YAMAHA VX110 2005 Service Manual

Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 191 of 347

5-92

EPOWRCONNECTING RODS AND PISTONS

9. Tighten:

Connecting rod nuts

WARNING

Replace the connecting rod bolts and

nuts with new ones.

Clean the connecting rod bolts and nuts.

NOTE:

The tightening procedure of the connecting rod

nuts is angle controlled, therefore tighten the

nuts using the following procedure.

Tightening steps:

Tighten the connecting rod nuts to the

specified torque.

T R..

Connecting rod nut:

1st:

20 N m (2.0 kgf m, 14 ft lb)

Tighten the connecting rod nuts further to

reach the specified angle 120°.

T R..

Connecting rod nut:

Final:

Specified angle 120

± 5°

WARNING

When the nuts are tightened more than

the specified angle, do not loosen the

nut and then retighten it.

Replace the bolt and nut with a new one

and perform the procedure again.

CAUTION:

Do not use a torque wrench to tighten

the nut to the specified angle.

Tighten the nut until it is at the speci-

fied angle.

NOTE:

When using a hexagonal nut, note that the

angle from one corner to another is 60°.

ProCarManuals.com

Page 192 of 347

5-93

EPOWRCRANKSHAFT

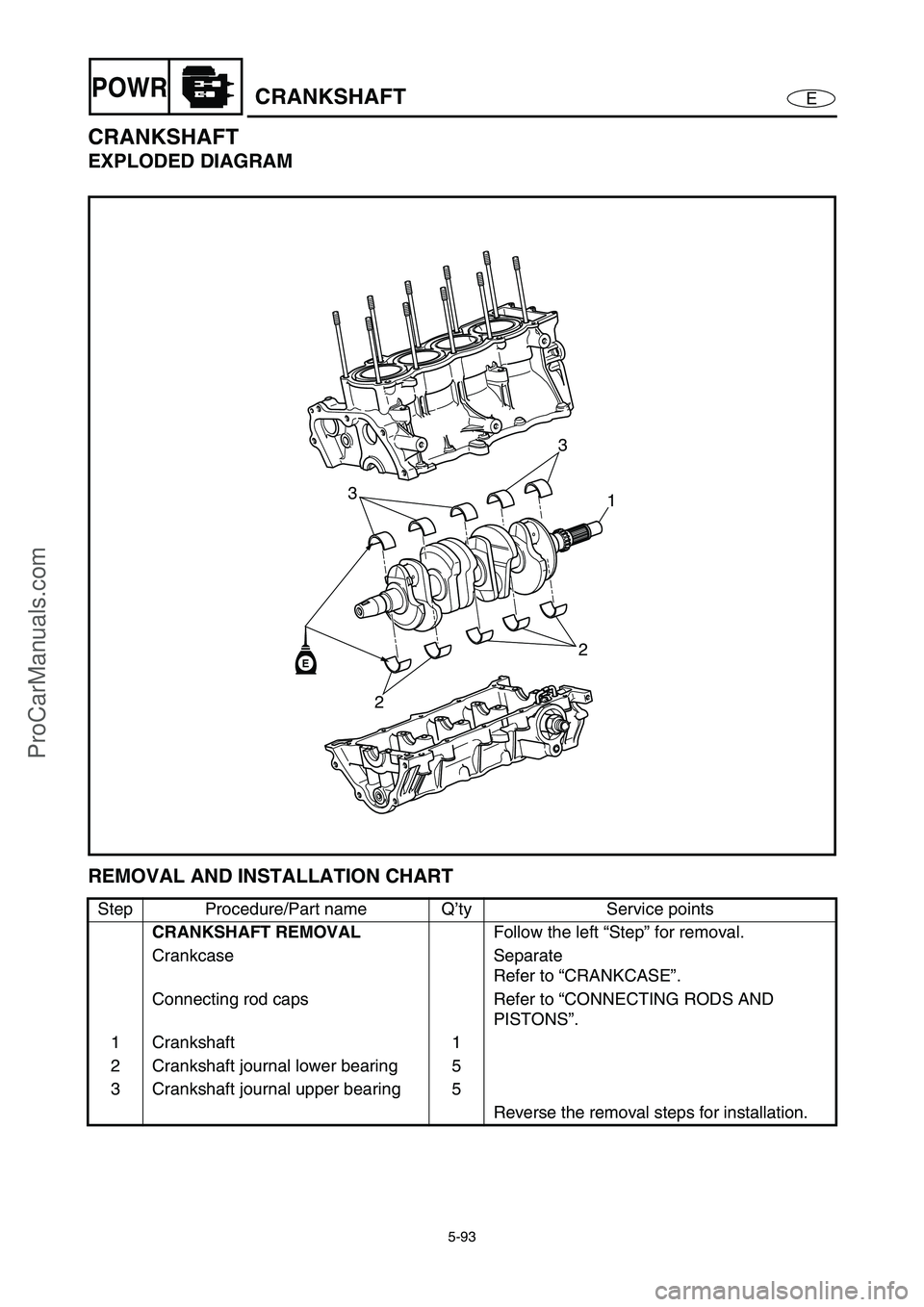

CRANKSHAFT

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

CRANKSHAFT REMOVAL

Follow the left “Step” for removal.

Crankcase Separate

Refer to “CRANKCASE”.

Connecting rod caps Refer to “CONNECTING RODS AND

PISTONS”.

1 Crankshaft 1

2 Crankshaft journal lower bearing 5

3 Crankshaft journal upper bearing 5

Reverse the removal steps for installation.

2

21 33E

ProCarManuals.com

Page 193 of 347

5-94

EPOWRCRANKSHAFT

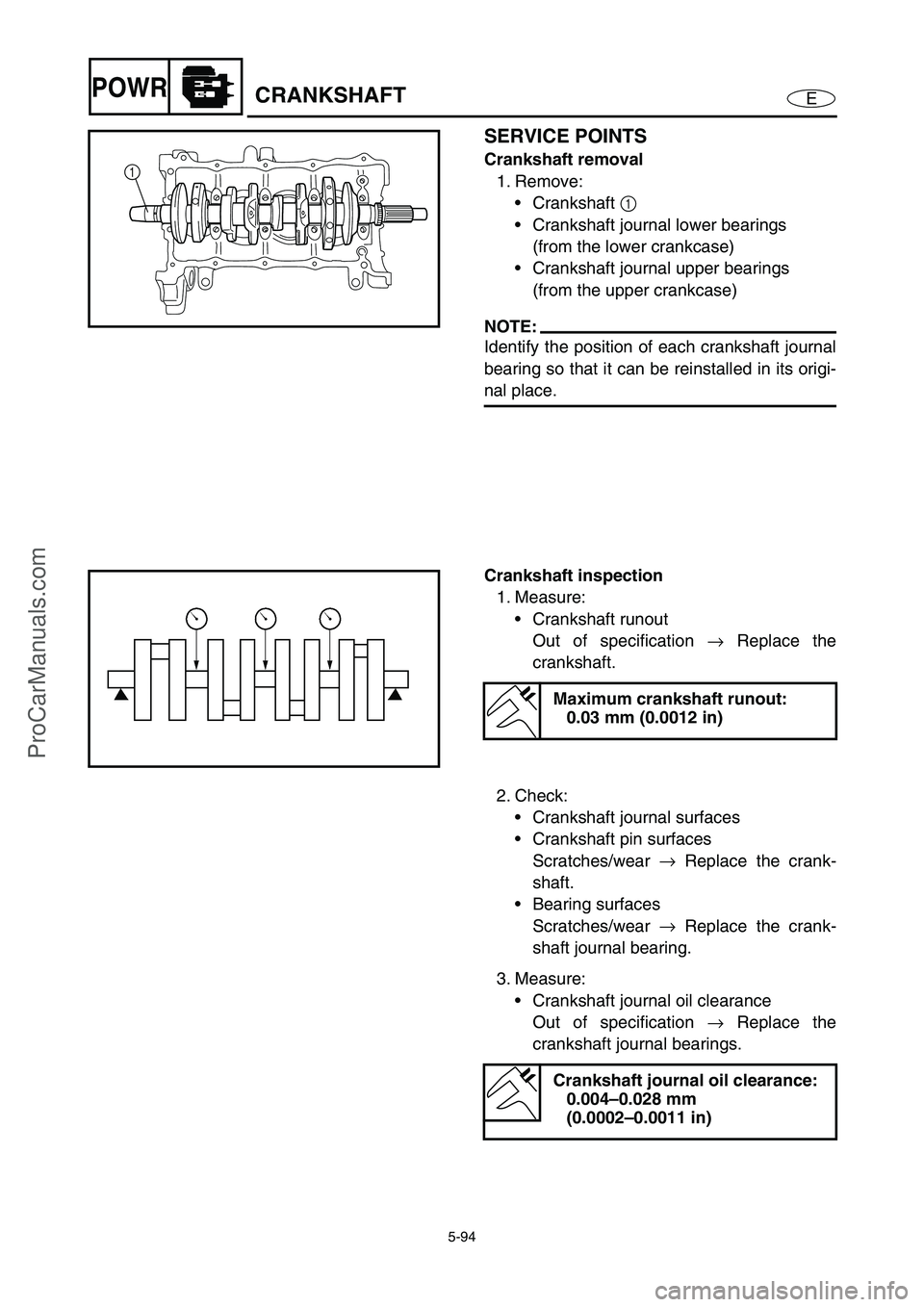

SERVICE POINTS

Crankshaft removal

1. Remove:

Crankshaft 1

Crankshaft journal lower bearings

(from the lower crankcase)

Crankshaft journal upper bearings

(from the upper crankcase)

NOTE:

Identify the position of each crankshaft journal

bearing so that it can be reinstalled in its origi-

nal place.

1

Crankshaft inspection

1. Measure:

Crankshaft runout

Out of specification →

Replace the

crankshaft.

Maximum crankshaft runout:

0.03 mm (0.0012 in)

2. Check:

Crankshaft journal surfaces

Crankshaft pin surfaces

Scratches/wear →

Replace the crank-

shaft.

Bearing surfaces

Scratches/wear →

Replace the crank-

shaft journal bearing.

3. Measure:

Crankshaft journal oil clearance

Out of specification →

Replace the

crankshaft journal bearings.

Crankshaft journal oil clearance:

0.004–0.028 mm

(0.0002–0.0011 in)

ProCarManuals.com

Page 194 of 347

5-95

EPOWRCRANKSHAFT

CAUTION:

Do not interchange the crankshaft journal

bearings. To obtain the correct crankshaft

journal oil clearance and prevent engine

damage, the crankshaft journal bearings

must be installed in their original positions.

Measurement steps:

Clean the crankshaft journal bearings,

crankshaft journals, and bearing portions

of the crankcase.

Place the upper crankcase upside down

on a bench.

Install the crankshaft journal upper bear-

ings 1

and the crankshaft into the upper

crankcase.

NOTE:

Align the projections a

of the crankshaft

journal upper bearings with the notches b

in the upper crankcase.

Put a piece of Plastigauge 2

on each

crankshaft journal.

NOTE:

Do not put the Plastigauge over the oil hole

in the crankshaft journal.

Install the crankshaft journal lower bear-

ings into the lower crankcase and assem-

ble the crankcase halves.

NOTE:

Align the projections a

of the crankshaft

journal lower bearings with the notches b

in the lower crankcase.

Do not move the crankshaft until the

clearance measurement has been com-

pleted.

1

a

b

2

ProCarManuals.com

Page 195 of 347

5-96

EPOWRCRANKSHAFT

Tighten the bolts to specification in the

order of the numbers on the crankcase.

Refer to “Crankcase assembly”—

“CRANKCASE”.

Remove the lower crankcase and the

crankshaft journal lower bearings.

Measure the compressed Plastigauge

width c

on each crankshaft journal.

If the crankshaft journal oil clearance is

out of specification, select replacement

crankshaft journal bearings.

c

4. Select:

Crankshaft journal bearings (J

1–J5)

NOTE:

The numbers stamped into the crankshaft

web and the numbers stamped into the lower

crankcase are used to determine the

replacement crankshaft journal bearing

sizes.

“J

1–J5” refer to the bearings shown in the

crankshaft illustration.

If “J

1–J5” are the same, use the same size

for all of the bearings.

For example, if the crankcase “J

1” and crank-

shaft web “J

1” numbers are “8” and “2” respec-

tively, then the bearing size for “J

1” is:

Bearing size of J

1:

“J

1” (crankcase) – “J1” (crankshaft web)

– 1

8 – 2 – 1 = 5 (Red/black)

BEARING COLOR CODE

3 Red/red

4Red/brown

5 Red/black

6 Red/blue

7Red/green

J5J4J3J2J1

J1J2J3J4J5

J5J4J3J2J1

ProCarManuals.com

Page 196 of 347

5-97

EPOWRCRANKSHAFT

Crankshaft installation

1. Install:

Crankshaft journal upper bearings

(into the upper crankcase)

Crankshaft journal lower bearings

(into the lower crankcase)

NOTE:

Align the projections a

on the crankshaft

journal upper bearings with the notches b

in

the upper crankcase.

Be sure to install each crankshaft journal

bearing in its original place.

a

b

2. Lubricate:

Crankshaft journals

Crankshaft journal bearings

(with the recommended lubricant)

Recommended lubricant:

Engine oil

ProCarManuals.com

Page 197 of 347

5-98

EPOWRCOOLING WATER HOSE

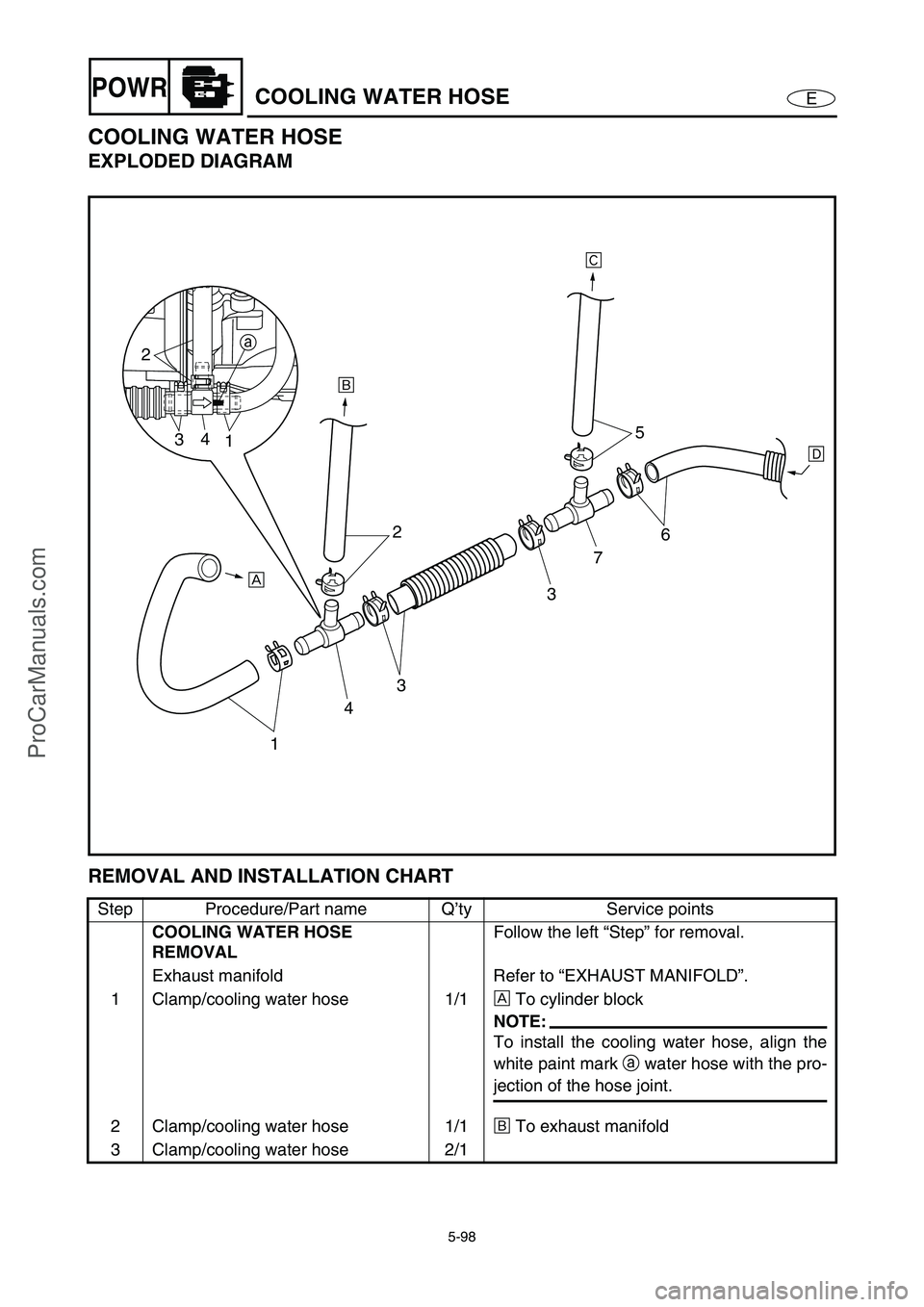

COOLING WATER HOSE

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

COOLING WATER HOSE

REMOVALFollow the left “Step” for removal.

Exhaust manifold Refer to “EXHAUST MANIFOLD”.

1 Clamp/cooling water hose 1/1È

To cylinder block

NOTE:

To install the cooling water hose, align the

white paint mark a

water hose with the pro-

jection of the hose joint.

2 Clamp/cooling water hose 1/1É

To exhaust manifold

3 Clamp/cooling water hose 2/1

143 2

375

6

ÈÉÊ

Ë

a

2

34

1

ProCarManuals.com

Page 198 of 347

5-99

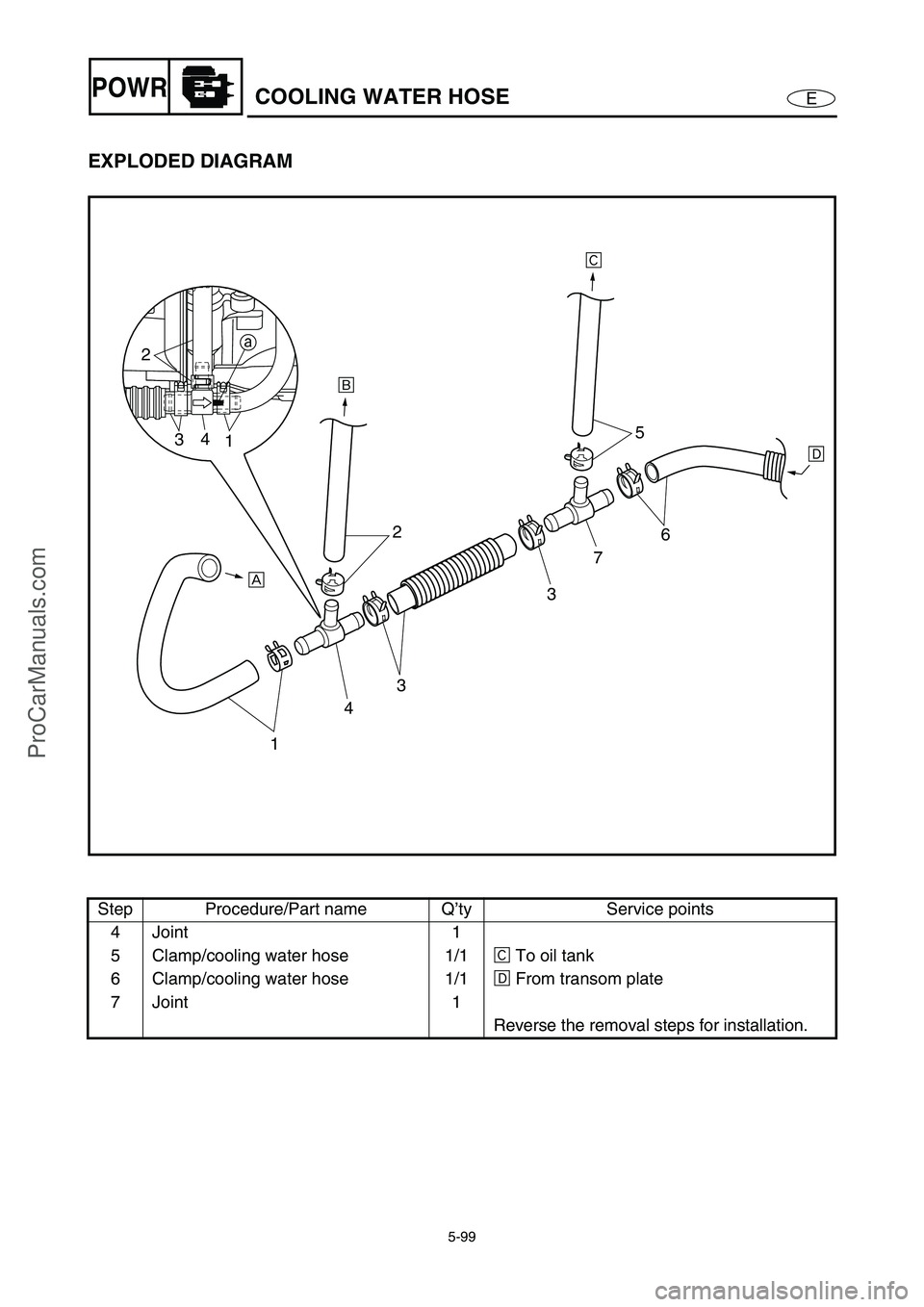

EPOWRCOOLING WATER HOSE

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

4 Joint 1

5 Clamp/cooling water hose 1/1Ê

To oil tank

6 Clamp/cooling water hose 1/1Ë

From transom plate

7 Joint 1

Reverse the removal steps for installation.

143 2

375

6

ÈÉÊ

Ë

a

2

34

1

ProCarManuals.com

Page 199 of 347

E

JET

PUMP

1

2

3

4

5

6

7

8

9

CHAPTER 6

JET PUMP UNIT

INTAKE GRATE AND RIDE PLATE ............................................................... 6-1

EXPLODED DIAGRAM ............................................................................. 6-1

REMOVAL AND INSTALLATION CHART ................................................ 6-1

JET PUMP UNIT .............................................................................................. 6-3

EXPLODED DIAGRAM ............................................................................. 6-3

REMOVAL AND INSTALLATION CHART ................................................ 6-3

REVERSE GATE (DELUXE MODEL ONLY) .................................................. 6-5

EXPLODED DIAGRAM ............................................................................. 6-5

REMOVAL AND INSTALLATION CHART ................................................ 6-5

JET THRUST NOZZLE, IMPELLER DUCT, AND

IMPELLER HOUSING 1 ................................................................................. 6-6

EXPLODED DIAGRAM ............................................................................. 6-6

REMOVAL AND INSTALLATION CHART ................................................ 6-6

IMPELLER DUCT AND DRIVE SHAFT .......................................................... 6-8

EXPLODED DIAGRAM ............................................................................. 6-8

REMOVAL AND INSTALLATION CHART ................................................ 6-8

SERVICE POINTS .................................................................................. 6-10

Drive shaft removal ........................................................................... 6-10

Impeller inspection ............................................................................ 6-11

Drive shaft inspection ........................................................................ 6-11

Drive shaft installation ....................................................................... 6-12

TRANSOM PLATE AND HOSES .................................................................. 6-15

EXPLODED DIAGRAM ........................................................................... 6-15

REMOVAL AND INSTALLATION CHART .............................................. 6-15

SERVICE POINTS .................................................................................. 6-17

Bilge strainer inspection .................................................................... 6-17

Bilge hose inspection ........................................................................ 6-17

Cooling water hose inspection .......................................................... 6-17

BEARING HOUSING ..................................................................................... 6-18

EXPLODED DIAGRAM ........................................................................... 6-18

REMOVAL AND INSTALLATION CHART .............................................. 6-18

SERVICE POINTS .................................................................................. 6-21

Driven coupling removal and installation........................................... 6-21

Intermediate drive shaft removal ....................................................... 6-21

Bearing removal ................................................................................ 6-22

Bearing and intermediate drive shaft inspection ............................... 6-22

Driven coupling inspection ................................................................ 6-22

Bearing and oil seals installation ....................................................... 6-23

Intermediate drive shaft installation................................................... 6-24

ProCarManuals.com

Page 200 of 347

6-1

E

JET

PUMP

INTAKE GRATE AND RIDE PLATE

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

INTAKE GRATE, RIDE PLATE,

AND INTAKE DUCT REMOVALFollow the left “Step” for removal.

1Bolt 2

2Bolt 2

3 Intake grate 1

4Screw 4

5 Speed sensor 1

NOTE:

Route the speed sensor lead between the

jet pump unit and the bilge hose.

INTAKE GRATE AND RIDE PLATE

ProCarManuals.com