YAMAHA VX110 2005 Service Manual

VX110 2005

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/57494/w960_57494-0.png

YAMAHA VX110 2005 Service Manual

Trending: fuses, fuel cap, fuel type, fuel consumption, service indicator, transmission oil, ECU

Page 211 of 347

6-12

E

JET

PUMPIMPELLER DUCT AND DRIVE SHAFT

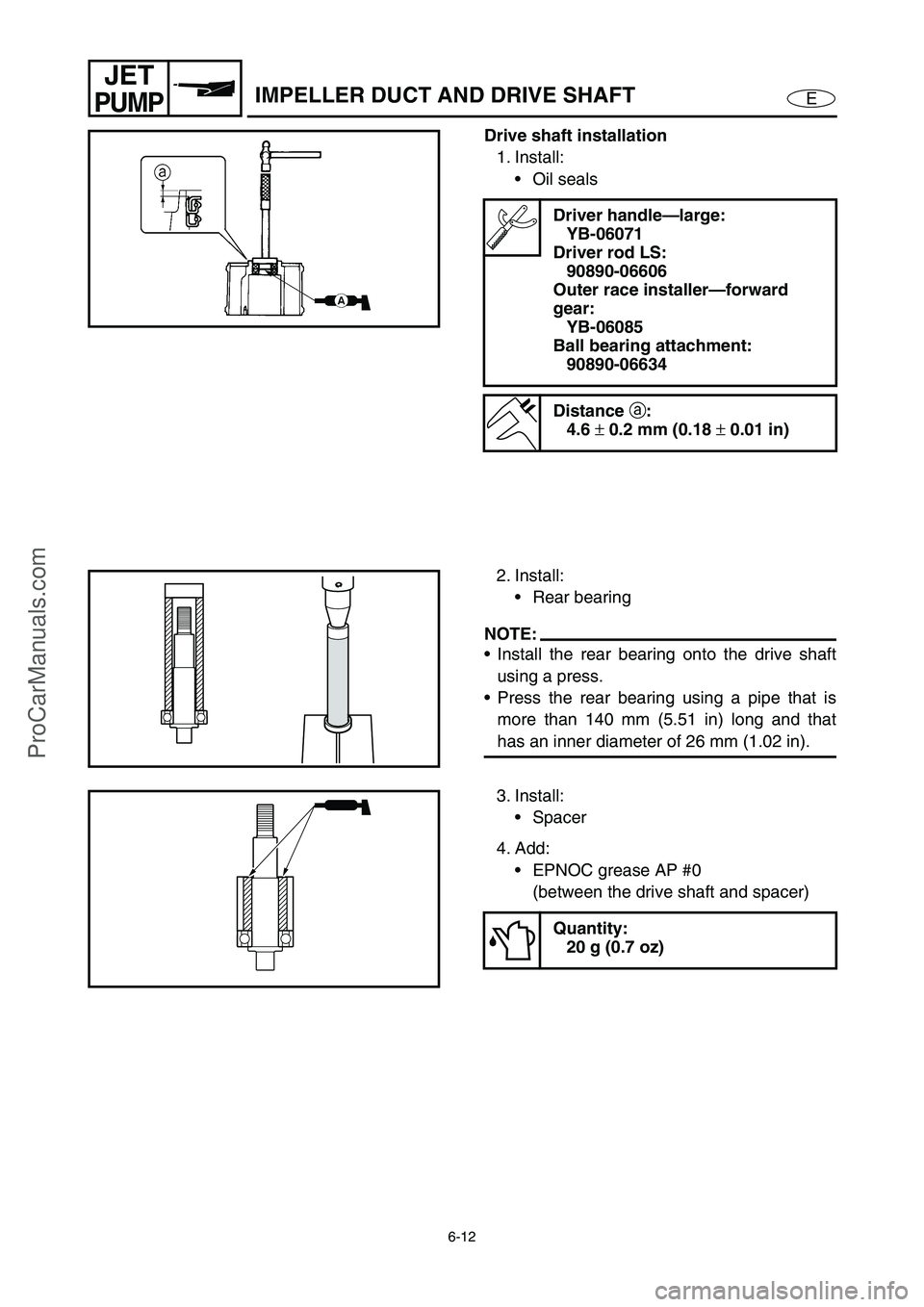

Drive shaft installation

1. Install:

Oil seals

Driver handle—large:

YB-06071

Driver rod LS:

90890-06606

Outer race installer—forward

gear:

YB-06085

Ball bearing attachment:

90890-06634

Distance

a:

4.6

± 0.2 mm (0.18

± 0.01 in)

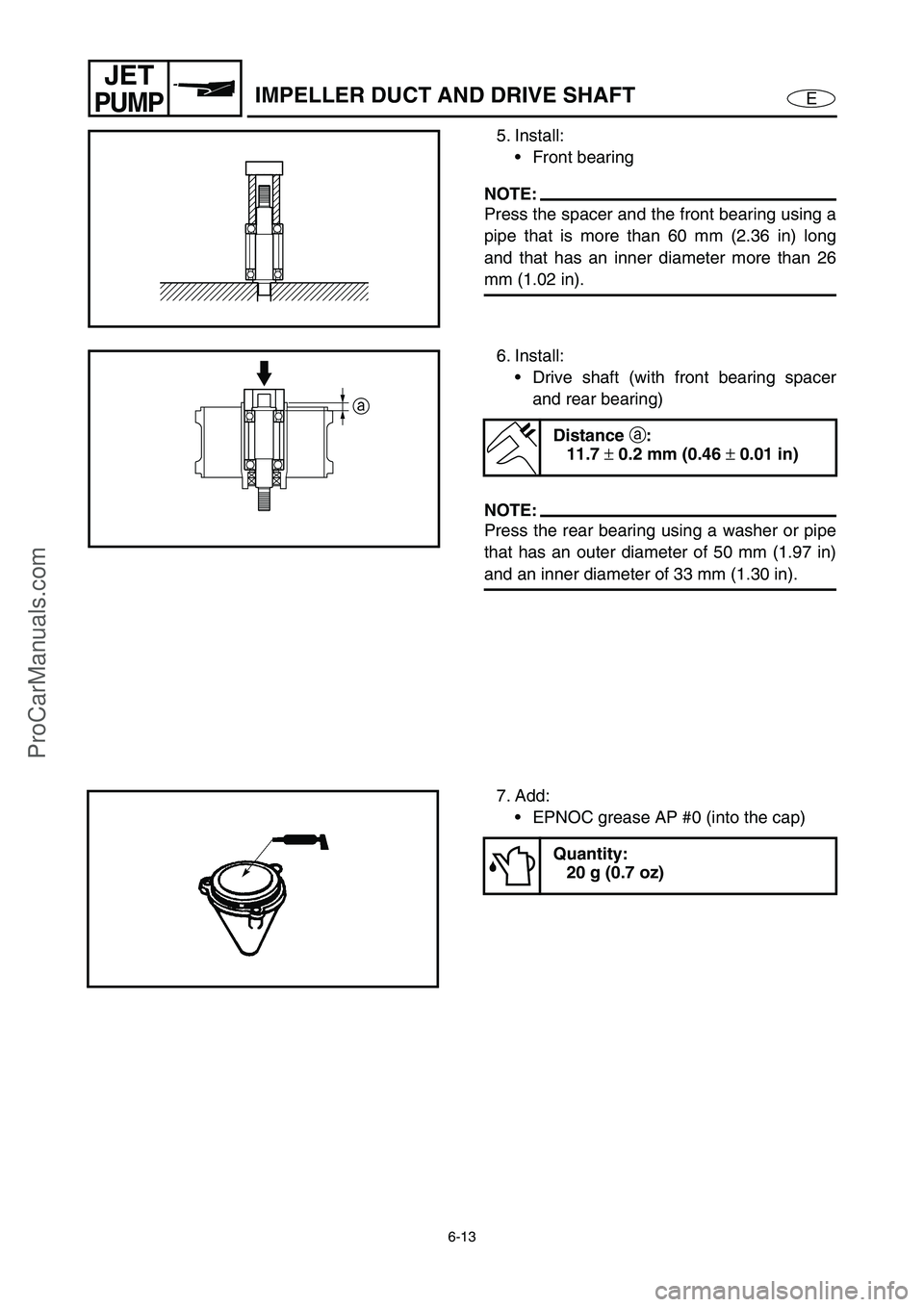

2. Install:

Rear bearing

NOTE:

Install the rear bearing onto the drive shaft

using a press.

Press the rear bearing using a pipe that is

more than 140 mm (5.51 in) long and that

has an inner diameter of 26 mm (1.02 in).

3. Install:

Spacer

4. Add:

EPNOC grease AP #0

(between the drive shaft and spacer)

Quantity:

20 g (0.7 oz)

ProCarManuals.com

Page 212 of 347

6-13

E

JET

PUMPIMPELLER DUCT AND DRIVE SHAFT

5. Install:

Front bearing

NOTE:

Press the spacer and the front bearing using a

pipe that is more than 60 mm (2.36 in) long

and that has an inner diameter more than 26

mm (1.02 in).

6. Install:

Drive shaft (with front bearing spacer

and rear bearing)

NOTE:

Press the rear bearing using a washer or pipe

that has an outer diameter of 50 mm (1.97 in)

and an inner diameter of 33 mm (1.30 in).

Distance

a:

11.7

± 0.2 mm (0.46

± 0.01 in)

a

7. Add:

EPNOC grease AP #0 (into the cap)

Quantity:

20 g (0.7 oz)

ProCarManuals.com

Page 213 of 347

6-14

E

JET

PUMP

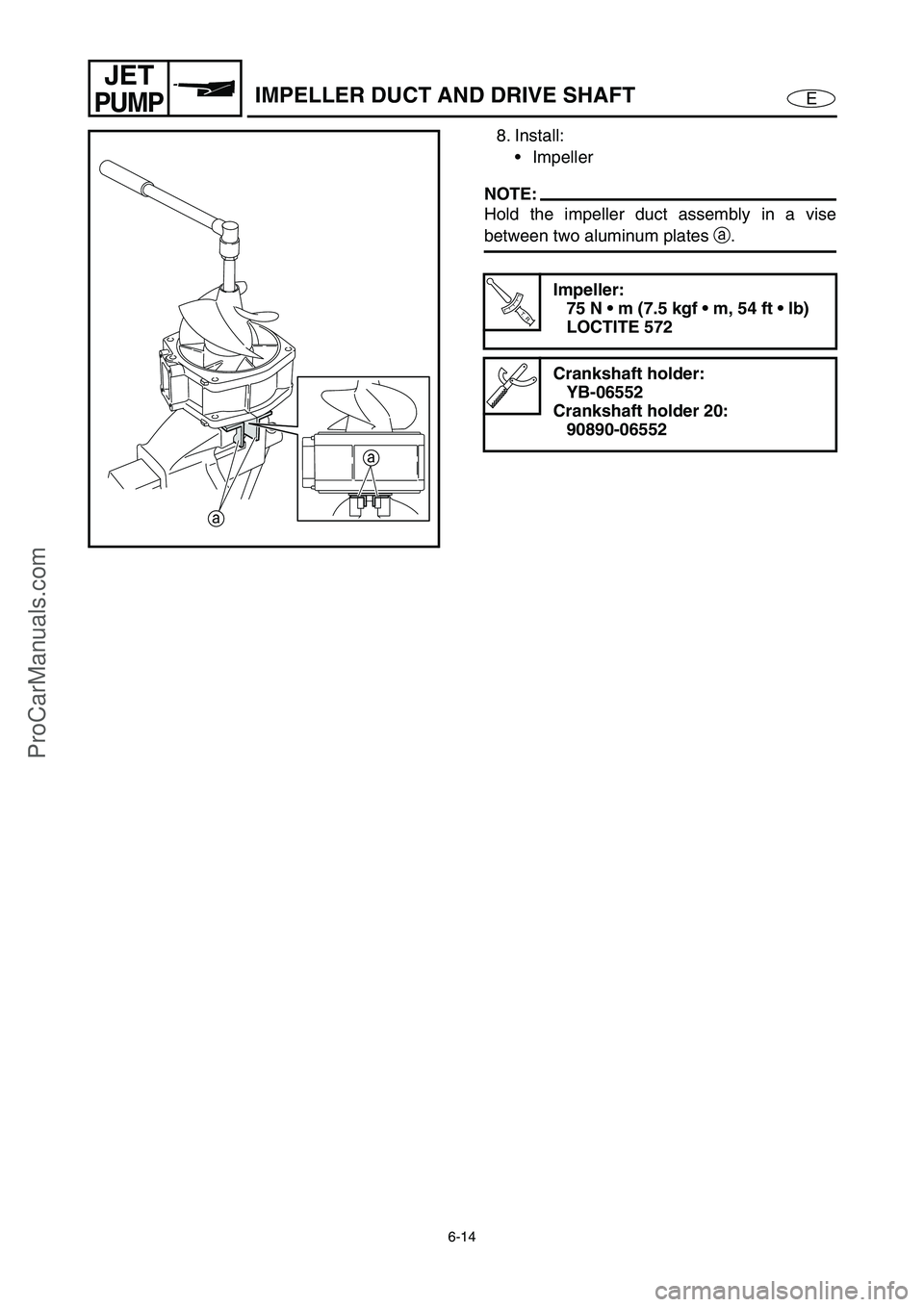

8. Install:

Impeller

NOTE:

Hold the impeller duct assembly in a vise

between two aluminum plates a

.

T R..

Impeller:

75 N m (7.5 kgf m, 54 ft lb)

LOCTITE 572

Crankshaft holder:

YB-06552

Crankshaft holder 20:

90890-06552

a

a

IMPELLER DUCT AND DRIVE SHAFT

ProCarManuals.com

Page 214 of 347

6-15

E

JET

PUMPTRANSOM PLATE AND HOSES

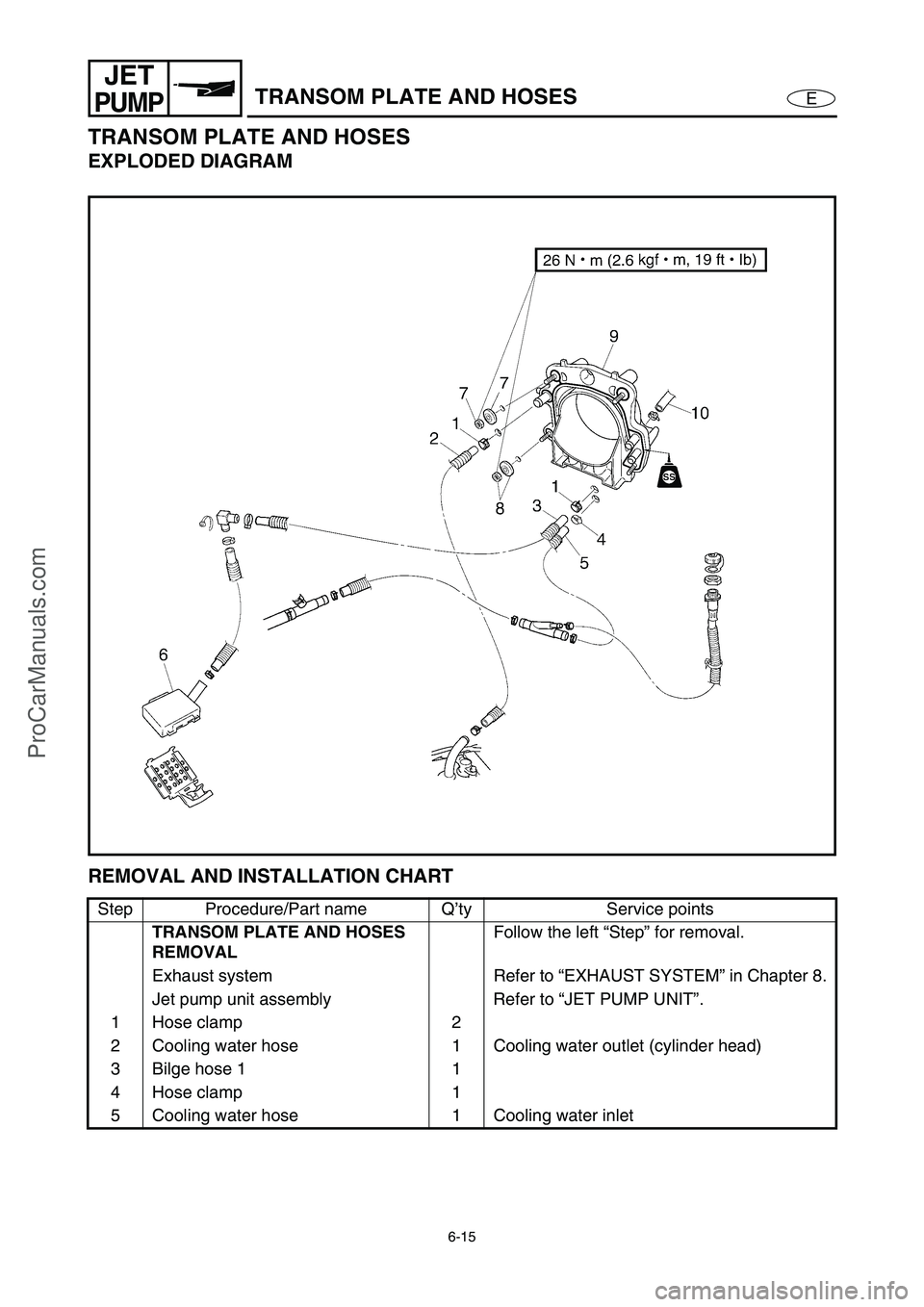

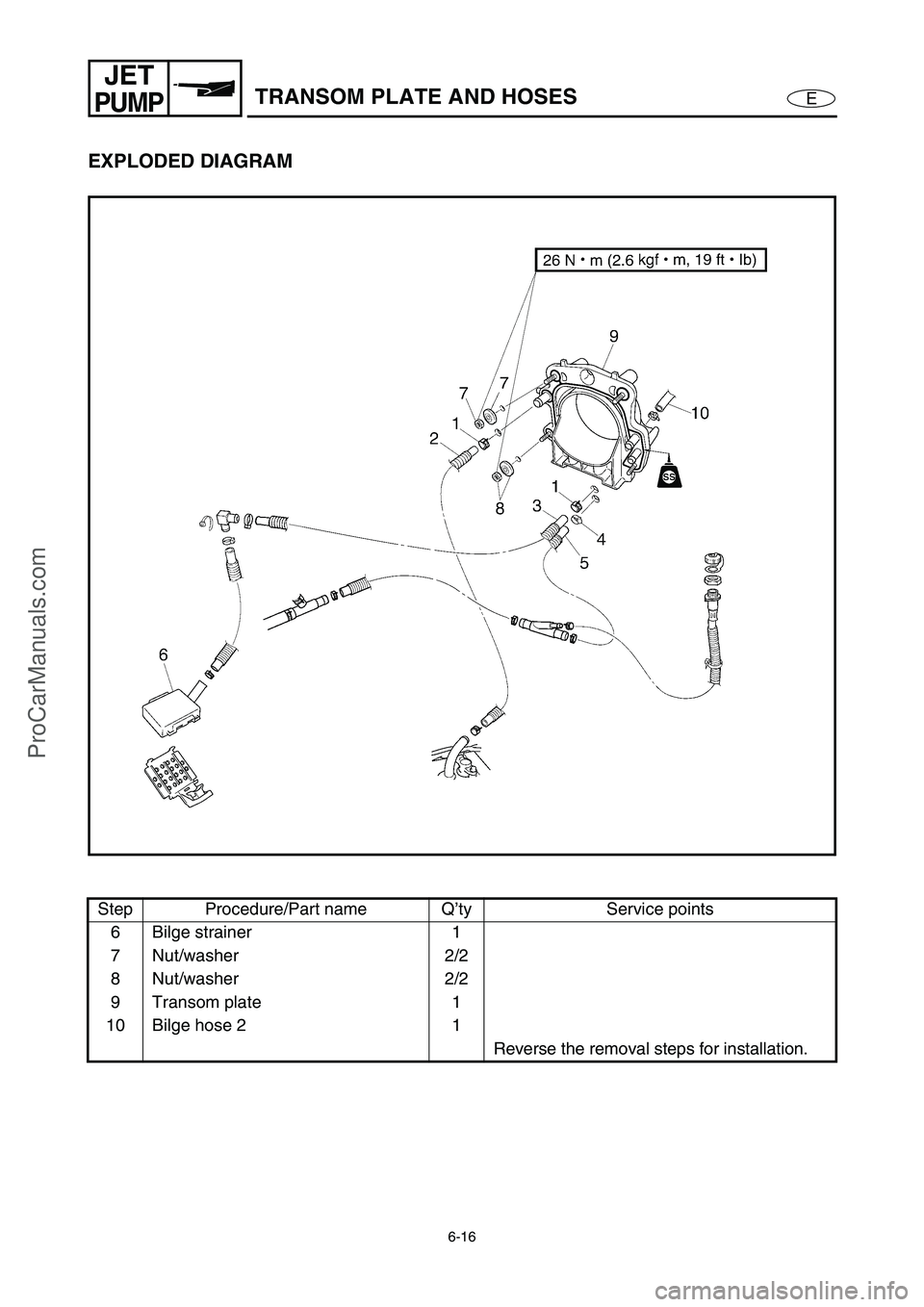

TRANSOM PLATE AND HOSES

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

TRANSOM PLATE AND HOSES

REMOVALFollow the left “Step” for removal.

Exhaust system Refer to “EXHAUST SYSTEM” in Chapter 8.

Jet pump unit assembly Refer to “JET PUMP UNIT”.

1 Hose clamp 2

2 Cooling water hose 1 Cooling water outlet (cylinder head)

3 Bilge hose 1 1

4 Hose clamp 1

5 Cooling water hose 1 Cooling water inlet

ProCarManuals.com

Page 215 of 347

6-16

E

JET

PUMPTRANSOM PLATE AND HOSES

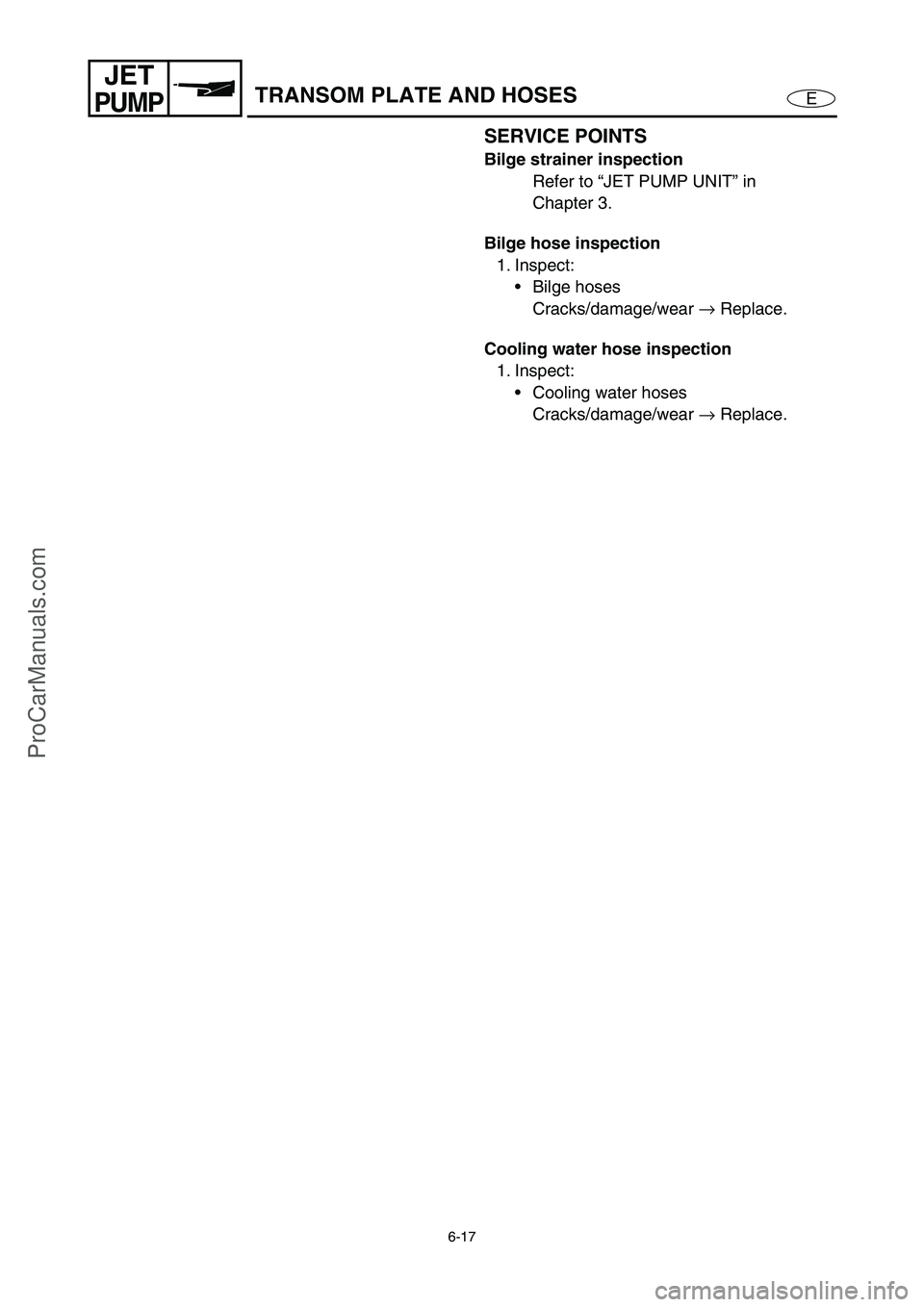

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

6 Bilge strainer 1

7 Nut/washer 2/2

8 Nut/washer 2/2

9 Transom plate 1

10 Bilge hose 2 1

Reverse the removal steps for installation.

ProCarManuals.com

Page 216 of 347

6-17

E

JET

PUMPTRANSOM PLATE AND HOSES

SERVICE POINTS

Bilge strainer inspection

Refer to “JET PUMP UNIT” in

Chapter 3.

Bilge hose inspection

1. Inspect:

Bilge hoses

Cracks/damage/wear →

Replace.

Cooling water hose inspection

1. Inspect:

Cooling water hoses

Cracks/damage/wear →

Replace.

ProCarManuals.com

Page 217 of 347

6-18

E

JET

PUMPBEARING HOUSING

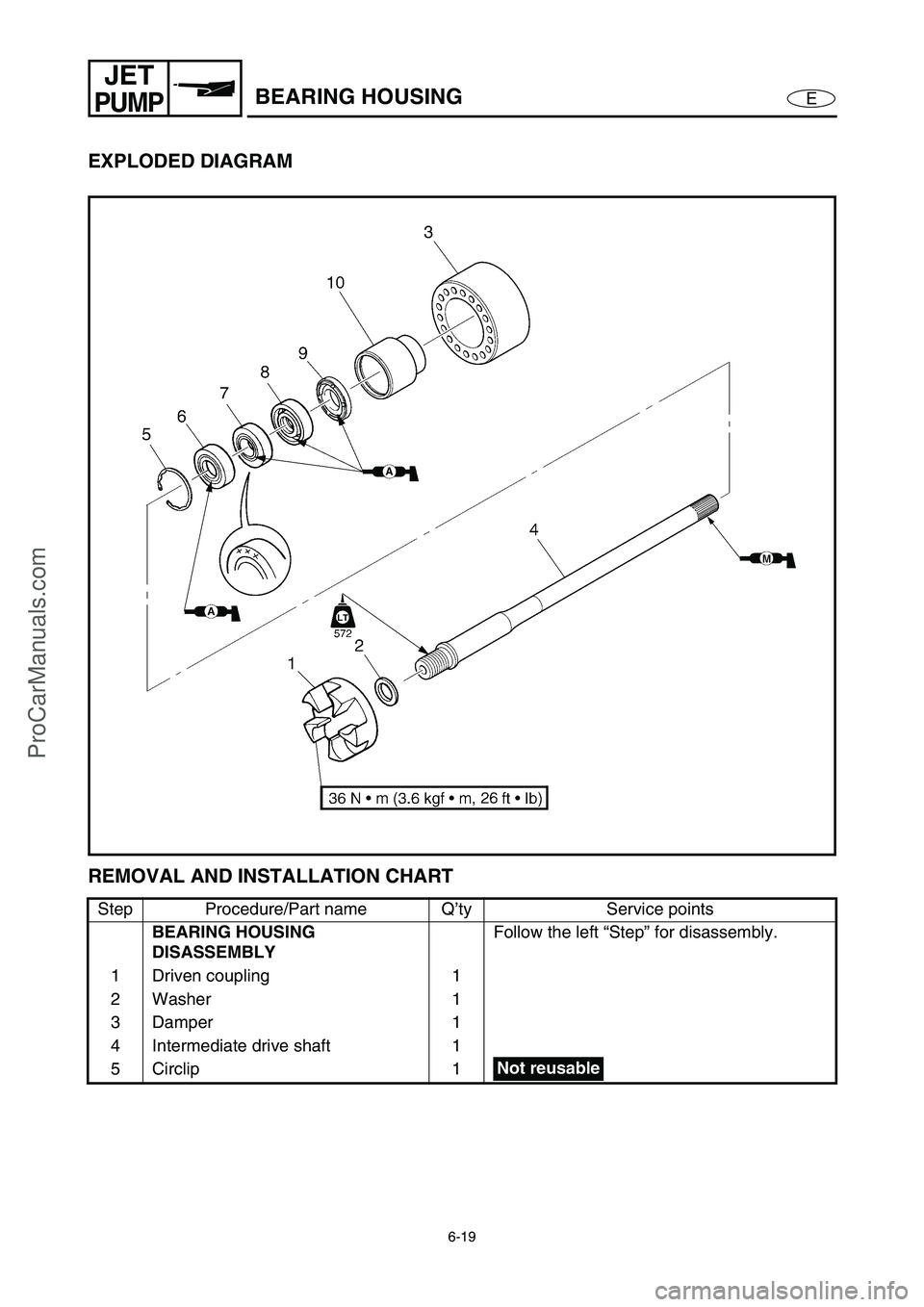

BEARING HOUSING

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

BEARING HOUSING REMOVAL

Follow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT” in Chapter 5.

1 Rubber coupling 1

2Bolt 4

3 Intermediate housing cover 1

4Clamp 2

5 Intermediate drive shaft assembly 1

6 Rubber hose 1

Reverse the removal steps for installation.

2

346

5

1

LT

271

8 × 48 mm

17 N • m (1.7 kgf • m, 12 ft • Ib)

4.2 N • m (0.42 kgf • m, 3.0 ft • Ib)

ProCarManuals.com

Page 218 of 347

6-19

E

JET

PUMPBEARING HOUSING

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

BEARING HOUSING

DISASSEMBLYFollow the left “Step” for disassembly.

1 Driven coupling 1

2 Washer 1

3 Damper 1

4 Intermediate drive shaft 1

5 Circlip 1

Not reusable

ProCarManuals.com

Page 219 of 347

6-20

E

JET

PUMPBEARING HOUSING

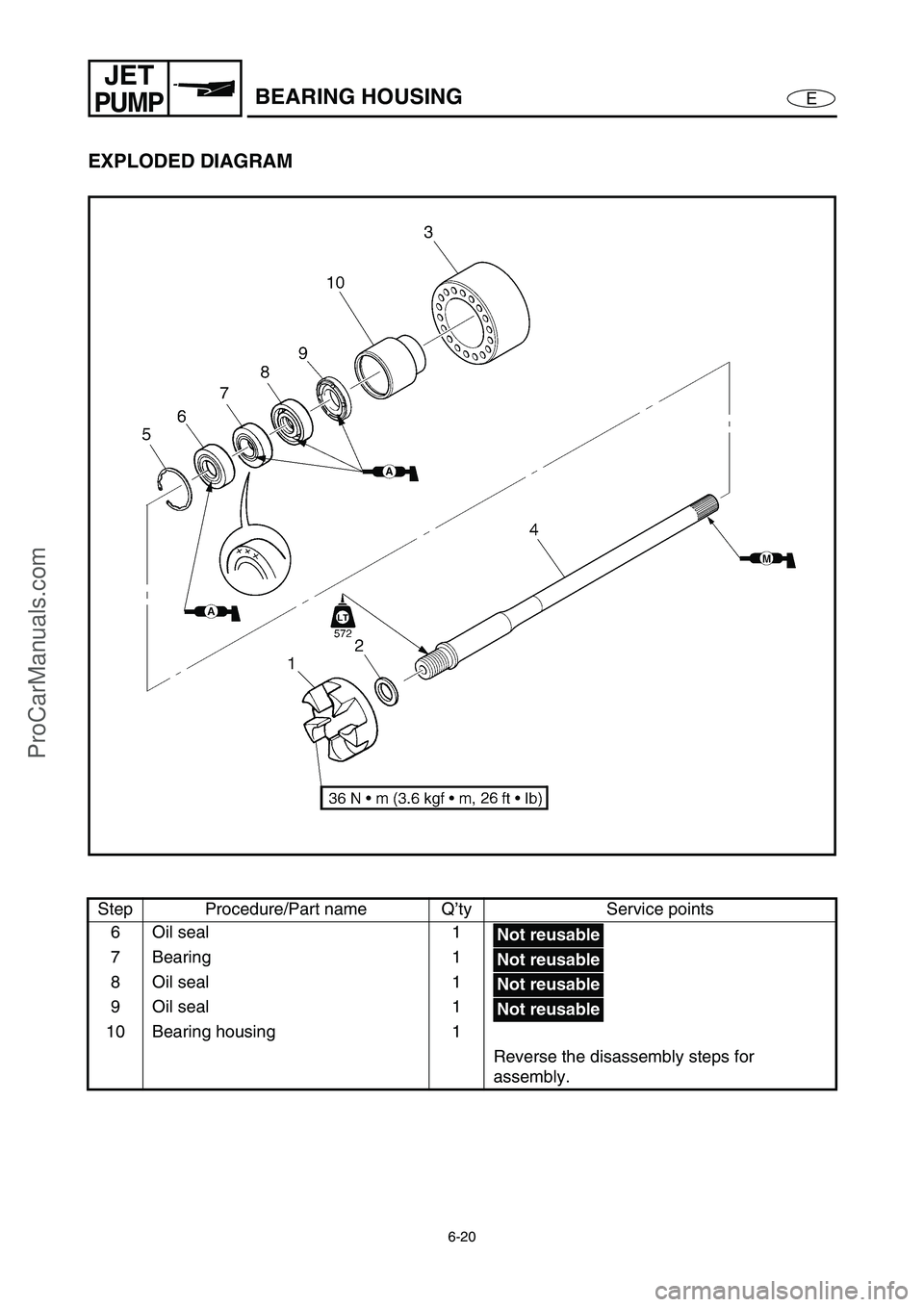

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

6 Oil seal 1

7 Bearing 1

8 Oil seal 1

9 Oil seal 1

10 Bearing housing 1

Reverse the disassembly steps for

assembly.

Not reusable

Not reusable

Not reusable

Not reusable

ProCarManuals.com

Page 220 of 347

6-21

E

JET

PUMPBEARING HOUSING

SERVICE POINTS

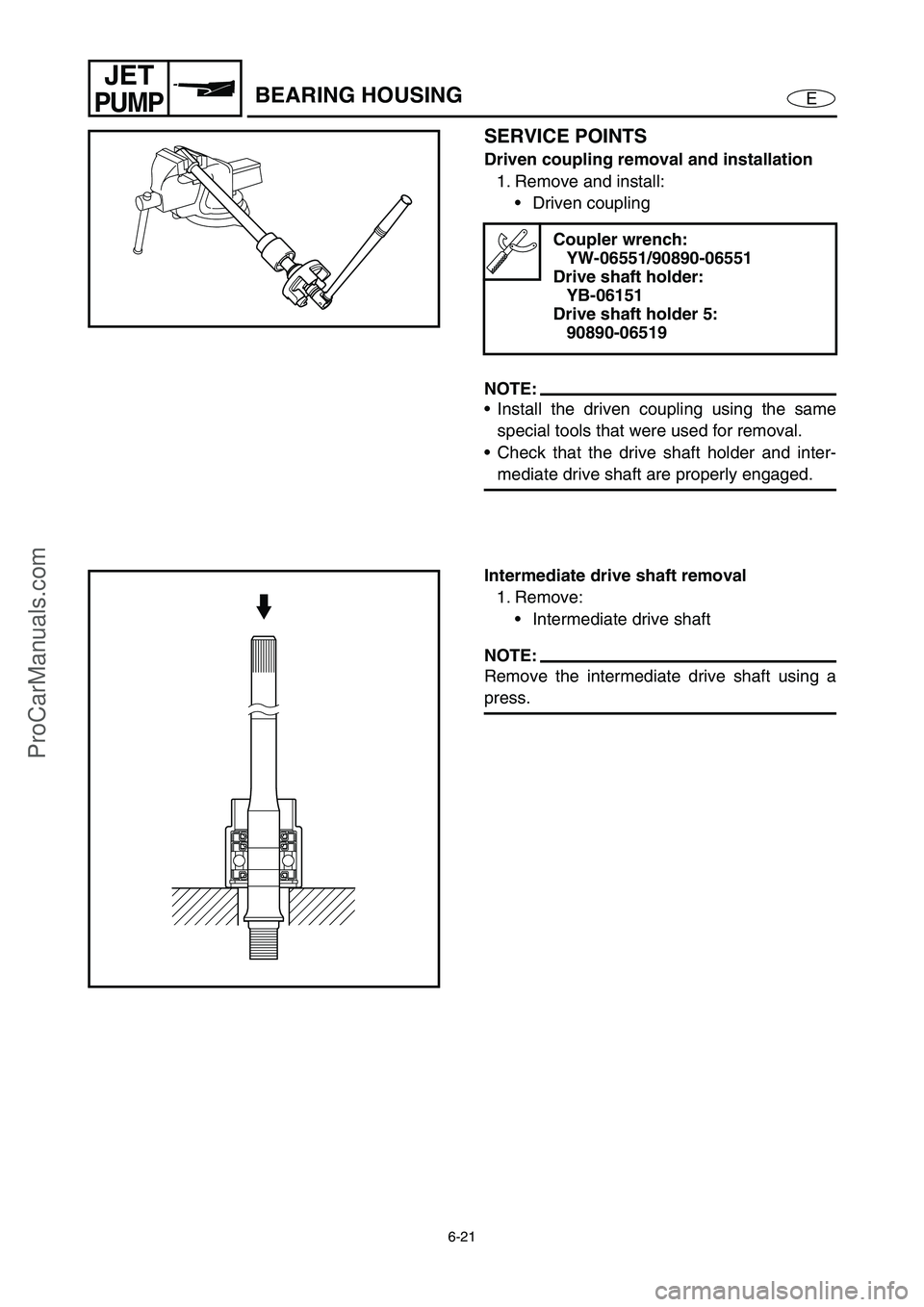

Driven coupling removal and installation

1. Remove and install:

Driven coupling

NOTE:

Install the driven coupling using the same

special tools that were used for removal.

Check that the drive shaft holder and inter-

mediate drive shaft are properly engaged.

Coupler wrench:

YW-06551/90890-06551

Drive shaft holder:

YB-06151

Drive shaft holder 5:

90890-06519

Intermediate drive shaft removal

1. Remove:

Intermediate drive shaft

NOTE:

Remove the intermediate drive shaft using a

press.

ProCarManuals.com

Trending: warning, heating, overheating, dimensions, adding oil, open gas tank, service indicator