YAMAHA VX110 2005 Service Manual

Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 181 of 347

5-82

EPOWRCONNECTING RODS AND PISTONS

SERVICE POINTS

Connecting rod and piston removal

The following procedure applies to all of the

connecting rods and pistons.

1. Remove:

Connecting rod cap 1

Big end bearings

NOTE:

Identify the position of each big end bearing so

that it can be reinstalled in its original place.

1

2. Remove:

Piston pin clips 1

Piston pin 2

Piston 3

Connecting rod 4

CAUTION:

Do not use a hammer to drive the piston

pin out.

NOTE:

For reference during installation, put an iden-

tification number a on the piston crown.

Before removing the piston pin, deburr the

piston pin clip’s groove and the piston’s pin

bore area.

3. Remove:

Top ring

2nd ring

Oil ring

NOTE:

When removing a piston ring, open the end

gap with your fingers and lift the other side of

the ring over the piston crown.

ProCarManuals.com

Page 182 of 347

5-83

EPOWRCONNECTING RODS AND PISTONS

Cylinder and piston inspection

The following procedure applies to all of the

cylinders and pistons.

1. Check:

Piston wall

Cylinder wall

Vertical scratches →

Replace the cylin-

der, and the piston and piston rings as a

set.

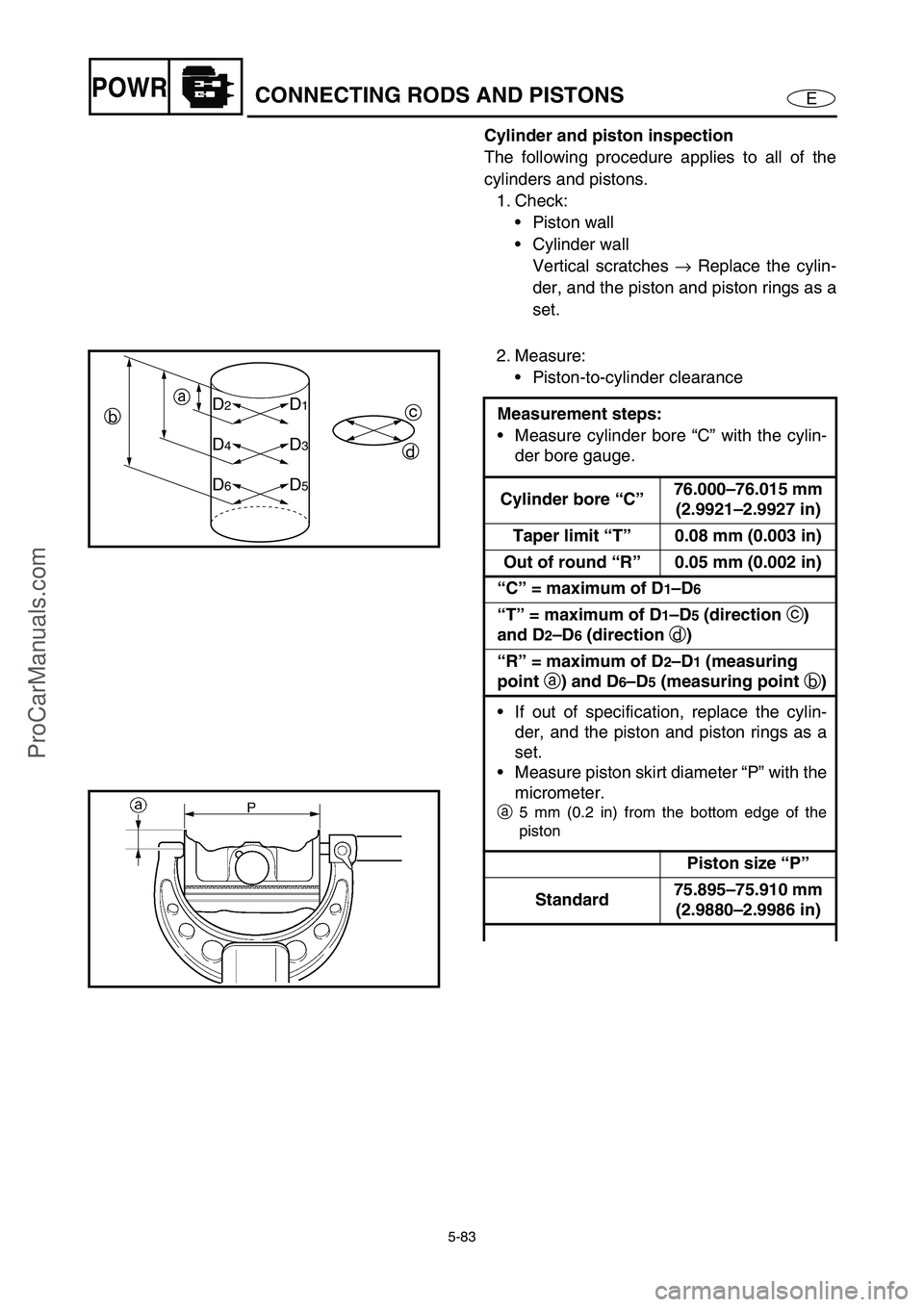

2. Measure:

Piston-to-cylinder clearance

Measurement steps:

Measure cylinder bore “C” with the cylin-

der bore gauge.

Cylinder bore “C”76.000–76.015 mm

(2.9921–2.9927 in)

Taper limit “T”0.08 mm (0.003 in)

Out of round “R”0.05 mm (0.002 in)

“C” = maximum of D

1–D6

“T” = maximum of D

1–D5 (direction

c)

and D

2–D6 (direction

d)

“R” = maximum of D

2–D1 (measuring

point

a) and D

6–D5 (measuring point

b)

If out of specification, replace the cylin-

der, and the piston and piston rings as a

set.

Measure piston skirt diameter “P” with the

micrometer.

a

5 mm (0.2 in) from the bottom edge of the

piston

Piston size “P”

Standard75.895–75.910 mm

(2.9880–2.9986 in)

D1D2

D3D4

D5D6

c

d a

b

ProCarManuals.com

Page 183 of 347

5-84

EPOWRCONNECTING RODS AND PISTONS

If out of specification, replace the piston

and piston rings as a set.

Calculate the piston-to-cylinder clearance

with the following formula.

Piston-to-cylinder clearance = Cylinder

bore “C” – Piston skirt diameter “P”

Piston-to-cylinder clearance:

0.10–0.11 mm (0.0039–0.0043 in)

If out of specification, replace the piston

and piston rings as a set.

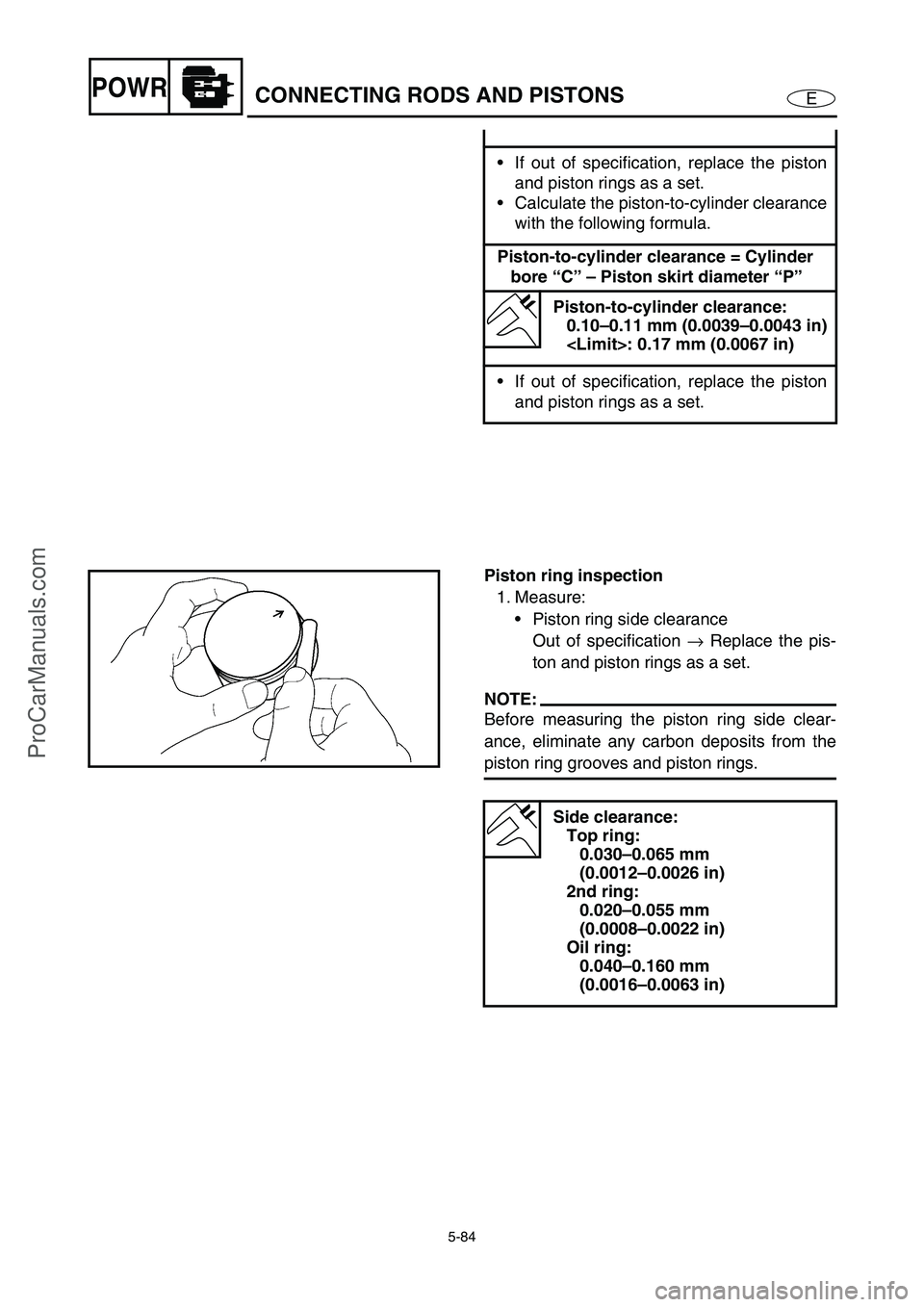

Piston ring inspection

1. Measure:

Piston ring side clearance

Out of specification →

Replace the pis-

ton and piston rings as a set.

NOTE:

Before measuring the piston ring side clear-

ance, eliminate any carbon deposits from the

piston ring grooves and piston rings.

Side clearance:

Top ring:

0.030–0.065 mm

(0.0012–0.0026 in)

2nd ring:

0.020–0.055 mm

(0.0008–0.0022 in)

Oil ring:

0.040–0.160 mm

(0.0016–0.0063 in)

ProCarManuals.com

Page 184 of 347

5-85

EPOWRCONNECTING RODS AND PISTONS

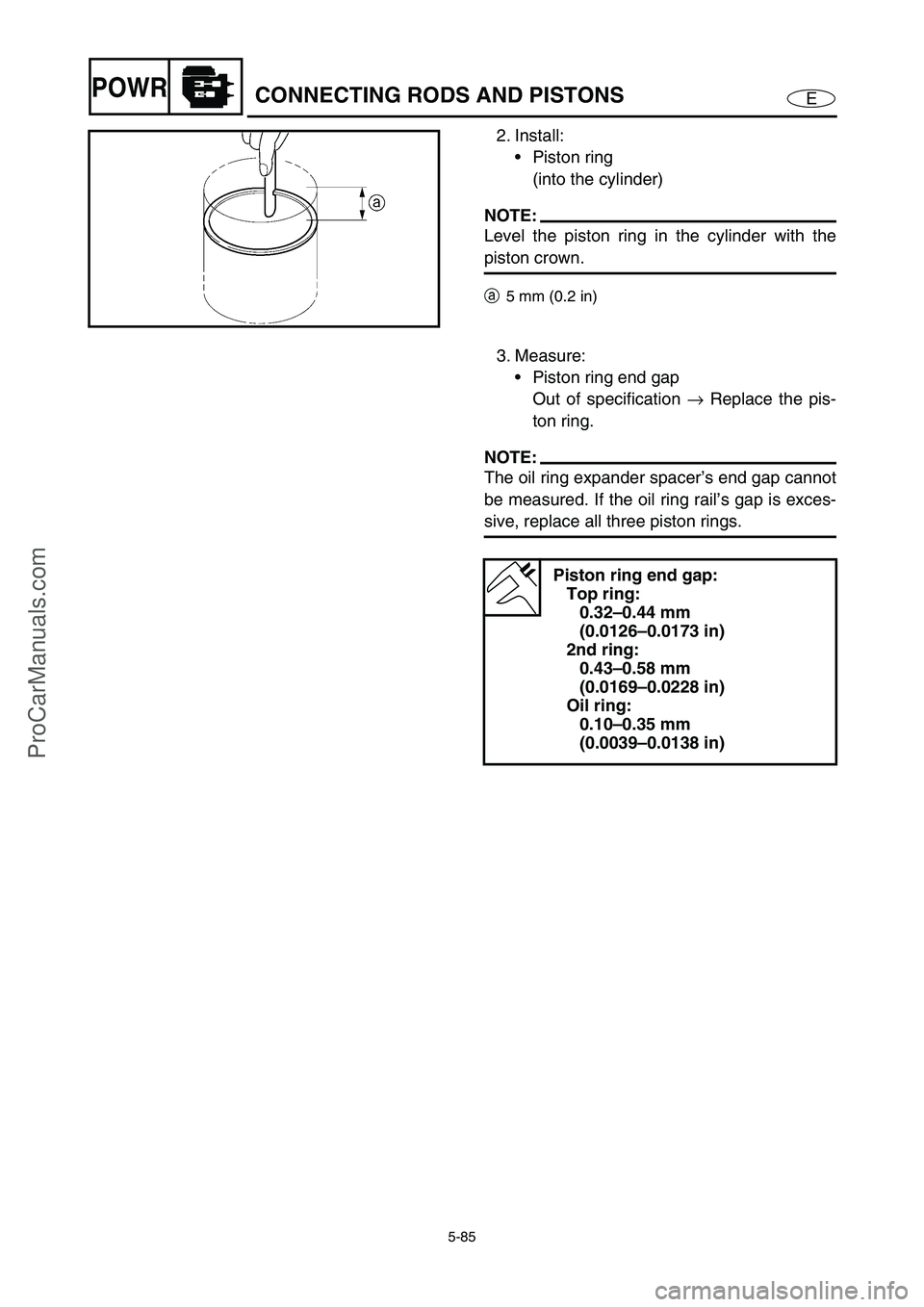

2. Install:

Piston ring

(into the cylinder)

NOTE:

Level the piston ring in the cylinder with the

piston crown.

a5 mm (0.2 in)

3. Measure:

Piston ring end gap

Out of specification →

Replace the pis-

ton ring.

NOTE:

The oil ring expander spacer’s end gap cannot

be measured. If the oil ring rail’s gap is exces-

sive, replace all three piston rings.

Piston ring end gap:

Top ring:

0.32–0.44 mm

(0.0126–0.0173 in)

2nd ring:

0.43–0.58 mm

(0.0169–0.0228 in)

Oil ring:

0.10–0.35 mm

(0.0039–0.0138 in)

ProCarManuals.com

Page 185 of 347

5-86

EPOWRCONNECTING RODS AND PISTONS

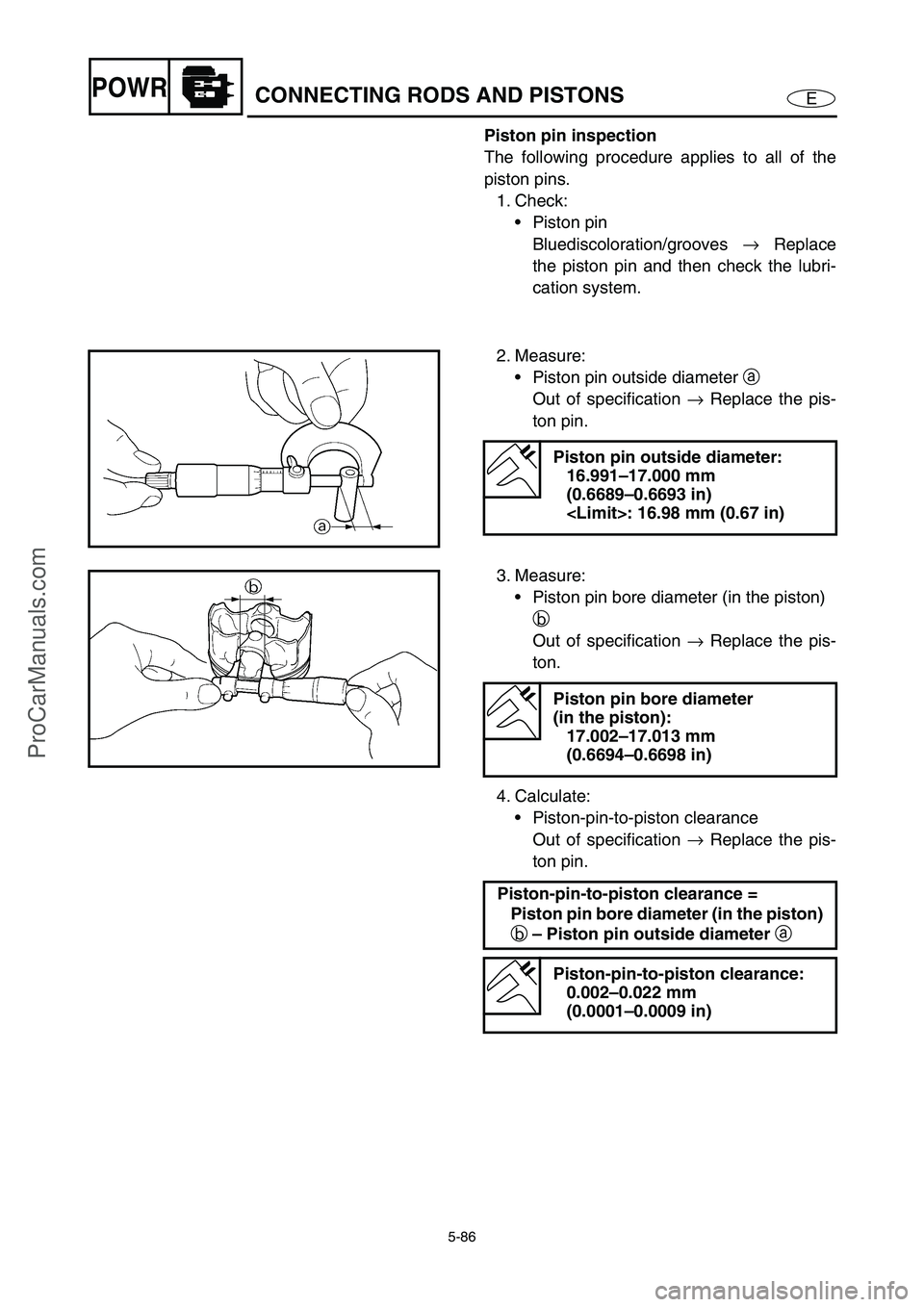

Piston pin inspection

The following procedure applies to all of the

piston pins.

1. Check:

Piston pin

Bluediscoloration/grooves →

Replace

the piston pin and then check the lubri-

cation system.

2. Measure:

Piston pin outside diameter a

Out of specification →

Replace the pis-

ton pin.

Piston pin outside diameter:

16.991–17.000 mm

(0.6689–0.6693 in)

3. Measure:

Piston pin bore diameter (in the piston)

b

Out of specification →

Replace the pis-

ton.

4. Calculate:

Piston-pin-to-piston clearance

Out of specification →

Replace the pis-

ton pin.

Piston pin bore diameter

(in the piston):

17.002–17.013 mm

(0.6694–0.6698 in)

Piston-pin-to-piston clearance =

Piston pin bore diameter (in the piston)

b – Piston pin outside diameter

a

Piston-pin-to-piston clearance:

0.002–0.022 mm

(0.0001–0.0009 in)

ProCarManuals.com

Page 186 of 347

5-87

EPOWRCONNECTING RODS AND PISTONS

Connecting rod inspection

1. Measure:

Big end oil clearance

Out of specification →

Replace the big

end bearings.

Big end oil clearance:

0.016–0.040 mm

(0.0006–0.0016 in)

Measurement steps:

The following procedure applies to all of the

connecting rods.

CAUTION:

Do not interchange the big end bearings

and connecting rods. To obtain the cor-

rect big end oil clearance and prevent

engine damage, the big end bearings

must be installed in their original posi-

tions.

Clean the big end bearings, crankshaft

pins, and the inside of the connecting rod

halves.

Install the big end upper bearing into the

connecting rod and the big end lower

bearing into the connecting rod cap.

NOTE:

Align the projections a

on the big end bear-

ings with the notches b

in the connecting

rod and connecting rod cap.

Put a piece of Plastigauge 1

on the

crankshaft pin.

Assemble the connecting rod halves.

1

ProCarManuals.com

Page 187 of 347

5-88

EPOWRCONNECTING RODS AND PISTONS

NOTE:

• Do not move the connecting rod or crank-

shaft until the clearance measurement

has been completed.

Lubricate the bolts threads and nut seats

with molybdenum disulfide grease.

Make sure the “Y” mark c on the con-

necting rod faces towards the front side of

the crankshaft.

Make sure the characters d on both the

connecting rod and connecting rod cap

are aligned.

Tighten the connecting rod nuts.

Refer to “Connecting rod and piston

installation”.

Remove the connecting rod and big end

bearings.

Refer to “Connecting rod and piston

removal”.

Measure the compressed Plastigauge

width e on the crankshaft pin.

If the big end oil clearance is out of speci-

fication, select replacement big end bear-

ings.

cd

e

2. Select:

Big end bearings (P

1–P4)

NOTE:

The numbers stamped into the crankshaft web

and the numbers on the connecting rods are

used to determine the replacement big end

bearing sizes.

P4

P3P2

P1

ProCarManuals.com

Page 188 of 347

5-89

EPOWRCONNECTING RODS AND PISTONS

For example, if the connecting rod “P1” and the

crankshaft web “P

1” numbers are “5” and “1”

respectively, then the bearing size for “P

1” is:

Bearing size of P

1:

“P

1” (connecting rod) –

“P

1” (crankshaft web)

5 – 1 = 4 (green)

BEARING COLOR CODE

1brown

2 black

3blue

4 green5 G

P4P3P2P1

Connecting rod and piston installation

The following procedure applies to all of the

pistons and connecting rods.

1. Install:

Oil ring

2nd ring

Top ring

NOTE:

Be sure to install the piston rings so that the

manufacturer’s marks or numbers face up.

2. Install:

Piston 1

Connecting rod 2

Piston pin 3

Piston pin clips 4

NOTE:

Apply engine oil onto the piston pin.

When installing the connecting rod to the pis-

ton, make sure that the “Y” mark a

on the

connecting rod faces towards the left when

the exhaust valve recesses b

on the piston

face upward. Refer to the illustration.

Reinstall each piston into its original cylinder

(numbering order starting from the front: #1

to #4).

ProCarManuals.com

Page 189 of 347

5-90

EPOWRCONNECTING RODS AND PISTONS

3. Offset:

Piston ring end gaps

aTop ring, oil ring expander spacer

b2nd ring, lower oil ring rail

cUpper oil ring rail

ÈExhaust sidebc

a È

90˚

45˚

90˚

4. Lubricate:

Piston

Piston rings

Cylinder

(with the recommended lubricant)

Recommended lubricant:

Engine oil

5. Lubricate:

Bolt threads

Nut seats

(with the recommended lubricant)

Recommended lubricant:

Molybdenum disulfide grease

6. Lubricate:

Crankshaft pins

Big end bearings

(with the recommended lubricant)

Recommended lubricant:

Engine oil

ProCarManuals.com

Page 190 of 347

5-91

EPOWRCONNECTING RODS AND PISTONS

7. Install:

Big end bearings

Connecting rod assembly 1

(into the cylinder and onto the

crankshaft pin)

Connecting rod cap

(onto the crankshaft pin)

NOTE:

Align the projections on the big end bearings

with the notches in the connecting rods and

connecting rod caps.

Be sure to reinstall each big end bearing in

its original place.

While compressing the piston rings with pis-

ton ring compressor 2

, install the connecting

rod assembly into the cylinder with the other

hand.

Make sure the “Y” marks a

on the connect-

ing rods face towards the front side of the

crankshaft.

Make sure the characters b

on both the con-

necting rod and connecting rod cap are

aligned.

8. Align:

Bolt heads

(with the connecting rod)

Piston ring compressor:

YM-08037/90890-05158

ProCarManuals.com