ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1031 of 1640

4. Working from the camshaft side, use the driver and

an air hammer to drive the guide about 2 mm

towards the combustion chamber. This will knock

off some of the carbon and make removal easier.

VALVE GUIDE DRIVER

07742–0010100

5. Turn the head over and drive the guide out toward the camshaft side of head.

If a valve guide still won't move, drill it out with a

5/16 inch bit, then try again.

CAUTION: Drill guides only in extreme cases: you

could damage the cylinder head if the guide breaks.

6. Remove the new guide(s) from the refrigerator, one

at a time, as you need them.

Do not use a torch; it may warp the head.

Do not get the head hotter than 300 °F (150°C)

excessive heat may loosen the valve seats.

To avoid burns, use heavy gloves when handling

the heated cylinder head.

Valve Guides

Replacement

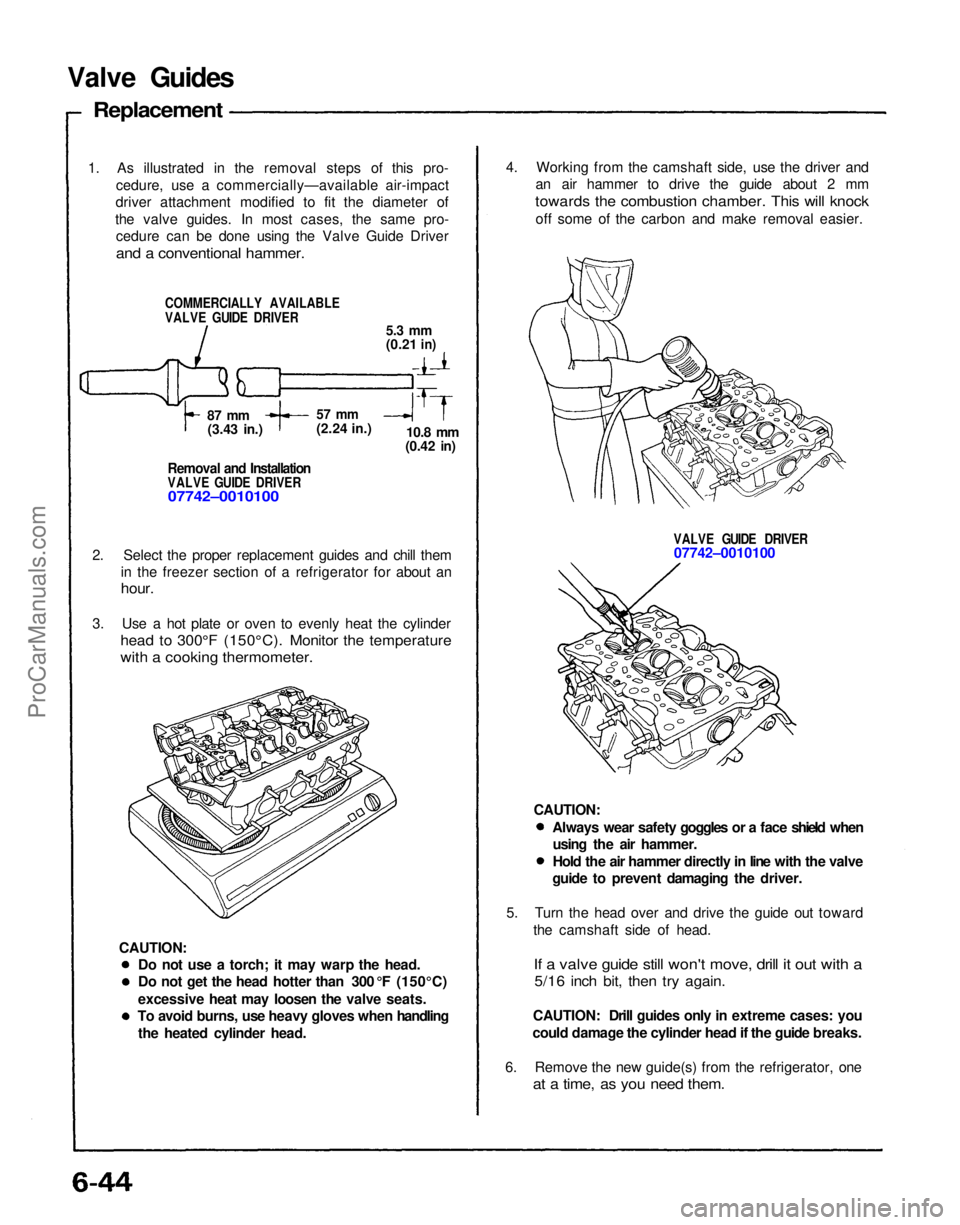

1. As illustrated in the removal steps of this pro- cedure, use a commercially—available air-impact

driver attachment modified to fit the diameter of

the valve guides. In most cases, the same pro- cedure can be done using the Valve Guide Driver

and a conventional hammer.

COMMERCIALLY AVAILABLE

VALVE GUIDE DRIVER

5.3 mm

(0.21

in)

87 mm

(3.43 in.)

57 mm

(2.24 in.)

10.8

mm

(0.42

in)

Removal and Installation

VALVE GUIDE DRIVER

07742–0010100

2. Select the proper replacement guides and chill them in the freezer section of a refrigerator for about an

hour.

3. Use a hot plate or oven to evenly heat the cylinder

head to 300°F (150°C). Monitor the temperature

with a cooking thermometer.

CAUTION: Always wear safety goggles or a face shield when

using the air hammer.

Hold the air hammer directly in line with the valve

guide to prevent damaging the driver.

CAUTION:ProCarManuals.com

Page 1032 of 1640

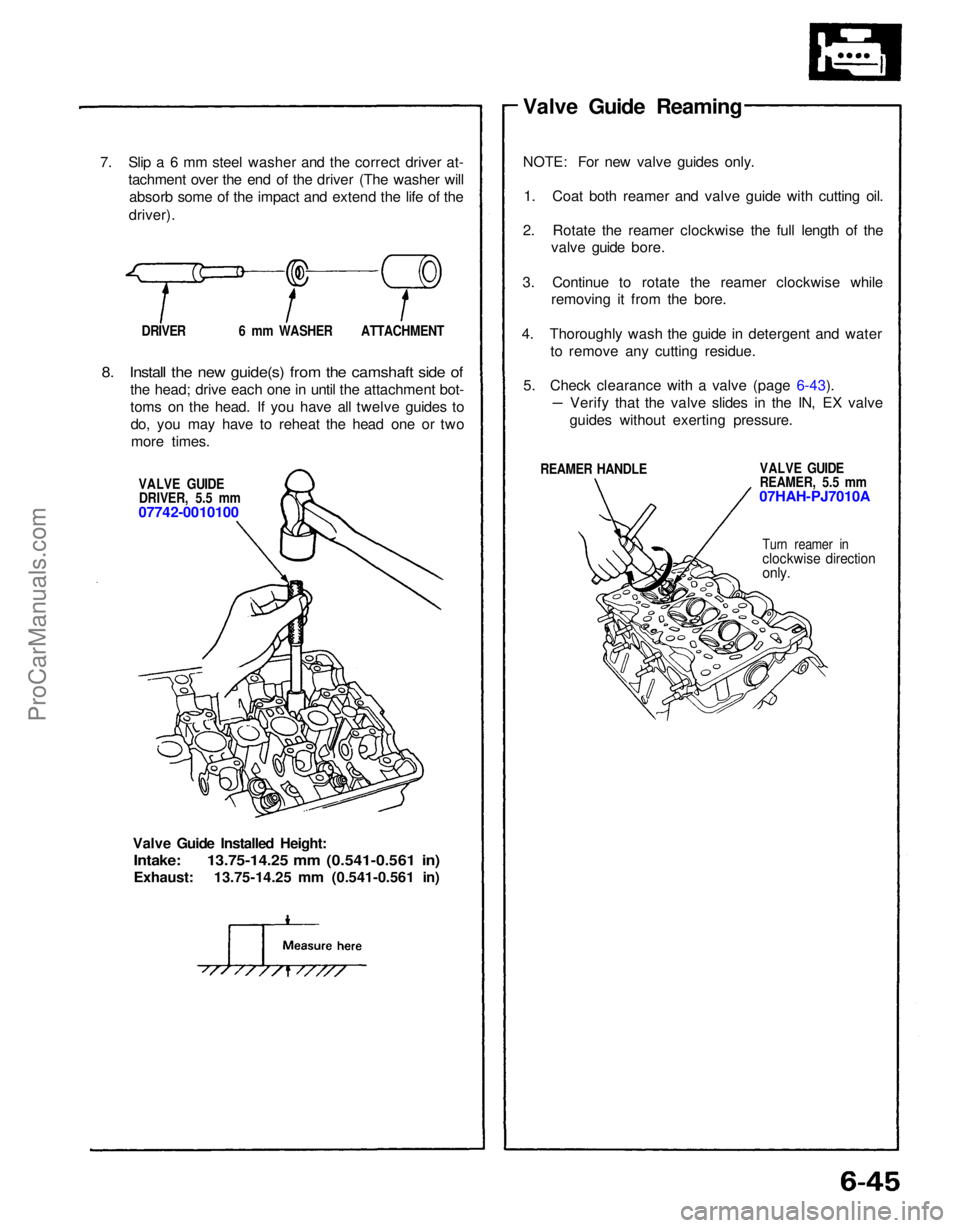

7. Slip a 6 mm steel washer and the correct driver at-

tachment over the end of the driver (The washer willabsorb some of the impact and extend the life of the

driver).

DRIVER 6 mm WASHER ATTACHMENT

8. Install the new guide(s) from the camshaft side of

the head; drive each one in until the attachment bot-

toms on the head. If you have all twelve guides todo, you may have to reheat the head one or twomore times.

VALVE GUIDEDRIVER, 5.5 mm

07742-0010100

Valve Guide Installed Height:

Intake: 13.75-14.25 mm (0.541-0.561 in)

Exhaust: 13.75-14.25 mm (0.541-0.561 in) Valve Guide Reaming

NOTE: For new valve guides only.

1. Coat both reamer and valve guide with cutting oil.

2. Rotate the reamer clockwise the full length of the valve guide bore.

3. Continue to rotate the reamer clockwise while removing it from the bore.

4. Thoroughly wash the guide in detergent and water to remove any cutting residue.

5. Check clearance with a valve (page 6-43).

REAMER HANDLE VALVE GUIDE

REAMER, 5.5 mm

07HAH-PJ7010A

Turn reamer in

clockwise direction

only.

Verify that the valve slides in the IN, EX valve

guides without exerting pressure.ProCarManuals.com

Page 1033 of 1640

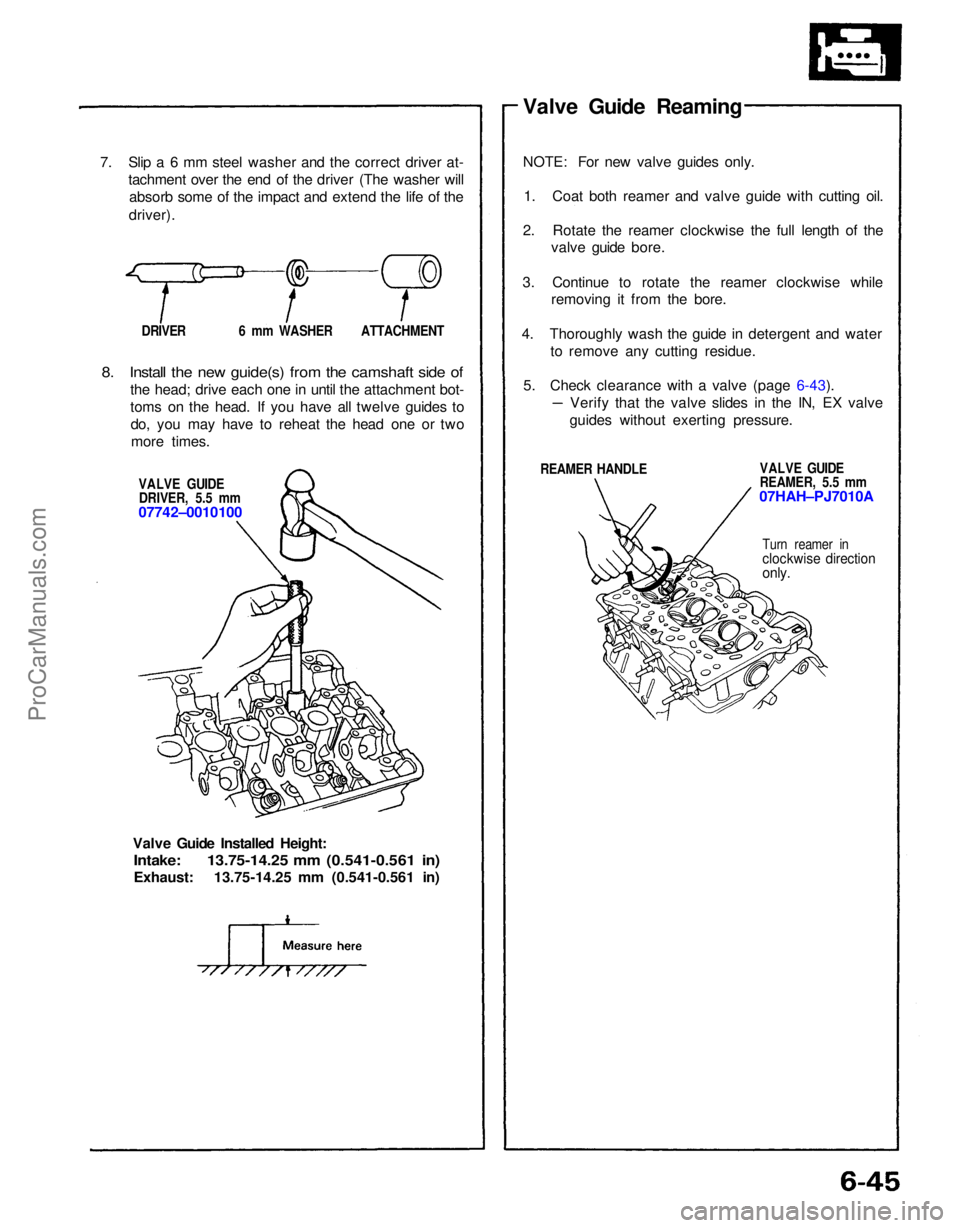

7. Slip a 6 mm steel washer and the correct driver at-

tachment over the end of the driver (The washer willabsorb some of the impact and extend the life of the

driver).

DRIVER 6 mm WASHER ATTACHMENT

8. Install the new guide(s) from the camshaft side of

the head; drive each one in until the attachment bot-

toms on the head. If you have all twelve guides todo, you may have to reheat the head one or twomore times.

VALVE GUIDEDRIVER, 5.5 mm

07742–0010100

Valve Guide Installed Height:

Intake: 13.75-14.25 mm (0.541-0.561 in)

Exhaust: 13.75-14.25 mm (0.541-0.561 in) Valve Guide Reaming

NOTE: For new valve guides only.

1. Coat both reamer and valve guide with cutting oil.

2. Rotate the reamer clockwise the full length of the valve guide bore.

3. Continue to rotate the reamer clockwise while removing it from the bore.

4. Thoroughly wash the guide in detergent and water to remove any cutting residue.

5. Check clearance with a valve (page 6-43).

REAMER HANDLE VALVE GUIDE

REAMER, 5.5 mm

07HAH–PJ7010A

Turn reamer in

clockwise direction

only.

Verify that the valve slides in the IN, EX valve

guides without exerting pressure.ProCarManuals.com

Page 1034 of 1640

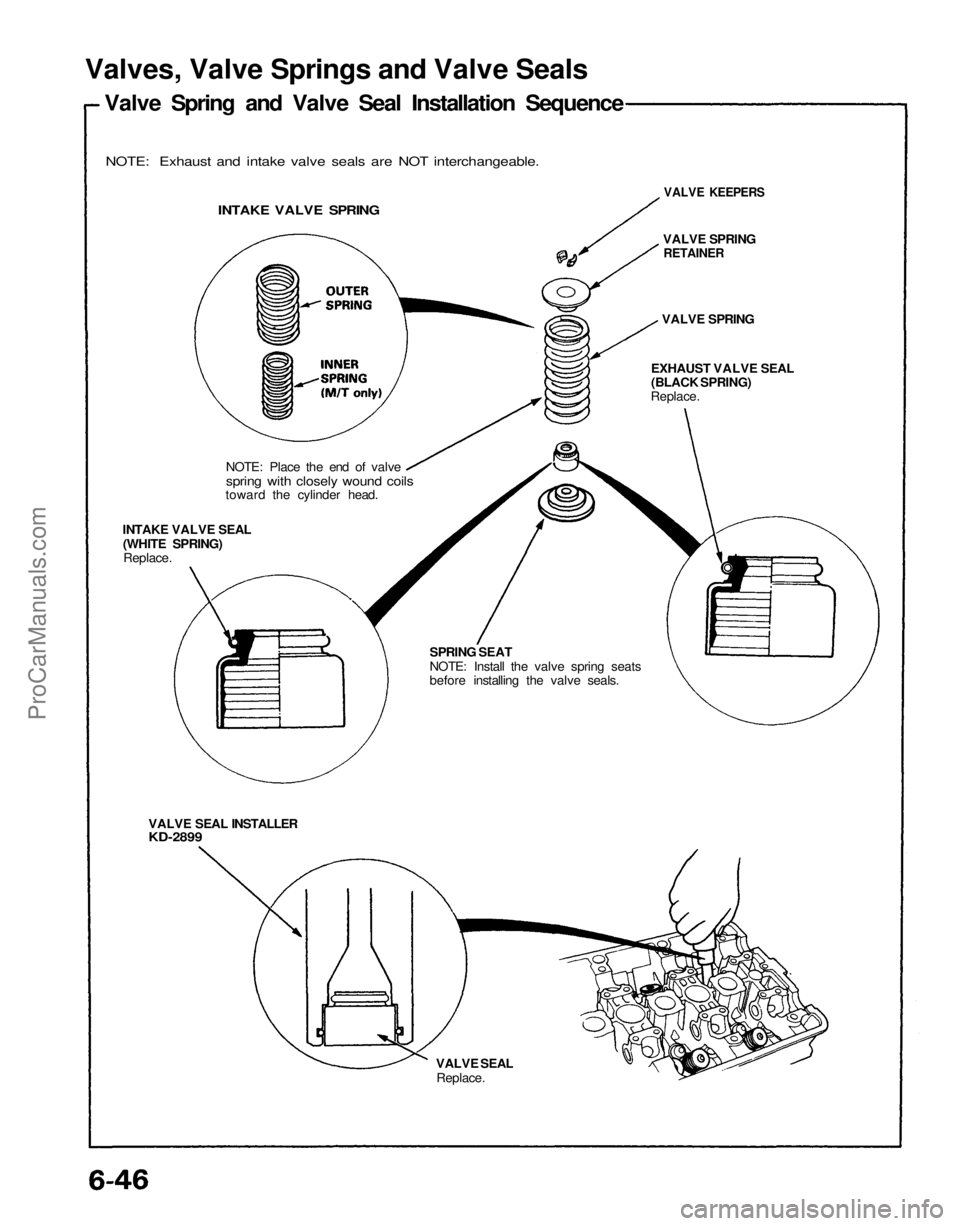

Valves, Valve Springs and Valve Seals

Valve Spring and Valve Seal Installation Sequence

NOTE: Exhaust and intake valve seals are NOT interchangeable.

INTAKE VALVE SPRING

NOTE: Place the end of valve

spring with closely wound coils

toward the cylinder head.

INTAKE VALVE SEAL

(WHITE SPRING)

Replace.

VALVE SEAL INSTALLER

KD-2899

VALVE SEAL

Replace.

VALVE KEEPERS

VALVE SPRING

RETAINER

VALVE SPRING

EXHAUST VALVE SEAL

(BLACK SPRING)

Replace.

SPRING SEAT

NOTE: Install the valve spring seats

before installing the valve seals.ProCarManuals.com

Page 1035 of 1640

Cylinder Heads

Installation

2. Install the exhaust manifold covers.

Front:

HEATED OXYGEN

SENSOR

45 N .

m (4.5 kg-m, 33 Ib-ft)

Be careful not to damage.

6 x 1.0 mm

12 N .

m

(1.2 kg-m.

9 Ib-ft)

GASKET

Replace.

SELF-LOCKING

NUT

8x

1.25

mm

34 N .

m

(3.4 kg-m,

25 Ib-ft)

Replace.

EXHAUST MANIFOLD

COVER

(cont'd)

8x

1.25

mm

22 N

.

m

(2.2 kg-m.

16 Ib-ft) FRONT EXHAUST

MANIFOLD

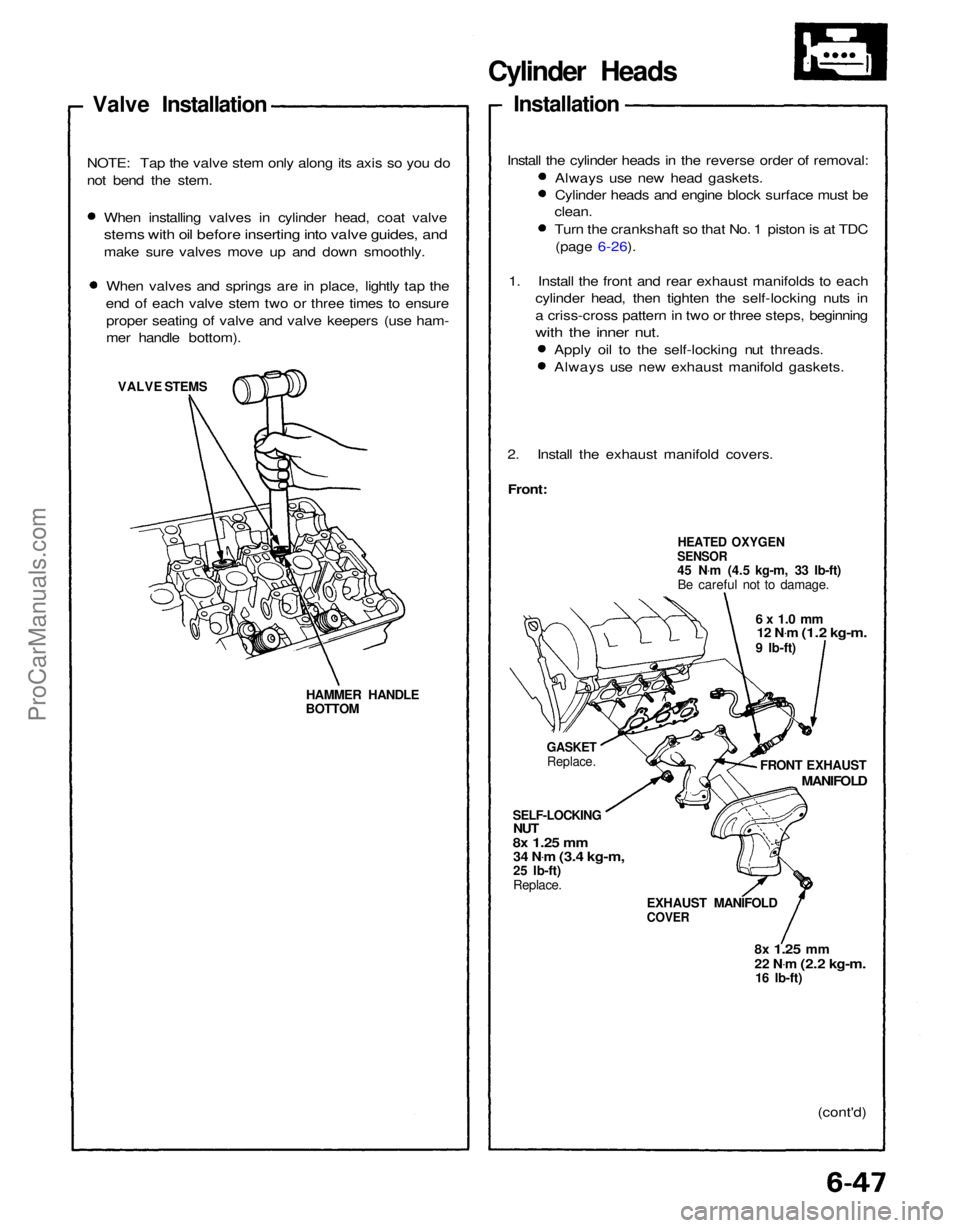

Valve Installation

When installing valves in cylinder head, coat valve

stems with oil before inserting into valve guides, and

make sure valves move up and down smoothly.When valves and springs are in place, lightly tap the

end of each valve stem two or three times to ensure proper seating of valve and valve keepers (use ham-

mer handle bottom).

VALVE STEMS

HAMMER HANDLE

BOTTOM

NOTE: Tap the valve stem only along its axis so you do

not bend the stem.

Apply oil to the self-locking nut threads.

Always use new exhaust manifold gaskets.

1. Install the front and rear exhaust manifolds to each

cylinder head, then tighten the self-locking nuts in

a criss-cross pattern in two or three steps, beginning

with the inner nut.

Always use new head gaskets.

Cylinder heads and engine block surface must be

clean.

Turn the crankshaft so that No. 1 piston is at TDC

(page 6-26).

Install the cylinder heads in the reverse order of removal:ProCarManuals.com

Page 1036 of 1640

Cylinder Heads

Installation (cont'd)

Rear:

8 x

1.25

mm

22 N .

m

(2.2 kg-m,

16 Ib-ft)

HEATED OXYGEN

SENSOR

45 N .

m

(4.5 kg-m,

33 Ib-ft) Be careful not to damage.

GASKET

Replace.

REAR EXHAUST

MANIFOLD

EXHAUST

MANIFOLD

COVER

SELF LOCKING NUTS

8 x

1.25

mm

34 N .

m

(3.4 kg-m,

25 Ib-ft)

Replace.

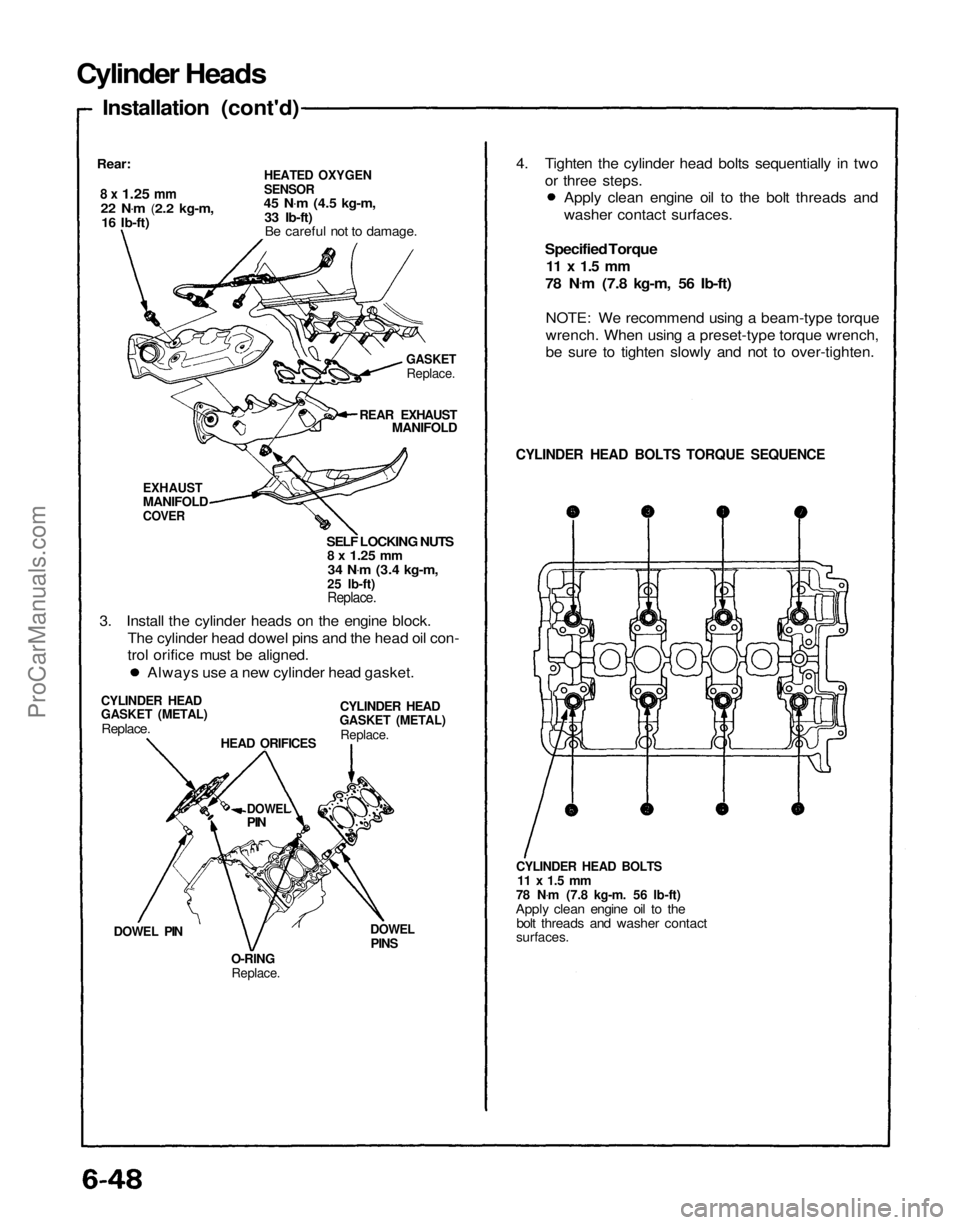

3. Install the cylinder heads on the engine block. The cylinder head dowel pins and the head oil con-

trol orifice must be aligned.

CYLINDER HEAD

GASKET (METAL)

Replace.

CYLINDER HEAD

GASKET (METAL)

Replace.

HEAD ORIFICES

DOWEL

PIN

DOWEL PIN

O-RING

Replace.

DOWEL

PINS

CYLINDER HEAD BOLTS

11 x 1.5 mm

78 N .

m (7.8 kg-m. 56 Ib-ft)

Apply clean engine oil to the bolt threads and washer contact

surfaces.

CYLINDER HEAD BOLTS TORQUE SEQUENCE

Specified Torque

11 x 1.5 mm

78 N .

m (7.8 kg-m, 56 Ib-ft)

NOTE: We recommend using a beam-type torque

wrench. When using a preset-type torque wrench,

be sure to tighten slowly and not to over-tighten.

Always use a new cylinder head gasket. Apply clean engine oil to the bolt threads and

washer contact surfaces.

4. Tighten the cylinder head bolts sequentially in two

or three steps.ProCarManuals.com

Page 1037 of 1640

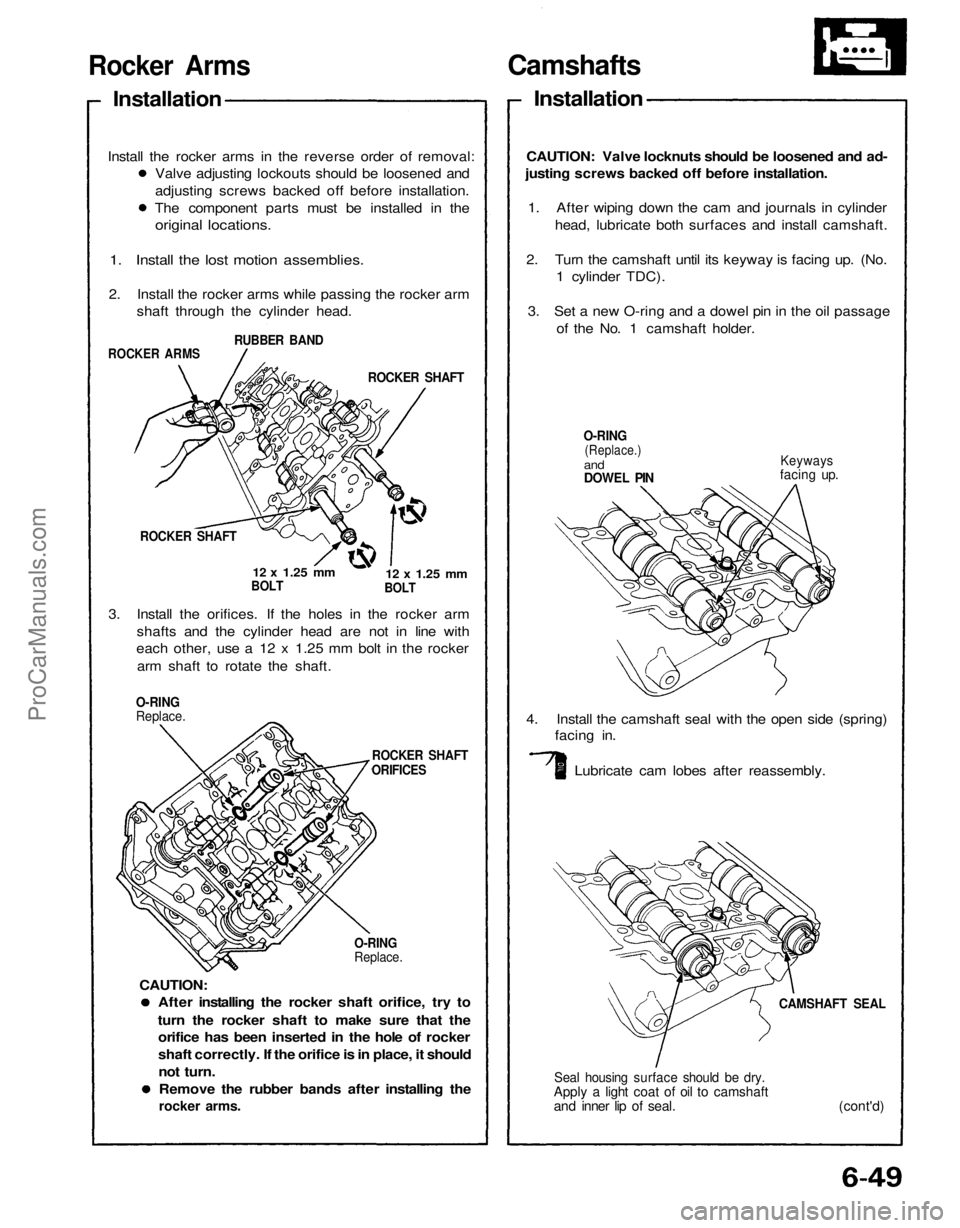

Camshafts

Installation

CAUTION: Valve locknuts should be loosened and ad-

justing screws backed off before installation.

1. After wiping down the cam and journals in cylinder

head, lubricate both surfaces and install camshaft.

2. Turn the camshaft until its keyway is facing up. (No.

1 cylinder TDC).

3. Set a new O-ring and a dowel pin in the oil passage

of the No. 1 camshaft holder.

O-RING

(Replace.)

and

DOWEL PIN

Keyways

facing up.

4. Install the camshaft seal with the open side (spring)

facing in.

Lubricate cam lobes after reassembly.

CAMSHAFT SEAL

Seal housing surface should be dry.

Apply a light coat of oil to camshaft

and inner lip of seal. (cont'd)

After installing the rocker shaft orifice, try to

turn the rocker shaft to make sure that the

orifice has been inserted in the hole of rocker

shaft correctly. If the orifice is in place, it should

not turn.

Remove the rubber bands after installing the

rocker arms.

O-RING

Replace.

ROCKER SHAFT

ORIFICES

O-RING

Replace.

3. Install the orifices. If the holes in the rocker arm

shafts and the cylinder head are not in line with

each other, use a 12 x 1.25 mm bolt in the rocker

arm shaft to rotate the shaft.

ROCKER SHAFT

12 x

1.25

mm

BOLT

12 x

1.25

mm

BOLT

ROCKER SHAFT

ROCKER ARMS

RUBBER BAND

1. Install the lost motion assemblies.

2. Install the rocker arms while passing the rocker arm

shaft through the cylinder head.

Rocker Arms

Installation

Valve adjusting lockouts should be loosened and

adjusting screws backed off before installation.

The component parts must be installed in the

original locations.

Install the rocker arms in the reverse order of removal:

CAUTION:ProCarManuals.com

Page 1038 of 1640

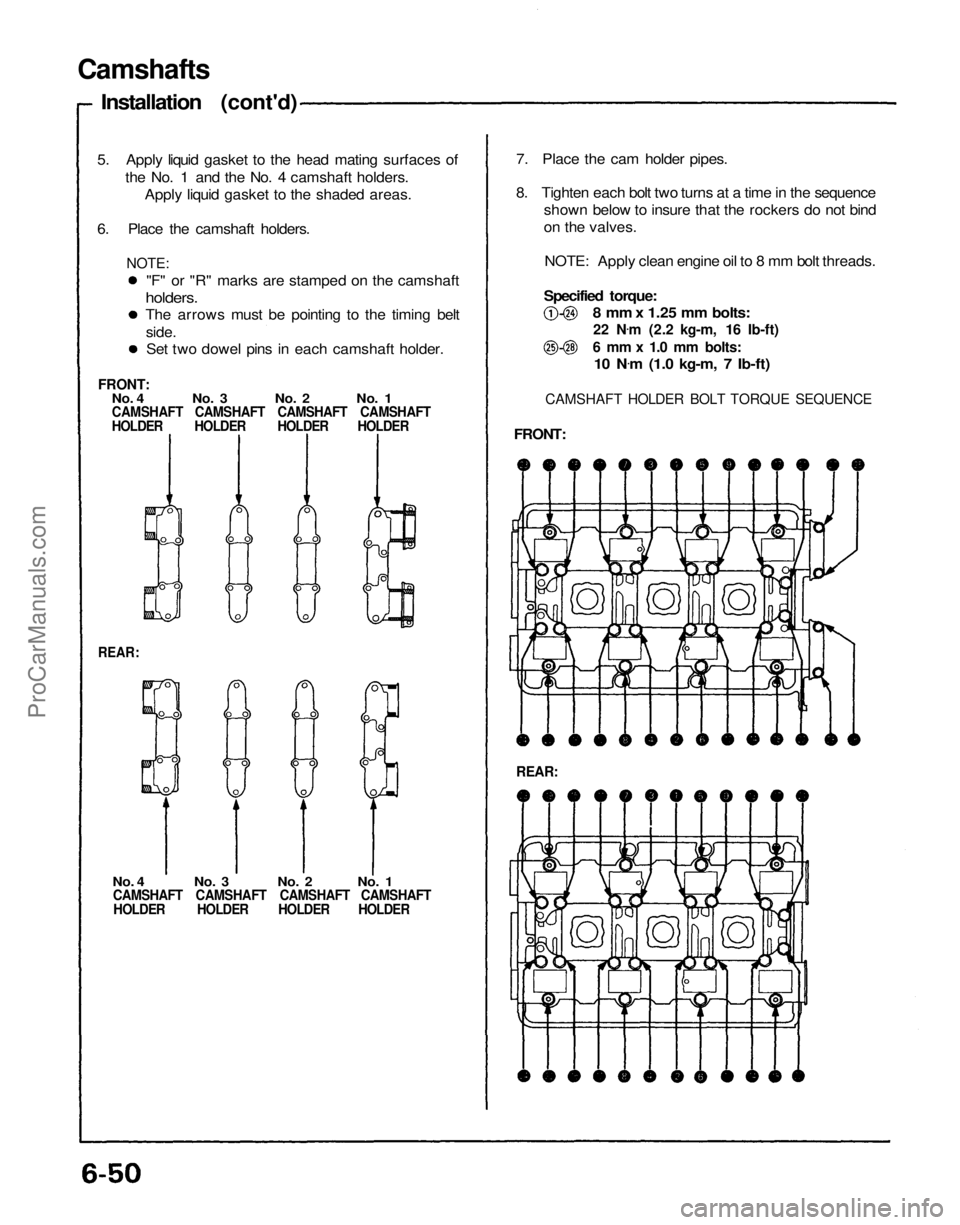

Camshafts

Installation (cont'd)

5. Apply liquid gasket to the head mating surfaces of the No. 1 and the No. 4 camshaft holders.Apply liquid gasket to the shaded areas.

6. Place the camshaft holders.

REAR:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDER

REAR:

7. Place the cam holder pipes.

8. Tighten each bolt two turns at a time in the sequence

shown below to insure that the rockers do not bind

on the valves.

NOTE: Apply clean engine oil to 8 mm bolt threads.

Specified torque: 8 mm x 1.25 mm bolts:

22 N .

m (2.2 kg-m, 16 Ib-ft)

6 mm x 1.0 mm bolts:

10 N .

m (1.0 kg-m, 7 Ib-ft)

CAMSHAFT HOLDER BOLT TORQUE SEQUENCE

FRONT:

NOTE:

"F" or "R" marks are stamped on the camshaft

holders.

The arrows must be pointing to the timing belt

side.Set two dowel pins in each camshaft holder.

FRONT:

No. 4 No. 3 No. 2 No. 1

CAMSHAFT CAMSHAFT CAMSHAFT CAMSHAFT

HOLDER HOLDER HOLDER HOLDERProCarManuals.com

Page 1039 of 1640

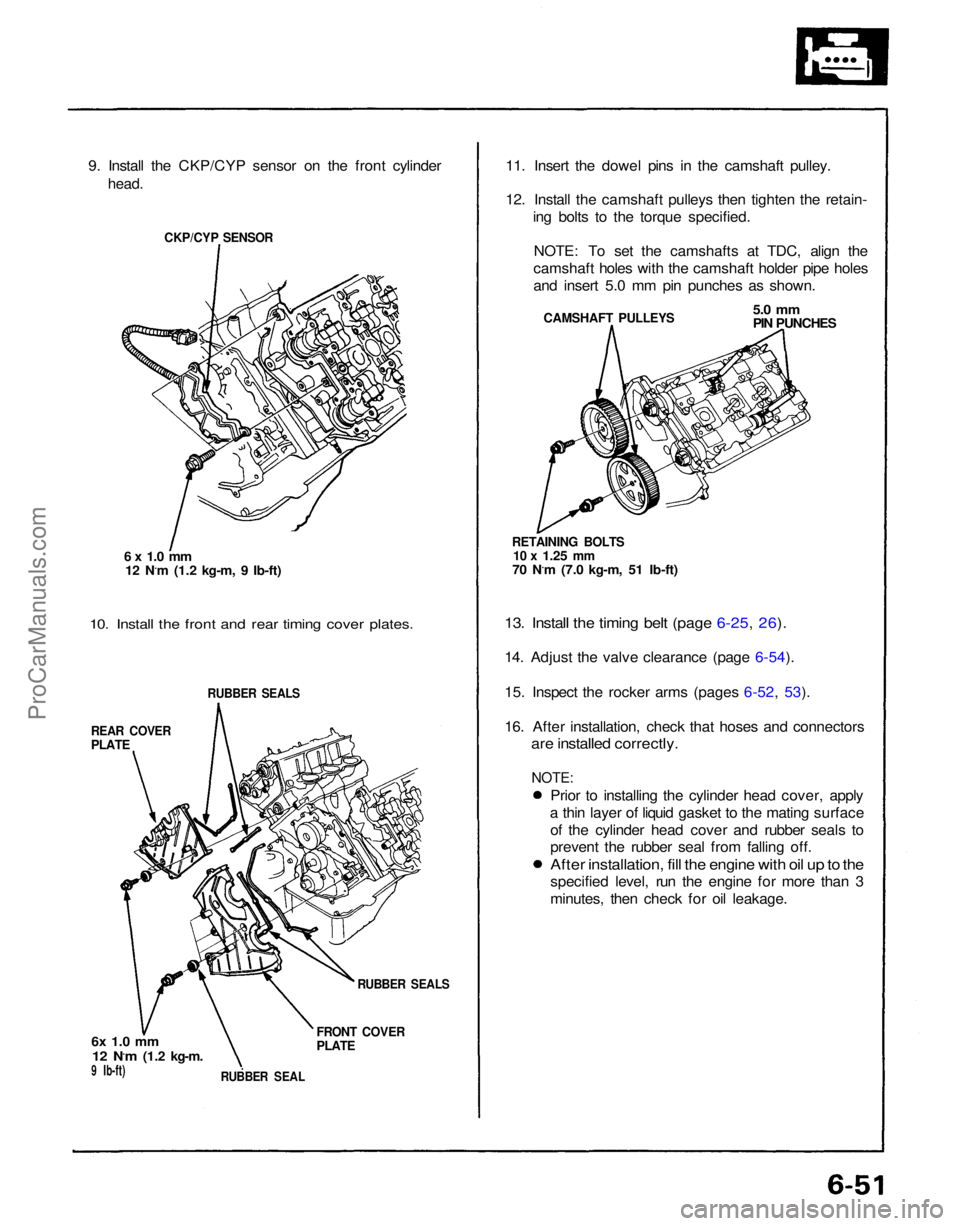

9. Install the CKP/CYP sensor on the front cylinder

head.

CKP/CYP SENSOR

6 x 1.0 mm

12 N.m (1.2 kg-m, 9 Ib-ft)

10. Install the front and rear timing cover plates.

RUBBER SEALS

REAR COVER

PLATE

6x 1.0 mm

12 N.m

(1.2 kg-m.

9 Ib-ft)

RUBBER SEAL

FRONT COVER

PLATE

RUBBER SEALS

11. Insert the dowel pins in the camshaft pulley.

12. Install the camshaft pulleys then tighten the retain-

ing bolts to the torque specified.

NOTE: To set the camshafts at TDC, align the

camshaft holes with the camshaft holder pipe holes

and insert 5.0 mm pin punches as shown.

CAMSHAFT PULLEYS

5.0 mm

PIN PUNCHES

RETAINING BOLTS

10 x

1.25

mm

70 N.m (7.0 kg-m, 51 Ib-ft)

13. Install the timing belt (page 6-25, 26).

14. Adjust the valve clearance (page 6-54).

15. Inspect the rocker arms (pages 6-52, 53).

16. After installation, check that hoses and connectors

are installed correctly.

Prior to installing the cylinder head cover, apply

a thin layer of liquid gasket to the mating surface of the cylinder head cover and rubber seals to

prevent the rubber seal from falling off.

After installation, fill the engine with oil up to the

specified level, run the engine for more than 3

minutes, then check for oil leakage.

NOTE:ProCarManuals.com

Page 1040 of 1640

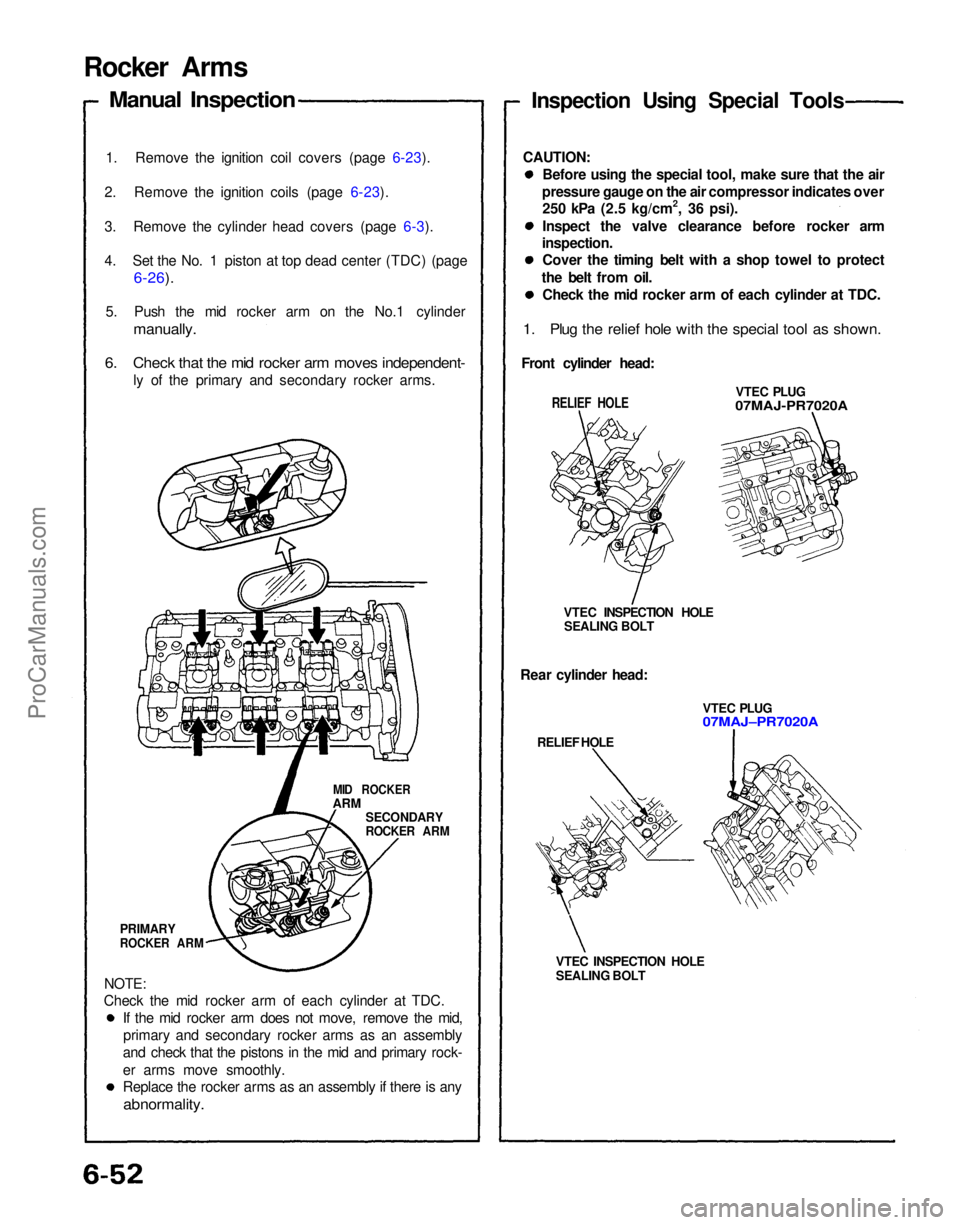

Rocker Arms

Manual Inspection

1. Remove the ignition coil covers (page 6-23).

2. Remove the ignition coils (page 6-23).

3. Remove the cylinder head covers (page 6-3).

4. Set the No. 1 piston at top dead center (TDC) (page

6-26).

5. Push the mid rocker arm on the No.1 cylinder

manually.

6. Check that the mid rocker arm moves independent-

ly of the primary and secondary rocker arms.

MID ROCKER

ARM

SECONDARY

ROCKER ARM

PRIMARY

ROCKER ARM

If the mid rocker arm does not move, remove the mid,primary and secondary rocker arms as an assembly

and check that the pistons in the mid and primary rock-

er arms move smoothly.

Replace the rocker arms as an assembly if there is any

abnormality.

VTEC INSPECTION HOLE

SEALING BOLT

RELIEF HOLE

VTEC PLUG

07MAJ–PR7020A

Rear cylinder head: VTEC INSPECTION HOLE

SEALING BOLT VTEC PLUG

07MAJ-PR7020A

Front cylinder head:

RELIEF HOLE

Before using the special tool, make sure that the air

pressure gauge on the air compressor indicates over 250 kPa (2.5 kg/cm2, 36 psi).

Inspect the valve clearance before rocker arm

inspection. Cover the timing belt with a shop towel to protect

the belt from oil. Check the mid rocker arm of each cylinder at TDC.

Inspection Using Special Tools

NOTE:

Check the mid rocker arm of each cylinder at TDC.

1. Plug the relief hole with the special tool as shown.

CAUTION:ProCarManuals.com