YAMAHA VX110 2005 Service Manual

VX110 2005

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/57494/w960_57494-0.png

YAMAHA VX110 2005 Service Manual

Trending: torque, heating, spark plugs replace, oil change, sensor, seat adjustment, clutch

Page 151 of 347

5-52

EPOWRCAMSHAFTS

T R..

Timing chain tensioner bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

Remove the screwdriver, make sure the

timing chain tensioner rod releases, and

then tighten the cap bolt to the specified

torque.

T R..

Cap bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

4. Turn:

Drive coupling

(several turns counterclockwise)

5. Check:

Turn the drive coupling counterclock-

wise, and then check if cylinder #1 is at

TDC of the compression stroke with a

dial gauge.

Camshaft punch marks a

Make sure that the camshaft punch

marks are aligned with the arrow marks

b

on the camshaft caps.

Out of alignment →

Adjust.

Refer to the installation steps above.

6. Measure:

Valve clearance

Out of specification →

Adjust.

Refer to “POWER UNIT” in Chapter 3.

ProCarManuals.com

Page 152 of 347

5-53

EPOWRCAMSHAFTS

7. Install:

Cylinder head cover gasket

Cylinder head cover

NOTE:

Apply sealant onto the mating surfaces of the

cylinder head cover gasket and cylinder

head.

Tighten the cylinder head cover bolts stages

and in a crisscross pattern.

T R..

Cylinder head cover bolt:

12 N m (1.2 kgf m, 8.7 ft lb)

ProCarManuals.com

Page 153 of 347

5-54

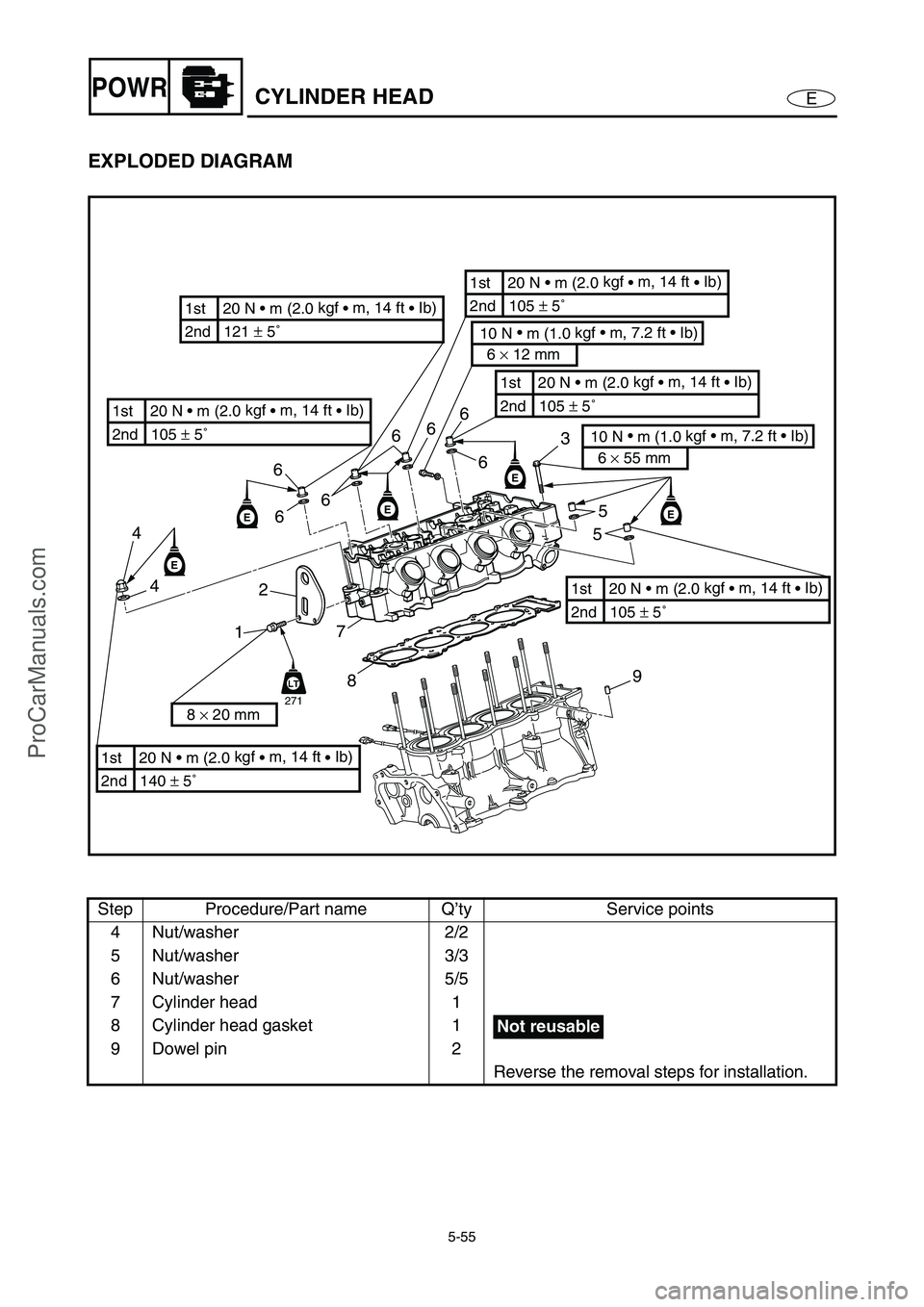

EPOWRCYLINDER HEAD

CYLINDER HEAD

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CYLINDER HEAD REMOVAL

Follow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

Intake assembly Refer to “FUEL INJECTION SYSTEM” in

Chapter 4.

Exhaust pipes 1 and 2 Refer to “EXHAUST PIPES 1 AND 2”.

Oil tank Refer to “OIL TANK”.

Intake and exhaust camshaft Refer to “CAMSHAFTS”.

1Bolt 2

2 Hunger 1

3Bolt 3

EEE

E

2 4

1

855

7

9 3 6

6

LT

271

2nd 121 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 140 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 12 mm

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 55 mm

8 × 20 mm

6

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

E6

4

66

6

ProCarManuals.com

Page 154 of 347

5-55

EPOWRCYLINDER HEAD

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

4 Nut/washer 2/2

5 Nut/washer 3/3

6 Nut/washer 5/5

7 Cylinder head 1

8 Cylinder head gasket 1

9 Dowel pin 2

Reverse the removal steps for installation.

EEE

E

2 4

1

855

7

9 3 6

6

LT

271

2nd 121 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 140 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 12 mm

10 N •

m (1.0 kgf • m, 7.2 ft • Ib)

6 × 55 mm

8 × 20 mm

6

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

2nd 105 ± 5˚ 1st 20 N • m (2.0 kgf

• m, 14 ft

• Ib)

E6

4

66

6

Not reusable

ProCarManuals.com

Page 155 of 347

5-56

EPOWRCYLINDER HEAD

SERVICE POINTS

Cylinder head removal

1. Remove:

Cylinder head bolts 1

2. Remove:

Cylinder head nuts

NOTE:

Loosen the cylinder head nuts in the sequence

shown.

Cylinder head inspection

1. Eliminate:

Combustion chamber carbon deposits

(with a rounded scraper)

NOTE:

Do not use a sharp instrument to avoid damag-

ing or scratching:

spark plug bore threads

valve seats

2. Check:

Cylinder head

Damage/scratches →

Replace.

Cylinder head water jacket

Mineral deposits/rust →

Eliminate.

ProCarManuals.com

Page 156 of 347

5-57

EPOWRCYLINDER HEAD

3. Measure:

Cylinder head warpage

Out of specification →

Replace the cyl-

inder head.

Cylinder head warpage limit:

0.1 mm (0.004 in)

Measurement steps:

Place a straightedge 1

and a thickness

gauge 2

across the cylinder head.

Measure the warpage.

If the limit is exceeded, replace the cylin-

der head.

Cylinder head installation

1. Install:

Cylinder head

NOTE:

Pass the timing chain through the timing

chain cavity.

Lubricate the cylinder head nuts with engine

oil.

Tighten the cylinder head nuts in the

sequence shown.

T R..

Cylinder head nut

1:

1st:

20 N m (2.0 kgf m, 14 ft lb)

2nd:

121

± 5°

Cylinder head nut

2:

1st:

20 N m (2.0 kgf m, 14 ft lb)

2nd:

105

± 5°

Cylinder head nut

3:

1st:

20 N m (2.0 kgf m, 14 ft lb)

2nd:

140

± 5°

ProCarManuals.com

Page 157 of 347

5-58

EPOWRCYLINDER HEAD

2. Tighten:

Cylinder head bolts 1

NOTE:

Lubricate the cylinder head bolts with engine

oil.

T R..

Cylinder head bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

ProCarManuals.com

Page 158 of 347

5-59

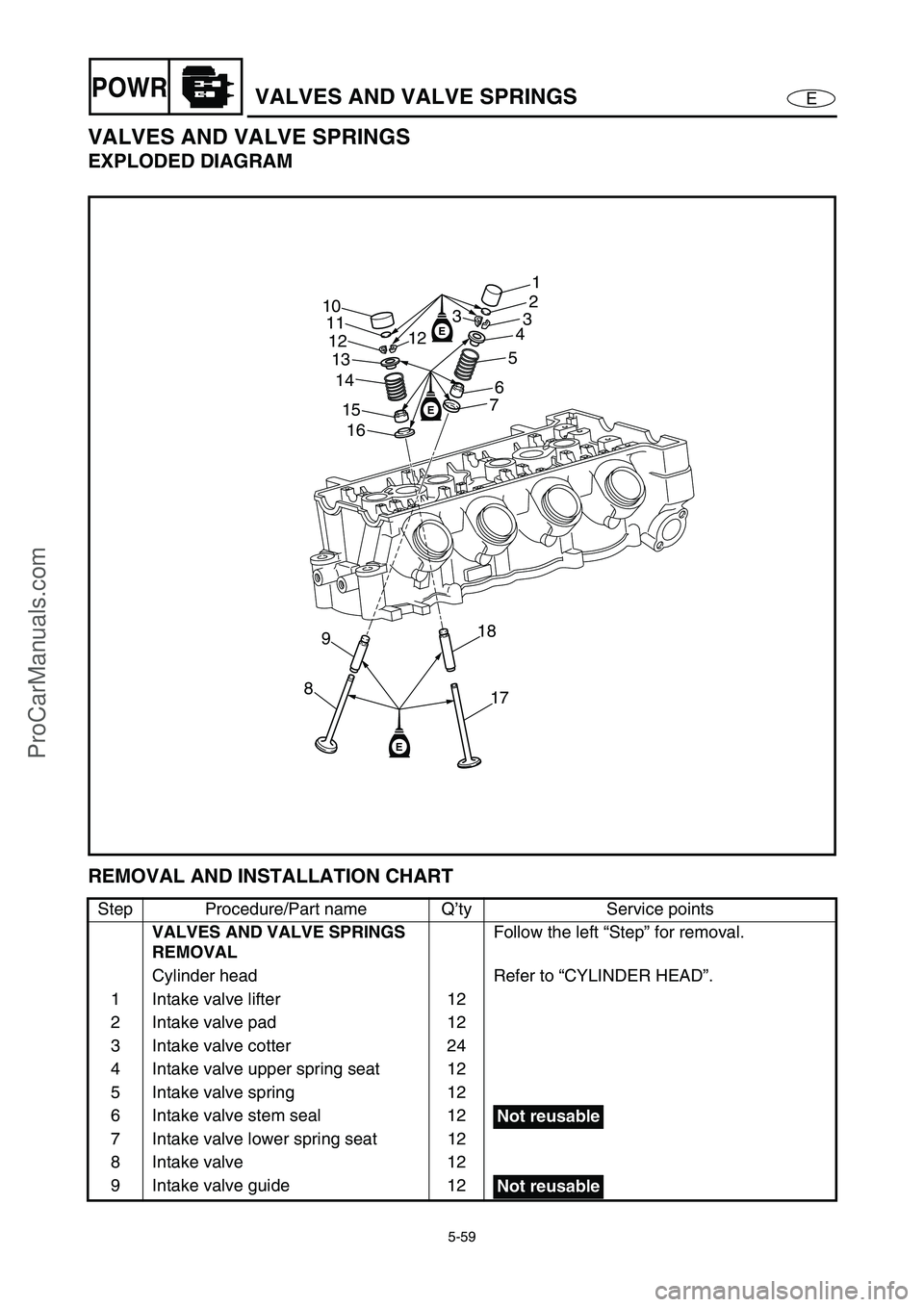

EPOWRVALVES AND VALVE SPRINGS

VALVES AND VALVE SPRINGS

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

VALVES AND VALVE SPRINGS

REMOVALFollow the left “Step” for removal.

Cylinder head Refer to “CYLINDER HEAD”.

1 Intake valve lifter 12

2 Intake valve pad 12

3 Intake valve cotter 24

4 Intake valve upper spring seat 12

5 Intake valve spring 12

6 Intake valve stem seal 12

7 Intake valve lower spring seat 12

8 Intake valve 12

9 Intake valve guide 12

E

E

E

89

17 18 16 15 14 13 10

11

121

2

3

4

5

6

7 3

12

Not reusable

Not reusable

ProCarManuals.com

Page 159 of 347

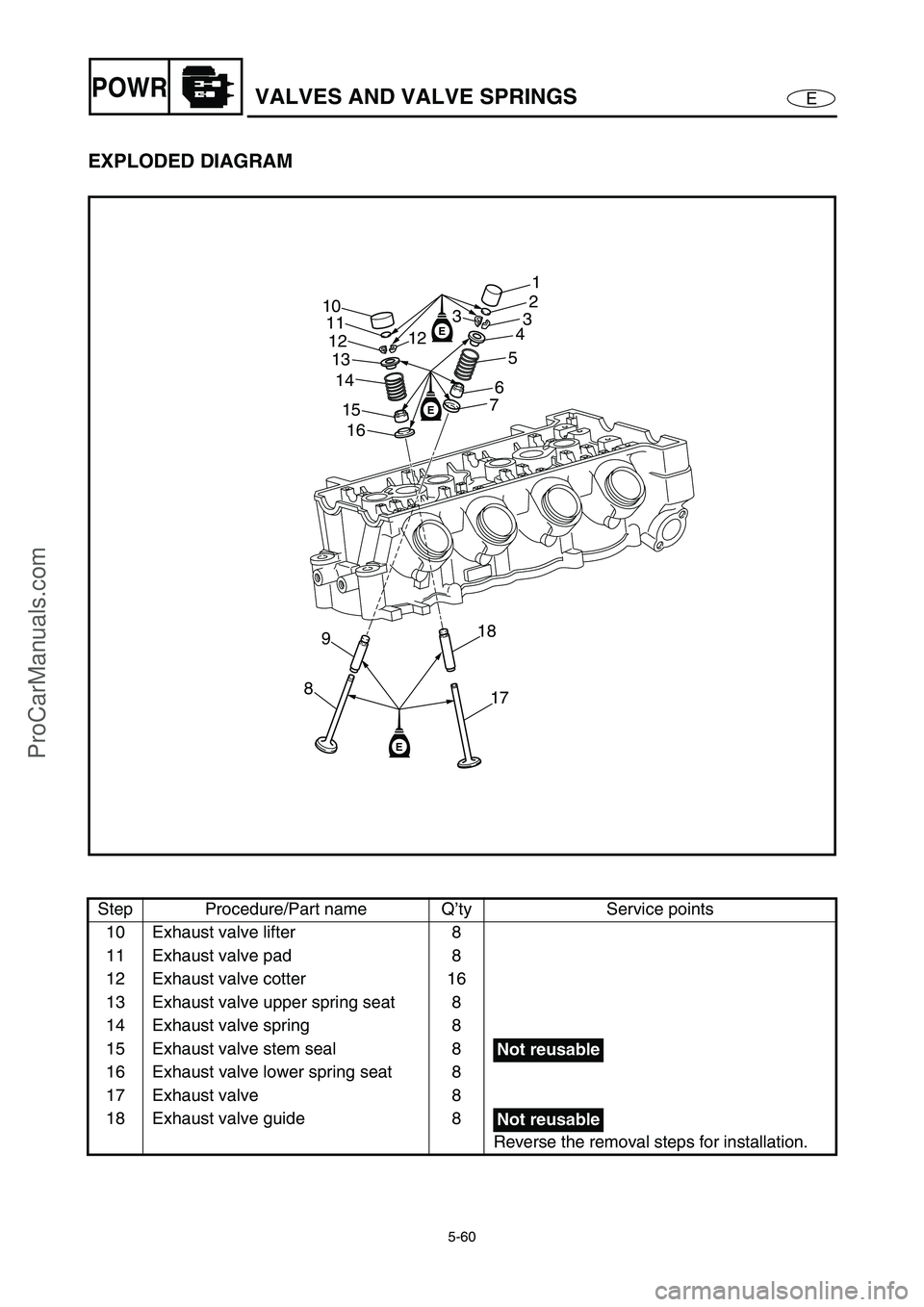

5-60

EPOWRVALVES AND VALVE SPRINGS

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

10 Exhaust valve lifter 8

11 Exhaust valve pad 8

12 Exhaust valve cotter 16

13 Exhaust valve upper spring seat 8

14 Exhaust valve spring 8

15 Exhaust valve stem seal 8

16 Exhaust valve lower spring seat 8

17 Exhaust valve 8

18 Exhaust valve guide 8

Reverse the removal steps for installation.

E

E

E

89

17 18 16 15 14 13 10

11

121

2

3

4

5

6

7 3

12

Not reusable

Not reusable

ProCarManuals.com

Page 160 of 347

5-61

EPOWRVALVES AND VALVE SPRINGS

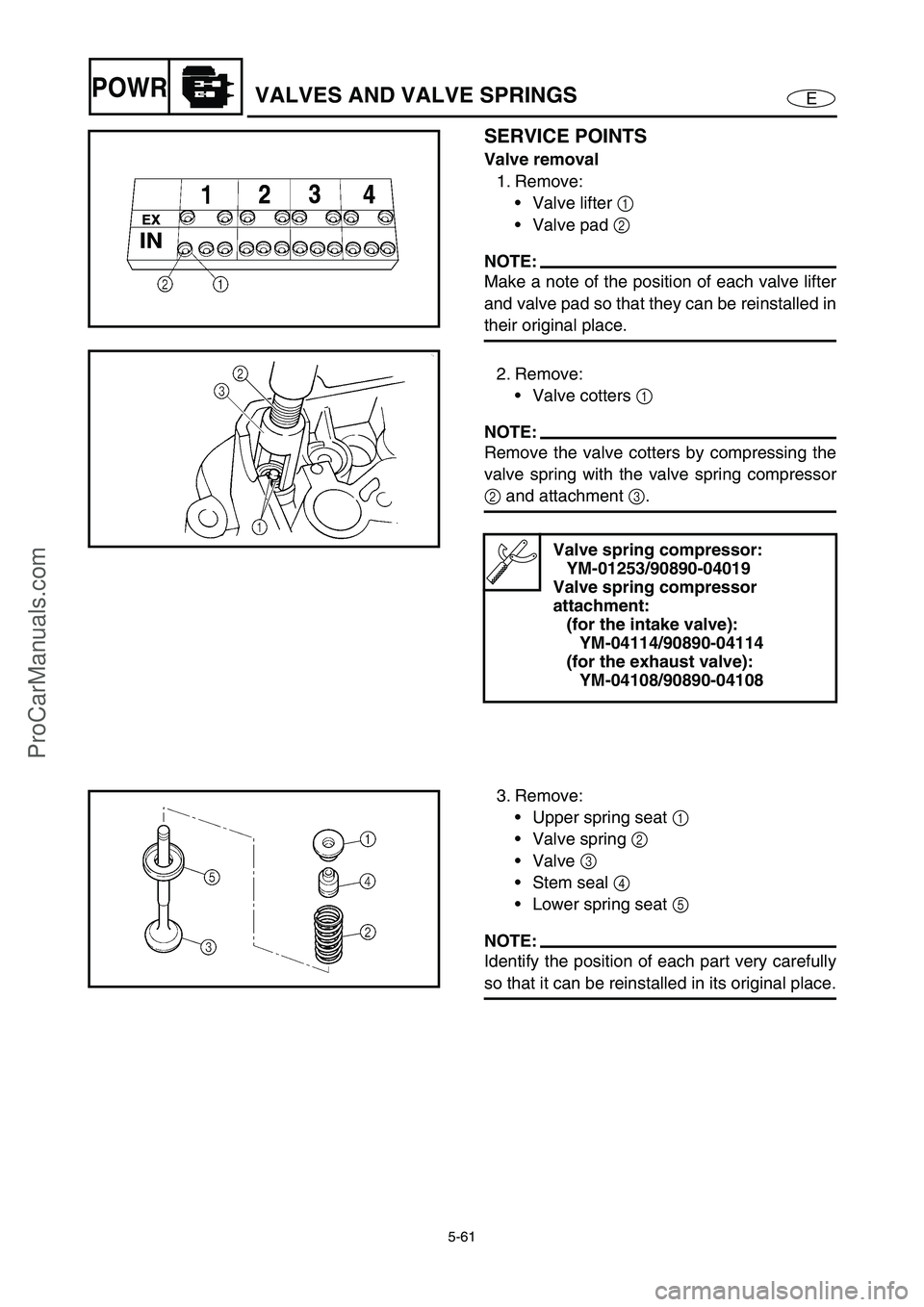

SERVICE POINTS

Valve removal

1. Remove:

Valve lifter 1

Valve pad 2

NOTE:

Make a note of the position of each valve lifter

and valve pad so that they can be reinstalled in

their original place.

2. Remove:

Valve cotters 1

NOTE:

Remove the valve cotters by compressing the

valve spring with the valve spring compressor

2

and attachment 3

.

Valve spring compressor:

YM-01253/90890-04019

Valve spring compressor

attachment:

(for the intake valve):

YM-04114/90890-04114

(for the exhaust valve):

YM-04108/90890-04108

3. Remove:

Upper spring seat 1

Valve spring 2

Valve 3

Stem seal 4

Lower spring seat 5

NOTE:

Identify the position of each part very carefully

so that it can be reinstalled in its original place.

ProCarManuals.com

Trending: wheel torque, recommended oil, lock, length, oil temperature, fuel tank capacity, fuse diagram