YAMAHA XT660Z 2010 Repair Manual

Manufacturer: YAMAHA, Model Year: 2010, Model line: XT660Z, Model: YAMAHA XT660Z 2010Pages: 100, PDF Size: 6.91 MB

Page 61 of 100

1

2

3

4

5

6

7

8

9

10

PERIODIC MAINTENANCE AND ADJUSTMENT

7-19

EAU21940

Spoke wheels

To maximize the performance, durabil-

ity, and safe operation of your motor-

cycle, note the following points regard-

ing the specified wheels.

●The wheel rims should be

checked for cracks, bends or

warpage, and the spokes for

looseness or damage before

each ride. If any damage is found,

have a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.●The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced.

An unbalanced wheel can result

in poor performance, adverse

handling characteristics, and a

shortened tire life.

●Ride at moderate speeds after

changing a tire since the tire sur-

face must first be "broken in" for it

to develop its optimal characteris-

tics.

XT660Z 05-07 ING-AUS:MY03 04-06 ING 11-05-2009 10:09 Pagina 7-19

Page 62 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

7-20

1

2

3

4

5

6

7

8

9

10

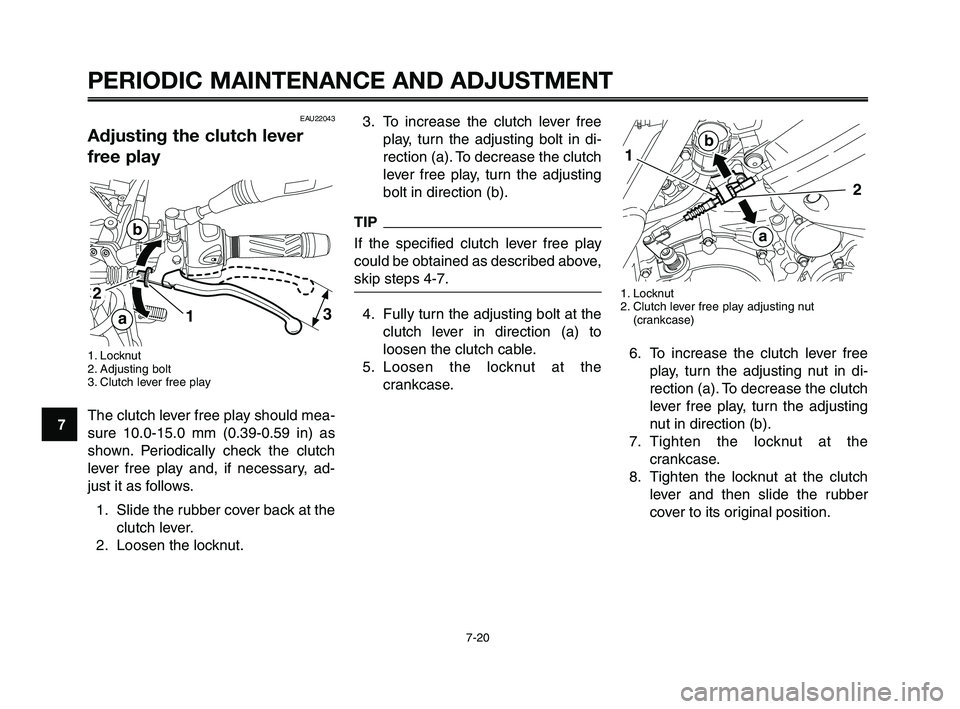

3. To increase the clutch lever free

play, turn the adjusting bolt in di-

rection (a). To decrease the clutch

lever free play, turn the adjusting

bolt in direction (b).

TIP

If the specified clutch lever free play

could be obtained as described above,

skip steps 4-7.

4. Fully turn the adjusting bolt at the

clutch lever in direction (a) to

loosen the clutch cable.

5. Loosen the locknut at the

crankcase.1. Locknut

2. Clutch lever free play adjusting nut

(crankcase)

6. To increase the clutch lever free

play, turn the adjusting nut in di-

rection (a). To decrease the clutch

lever free play, turn the adjusting

nut in direction (b).

7. Tighten the locknut at the

crankcase.

8. Tighten the locknut at the clutch

lever and then slide the rubber

cover to its original position.

1

b

a

2

EAU22043

Adjusting the clutch lever

free play

1. Locknut

2. Adjusting bolt

3. Clutch lever free play

The clutch lever free play should mea-

sure 10.0-15.0 mm (0.39-0.59 in) as

shown. Periodically check the clutch

lever free play and, if necessary, ad-

just it as follows.

1. Slide the rubber cover back at the

clutch lever.

2. Loosen the locknut.

31

2

b

a

XT660Z 05-07 ING-AUS:MY03 04-06 ING 11-05-2009 10:09 Pagina 7-20

Page 63 of 100

1

2

3

4

5

6

7

8

9

10

PERIODIC MAINTENANCE AND ADJUSTMENT

7-21

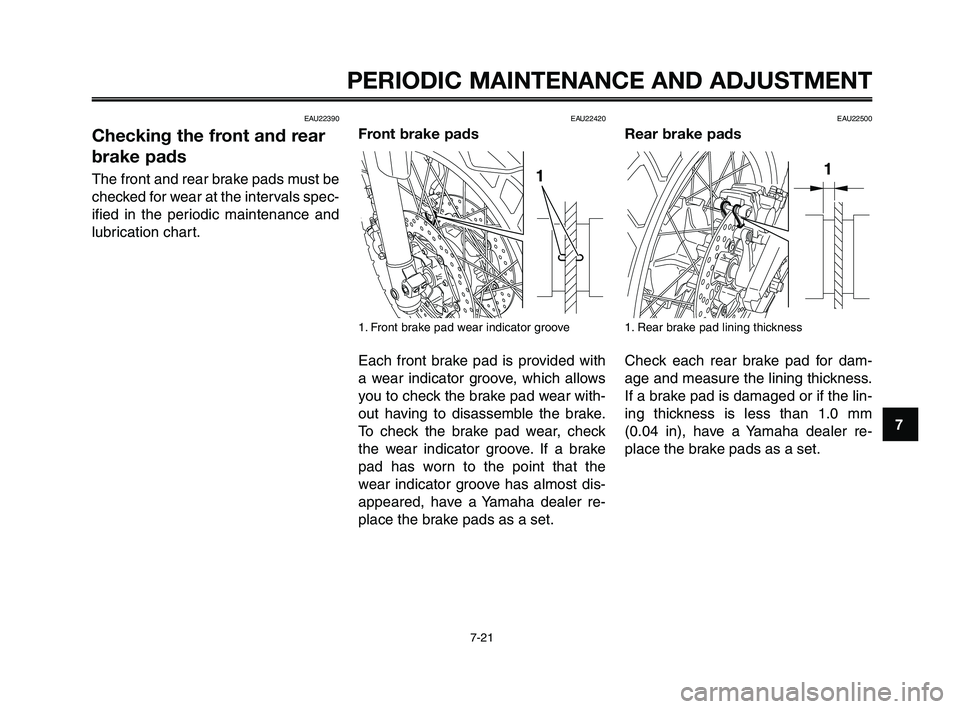

EAU22390

Checking the front and rear

brake pads

The front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU22420

Front brake pads

1. Front brake pad wear indicator groove

Each front brake pad is provided with

a wear indicator groove, which allows

you to check the brake pad wear with-

out having to disassemble the brake.

To check the brake pad wear, check

the wear indicator groove. If a brake

pad has worn to the point that the

wear indicator groove has almost dis-

appeared, have a Yamaha dealer re-

place the brake pads as a set.

EAU22500

Rear brake pads

1. Rear brake pad lining thickness

Check each rear brake pad for dam-

age and measure the lining thickness.

If a brake pad is damaged or if the lin-

ing thickness is less than 1.0 mm

(0.04 in), have a Yamaha dealer re-

place the brake pads as a set.

XT660Z 05-07 ING-AUS:MY03 04-06 ING 11-05-2009 10:09 Pagina 7-21

Page 64 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

7-22

1

2

3

4

5

6

7

8

9

10

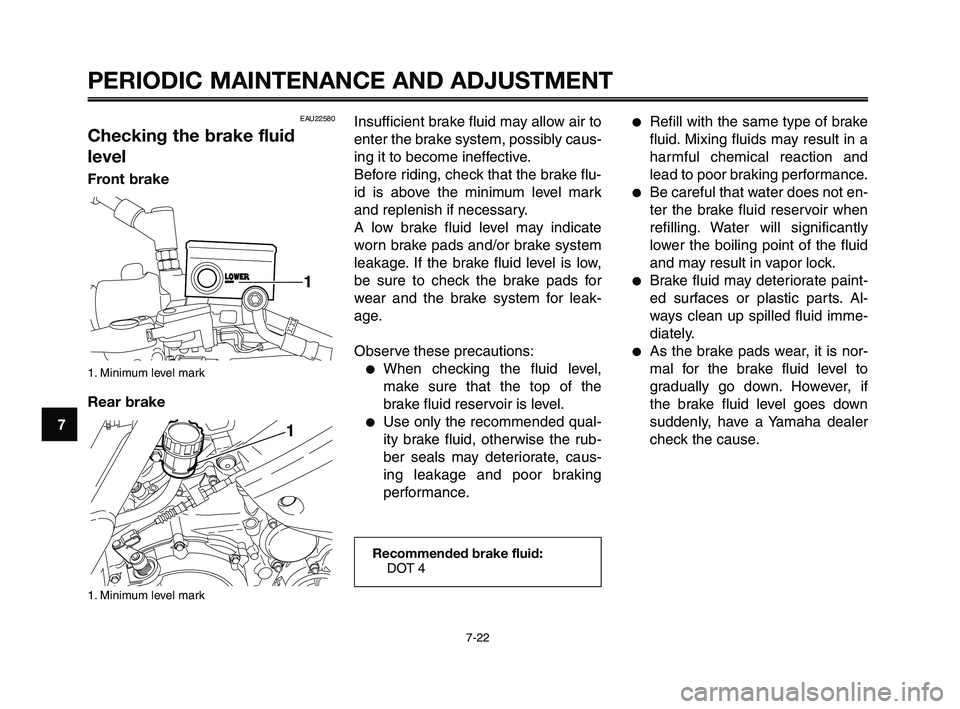

Insufficient brake fluid may allow air to

enter the brake system, possibly caus-

ing it to become ineffective.

Before riding, check that the brake flu-

id is above the minimum level mark

and replenish if necessary.

A low brake fluid level may indicate

worn brake pads and/or brake system

leakage. If the brake fluid level is low,

be sure to check the brake pads for

wear and the brake system for leak-

age.

Observe these precautions:

●When checking the fluid level,

make sure that the top of the

brake fluid reservoir is level.

●Use only the recommended qual-

ity brake fluid, otherwise the rub-

ber seals may deteriorate, caus-

ing leakage and poor braking

performance.

●Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor braking performance.

●Be careful that water does not en-

ter the brake fluid reservoir when

refilling. Water will significantly

lower the boiling point of the fluid

and may result in vapor lock.

●Brake fluid may deteriorate paint-

ed surfaces or plastic parts. Al-

ways clean up spilled fluid imme-

diately.

●As the brake pads wear, it is nor-

mal for the brake fluid level to

gradually go down. However, if

the brake fluid level goes down

suddenly, have a Yamaha dealer

check the cause.

Recommended brake fluid:

DOT 4

EAU22580

Checking the brake fluid

level

Front brake

1. Minimum level mark

Rear brake

1. Minimum level mark

XT660Z 05-07 ING-AUS:MY03 04-06 ING 11-05-2009 10:10 Pagina 7-22

Page 65 of 100

1

2

3

4

5

6

7

8

9

10

PERIODIC MAINTENANCE AND ADJUSTMENT

7-23

EAU22731

Changing the brake fluid

Have a Yamaha dealer change the

brake fluid at the intervals specified in

the TIP after the periodic maintenance

and lubrication chart. In addition, have

the oil seals of the master cylinders

and calipers as well as the brake

hoses replaced at the intervals listed

below or whenever they are damaged

or leaking.

●Oil seals: Replace every two

years.

●Brake hoses: Replace every four

years.

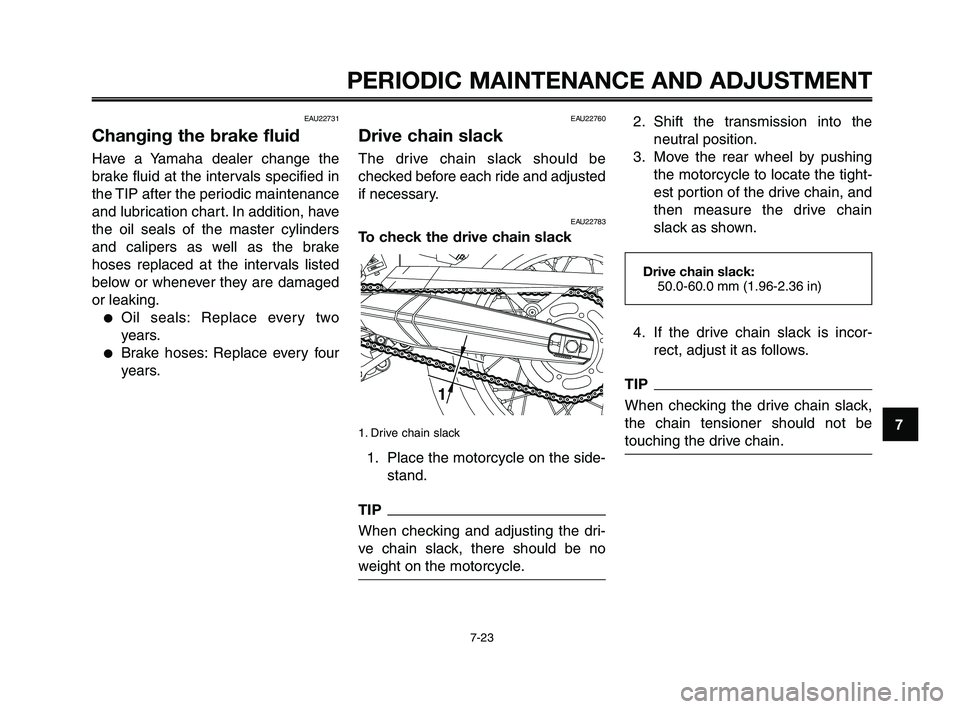

EAU22760

Drive chain slack

The drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22783

To check the drive chain slack

1. Drive chain slack

1. Place the motorcycle on the side-

stand.

TIP

When checking and adjusting the dri-

ve chain slack, there should be no

weight on the motorcycle.

2. Shift the transmission into the

neutral position.

3. Move the rear wheel by pushing

the motorcycle to locate the tight-

est portion of the drive chain, and

then measure the drive chain

slack as shown.

4. If the drive chain slack is incor-

rect, adjust it as follows.

TIP

When checking the drive chain slack,

the chain tensioner should not be

touching the drive chain.

Drive chain slack:

50.0-60.0 mm (1.96-2.36 in)

XT660Z 05-07 ING-AUS:MY03 04-06 ING 11-05-2009 10:10 Pagina 7-23

Page 66 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

7-24

1

2

3

4

5

6

7

8

9

10

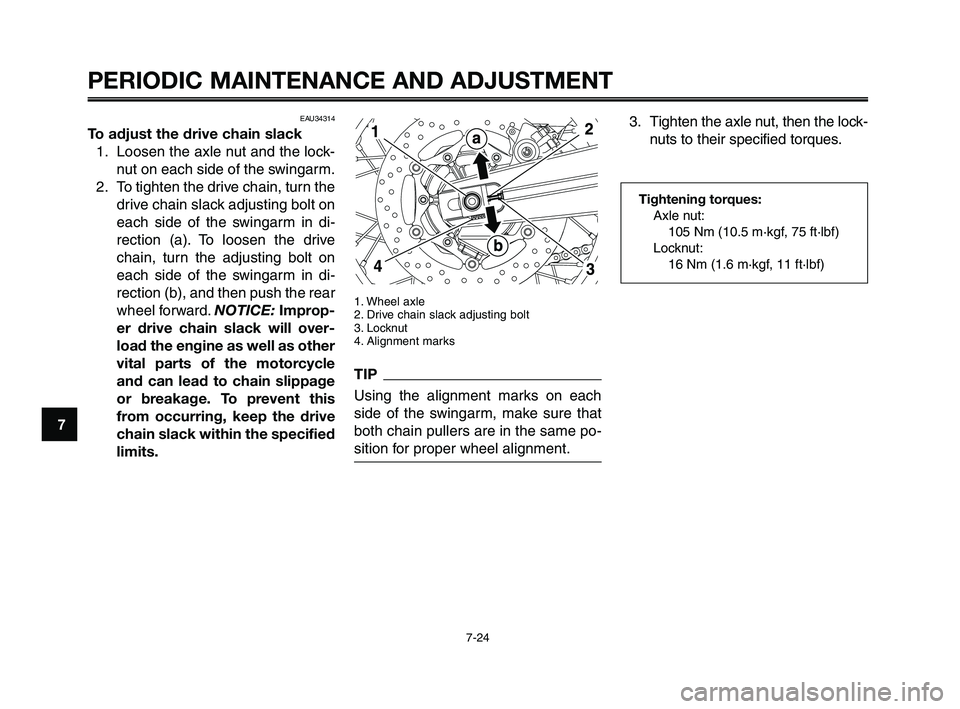

1. Wheel axle

2. Drive chain slack adjusting bolt

3. Locknut

4. Alignment marks

TIP

Using the alignment marks on each

side of the swingarm, make sure that

both chain pullers are in the same po-

sition for proper wheel alignment.

3. Tighten the axle nut, then the lock-

nuts to their specified torques.

Tightening torques:

Axle nut:

105 Nm (10.5 m·kgf, 75 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 11 ft·lbf)

EAU34314

To adjust the drive chain slack

1. Loosen the axle nut and the lock-

nut on each side of the swingarm.

2. To tighten the drive chain, turn the

drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward. NOTICE: Improp-

er drive chain slack will over-

load the engine as well as other

vital parts of the motorcycle

and can lead to chain slippage

or breakage. To prevent this

from occurring, keep the drive

chain slack within the specified

limits.

XT660Z 05-07 ING-AUS:MY03 04-06 ING 11-05-2009 10:10 Pagina 7-24

Page 67 of 100

1

2

3

4

5

6

7

8

9

10

PERIODIC MAINTENANCE AND ADJUSTMENT

7-25

EAU23023

Cleaning and lubricating

the drive chain

The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly

wear out, especially when riding in

dusty or wet areas. Service the drive

chain as follows.

ECA10581

NOTICE

The drive chain must be lubricated

after washing the motorcycle and

riding in the rain.

1. Clean the drive chain with kerosene

and a small soft brush. NOTICE:

To prevent damaging the O-

rings, do not clean the drive

chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive

chain with a special O-ring chain

lubricant. NOTICE:Do not use

engine oil or any other lubri-

cants for the drive chain, as

they may contain substances

that could damage the O-rings.

EAU23101

Checking and lubricating

the cables

The operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubri-

cated if necessary. If a cable is dam-

aged or does not move smoothly, have

a Yamaha dealer check or replace it.

WARNING! Damage to the outer

sheath may interfere with proper

cable operation and will cause the

inner cable to rust. Replace a dam-

aged cable as soon as possible to

prevent unsafe conditions.

Recommended lubricant:

Engine oil

XT660Z 05-07 ING-AUS:MY03 04-06 ING 11-05-2009 10:10 Pagina 7-25

Page 68 of 100

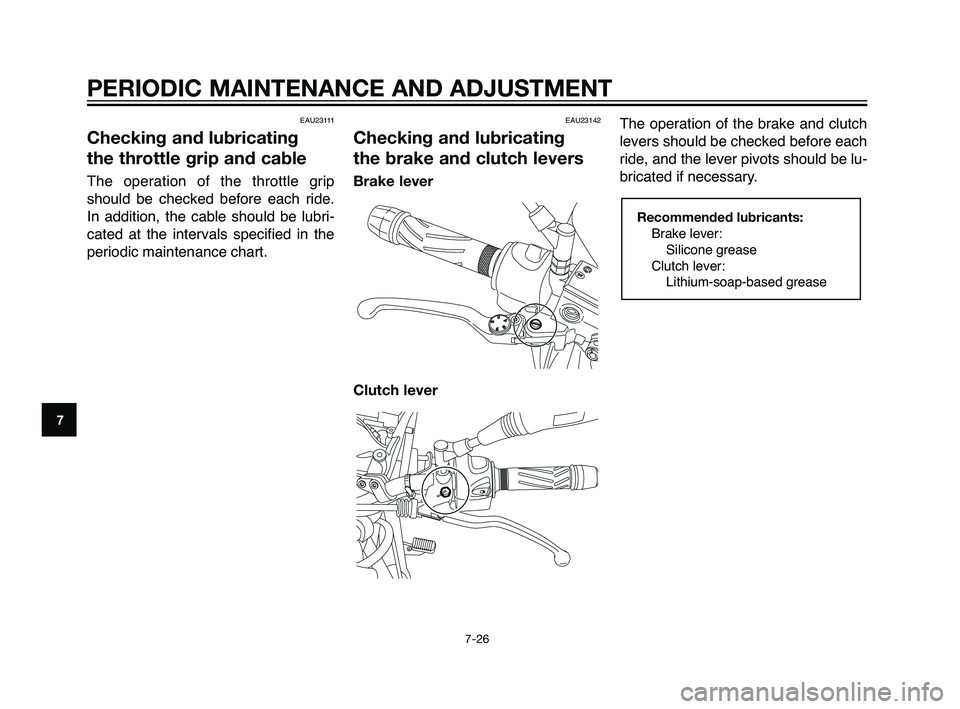

EAU23111

Checking and lubricating

the throttle grip and cable

The operation of the throttle grip

should be checked before each ride.

In addition, the cable should be lubri-

cated at the intervals specified in the

periodic maintenance chart.

EAU23142

Checking and lubricating

the brake and clutch levers

Brake lever

Clutch leverThe operation of the brake and clutch

levers should be checked before each

ride, and the lever pivots should be lu-

bricated if necessary.

Recommended lubricants:

Brake lever:Silicone grease

Clutch lever: Lithium-soap-based grease

PERIODIC MAINTENANCE AND ADJUSTMENT

7-26

7

03 ingles -australia 3/5/10 06:00 Página 68

Page 69 of 100

1

2

3

4

5

6

7

8

9

10

PERIODIC MAINTENANCE AND ADJUSTMENT

EAU23182

Checking and lubricating

the brake pedal

The operation of the brake pedal

should be checked before each ride,

and the pedal pivot should be lubricat-

ed if necessary.

Recommended lubricant:

Lithium-soap-based grease

EAU23202

Checking and lubricating

the sidestand

The operation of the sidestand should

be checked before each ride, and the

sidestand pivot and metal-to-metal

contact surfaces should be lubricated

if necessary.

EWA10730

WARNING0

If the sidestand does not move up

and down smoothly, have a Yamaha

dealer check or repair it. Otherwise,

the sidestand could contact the

ground and distract the operator, re-

sulting in a possible loss of control.

Recommended lubricant:

Lithium-soap-based grease

EAU23250

Lubricating the rear

suspension

The pivoting points of the rear suspen-

sion must be lubricated at the intervals

specified in the periodic maintenance

and lubrication chart.

Recommended lubricant:

Lithium-soap-based grease

7-27

XT660Z 05-07 ING-AUS:MY03 04-06 ING 11-05-2009 10:10 Pagina 7-27

Page 70 of 100

PERIODIC MAINTENANCE AND ADJUSTMENT

7-28

1

2

3

4

5

6

7

8

9

10

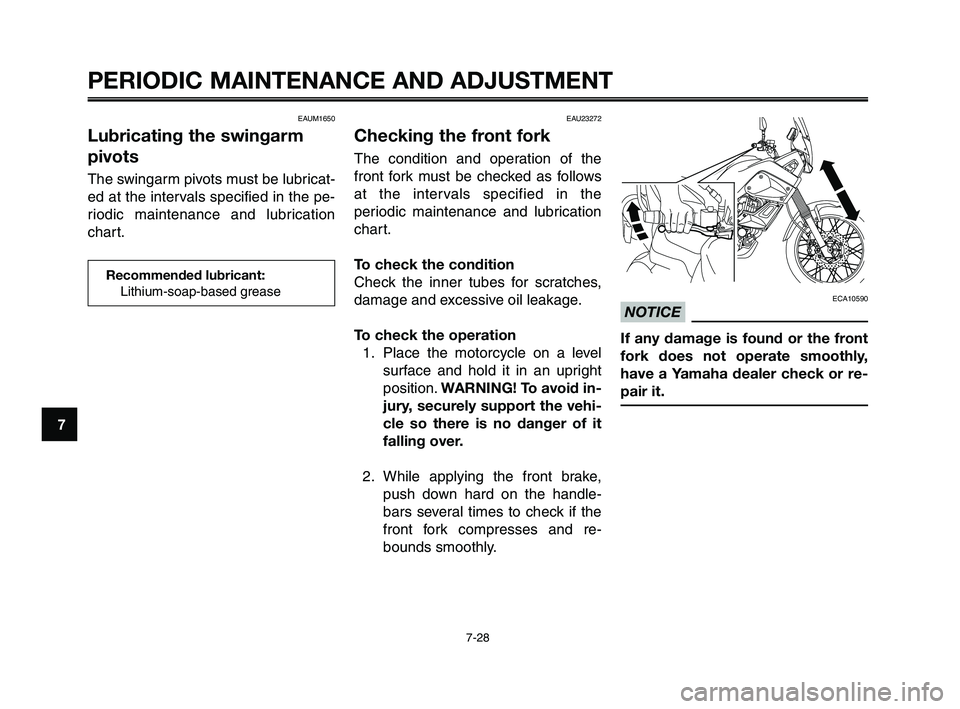

EAU23272

Checking the front fork

The condition and operation of the

front fork must be checked as follows

at the intervals specified in the

periodic maintenance and lubrication

chart.

To check the condition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation

1. Place the motorcycle on a level

surface and hold it in an upright

position. WARNING! To avoid in-

jury, securely support the vehi-

cle so there is no danger of it

falling over.

2. While applying the front brake,

push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

ECA10590

NOTICE

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

EAUM1650

Lubricating the swingarm

pivots

The swingarm pivots must be lubricat-

ed at the intervals specified in the pe-

riodic maintenance and lubrication

chart.

Recommended lubricant:

Lithium-soap-based grease

XT660Z 05-07 ING-AUS:MY03 04-06 ING 11-05-2009 10:10 Pagina 7-28