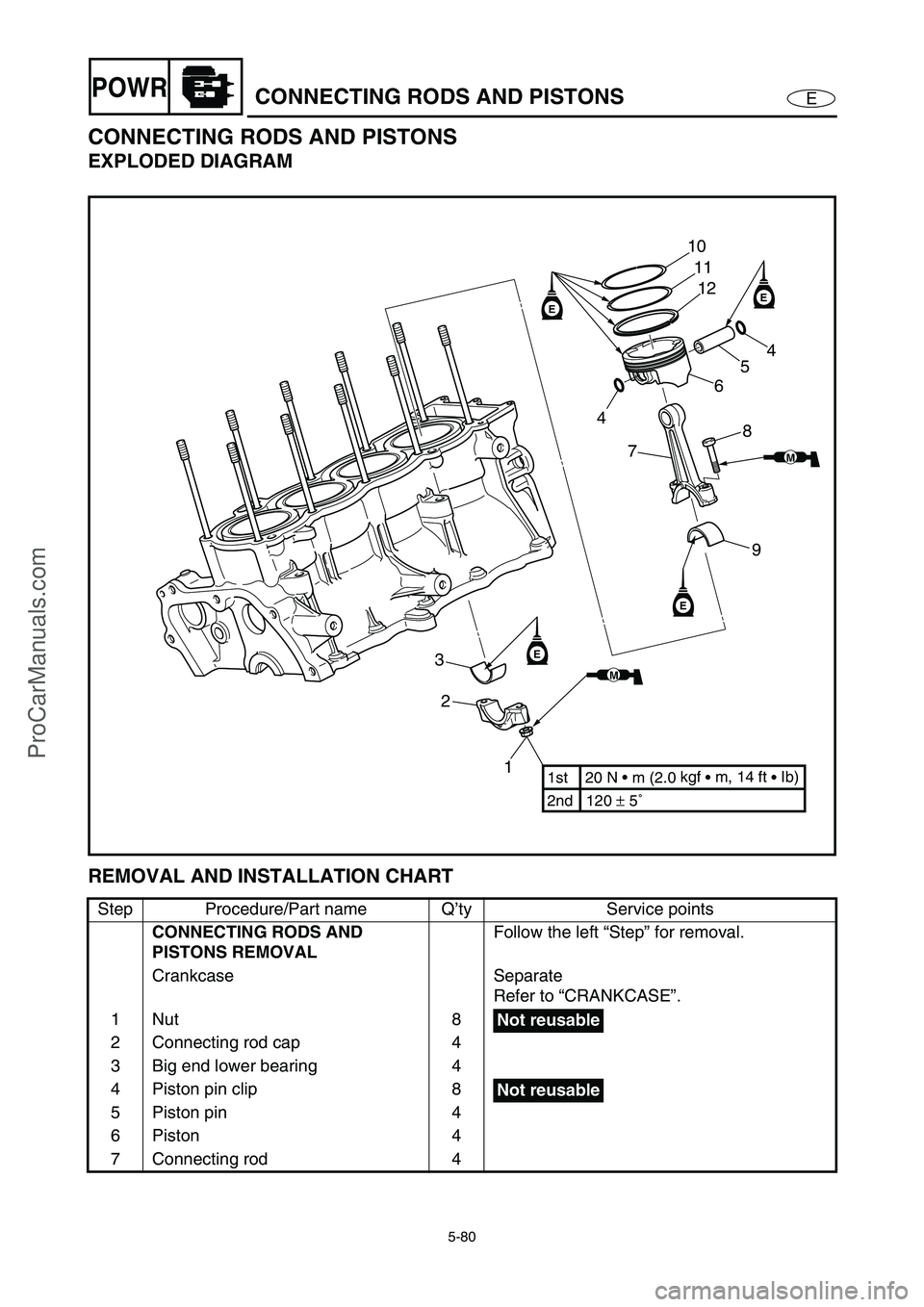

EPOWRCONNECTING RODS AND PISTONS

CONNECTING RODS AND PISTONS

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CONNECTING RODS AND

PISTONS REMOVALFollow the left “Step” for removal.

Crankcase Separate

Refer to “CRANKCASE”.

1Nut 8

2 Connecting rod cap 4

3 Big end lower bearing 4

4 Piston pin clip 8

5 Piston pin 4

6Piston 4

7 Connecting rod 4

EE

E

E

1 2 310

11

12

4

5

6

8

7

9

2nd 120 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

MM

MM

4

Not reusable

Not reusable

ProCarManuals.com

Page 180 of 347

5-81

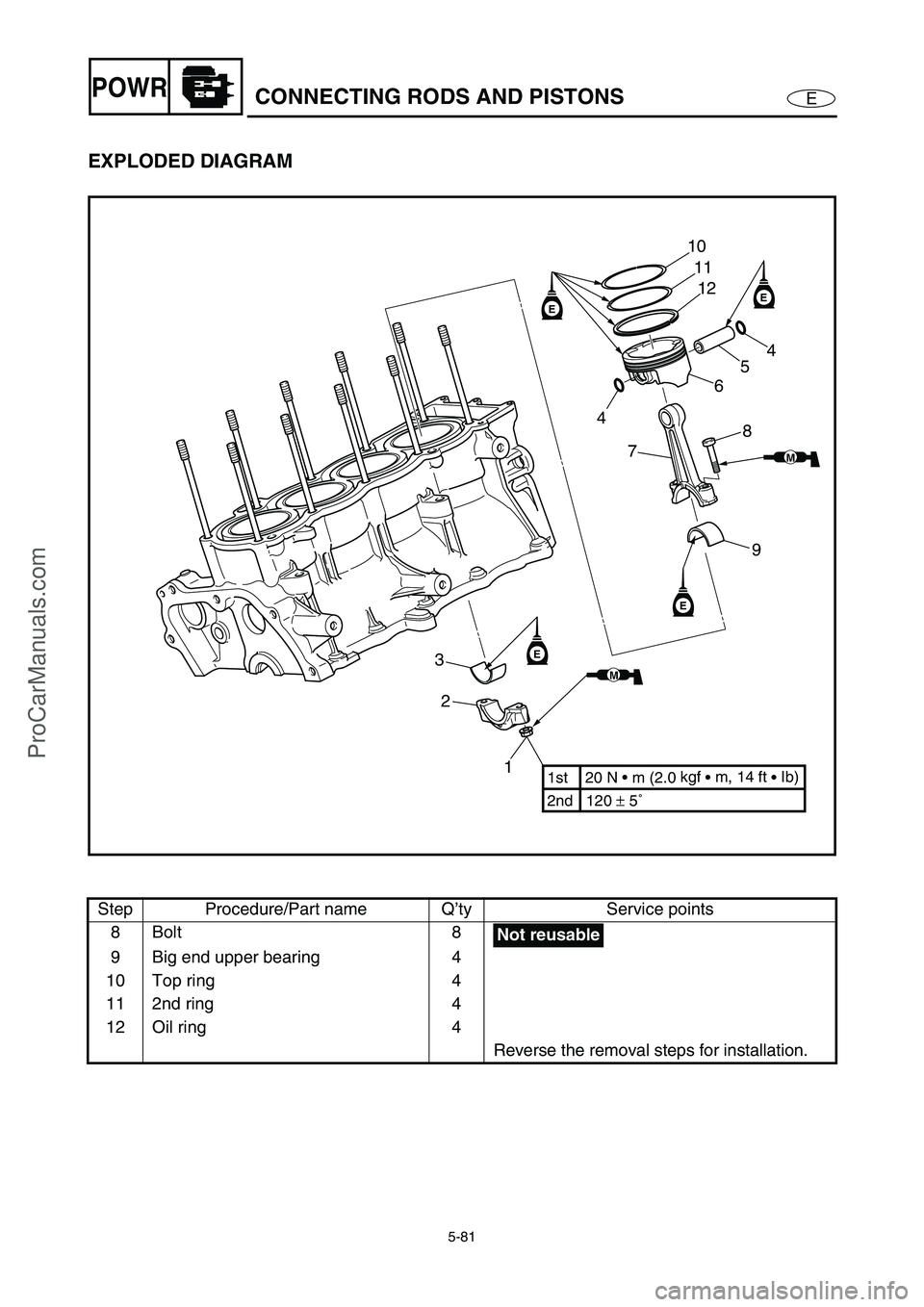

EPOWRCONNECTING RODS AND PISTONS

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

8Bolt 8

9 Big end upper bearing 4

10 Top ring 4

11 2nd ring 4

12 Oil ring 4

Reverse the removal steps for installation.

EE

E

E

1 2 310

11

12

4

5

6

8

7

9

2nd 120 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

MM

MM

4

Not reusable

ProCarManuals.com

Trending: wheel bolt torque, wheel, oil temperature, remote control, seats, dimensions, octane