YAMAHA VX110 2005 Service Manual

Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 161 of 347

5-62

EPOWRVALVES AND VALVE SPRINGS

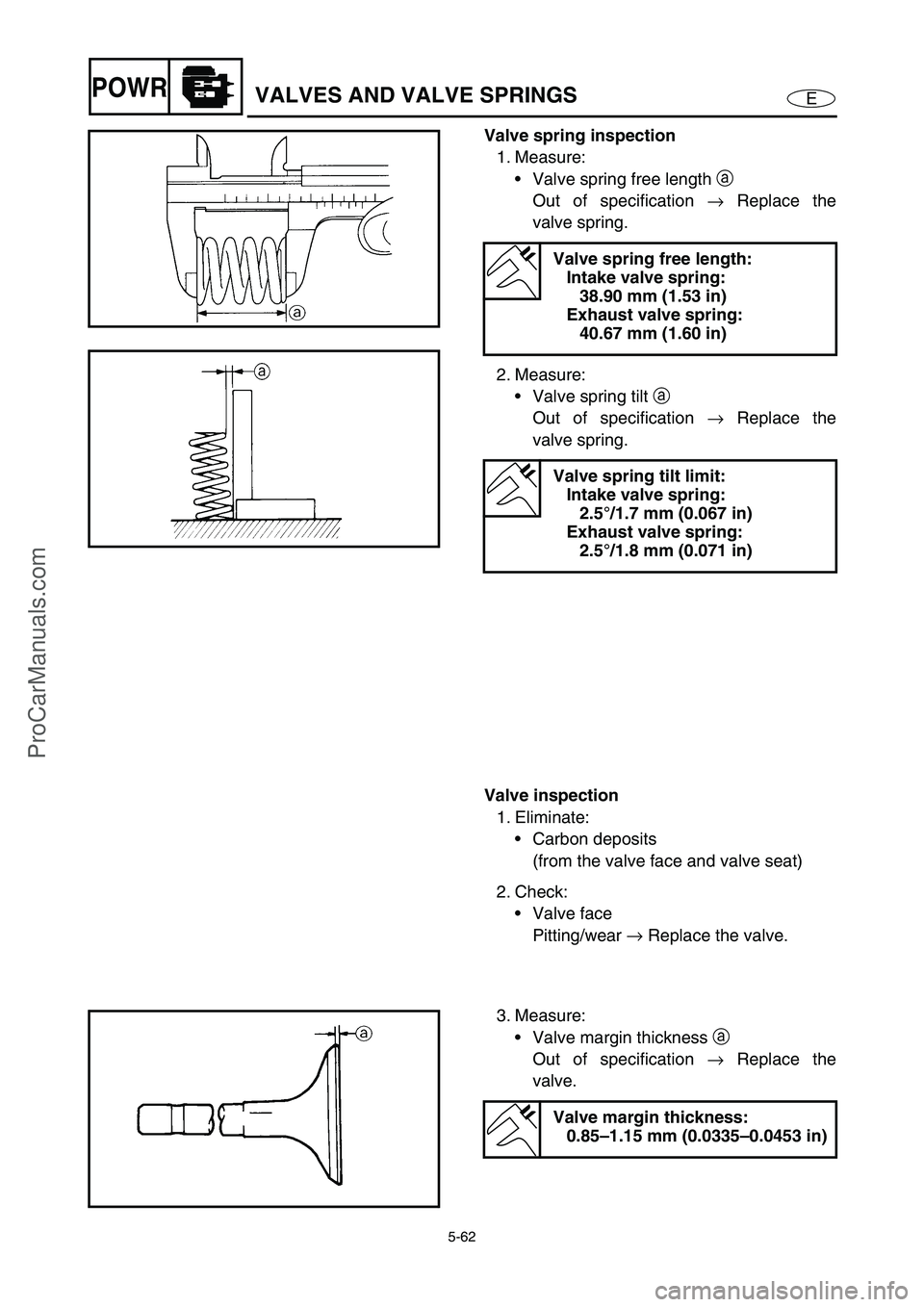

Valve spring inspection

1. Measure:

Valve spring free length a

Out of specification →

Replace the

valve spring.

2. Measure:

Valve spring tilt a

Out of specification →

Replace the

valve spring.

Valve spring free length:

Intake valve spring:

38.90 mm (1.53 in)

Exhaust valve spring:

40.67 mm (1.60 in)

Valve spring tilt limit:

Intake valve spring:

2.5°/1.7 mm (0.067 in)

Exhaust valve spring:

2.5°/1.8 mm (0.071 in)

Valve inspection

1. Eliminate:

Carbon deposits

(from the valve face and valve seat)

2. Check:

Valve face

Pitting/wear →

Replace the valve.

3. Measure:

Valve margin thickness a

Out of specification →

Replace the

valve.

Valve margin thickness:

0.85–1.15 mm (0.0335–0.0453 in)

ProCarManuals.com

Page 162 of 347

5-63

EPOWRVALVES AND VALVE SPRINGS

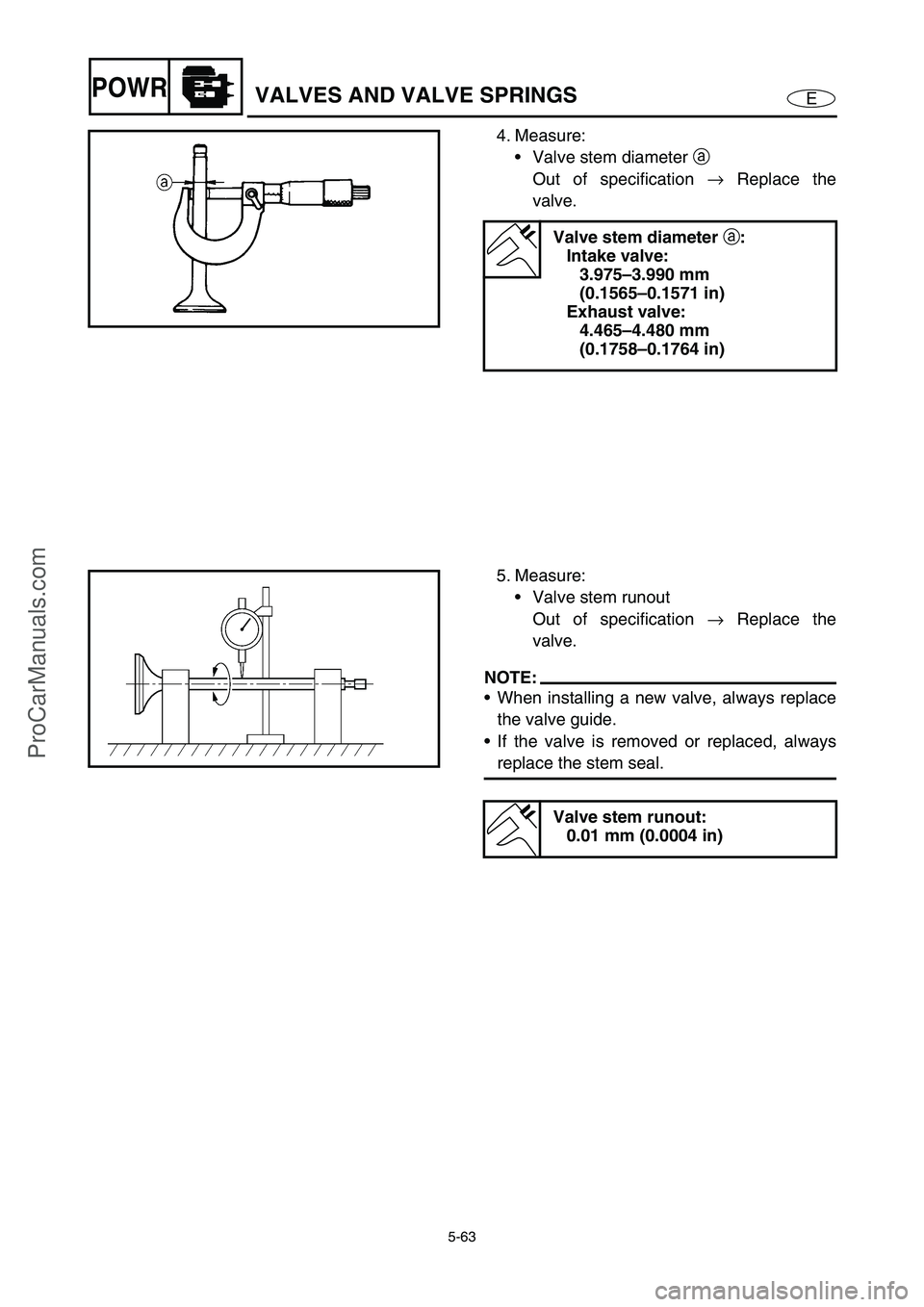

4. Measure:

Valve stem diameter a

Out of specification →

Replace the

valve.

Valve stem diameter

a:

Intake valve:

3.975–3.990 mm

(0.1565–0.1571 in)

Exhaust valve:

4.465–4.480 mm

(0.1758–0.1764 in)

5. Measure:

Valve stem runout

Out of specification →

Replace the

valve.

NOTE:

When installing a new valve, always replace

the valve guide.

If the valve is removed or replaced, always

replace the stem seal.

Valve stem runout:

0.01 mm (0.0004 in)

ProCarManuals.com

Page 163 of 347

5-64

EPOWRVALVES AND VALVE SPRINGS

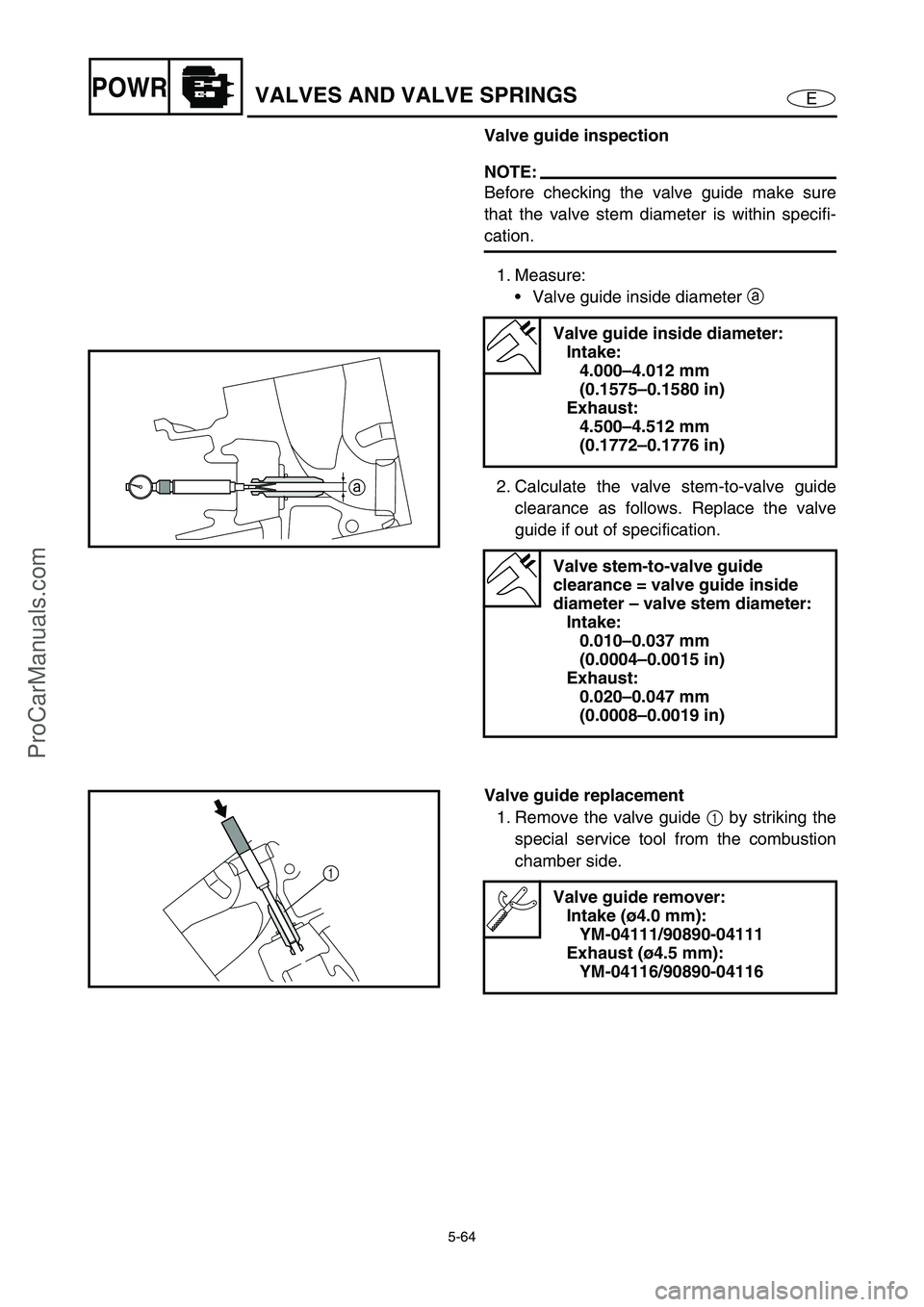

Valve guide inspection

NOTE:

Before checking the valve guide make sure

that the valve stem diameter is within specifi-

cation.

1. Measure:

Valve guide inside diameter a

2. Calculate the valve stem-to-valve guide

clearance as follows. Replace the valve

guide if out of specification.

Valve guide inside diameter:

Intake:

4.000–4.012 mm

(0.1575–0.1580 in)

Exhaust:

4.500–4.512 mm

(0.1772–0.1776 in)

Valve stem-to-valve guide

clearance = valve guide inside

diameter – valve stem diameter:

Intake:

0.010–0.037 mm

(0.0004–0.0015 in)

Exhaust:

0.020–0.047 mm

(0.0008–0.0019 in)

a

Valve guide replacement

1. Remove the valve guide 1

by striking the

special service tool from the combustion

chamber side.

Valve guide remover:

Intake (ø4.0 mm):

YM-04111/90890-04111

Exhaust (ø4.5 mm):

YM-04116/90890-04116

1

ProCarManuals.com

Page 164 of 347

5-65

EPOWRVALVES AND VALVE SPRINGS

2. Install the new valve guide 2

by striking

the special service tool from the camshaft

side until the valve guide clip 3

contacts

the cylinder head.

NOTE:

Apply engine oil to the surface of the new

valve guide.

Valve guide remover:

Intake (ø4.0 mm):

YM-04111/90890-04111

Exhaust (ø4.5 mm):

YM-04116/90890-04116

Valve guide installer:

Intake (ø4.0 mm):

YM-04112/90890-04112

Exhaust (ø4.5 mm):

YM-04117/90890-04117

3

E

2

3. Insert the special service tool into the

valve guide 2

, and then ream the valve

guide.

NOTE:

Turn the valve guide reamer clockwise to

ream the valve guide.

Do not turn the reamer counterclockwise

when removing the reamer.

4. Measure:

Valve guide inside diameter

Valve guide reamer:

Intake (ø4.0 mm):

YM-04113/90890-04113

Exhaust (ø4.5 mm):

YM-04118/90890-04118

Valve guide inside diameter:

Intake:

4.000–4.012 mm

(0.1575–0.1580 in)

Exhaust:

4.500–4.512 mm

(0.1772–0.1776 in)

2

ProCarManuals.com

Page 165 of 347

5-66

EPOWRVALVES AND VALVE SPRINGS

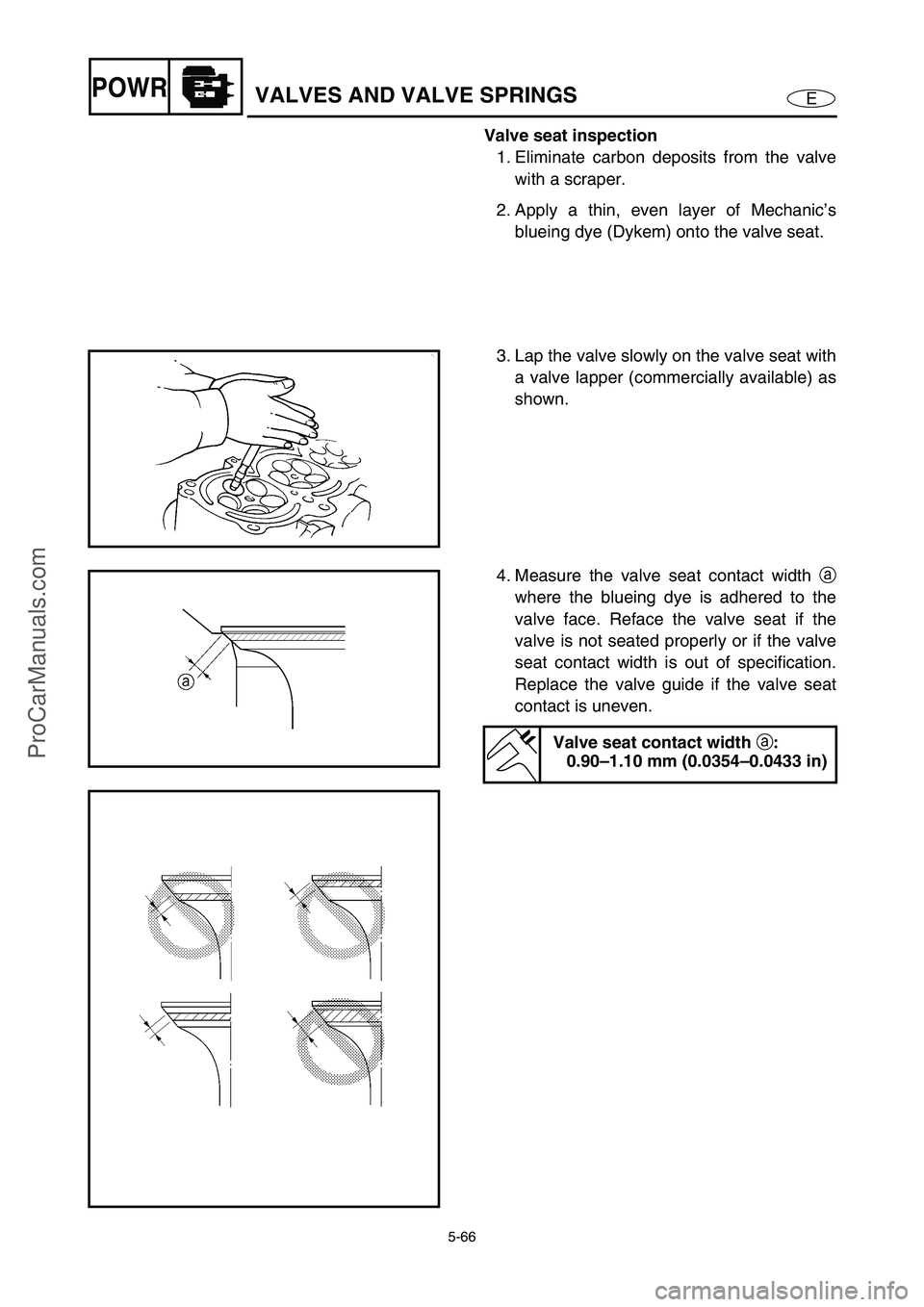

Valve seat inspection

1. Eliminate carbon deposits from the valve

with a scraper.

2. Apply a thin, even layer of Mechanic’s

blueing dye (Dykem) onto the valve seat.

3. Lap the valve slowly on the valve seat with

a valve lapper (commercially available) as

shown.

4. Measure the valve seat contact width a

where the blueing dye is adhered to the

valve face. Reface the valve seat if the

valve is not seated properly or if the valve

seat contact width is out of specification.

Replace the valve guide if the valve seat

contact is uneven.

Valve seat contact width

a:

0.90–1.10 mm (0.0354–0.0433 in)

ProCarManuals.com

Page 166 of 347

5-67

EPOWRVALVES AND VALVE SPRINGS

Valve seat reface

1. Reface the valve seat with the valve seat

cutter.

2. Cut the surface of the valve seat with a 45°

cutter by turning the cutter clockwise until

the valve seat face has become smooth.

aSlag or rough surface

CAUTION:

Do not over cut the valve seat. Be sure to

turn the cutter evenly downward at a pres-

sure of 40–50 N (4–5 kgf, 8.8–11 lbf) to pre-

vent chatter marks.

Valve seat cutter holder:

Intake (ø4.0 mm):

90890-06811

Exhaust (ø4.5 mm):

90890-06812

Valve seat cutter:

30° (intake):

90890-06815

45° (intake):

90890-06814

60° (intake):

90890-06813

30° (exhaust):

90890-06328

45° (exhaust):

90890-06312

60° (exhaust):

90890-06315

Neway valve seat cutter kit:

YM-91044

3. Use a 30° cutter to adjust the contact width

of the top edge of the valve seat.

bPrevious contact width

30˚

b

ProCarManuals.com

Page 167 of 347

5-68

EPOWRVALVES AND VALVE SPRINGS

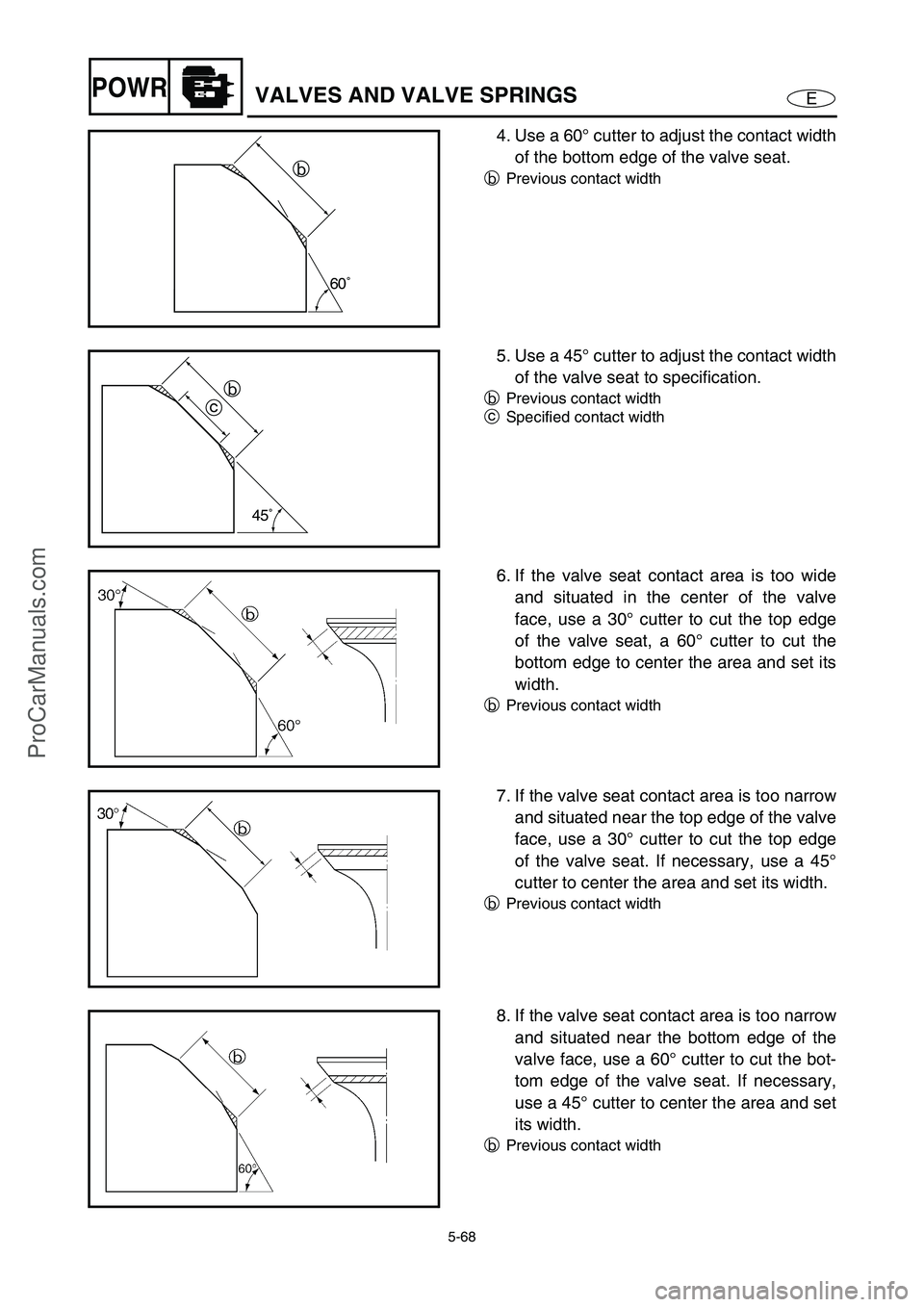

4. Use a 60° cutter to adjust the contact width

of the bottom edge of the valve seat.

bPrevious contact width

60˚

b

5. Use a 45° cutter to adjust the contact width

of the valve seat to specification.

bPrevious contact width

cSpecified contact width

45˚

b

c

6. If the valve seat contact area is too wide

and situated in the center of the valve

face, use a 30° cutter to cut the top edge

of the valve seat, a 60° cutter to cut the

bottom edge to center the area and set its

width.

bPrevious contact width

7. If the valve seat contact area is too narrow

and situated near the top edge of the valve

face, use a 30° cutter to cut the top edge

of the valve seat. If necessary, use a 45°

cutter to center the area and set its width.

bPrevious contact width

8. If the valve seat contact area is too narrow

and situated near the bottom edge of the

valve face, use a 60° cutter to cut the bot-

tom edge of the valve seat. If necessary,

use a 45° cutter to center the area and set

its width.

bPrevious contact width

ProCarManuals.com

Page 168 of 347

5-69

EPOWRVALVES AND VALVE SPRINGS

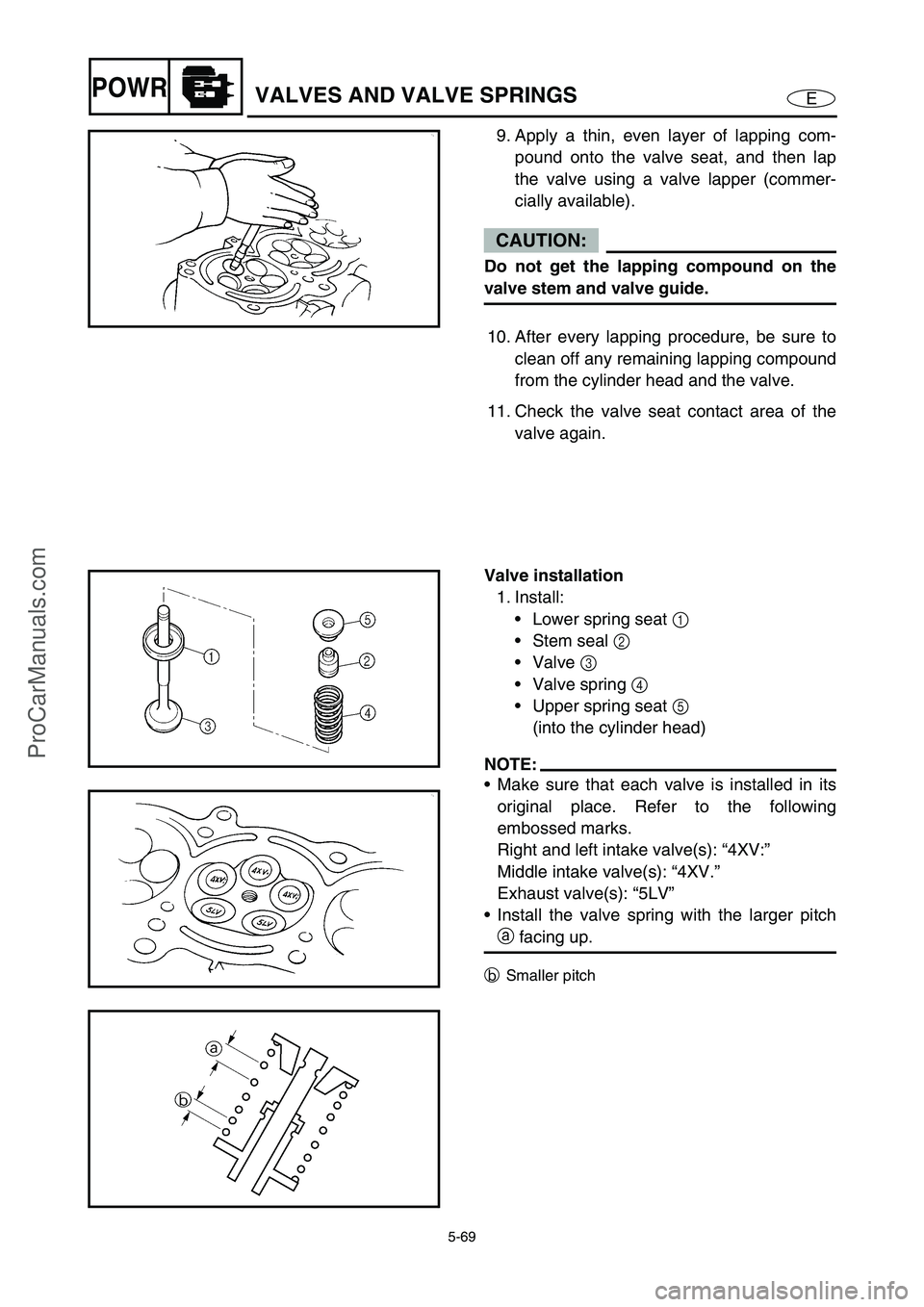

9. Apply a thin, even layer of lapping com-

pound onto the valve seat, and then lap

the valve using a valve lapper (commer-

cially available).

CAUTION:

Do not get the lapping compound on the

valve stem and valve guide.

10. After every lapping procedure, be sure to

clean off any remaining lapping compound

from the cylinder head and the valve.

11. Check the valve seat contact area of the

valve again.

Valve installation

1. Install:

Lower spring seat 1

Stem seal 2

Valve 3

Valve spring 4

Upper spring seat 5

(into the cylinder head)

NOTE:

Make sure that each valve is installed in its

original place. Refer to the following

embossed marks.

Right and left intake valve(s): “4XV:”

Middle intake valve(s): “4XV.”

Exhaust valve(s): “5LV”

Install the valve spring with the larger pitch

a

facing up.

b

Smaller pitch

ProCarManuals.com

Page 169 of 347

5-70

EPOWRVALVES AND VALVE SPRINGS

2. Compress the valve spring, and then

install the valve cotter 1

using a thin

screwdriver with a small amount of grease

applied to it.

Valve spring compressor:

YM-01253/90890-04019

Valve spring compressor

attachment:

(for the intake valve):

YM-04114/90890-04114

(for the exhaust valve):

YM-04108/90890-04108

3. Lightly tap the valve spring retainer with a

plastic hammer to set the valve cotter

securely.

NOTE:

Apply engine oil to the valve pads and valve

lifters before installation.

ProCarManuals.com

Page 170 of 347

5-71

EPOWRCRANKCASE

CRANKCASE

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

OIL PAN AND CRANKCASE

REMOVALFollow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

Intake assembly Refer to “FUEL INJECTION SYSTEM” in

Chapter 4.

Exhaust pipes 1 and 2 Refer to “EXHAUST PIPES 1 AND 2”.

Exhaust manifold Refer to “EXHAUST MANIFOLD”.

Generator cover Refer to “GENERATOR AND STARTER

MOTOR”.

Oil tank Refer to “OIL TANK”.

Oil pump Refer to “OIL PUMP”.

*: Loosen completely

6

21 20

20 11

10 9

87

23

4

5

16

151718

13 14

1219

1

LT

271

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

LT

572

LT

E

E

AA

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 70 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

20 N •

m (2.0 kgf • m, 14 ft • Ib)

8 × 40 mm

2nd *

3rd 15 N • m (1.5 kgf

• m, 11 ft

• Ib) 1st 7.8 N • m (0.78 kgf

• m, 5.6 ft

• Ib)

9 × 105 mm

4th 49 ± 5˚

8.4 N •

m (0.84 kgf • m, 6.1 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 55 mm

7.6 N •

m (0.76 kgf • m, 5.5 ft • Ib)

6 × 16 mm

15 N •

m (1.5 kgf • m, 11 ft • Ib)

12 N •

m (1.2 kgf • m, 8.7 ft • Ib)

6 × 20 mm

18

AA

1280B

ProCarManuals.com