ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1041 of 1640

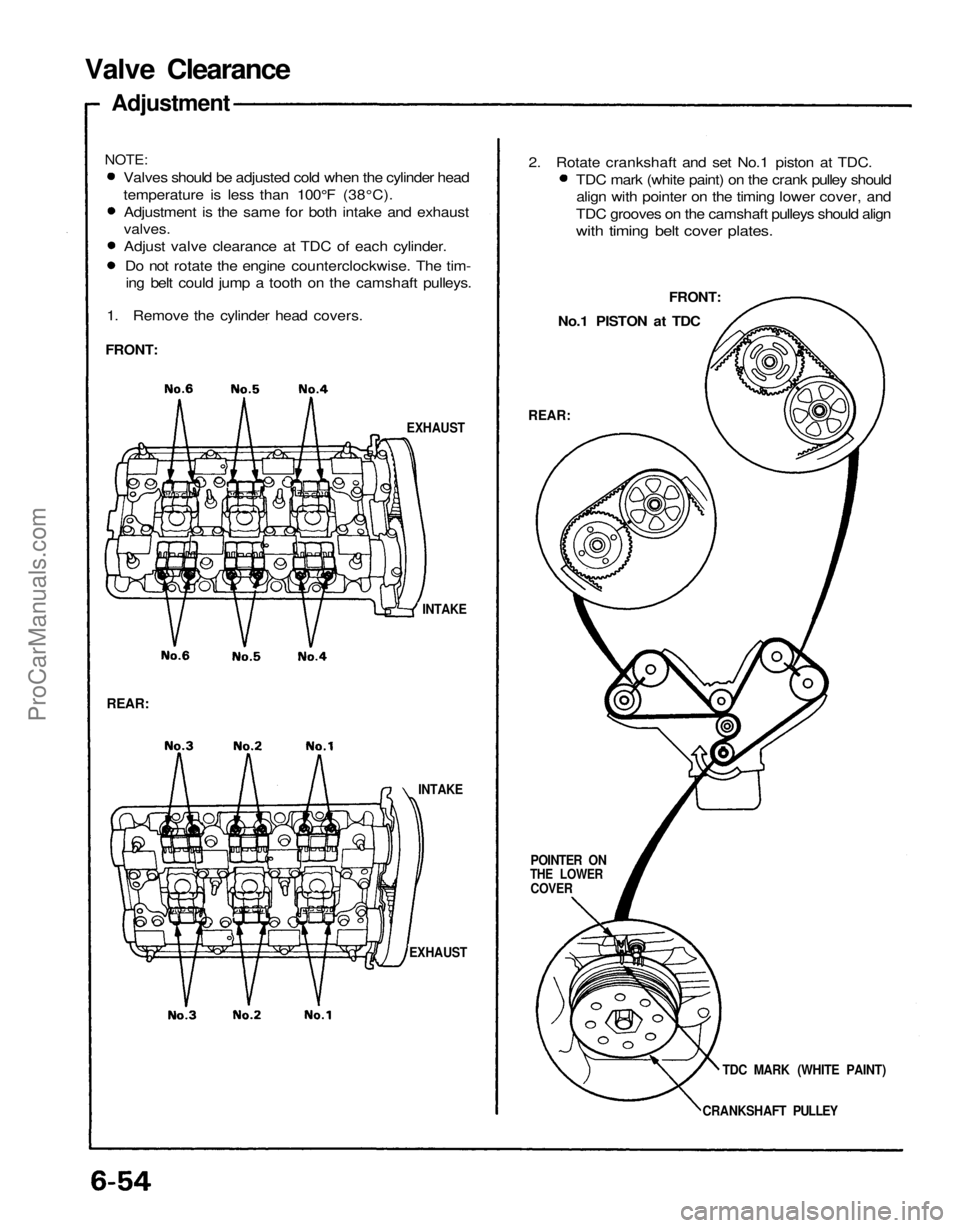

Valve Clearance

Adjustment

Valves should be adjusted cold when the cylinder head

temperature is less than 100°F (38°C).

Adjustment is the same for both intake and exhaust

valves.

Adjust valve clearance at TDC of each cylinder.

Do not rotate the engine counterclockwise. The tim-

ing belt could jump a tooth on the camshaft pulleys.

EXHAUST

INTAKE

INTAKE

EXHAUST

TDC MARK (WHITE PAINT)

CRANKSHAFT PULLEY

POINTER ON

THE LOWER

COVER

TDC mark (white paint) on the crank pulley should

align with pointer on the timing lower cover, and

TDC grooves on the camshaft pulleys should align

with timing belt cover plates.

FRONT:

No.1 PISTON at TDC

REAR:

NOTE:

1. Remove the cylinder head covers.

FRONT:

REAR:

2. Rotate crankshaft and set No.1 piston at TDC.ProCarManuals.com

Page 1042 of 1640

(cont'd)

LOCKNUT

7 x

0.75

mm

20 N

.

m

(2.0 kg-m.

14 Ib-ft)

LOCKNUT

7 x

0.75

mm

20 N .

m

(2.0 kg-m.

14 Ib-ft)

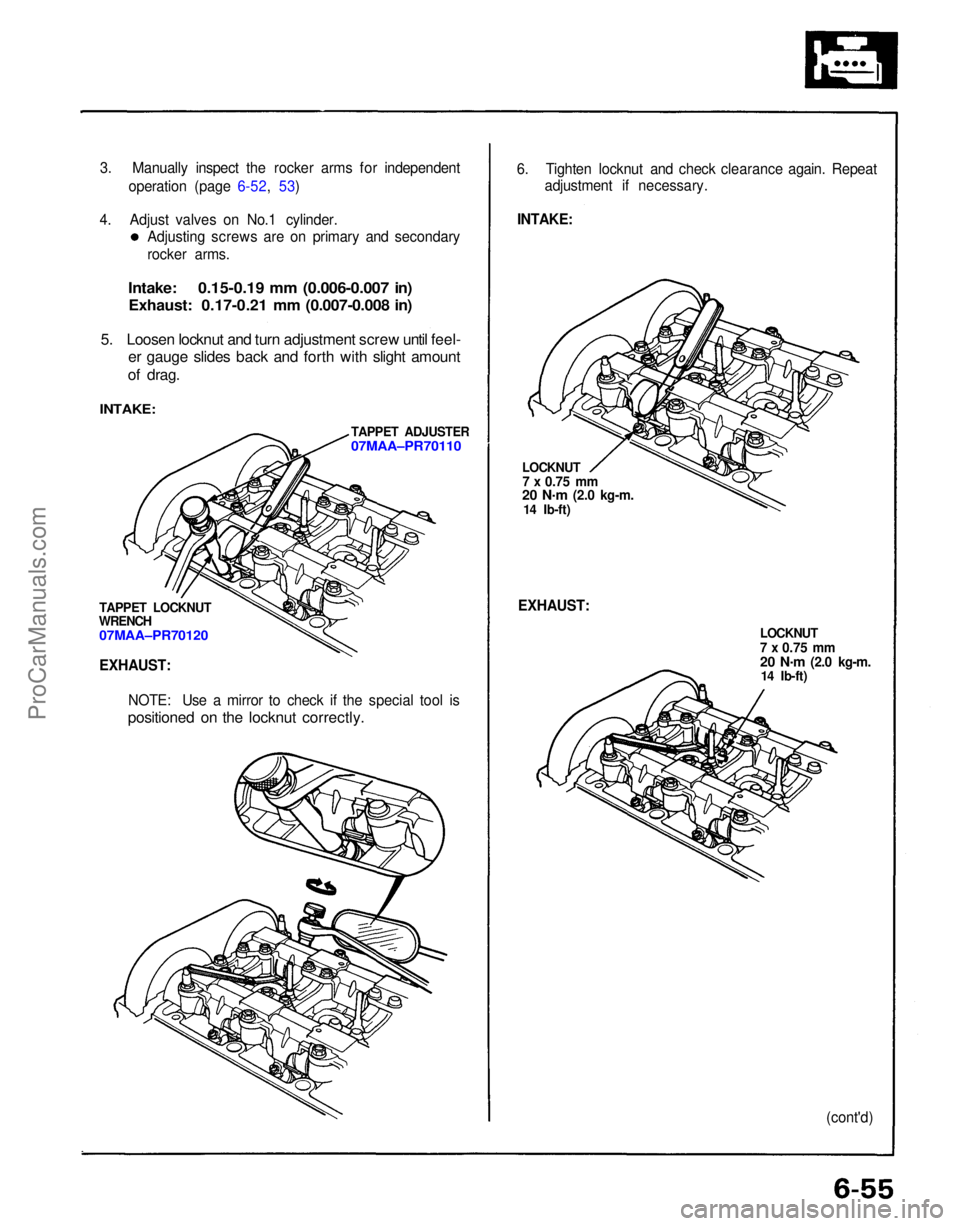

EXHAUST:

6. Tighten locknut and check clearance again. Repeat

adjustment if necessary.

INTAKE:

3. Manually inspect the rocker arms for independent

operation (page 6-52, 53)

4. Adjust valves on No.1 cylinder.

TAPPET ADJUSTER

07MAA–PR70110

TAPPET LOCKNUT

WRENCH

07MAA–PR70120

EXHAUST:

NOTE: Use a mirror to check if the special tool is

positioned on the locknut correctly.

Adjusting screws are on primary and secondary

rocker arms.

Intake: 0.15-0.19 mm (0.006-0.007 in)

Exhaust: 0.17-0.21 mm (0.007-0.008 in)

5. Loosen locknut and turn adjustment screw until feel-

er gauge slides back and forth with slight amount

of drag.

INTAKE:ProCarManuals.com

Page 1043 of 1640

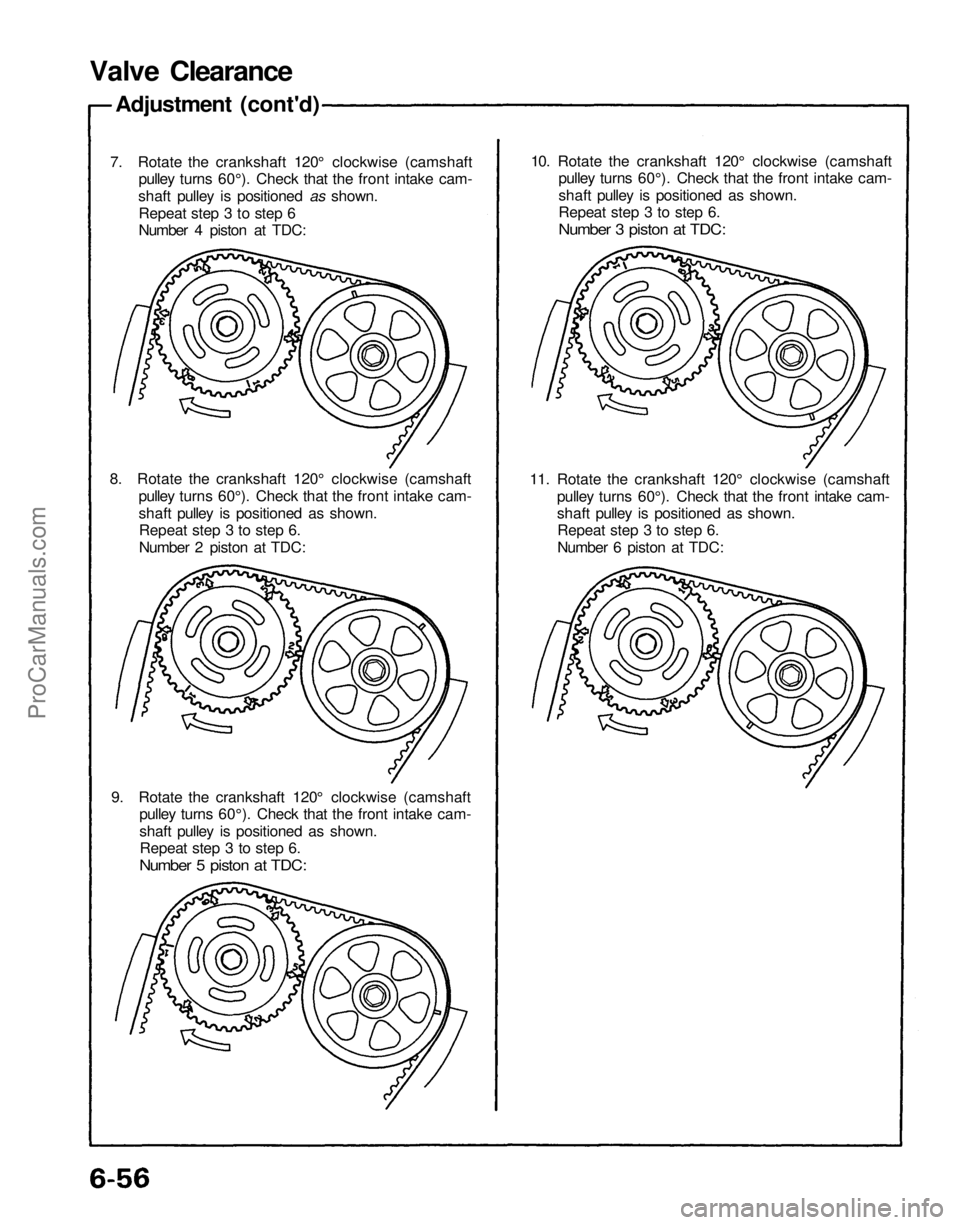

Valve Clearance

Adjustment (cont'd)

7. Rotate the crankshaft 120° clockwise (camshaft

pulley turns 60°). Check that the front intake cam-

shaft pulley is positioned as shown.

Repeat step 3 to step 6

Number 4 piston at TDC:

8. Rotate the crankshaft 120° clockwise (camshaft

pulley turns 60°). Check that the front intake cam-

shaft pulley is positioned as shown.

Repeat step 3 to step 6.

Number 2 piston at TDC:

9. Rotate the crankshaft 120° clockwise (camshaft

pulley turns 60°). Check that the front intake cam-

shaft pulley is positioned as shown.

Repeat step 3 to step 6.

Number 5 piston at TDC:

11. Rotate the crankshaft 120° clockwise (camshaft

pulley turns 60°). Check that the front intake cam-

shaft pulley is positioned as shown.

Repeat step 3 to step 6.

Number 6 piston at TDC:

10. Rotate the crankshaft 120° clockwise (camshaft

pulley turns 60°). Check that the front intake cam-

shaft pulley is positioned as shown.

Repeat step 3 to step 6.

Number 3 piston at TDC:ProCarManuals.com

Page 1044 of 1640

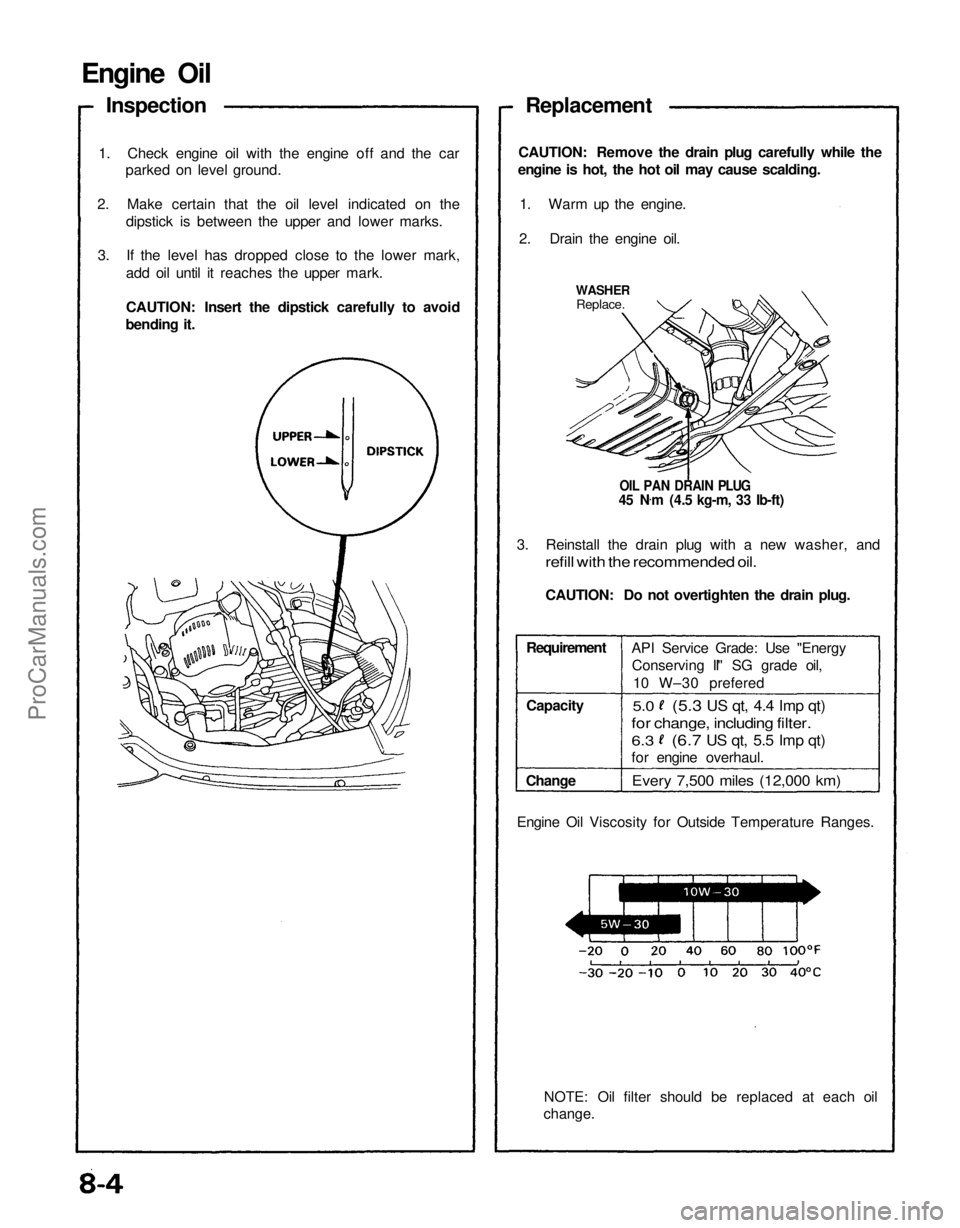

Engine Oil

Inspection

1. Check engine oil with the engine off and the car parked on level ground.

2. Make certain that the oil level indicated on the dipstick is between the upper and lower marks.

3. If the level has dropped close to the lower mark, add oil until it reaches the upper mark.

CAUTION: Insert the dipstick carefully to avoid

bending it. Replacement

CAUTION: Remove the drain plug carefully while the

engine is hot, the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHER

Replace.

OIL PAN DRAIN PLUG

45 N .

m (4.5 kg-m, 33 Ib-ft)

3. Reinstall the drain plug with a new washer, and

refill with the recommended oil.

CAUTION: Do not overtighten the drain plug.

Requirement

Capacity

Change API Service Grade: Use "Energy

Conserving II" SG grade oil,

10 W–30 prefered

5.0

Every 7,500 miles (12,000 km)

NOTE: Oil filter should be replaced at each oil

change.

Engine Oil Viscosity for Outside Temperature Ranges.

(5.3

US qt, 4.4 Imp qt)

for change, including filter.

6.3

(6.7

US qt, 5.5 Imp qt)

for engine overhaul.ProCarManuals.com

Page 1045 of 1640

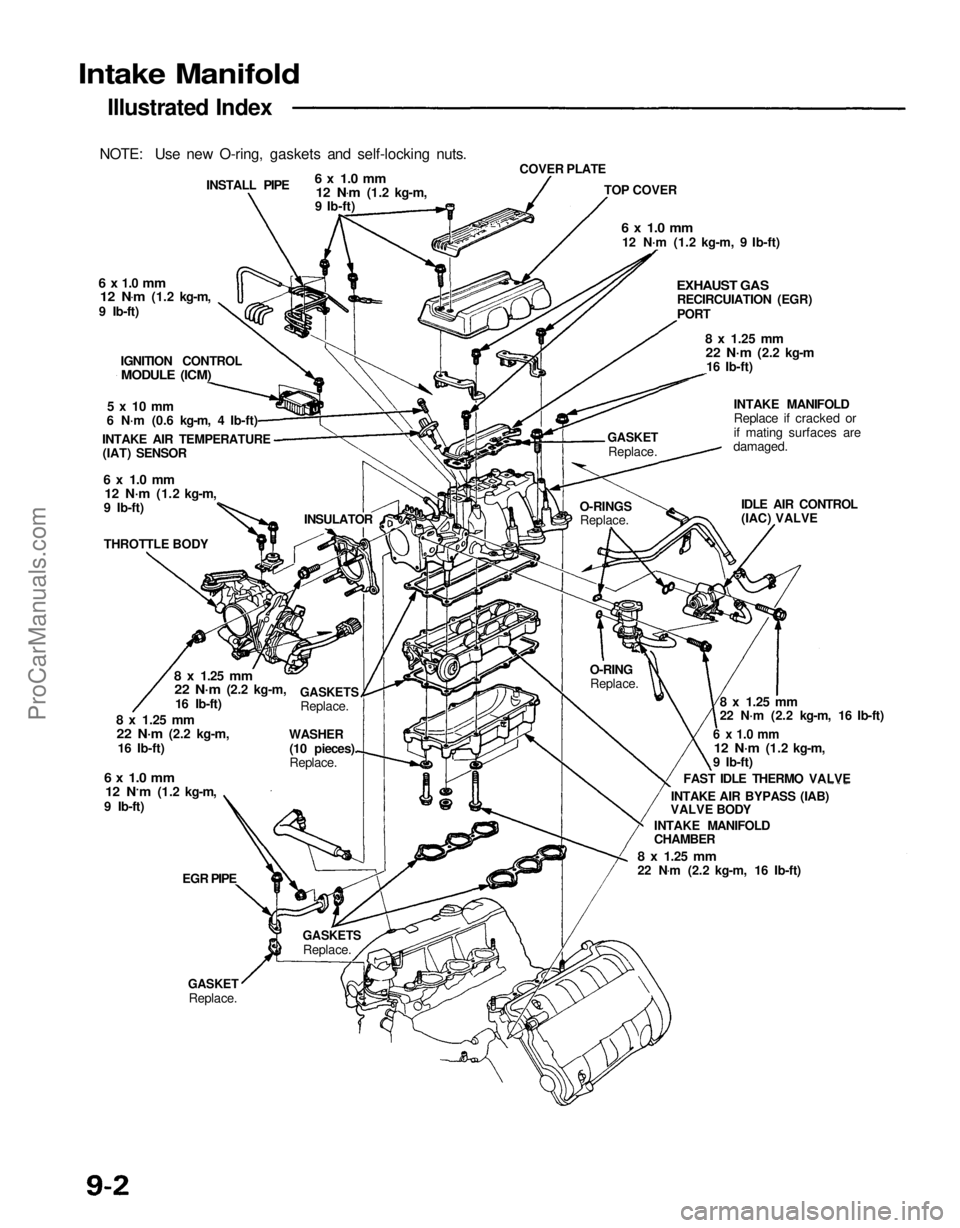

Intake Manifold

Illustrated Index

NOTE: Use new O-ring, gaskets and self-locking nuts. INSTALL PIPE

6 x 1.0 mm

12 N .

m

(1.2 kg-m,

9 Ib-ft)

6 x

1.0

mm

12 N .

m

(1.2 kg-m,

9 Ib-ft)

IGNITION CONTROL

MODULE (ICM)

5 x 10 mm

6 N·m (0.6 kg-m, 4 Ib-ft)

INTAKE AIR TEMPERATURE (IAT) SENSOR

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

THROTTLE BODY

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)

6 x 1.0 mm

12 N ·

m

(1.2 kg-m,

9 Ib-ft)

GASKETS

Replace.

WASHER (10 pieces).

Replace.

EGR PIPE

GASKET

Replace.

GASKETS

Replace. INSULATOR

COVER PLATE

TOP COVER

6 x 1.0 mm

12 N·m (1.2 kg-m, 9 Ib-ft)

EXHAUST GAS

RECIRCUIATION (EGR)

PORT

8 x

1.25

mm

22 N·m

(2.2 kg-m 16 Ib-ft)

GASKET

Replace. INTAKE MANIFOLD

Replace if cracked or

if mating surfaces are

damaged.

IDLE AIR CONTROL

(IAC) VALVE

O-RINGS

Replace.

O-RINGReplace.

8 x

1.25

mm

22 N·m (2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

FAST IDLE THERMO VALVE

INTAKE AIR BYPASS (IAB)

VALVE BODY

INTAKE MANIFOLD

CHAMBER

8 x

1.25

mm

22 N .

m (2.2 kg-m, 16 Ib-ft)ProCarManuals.com

Page 1046 of 1640

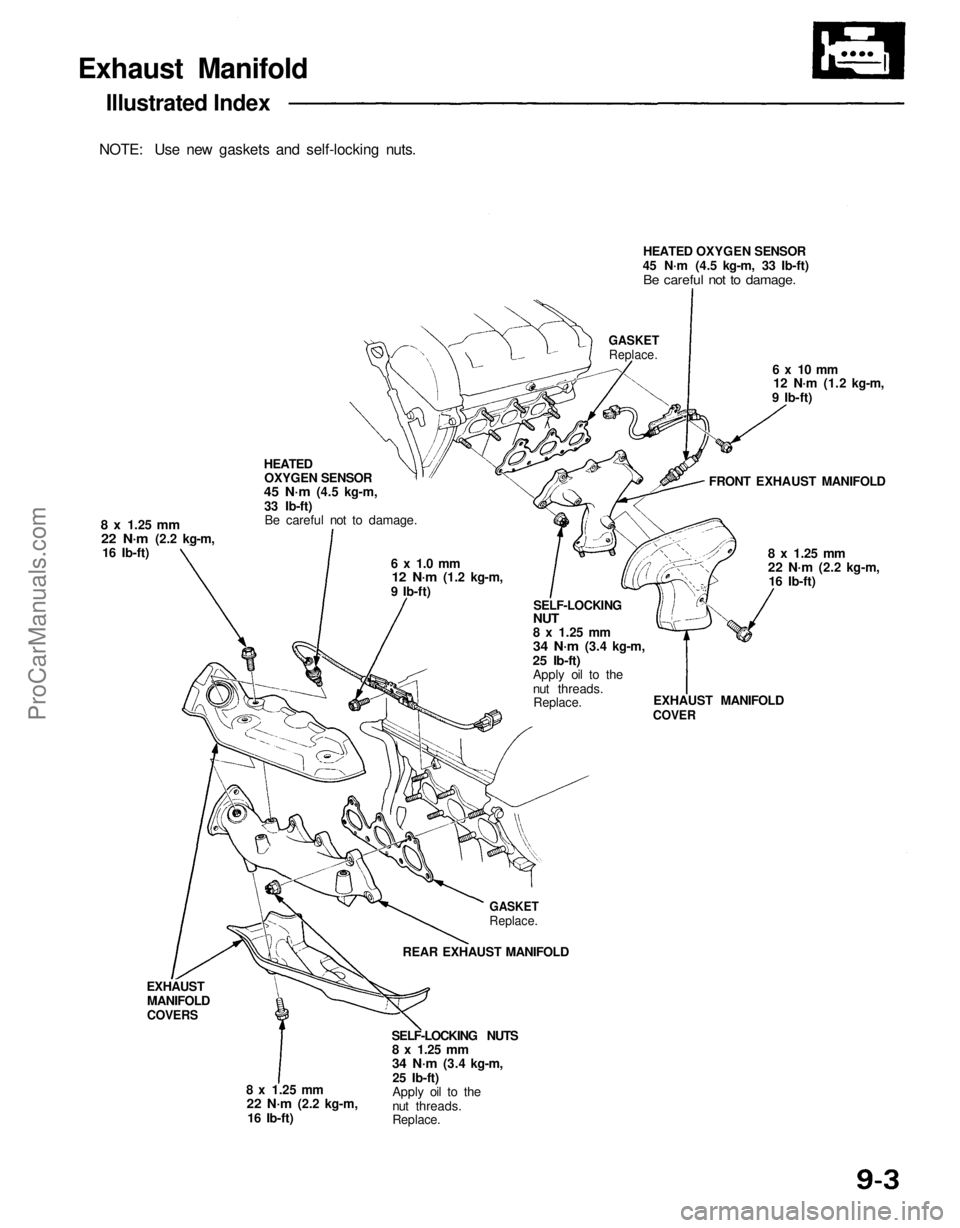

Exhaust Manifold

Illustrated Index

NOTE: Use new gaskets and self-locking nuts.

HEATEDOXYGEN SENSOR

45 N·m

(4.5 kg-m,

33 Ib-ft)Be careful not to damage.

8 x

1.25

mm

22 N·m

(2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

EXHAUST MANIFOLD

COVERS

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft) SELF-LOCKING NUTS

8 x

1.25

mm

34 N·m

(3.4 kg-m,

25 Ib-ft)

Apply oil to the

nut threads.

Replace.

REAR EXHAUST MANIFOLD

GASKET

Replace.

SELF-LOCKING

NUT

8 x

1.25

mm

34 N·m

(3.4 kg-m,

25 Ib-ft)

Apply oil to the

nut threads.

Replace.

EXHAUST MANIFOLD

COVER

HEATED OXYGEN SENSOR

45 N·m (4.5 kg-m, 33 Ib-ft)

Be careful not to damage.

GASKET

Replace.

6 x 10 mm

12 N·m

(1.2 kg-m,

9 Ib-ft)

FRONT EXHAUST MANIFOLD

8 x

1.25

mm

22 N·m

(2.2 kg-m,16 Ib-ft)ProCarManuals.com

Page 1047 of 1640

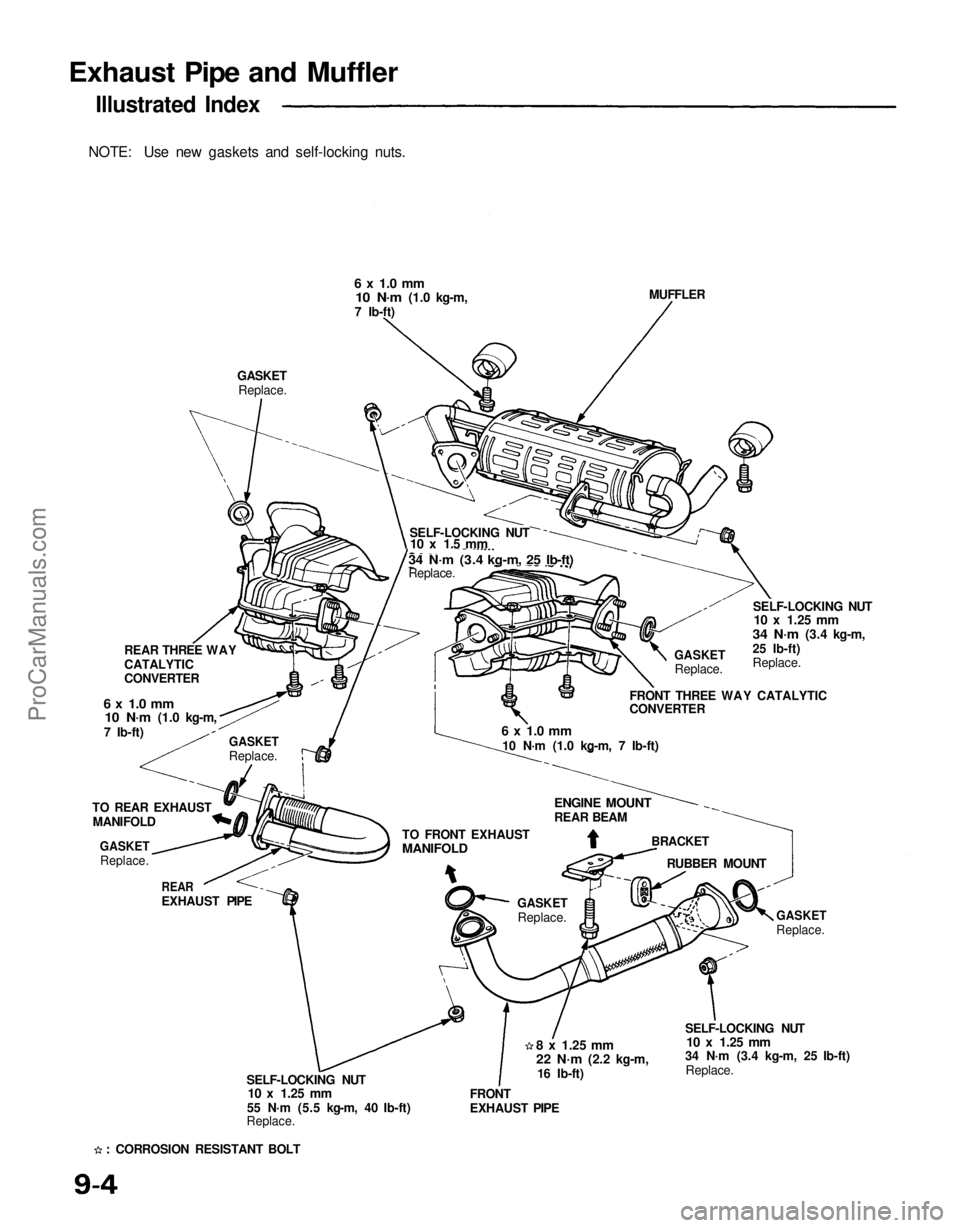

Exhaust Pipe and Muffler

Illustrated Index

NOTE: Use new gaskets and self-locking nuts.

6 x 1.0 mm

10 N·m

(1.0 kg-m,

7 Ib-ft)

GASKET Replace.

REAR THREE WAY

CATALYTIC

CONVERTER

6 x 1.0 mm

10 N·m

(1.0 kg-m,

7 Ib-ft)

GASKET

Replace.

TO REAR EXHAUST MANIFOLD

GASKET

Replace.

EXHAUST PIPE

REAR

TO FRONT EXHAUST

MANIFOLD

GASKET

Replace.

SELF-LOCKING NUT

10 x

1.25

mm

55 N·m (5.5 kg-m, 40 Ib-ft)

Replace.

: CORROSION RESISTANT BOLT FRONT

EXHAUST PIPEMUFFLER

SELF-LOCKING NUT

10 x

1.5

mm

34 N·m (3.4 kg-m, 25 Ib-ft)

Replace.

6 x 1.0 mm

10 N·m (1.0 kg-m, 7 Ib-ft) FRONT THREE WAY CATALYTIC

CONVERTER

GASKET

Replace. SELF-LOCKING NUT

10 x

1.25

mm

34 N·m

(3.4 kg-m,

25 Ib-ft)

Replace.

ENGINE MOUNT

REAR BEAM

BRACKET

RUBBER MOUNT

GASKET

Replace.

SELF-LOCKING NUT

10 x

1.25

mm

34 N·m (3.4 kg-m, 25 Ib-ft)

Replace.

8 x

1.25

mm

22 N·m

(2.2 kg-m,

16 Ib-ft)ProCarManuals.com

Page 1048 of 1640

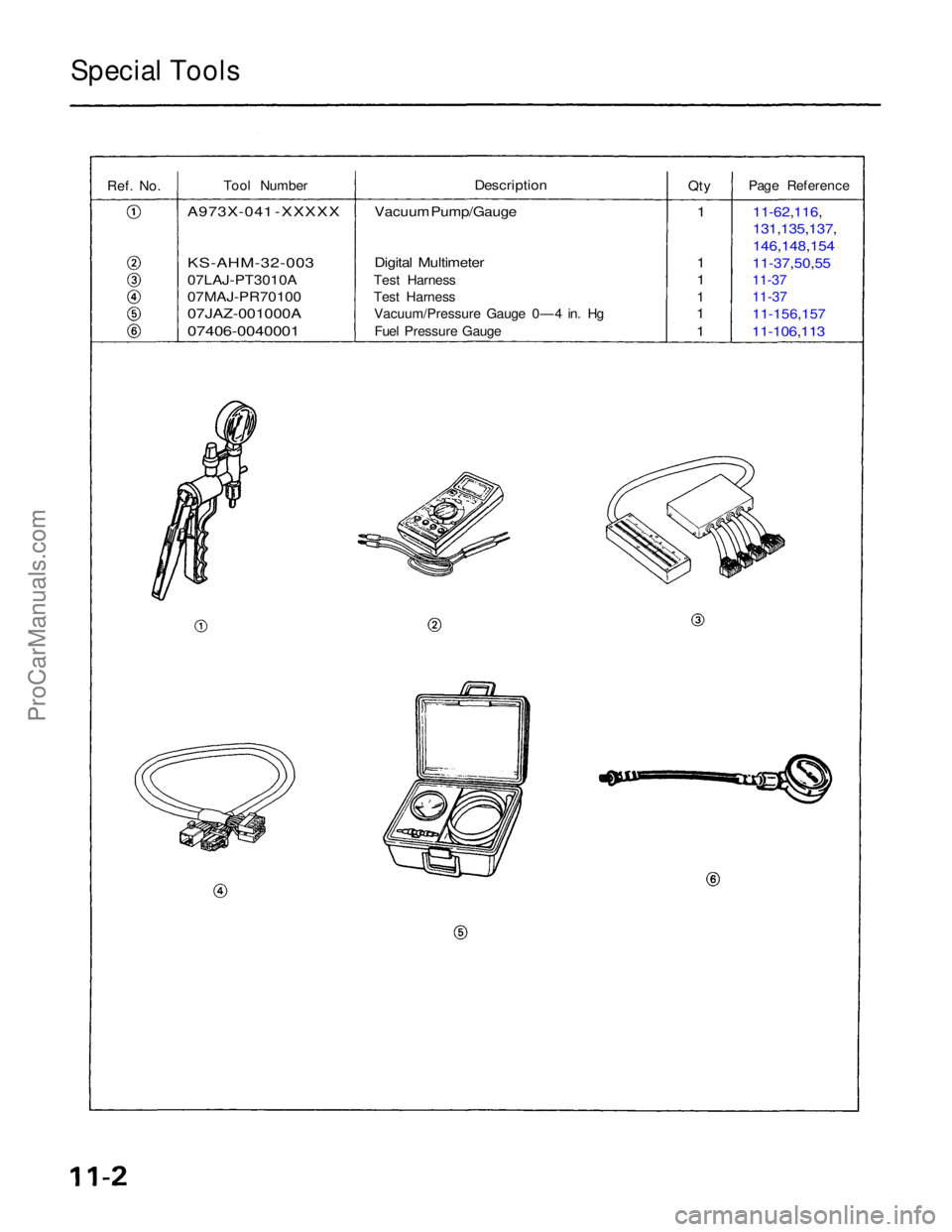

Special Tools

Ref. No.

Tool Number

A973X-041 -XXXXX

KS-AHM-32-003

07LAJ-PT3010A

07MAJ-PR70100

07JAZ-001000A

07406-0040001

Page Reference

11-62,116,

131,135,137,

146,148,154

11-37,50,55

11-37

11-37

11-156,157

11-106,113

Description

Vacuum Pump/Gauge

Digital Multimeter

Test Harness

Test Harness Vacuum/Pressure Gauge 0—4 in. Hg

Fuel Pressure Gauge

Qty

1

1

1

1

1

1ProCarManuals.com

Page 1049 of 1640

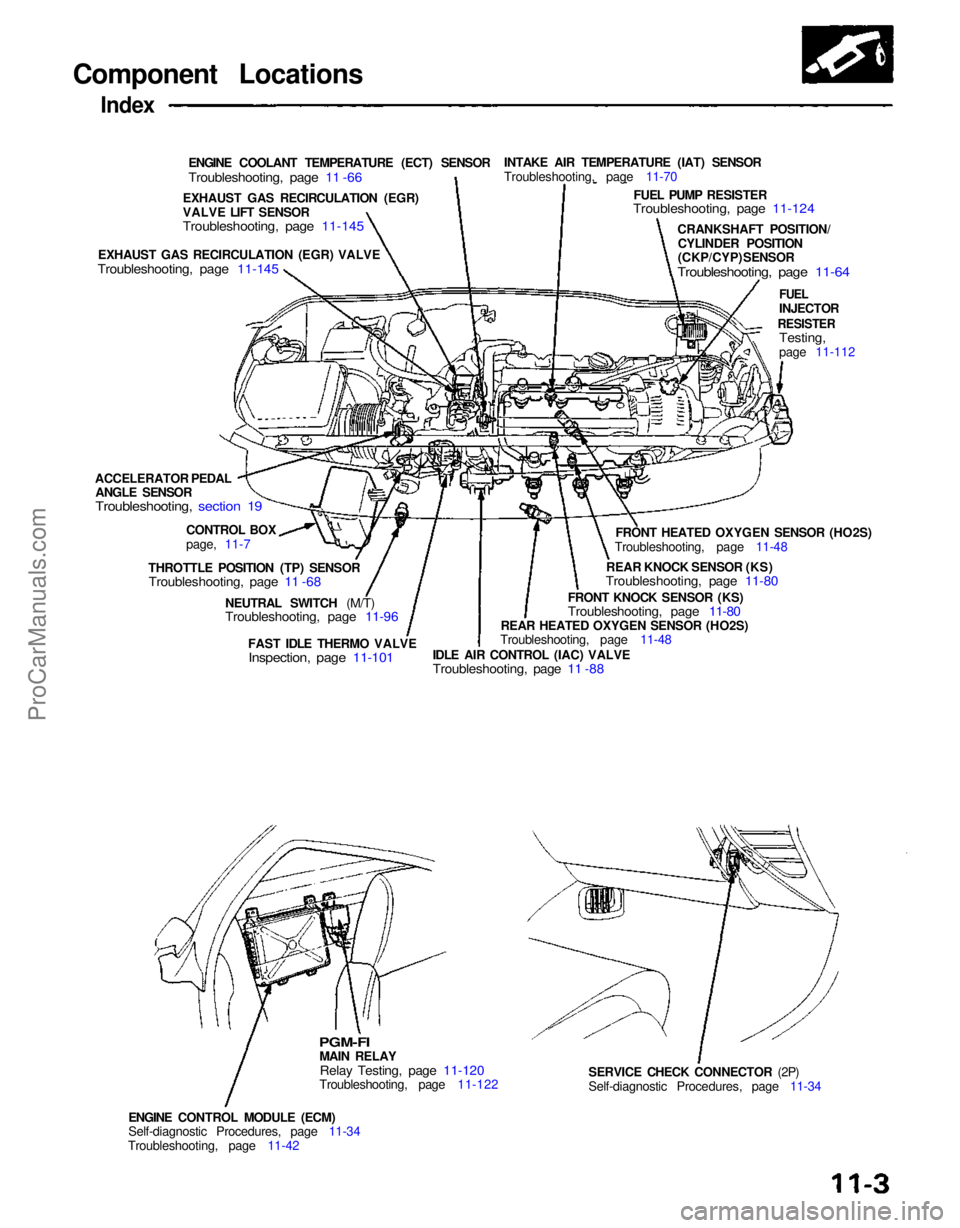

Component Locations

Index

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

Troubleshooting, page 11 -66

INTAKE AIR TEMPERATURE (IAT) SENSOR

Troubleshooting, page 11-70

FUEL PUMP RESISTER

Troubleshooting, page 11-124

CRANKSHAFT POSITION/CYLINDER POSITION

(CKP/CYP) SENSOR

Troubleshooting, page 11-64

FUEL

INJECTOR

RESISTER

Testing,

page 11-112

FRONT HEATED OXYGEN SENSOR (HO2S)

Troubleshooting, page 11-48

REAR KNOCK SENSOR (KS)

Troubleshooting, page 11-80

FRONT KNOCK SENSOR (KS)

Troubleshooting, page 11-80

REAR HEATED OXYGEN SENSOR (HO2S)

Troubleshooting, page 11-48

IDLE AIR CONTROL (IAC) VALVE

Troubleshooting, page 11 -88

FAST IDLE THERMO VALVE

Inspection, page 11-101

NEUTRAL SWITCH (M/T)

Troubleshooting, page 11-96

SERVICE CHECK CONNECTOR (2P)

Self-diagnostic Procedures, page 11-34

ENGINE CONTROL MODULE (ECM)

Self-diagnostic Procedures, page 11-34

Troubleshooting, page 11-42

PGM-FI

MAIN RELAY

Relay Testing, page 11-120

Troubleshooting, page 11-122

THROTTLE POSITION (TP) SENSOR

Troubleshooting, page 11 -68

CONTROL BOX

page, 11-7

ACCELERATOR PEDAL

ANGLE SENSOR

Troubleshooting, section 19

EXHAUST GAS RECIRCULATION (EGR) VALVE

Troubleshooting, page 11-145

EXHAUST GAS RECIRCULATION (EGR)

VALVE LIFT SENSOR

Troubleshooting, page 11-145ProCarManuals.com

Page 1050 of 1640

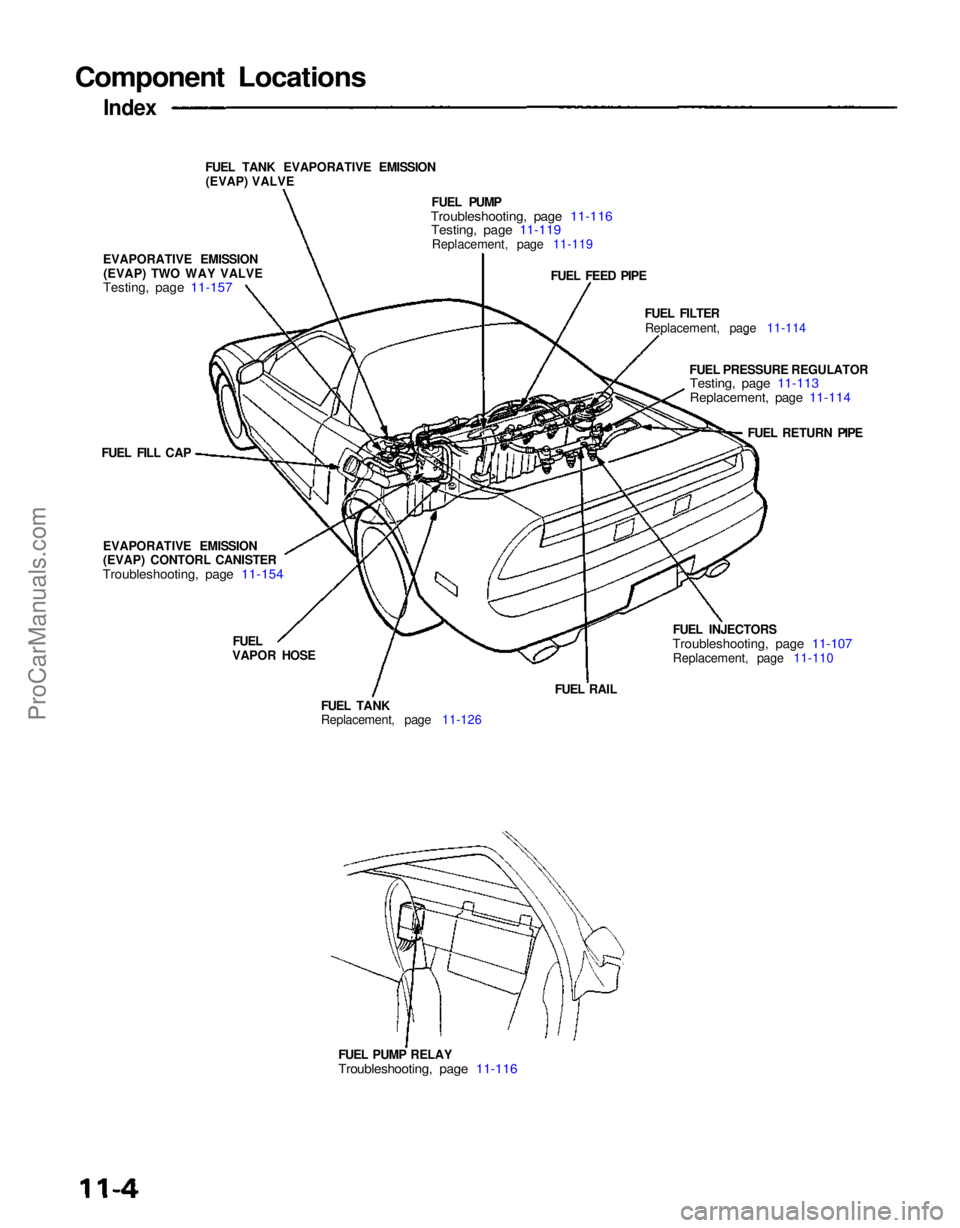

Component Locations

Index

FUEL TANK EVAPORATIVE EMISSION(EVAP) VALVE

EVAPORATIVE EMISSION (EVAP) TWO WAY VALVE

Testing, page 11-157

FUEL PUMP

Troubleshooting, page 11-116

Testing, page 11-119

Replacement, page 11-119

FUEL FEED PIPE

FUEL FILTERReplacement, page 11-114

FUEL PRESSURE REGULATOR

Testing, page 11-113

Replacement, page 11-114

FUEL RETURN PIPE

FUEL INJECTORS

Troubleshooting, page 11-107

Replacement, page 11-110

FUEL PUMP RELAY

Troubleshooting, page 11-116

FUEL RAIL

FUEL TANK

Replacement, page 11-126

FUEL

VAPOR HOSE

EVAPORATIVE EMISSION

(EVAP) CONTORL CANISTER

Troubleshooting, page 11-154

FUEL FILL CAPProCarManuals.com